Inner self-locking rivet, and rivet composite connection device and connection method

A composite connection and rivet technology, which is applied in the direction of rivets, connection members, thin plate connections, etc., can solve the problems of poor sealing of joints, reduction of corrosion resistance of joints, and large application limitations, so as to prevent upset and deformation and reduce riveting force , reducing the effect of the required sum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] Embodiment 1 is a preferred example of the basic embodiment.

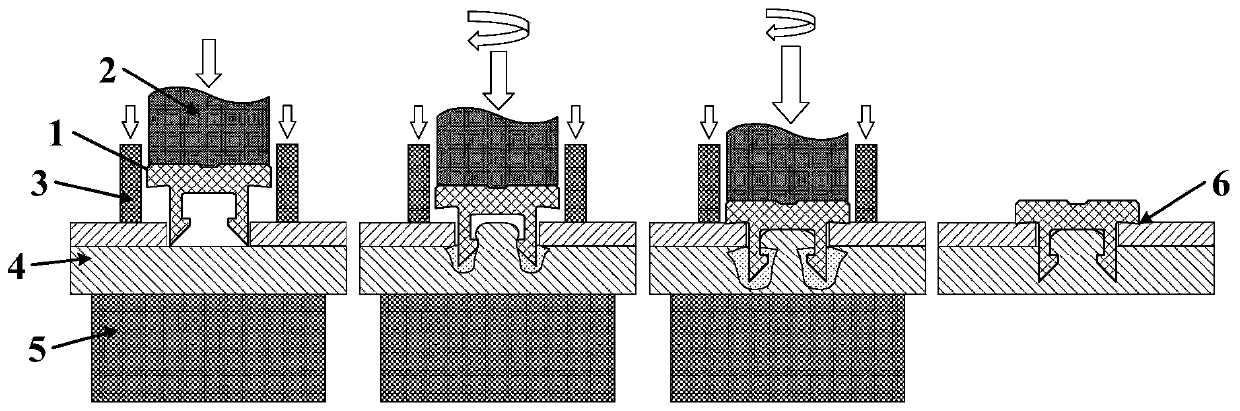

[0149] Such as figure 2 As shown, this embodiment includes: a semi-hollow rivet 1, a drive head 2 with a central positioning boss, a blank holder 3, a plate to be connected 4, and a flat-bottom mold 5, wherein: the driving head 2 with a central positioning boss passes through the convex The raised teeth engage with the recessed teeth on the top of the semi-hollow rivet cover 101, the positioning boss matches the positioning groove 102 on the rivet cover 101, and is jointly located above the plates 4 to be connected, and the blank holder 3 is located at the top of the rivet cover 101. Above the plates 4, the mold 5 is located below the plates 4 to be connected.

