Patents

Literature

117results about How to "Large maintenance space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

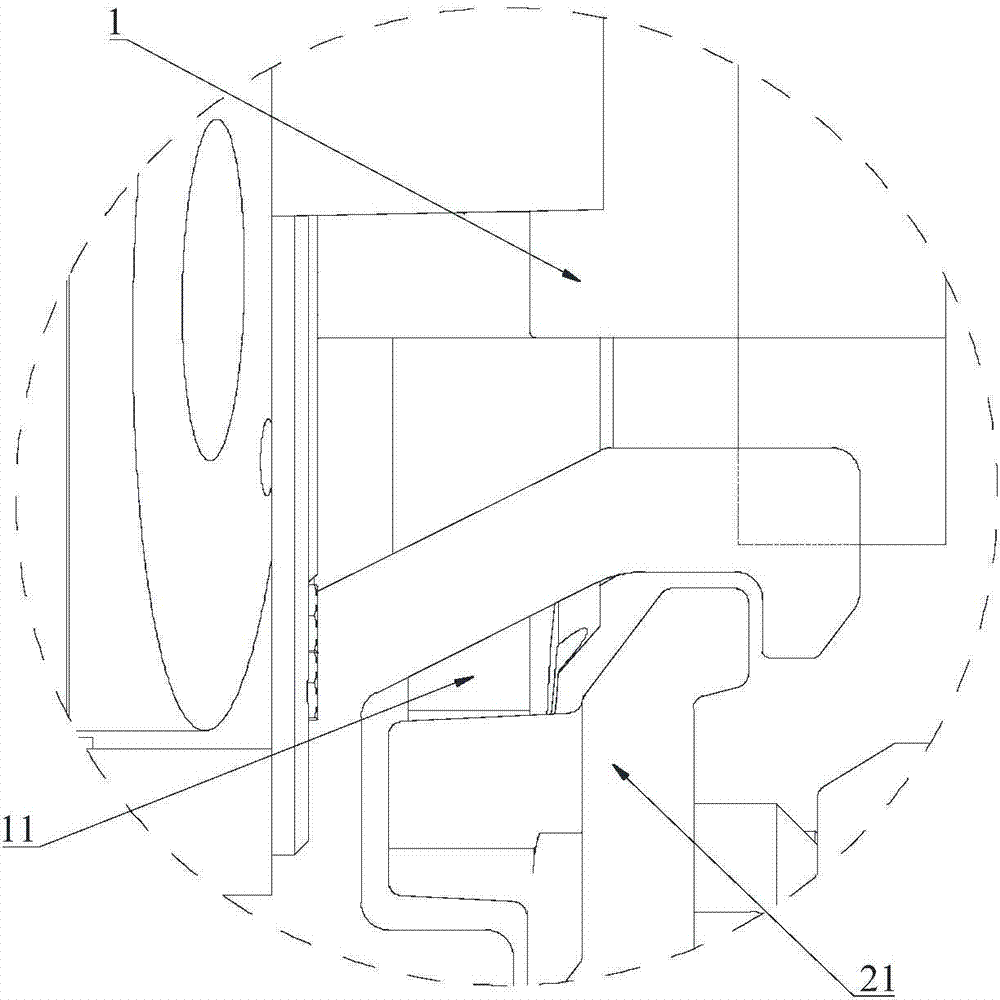

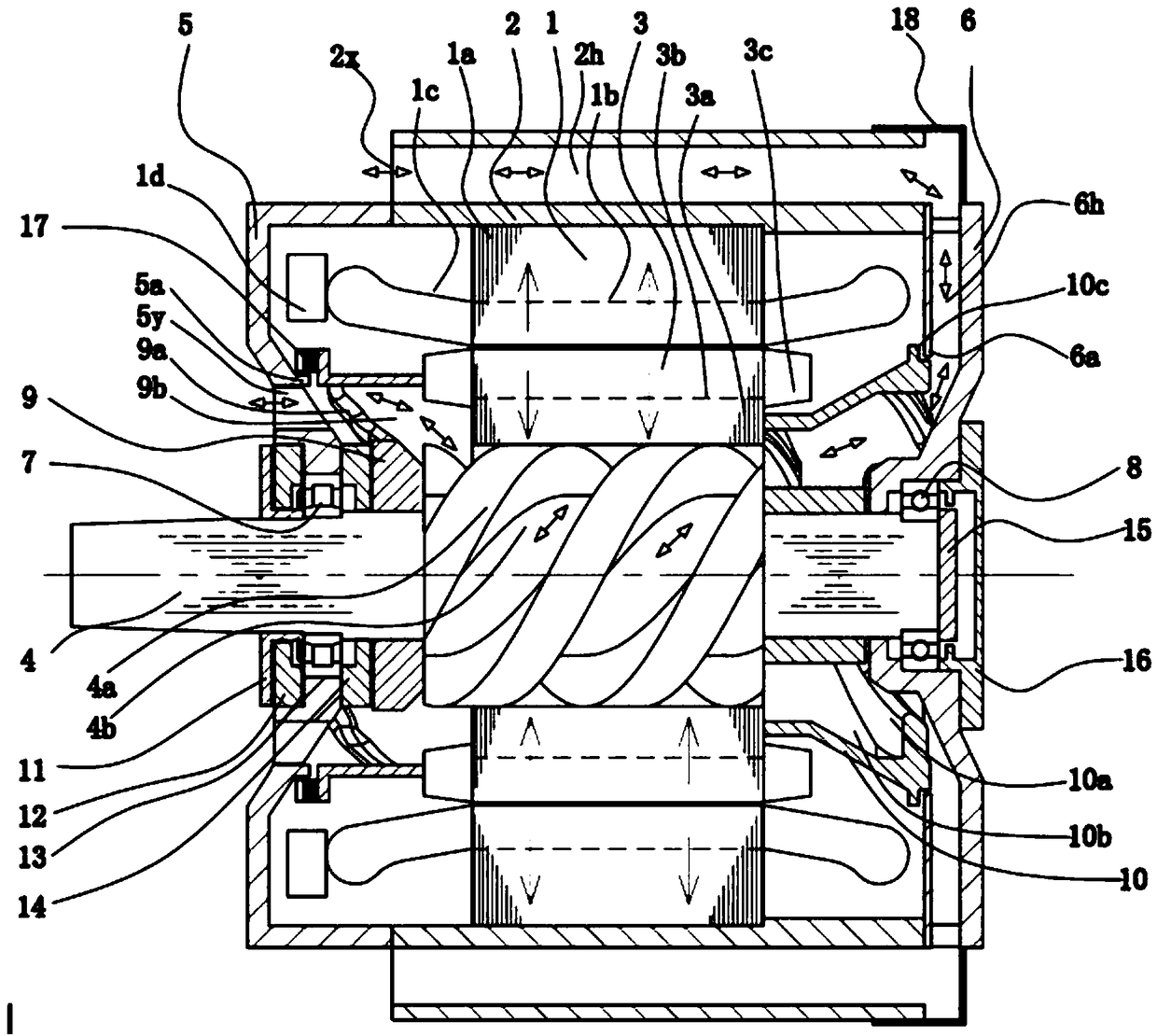

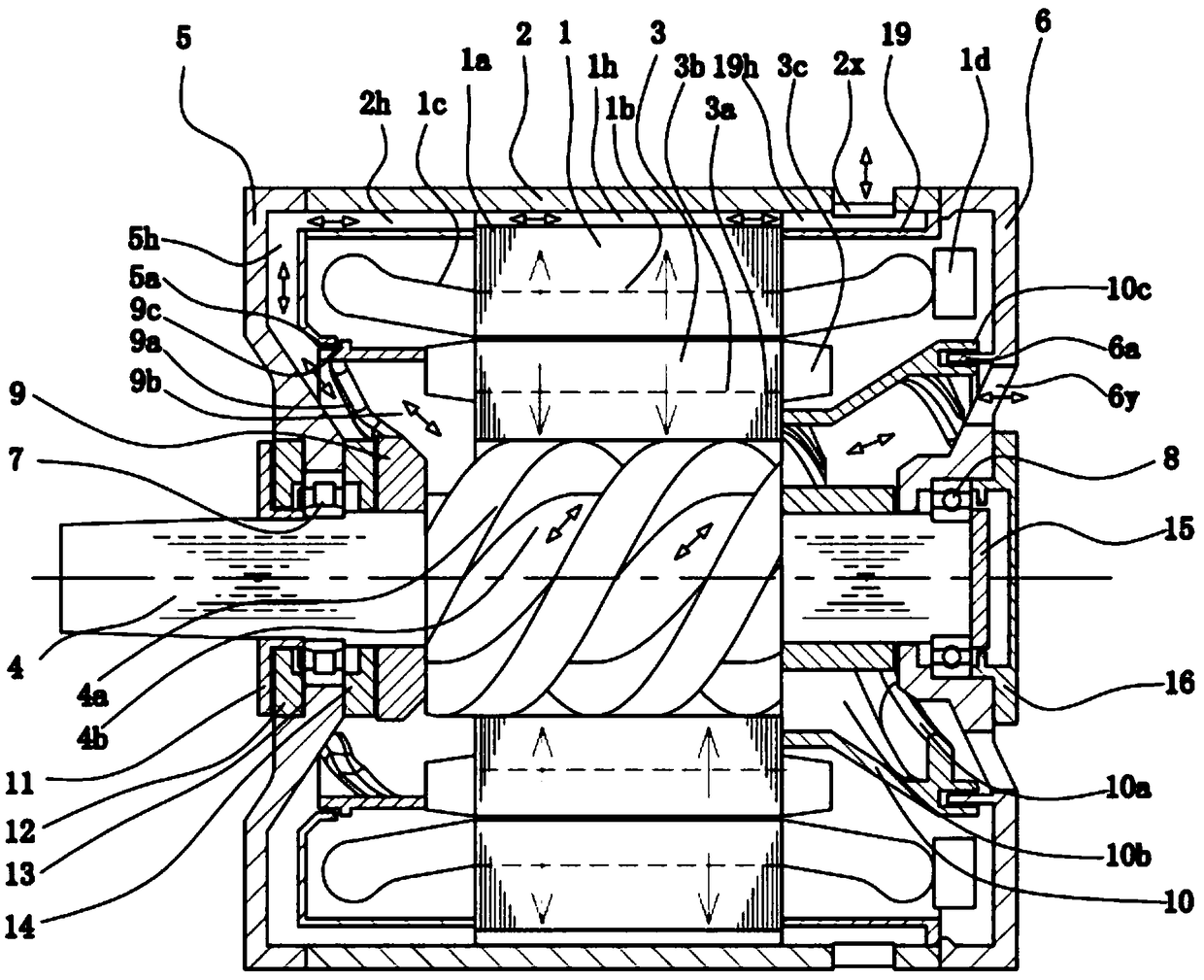

Motor capable of realizing stator closed and rotor open ventilation mode by adopting axial-flow ventilation

ActiveCN105634210AImprove power densityCompactMagnetic circuit rotating partsCooling/ventillation arrangementVentilation modeExtra axial

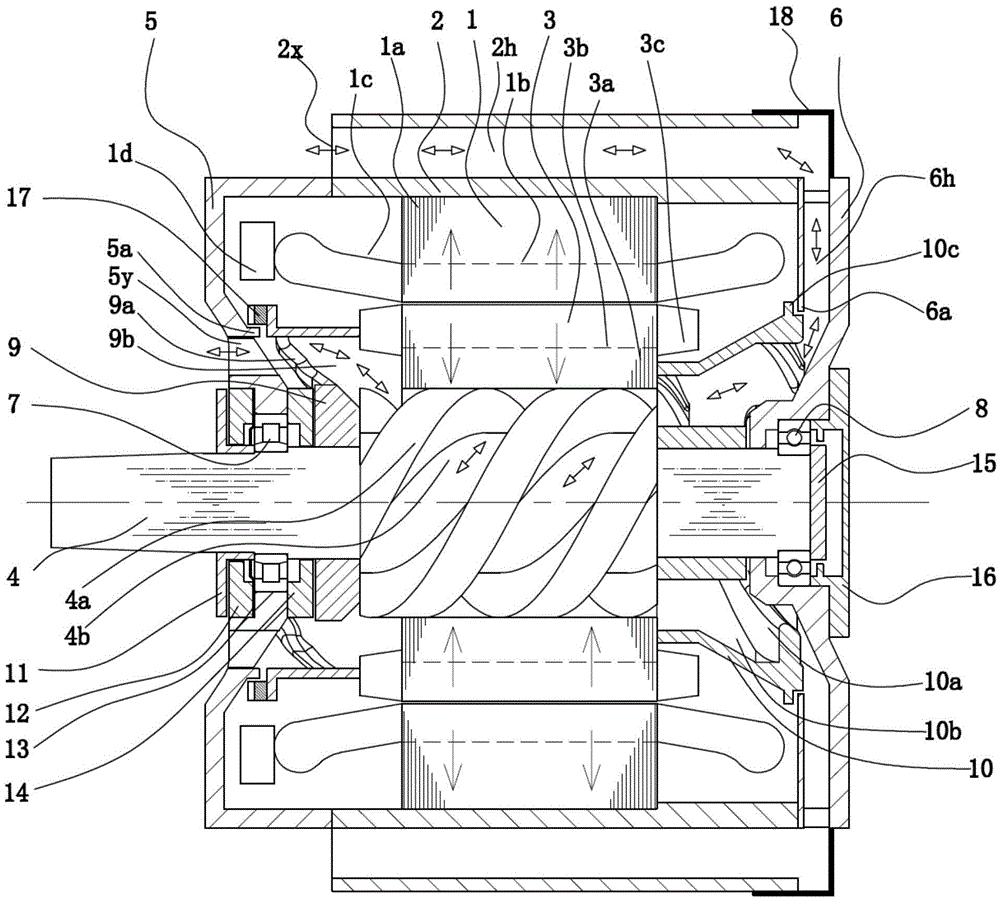

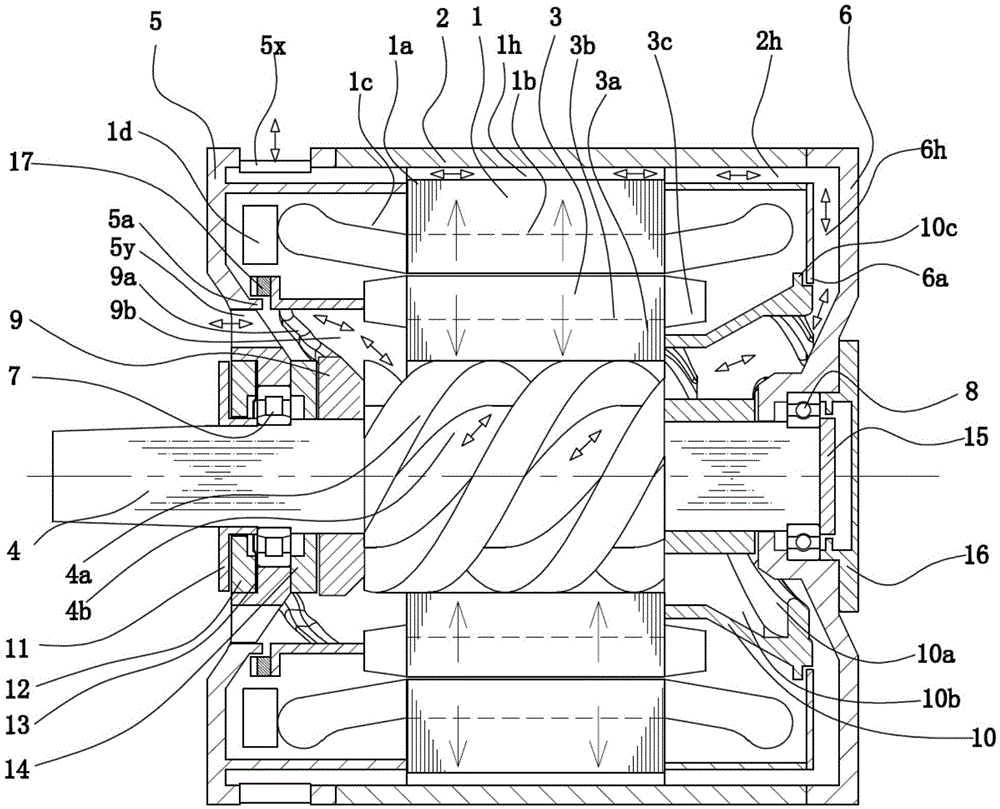

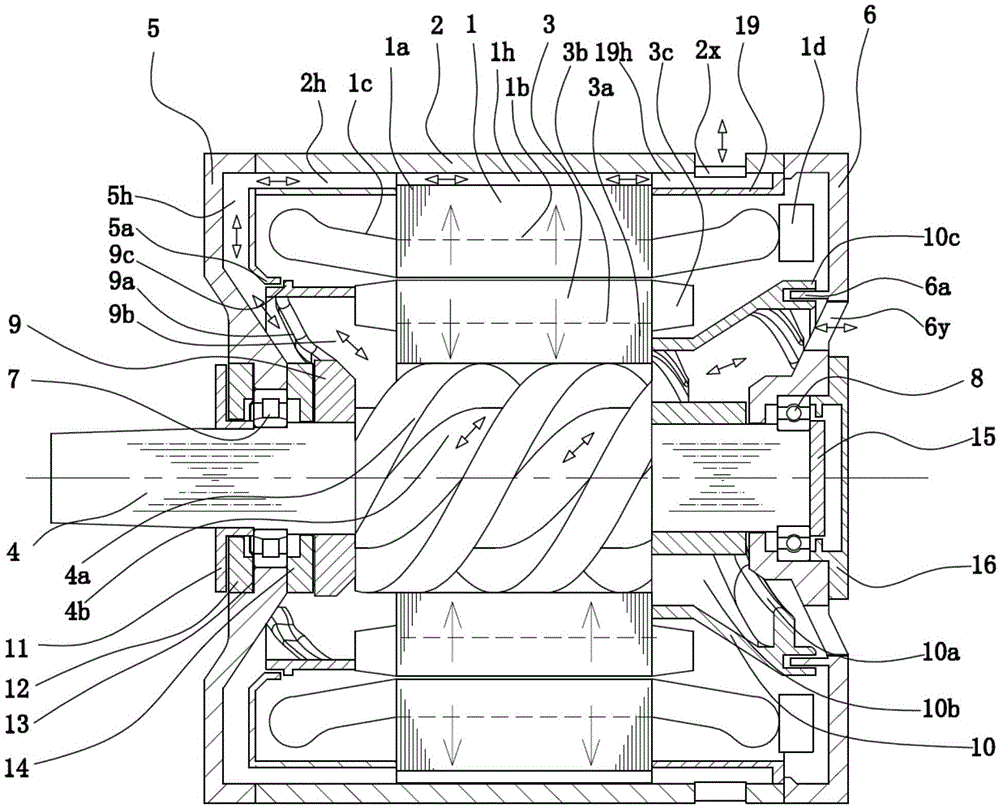

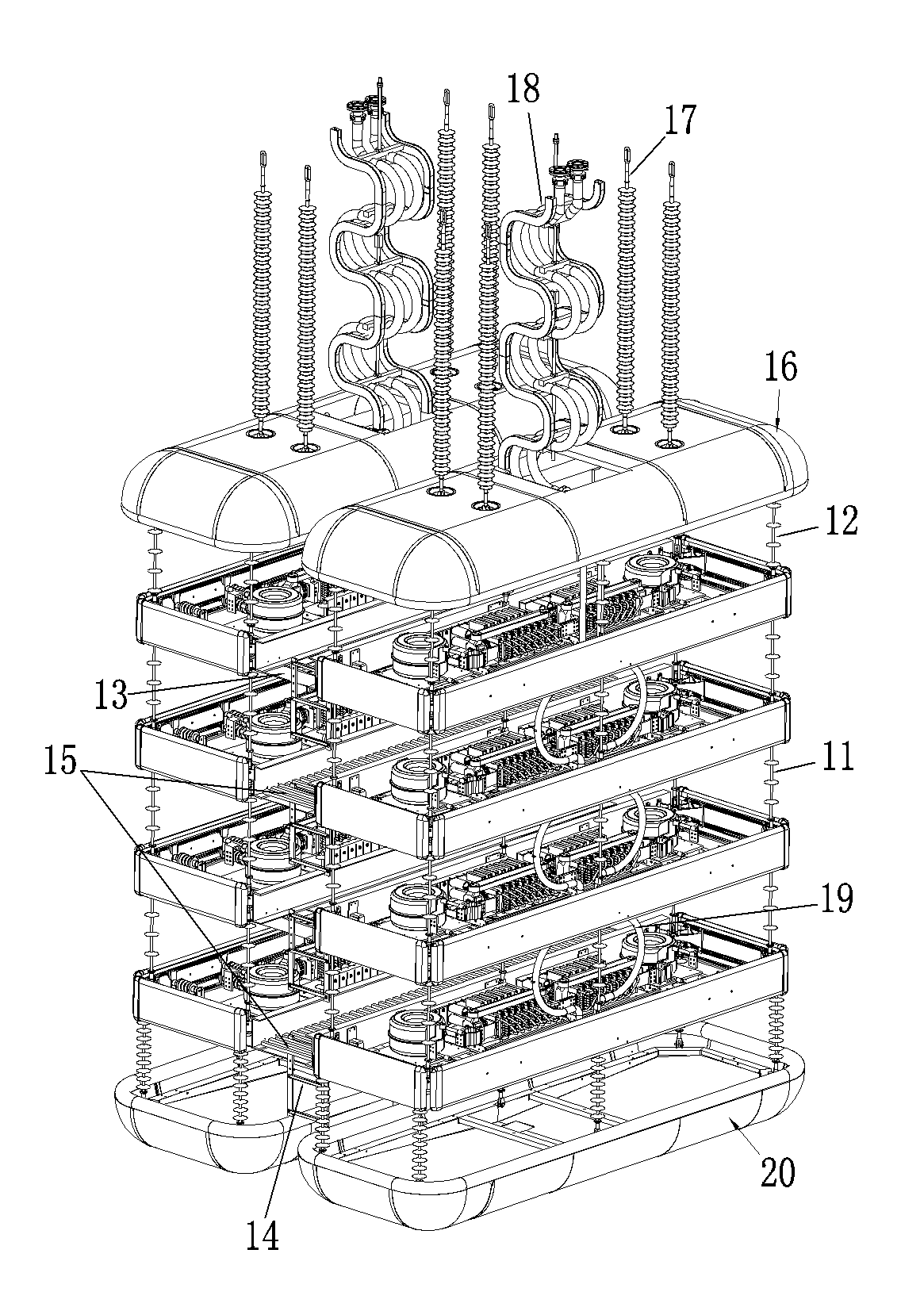

The invention discloses a motor capable of realizing a stator closed and rotor open ventilation mode by adopting axial-flow ventilation. An adopted shaft is provided with an external circumferential spiral groove, and the spiral groove matches with axial-flow fans with two clingy ends and the same spiral directions to form an axial-flow combined ventilation apparatus; the apparatus is arranged in a rotor and at two ends of the rotor, and the extra axial space of the motor is not occupied, so that the motor is compact in structure; due to different steering directions, airflow directions are also different but the motor can be cooled; in combination with labyrinth seal, a combined cooling mode of stator closed ventilation cooling and rotor open ventilation cooling of the motor is realized, and the combined cooling mode enables the insulation reliability of a stator and the heat dissipation capability of a rotor to be both ensured and improves the motor efficiency; a stator cooling air duct consists of vent holes (2x), a stator air duct (2h) and an air duct section (6h); a rotor cooling air duct consists of vent holes (5y), gaps (9b), a spiral groove (4b) and gaps (10b); the two cooling air ducts are connected in series; and the spiral combined apparatus provides air pressures for the cooling air ducts.

Owner:滁州精镁装备模具制造有限公司

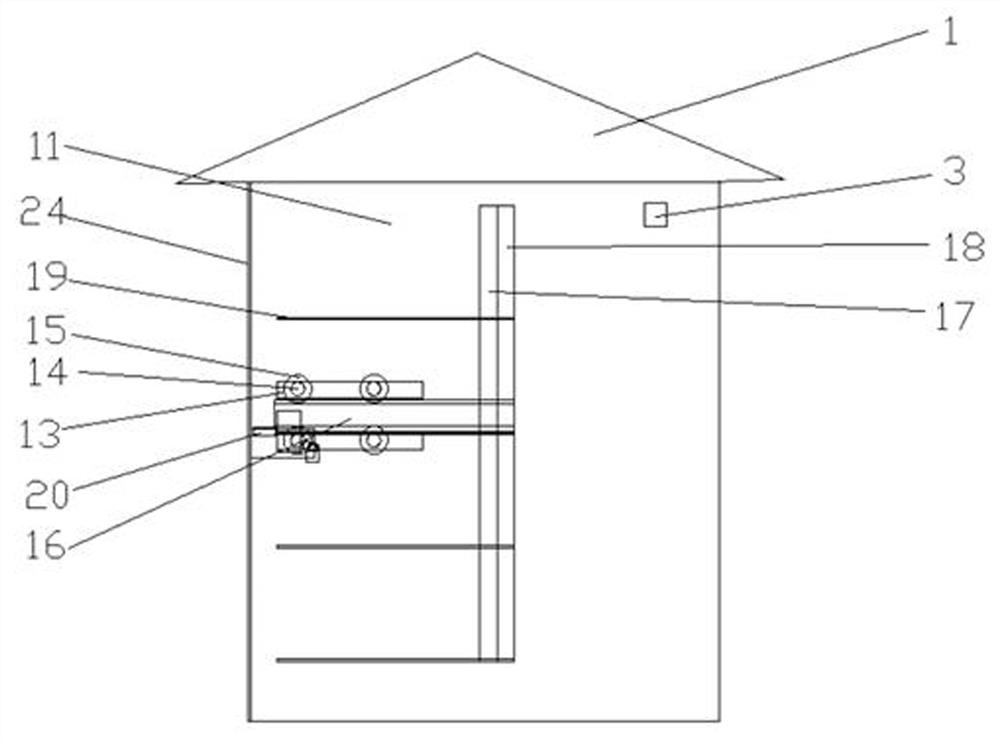

Valve tower for thyristor converter valves

The present invention relates to a high-power electrical electronic rectification and inversion apparatus, and specifically relates to a valve tower for thyristor converter valves, applicable in the fields of high-power high-voltage power transmission engineering and high-power direct-current ice melting. The valve tower comprises two or more valve layers which are laminated from top to bottom. Each valve layer includes at least two converter valve assemblies arranged side by side, and adjacent two converter valve assemblies in the same valve layer are arranged with an interval therebetween and fixedly connected together. A maintenance area is formed in the interval between adjacent two converter valve assemblies in the same valve layer, and a maintenance channel for maintenance personnel to get in and out is formed by the maintenance areas in different valve layers in up-down correspondence. According to the invention, the valve tower has the maintenance channel which provides a space for the operation of the maintenance personnel, such that the operation of the maintenance personnel is convenient, and the problem of the inconvenience in the maintenance caused by the small maintenance space of the conventional valve tower for the converter valves is solved.

