Modular integrated hoisting mechanism of crawler crane

A technology of crawler cranes and hoisting mechanisms, which is applied to hoisting devices, clockwork mechanisms, etc., can solve the problems of large processing volume, large assembly size error, and inconvenient structural maintenance of turntables, and achieve large maintenance space and reduced processing error, reducing the time for mounting and dismounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

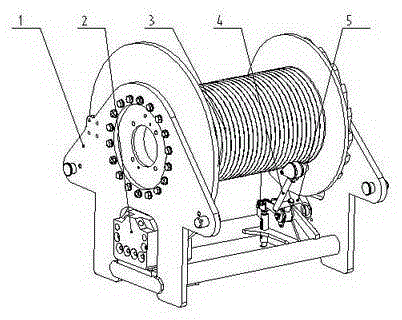

[0010] The modular integrated winch mechanism of crawler crane is composed of frame 1, winch 3, caliper disc brake 2, three-ring protector 4, and pawl 5. The frame 1 adopts a welded structure, the three-ring protector 4 and the pawl 5 are connected with the frame 1 through the pin shaft, the caliper brake 2 is fixed on the base plate of the frame 1 with bolts, and the hoist 3 is connected with the planetary reducer by bolts. The fixed end of the planetary reducer is fixed to the frame 1 through bolts, and the whole hoisting mechanism is connected with the turntable by four pins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com