Gas turbine main combustion chamber multi-channel diffuser with intelligently adjustable diffusion ratio

A technology for gas turbines and main combustion chambers, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of small total pressure loss, low pollution emission performance, and difficulty in ensuring the uniformity of the temperature field at the outlet of the combustion chamber, etc., to achieve The effect of improving the pressure recovery coefficient, low pollution emission performance, and avoiding a large-scale stall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

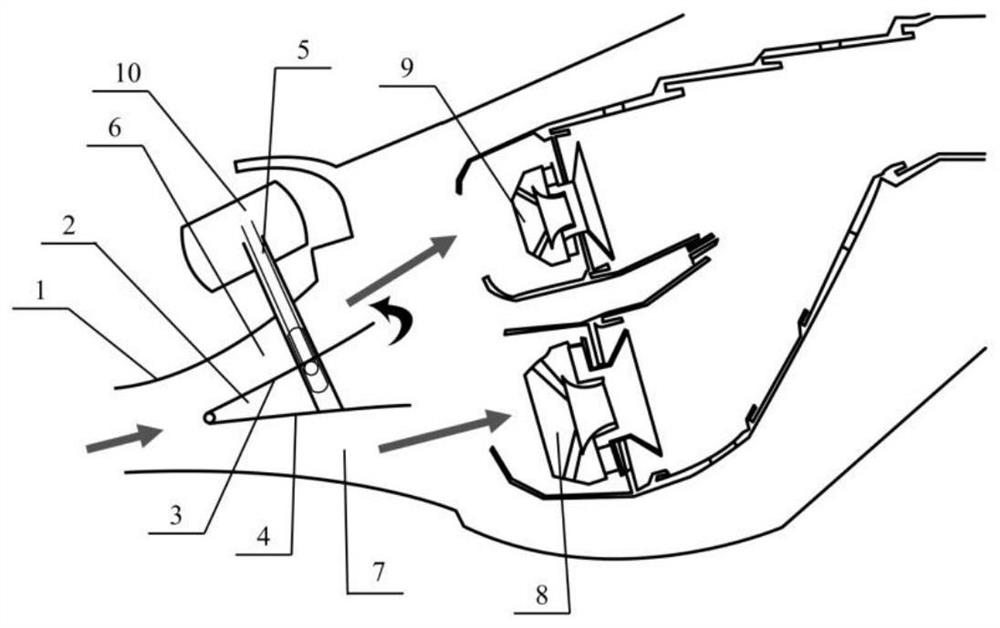

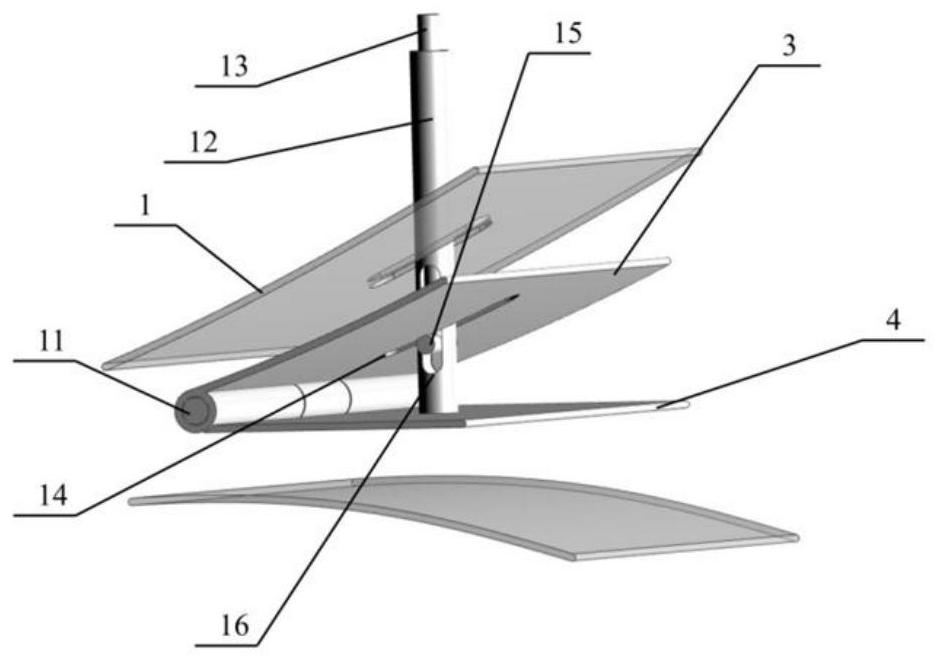

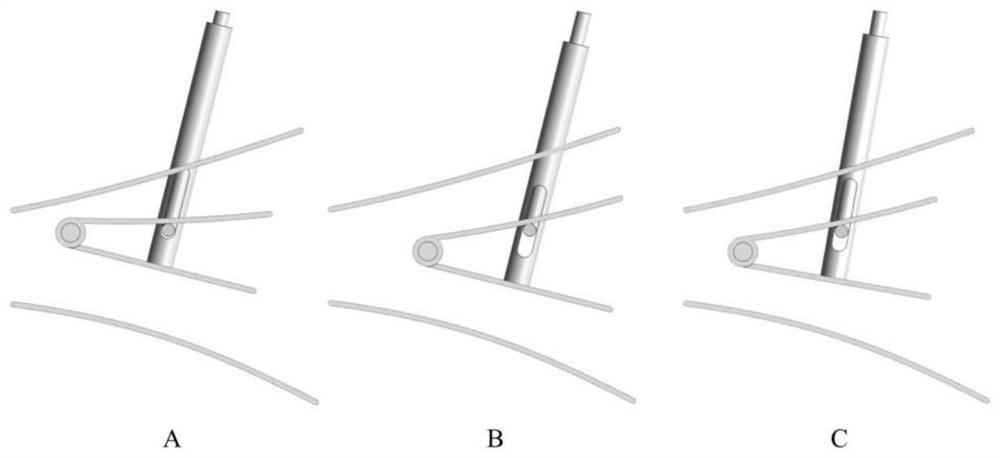

[0028] Such as figure 1 and figure 2 As shown, it is a structural schematic diagram of a multi-channel diffuser in the main combustion chamber of a gas turbine with an intelligently adjustable diffusion ratio according to the present invention. The present invention includes a diffuser casing 1, and the diffuser casing 1 is provided with a And the splitter cone 2 with intelligently adjustable expansion angle, the splitter cone 2 is divided into three parts, namely the upper wing 3 of the cone, the lower wing 4 of the cone and the adjustment mechanism 5. The upper wing 3 of the cone and the lower wing 4 of the cone are hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com