Novel anti-shearing branch polymer oil displacement agent and synthetic method thereof

A technology of dendritic polymers and synthesis methods, applied in the field of new anti-shearing dendritic polymer oil displacement agents and their synthesis, can solve the problem of reducing the actual control degree of polymer flooding, affecting the application effect of polymer flooding, and polymer solutions Low viscosity retention rate and other problems, to achieve strong promotion and application value, reduce water phase permeability, and improve oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: 1,3-propanediamine is the preparation of the polyamide-amine modified dendritic skeleton GA of nucleus

[0053] Add 30g of methanol into a 250mL flask, slowly add 11.1g of 1,3-propanediamine under stirring, and add 103.2g of methyl acrylate dropwise using a constant pressure dropping funnel in a constant temperature water bath at 15-25°C. After stirring for 24 hours, reduce The solvent methanol and excess methyl acrylate were removed by pressure distillation to obtain the macromolecule G0.5 with a yield of 97-99.3%.

[0054] Dissolve 20.9g of the prepared G0.520.9g in 60g of methanol solvent, add 88.8g of 1,3-propylenediamine dropwise through a constant pressure dropping funnel at a constant temperature of 15-25°C, react for 24h, and distill off the solvent methanol and excess 1,3-propanediamine, the yield of 96.8-98.7% of the macromolecule G1.0 was obtained.

[0055] Dissolve 17.85g of the prepared G1.017.85g with 58g of methanol solvent. At a constant t...

Embodiment 2

[0059] Embodiment 2: the synthesis of terpolymer AM / NaAA / GA

[0060]Weigh 2.0g of sodium acrylate into a 125mL jar, add 20g of deionized water, adjust the pH of the system to 6.5-7.5 with NaOH, add 8.0g of acrylamide and 0.8mL of GA aqueous solution (mass concentration 1%) under stirring conditions, The total mass percentage concentration of the prepared monomer is 15-30% aqueous solution, nitrogen gas is passed for 20 minutes, and it is placed in a constant temperature water bath;

[0061] Add 1mL of sodium formate solution (mass concentration 0.1%), and then add redox initiator system ammonium persulfate solution and sodium bisulfite solution. 0.08-0.5% of the mass, continue to feed nitrogen for 10-20min, and react at a temperature of 30-60°C for 3-10h;

[0062] Wash three times with absolute ethanol, pulverize and dry to obtain AM / NaAA / GA terpolymer.

Embodiment 3

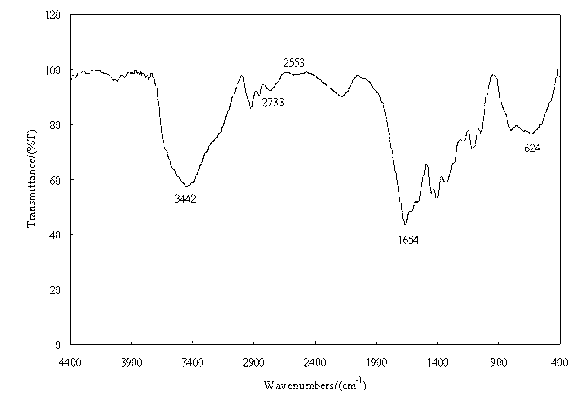

[0063] Embodiment 3: Structural characterization of terpolymer AM / NaAA / GA

[0064] The infrared spectrogram of the ternary polymer AM / NaAA / GA synthesized by embodiment 2 is as follows figure 1 shown. It is known from the figure that the amide group (-CONH 2 ) characteristic vibration peaks at 3442cm -1 、1660-1640cm -1 、624cm -1 , the stretching vibration peak of the secondary amino group (-NH-) is at 3500-3200cm -1 , the carbonyl (-C=O) vibration peak of the carboxylic acid group is at 2733cm -1 、2553cm -1 、1654cm -1 place.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com