Biomass gasified gas re-burning mode and system for coal-fired fluidized bed

A biomass and gasification gas technology, applied in fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, etc., can solve problems such as gas quality and economic constraints, coking corrosion, application effects, etc., to avoid contamination. Slag and corrosion problems, reduced emissions, efficient and clean utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

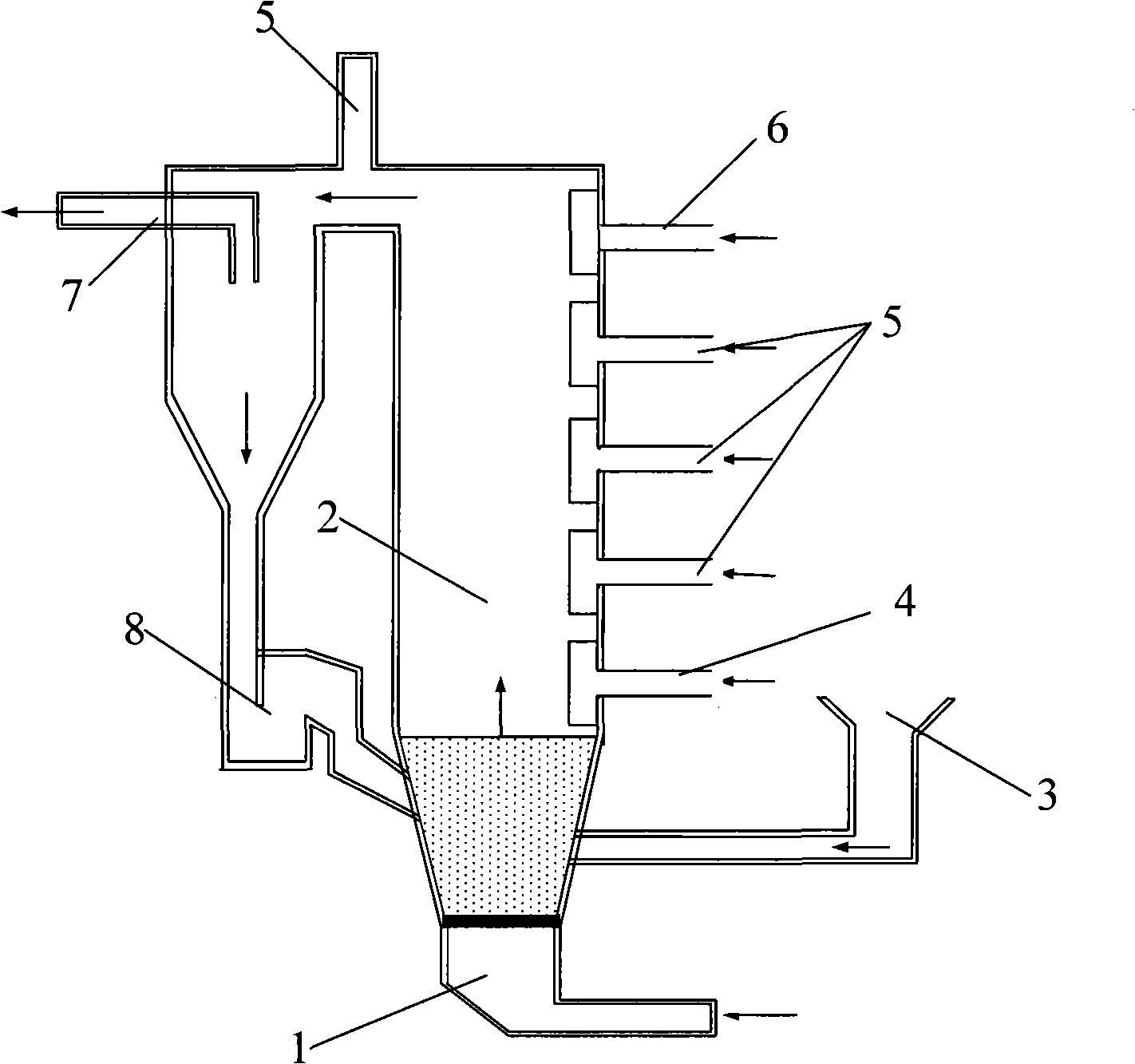

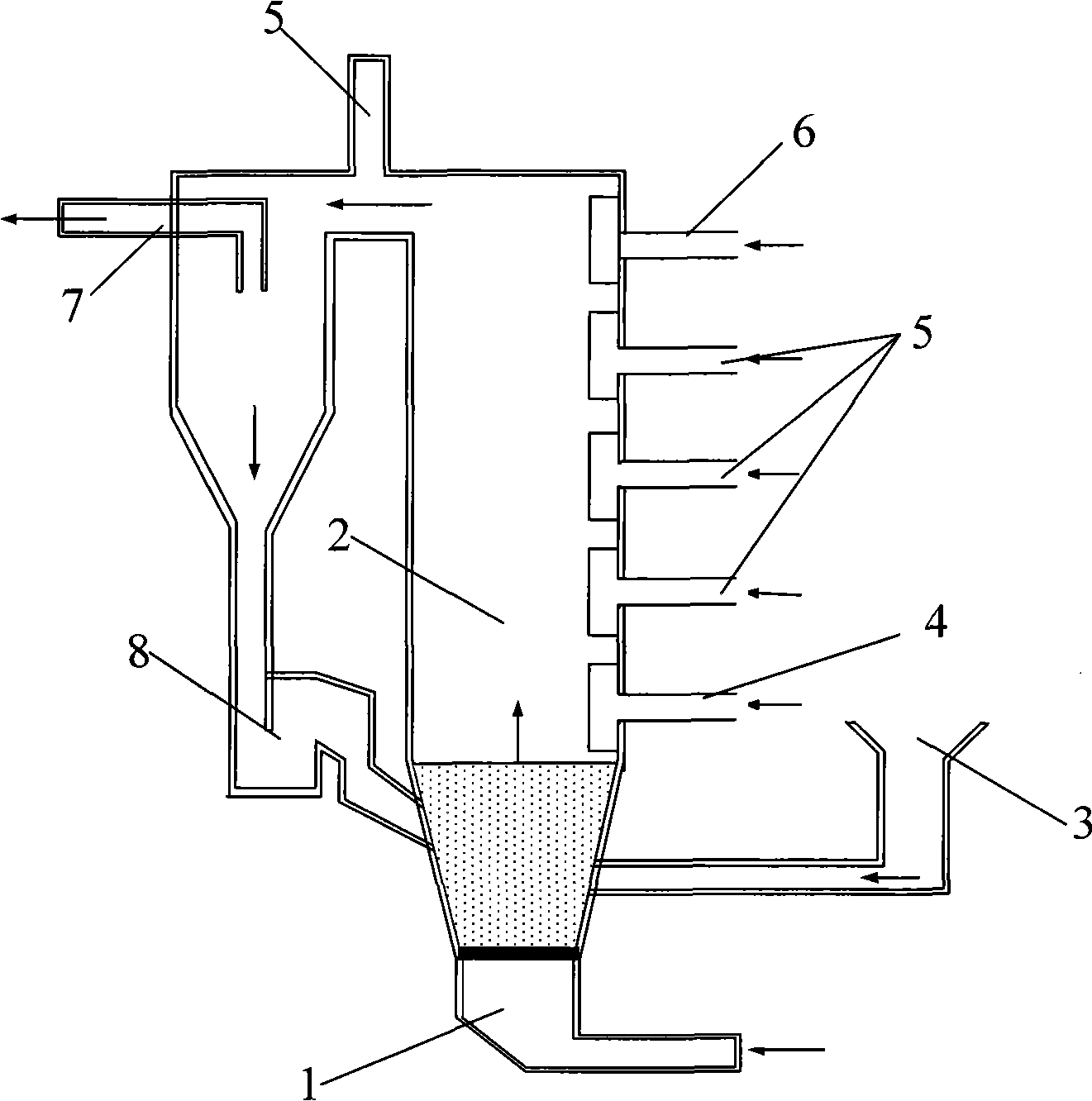

[0030] Biomass gasification gas reburning system in 135MW circulating fluidized bed boiler.

[0031] In this embodiment, the present invention is used to replace the original combustion method to reduce N 2 O emissions. 135MW circulating fluidized bed boiler, fuel low calorific value is 12435kJ / kg, fuel consumption is 78230kg / h. Annual consumption of 200,000 tons of biomass, biomass gasification temperature 680 ℃. In this embodiment, 3m up from the air distribution plate to the top of the furnace, there are 7 stages of combustion nozzles arranged according to the four corners tangentially, of which the bottom 2 stages are burner nozzles, and the middle 3 stages are biomass gasification gas nozzles. The biomass gas flow rate is 42m / s, and the top two stages are supplementary combustion air nozzles.

[0032] The boiler uses a biomass gasification gas reburning system. The calorific value of biomass gas accounts for 13.22% of the total calorific value, and the biomass gas acco...

Embodiment 2

[0034] Biomass gasification gas reburning system in 300MW circulating fluidized bed boiler.

[0035] In this embodiment, by adding biomass gasification gas nozzles around the furnace, the combustion system is transformed into a combustion system for fuel graded biomass gasification gas reburning. 300MW circulating fluidized bed boiler, fuel low calorific value is 19887kJ / kg, fuel consumption is 148600kg / h. Annual consumption of 200,000 tons of biomass, biomass gasification temperature 690 ℃. In this embodiment, from 2.5m up from the air distribution plate to the top of the furnace, there are 6 stages of combustion nozzles arranged in accordance with the four-corner tangential circle, which are respectively 2-stage burner nozzles, 2-stage biomass gasification gas nozzles, and 2-stage supplementary combustion The air nozzle, the flow rate of the biomass flow into it is 40m / s.

[0036] The boiler uses a biomass gasification gas reburning system. The calorific value of biomass g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com