Patents

Literature

61results about How to "Avoid insulation failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

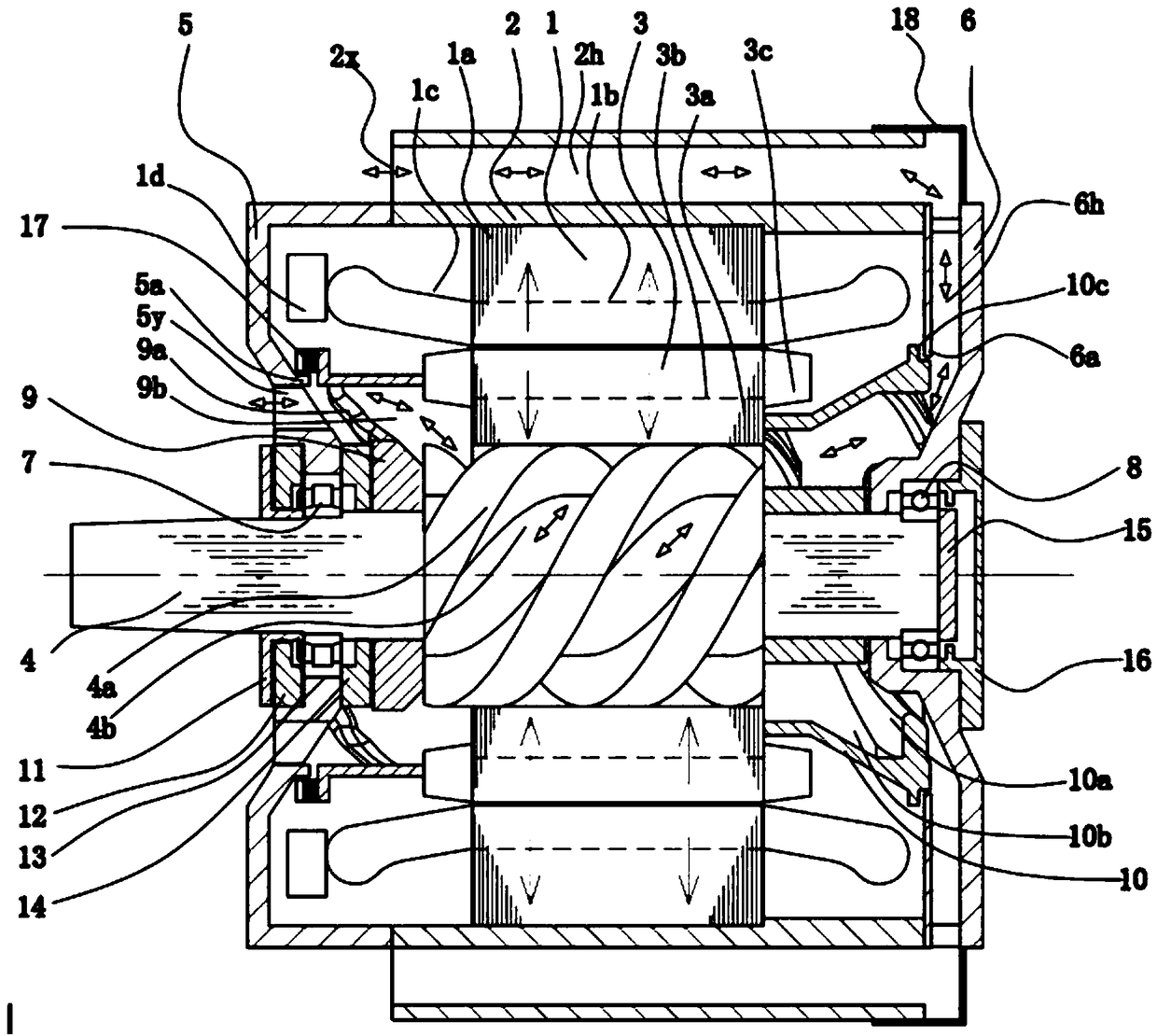

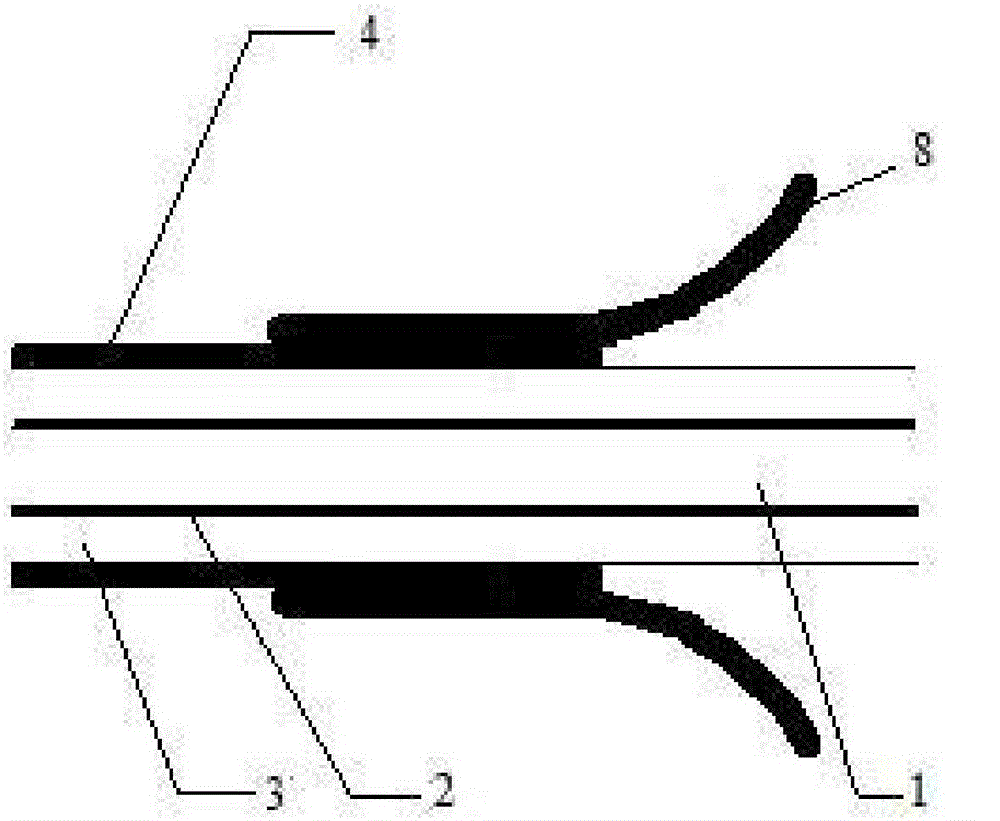

Motor capable of realizing stator closed and rotor open ventilation mode by adopting axial-flow ventilation

ActiveCN105634210AImprove power densityCompactMagnetic circuit rotating partsCooling/ventillation arrangementVentilation modeExtra axial

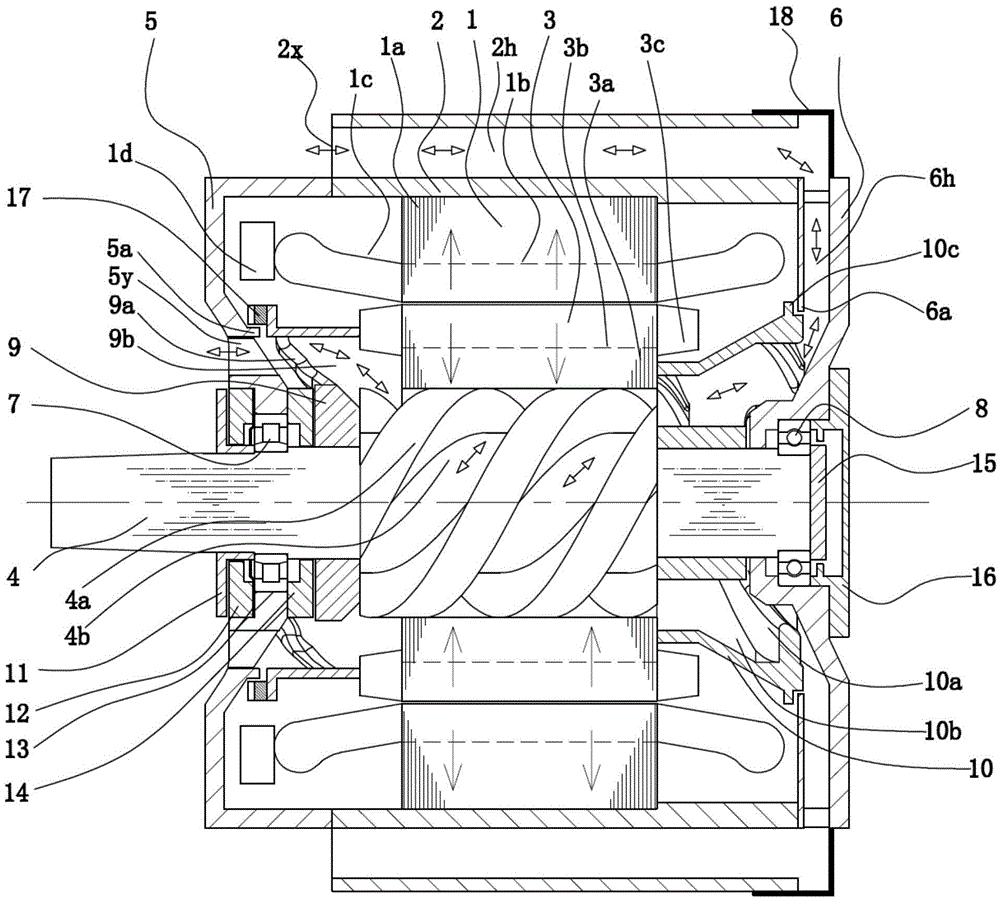

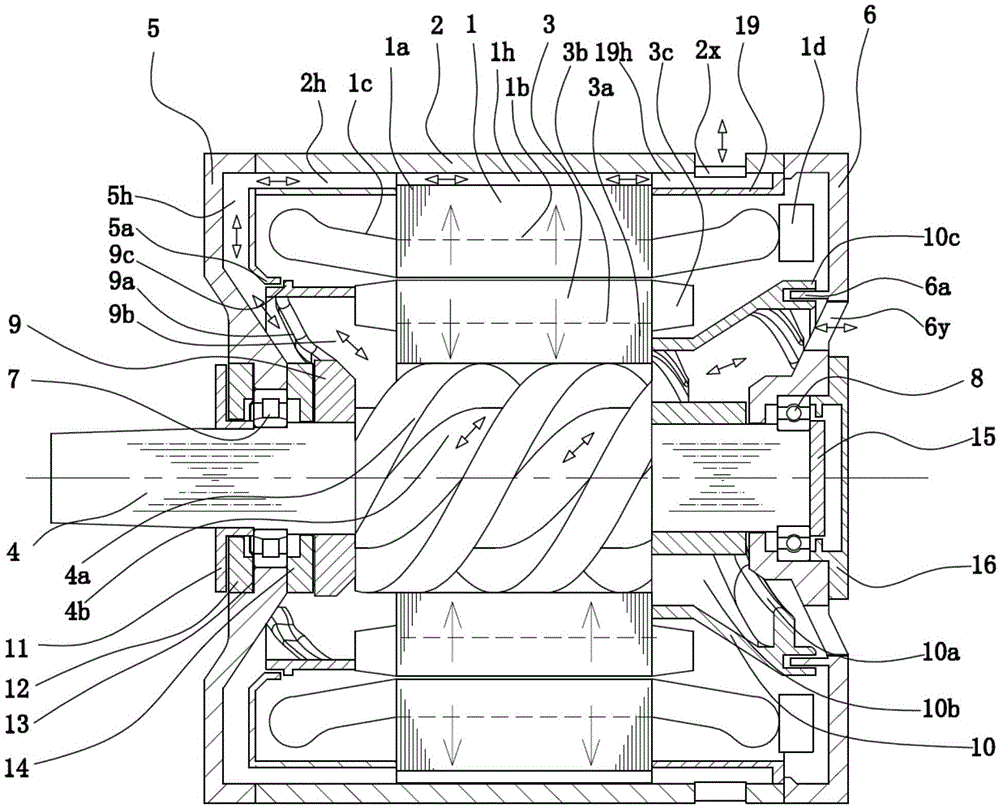

The invention discloses a motor capable of realizing a stator closed and rotor open ventilation mode by adopting axial-flow ventilation. An adopted shaft is provided with an external circumferential spiral groove, and the spiral groove matches with axial-flow fans with two clingy ends and the same spiral directions to form an axial-flow combined ventilation apparatus; the apparatus is arranged in a rotor and at two ends of the rotor, and the extra axial space of the motor is not occupied, so that the motor is compact in structure; due to different steering directions, airflow directions are also different but the motor can be cooled; in combination with labyrinth seal, a combined cooling mode of stator closed ventilation cooling and rotor open ventilation cooling of the motor is realized, and the combined cooling mode enables the insulation reliability of a stator and the heat dissipation capability of a rotor to be both ensured and improves the motor efficiency; a stator cooling air duct consists of vent holes (2x), a stator air duct (2h) and an air duct section (6h); a rotor cooling air duct consists of vent holes (5y), gaps (9b), a spiral groove (4b) and gaps (10b); the two cooling air ducts are connected in series; and the spiral combined apparatus provides air pressures for the cooling air ducts.

