Two-stage impeller embedded submersible axial-flow pump

An axial-flow pump and built-in technology, applied in the field of submersible axial-flow pumps with built-in impellers, can solve the problems of application limitations, low efficiency of submersible axial-flow pumps, and inability to make full use of axial length, etc. Metal consumption, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

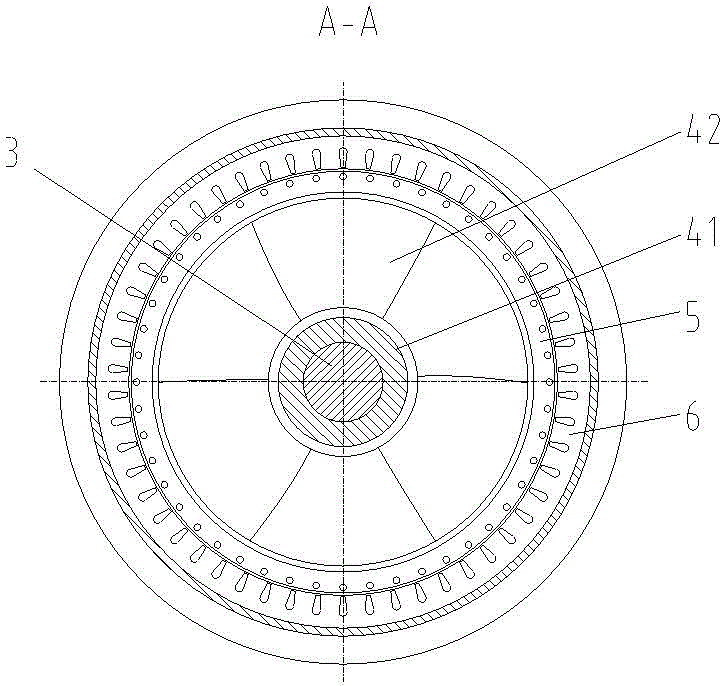

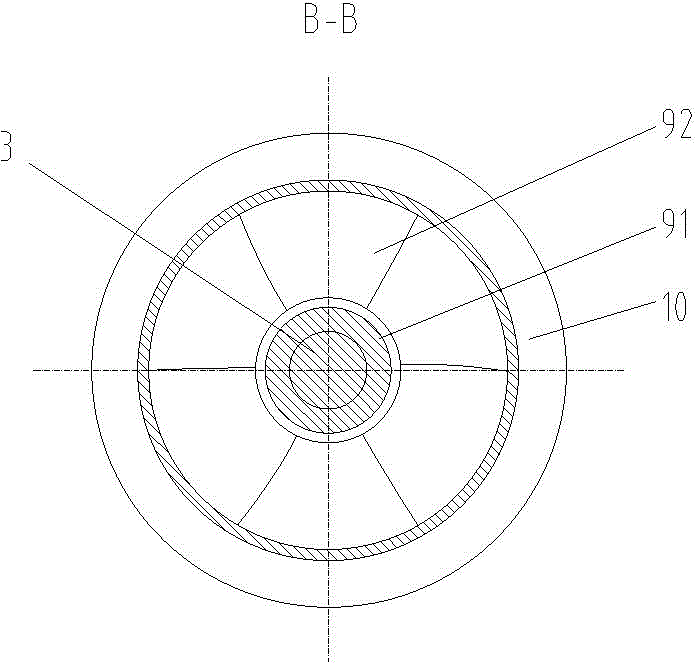

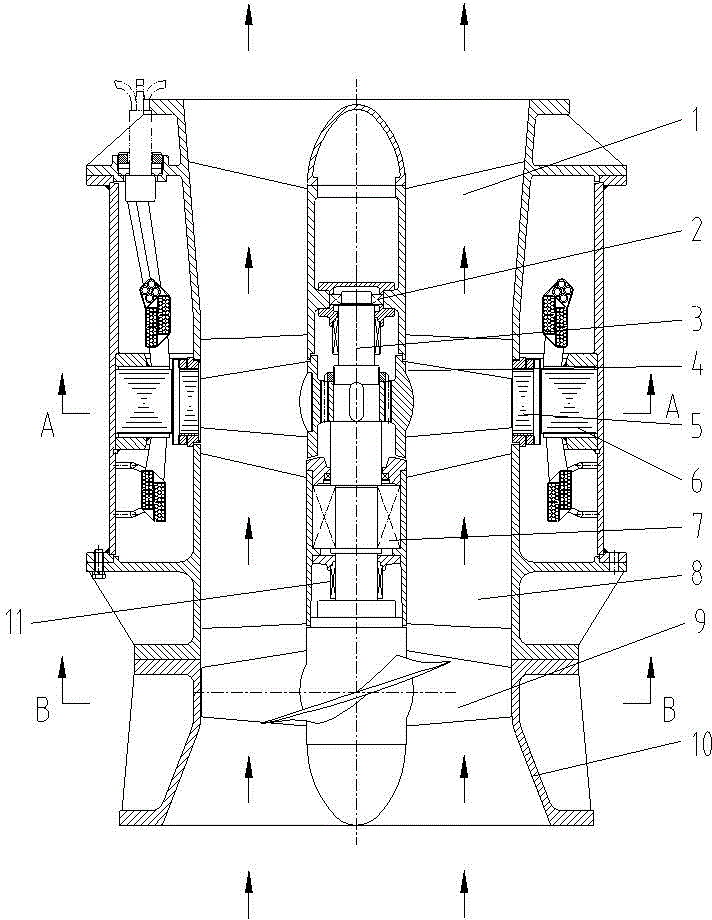

[0027] see figure 1 , a two-stage impeller built-in submersible axial flow pump includes a housing, and the housing is provided with a water suction chamber 10, a secondary impeller 4, a first stage impeller 9 and a water outlet chamber 1, which are coaxially connected sequentially, corresponding to the secondary impeller 4. A motor is provided in the housing, and the second-stage impeller 4 and the first-stage impeller 9 are fixed on the rotating shaft 3 . The stator 6 of the motor is fixedly installed on the inner wall of the casing, the winding coil of the stator 6 is a water-resistant winding coil, and the material of the water-resistant winding coil is high-strength irradiation cross-linked polyethylene, and the rotor 5 is fixedly installed on the annular secondary impeller 4 on the outer circumference of the shell.

[0028] see figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com