Combination method using semi-coke tail gas for power generation to cogenerate liquefied natural gas

A technology for liquefied natural gas and blue carbon tail gas, which is applied in the fields of combustible gas purification, gaseous engine fuel, and combustible gas purification/transformation. The effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

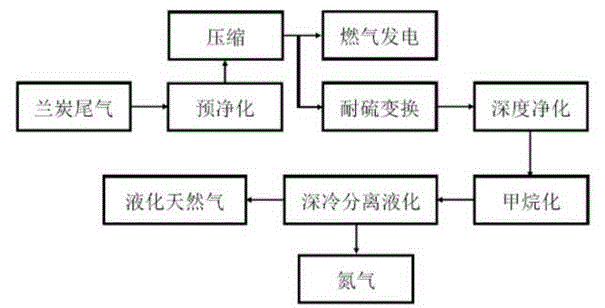

Image

Examples

Embodiment 1

[0050] The main composition (vol%) of the semi-coke tail gas in this embodiment is: H 2 : 28.2, CH 4 : 7.3, CO: 16.0, CO 2 : 10, C n h m : 0.5, N 2 : 37.9, O 2 : 0.1. Air volume 50000Nm 3 / h, temperature 40°C.

[0051] (1) Blast: Use a Roots blower or a centrifugal blower to pressurize the semi-coke tail gas to 0.05~0.08MPa(G).

[0052] (2) Pre-purification

[0053] A dry purification temperature swing adsorption method is used to remove macromolecular impurities such as tar, naphthalene, benzene and dust in the semi-coke tail gas, and a rough purified semi-coke tail gas is obtained.

[0054] (3) Compression: Use a reciprocating compressor or a centrifugal compressor to pressurize the pre-purified gas to ~5.5MPa (G).

[0055] (4) Power generation: Part of the pre-purified gas is extracted from the compressor and enters the gas-fired generator set. The pre-purified gas is preheated to 100°C~500°C and mixed with air according to the volume ratio of 1:2~4 and passed in...

Embodiment 2

[0070] The main composition (vol%) of the semi-coke tail gas in this embodiment is: H 2 : 28.2, CH 4 : 7.3, CO: 16.0, CO 2 : 10, C n h m : 0.5, N 2 : 37.9, O 2 : 0.1. Air volume 50000Nm 3 / h, temperature 40°C.

[0071] (1) Blast: Use a Roots blower or a centrifugal blower to pressurize the semi-coke tail gas to 0.05~0.08MPa(G).

[0072] (2) Pre-purification

[0073] A dry purification temperature swing adsorption method is used to remove macromolecular impurities such as tar, naphthalene, benzene and dust in the semi-coke tail gas, and a rough purified semi-coke tail gas is obtained.

[0074] (3) Compression: Use a reciprocating compressor or a centrifugal compressor to pressurize the pre-purified gas to 0.5~2.0MPa (G).

[0075] (4) Power generation: Part of the pre-purified gas is extracted from the compressor and enters the gas-fired generator set. The pre-purified gas is preheated to 100°C~500°C and mixed with air according to the volume ratio of 1:2~4 and passed...

Embodiment 3

[0090] The main composition (vol%) of the semi-coke tail gas in this embodiment is: H 2 : 26.6, CH 4 : 7.7, CO: 13.2, CO 2 : 11.4, C n h m : 0.6, N 2 : 40.1, O 2 : 0.4. Air volume 50000Nm 3 / h, temperature 40°C.

[0091] (1) Blast: Use a Roots blower or a centrifugal blower to pressurize the semi-coke tail gas to 0.05~0.08MPa(G).

[0092] (2) Pre-purification

[0093] A dry purification temperature swing adsorption method is used to remove macromolecular impurities such as tar, naphthalene, benzene and dust in the semi-coke tail gas, and a rough purified semi-coke tail gas is obtained.

[0094] (3) Compression: Use a reciprocating compressor or a centrifugal compressor to pressurize the pre-purified gas to ~5.5MPa (G).

[0095] (4) Power generation: Part of the pre-purified gas is extracted from the compressor and enters the gas-fired generator set. The pre-purified gas is preheated to 100~500°C and mixed with air according to the volume ratio of 1:2~4 and passed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com