Acquisition method of combustion characteristic under different circumference air quantities after boiler improvement

A technology for combustion characteristics and boiler transformation, used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] In this embodiment, the following modified boilers are used as simulation calculation objects, and a method for obtaining combustion characteristics under different peripheral air volumes after the modification of the boiler is implemented.

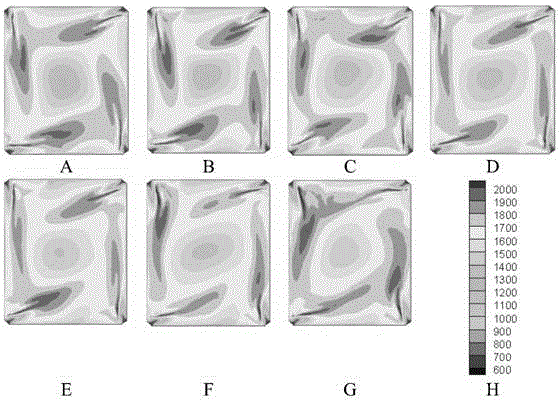

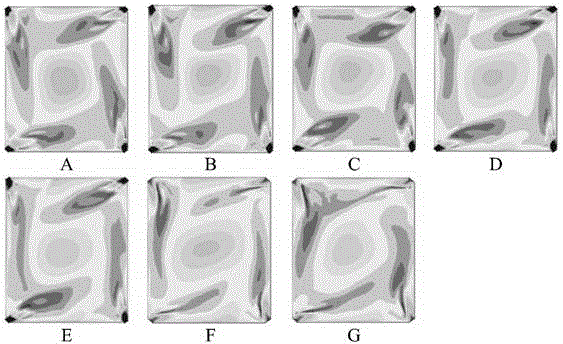

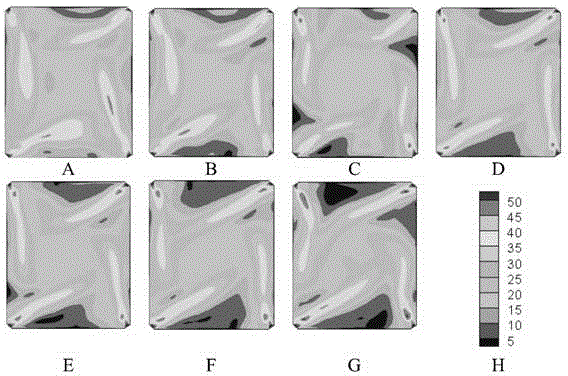

[0048] The boiler is 660MW, subcritical pressure, once reheated, single steam drum, control cycle, four-corner injection combustion double tangential combustion coal-fired boiler, the boiler body is as follows figure 1 shown. The open-air layout is adopted, and the boiler is a product of ABB-CE company. The combustion pulverizing system is a medium-speed grinding direct blowing type, and a straight-line wide adjustment ratio swing burner is used. The cross section of the burner is as follows: figure 2 shown. Four DC swing burners are arranged at the four corners of the boiler in a tangential c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com