Arrangement structure of stacker device

A technology for arranging structures and reclaiming devices, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of insufficient utilization of the internal space of the material yard, poor rationality of the force of the support structure, and narrow space for the walking platform, etc. The effect of stockpile volume loss, reduction of civil works and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

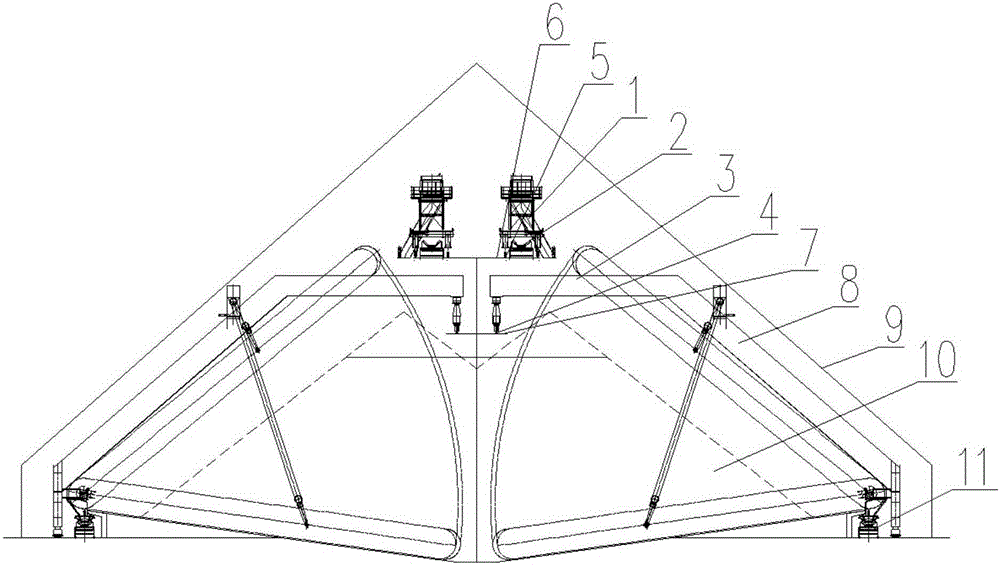

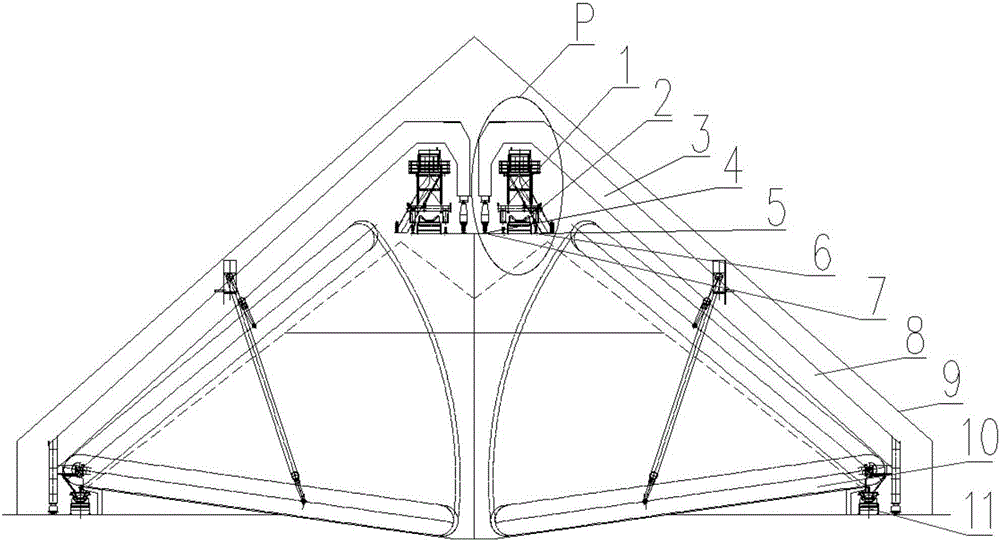

[0040] Such as Figure 2 to Figure 4 As shown, the present invention provides a layout structure of a stacking device, including a stacking device 1, a retrieving device 3, a stacking device running track 5, a material picking device running track, a material input conveyor 2, and a material output conveyor 11 , storage yard 10, closed material storage shed 9, the reclaimer running track includes the upper part of the reclaimer running track 4 and the lower part of the reclaiming device running track, in this example the upper part of the reclaiming device running track 4 and the stacking device running track 5 Be arranged on the same platform, that is, the stacking device running platform 6 and the reclaiming device upper running platform 7 are the same platform, and the reclaiming device lower running track and the material output conveyor 11 are arranged on the side of the storage yard 10 .

[0041] Among them, the stocking device running track 5 is two groups of left and r...

Embodiment 2

[0047] Such as Figure 6 As shown, in this example, the difference from Example 1 is that the number of paths for stacking and reclaiming increases, the running track 5 of the stacking device is increased to 3 paths, and the running track 4 on the upper part of the reclaiming device is located in two adjacent piles. Between the running tracks 5 of the material device, two reclaiming devices 3 straddle the stocking device 1 and the stocking device running track 5 on the same side respectively.

Embodiment 3

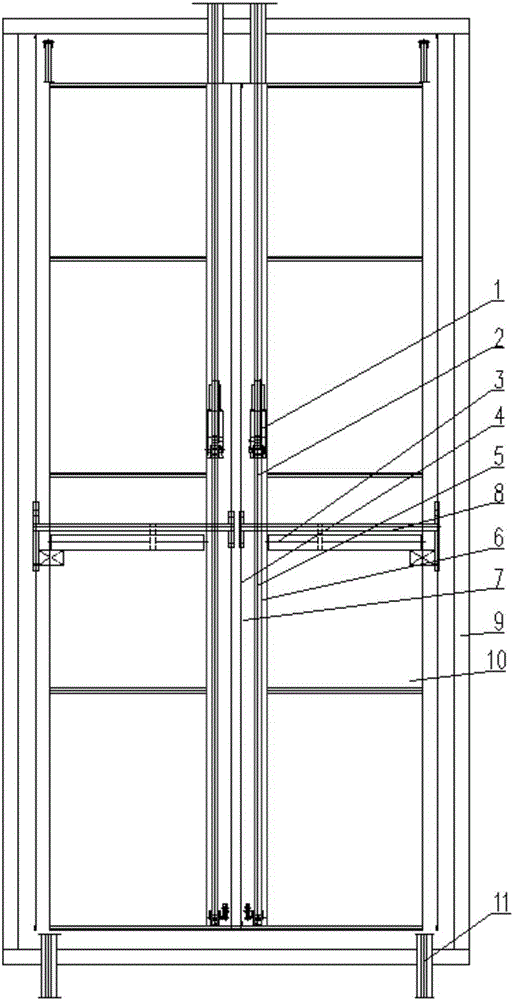

[0049] Such as Figure 7 As shown, in this example, the difference from Example 2 is that the upper running track 4 of the reclaiming device and the running track 5 of the stacking device are installed on platforms with different heights, and the height of the running platform 7 at the upper part of the reclaiming device is higher than that of the stacking device Walk the height of platform 6. This arrangement structure can also avoid cross interference between the stacking device 1 and the reclaiming device 3, and improve the utilization rate of the internal space of the stock yard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com