Owner:XJ ELECTRIC

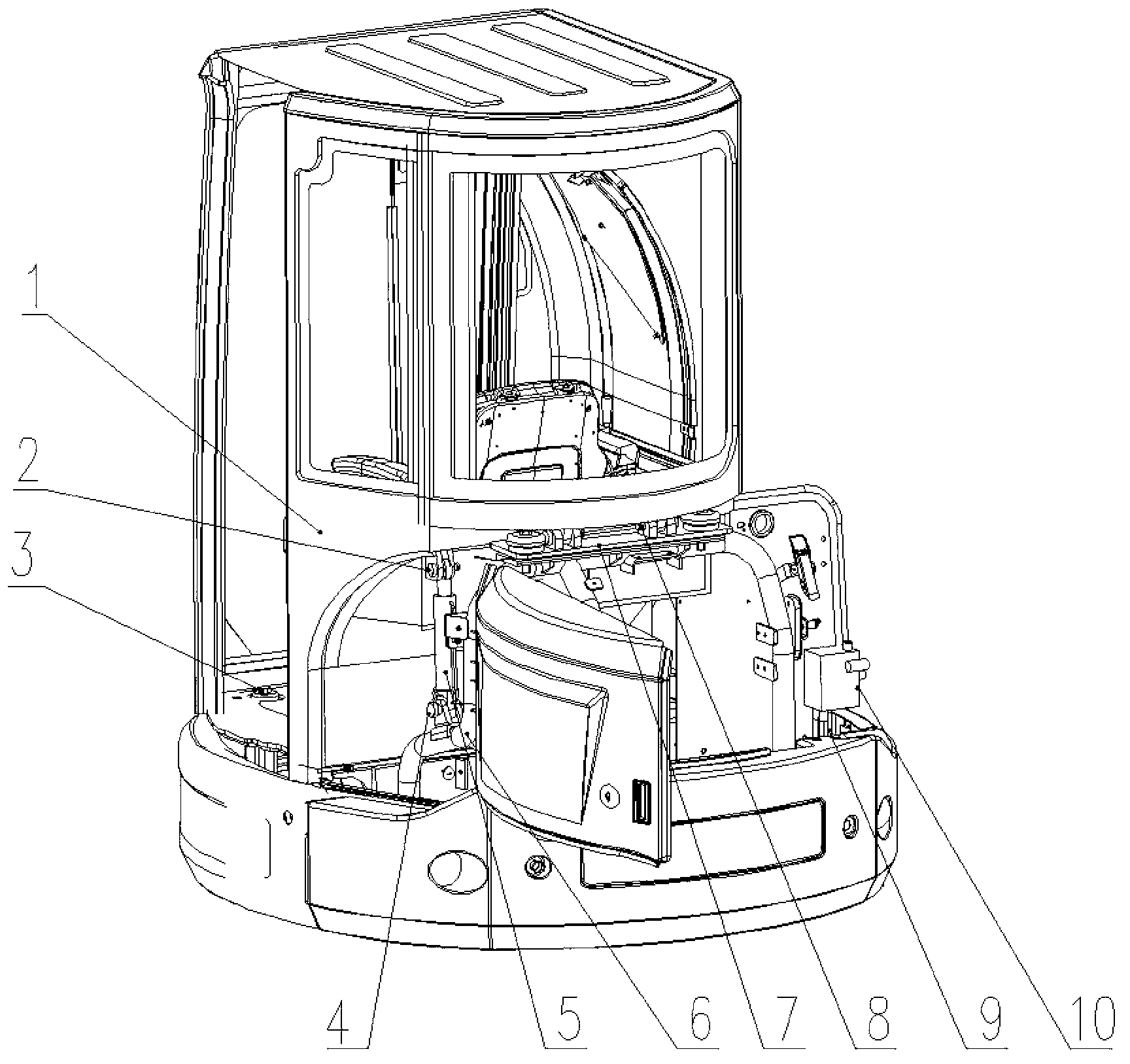

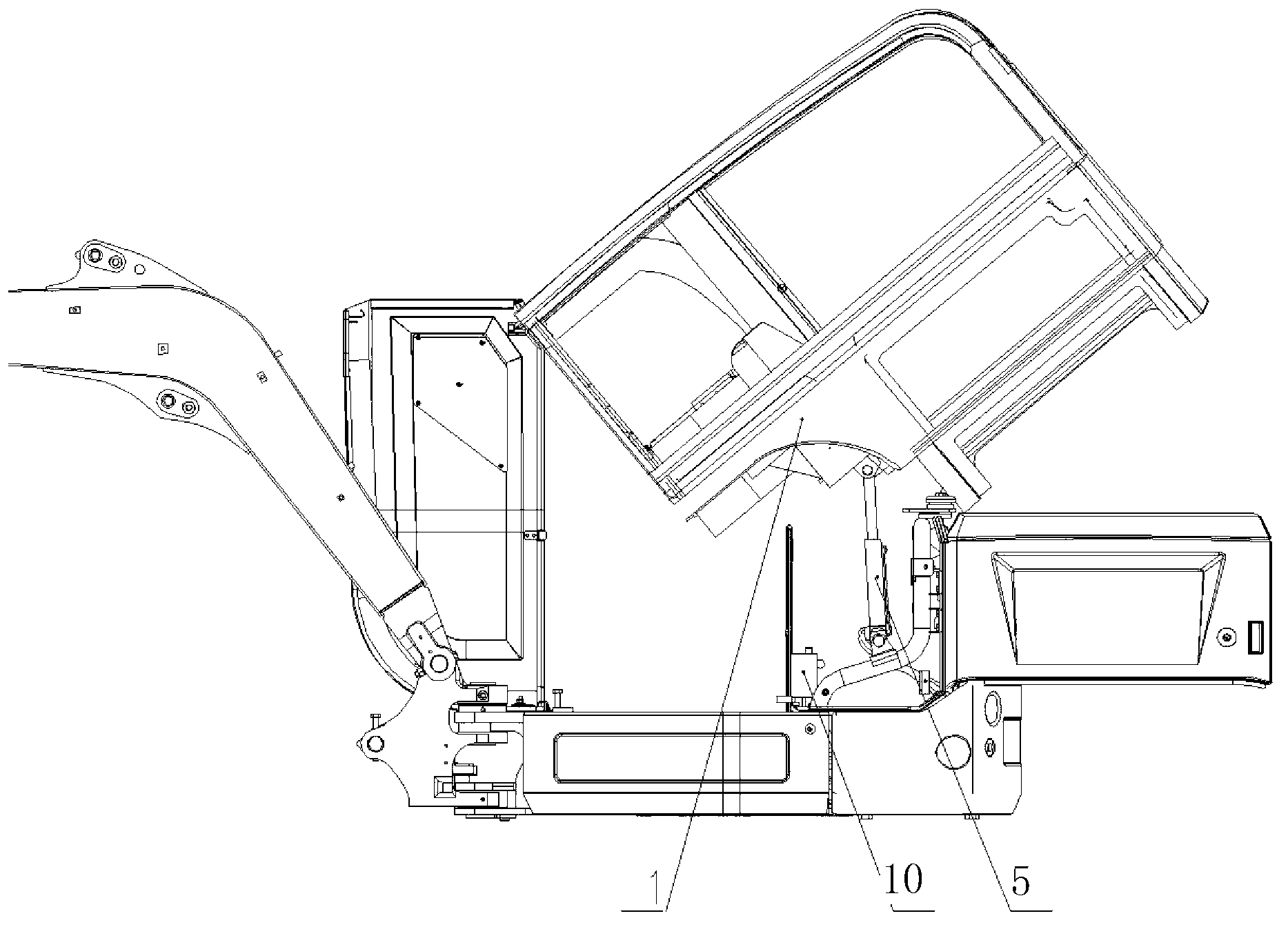

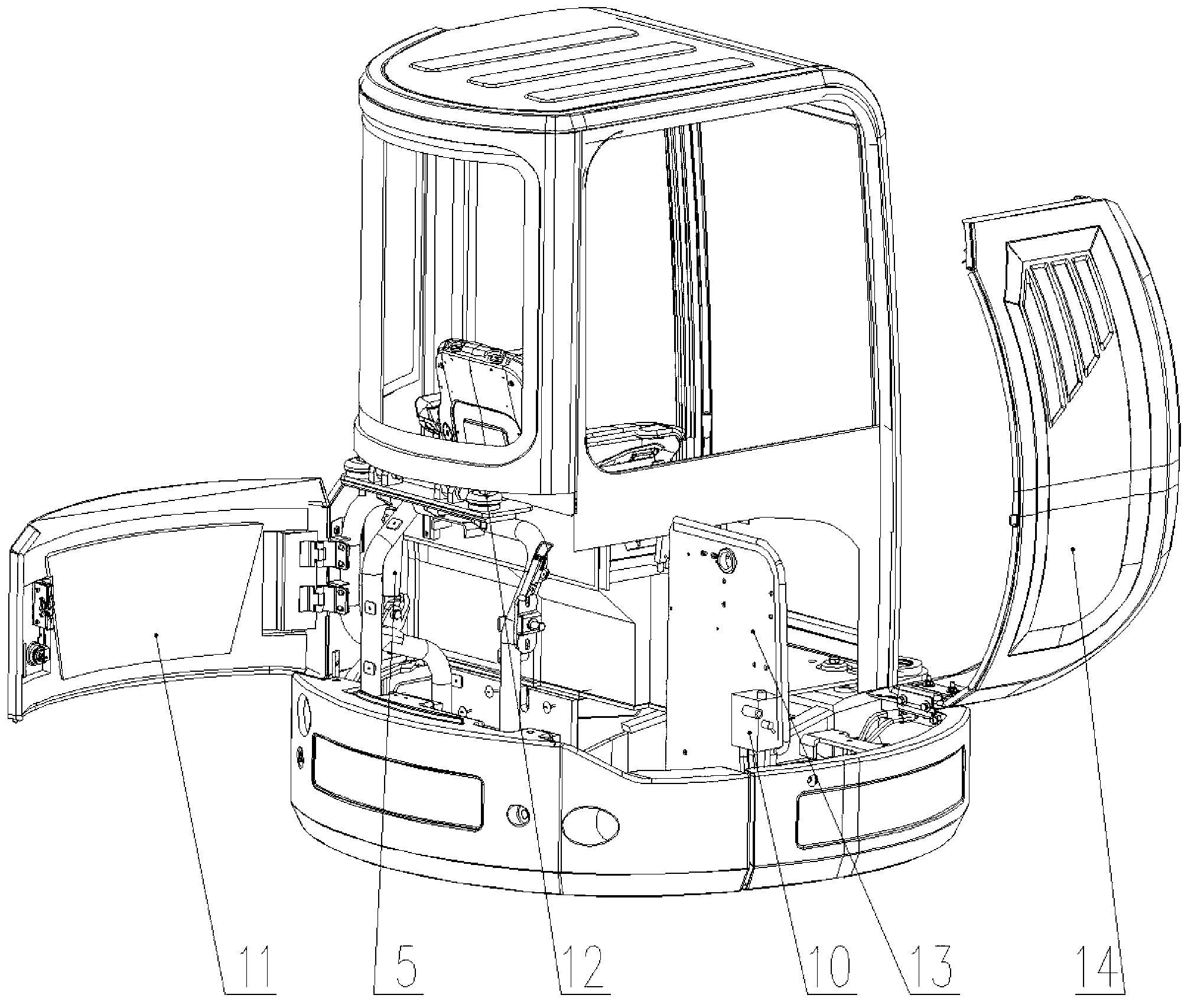

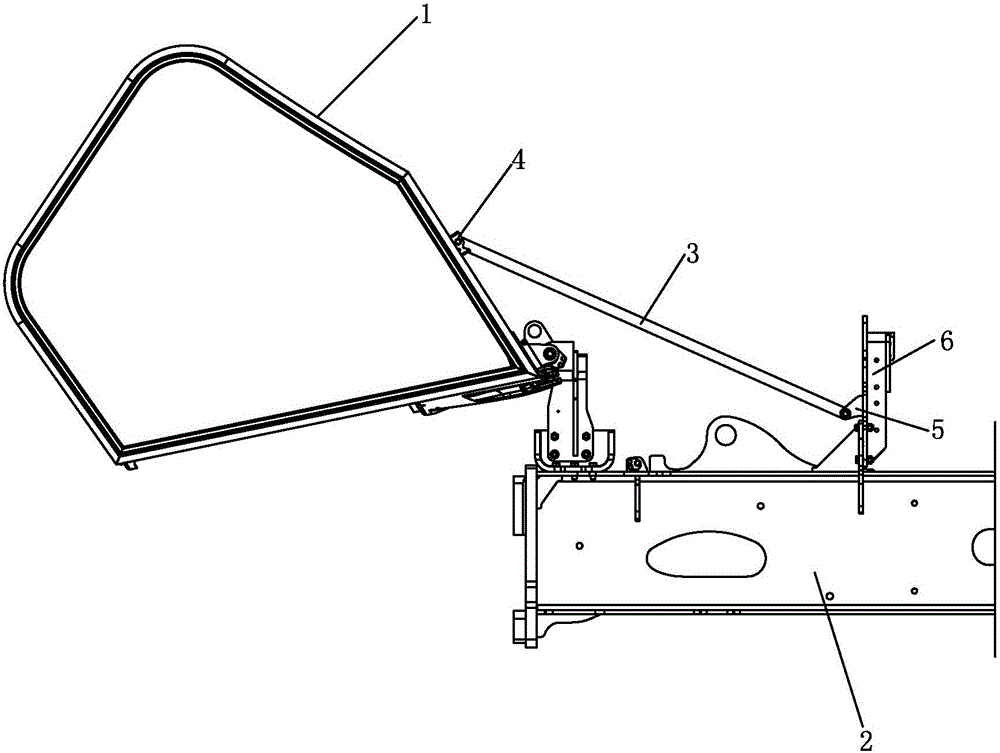

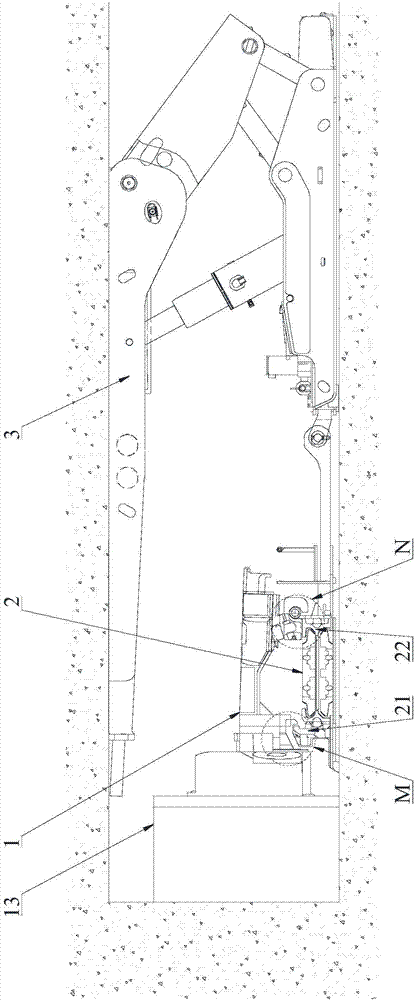

Small excavator

The invention relates to a small excavator which aims to overcome the defects that for an existing small excavator with a cab mounted in a hinged mode, turning up of the cab is limited, and consequently the existing small excavator with the cab mounted in the hinged mode is inconvenient to repair. The small excavator is structured and comprises a cab and a mounting platform for mounting the cab, wherein the cab is connected and mounted the mounting platform in the hinged mode, a turning hinged point of the cab is arranged at the rear of the front-and-rear direction of the cab and hinged to the mounting platform at the top of the mounting platform, a lifting device is arranged on the lower portion of the cab and lifts the cab to make the cab rotate around the hinged point. According to the small excavator, the hinged point is located at the rear of the cab and hinged to the top of the mounting platform, the distance from the hinged point to the bottom of the cab is large, when the cab turns by a small angle around the hinged point, the bottom of the cab can be wholly lifted by a large height, and large space is provided for repairing of other parts which are mounted on the mounting platform and located below the cab.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

