Thermal power plant peak regulating system based on water-electrolysis hydrogen production

A technology for electrolyzing water and thermal power plants, which is applied in the direction of electric energy storage system, electrolysis process, electrolysis components, etc., which can solve the problems of supply model competitiveness and low economic benefits, inconvenient use and adjustment, pollutant discharge, etc., to facilitate the later equipment Maintenance, convenience for later maintenance, effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

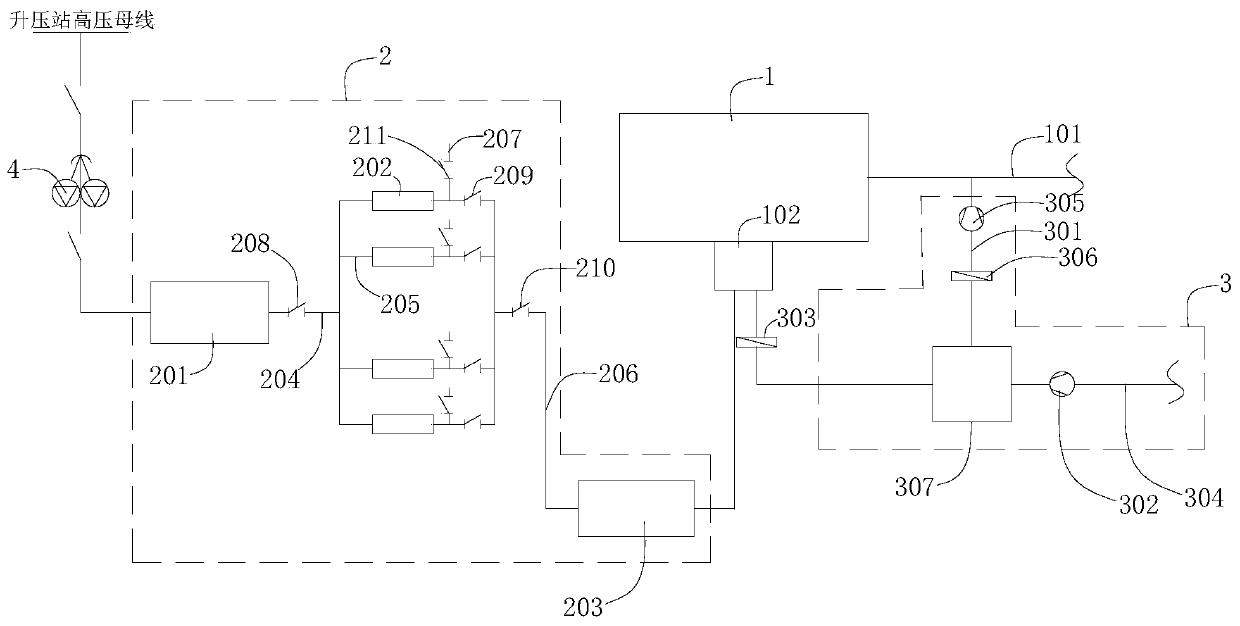

[0046] see figure 1 shown;

[0047] A thermal power plant peak shaving system based on electrolysis of water for hydrogen production of the present invention includes:

[0048] coal-fired boiler 1;

[0049] The hydrogen production unit 2 placed upstream of the coal-fired boiler 1 process;

[0050] The flue gas recovery unit 3 placed downstream of the coal-fired boiler 1 process;

[0051] The process upstream of the hydrogen production unit 2 has a high-voltage transformer 4, and the input end of the high-voltage transformer 4 is connected to the high-voltage bus of the booster station;

[0052] The coal-fired boiler 1 has a tail gas discharge flue 101;

[0053] The flue gas recovery unit 3 is communicated with the exhaust gas discharge flue 101 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com