Owner:滁州精镁装备模具制造有限公司

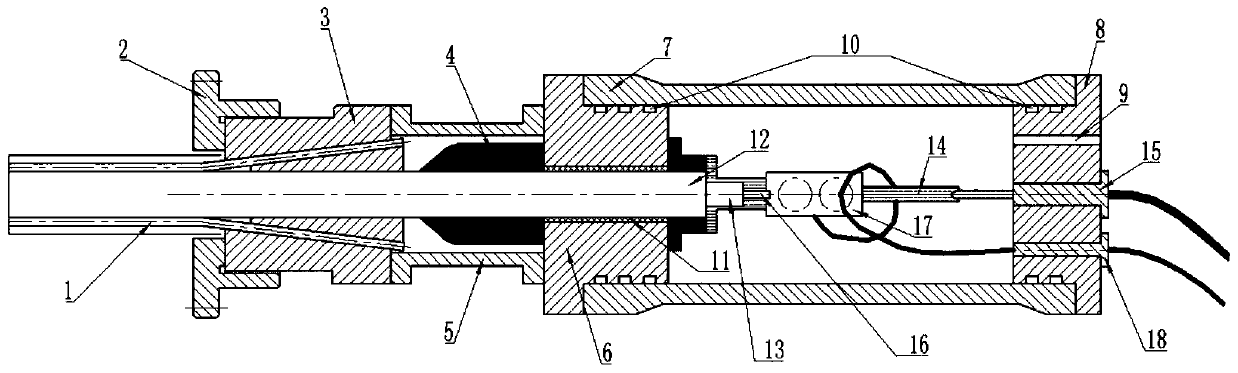

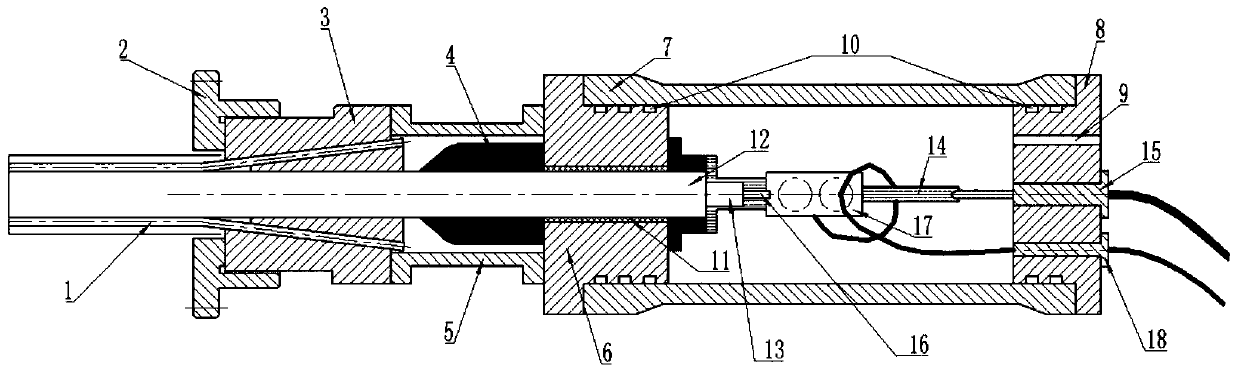

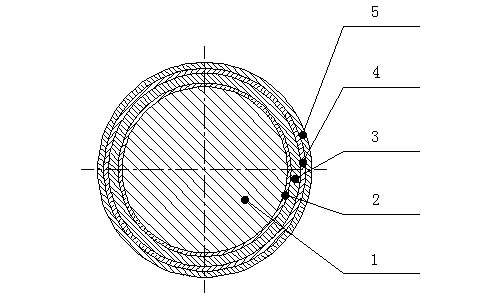

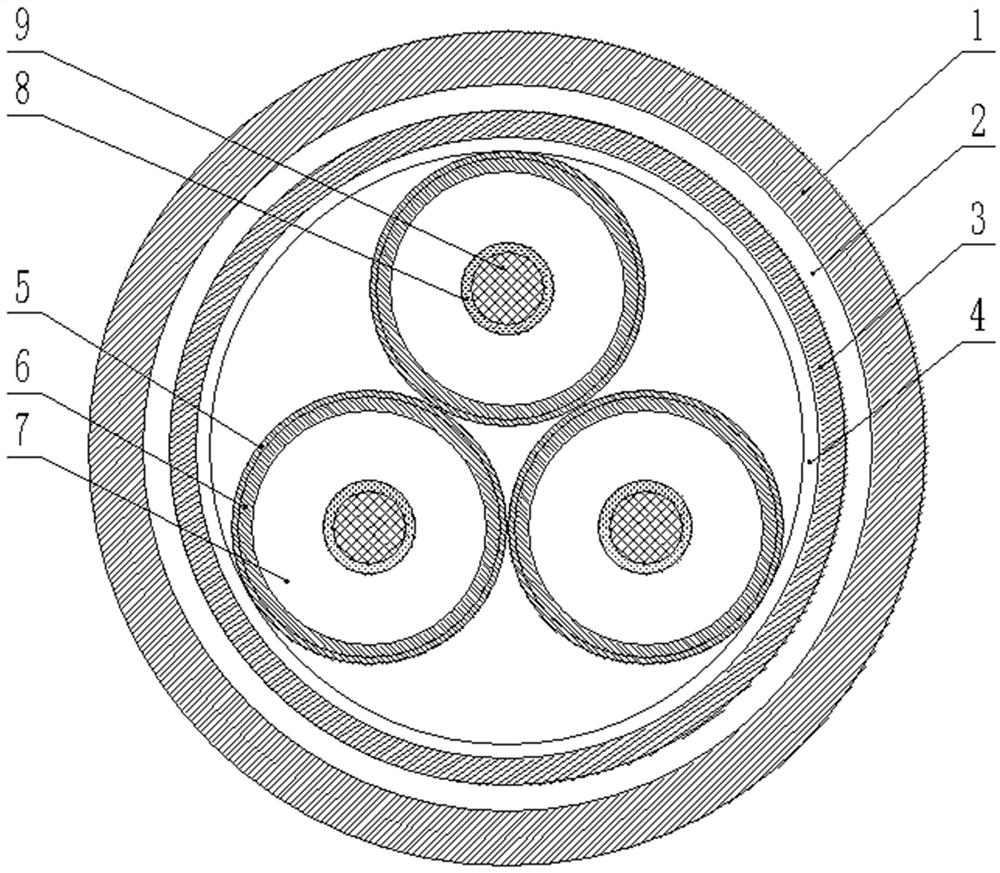

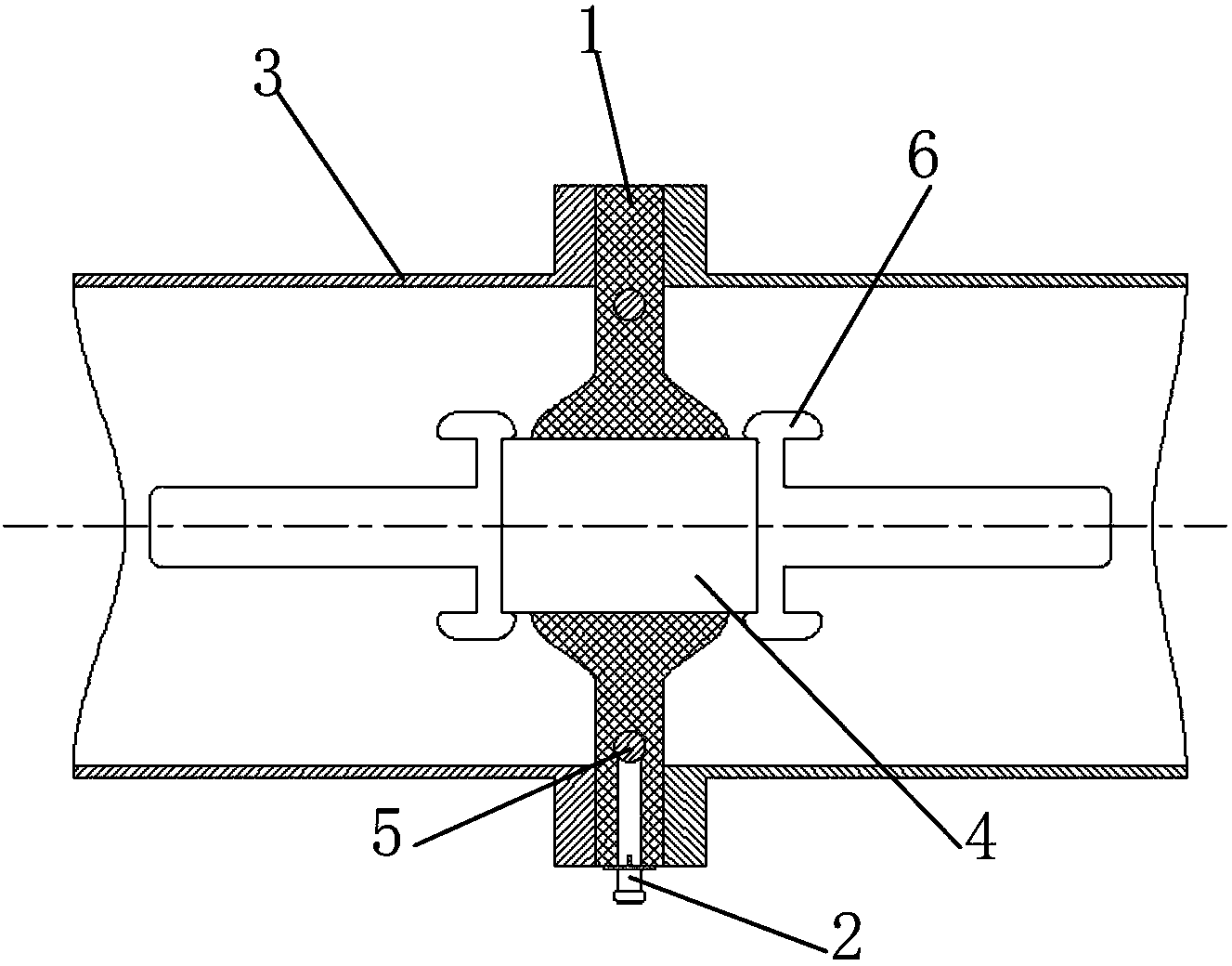

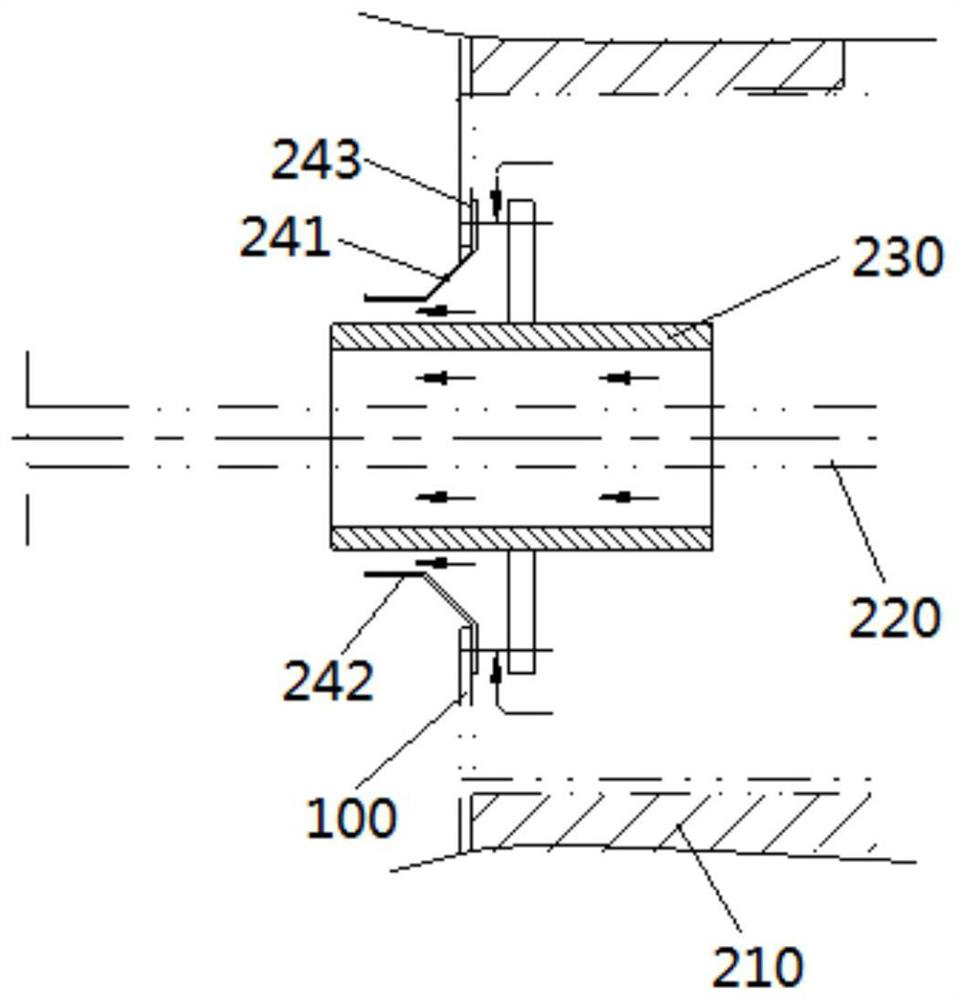

Pressure-balanced photoelectric separation device for main submarine base stations

InactiveCN109842085AImprove reliabilityPrevent creepCable fittings in presence of gas/oilCopper conductorFiber

The invention relates to the technical field of submarine observation equipment, in particular to a pressure-balanced photoelectric separation device for main submarine base stations. The device includes a submarine cable, an armored steel wire fixing mechanism, a cable core sealing protection mechanism and an oil-filled tank body mechanism. The submarine cable includes an armored steel wire (1) and a submarine cable core (12). The submarine cable core (12) is wrapped with a PE insulating layer, and a copper conductor (13) and an optical fiber unit (16) are arranged inside the submarine cablecore (12). The armored steel wire fixing mechanism is in butt joint with the cable core sealing protection mechanism, and the cable core sealing protection mechanism is in butt joint with the oil-filled tank body mechanism. The submarine cable is inserted into the armored steel wire fixing mechanism, and passes through the cable core sealing protection mechanism to the inside of the oil-filled tank body mechanism. The copper conductor (13) is connected through electrical leading with an electrical cable cabin-penetrating part (15) arranged at the end of the oil-filled tank body mechanism. Theoptical fiber unit (16) is directly welded to an optical cable cabin-penetrating part (18). The problem that a submarine cable core creeps into a photoelectric separation cabin under the pressure of deep water is solved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

