Direct injection natural gas engine system based on ammonia pyrolysis device and control method of direct injection natural gas engine system

An engine system and natural gas technology, applied in engine control, electrical control, charging system, etc., can solve problems affecting the measurement and control accuracy of consumption rate, elimination of after-treatment system, high HC emission, etc., to improve combustion characteristics and emission characteristics , Reduce energy consumption, reduce the effect of HC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

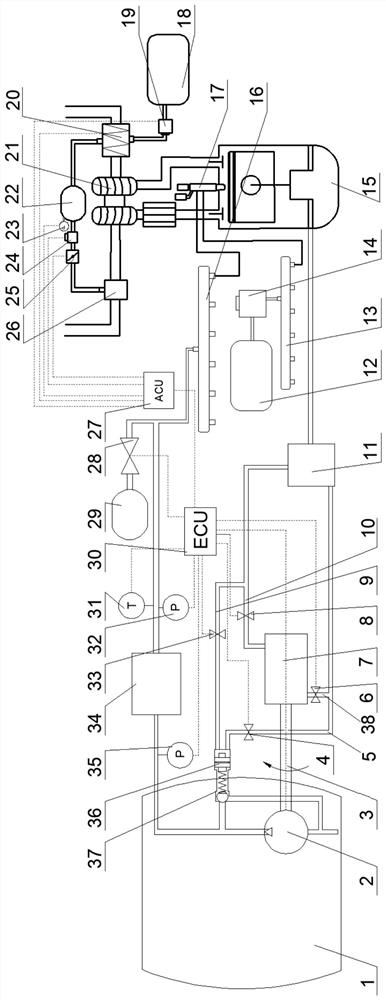

[0023] The present invention provides a direct-injection natural gas engine system (engine system for short) based on an ammonia pyrolysis device, the engine system includes an LNG tank 1, a diesel tank 12, a diesel rail 13, a high-pressure diesel pump 14, and a high-pressure direct-injection natural gas engine 15 , high-pressure natural gas rail 16, concentric biaxial needle injector 17, turbocharger 21, buffer tank stop valve 28, buffer tank 29, engine electronic control unit 30, natural gas temperature sensor 31, natural gas pressure sensor 32 and LNG vaporizer 34;

[0024] The high-pressure direct-injection natural gas engine 15 is provided with a concentric biaxial needle injector 17 and a turbocharger 21; the high-pressure natural gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com