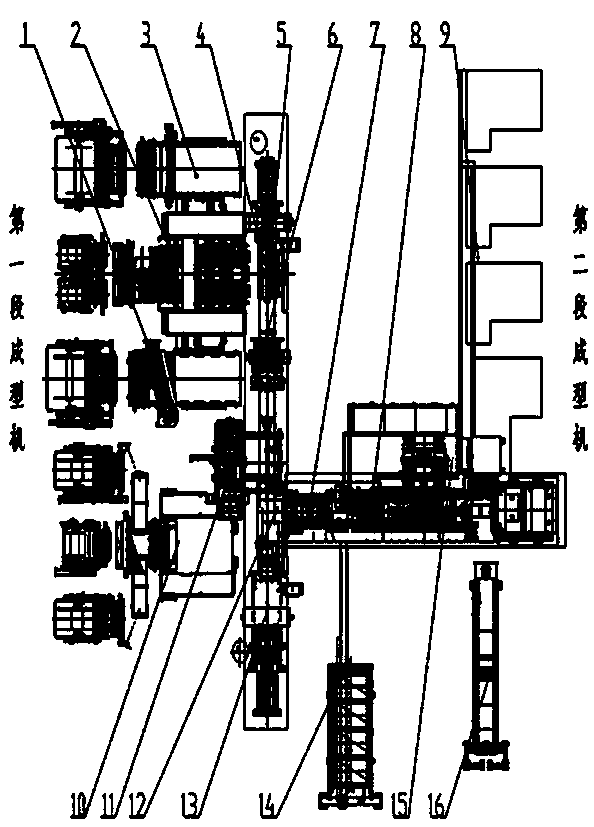

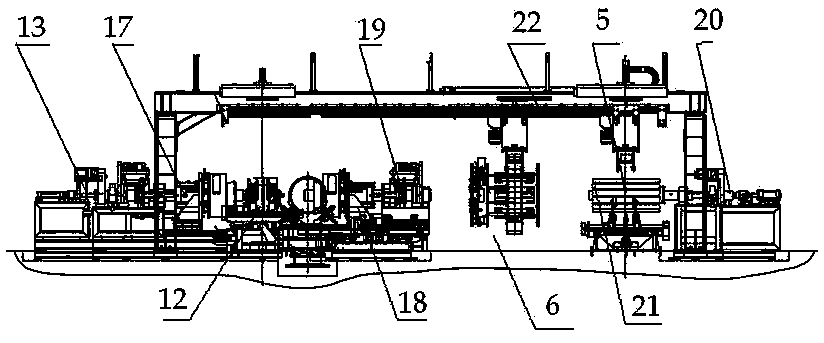

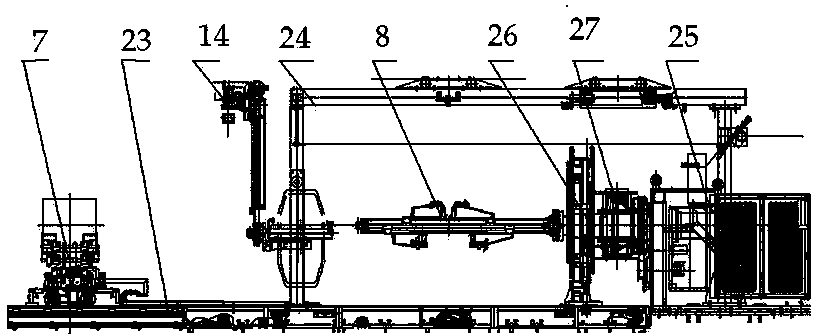

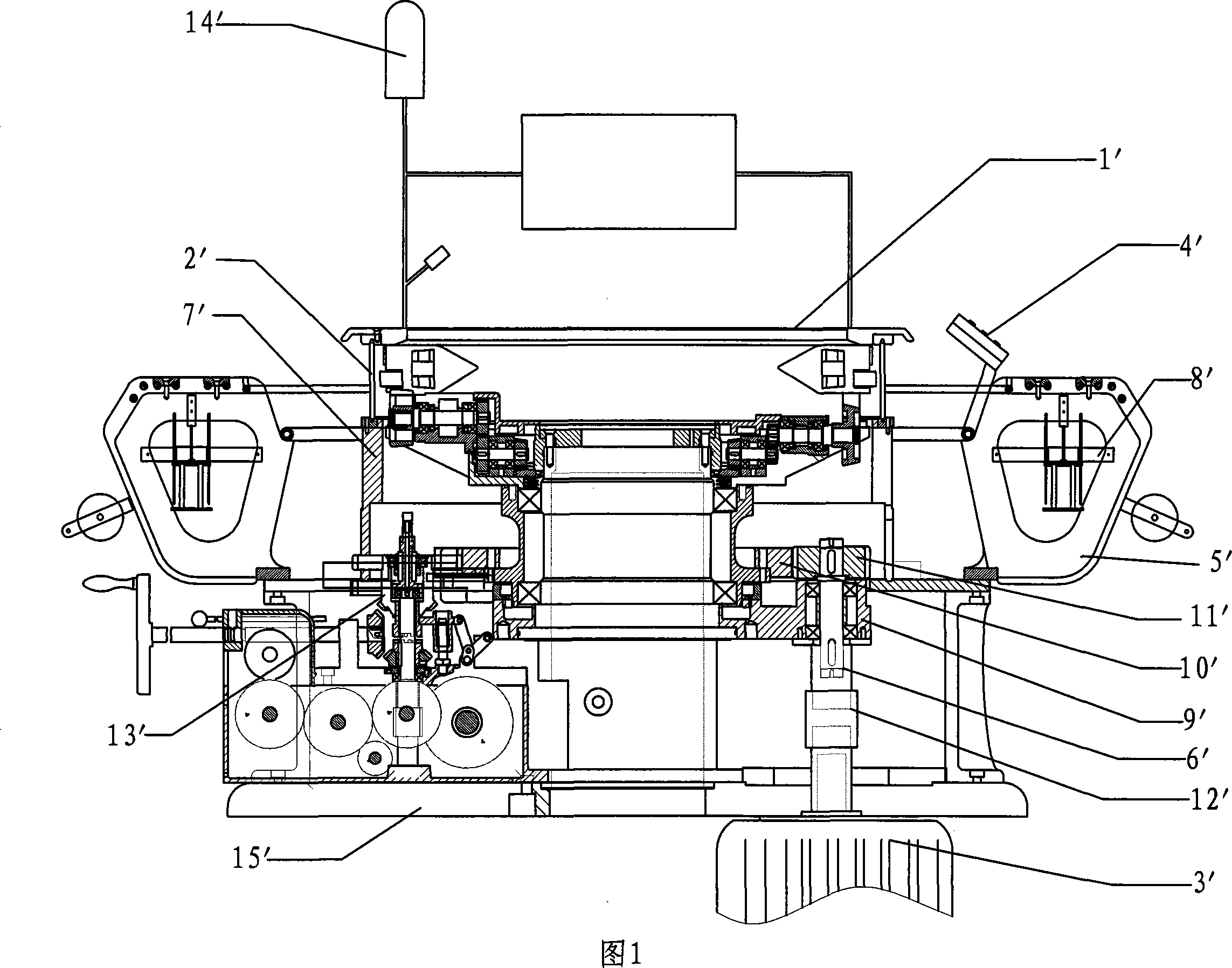

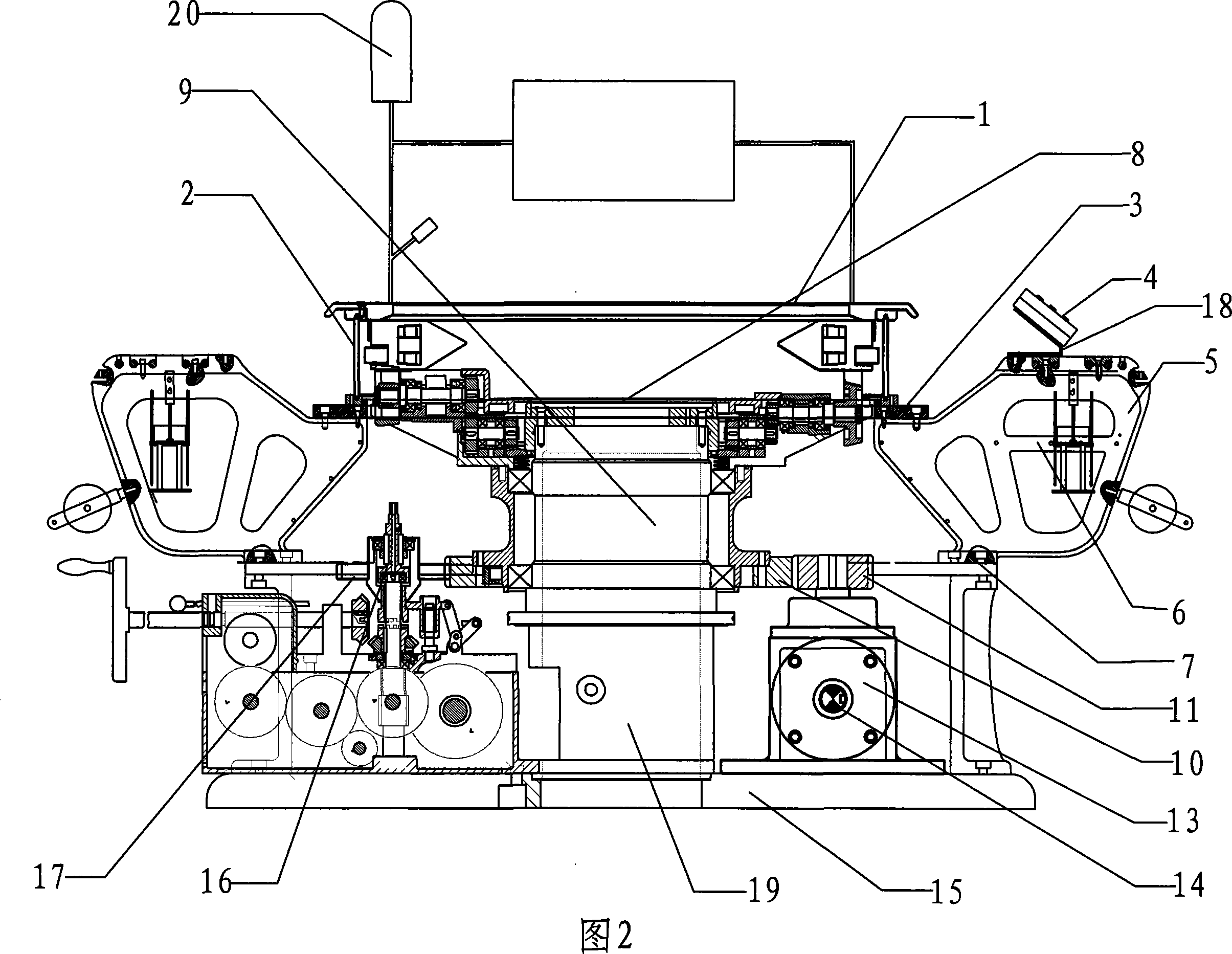

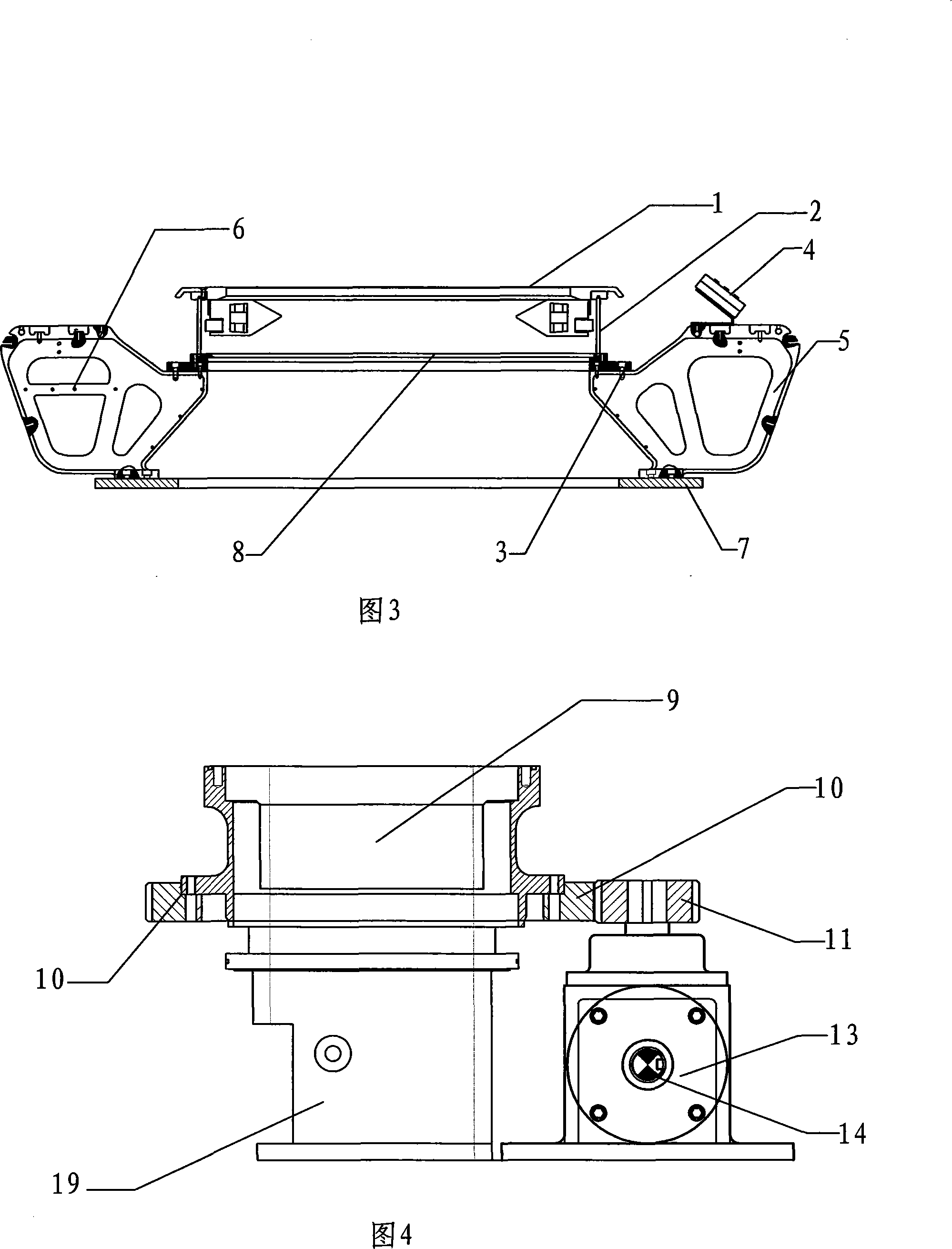

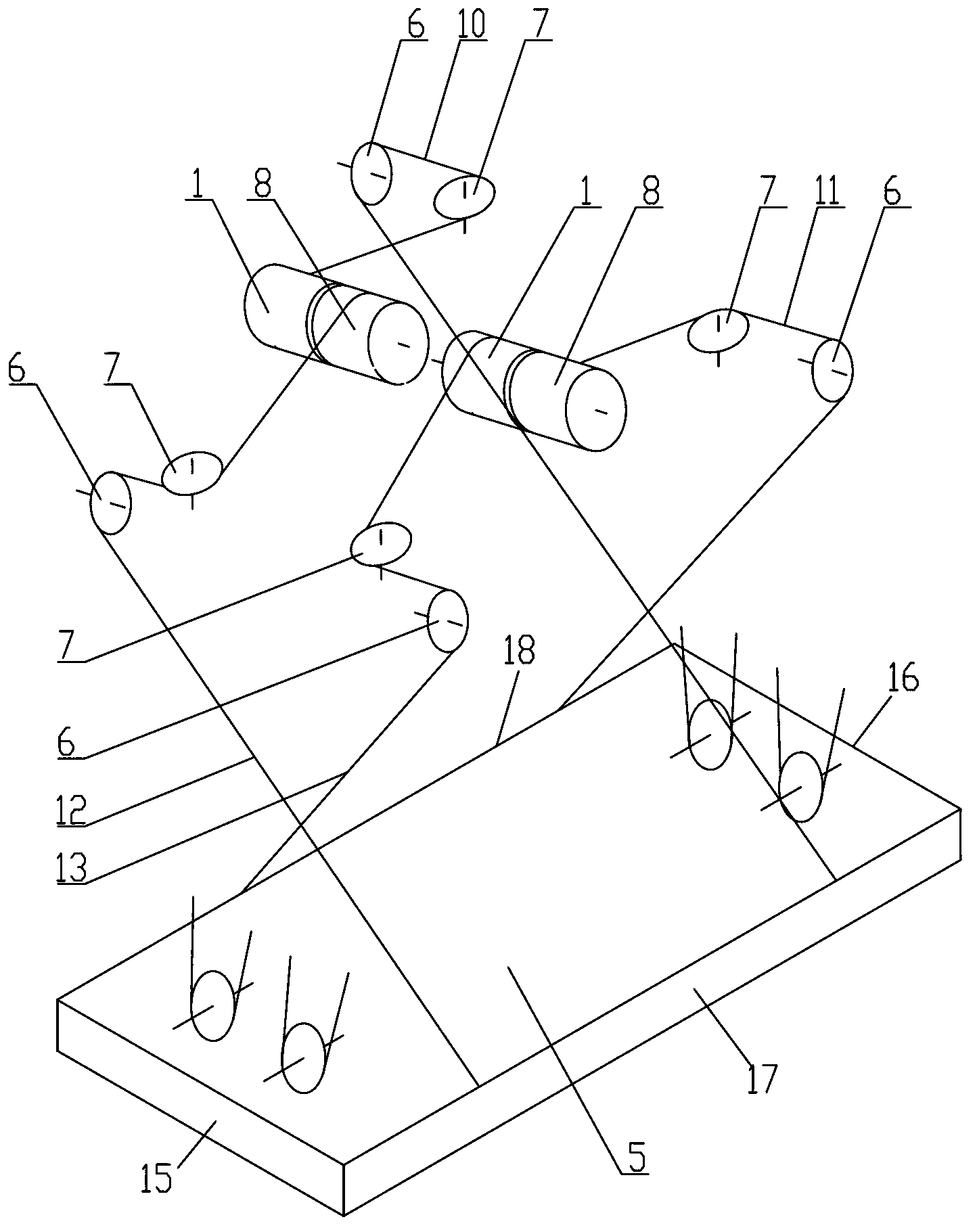

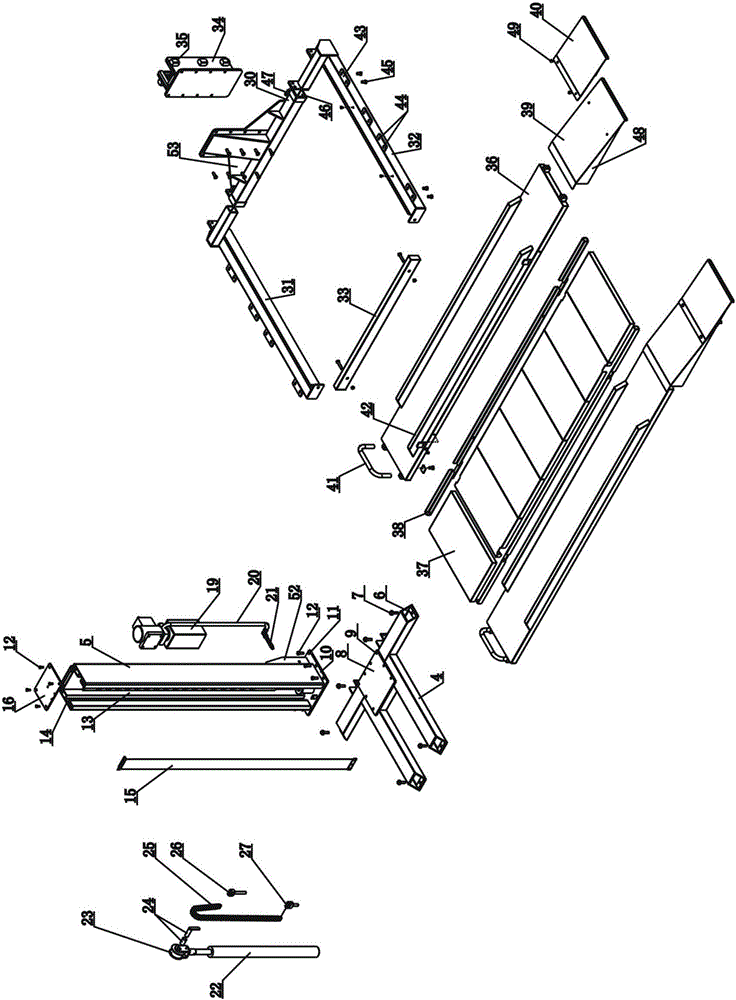

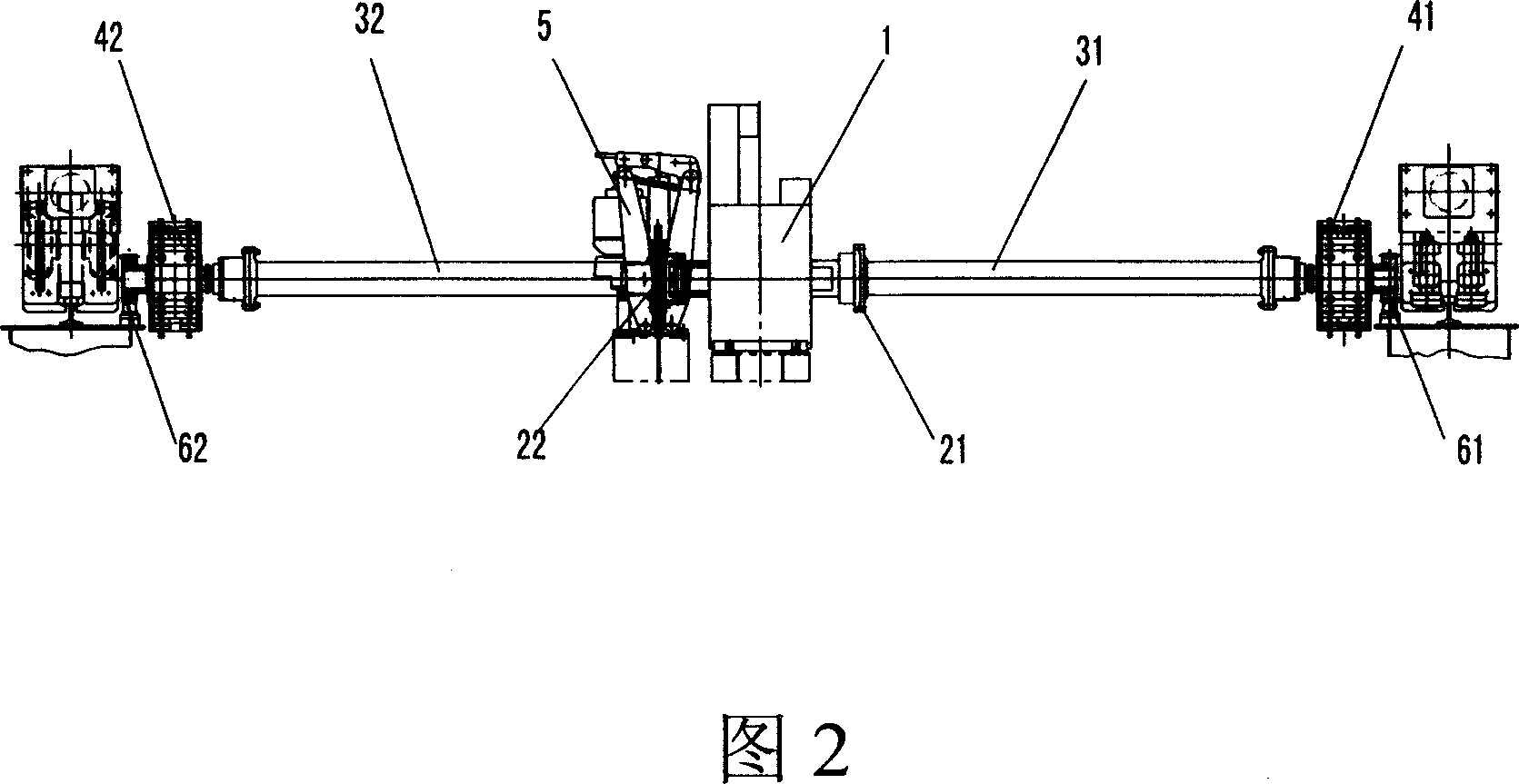

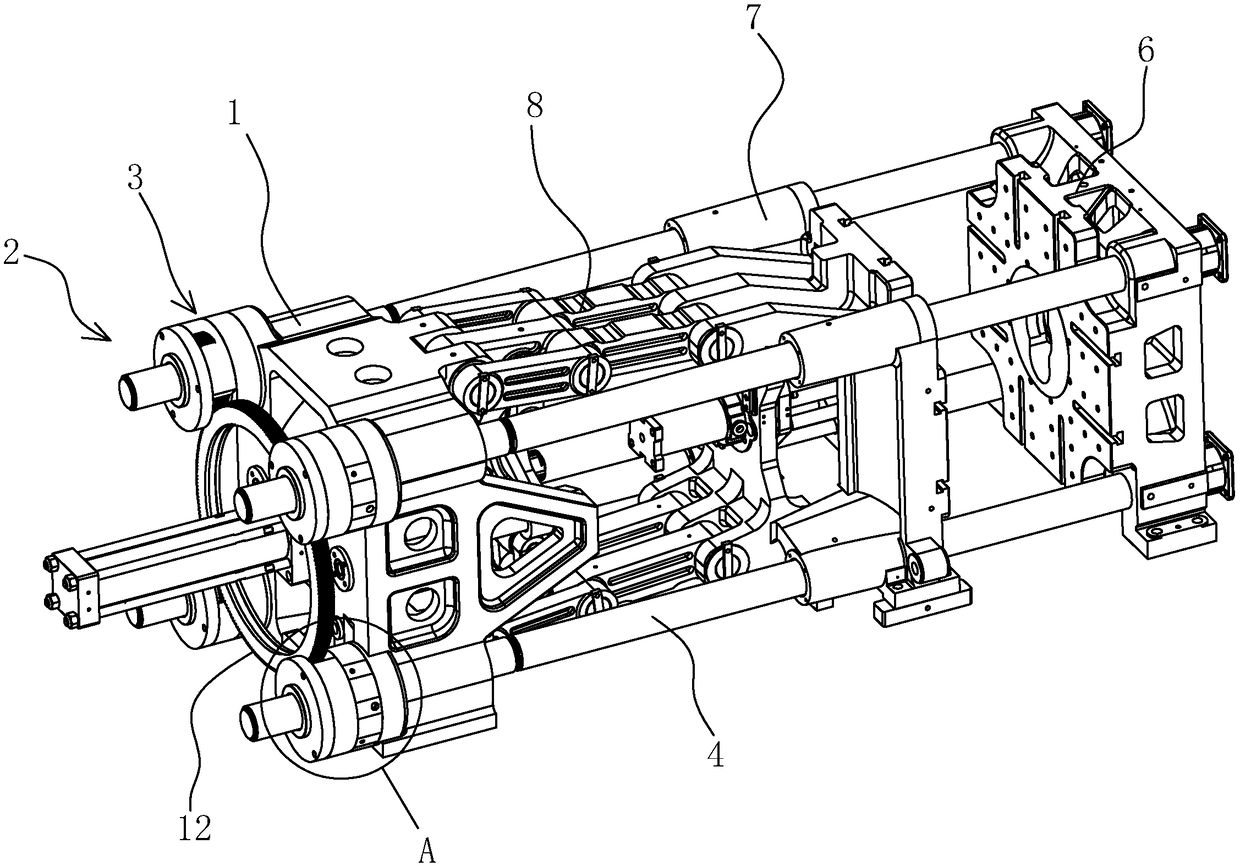

Two-stage four-drum forming machine for all-steel truck radical tires

The invention relates to a two-stage four-drum forming machine for all-steel truck radical tires, which is characterized by being composed of a first-section forming machine and a second-section forming unit, wherein the first-section forming machine comprises a truss, a first-section tire-body attaching drum, a feeding rack mechanism, a tire-body transfer ring, a first-section forming drum host and a tire-body tube transfer carriage; and the truss is of an inverted U-shaped structure, the first-section tire-body attaching drum and the tire-body transfer ring are sequentially arranged on a cross beam above the truss, a tire-body attaching drum transmission case and a set of tire-body rolling device are arranged in the first-section tire-body attaching drum, the first-section forming drum host comprises left and right reverse packing devices, left and right forward packing devices, a first-section forming drum and rear compression roller device, and a first-section forming drum tail seat, and the left and right reverse packing devices are arranged below the truss. According to the invention, a two-stage four-drum forming machine for all-steel truck radical tires is specially used for producing loaded all-steel radial tires with large bearing, and can achieve an extremely good effect on solving heavy load and seam allowance problems.

Owner:青岛海琅智能装备有限公司

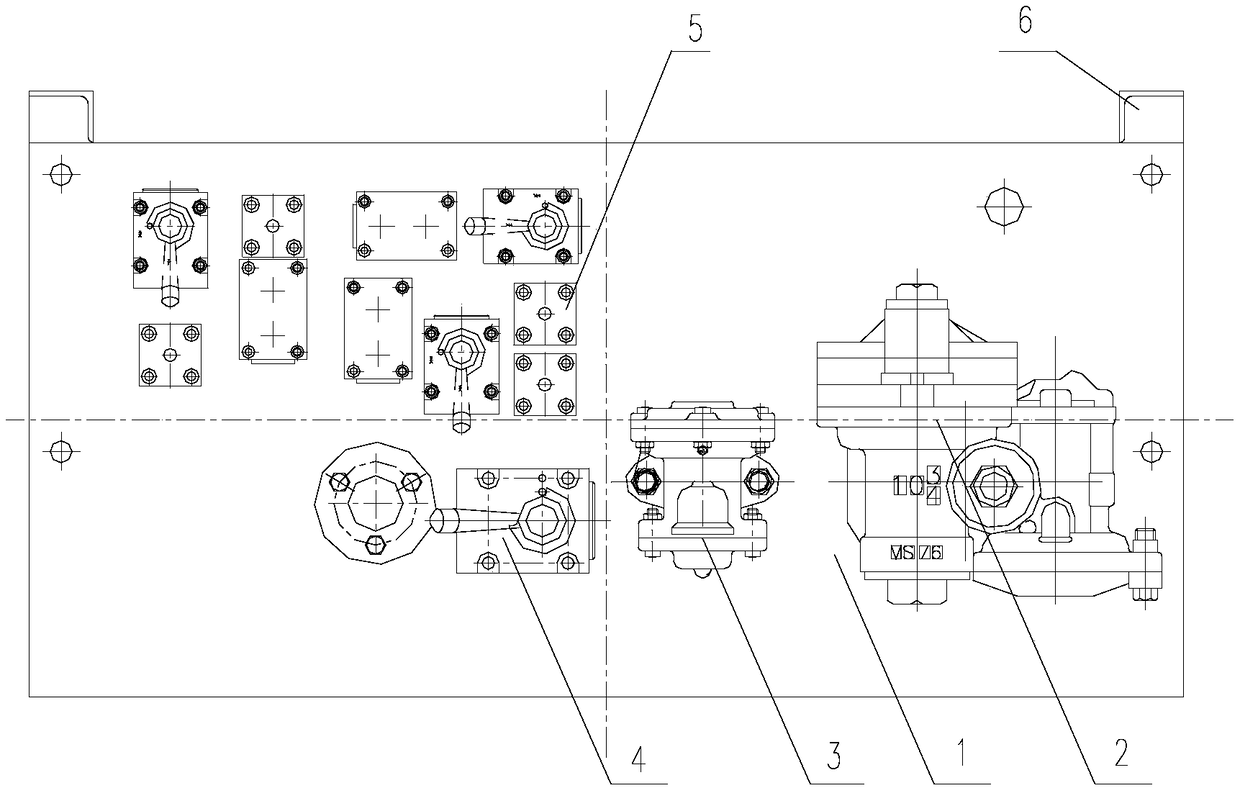

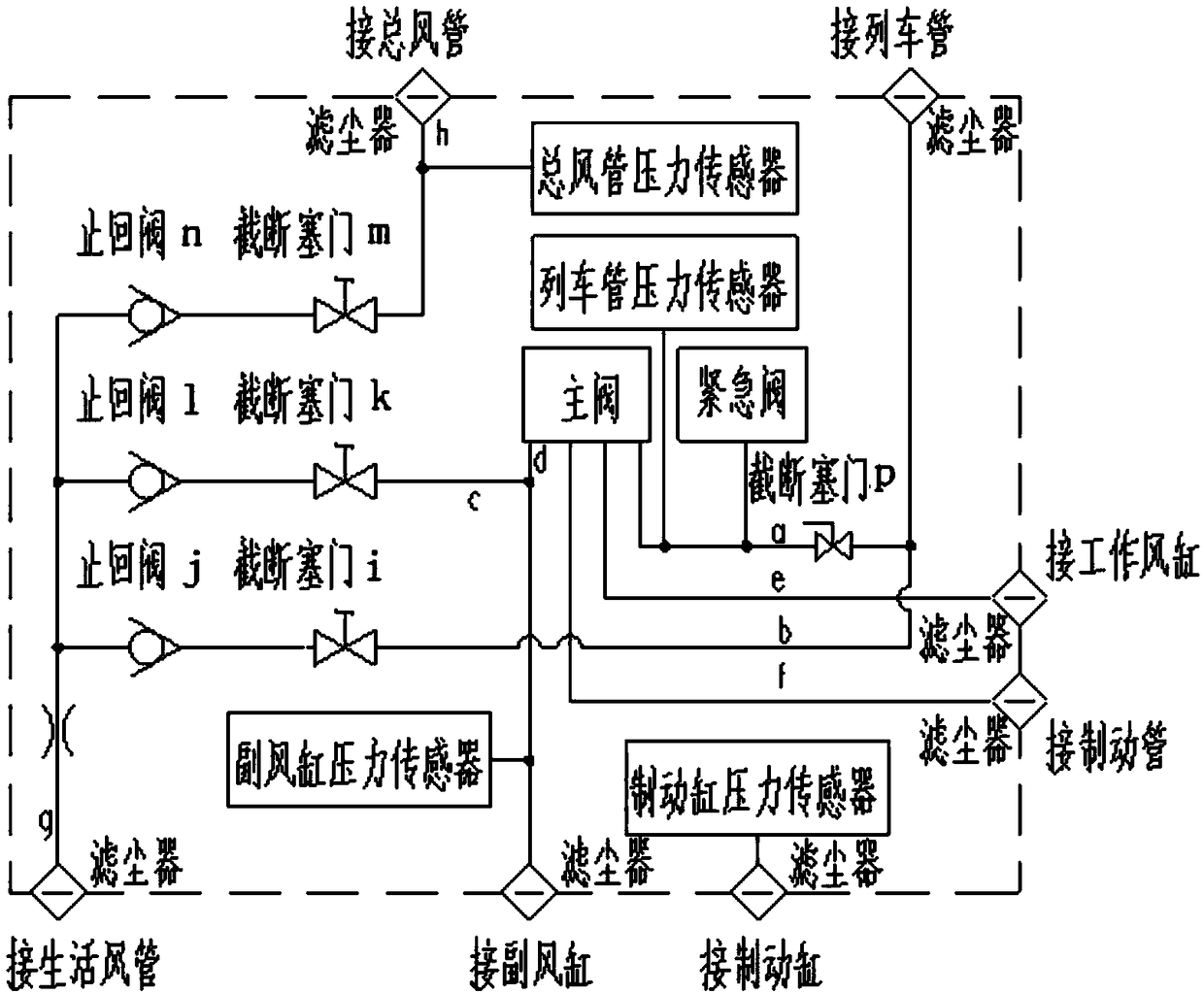

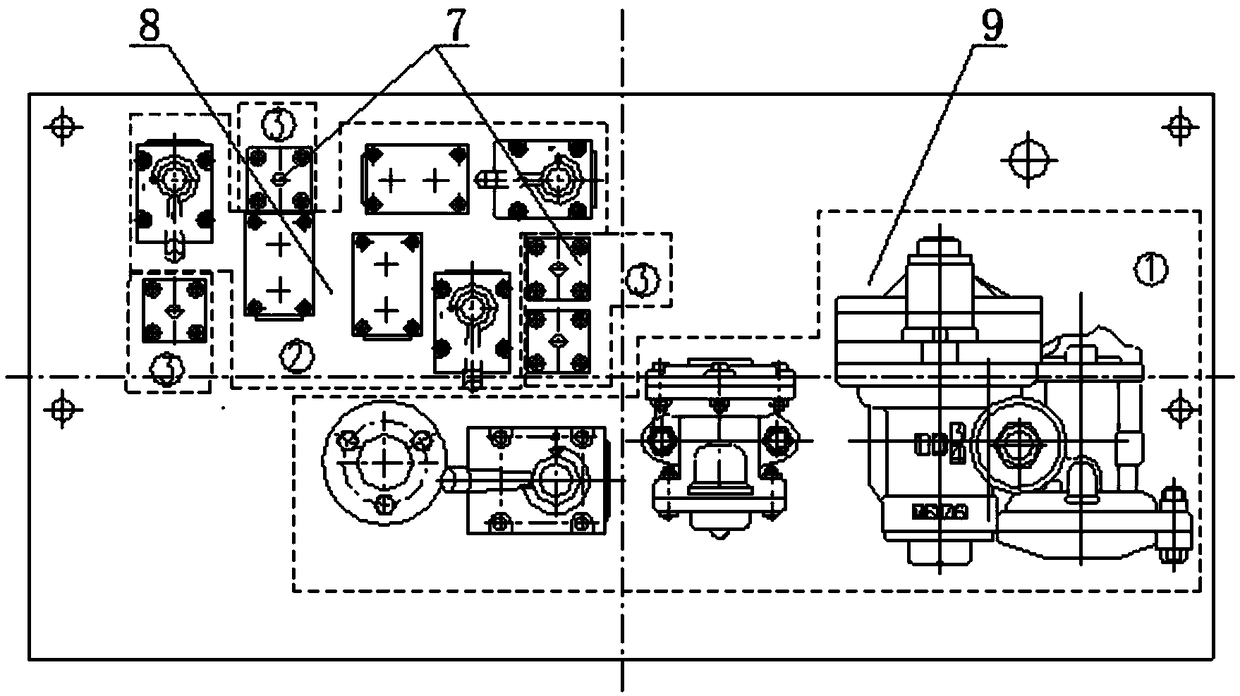

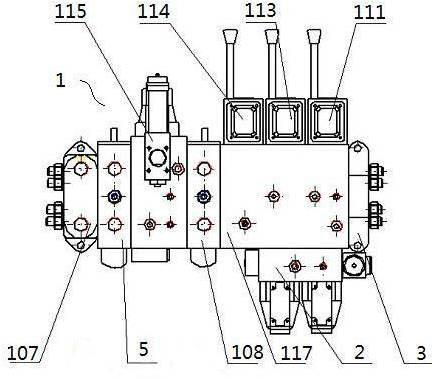

Integrated air braking device for rail vehicles

ActiveCN109204373AImprove reliabilityImprove securityRailway hydrostatic brakesRailway hydrodynamic brakesCheck valveAuxiliary system

The invention relates to an integrated air braking device for rail vehicles, which comprises a brake integrated plate and a main valve, an emergency valve, a stopper valve, a check valve, a column pipe pressure sensor, a main air pipe pressure sensor, a brake cylinder pressure sensor and an auxiliary air cylinder pressure sensor mounted on the brake integrated plate. The brake integrated plate isalso provided with a train pipe interface, a working air cylinder interface, a brake pipe interface, an auxiliary air cylinder interface, a main air pipe interface, a brake cylinder interface and a living air pipe interface, and the brake integrated plate is internally provided with an air path to ensure the communication between each equipment of the air path plate. The device of the invention centralizes the function of the 104 distribution valve, and can brake the vehicle and alleviate the effect; the QD-G function can realize the conversion of single pipe and two pipes of the vehicle, andat the same time provide the wind demand for the auxiliary system of the vehicle; pressure sensors are also installed to detect the pressure in each piping when the vehicle is braked.

Owner:CRRC NANJING PUZHEN CO LTD +1

Energy-saving circular weaving machine

The invention provides an energy-saving circular loom which has optimum structural design, increases motor rotational speed and reduces motor power, thereby reduces power consumption, which improves the shortcoming that the existing circular loom has large energy consumption, convenient maintain and the like. The invention mainly comprises a circular guideway, a shuttle guiding frame, a wallboard, a shuttle-race, a bearing support of the shuttle-race, a central seat, a main drive nylon large gear, a drive gear wheel, a beveled wheel, a button box, an electric motor and a large chassis, wherein the shuttle-race is fixed on the bearing seat of the shuttle-race, the lower end of the bearing seat of the shuttle-race is connected with the central seat, the central seat is fixed on the large chassis, the drive gear wheel is connected with the main drive nylon large gear, and the inner lateral of the circular guideway is provided with a line breaking alarm indicator light. The invention is characterized in that the electric motor is horizontally arranged and horizontally connected with a reversing decelerator through a shaft coupling, the drive gear wheel is sleeved on the vertical output end of the reversing decelerator and engaged with the main drive nylon large gear which is fixed on the lower end of the bearing seat of the shuttle-race, and both the electric motor and the reversing decelerator are mounted on the surface of the large chassis.

Owner:NANTONG BECA MACHINERY TECH

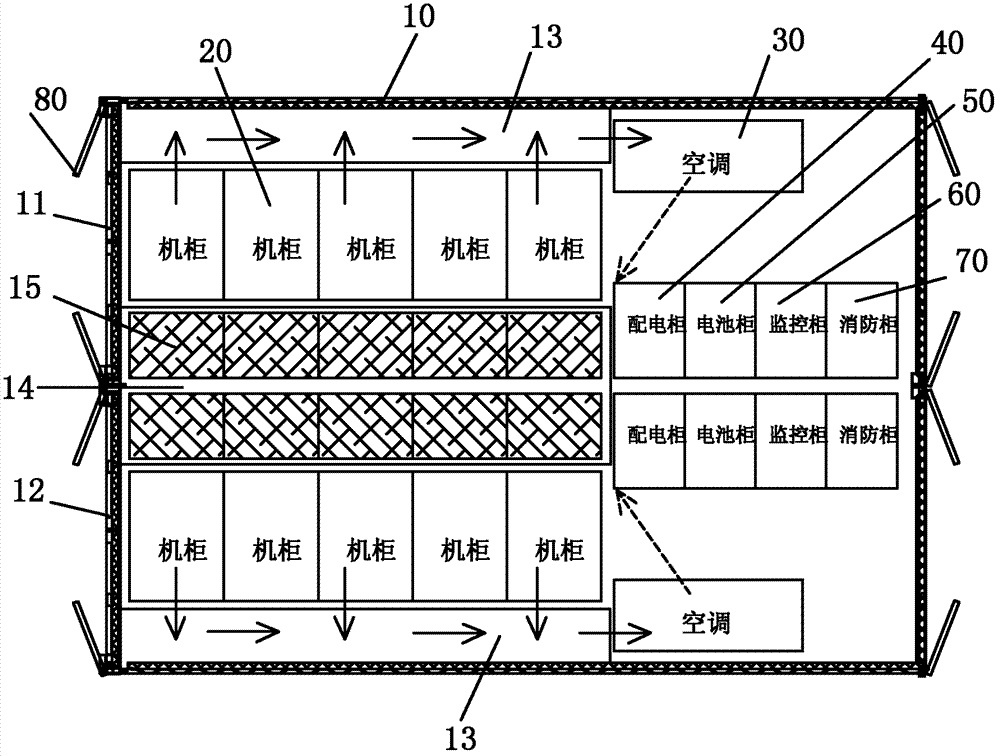

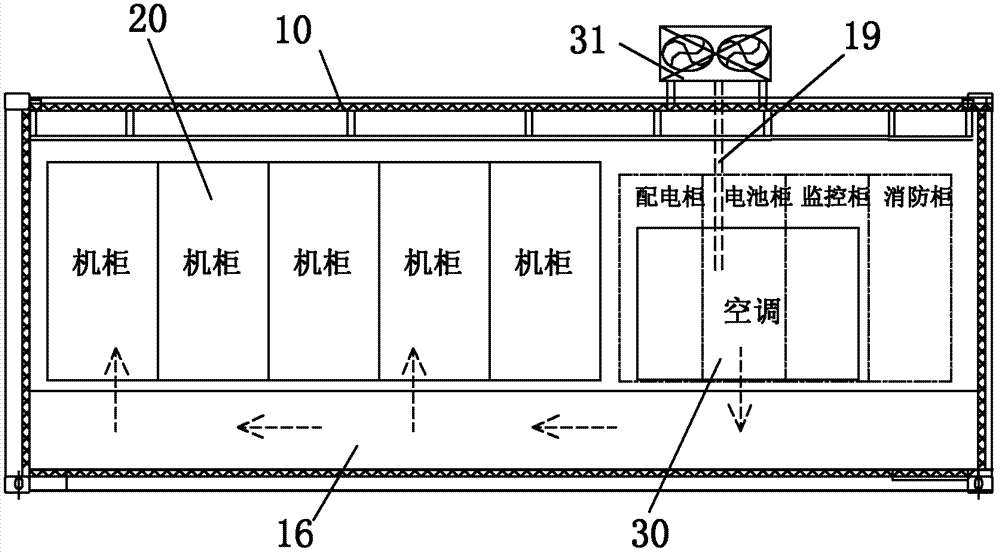

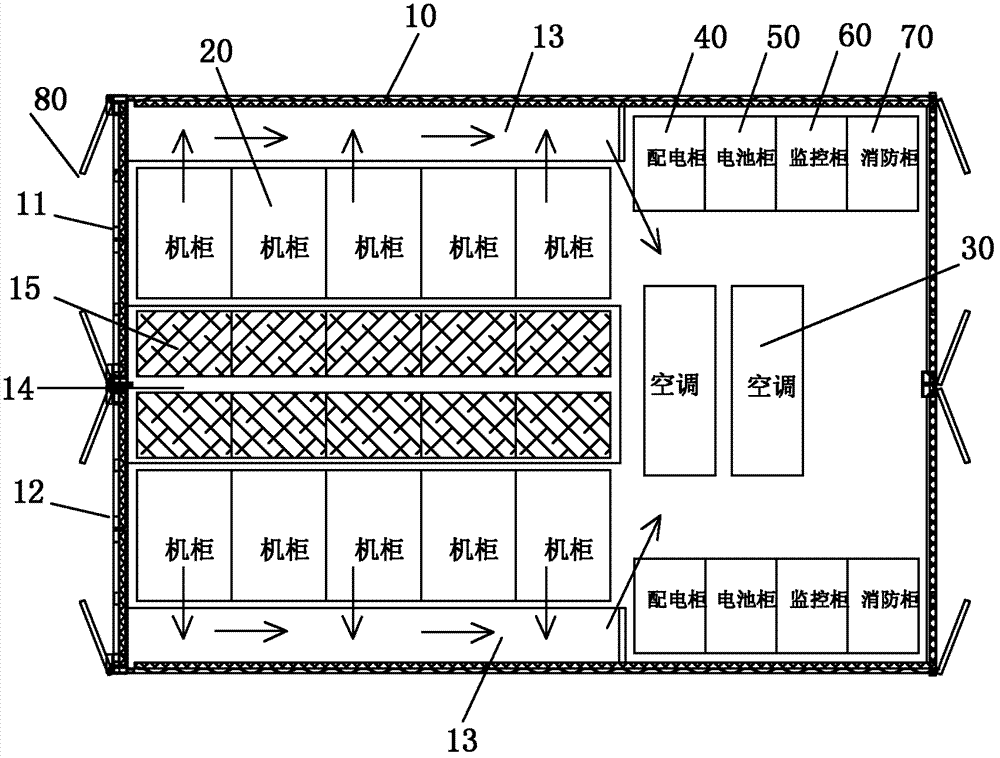

Container type data system

ActiveCN103369917AImprove convenienceReduce energy consumptionCooling/ventilation/heating modificationsCold airComplete data

The invention relates to a container type data system, which comprises a setting container body, wherein the container body is internally provided with an air conditioner and a plurality of cabinets used for completing data calculation. The container body is formed by splicing a first container and a second container along the long side direction, wherein the first container and the second container are internally provided with a row of cabinets respectively, and front doors of the two rows of cabinets are oppositely arranged; a hot air channel is arranged between rear doors of the two rows of cabinets and the inner side walls of long sides of the first container and the second container, and a cold air channel, which facilitates the air conditioner to circulate generated cold air after cooling hot air, is arranged between front doors of the two rows of cabinets; and an air outlet of the air conditioner is communicated with the cold air channel, and the air conditioner is internally provided with a fan used for absorbing hot air in the hot air channel into the internal part of the air conditioner. The container type data system provided by the invention improves the cooling efficiency, reduces the ratio of the total equipment energy consumption of the container type data system to IT equipment energy consumption, increases the maintenance space at the same time, and improves the convenience in operation for maintainers.