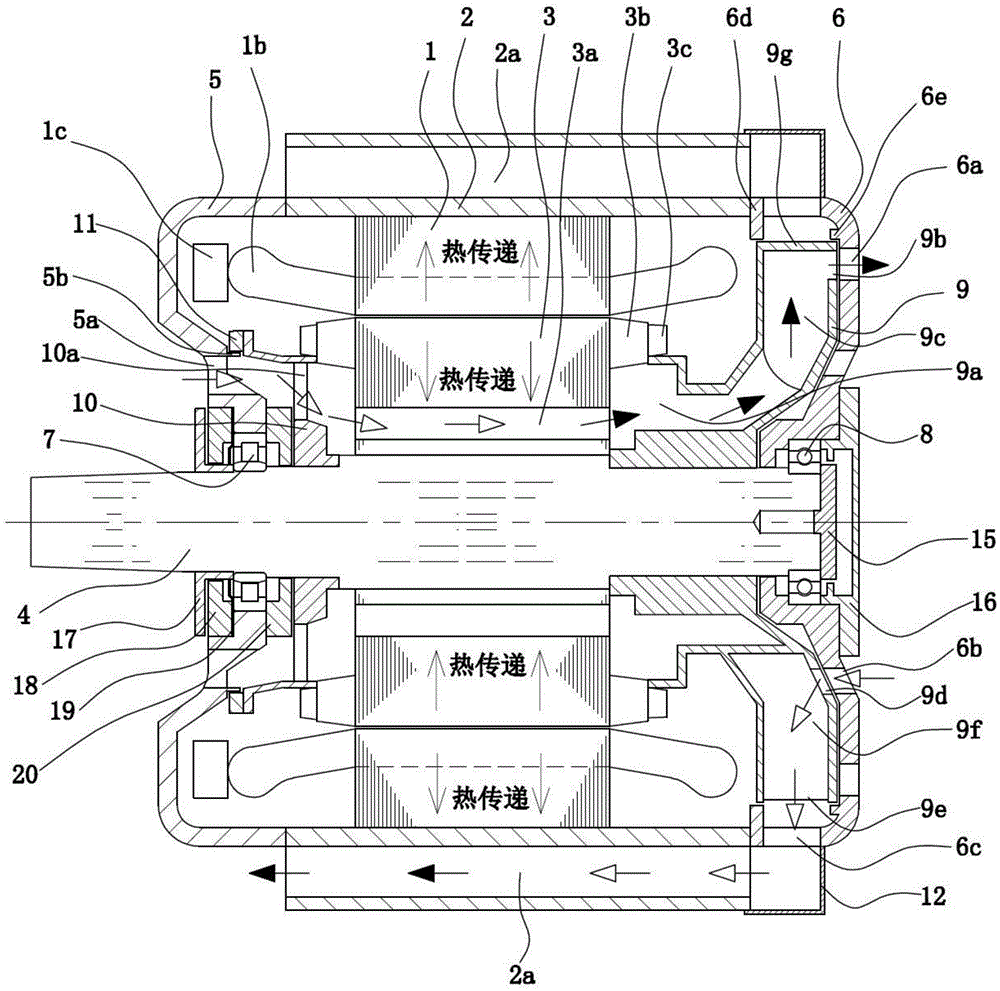

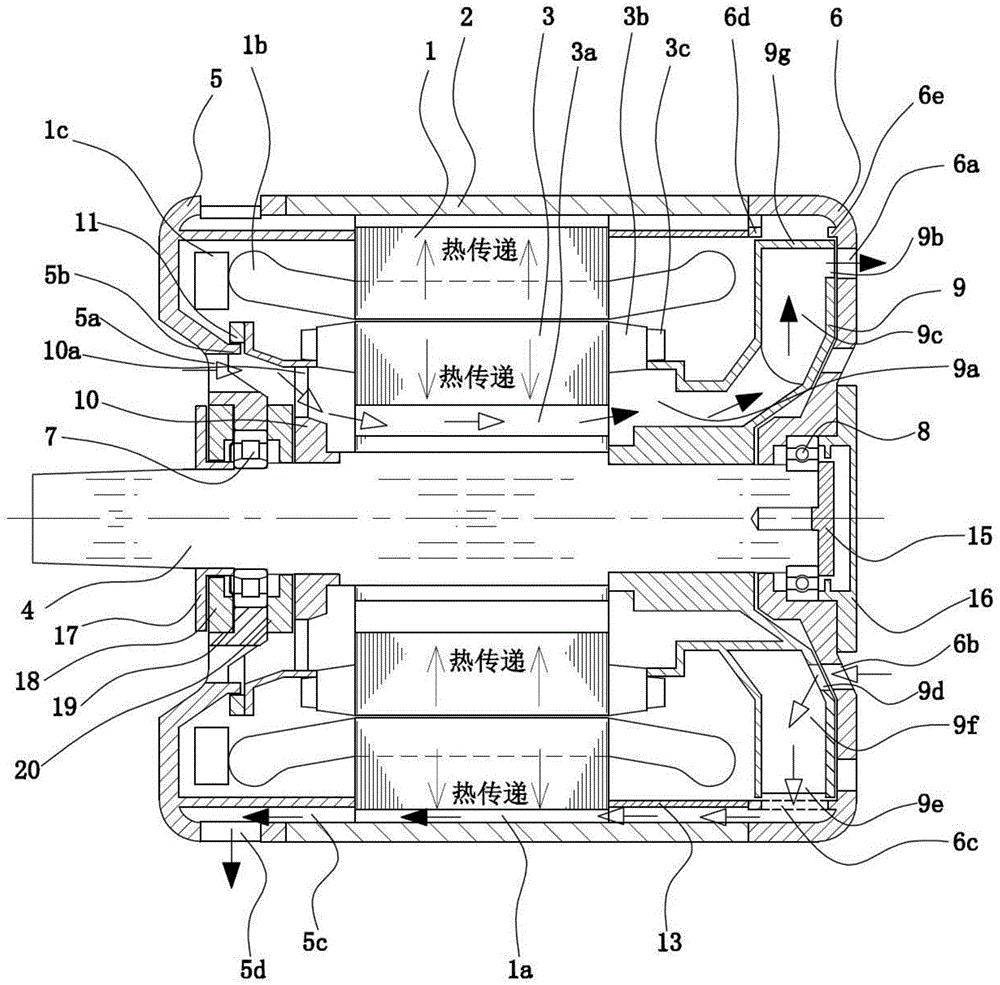

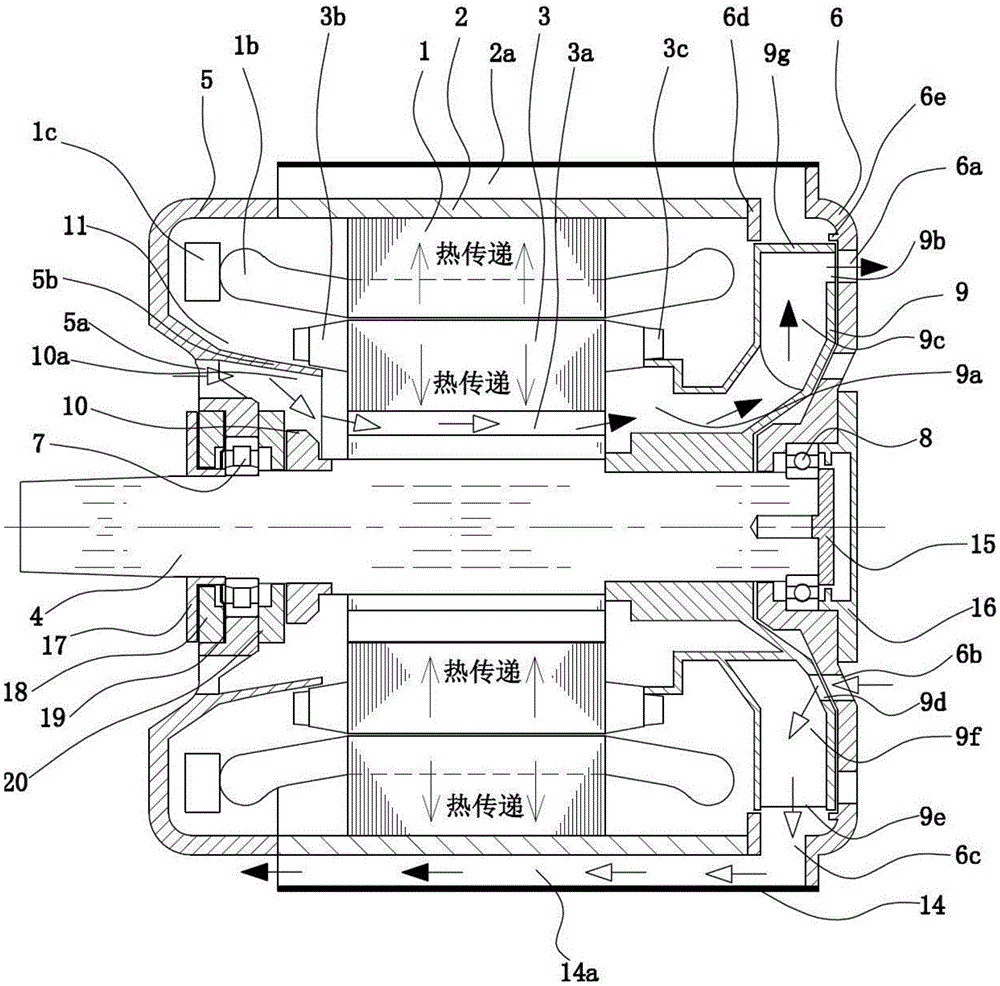

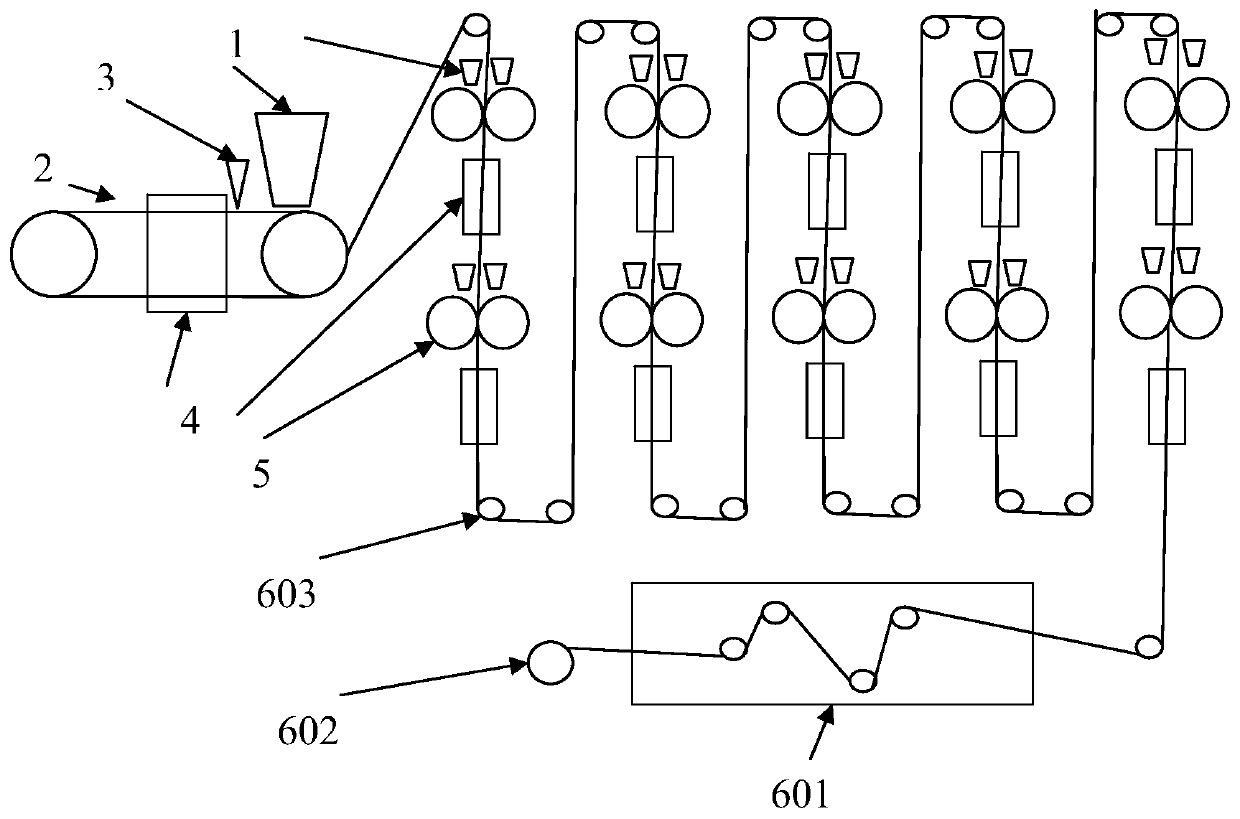

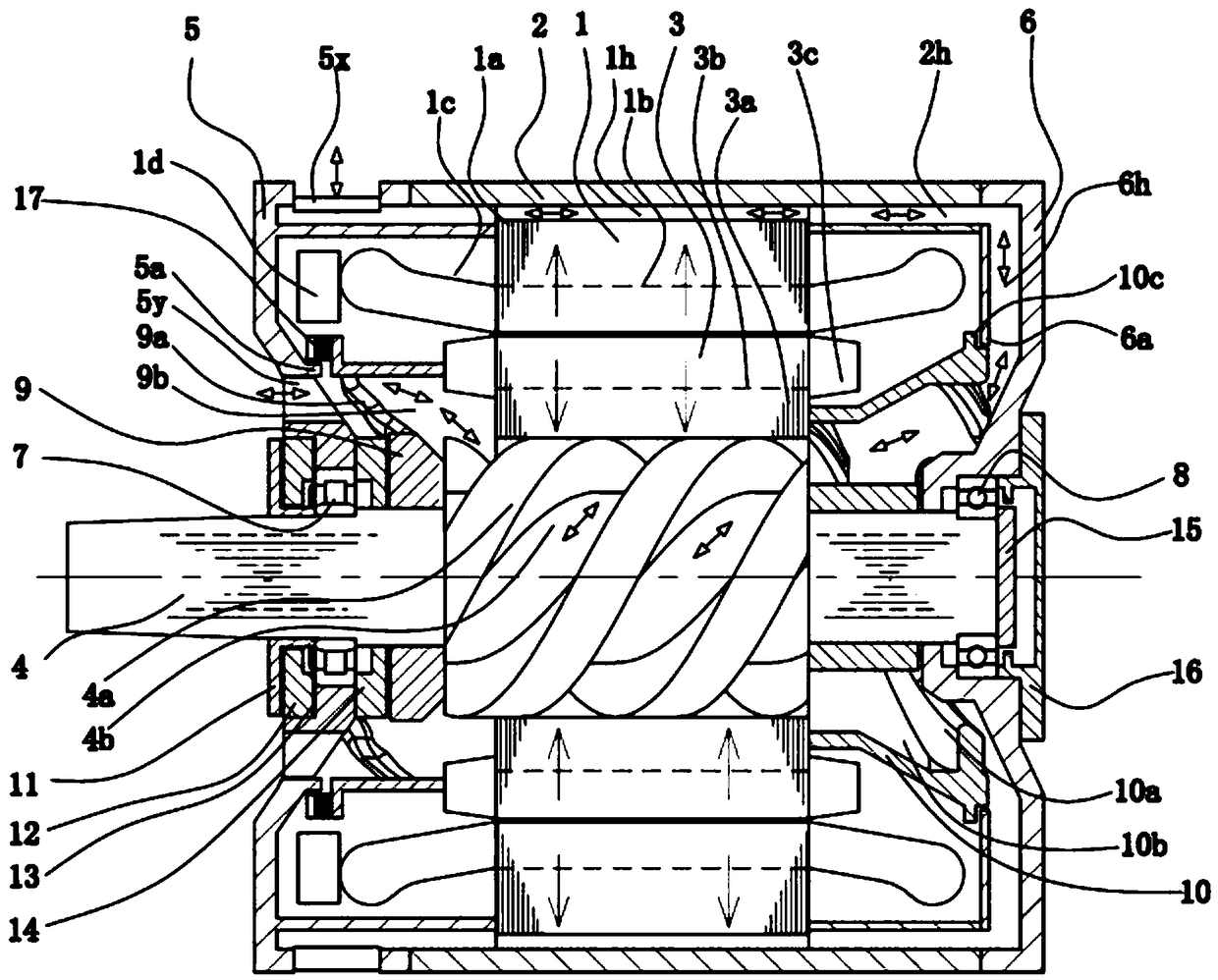

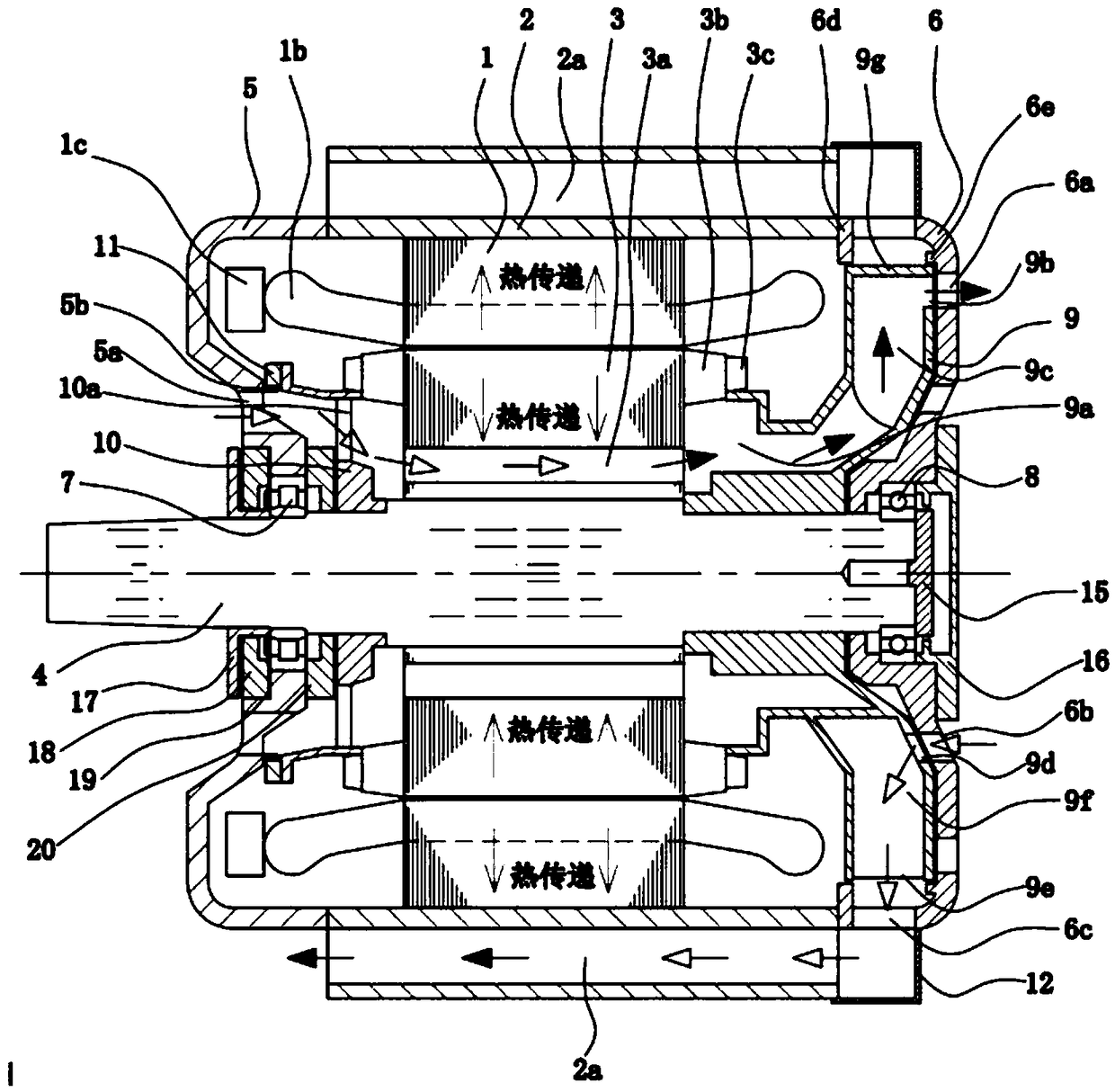

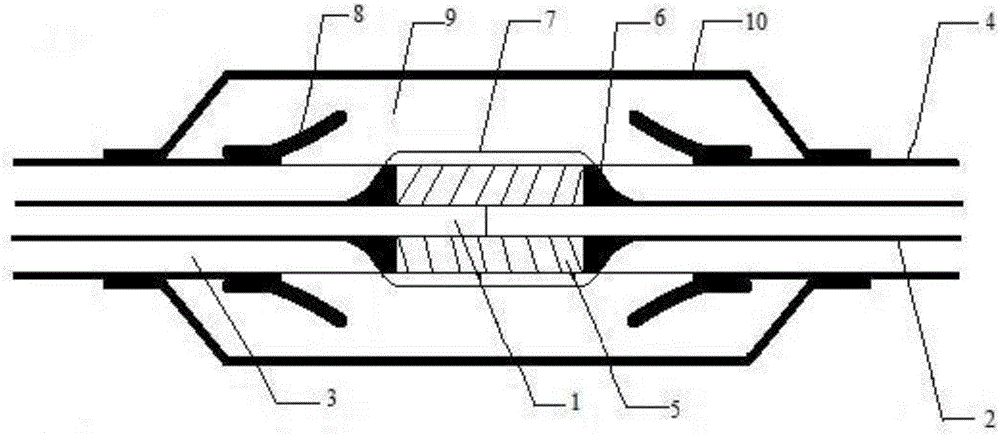

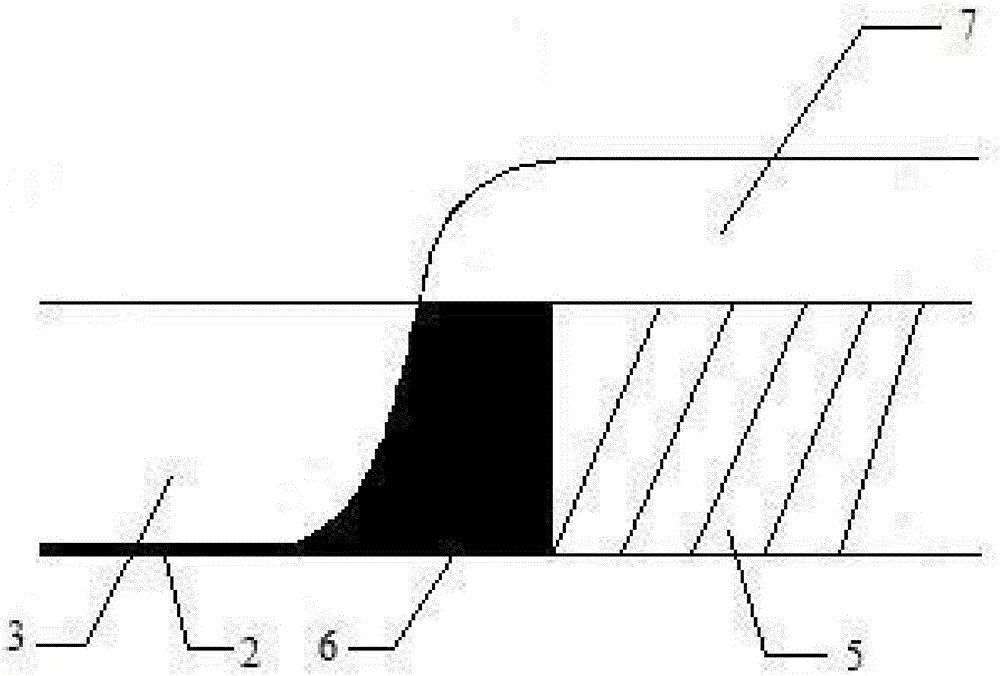

Totally enclosed motor for achieving separate cooling of stator and rotor by dual-channel fan

ActiveCN105634209AImprove power densitySmall form factorMagnetic circuit rotating partsMagnetic circuit stationary partsMotor efficiencyEngineering

