Vertical star high pressure air compressor

An air compressor and high-pressure technology, applied in the field of high-pressure air compressors, can solve the problems of inconvenient maintenance, complicated pipelines, and many fault points, and achieve the effects of convenient disassembly and assembly, large maintenance space, and few fault points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The vertical star-type high-pressure air compressor of the present invention will be described in further detail below in conjunction with the accompanying drawings.

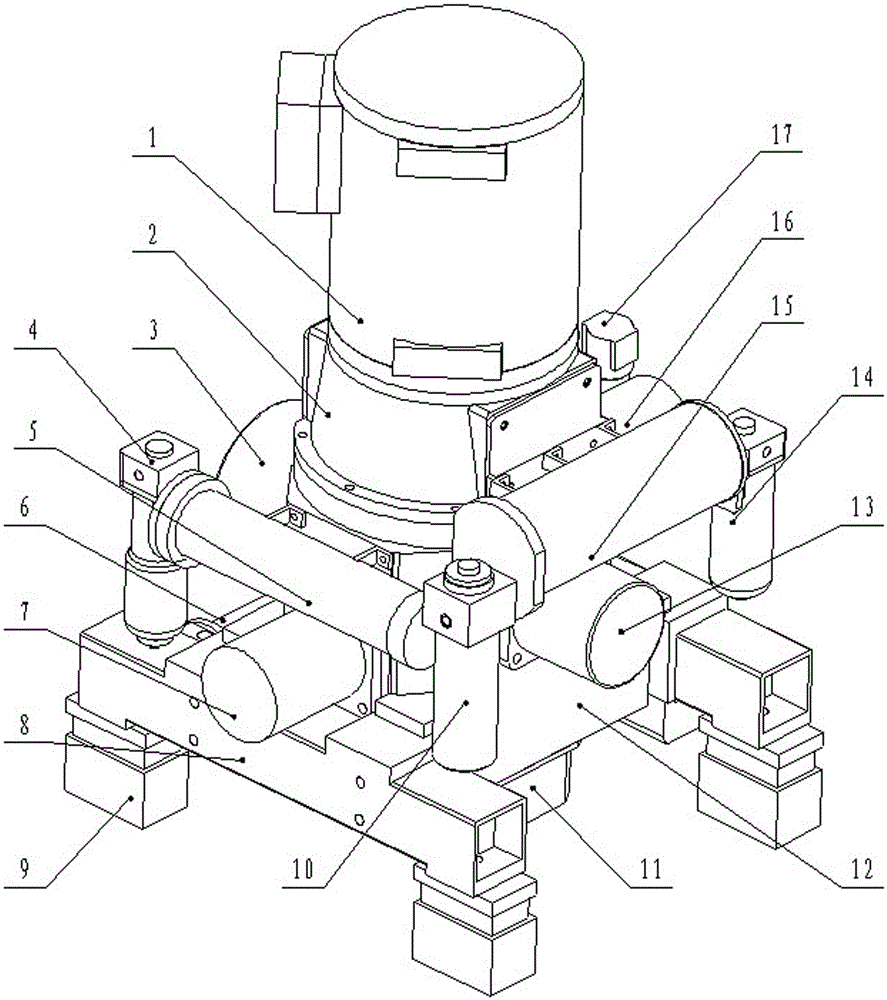

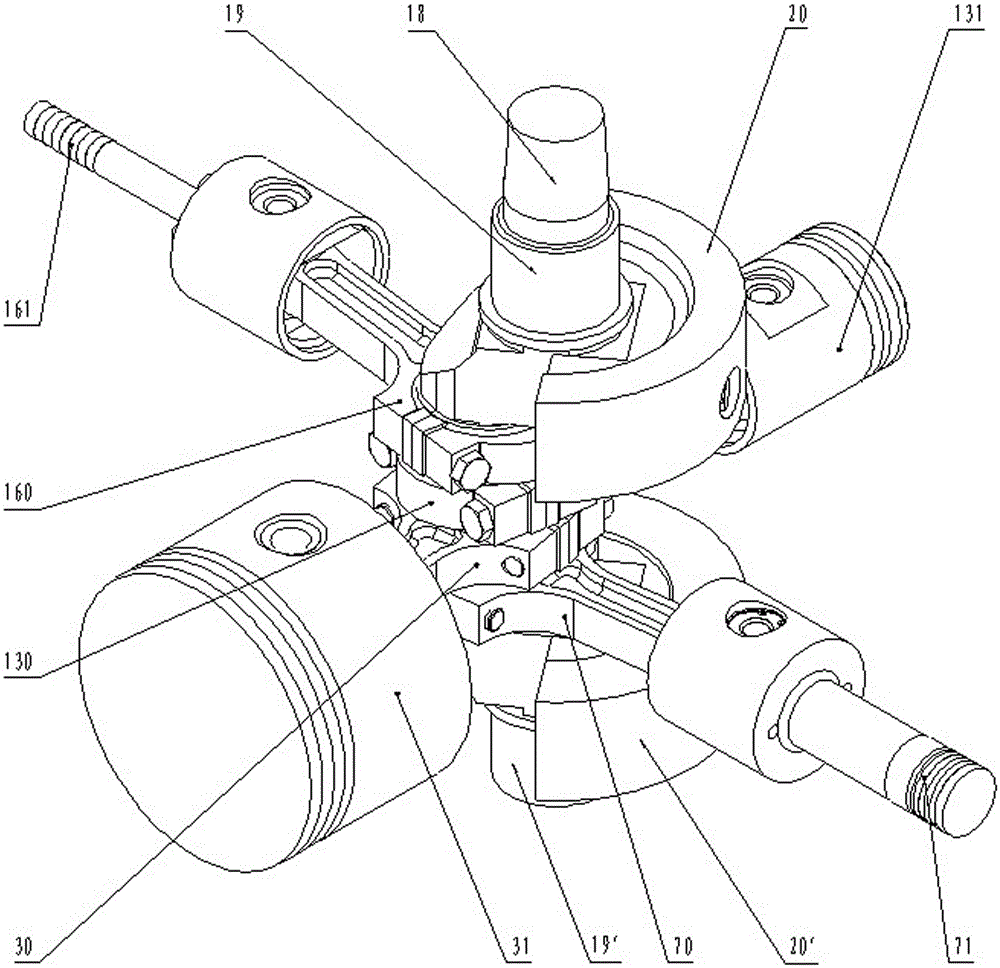

[0012] Depend on figure 1 , figure 2 It can be seen that the vertical star-type high-pressure air compressor of the present invention includes a vertically arranged motor 1, and also includes a crankcase 12. A crankshaft 18 is arranged in the crankcase 12, and the main shaft of the motor 1 is connected with the crankshaft 18. The motor 1 is connected to the crankcase 12 through the casing 2; it also includes the first-stage cylinder 3, the second-stage cylinder 13, the third-stage cylinder 7 and the fourth-stage cylinder 16 radially arranged radially along the crankshaft 18. , the four cylinders are evenly distributed on the circumference, arranged at 90° to each other. The first-stage cylinder 3 is arranged opposite to the second-stage cylinder 13 , and the third-stage cylinder 7 is arranged opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com