Owner:EMERSON NETWORK POWER CO LTD

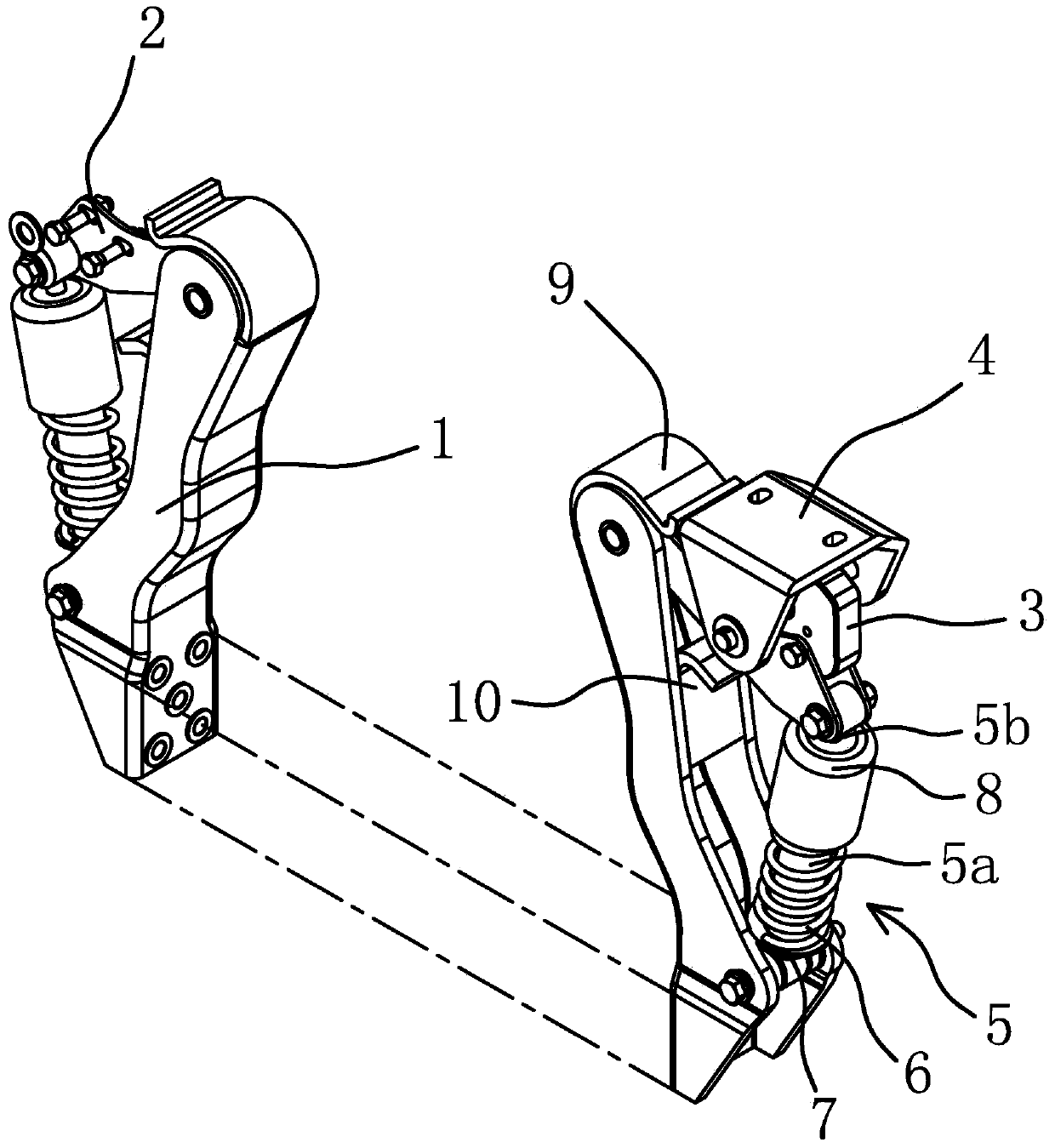

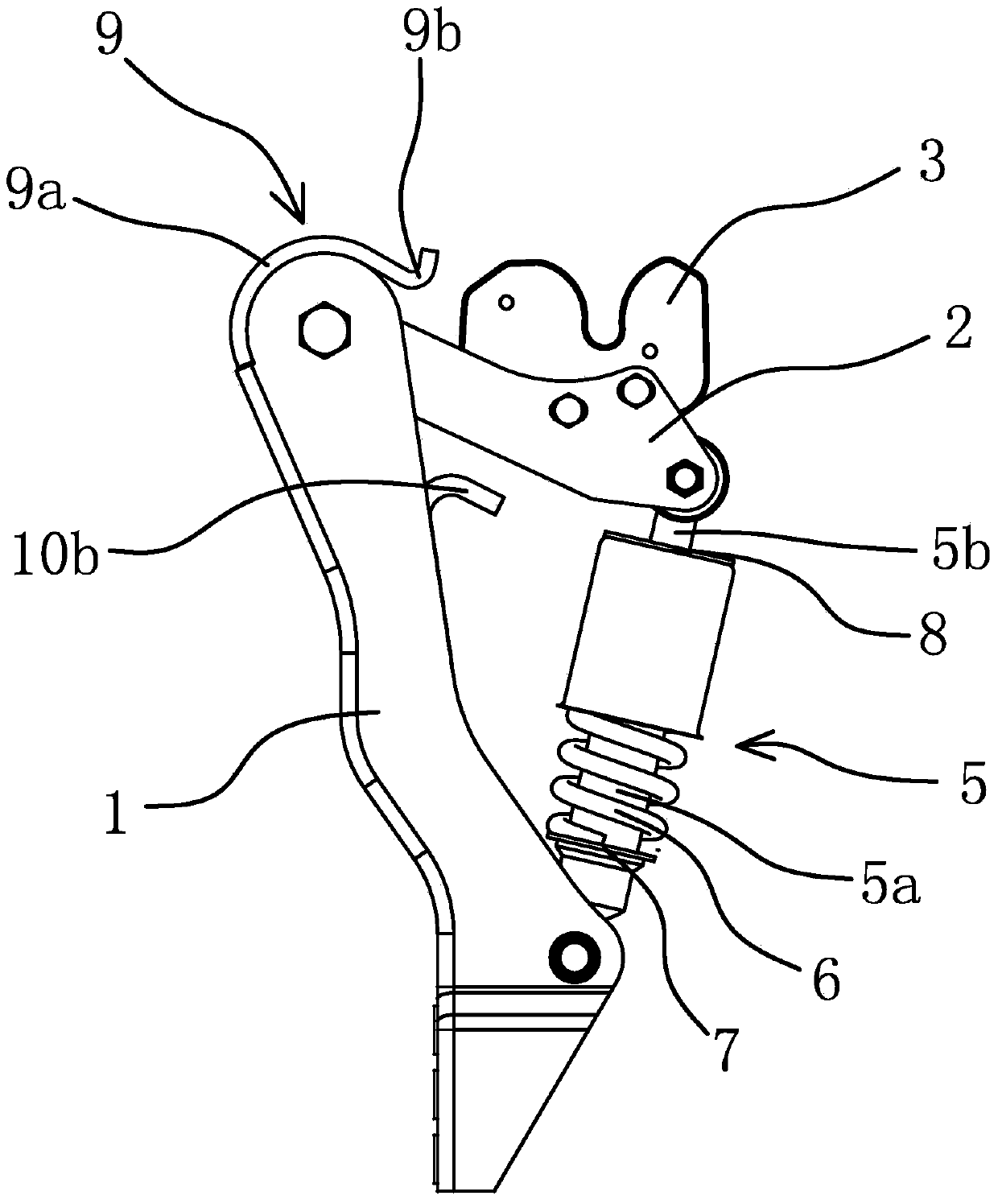

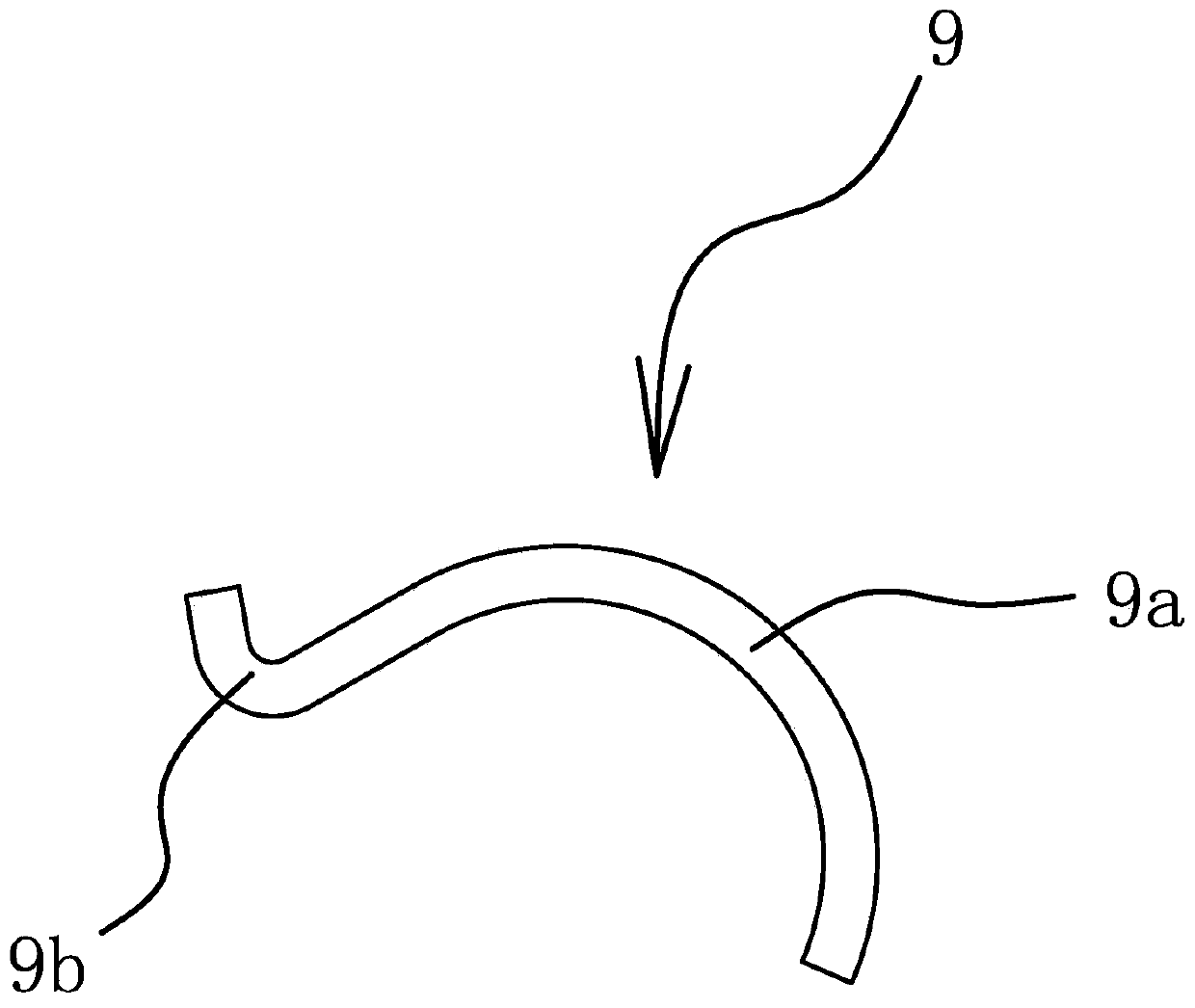

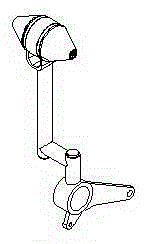

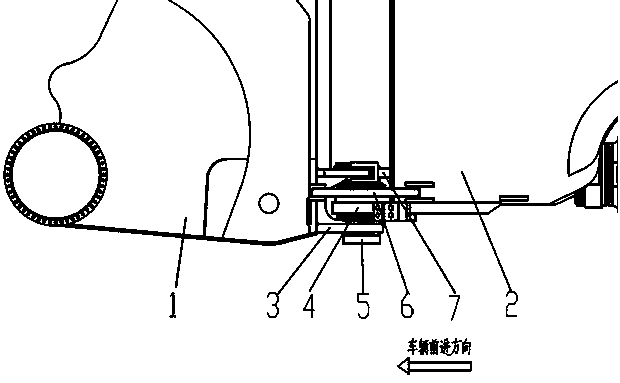

Heavily-loaded vehicle cab rear suspension device

InactiveCN103693117AImprove comfortRelease the impactLoading-carrying vehicle superstructuresCar drivingEngineering

The invention provides a heavily-loaded vehicle cab rear suspension device, belongs to the technical field of machinery and solves the problem that existing suspension devices are complex in structure, large in mounting occupation space, low in comfortableness and the like. The device comprises a pair of supports in left-right symmetry, a pair of damping shock absorbers and a pair of springs, a pair of rocker arms is hinged at the upper end of each support, a lock bolt is connected between each pair of the rocker arms, a connecting block is arranged on each lock bolt and used for being fixedly connected with a cab, the lower end of each support is fixedly connected with a crossbeam of a vehicle, each damping shock absorber comprises a cylinder and a piston rod, the inner end of each piston rod is positioned in the corresponding cylinder while the outer end of the same extends out of the cylinder to be hinged with the corresponding pair of the rocker arms, the bottom of each cylinder is hinged to the middle lower end of the corresponding support, each spring is sleeved on the corresponding damping shock absorber, and one end of each spring is abutted against the corresponding cylinder while the other end of the same is abutted against the corresponding piston rod. The heavily-loaded vehicle cab rear suspension device has the advantages of convenience for processing, low production cost, small mounting occupation space and the like.

Owner:浙江玉强机械股份有限公司

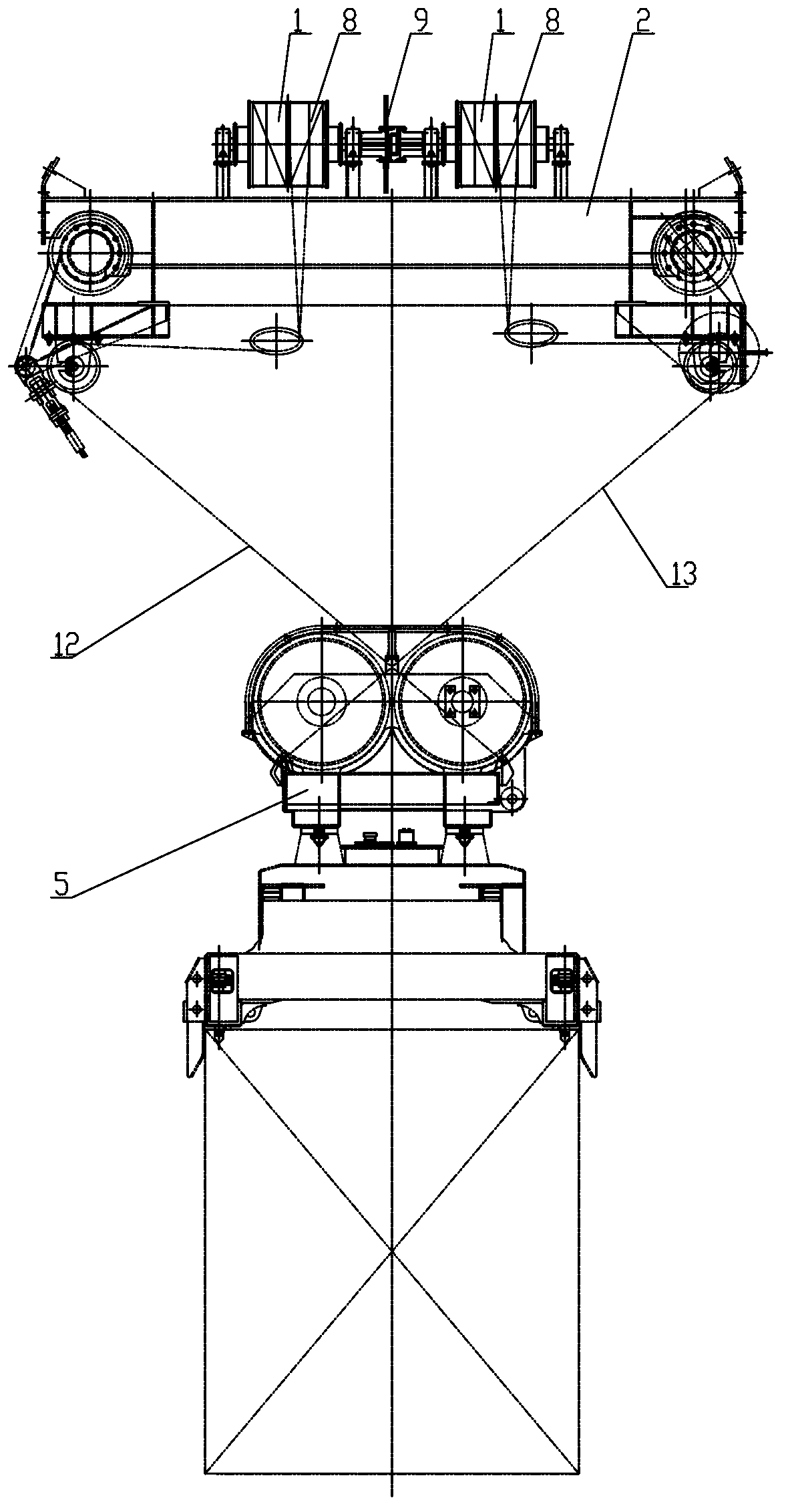

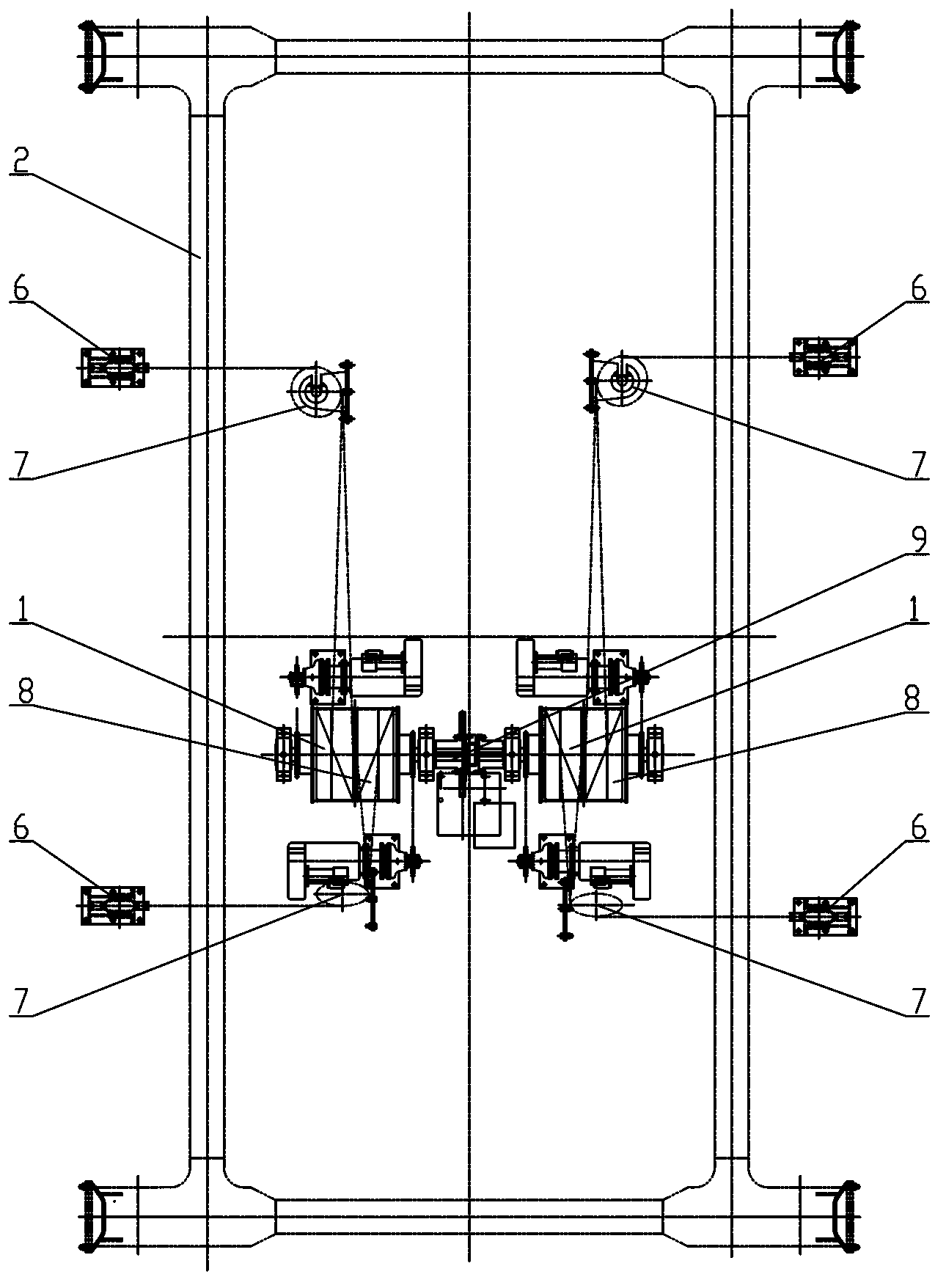

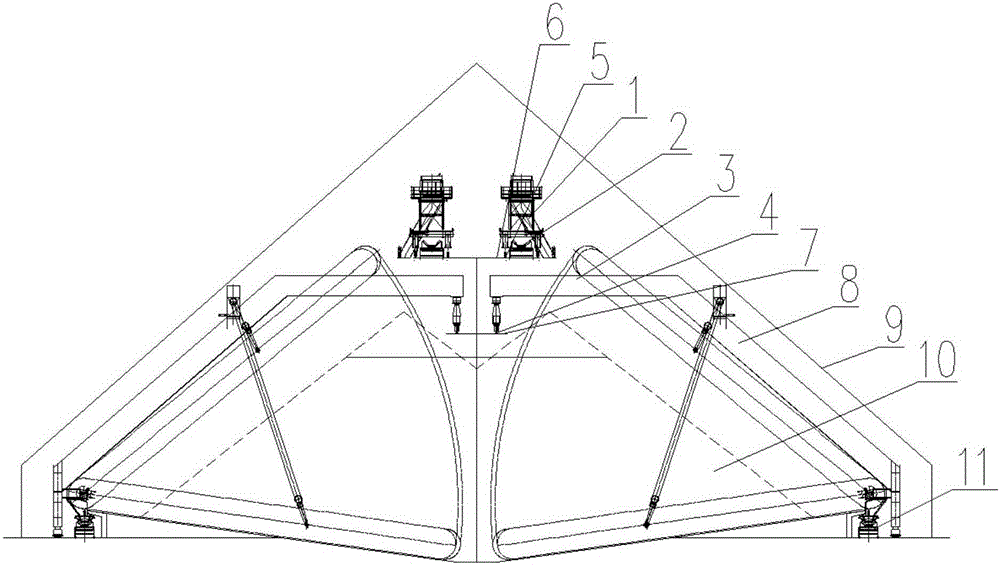

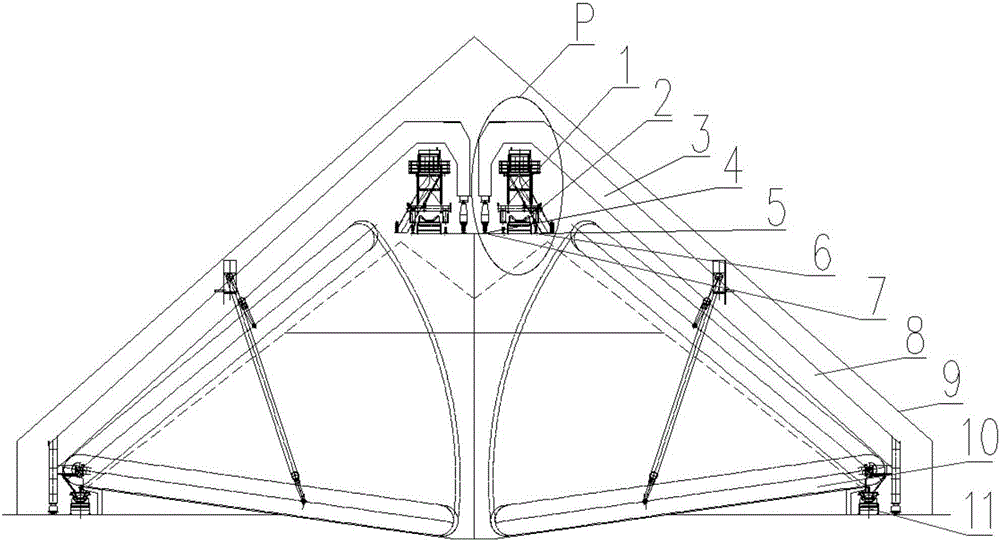

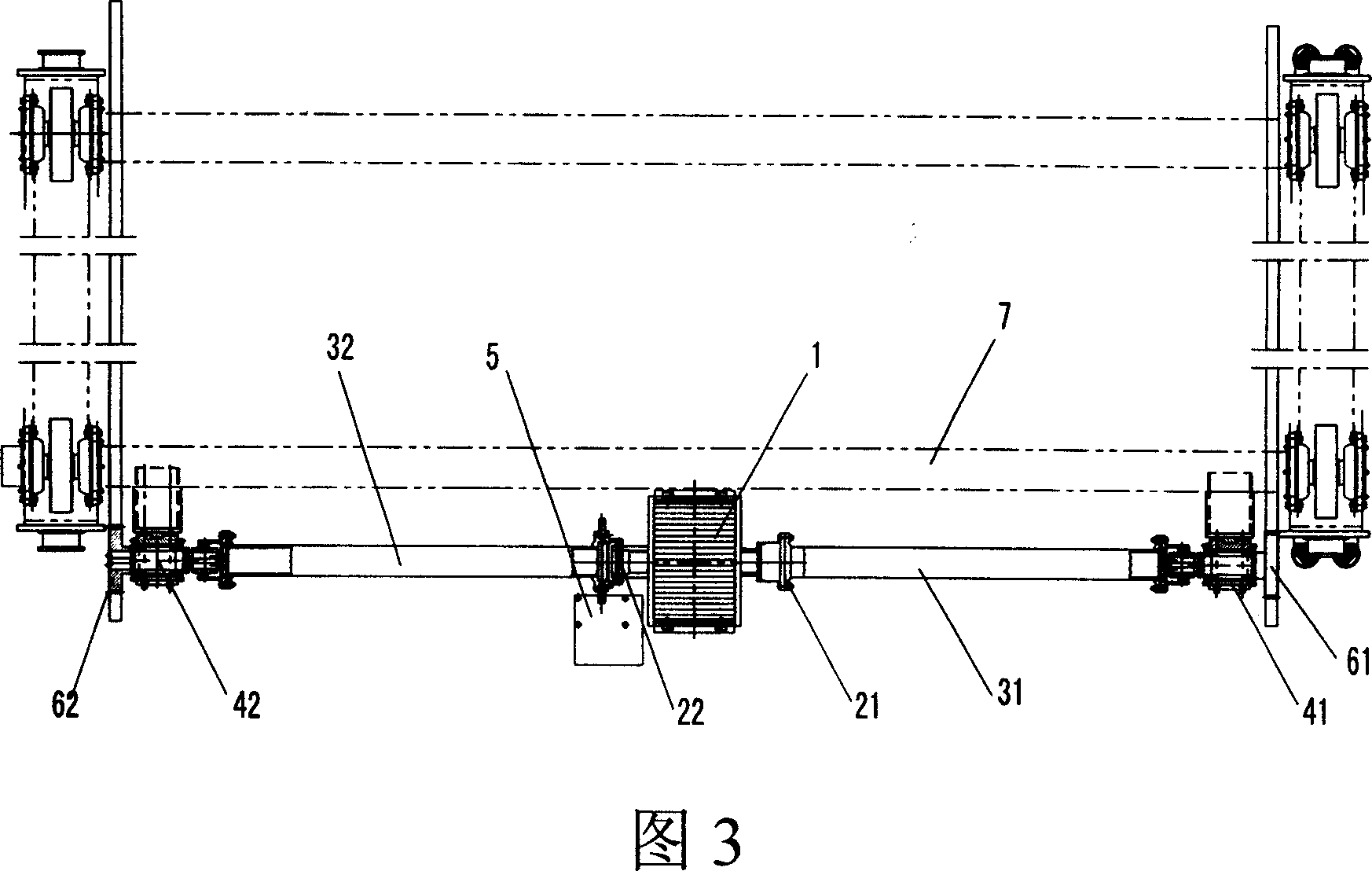

Stabilizing device of tire-type crane lift

The invention relates to a stabilizing device of a tire-type crane lift. A trolley frame is provided with two sets of driving mechanisms and four sets of pulley blocks, each driving mechanism comprises a first driver and a second driver, four stabilization steel wire ropes are arranged between each of the two sets of driving mechanisms and a lift, the upper ends of a first stabilization steel wire rope and a second stabilization steel wire rope are respectively fixed on a first drum and a second rum of one of the two sets of driving mechanism, and the lower ends of the first stabilization steel wire rope and the second stabilization steel wire rope respectively bypass a group of pulley blocks and then are fixed on a first side of the lift; and the upper ends of a third stabilization steel wire rope and a fourth stabilization steel wire rope are respectively fixed on a first drum and a second drum of the other set of the driving mechanism, and the lower ends of the third stabilization steel wire rope and the fourth stabilization steel wire rope bypass the group of pulley blocks and then are fixed on a second side of the lift. The stabilizing device disclosed by the invention is arranged on a plane of a trolley frame so as to be capable of reducing the total height of a crane, reduce the cost of the crane, expand the maintenance space and be convenient for daily maintenance; and the stabilizing device disclosed by the invention can reduce the vibration of the lift and improves the loading and unloading efficiency and the operation safety.

