Double-side exposal device

An exposure device and two-sided technology, which are applied to photolithographic process exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of difficulty in adjustment and control, large-scale devices, and high costs, shortening the replacement operation time, and reducing the size of the device. Optimizing, setting the effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

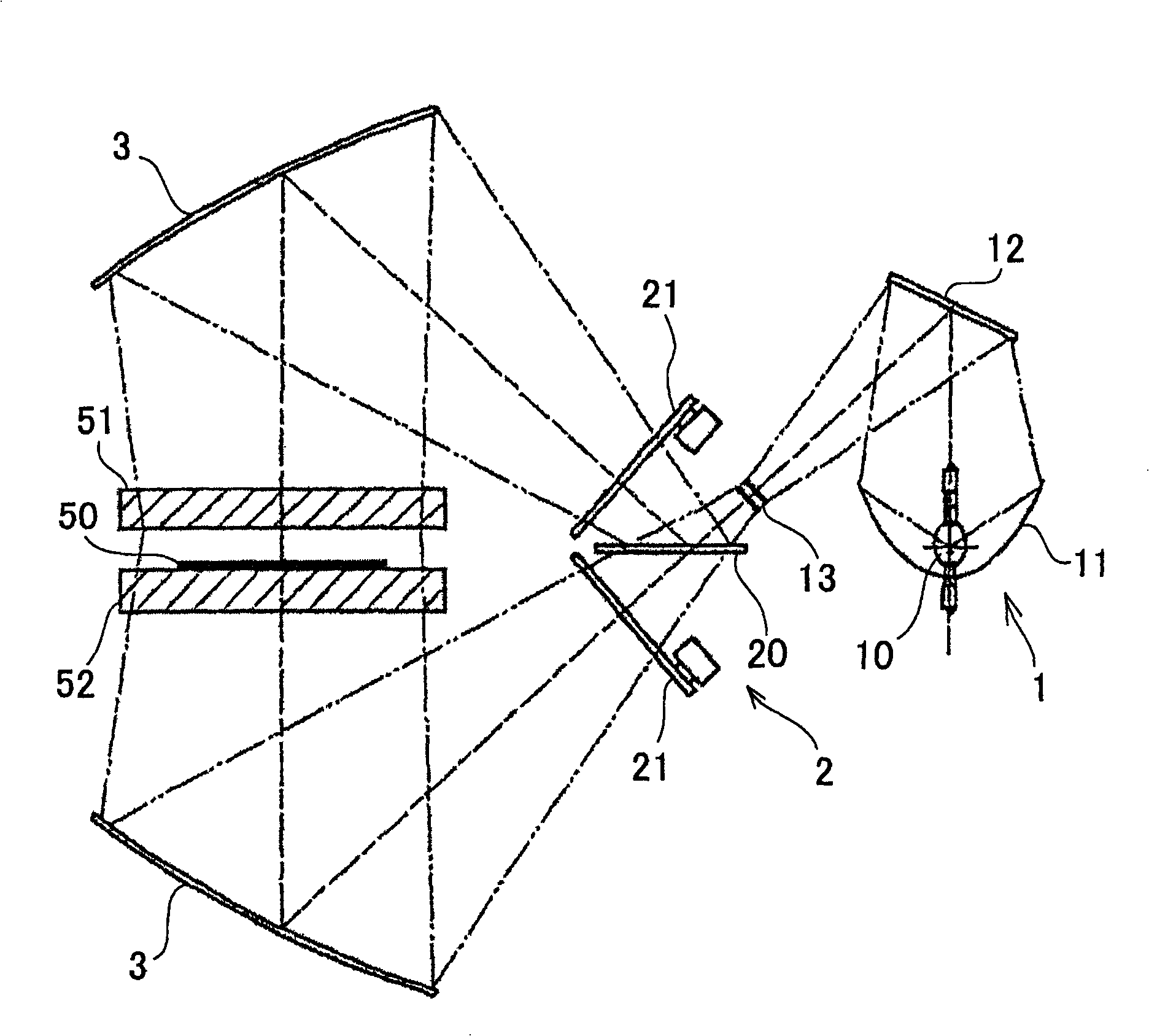

[0012] Embodiments of the present invention will be described below with reference to the drawings.

[0013] exist figure 1 In the configuration, the substrate 50 to be exposed is placed on the photomask 52 , and the patterns drawn on the photomask 51 and the photomask 52 located above the substrate 50 are exposed on the front and rear surfaces of the substrate 50 .

[0014] The light source device of this double-sided exposure apparatus includes: a single light source unit 1; a spectroscopic unit 2; and collimator mirrors 3, 3 provided on the front side and the back side of the substrate 50, respectively.

[0015] The light source unit 1 has a light source lamp 10, an elliptical mirror 11, a reflector 12, and a fly-eye lens 13. The light emitted from the light source lamp 10 is converged by the elliptical mirror 11 and returned by the reflector 12, and then passes through the fly-eye lens ( fly eye lens) 13 partial focus.

[0016] The spectroscopic unit 2 has a spectroscopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com