Device and method for joint production of iron, sulfur and gas in smelting process of pyrite

A smelting process and pyrite technology, which is applied to the gas tri-generation device, the field of iron in the smelting process of sulfur and pyrite, can solve problems such as not being used efficiently, and achieve increased annual output, clean utilization, and alleviation of sulfur The effect of shortage of resources and natural gas resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

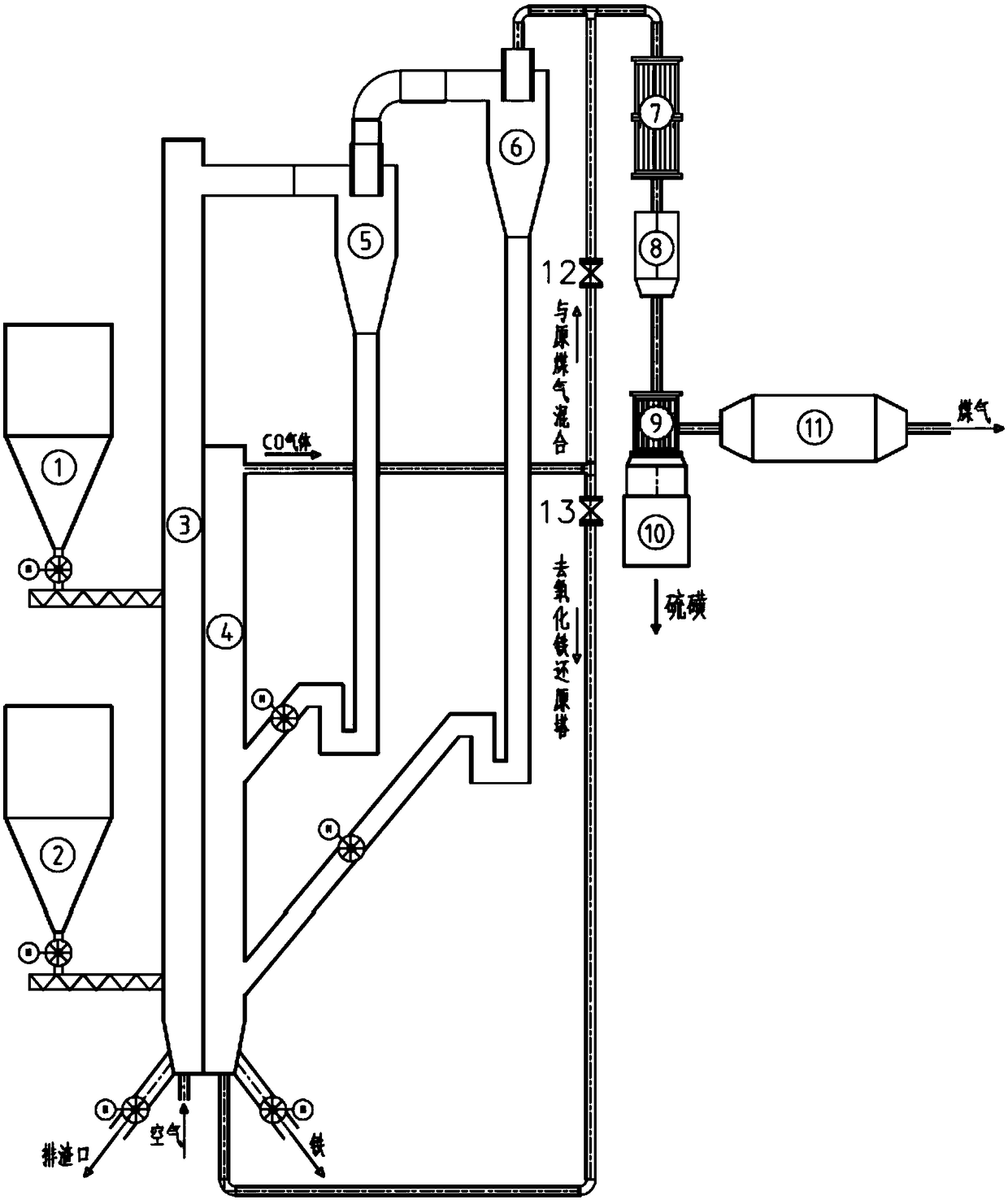

[0043] Method for triple production of iron, sulfur and gas in pyrite smelting process

[0044] 1) In the calcination-coal gasification reaction tower, the particle size of pyrite is 80 μm, calcined at the bottom temperature of 1100 ° C, the reaction time is 30 s, the excess air coefficient is 1.1, and the SO 2 The concentration is 8%. Coal gasification reaction occurs in the middle and upper part of coal powder and coal ash. The reaction temperature is 800°C. Coal gas and coke are mixed, and oxidation-reduction reaction occurs. The temperature of oxidation-reduction reaction is 800°C, and raw gas and reduction reaction products are obtained.

[0045] 2) Step 1) The solid particles obtained in the calcining-coal gasification reaction tower are separated by the iron-based high-temperature separator and the carbon-based high-temperature separator respectively and sent to the iron oxide reduction tower. The oxide undergoes a secondary reduction reaction at a reaction temperature...

Embodiment 2

[0048] Method for triple production of iron, sulfur and gas in pyrite smelting process

[0049] 1) In the calcination-coal gasification reaction tower, the particle size of pyrite is 1mm, the temperature of the bottom is 1200°C, the reaction time is 60s, the excess air coefficient is 1.3, and the SO 2 The concentration is 14%. Coal gasification reaction occurs in the middle and upper part of coal powder and coal ash. The reaction temperature is 900°C. Coal gas and coke are mixed, and oxidation-reduction reaction occurs. The temperature of oxidation-reduction reaction is 900°C, and raw gas and reduction reaction products are obtained.

[0050] 2) Step 1) The solid particles obtained in the calcining-coal gasification reaction tower are separated by the iron-based high-temperature separator and the carbon-based high-temperature separator respectively and sent back to the iron oxide reduction tower. The oxide undergoes a secondary reduction reaction at a reaction temperature of ...

Embodiment 3

[0053] 1) In the calcination-coal gasification reaction tower, the particle size of pyrite is 2mm, the temperature of the bottom is 1300℃, the reaction time is 120s, the excess air coefficient is 1.5, and the SO 2 The concentration is 16%; coal powder and coal ash undergo coal gasification reaction in the middle and upper part, and the reaction temperature is 1000°C. The high-valent oxides of iron generated by calcination at the bottom of the tower are carried by the sulfur-containing flue gas to the middle and upper part of the reaction tower to be mixed with the coal gasification. Coal gas and coke are mixed, and oxidation-reduction reaction occurs. The temperature of oxidation-reduction reaction is 1000°C, and raw gas and reduction reaction products are obtained.

[0054] 2) Step 1) The solid particles obtained in the calcining-coal gasification reaction tower are separated by the iron-based high-temperature separator and the carbon-based high-temperature separator respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com