Owner:WUXI HUADONG HEAVY MACHINERY

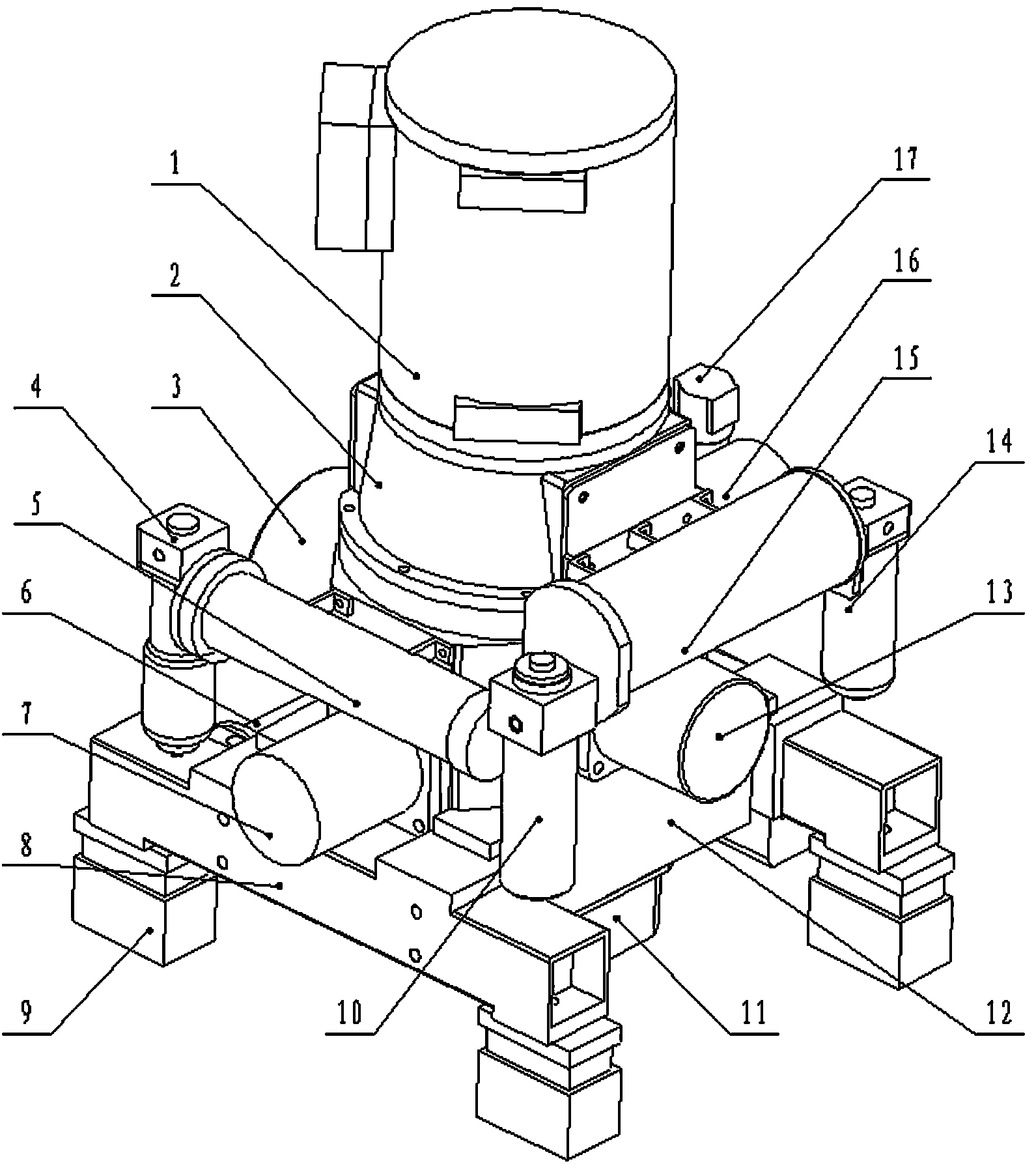

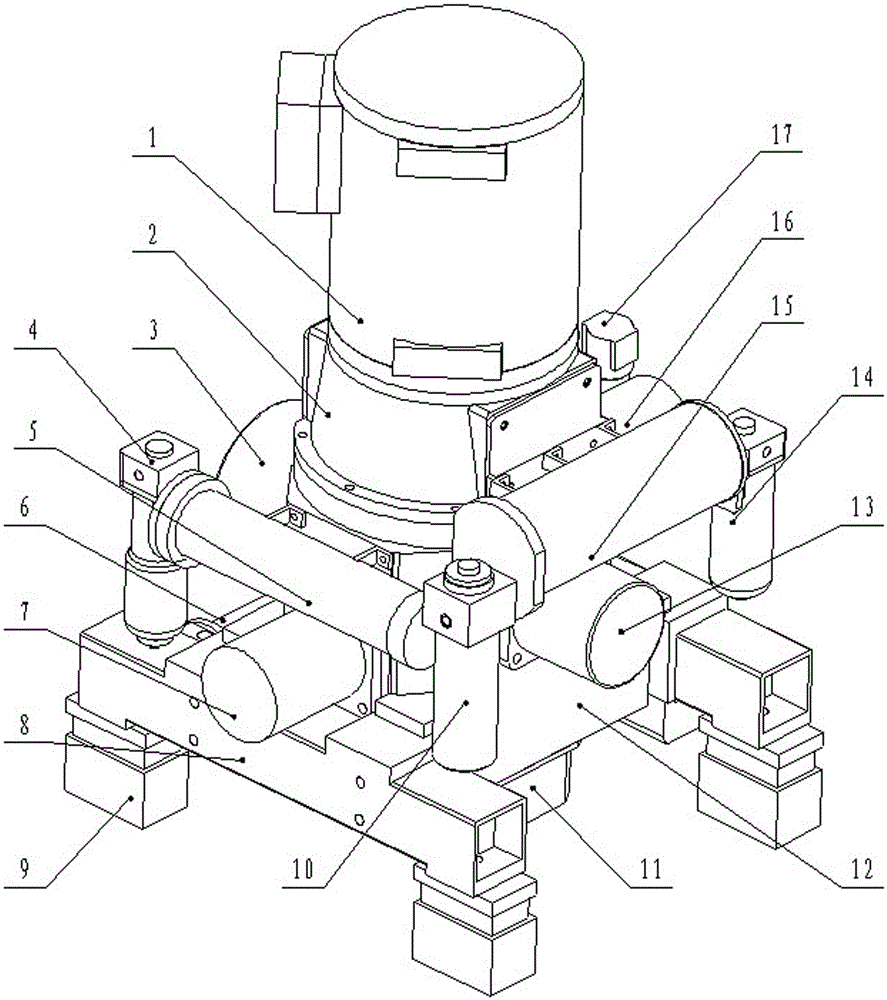

Vertical star-shape high-pressure air compressor

ActiveCN103437973AReduce volumeCompact layoutPiston pumpsPositive-displacement liquid enginesFailure rateCrankcase

The invention discloses a vertical star-shape high-pressure air compressor. The air compressor is high in gas compression rate, stable in machine working, small in noise, low in failure rate, small in integral machine size, compact in arrangement, and convenient to repair and inspect. The air compressor comprises a vertically arranged motor, a crank shaft case, a first-stage cylinder, a second-stage cylinder, a third-stage cylinder a fourth-stage cylinder, a first-stage cooler, a second-stage cooler, a third-stage cooler and a fourth-stage cooler, wherein a crank shaft is connected with a main shaft of the motor; the first-stage cylinder, the second-stage cylinder, the third-stage cylinder and the fourth-stage cylinder are arranged in a radial star shape along the radial direction of the main shaft of the motor; four vibration isolators which are connected under the crank shaft case through a bracket; the first-stage cooler is arranged under the first-stage cylinder, the second-stage cooler and a second-stage oil-water separator are combined into a whole and are arranged above the third-stage cylinder; two ends of the third-stage cooler and the fourth-stage cooler and a third-stage oil-water separator and a fourth-stage oil-water separator are combined into whole and are arranged above the second-stage cylinder; an oil holding disc is arranged above the crank shaft case; the cylinders are connected through pipelines; two ends of the crank shaft are connected with an upper balance weight and a lower balance weight; an oil groove is formed in the lower end surface of each connecting rod.

Owner:ANHUI HUAJING MACHINERY

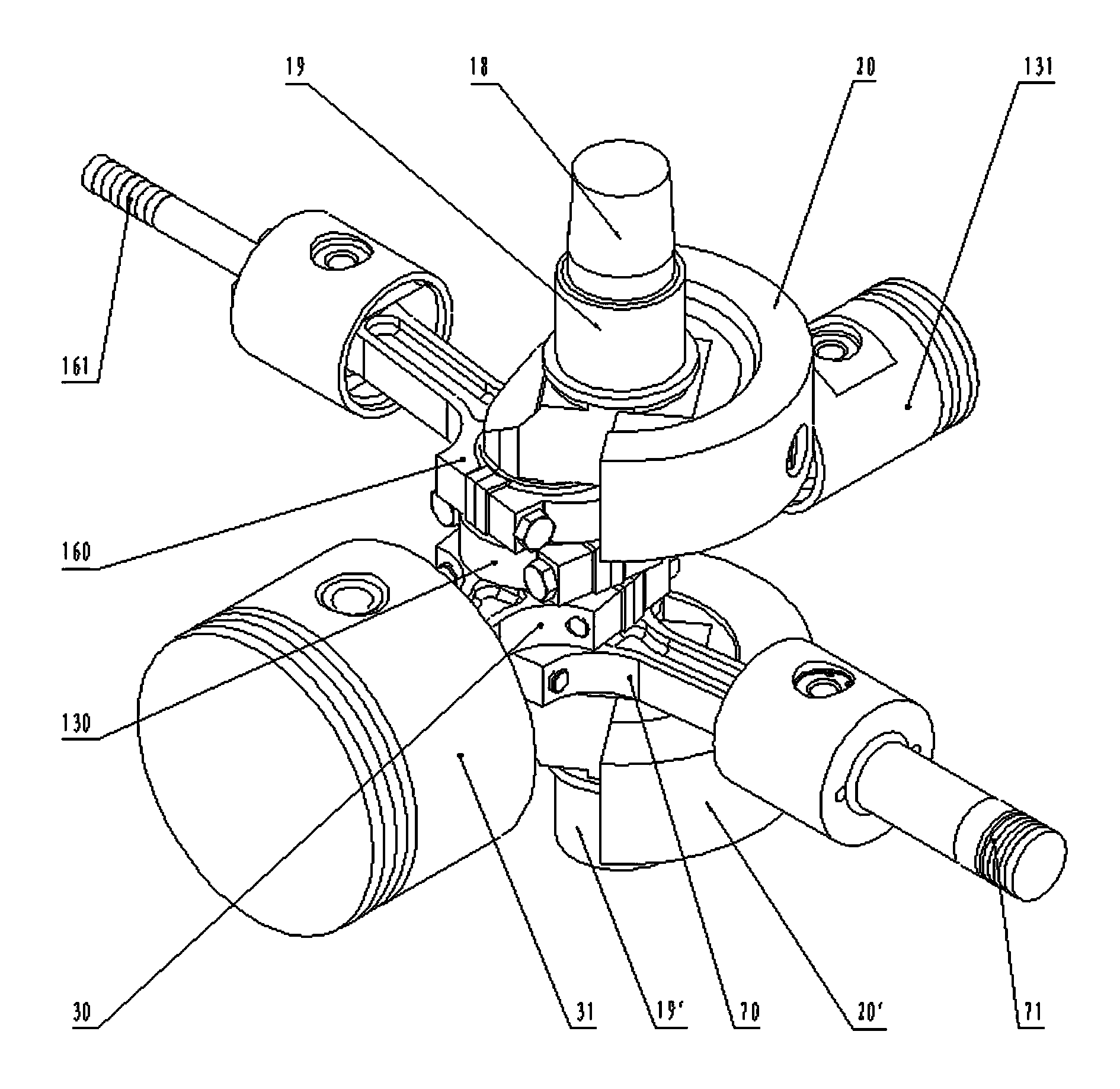

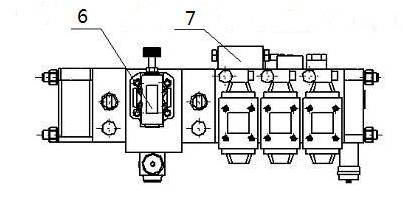

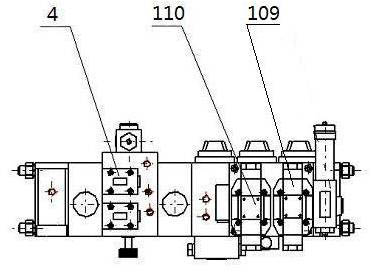

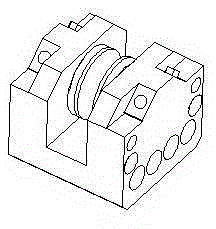

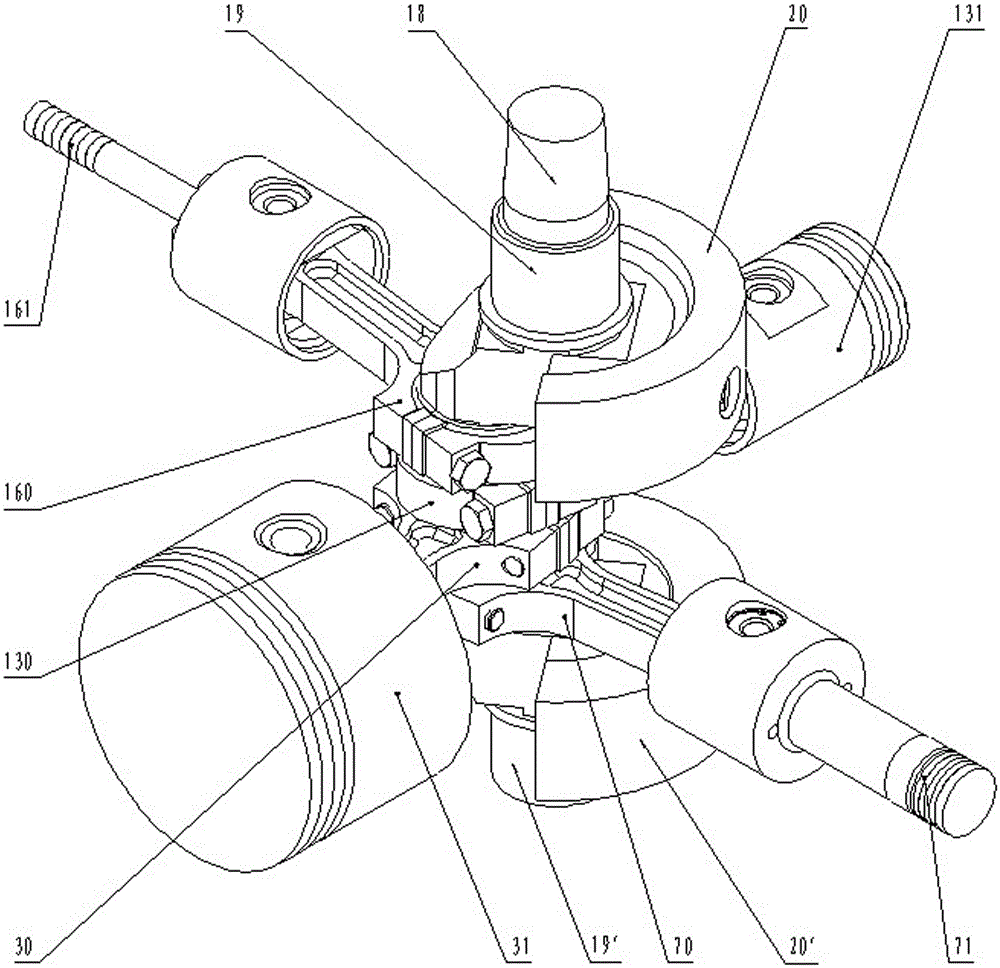

Integrated linkage control valve bank for all-hydraulic coal mine drill

The invention discloses an integrated linkage control valve group for an all-hydraulic coal mine drill, which comprises a valve body, a rotating sheet, a pushing sheet, a hydraulic control reversing valve I, a hydraulic control reversing valve II, a chuck function valve, a gripper function valve, an advancing and withdrawing rod function valve and a sequence valve. An oil channel is arranged in the valve body, the rotating sheet is connected with a motor, the pushing sheet is connected with a feed cylinder, the hydraulic control reversing valve I and the hydraulic control reversing valve II are connected with a chuck and a gripper respectively, output ends of the chuck function valve, the gripper function valve and the advancing and withdrawing rod function valve are connected with the hydraulic control reversing valve I, the hydraulic control reversing valve II and the motor, an input end of the sequence valve is connected with an oil pump, an output end of the sequence valve is respectively connected with the rotating sheet, the pushing sheet, the hydraulic control reversing valve I and the hydraulic control reversing valve II, and one-way valves and shuttle valves are further arranged on rotation advancing oil circuits between the rotating sheet and the pushing sheet and between the hydraulic control reversing valve I and the hydraulic control reversing valve II.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Ship electric frying oven with fire extinguisher plant

InactiveCN101879044ALong storage periodReasonable structureDeep fat fryersShip galleysMarine engineeringFire extinguisher

The invention discloses a ship electric frying oven with a fire extinguisher plant, mainly comprising a frying oven which consists of an upper cover body and a lower cover body, wherein the upper cover body is internally provided with a filter screen and an exhaust fan. The ship electric frying oven is characterized in that the lower cover body is internally provided with the fire extinguisher plant, an electrical controller and a control box. The invention has reasonable structure and ingenious conception and is convenient and close to an actual operation due to the development based on a large amount of market researches, and meanwhile, the invention also adopts front operation and front maintenance by considering that the area of kitchen positioned on the ship is smaller and equipment is more compactly arranged; and besides, the invention has convenient domestic procurement by adopting an MJPZ type portable mechanical foam extinguisher recognized by CCS (China Classification Society) , obvious Chinese characteristics and relative autonomy, uniqueness and economy and also has great popularization value due to the adoption of an aqueous film-forming foam extinguishing agent.

Owner:上海海克酒店设备制造有限公司

Arrangement structure of stacker device

ActiveCN105173770AReasonable forceReduce the amount of civil worksLoading/unloadingInterior spaceEconomic benefits

The invention provides an arrangement structure of a stacker device. The arrangement structure of the stacker device comprises stacking devices, fetching devices, stacking device traveling tracks, fetching device traveling tracks, material input conveyors, material output conveyors, a bedding plant and a closed material storage shed, wherein the stacking devices and the material input conveyors are located on the inner sides of the fetching devices; the fetching devices are across the stacking devices and the material input conveyors. The stacking devices and the material input conveyors penetrate through the internal space of the fetching devices, and the arrangement mode that machine frames of the fetching devices are across the stacking devices, so that the interference problem caused when traveling platforms of the stacking devices are as high as upper traveling platforms of the fetching devices is solved. The upper walking platforms of the fetching devices do not need to be independently arranged; the traveling devices are more convenient to maintain; meanwhile, material pile volume loss caused in order to elude upper traveling platforms of fetching devices in the existing process arrangement mode is avoided, the utilization rate of the internal space of a stockyard is increased, the civil engineering quantity is reduced, economic benefits are remarkable, and great engineering application value is achieved.

Owner:CISDI ENG CO LTD +1

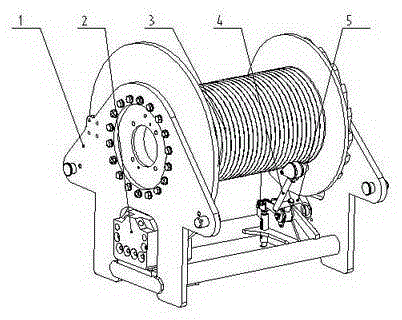

Modular integrated hoisting mechanism of crawler crane

The invention discloses a modular integrated hoisting mechanism of a crawler crane, which comprises a rack, a hoist, a clamp plate brake, a three-coil protector and a pawl, wherein the three-coil protector and the pawl are connected on the rack through pin shafts, the clamp plate bake is fixed on a base of the rack through bolts, the hoist is connected with a flange of a planetary reducer through bolts, the fixed end of the planetary reducer is fixed with the rack through bolts, and the hoisting mechanism is integrally connected with a turnplate through pin shafts. According to the invention, the modular design concept is adopted, the hoist, the brake, the three-coil protector and the pawl are modularly integrated on the hoisting mechanism, and the hoisting mechanism is integrally connected with the turnplate through the pin shafts. In assembly and maintenance, the quick assembly and disassembly can be realized, the maintenance space is large, the processing errors can be greatly reduced, the maintenance is simple, the assembly and disassembly are convenient, the assembly and disassembly time can be greatly shortened, the maintenance cost is reduced, and the production efficiency can be improved.

Owner:山推抚起机械有限公司

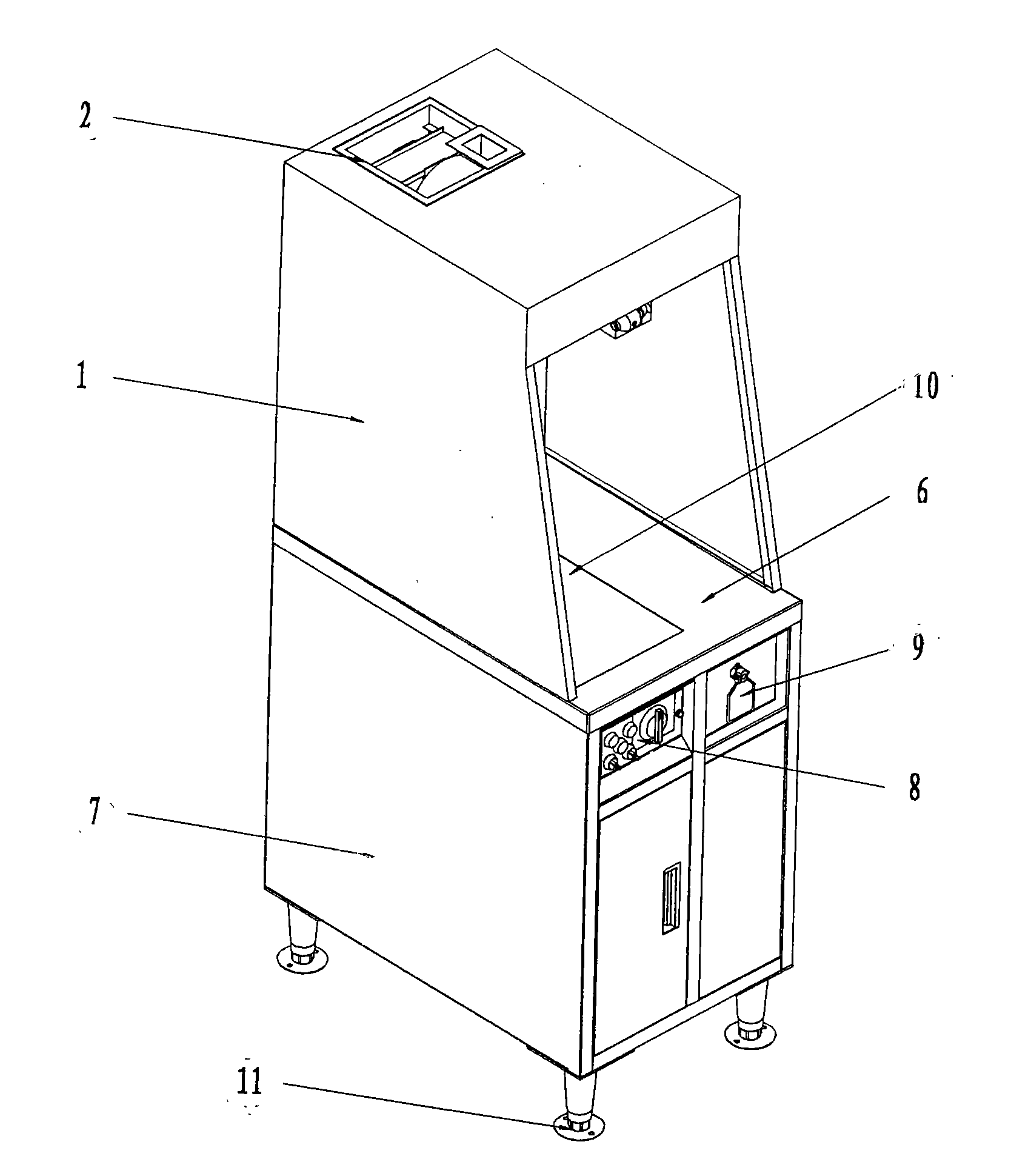

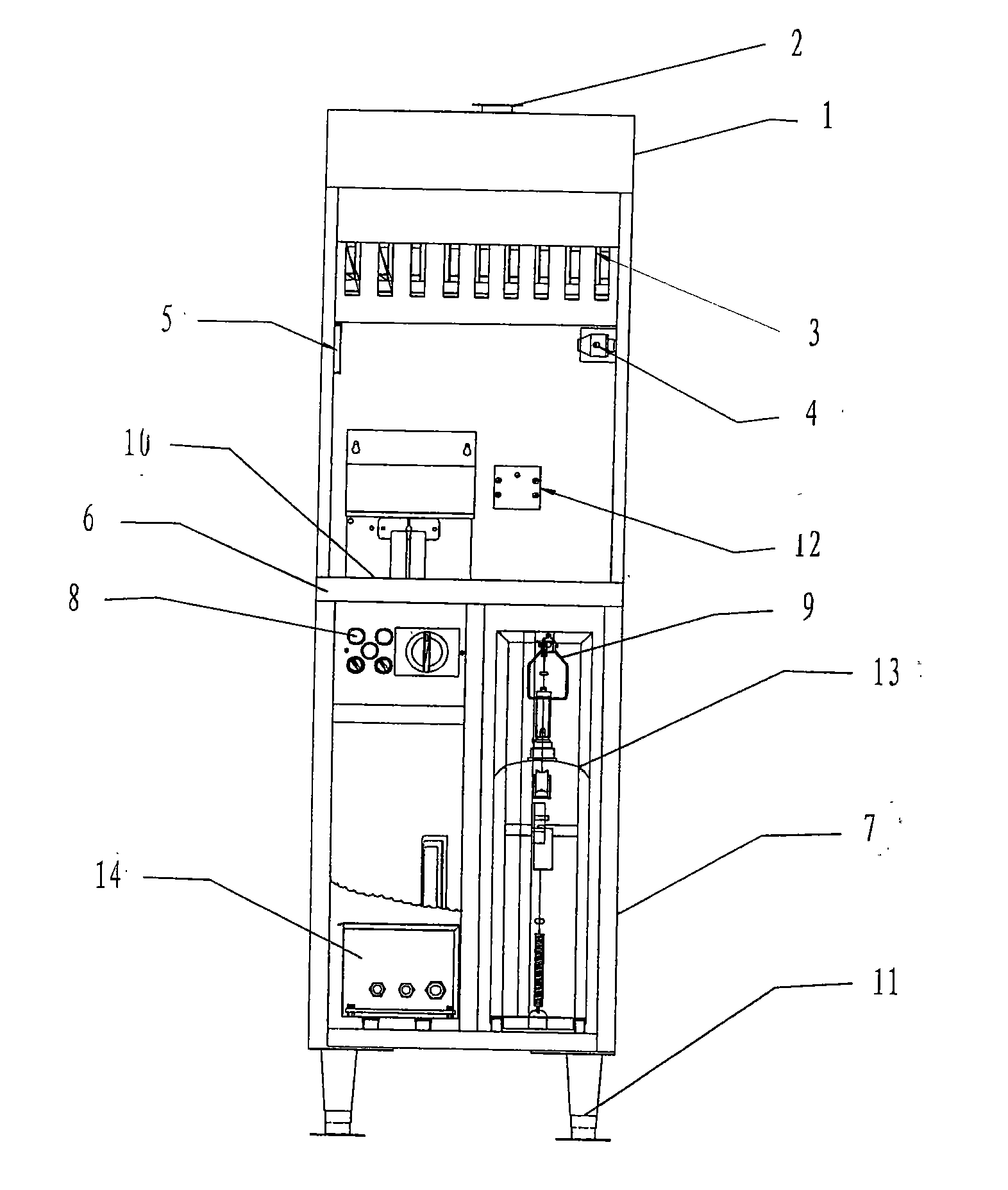

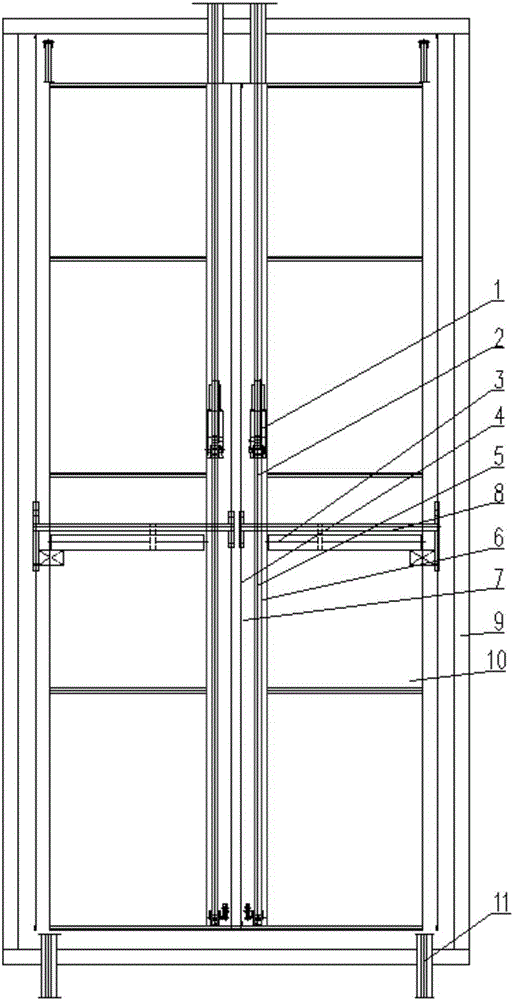

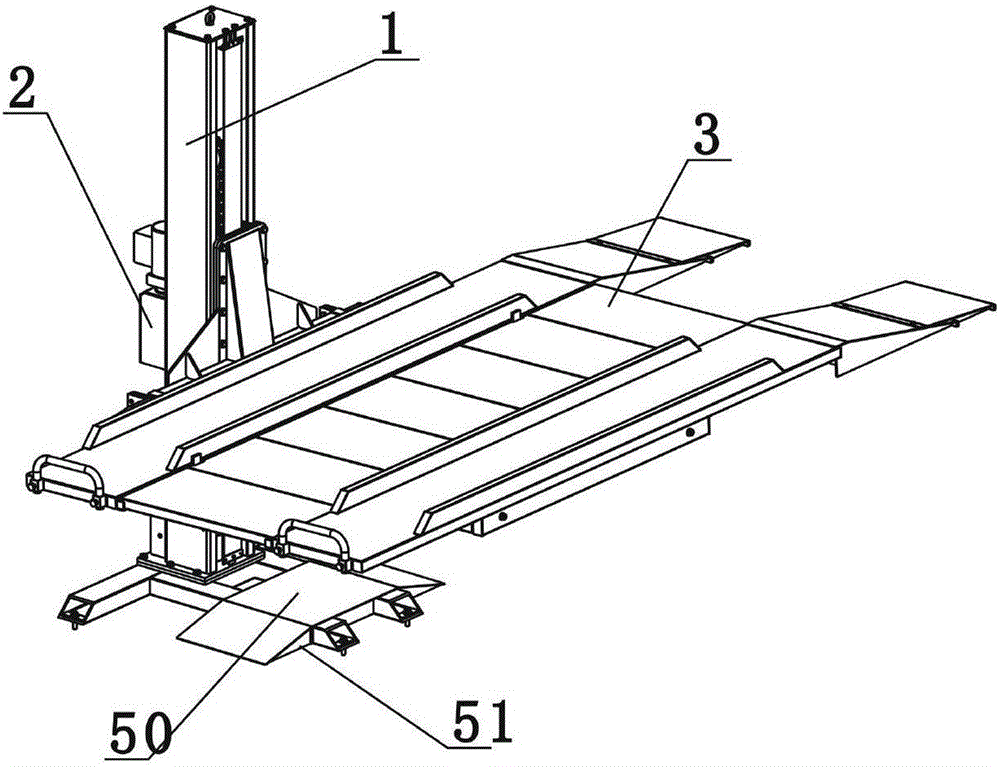

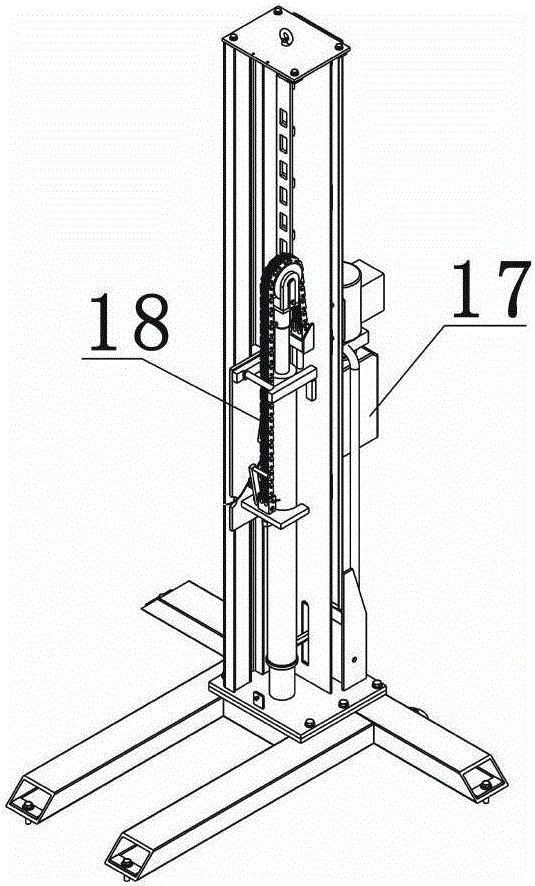

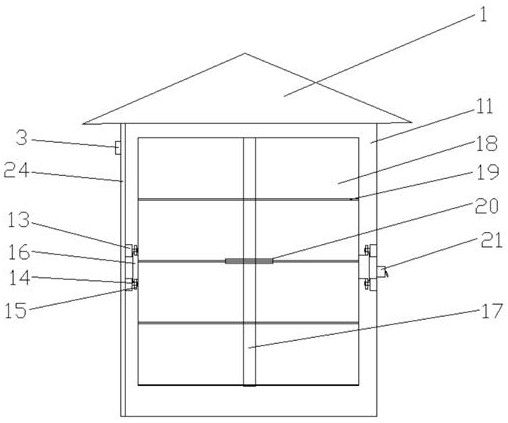

Lifting machine

InactiveCN105905832ALarge maintenance spaceMultiple maintenance spacesLifting framesHigh pressureLift system

The invention relates to the technical field of vehicle maintenance and detection, and particularly relates to a lifting machine. The lifting machine comprises a frame body, a hydraulic system and a lifting system, wherein the frame body comprises an underframe and vertical columns; the hydraulic system is arranged on the vertical columns; the lifting system is connected to the hydraulic system; the hydraulic system comprises a hydraulic power assembly and a lifting assembly; the hydraulic power assembly comprises a hydraulic power part, a high-pressure oil pipe and an oil pipe joint; the lifting assembly comprises an oil cylinder, a chain wheel, a chain mounting base and a plate chain; the lifting system comprises a parking platform and a lifting frame body; the lifting frame body comprises a lifting frame, a left arm, a right arm, a connecting pipe and a lifting frame; and the parking platform comprises two parking plates and a middle plate.

