Mixed firing boiler of industrial waste and domestic waste

A technology of domestic waste and industrial waste, which is applied in the direction of combustion chamber, combustion type, combustion equipment, etc., can solve problems such as the inability of engineering vehicles to enter and exit normally, unsuitable calorific value industrial waste, and large fluctuations in waste components, so as to promote the combustion of combustible gas. Mix with air, improve the fullness of airflow in the furnace, and solve the effect of incomplete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

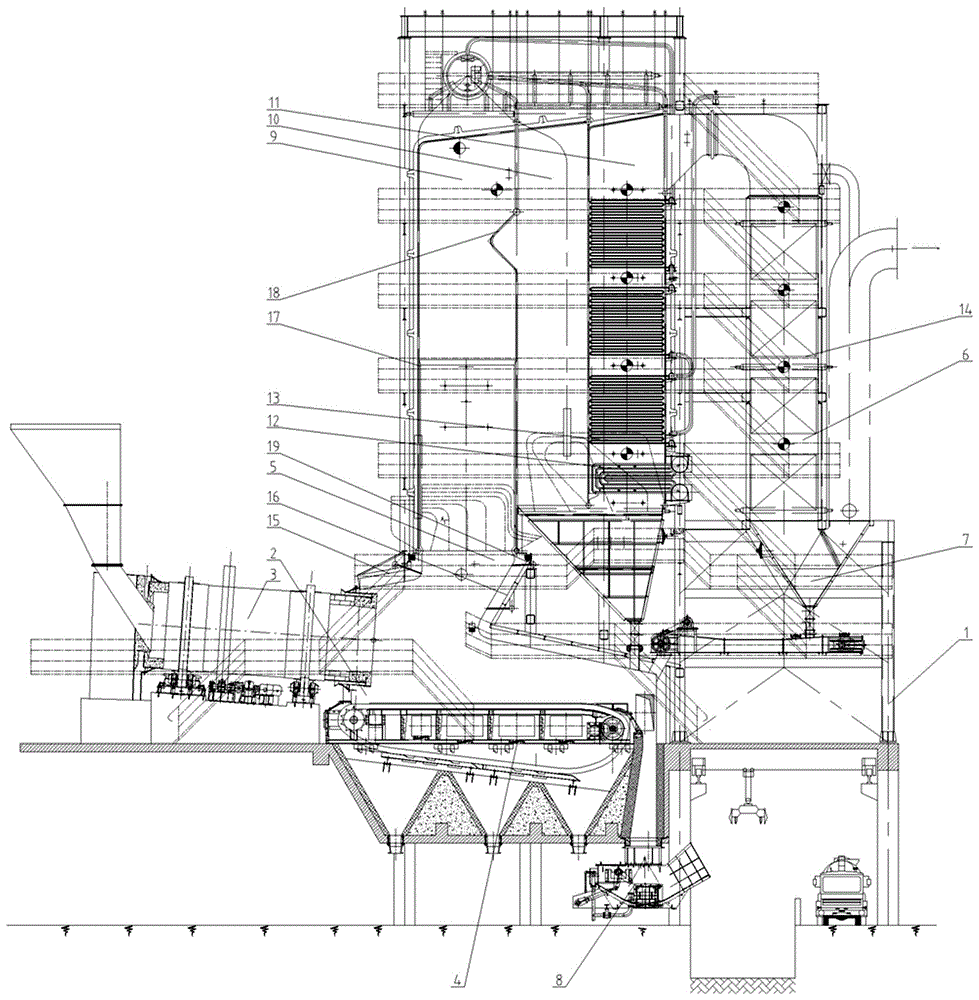

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 As shown, the boiler for the mixed combustion of industrial waste and domestic waste of the present invention includes a combined combustion equipment 2 , and the combined combustion equipment 2 includes a rotary kiln 3 and a fire grate 4 . Industrial waste and domestic waste enter from the feed inlet of the rotary kiln 3 kiln head, and the kiln tail of the rotary kiln 3 is connected with the furnace chamber 5 inlet. The outlet of the furnace chamber 5 is connected to the tail flue 6, and the furnace chamber 5 and the tail flue 6 are installed on the steel frame 1. The last column of the steel frame 1 is arranged in a dislocation manner and reinforced by diagonal braces. An ash falling device 7 is arranged below the tail flue 6, and a trough separator is installed in the ash falling device 7, and the ash falling device 7 sends the separated fly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com