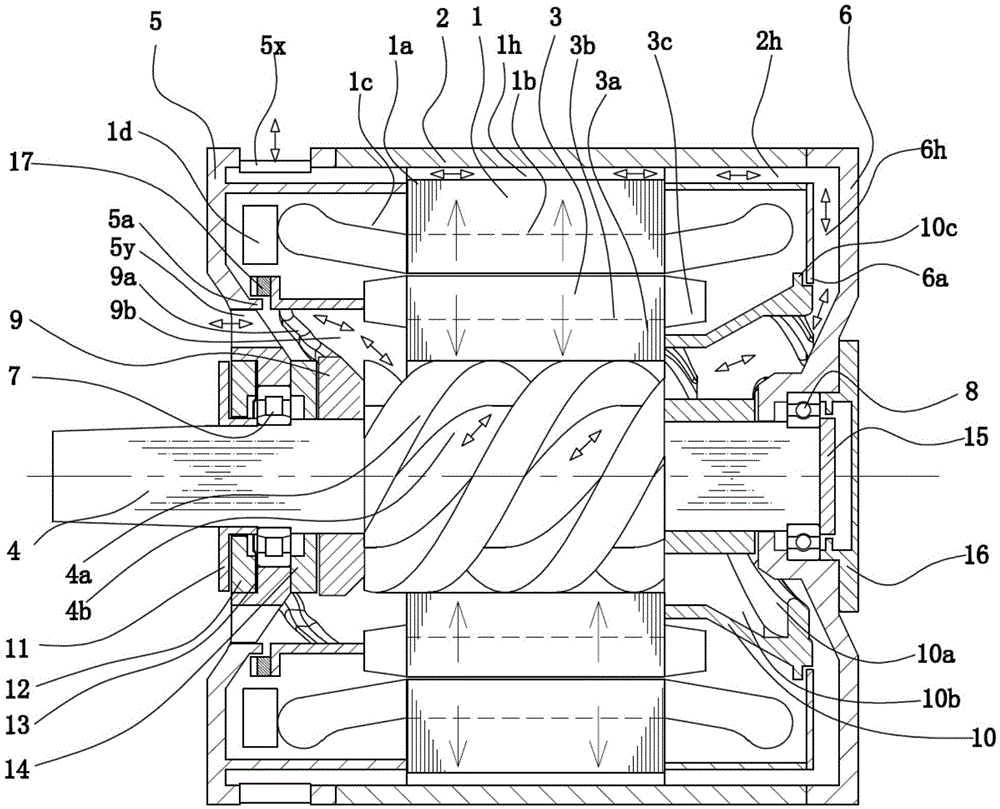

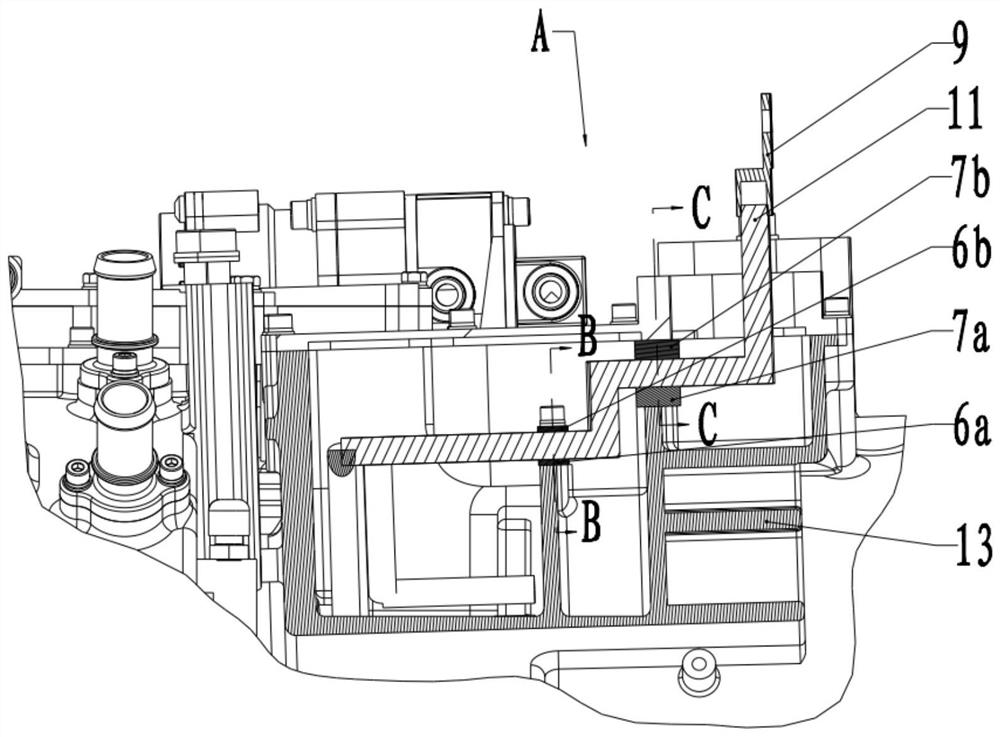

The invention discloses a totally enclosed motor for achieving separate cooling of a stator and a rotor by a dual-channel fan. The dual-channel fan 9 with a unique design is adopted and matched with a motor structure, so that a combined cooling mode of enclosed ventilation cooling of the stator and open ventilation cooling of the rotor of a three-phase asynchronous motor is achieved. By the combined cooling mode, the stator insulating reliability and the rotor cooling capacity are ensured; and the motor efficiency is improved. The dual-channel fan 9 can play roles of two fans, so that the motor structure is compact. Fan blades of the dual-channel fan are divided into two groups 9c and 9f, and are in staggered distribution in the circumference. Air ducts 5a, 10a, 3a, 9a, 9c, 9b and 6a form independent rotor cooling air ducts; the air ducts 6b, 9d, 9f, 9e and 2a form independent stator cooling air ducts; a convex edge 5b and a toothed plate 11 form a labyrinth seal; a fan excircle 9g and the convex edges 6d and 6e are in small-gap fit; and a stator space is isolated from a rotor space.