Owner:JIAXING HUAYING PRECISION MACHINE MFG CO LTD

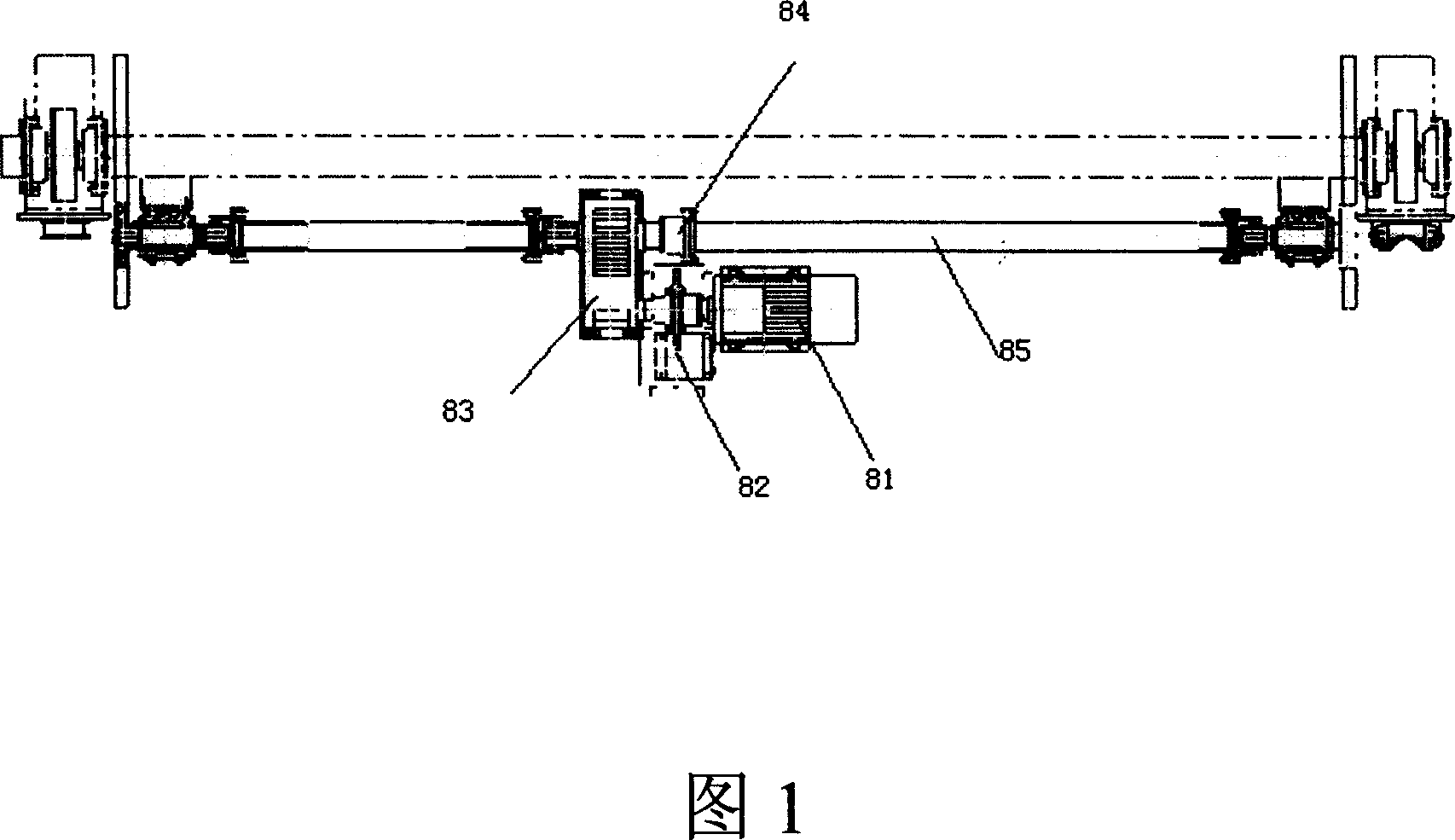

Operating mechanism of crane trolley

InactiveCN1948114ASave manpower and material resourcesImprove securityTravelling gearLow speedWheel and axle

A carriage running mechanism for hoister is composed of a multi-stage motor, two shaft couplings connected respectively to the high-speed terminal and low-speed terminal of said multi-stage motor, two floating axles with one end connected respectively with another ends of said shaft couplings and another end linked with the gear in gear-rack bar mechanism, two bearings, and a brake.

Owner:SHANGHAI PORT MACHINERY HEAVY IND

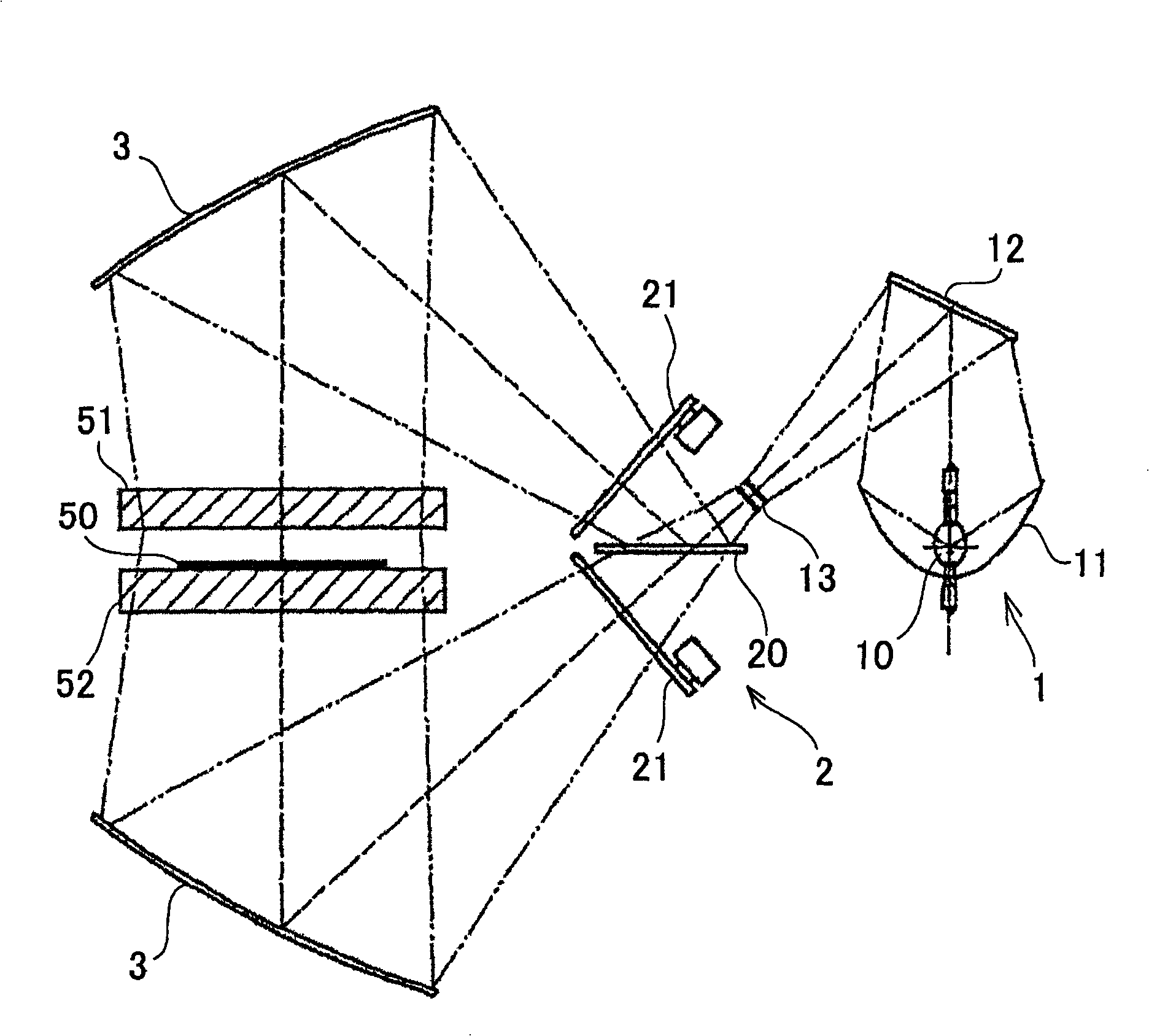

Double-side exposal device

InactiveCN101403863AEasy maintenance and storageReduce replacement work timePhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronicsEye lens

The invention provides a two-sided exposure device, which can expose the surface and back face of the substrate under identical exposure condition without any bothersome modulation and control. The lights emitted from a light source lamp (10) converge at an oval mirror (11) convergence, turn back through a reflector (12), partly focus at a fly's-eye lens (13); and then the light is divided into a reflected light and a transmitted light through a spectroscope (20), pass through a light source light shutter (21) to control the luminous quantity, further it is reflected by a collimating mirror (3) as a parallel light, and then permeates a photo mask (51) and a light mask (52) to irradiate on the surface side and back face side of the substrate (50).

Owner:ADTEC ENG

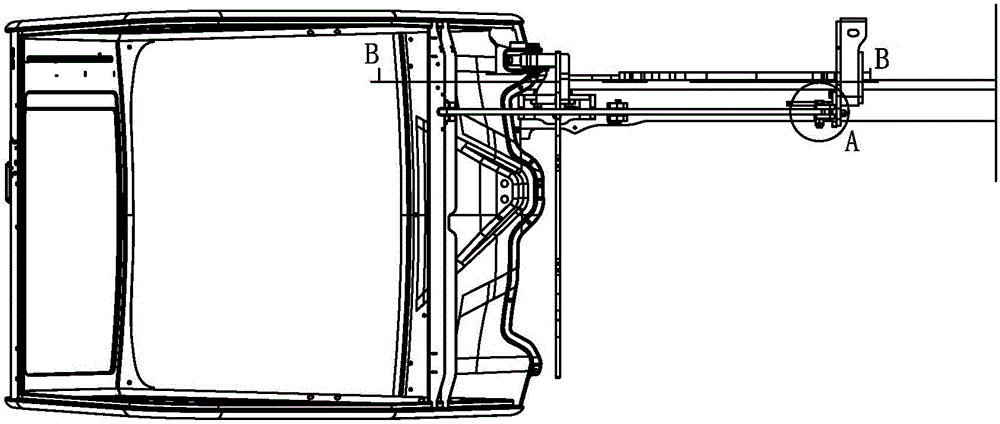

Forklift with cab capable of overturning forwards and method for reducing height of container loading of forklift

InactiveCN105271063ALower the altitudeReduce the overall heightLifting devicesVehicle frameElectrical and Electronics engineering

