Method for operating at least one precombustion chamber-fired internal combustion engine

A technology of internal combustion engine and pre-combustion chamber, applied in the direction of internal combustion piston engine, engine ignition, combustion engine, etc., to achieve the effect of small combustion characteristics and high combustion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

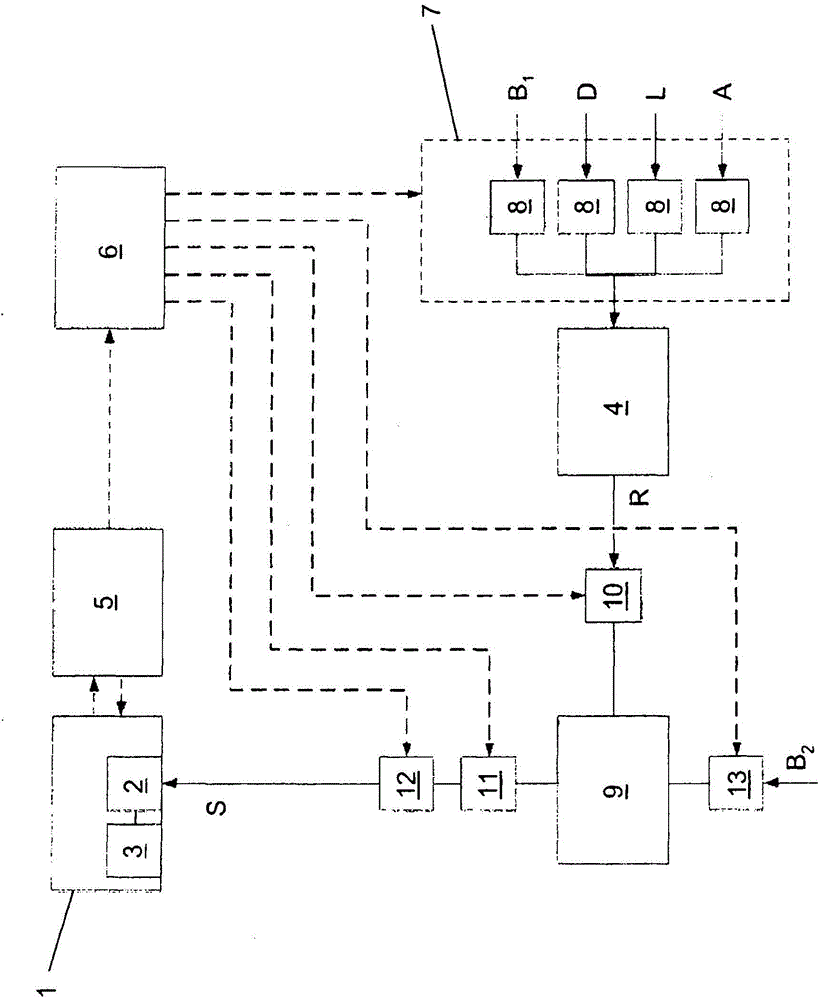

[0051] figure 1 Shown is a schematic view of an internal combustion engine 1 with a pre-chamber 2 and a main combustion chamber 3 assigned to the pre-chamber 2 . The purge gas S is fed to the prechamber 2 . This purge gas S consists of synthesis gas R and propellant B 2 . Synthetic gas R and propellant B 2 The mixture is mixed in the purging gas mixer 9 and the resulting gas mixture is supplied as purging gas S to a pre-chamber 2 or pre-chambers 2 of the internal combustion engine 1 .

[0052] Here, synthesis gas R is produced in fuel converter 4 . multiple streams B 1 , D, L, A are fed to the fuel converter 4 for a conversion process known per se, in which hydrocarbon-containing fuel B 1 The reaction produces H 2 and CO synthesis gas R. These streams B are carried out in this example by means of the stream mixer 7 1 , D, L, A delivery, the stream mixer will be delivered to its stream B 1 , D, L, A are mixed into a stream gas mixture and sent to the fuel converter 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com