Owner:FOSHAN SHUNDE E MOTOR MACHINERY CO LTD

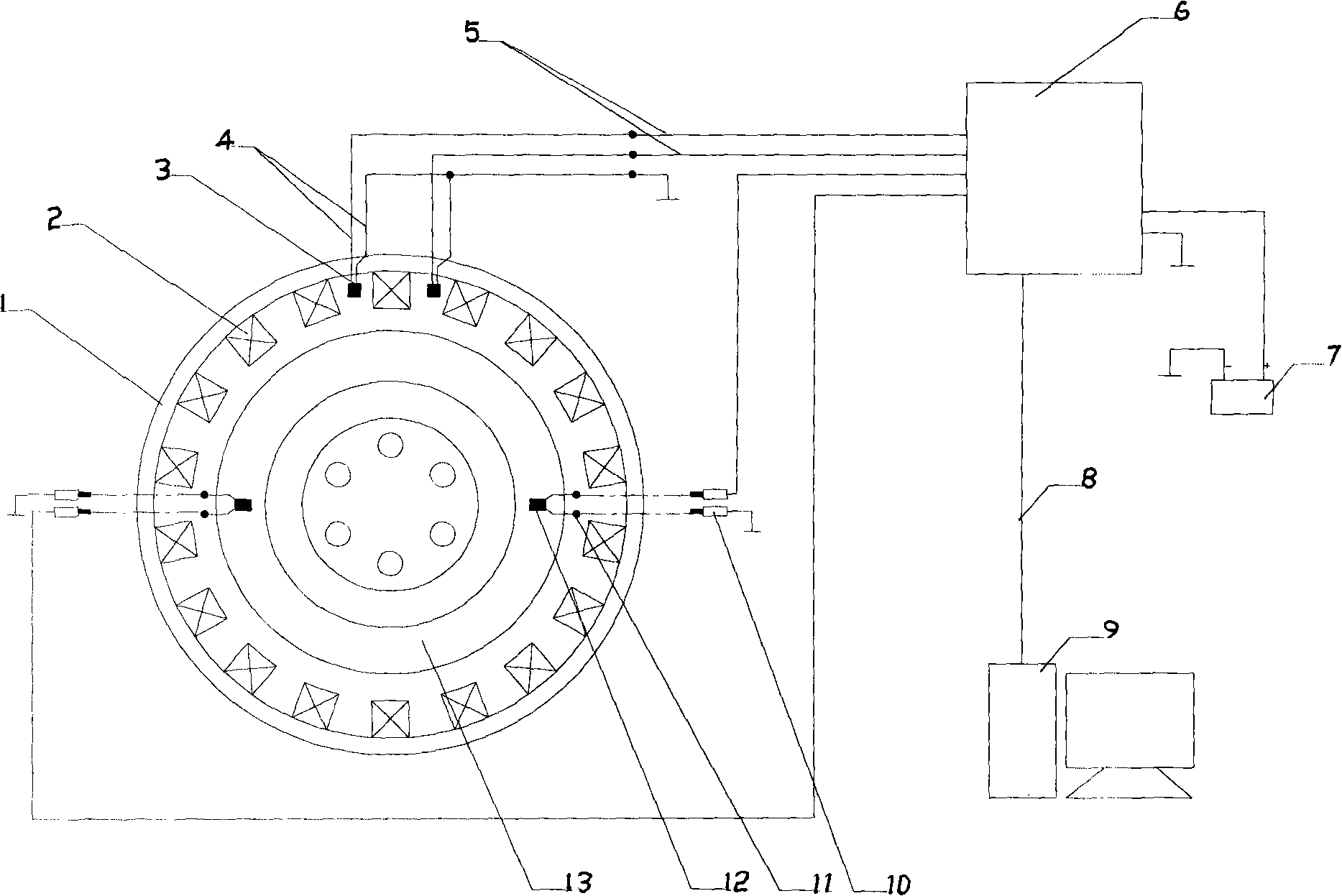

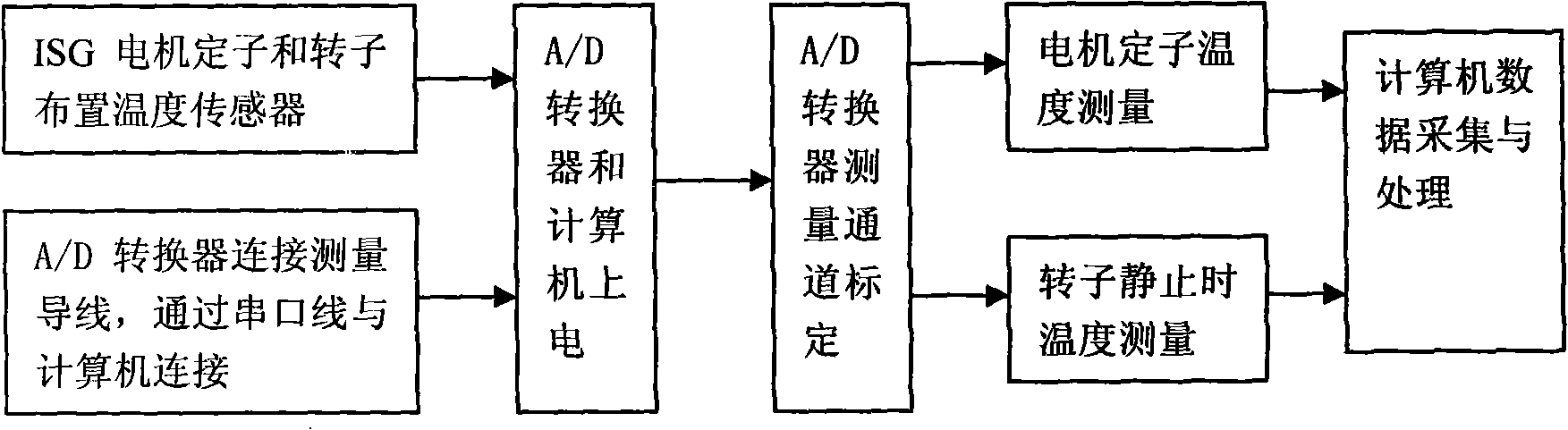

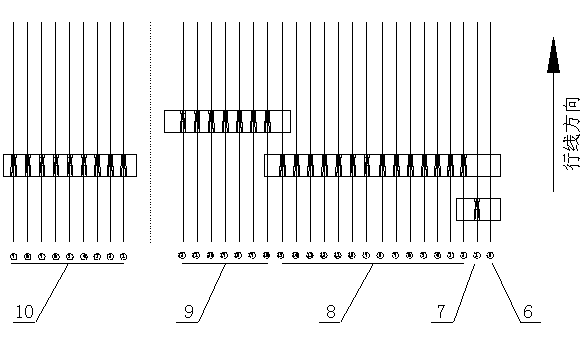

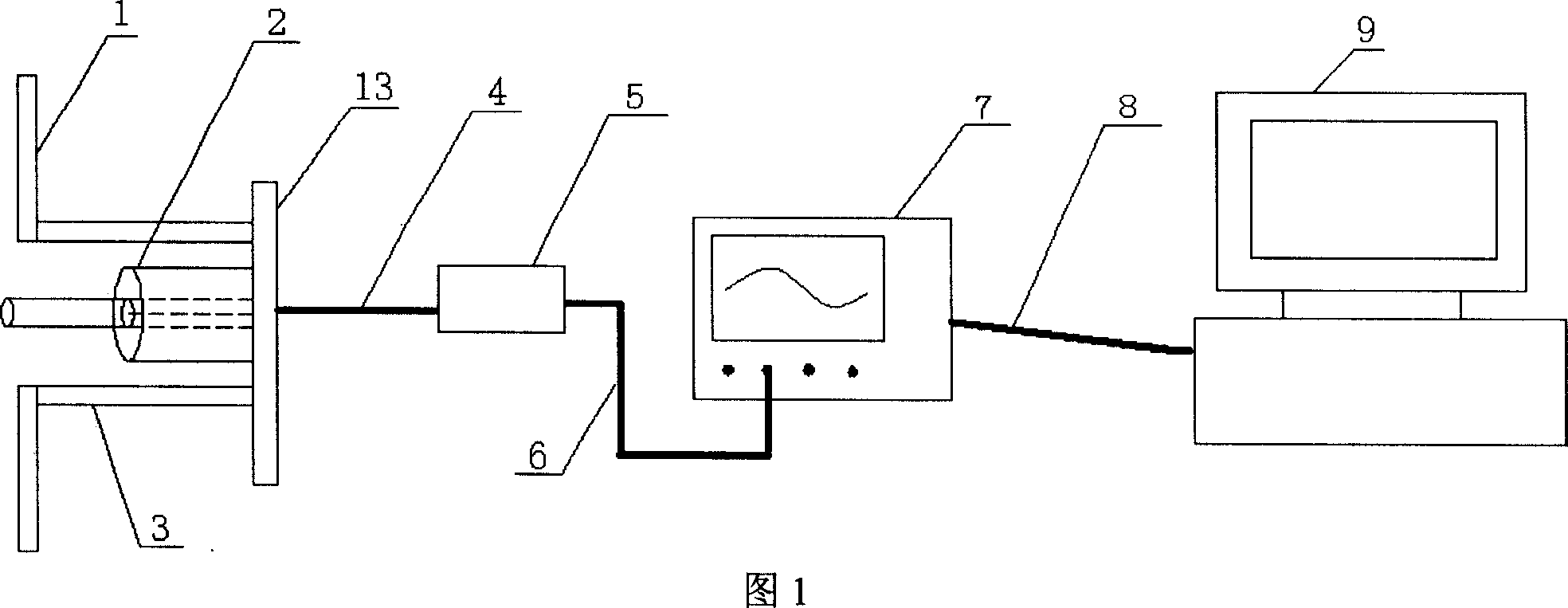

Hybrid power automobile start-up energy production integrated electric motor temperature field measuring systems

InactiveCN101261162ASolving temperature field measurement problemsExtended service lifeThermometers using electric/magnetic elementsUsing electrical meansElectric machineField tests

The invention discloses a stator and rotor temperature field measurement system of a starting and generating integrated motor used for a hybrid vehicle. Patch-typed stator temperature sensors are arranged in different winding coil clearances of an ISG motor stator; signal output leads of the patch-typed stator temperature sensors are connected with an A / D converter by which the patch-typed stator temperature sensors are connected with a computer; patch-typed rotor temperature sensors are arranged in magnetic steel sheets of the ISG motor rotor, with signal output wires connected with signal output contacts of the external edge of the motor rotor; the signal is input into the A / D converter by a measurement probe and is then transmitted into the computer. The temperature increment curve of the stator winding and rotor magnetic steel sheets can be output by an ISG motor temperature field test when the ISG motor outputs fixed power; meanwhile, the temperature distribution of the ISG motor can be measured under the output states of various rotation speeds and various powers.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

