Rotary drilling rig and chassis platform thereof

A technology for rotary drilling rigs and platforms, which is applied in rotary drilling rigs, rotary drilling, earthwork drilling and mining, etc. It can solve the problems of high pressure on the luffing mechanism and large load on the platform, and achieve lower rigidity requirements and large layout space , the effect of reducing the load level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

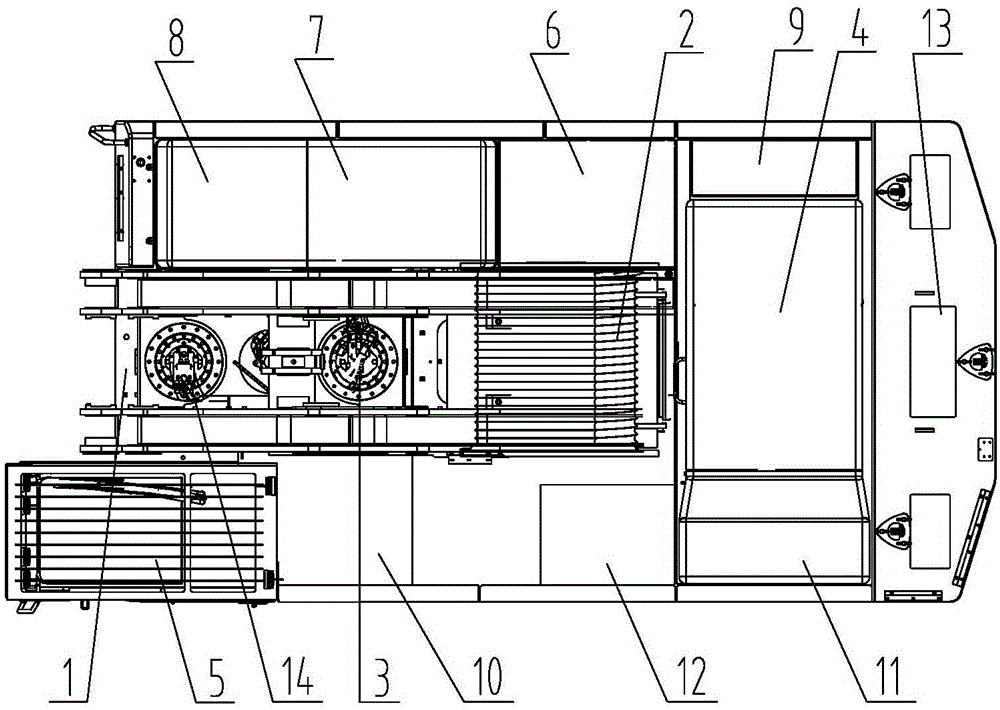

[0030] It should be clear that the orientation used in the present invention is based on the use status of the rotary drilling rig. Specifically, in figure 1 The views shown are "front" on the left and "rear" on the right.

[0031] figure 1 Shown is a structural schematic diagram of a chassis platform of a rotary drilling rig according to an embodiment of the present invention. The chassis platform of the rotary drilling rig in this embodiment at least includes a platform base 1, a main winch 2, a rotary reducer 3 and an engine 4, and the structure of each part can refer to existing and improved technologies.

[0032] The aforementioned main winch 2 , engine 4 and rotary reducer 3 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com