Owner:LINDE CHINA FORKELEVATOR TRUCK CORP

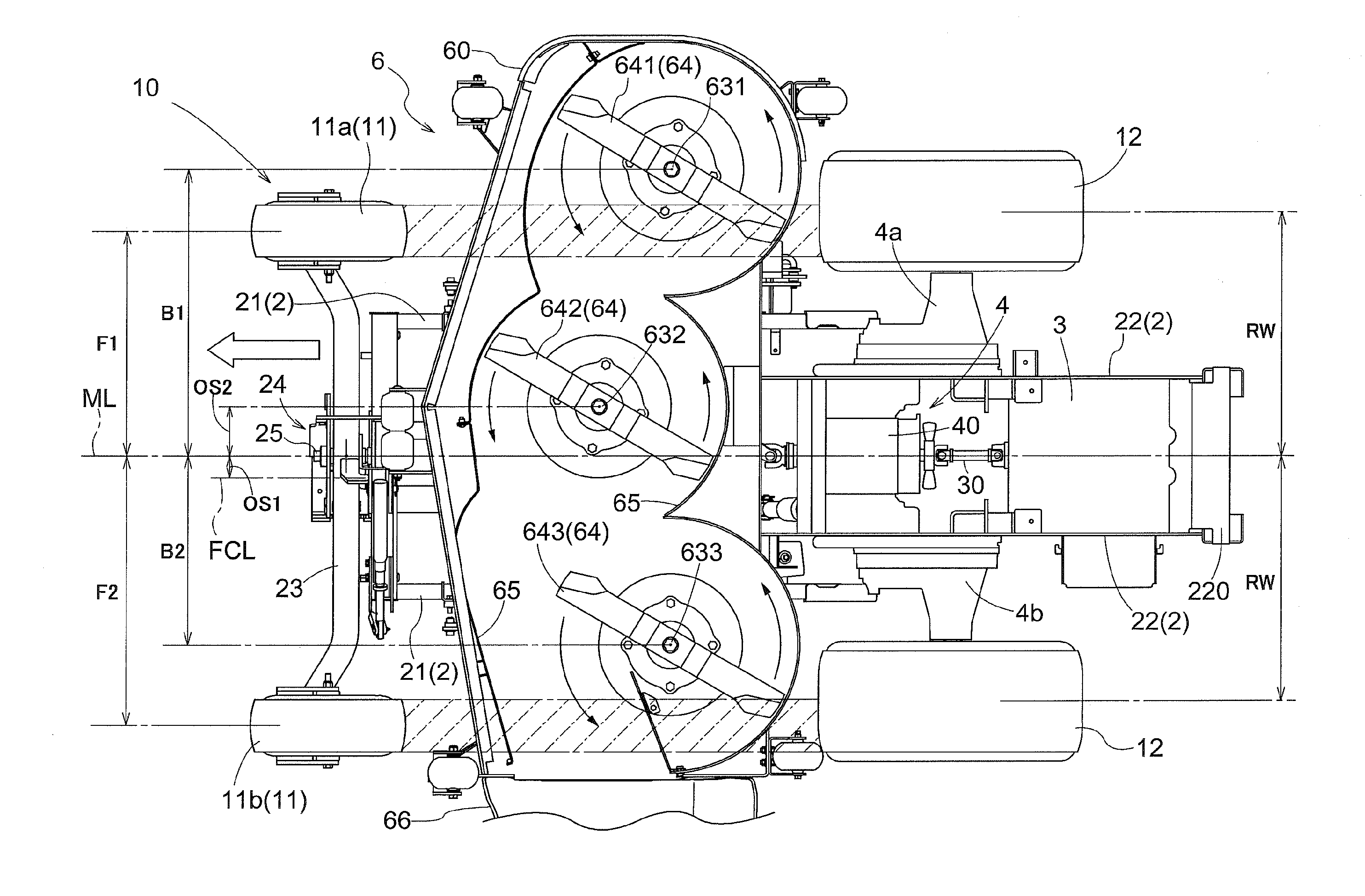

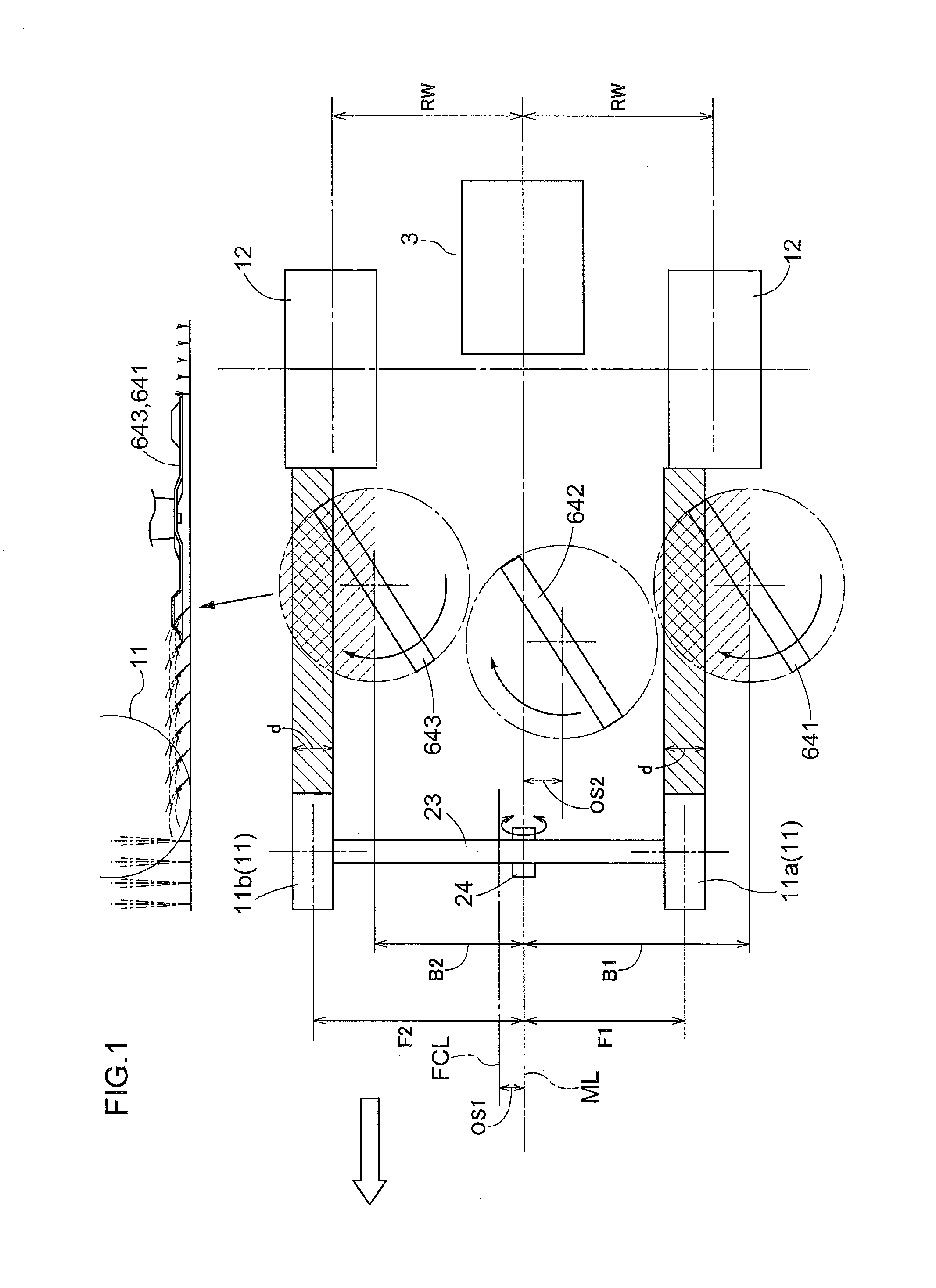

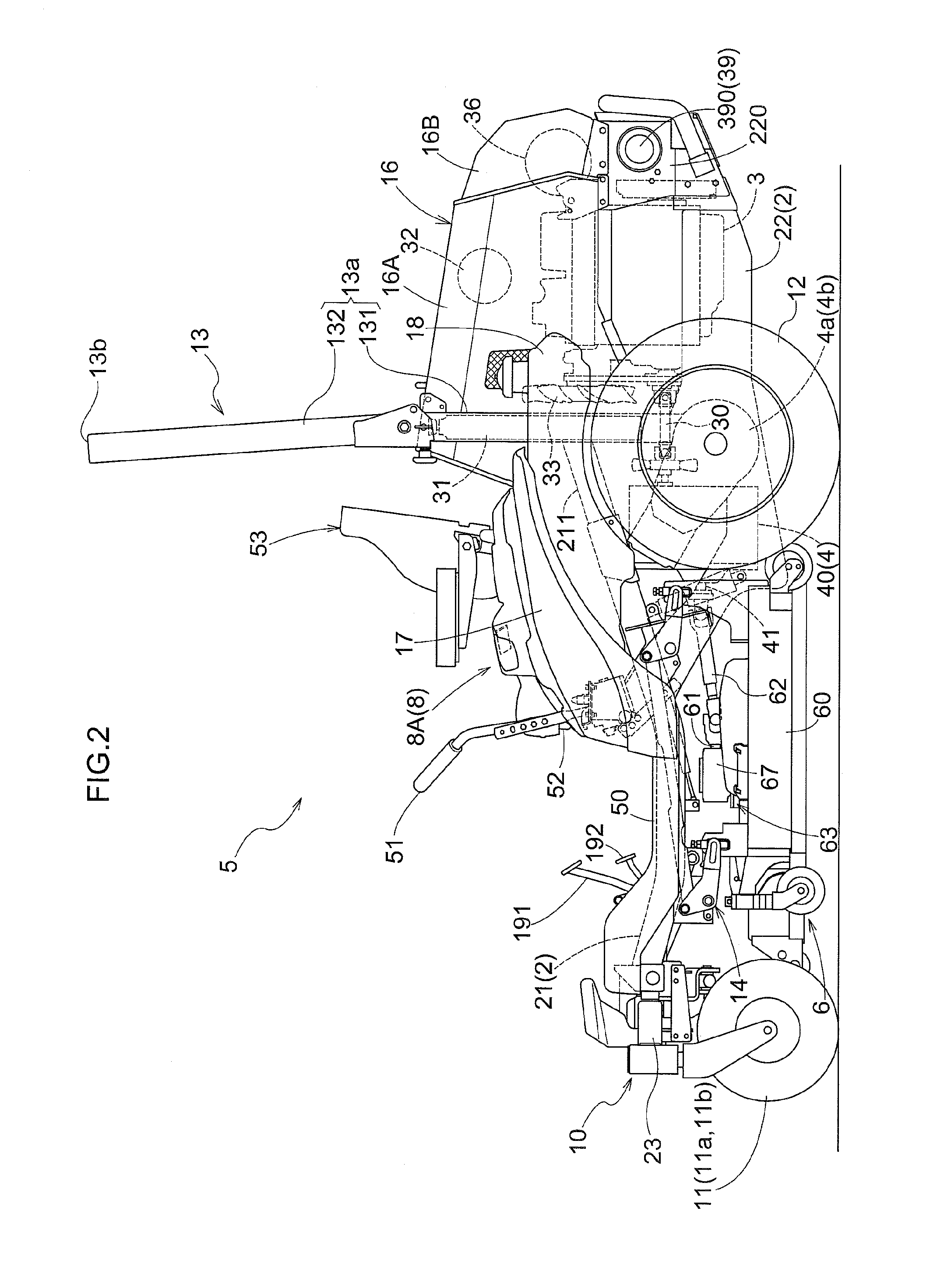

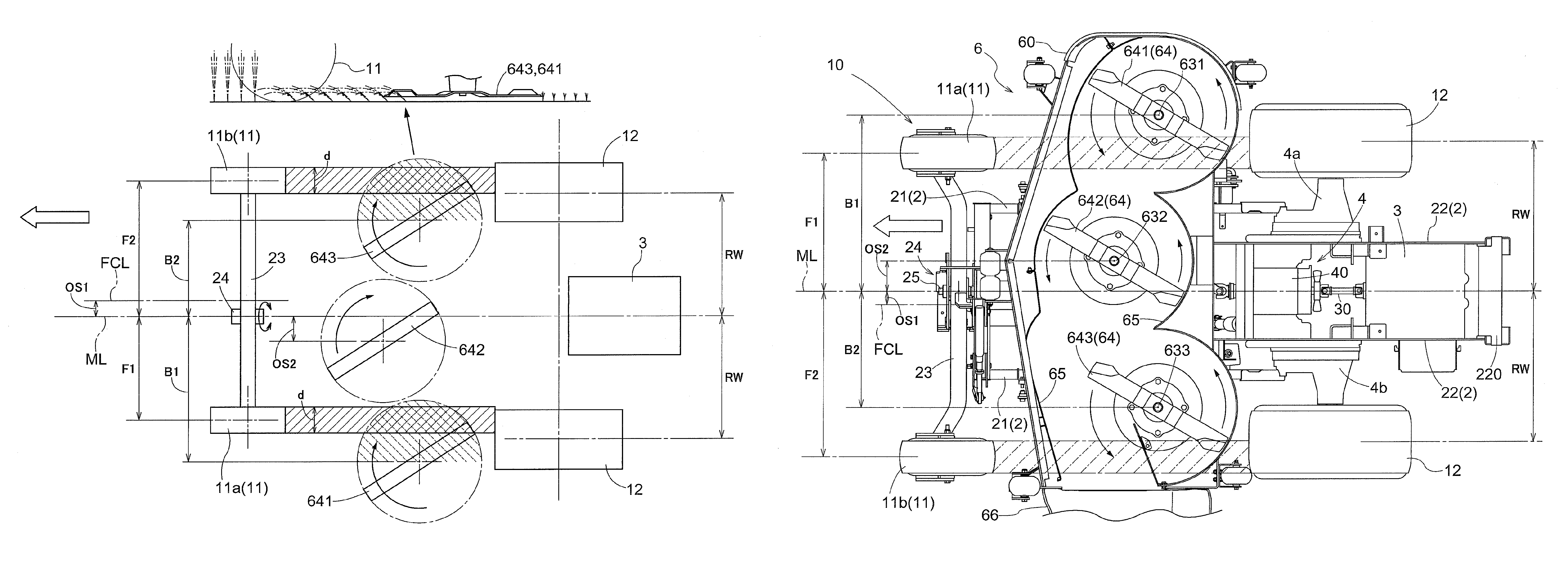

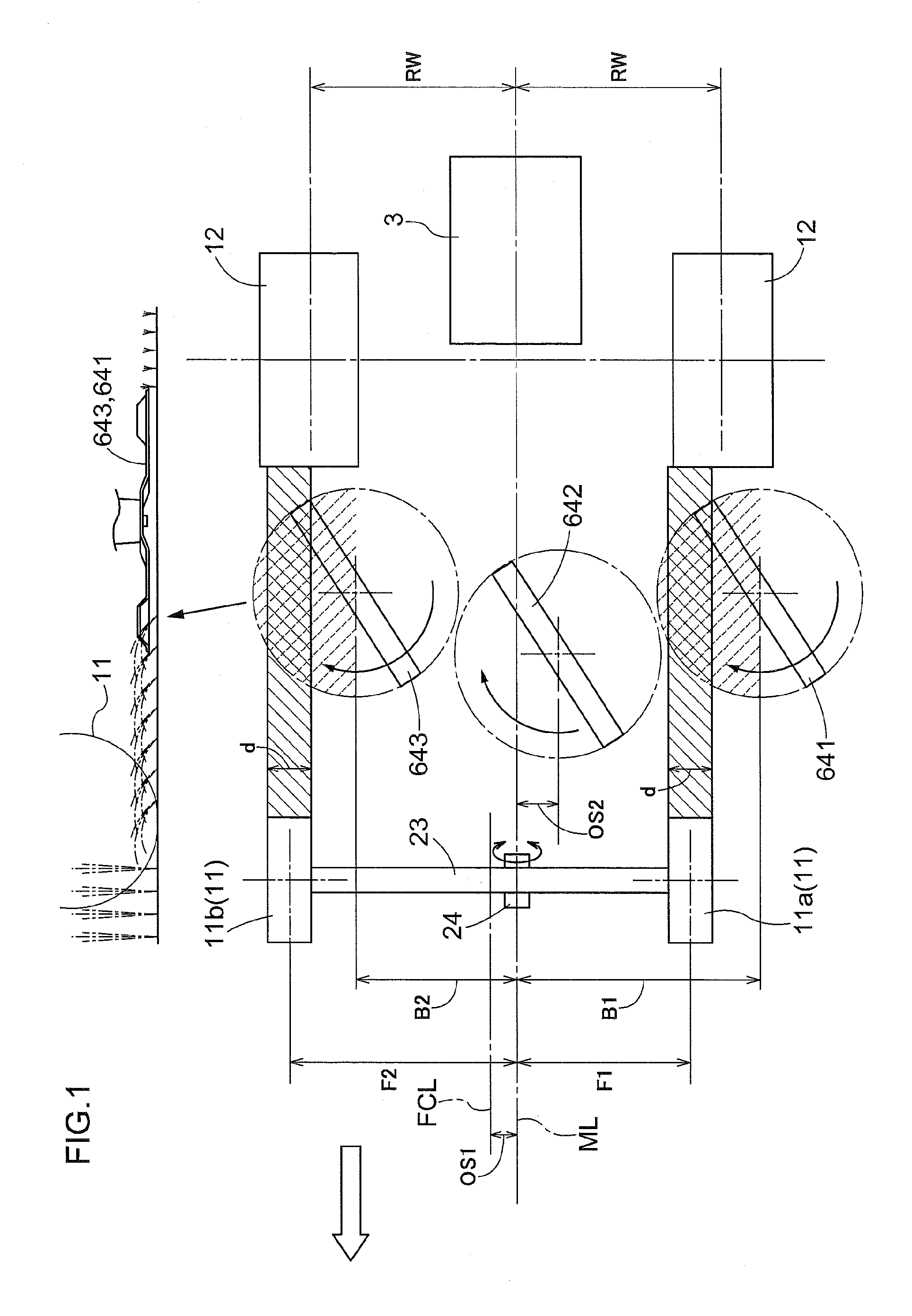

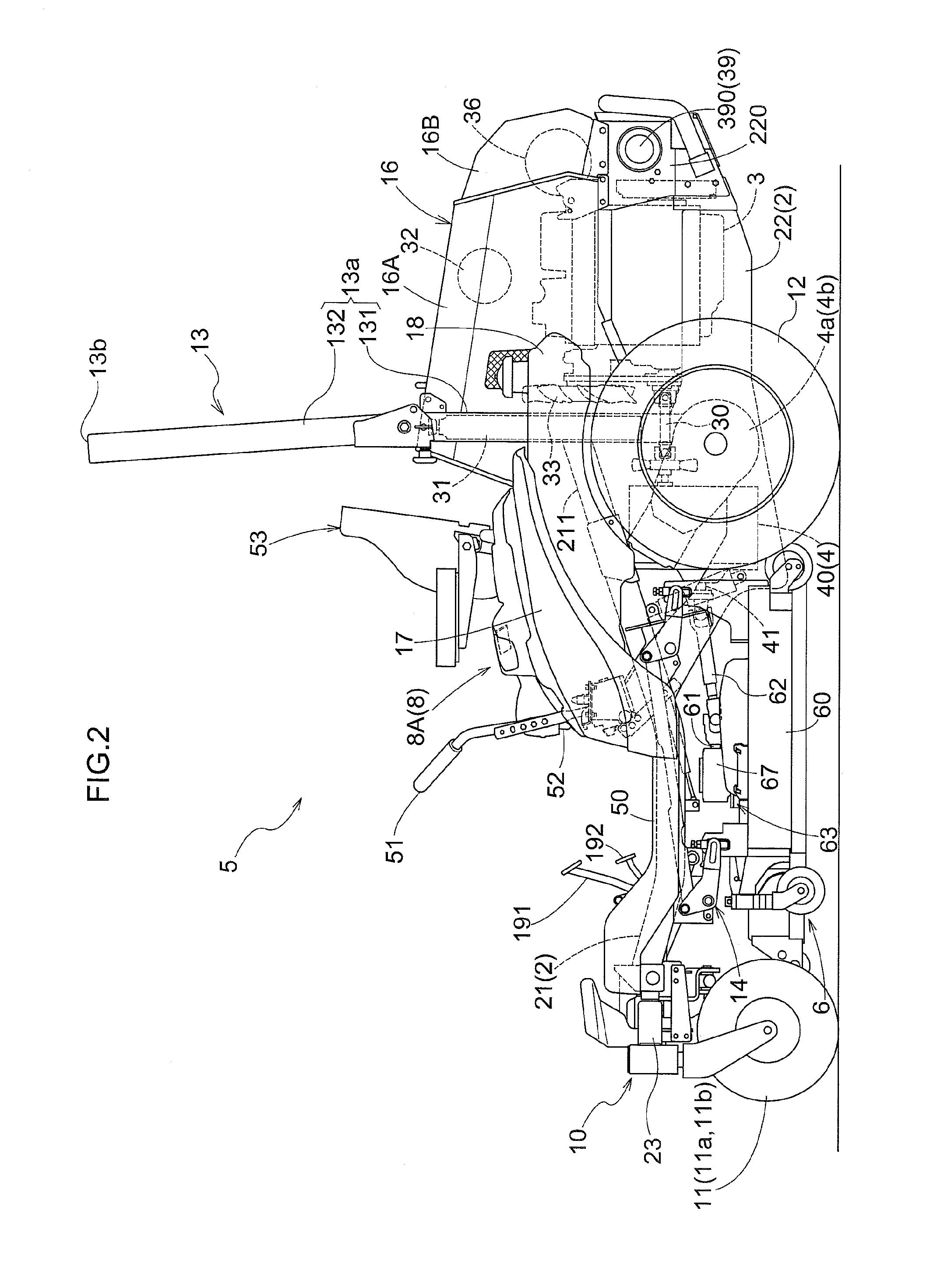

Grass Mower

ActiveUS20160192585A1Easy to implementCutting leftovers can be restrictedLawn-mowersEngineeringMower

The grass mower includes a front wheel unit having a left front wheel and a right front wheel which are mounted to a vehicle body frame, a rear wheel unit having a left rear wheel and a right rear wheel which are mounted to the vehicle body frame and a mower unit disposed between the front wheel unit and the rear wheel unit downwardly of the vehicle body frame, the mower unit including a rotary blade unit that has at least a left blade and a right blade which are disposed side by side in a vehicle body left / right direction. The rotary blade unit is configured such that a tread-on track of the left front wheel is overlapped with a rotation locus portion of the left blade from the front side to the rear side thereof and a tread-on track of the right front wheel is overlapped with a rotation locus portion of the right blade from the front side to the rear side thereof.

Owner:KUBOTA LTD

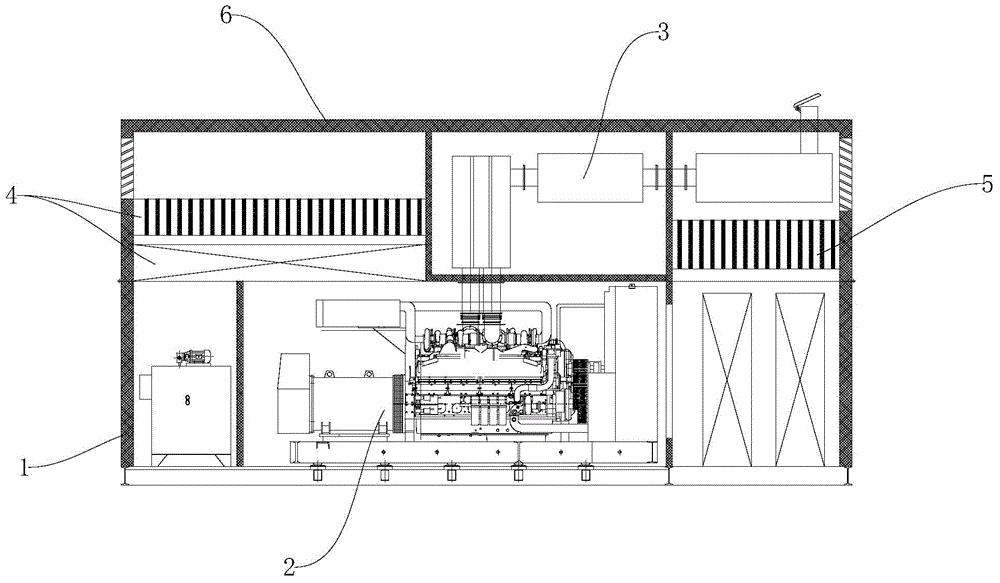

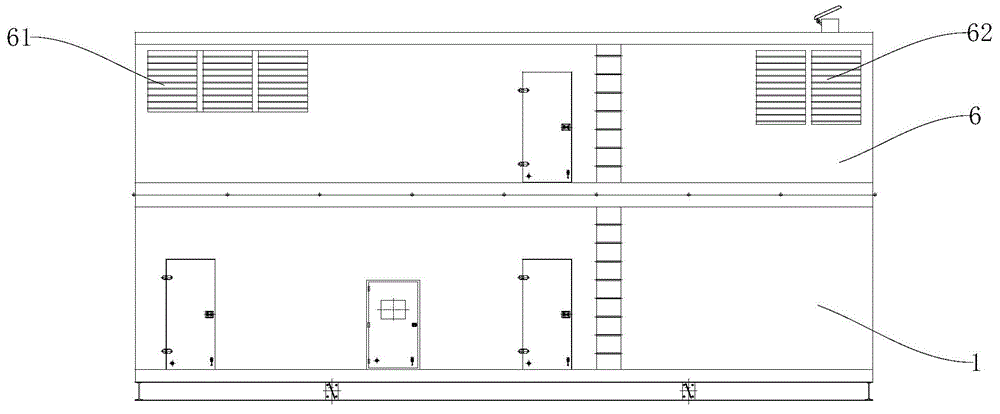

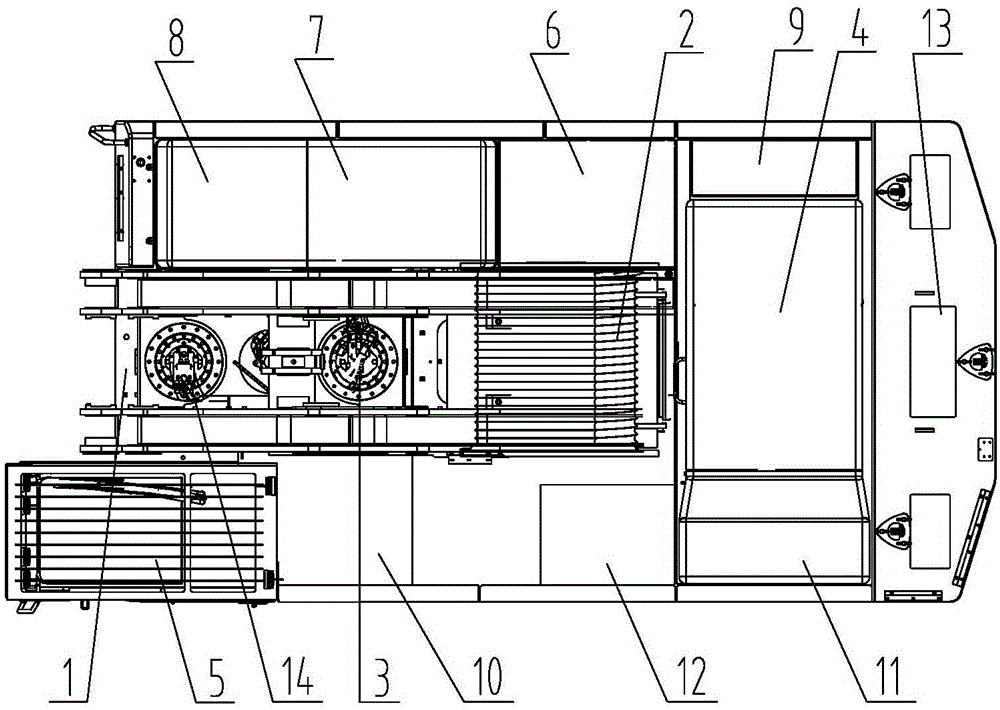

Double-layer low-noise container power station

InactiveCN105275604ALow costLarge maintenance spaceExhaust apparatusSilencing apparatusLow noisePower station

The invention discloses a double-layer low-noise container power station. The double-layer low-noise container power station comprises a lower container body, a power generator set, a silencer, an air inlet silencing body and an air outlet silencing body, and the power generator set is arranged in the lower container body. The double-layer low-noise container power station further comprises an upper container body, the upper container body and the lower container body are partitioned through a partition plate, the silencer is arranged in the middle portion of the upper container body, the air inlet silencing body is arranged at the left end of the upper container body, the air outlet silencing body is arranged at the right end of the upper container body, and an air inlet shutter is arranged at the left end of the upper container body. The double-layer low-noise container power station has the beneficial effects that a double-layer low-noise container is arranged, the power generator set and a noise reducing and smoothing part can be separately arranged, the pipe design cost is lower, the maintaining space is larger, maintaining is relatively convenient, and the maintaining cost is low; and meanwhile a noise reduction part with large volume can be installed, and the noise reducing effect can be improved.

Owner:JIANGSU DAOKANG DIESEL GENERATOR CO LTD

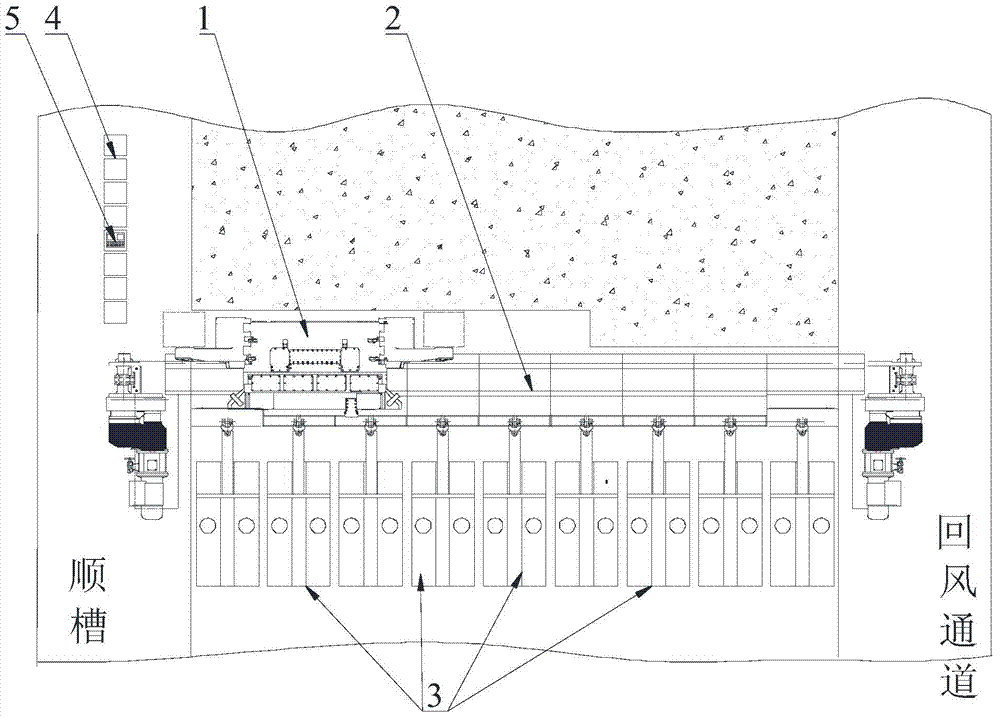

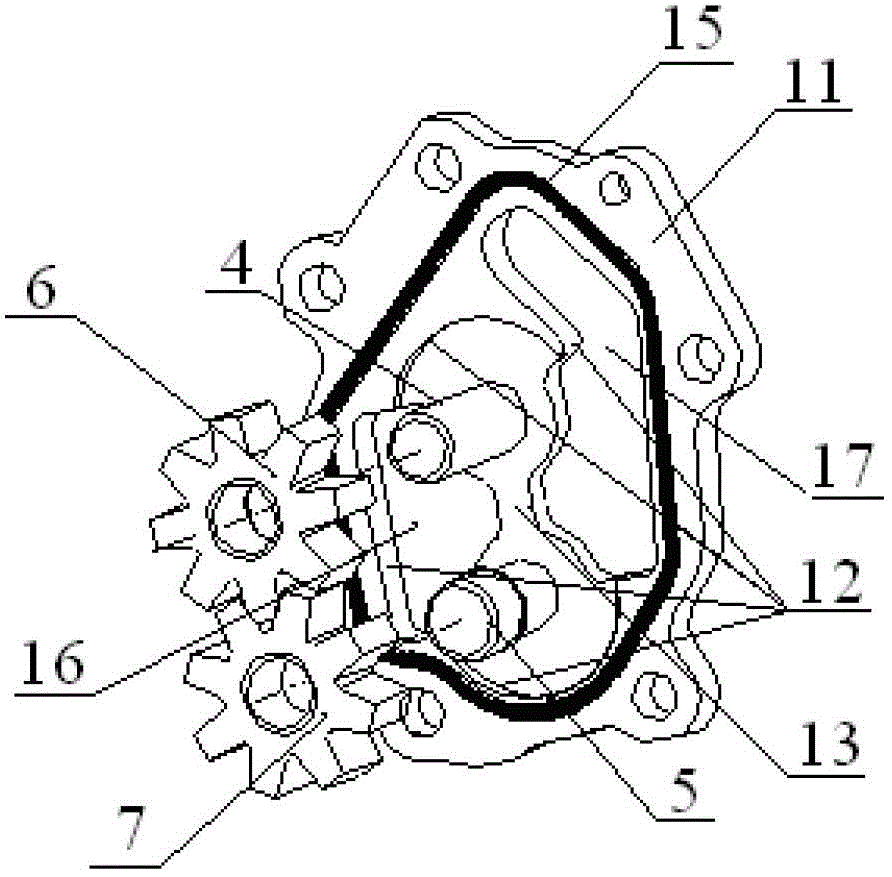

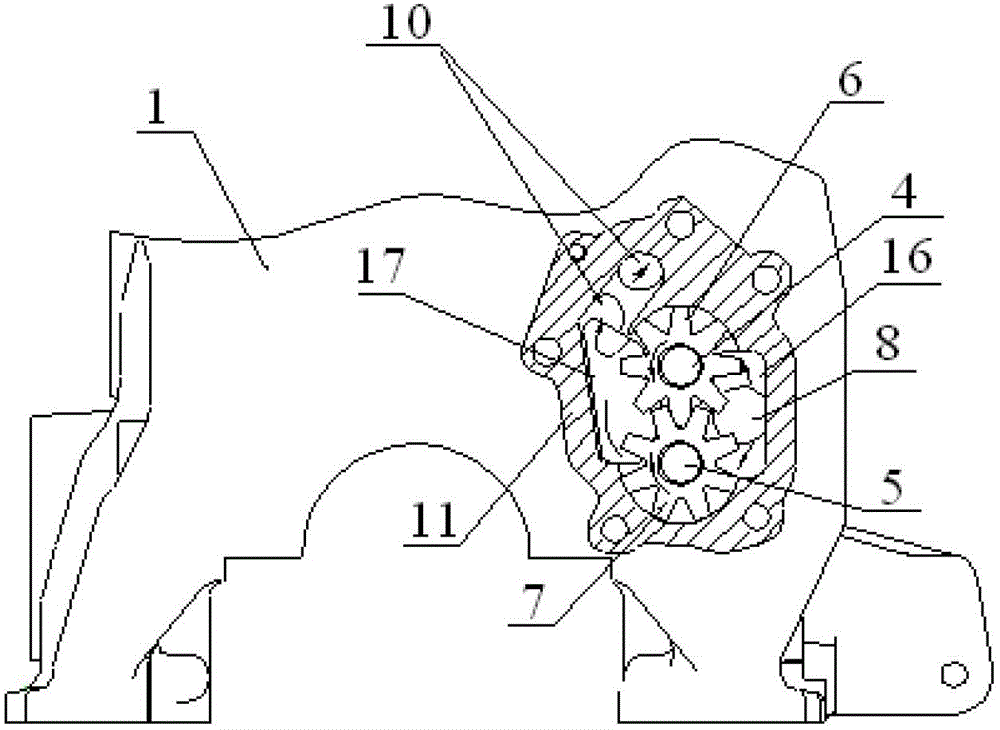

Thin seam combined coal mining unit as well as coal mining machine and scraper conveyer

InactiveCN103899306AReduce the height of the fuselageLarge maintenance spaceSlitting machinesCutting machinesSprocketOperations security

The invention discloses a thin seam combined coal mining unit as well as a coal mining machine and a scraper conveyer. The thin seam combined coal mining unit comprises the coal mining machine and the scraper conveyer. The coal mining machine comprises a body, a cutting part and a driving part, wherein the driving part is arranged on the side of a rib of the body; the scraper conveyer comprises a front side plate, a rear side plate and a scraper chain and a chain wheel arranged between the front side plate and the rear side plate. A pin track of the coal mining machine is arranged outside the front side plate, and the driving part is engaged with the pin track of the coal mining machine. According to the thin seam combined coal mining unit provided by the invention, the coal mining machine and the scraper conveyer are matched on the side of the rib, so that the height of the body of the coal mining machine can be reduced so as to reduce the coal mining height of the coal mining machine, so that the unit is easily arranged in the working face of the thin seam to more effectively explore aiming at the characteristic of height of the thin seam, thereby improving the extraction efficiency. Meanwhile, the maintenance space of the coal mining machine can be enlarged to facilitate maintenance work, the labor intensity of underground operators is reduced, and the operating safety is enhanced.

Owner:SANY HEAVY EQUIP

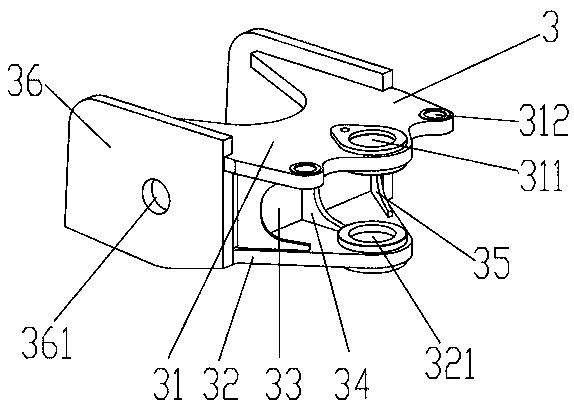

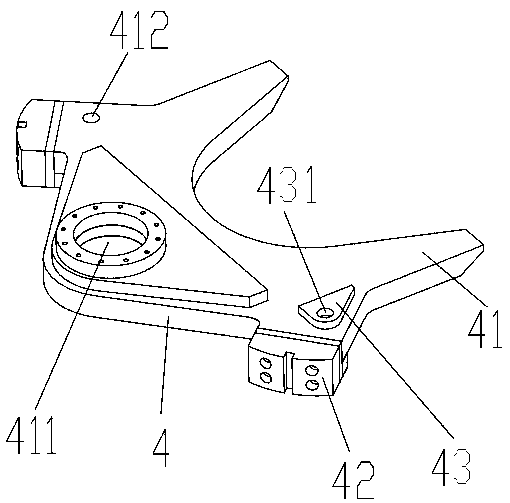

Loader and integrated hinge mechanism thereof

PendingCN110565728ACompact layoutReduce load-bearing conditionsSoil-shifting machines/dredgersVehicle frameEngineering

The invention discloses a loader and an integrated hinge mechanism thereof, and belongs to the technical field of loaders. According to the loader and the integrated hinge mechanism thereof, a front-rear frame hinge mechanism of the loader is divided into independent modules which are subjected to local reinforcement design, and then the independent modules are welded together with a frame body, so that the increment of the weight of a frame is minimized; meanwhile, based on matched installation of a redesigned front hinge mechanism and a redesigned rear hinge mechanism, and integration of thefunctions such as active steering of the frame, steering limiting, oil cylinder installation support and locking of front and rear frames can be realized, so that mechanism arrangement is more compact, and a larger maintenance space is reserved for a hinge portion; furthermore, the center face of an upper hinge plate integrated with a steering hinge point and the center of a front drive axle arelocated on a same horizontal plane, so that generation of a steering biasing torque is avoided, bearing working conditions of the frame is relieved, and steering force transmission is more scientificand efficient; and in addition, the steering limiting function integrated in the hinge mechanisms is achieved by utilizing a hinge mechanism body to share the steering limiting impact force, and therefore the steering limit fatigue strength can be effectively improved.

Owner:XCMG CONSTR MACHINERY

Grass mower

ActiveUS9516808B2Cutting leftovers can be restrictedLarge maintenance spaceLawn-mowersEngineeringMower

The grass mower includes a front wheel unit having a left front wheel and a right front wheel which are mounted to a vehicle body frame, a rear wheel unit having a left rear wheel and a right rear wheel which are mounted to the vehicle body frame and a mower unit disposed between the front wheel unit and the rear wheel unit downwardly of the vehicle body frame, the mower unit including a rotary blade unit that has at least a left blade and a right blade which are disposed side by side in a vehicle body left / right direction. The rotary blade unit is configured such that a tread-on track of the left front wheel is overlapped with a rotation locus portion of the left blade from the front side to the rear side thereof and a tread-on track of the right front wheel is overlapped with a rotation locus portion of the right blade from the front side to the rear side thereof.

Owner:KUBOTA LTD

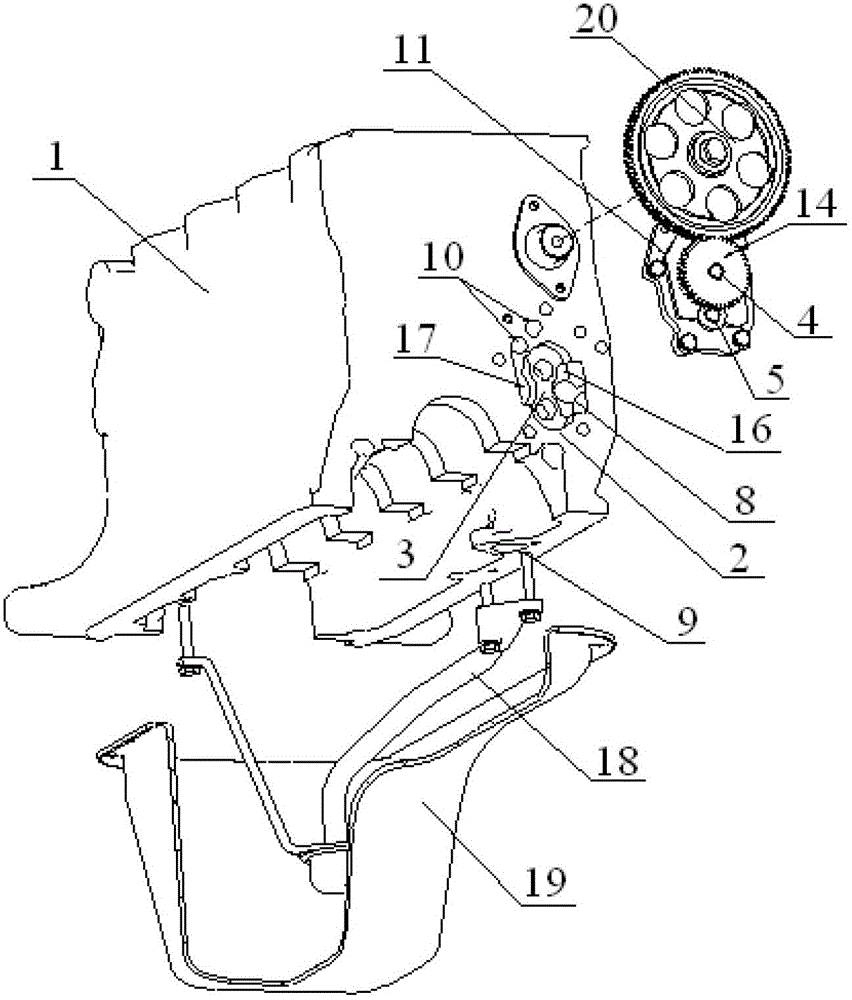

Fuel pump system integrated with engine body

InactiveCN102748087ASmall sizeReduce the difficulty of matchingCasingsCylinder headsRubber ringDrive shaft

The invention discloses a fuel pump system integrated with an engine body. The structure is that an engine body recessed cavity of a fuel pump is arranged on the engine body, and a casing recessed cavity identical with the engine body recessed cavity in shape is arranged on a fuel pump casing. A driving shaft and a driven shaft are respectively arranged on boss shaft sleeves in the recessed cavities, and a driving gear and a driven gear are respectively embedded in the driving shaft and the driven shaft. The driving shaft with the driving gear penetrates through the boss shaft sleeve of the fuel pump casing to be connected with a fuel pump gear outside the fuel pump casing. The fuel pump casing and the engine body recessed cavities are fastened and sealed through bolts and rubber rings to form a complete fuel pump working cavity. A large portion of the fuel pump working pump occupies space in the engine body to enable structure outside the fuel pump to be very small. When identical pressure and flow in a main oil channel are achieved, overall dimension of the engine is remarkably reduced. Therefore, the matching difficulty of the engine and a whole vehicle can be reduced, and large maintenance space is retained for the whole vehicle. The structure can be widely applied to any engine due to the fact that the system is simple and compact in structure.