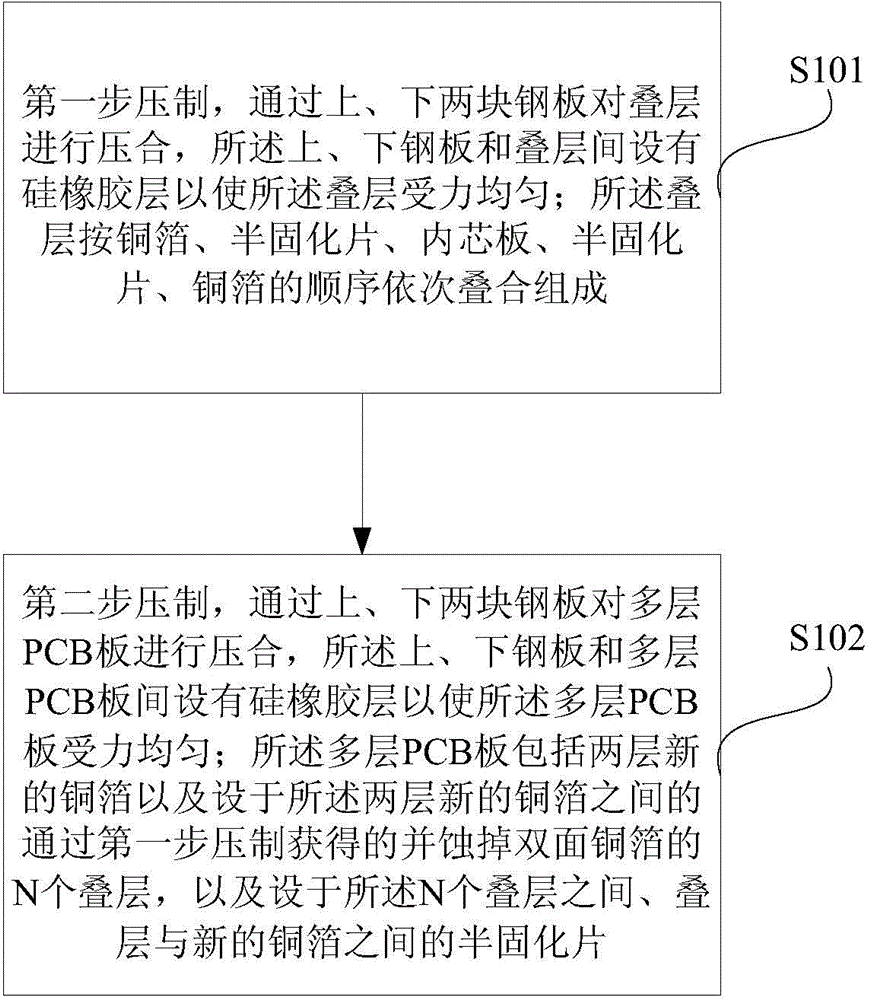

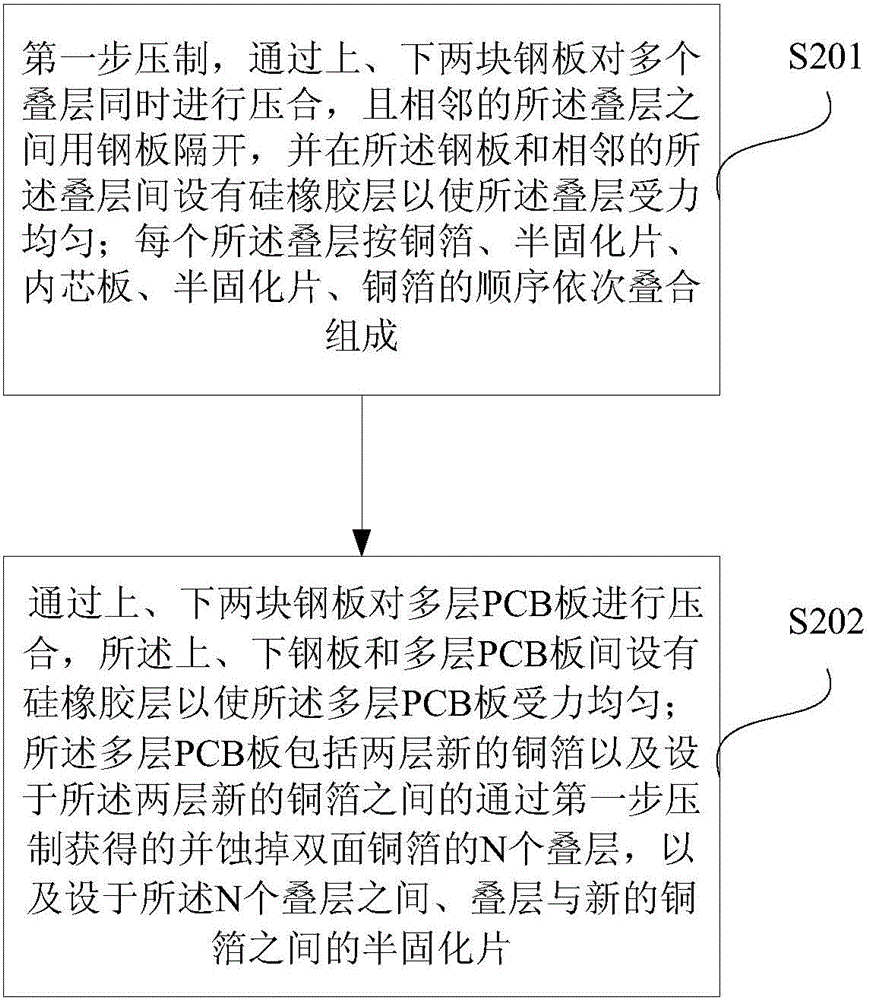

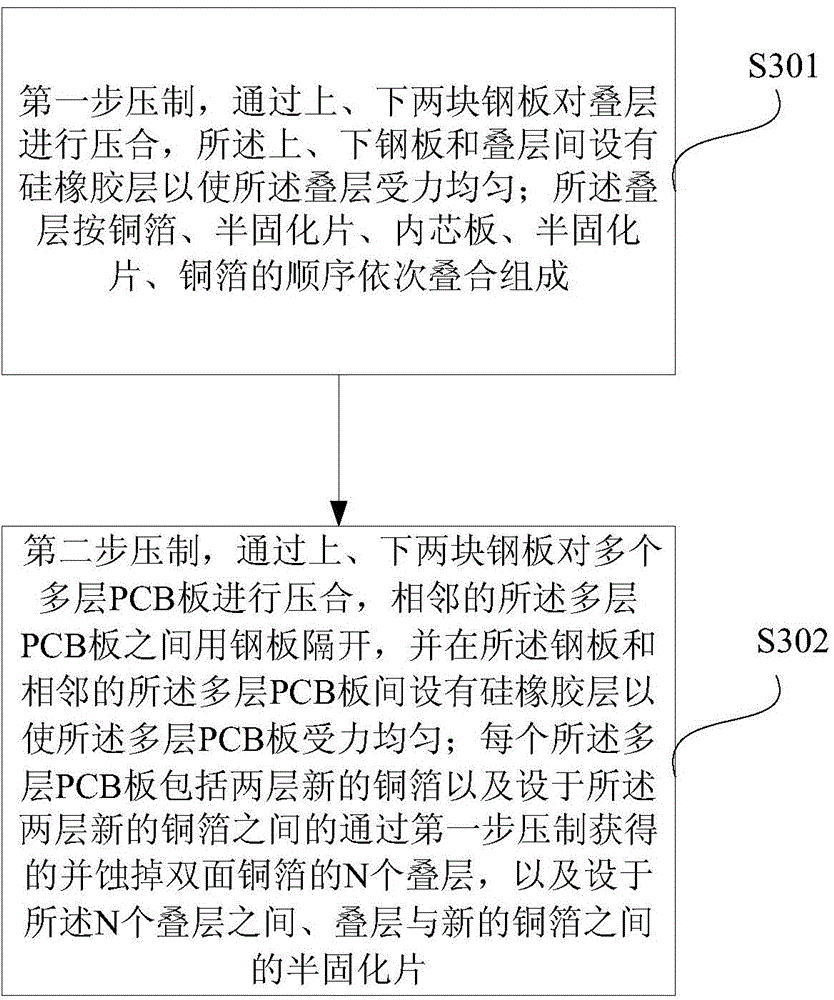

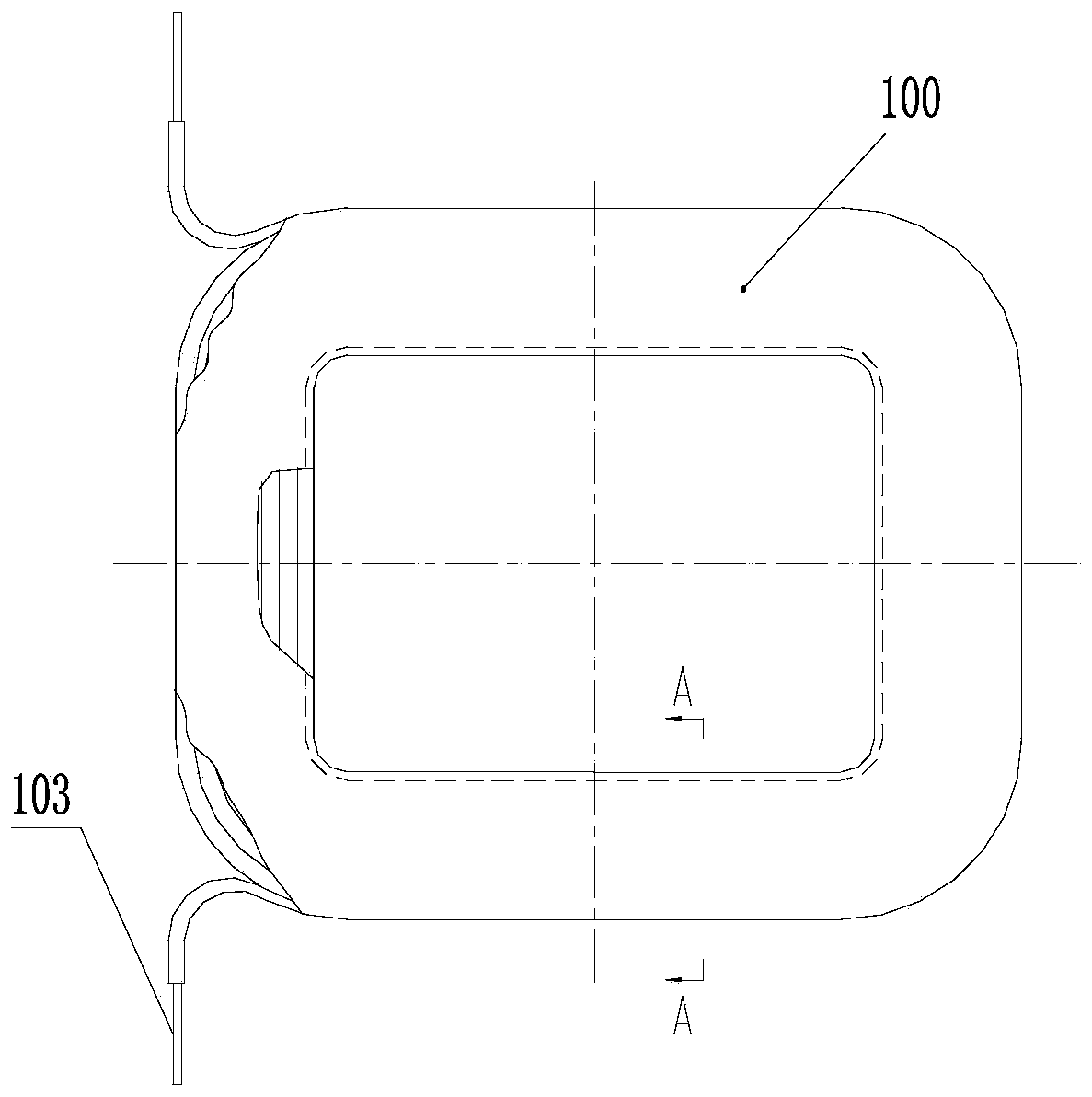

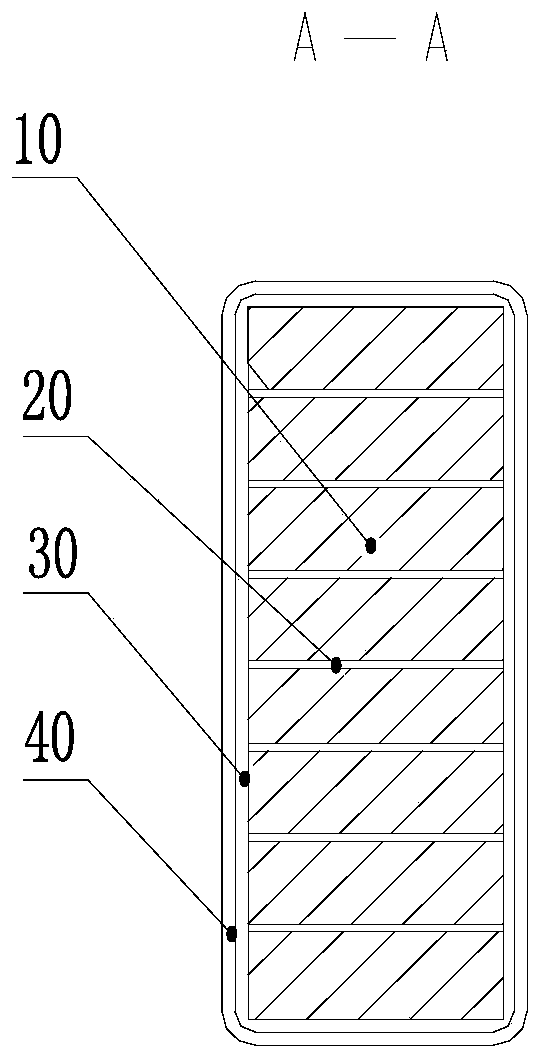

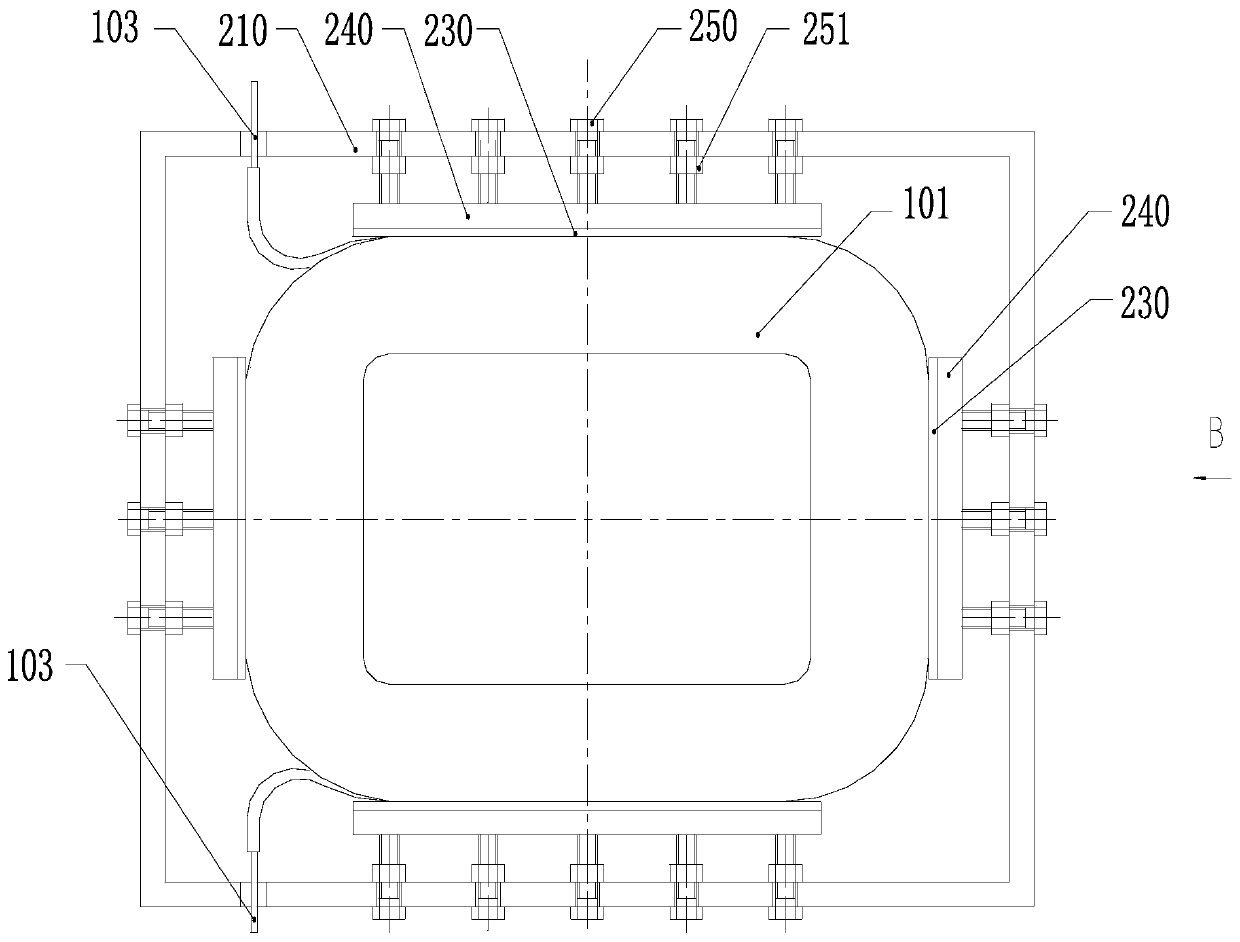

Method for manufacturing multilayer PCB in plate pressing mode

The invention discloses a method for manufacturing a multilayer PCB in a plate pressing mode. The method comprises the steps that plate pressing is conducted through two steps, wherein the first step of pressing is conducted, press fitting is conducted on stacked layers through an upper steel plate and a lower steel plate, silicone rubber layers are arranged between the upper steel plate and the stacked layers and between the lower steel plate and the stacked layers so that the stacked layers can be evenly stressed, and the stacked layers are formed by sequentially stacking copper foil, prepreg, an inner core plate, prepreg and copper foil; the second step of pressing is conducted, press fitting is conducted on the multilayer PCB through the upper steel plate and the lower steel plate, and silicone rubber layers are arranged between the upper steel plate and the multilayer PCB and between the lower steel plate and the multilayer PCB so that the multilayer PCB can be evenly stressed, and the multilayer PCB comprises two layers of new copper foil, the N stacked layers which are arranged between the two layers of new copper foil and obtained through the first step of pressing with the double-face copper foil corroded, and prepreg arranged between the N stacked layers and between the stacked layers and the new copper foil. By means of the method for manufacturing the multilayer PCB in the plate pressing mode, the phenomena of interlayer cavities, insufficient interlayer combining force and layer deviation can be effectively controlled.