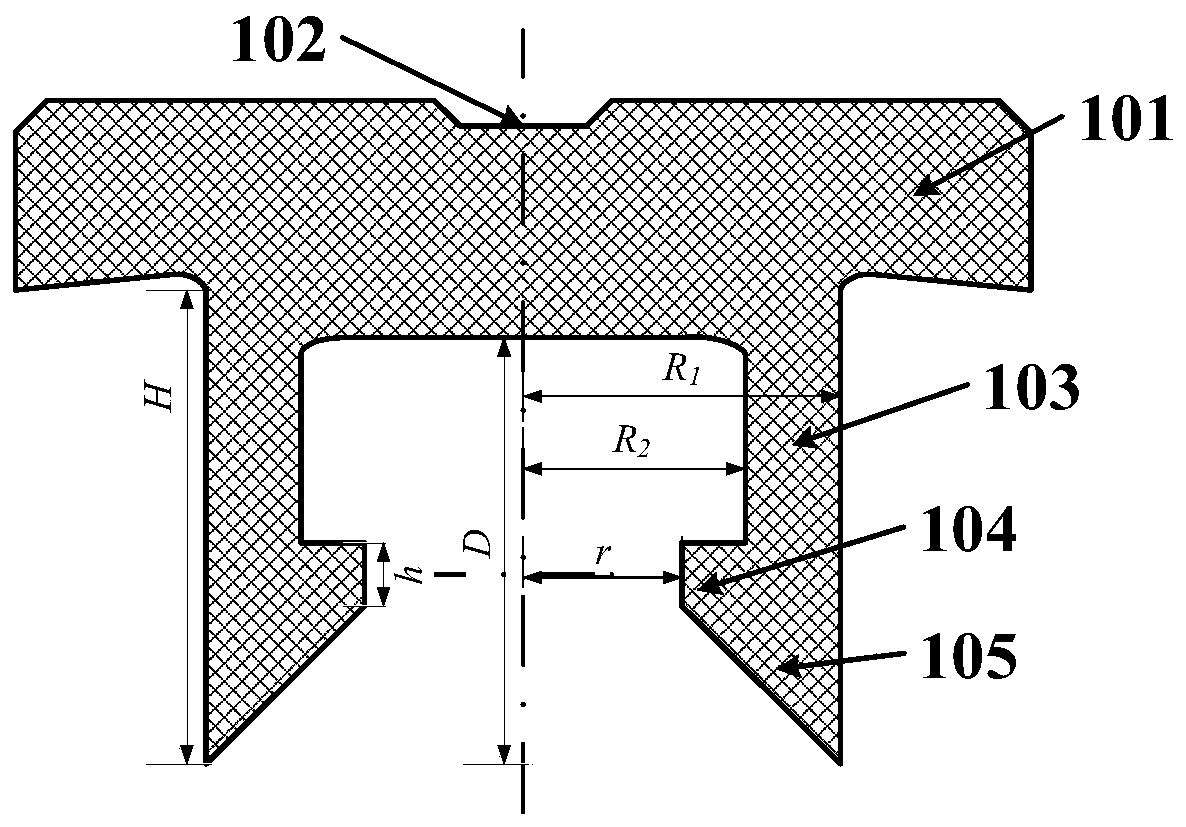

[0150] Such as figure 1 As shown, the semi-tubular rivet 1 includes: a rivet cover 101 and a semi-tubular rivet body 103 integrally connected, wherein: the central positioning boss 102 of the rivet cover 101 and the rivet body 103 are arranged coa...

Embodiment 2

[0165] Embodiment 2 is a preferred example of the basic embodiment.

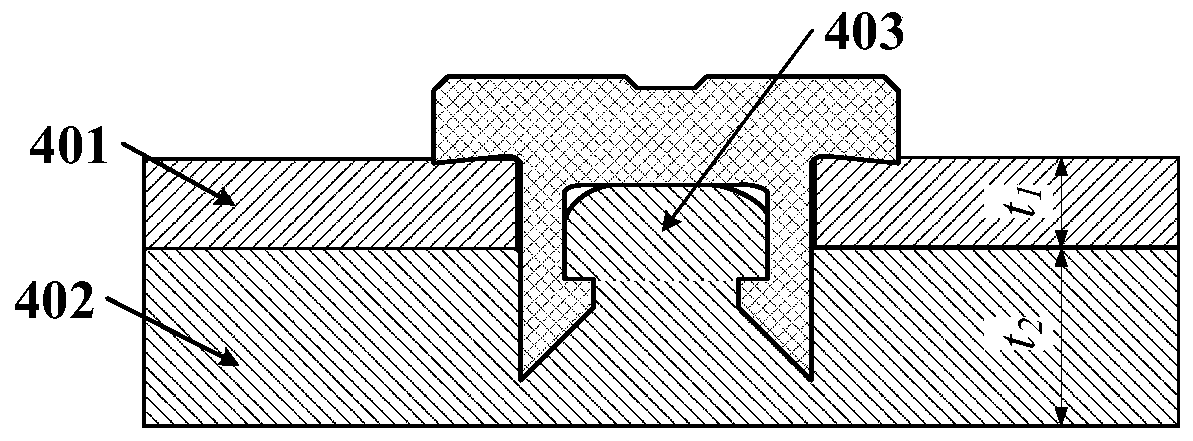

[0166] Such as Figure 8 As shown, the first layer 401 of the plates 4 to be connected in this embodiment is a 10mm 45 steel plate, and the second layer 402 is a 20mm 7075 aluminum alloy.

[0167] Compared with Example 1, the total thickness of the upper and lower panels is larger, and considering that the upper panel needs to be detachable for easy maintenance and replacement, the third variation of the present invention is adopted, that is, the inner panel without umbrella-shaped nail caps. Screw thread 108 holes 107 rivets 1, and cooperate with the bolt 8 of corresponding size. The height of the rivet body 103 is 20.0 mm, the outer diameter is 12.0 mm, the inner wall is an M10 internal thread 108, the inner diameter of the inner self-locking boss 104 is 7.0 mm, and the height of the boss is 1.5 mm. The diameter of the M10 bolt 8 cap matched with the internal thread 108 is 15.0mm;

[0168] Compared with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com