Owner:东风朝阳朝柴动力有限公司

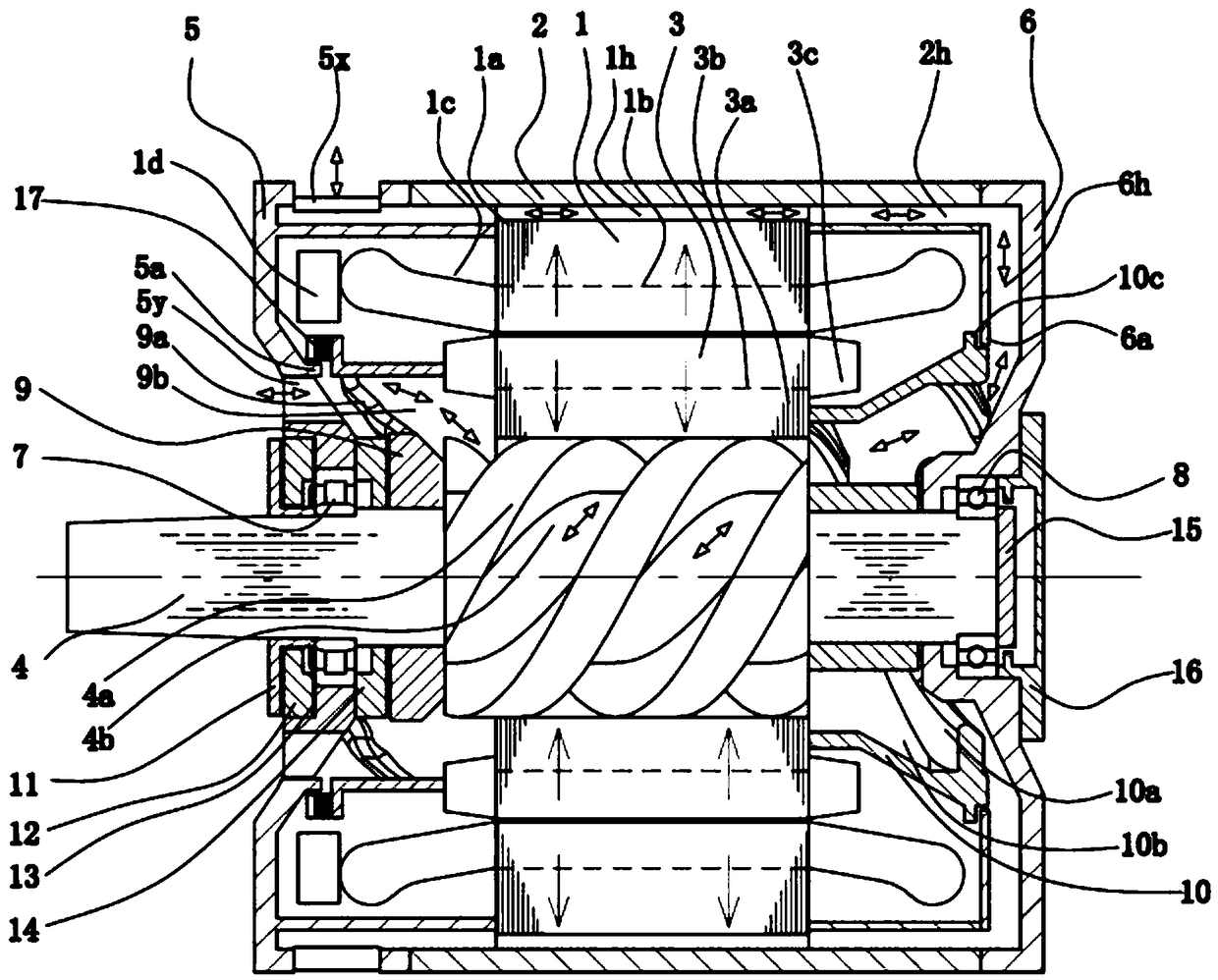

Electromotor

ActiveCN108808986AGuaranteed cooling effectImprove working environmentMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineEngineering

The invention discloses an electromotor for realizing stator sealing and rotor opening ventilation manners by adopting axial flow ventilation. An adopted shaft is provided with an external circumference spiral groove and is matched with an axial flow fan with two ends clinging to each other and same spiral direction so as to form an axial flow combination ventilation device; the devices are arranged on the inner part of a rotor and two ends of the rotor so as not to occupy an extra motor axial space, so that the electromotor is compact in structure; due to different steering directions, the air flow direction is also different, but the motor can be cooled; by matching with labyrinth seal, a cooling manner combining stator seal type ventilation cooling with rotor open type ventilation cooling of the electromotor is realized, so that the stator insulation reliability and the rotor heat radiation capacity are ensured through the combined cooling manner, and the motor efficiency is improved; a stator cooling air flue is formed by (2x), (2h) and (6h); a rotor cooling air flue is formed by (5y), (9b), (4b) and (10b); the two cooling air flues are connected with each other in series and is jointly supplied with air pressure by the spiral combination device.

Owner:胜利油田顺天节能技术有限公司

Rotary drilling rig and chassis platform thereof

InactiveCN105019823AReduced stiffness requirementsReduce stress levelsConstructionsDerricks/mastsEngineeringChassis

The invention provides a rotary drilling rig and a chassis platform thereof. The chassis platform at least comprises a platform substrate, a main windlass, a rotary speed reducer and an engine. The engine and the rotary speed reducer are arranged on the platform substrate. Only the main windlass is arranged on the platform substrate. The rotary speed reducer is arranged in front of the main windlass. The engine is arranged behind the main windlass. According to the structure configuration manner of the rotary drilling rig, the working load of a mast cylinder can be reduced and furthermore a requirement for the rigidity of the platform is reduced.

Owner:BEIJING SANY HEAVY MASCH CO LTD

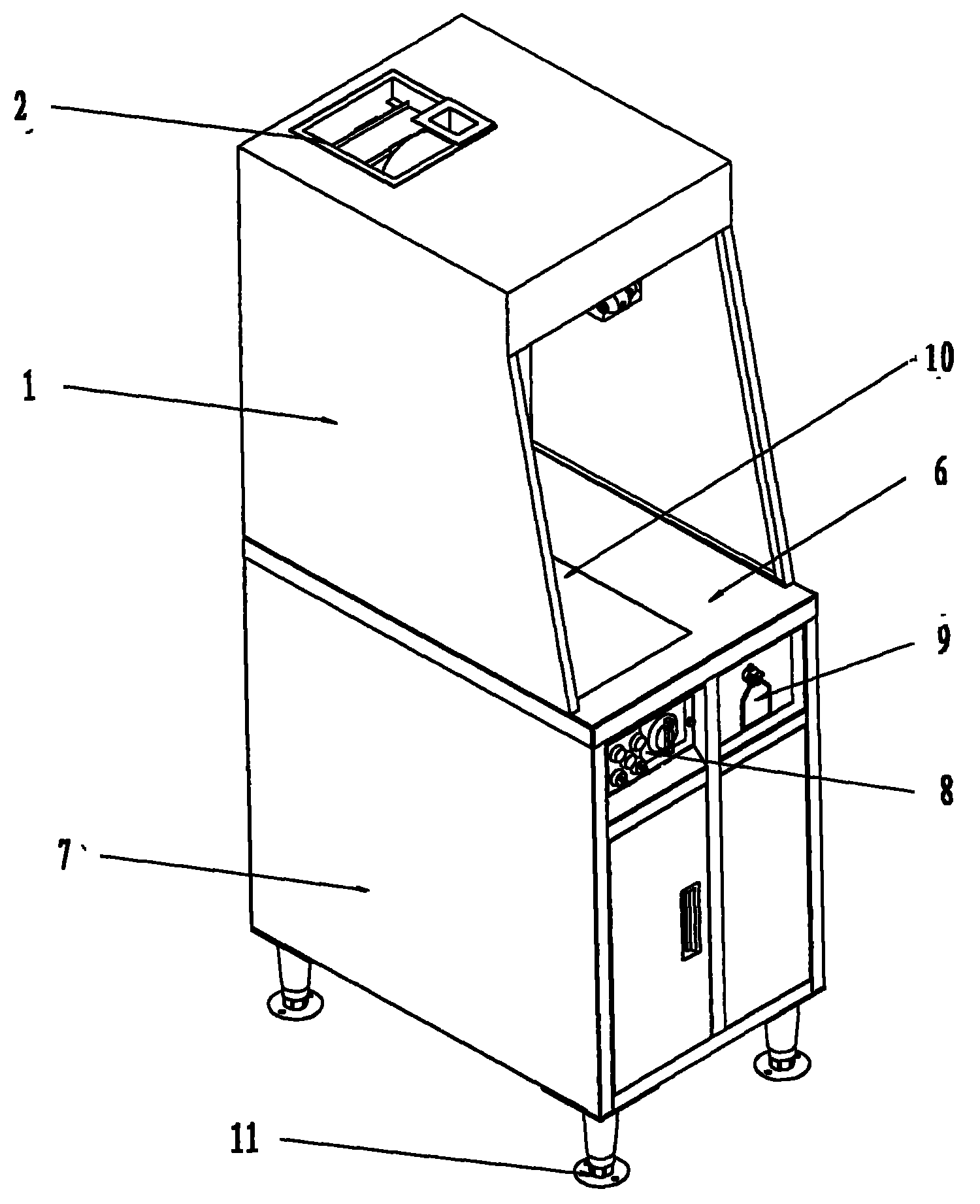

Power cabinet convenient to maintain

InactiveCN111817148AEasy to complete maintenanceLarge maintenance spaceWing fastenersSubstation/switching arrangement casingsPulleyElectrical and Electronics engineering

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Vertical star high pressure air compressor

ActiveCN103437973BReduce volumeCompact layoutPiston pumpsPositive-displacement liquid enginesFailure rateEngineering

Owner:ANHUI HUAJING MACHINERY

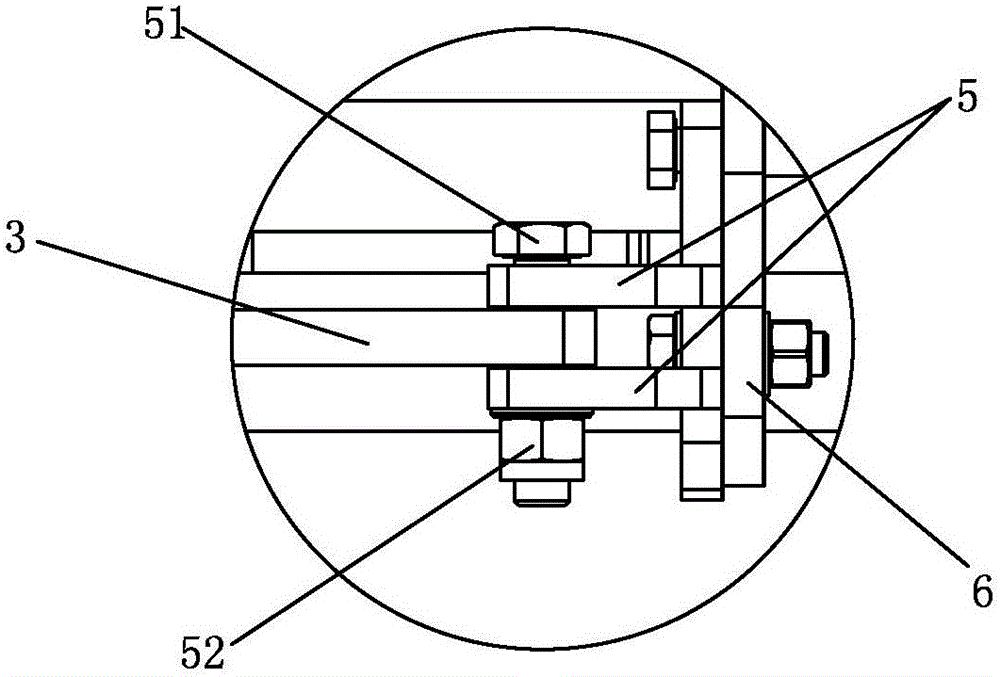

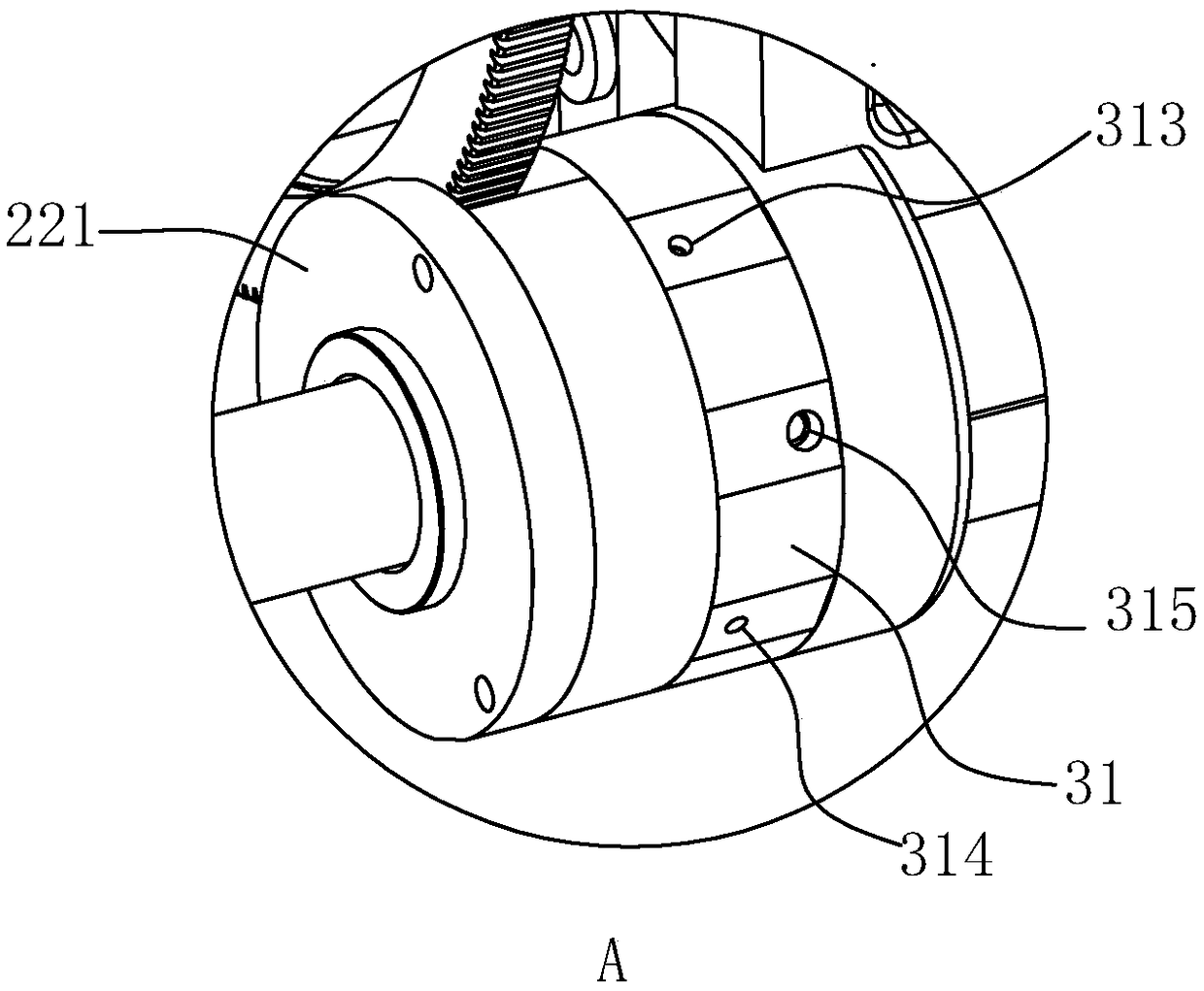

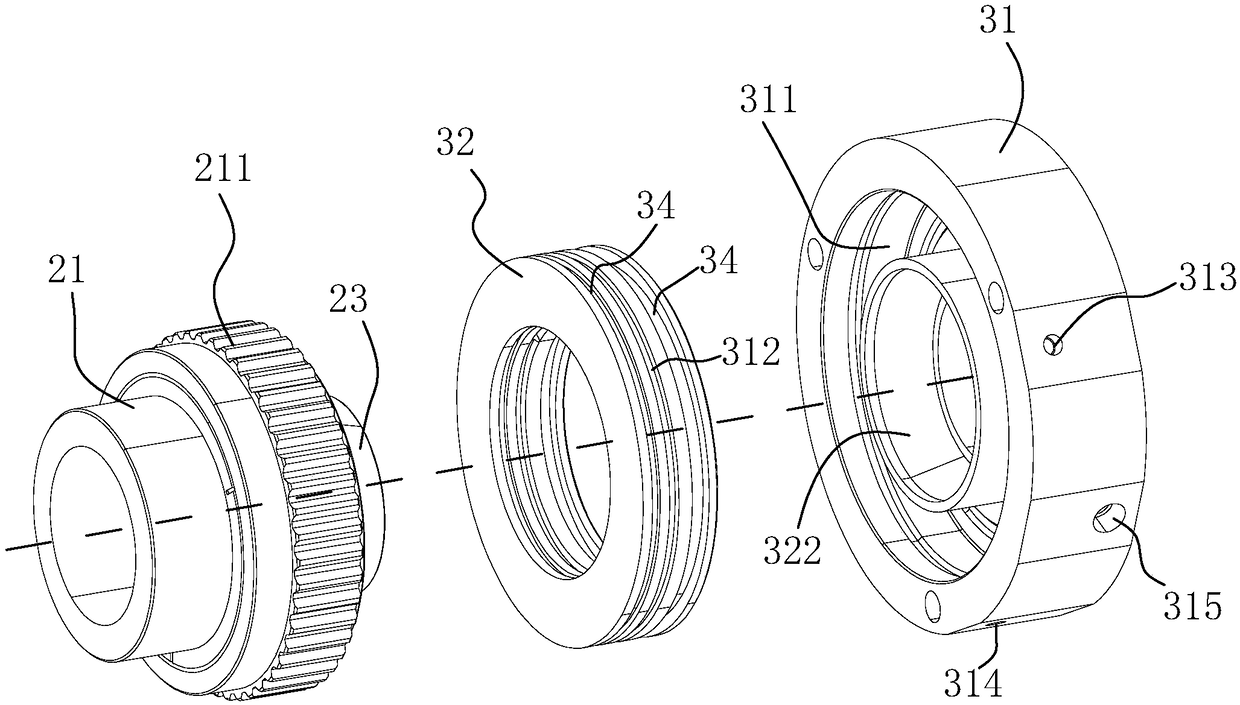

Connecting rod clamping mechanism and injection molding machine comprising same

The invention discloses a connecting rod clamping mechanism and solves the problems of high wear of five-fulcrum connecting rods, arrangement positions of oil cylinder assemblies, high probability offires in high-temperature regions and inconvenience in maintenance. The connecting rod clamping mechanism comprises a moving mold plate, a fixed mold plate and a base plate, wherein the moving mold plate is connected with the base plate through a mold plate hinge assembly, the connecting rod clamping mechanism also comprises a threaded mold adjusting assembly arranged on the outer side of the baseplate, a mode locking oil cylinder assembly and a mode locking pull rod, the mode locking oil cylinder assembly is arranged on the same side of the base plate; one end of the mode locking pull rod penetrates the moving mold plate and the base plate and is matched with the mode locking oil cylinder assembly and the threaded mold adjusting assembly on the outer side of the base plate respectively,and the other end of the mode locking pull rod penetrates the fixed mold plate; a drive part is also arranged on the base plate and connected with the mold plate hinge assembly. The connecting rod clamping mechanism is good in mode locking accuracy, high in efficiency and convenient to maintain and cannot cause safety accidents easily.

Owner:宁波云上塑料机械有限公司

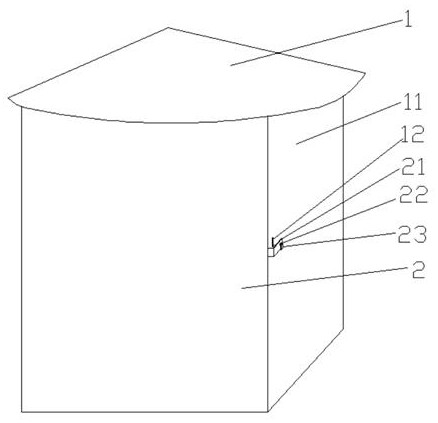

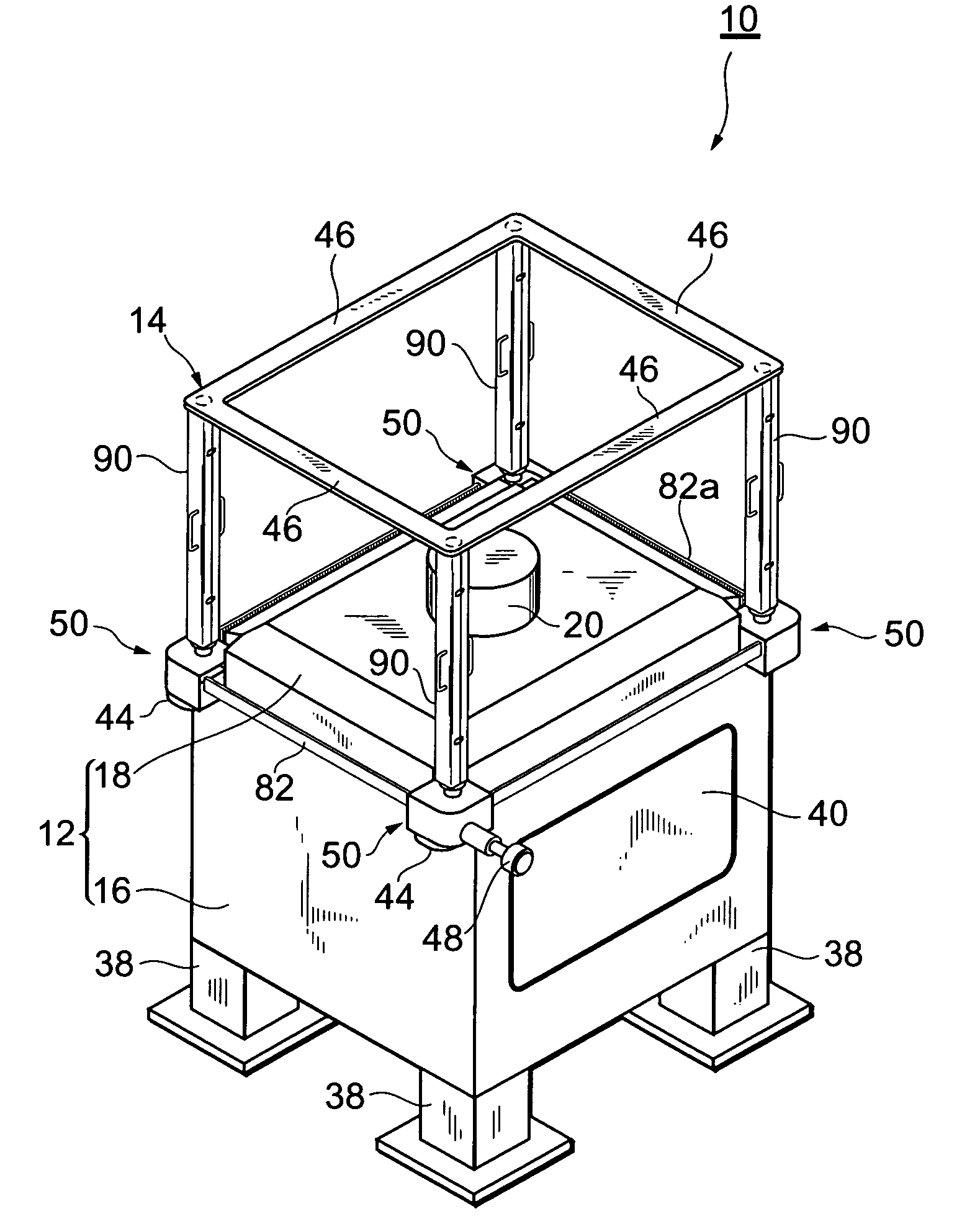

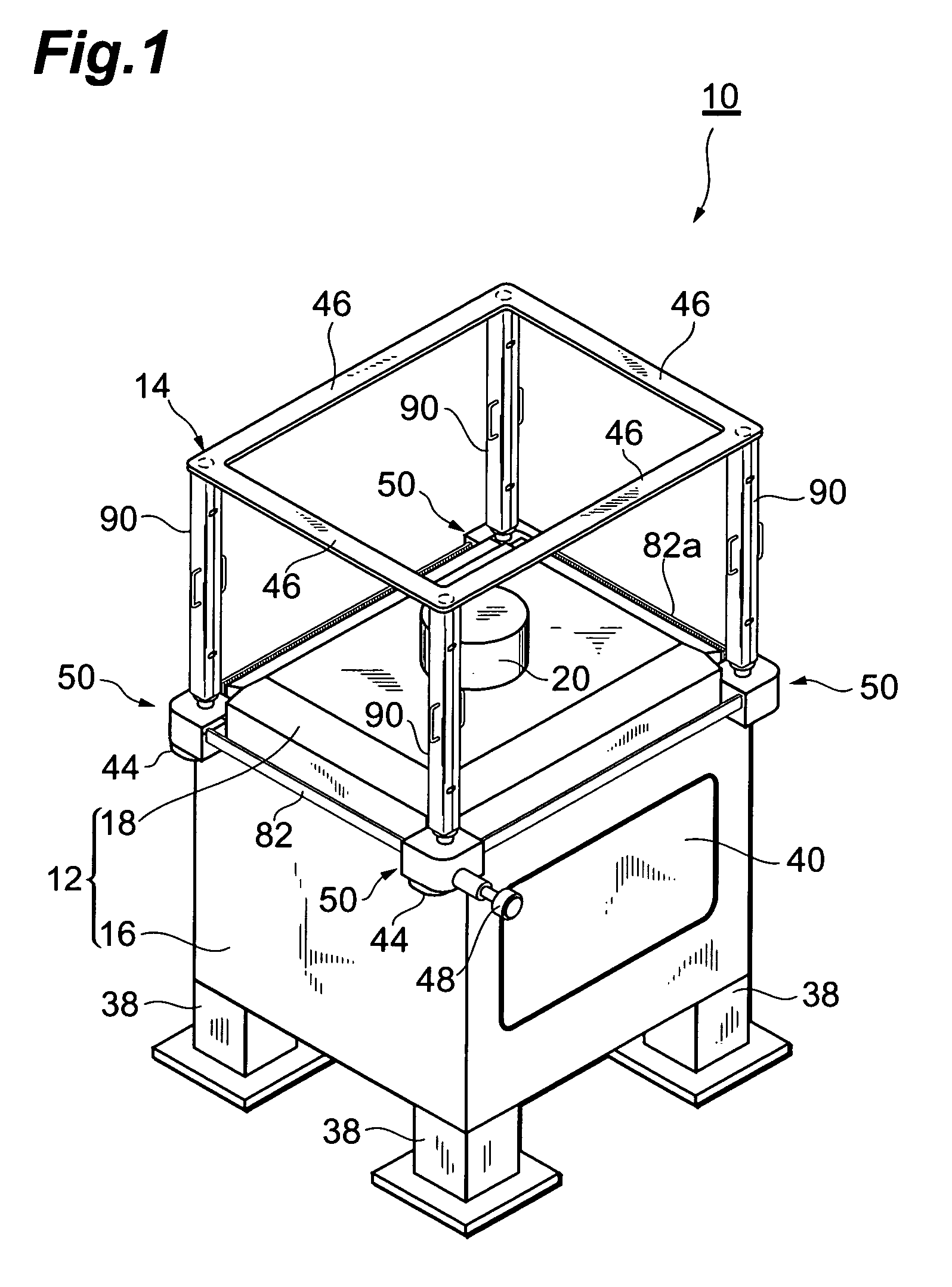

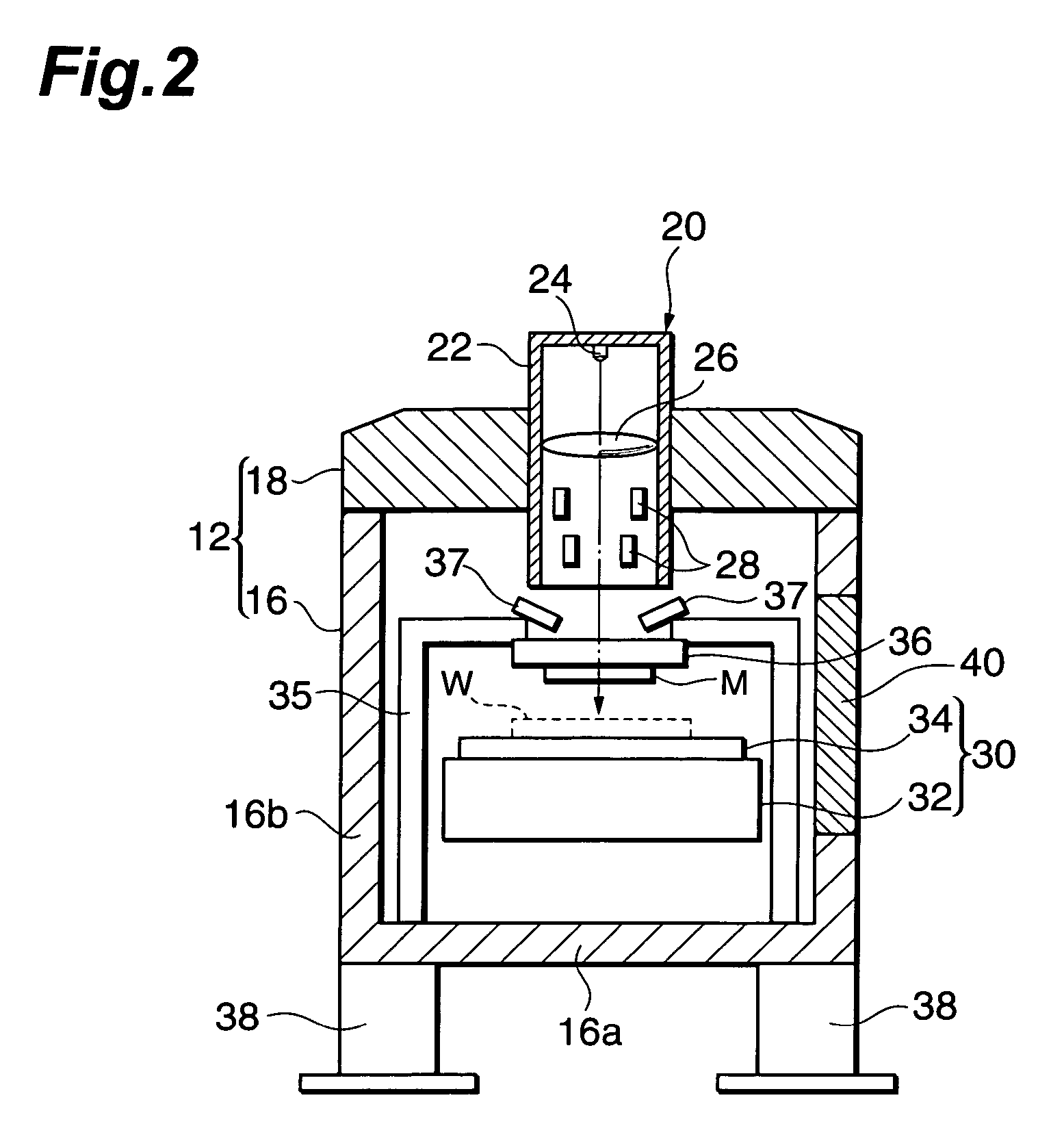

Substrate processing apparatus and maintenance method therefor

InactiveUS7361905B2Increase costLow efficiencyElectric discharge tubesPhotomechanical apparatusEngineeringMechanical engineering

A substrate processing apparatus comprises a chamber. The chamber includes a container and an upper lid for closing an upper opening of the container. On the upper side of the chamber, an elevator for vertically moving the upper lid is disposed integrally with the chamber.

Owner:SUMITOMO HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com