Method for optimizing the operation of a charged reciprocating internal combustion engine in the lower engine speed range

An internal combustion engine, piston type technology, applied in low pressure fuel injection, low pressure fuel injection, internal combustion piston engine, etc., can solve problems such as insufficient load bearing characteristics, and achieve the effect of improving the level of air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

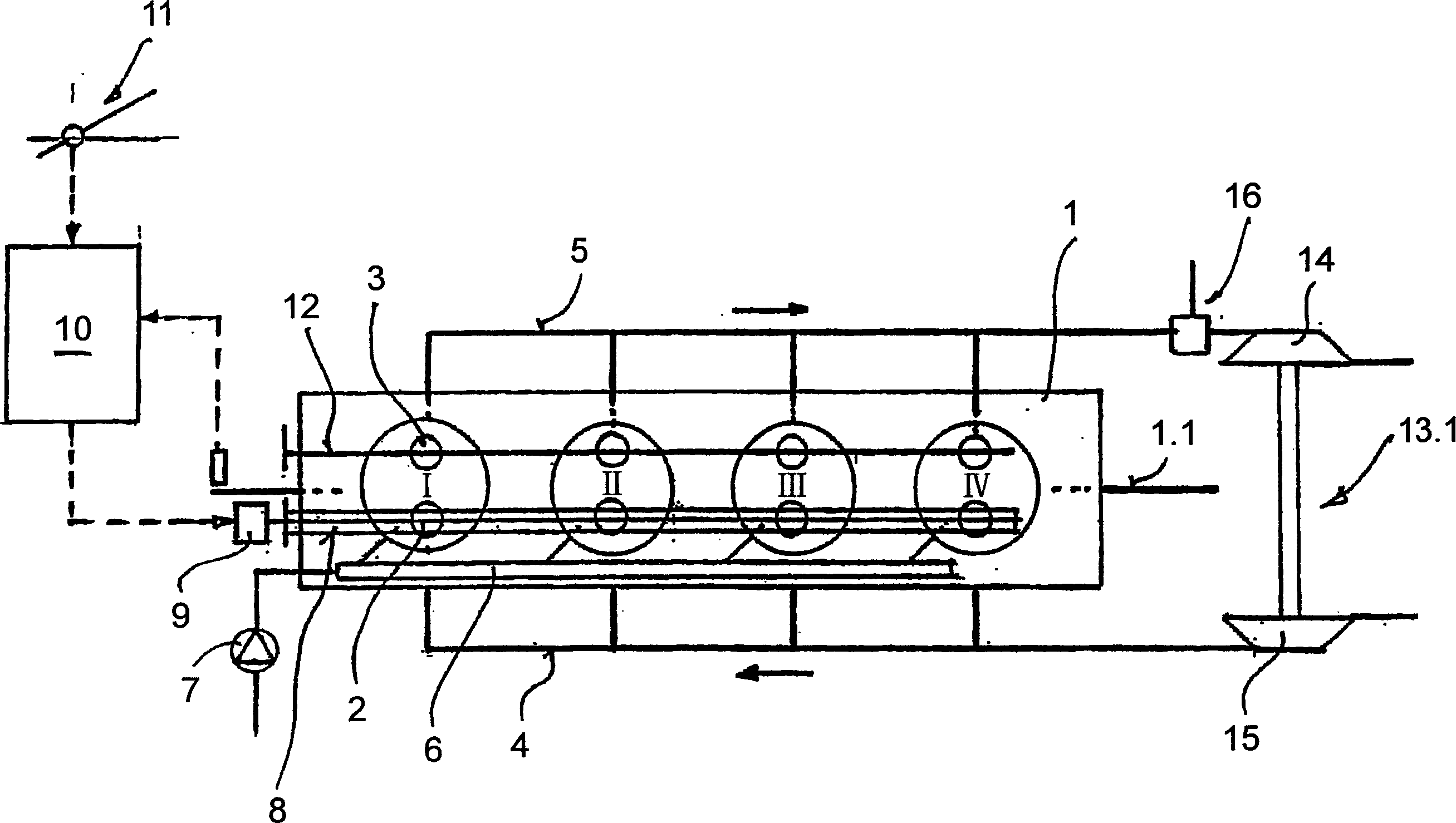

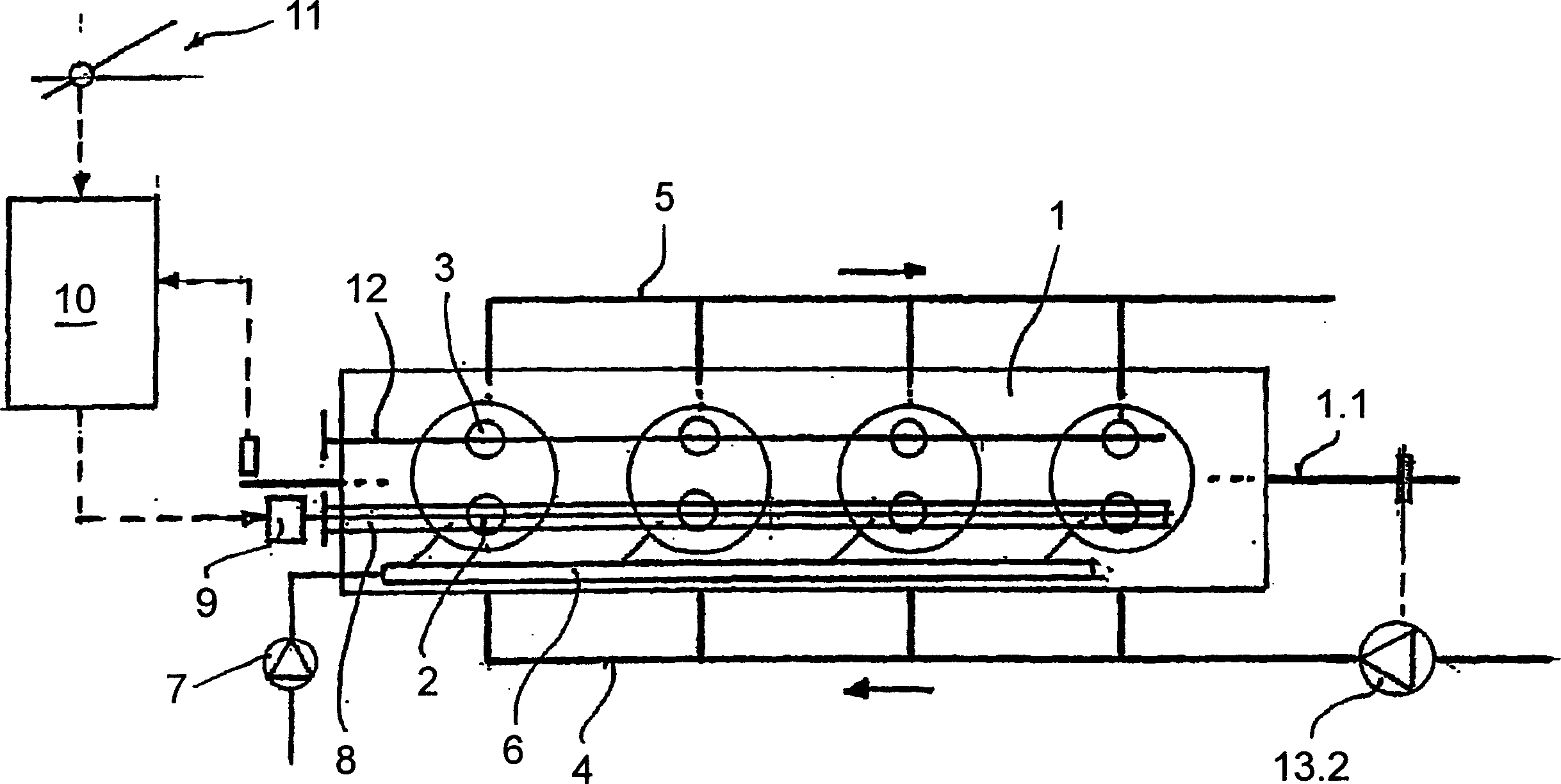

[0027] exist figure 1 shows a piston internal combustion engine with four cylinders I, II, III, IV each having an intake valve 2 and an exhaust valve 3 . The intake valve 2 is connected to an intake system 4 and the exhaust valve 3 is connected to an exhaust system 5 .

[0028] Furthermore, the piston internal combustion engine shown has a direct fuel injection, for example in the form of a common injection system 6 . Fuel is sent to the common fuel injection system 6 via a pump 7 .

[0029] For actuating the intake valves, a camshaft 8 is provided, the cams of which are adjustable with respect to the opening process of the intake valves 2 and are adjustable via a cam adjuster 9 . The cam adjuster 9 is connected to a control unit 10 via which the fuel injection system, the ignition system, not shown in detail, etc., is actuated via a throttle pedal 11 as a function of a predetermined load.

[0030] In the exemplary embodiment shown in the figure, the exhaust valve 3 is actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com