Owner:GCI SCI & TECH

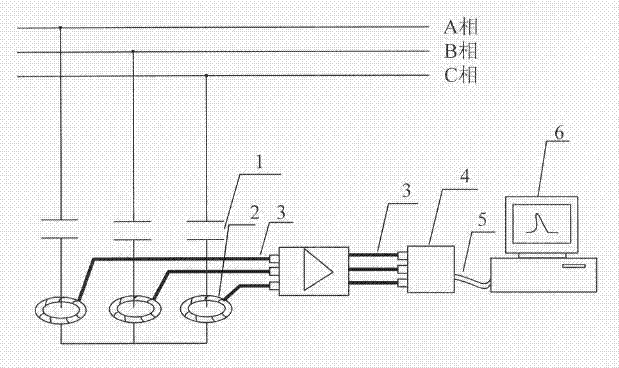

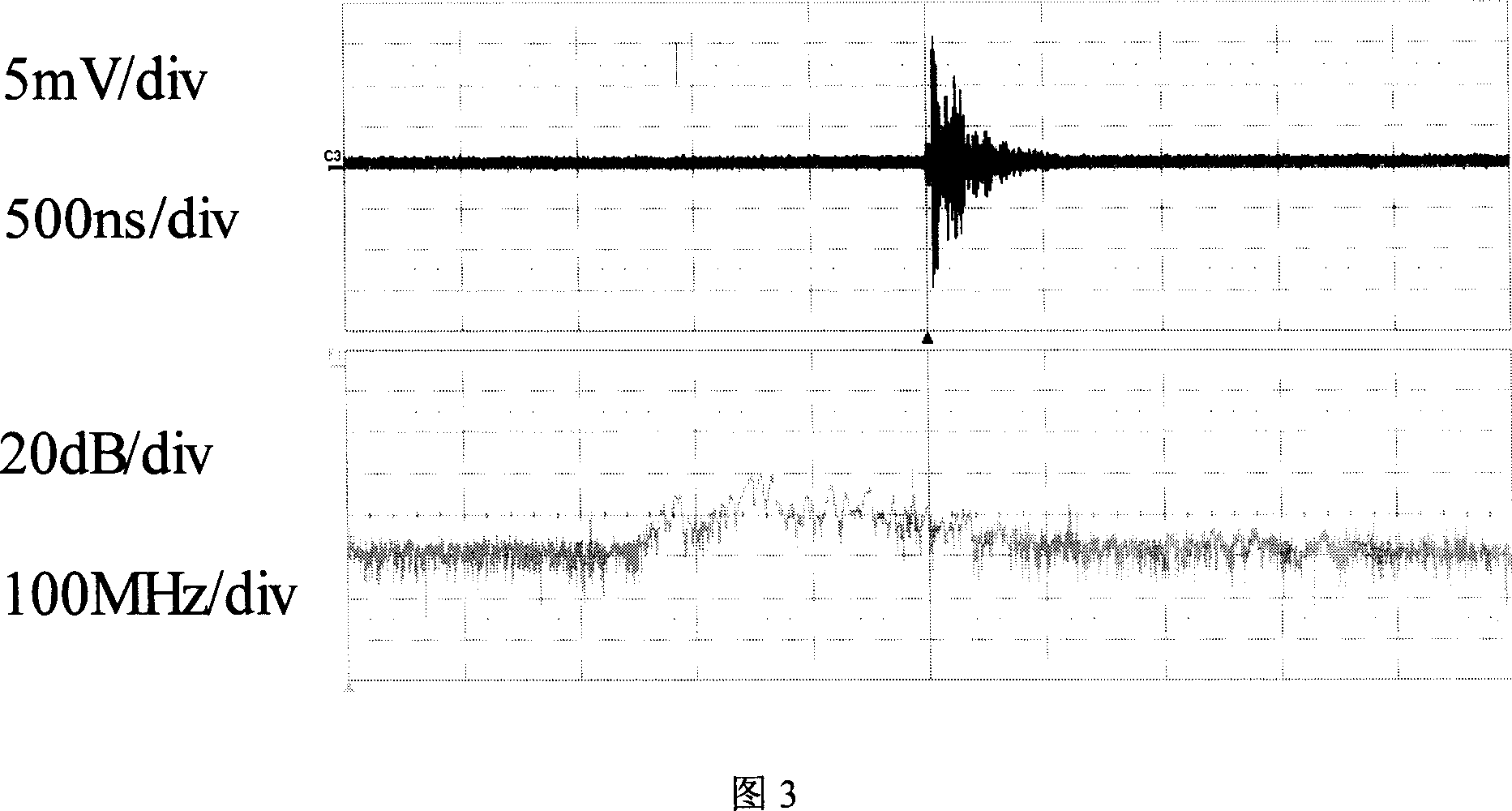

Device and method for online monitoring of partial discharge of shunt capacitor

InactiveCN102680862AReal-time understanding of partial discharge statusHigh detection sensitivityTesting dielectric strengthShunt capacitorsBand-pass filter

The invention relates to a device and a method for online monitoring of partial discharge of a shunt capacitor. The device comprises a capacitor, a broadband partial discharge sensor, a high-frequency coaxial cable, a signal hardware adjusting unit, an A / D (analog / digital) acquisition card and an industrial personal computer. The broadband partial discharge sensor is installed at the lower end connecting wire of the capacitor in a sleeving way and connected with the signal hardware adjusting unit through the high-frequency coaxial cable; the signal hardware adjusting unit is connected with a data acquisition device through the high-frequency coaxial cable; and the data acquisition device is connected with the industrial personal computer through a USB (universal serial bus) connecting wire. According to the device for online monitoring of partial discharge of the shunt capacitor, a partial discharge signal is sensed by a wide-band rogowski coil partial discharge sensor, the original connection way of equipment is not changed and high detection sensitivity is obtained. A band-pass filter with adjustable frequency band width and a broadband amplifier are adopted by the device, so that the detection sensitivity is improved greatly, the partial discharge signal can be effectively monitored, the partial discharge state of the capacitor in operation can be known in real time, and an equipment insulation fault is avoided.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST

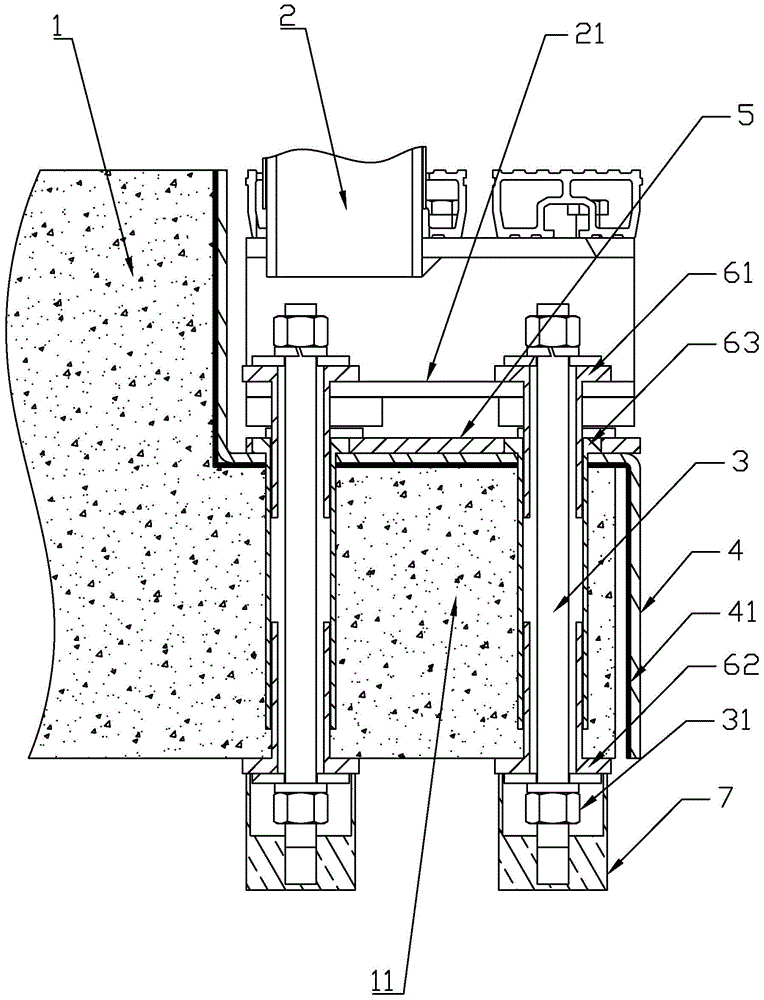

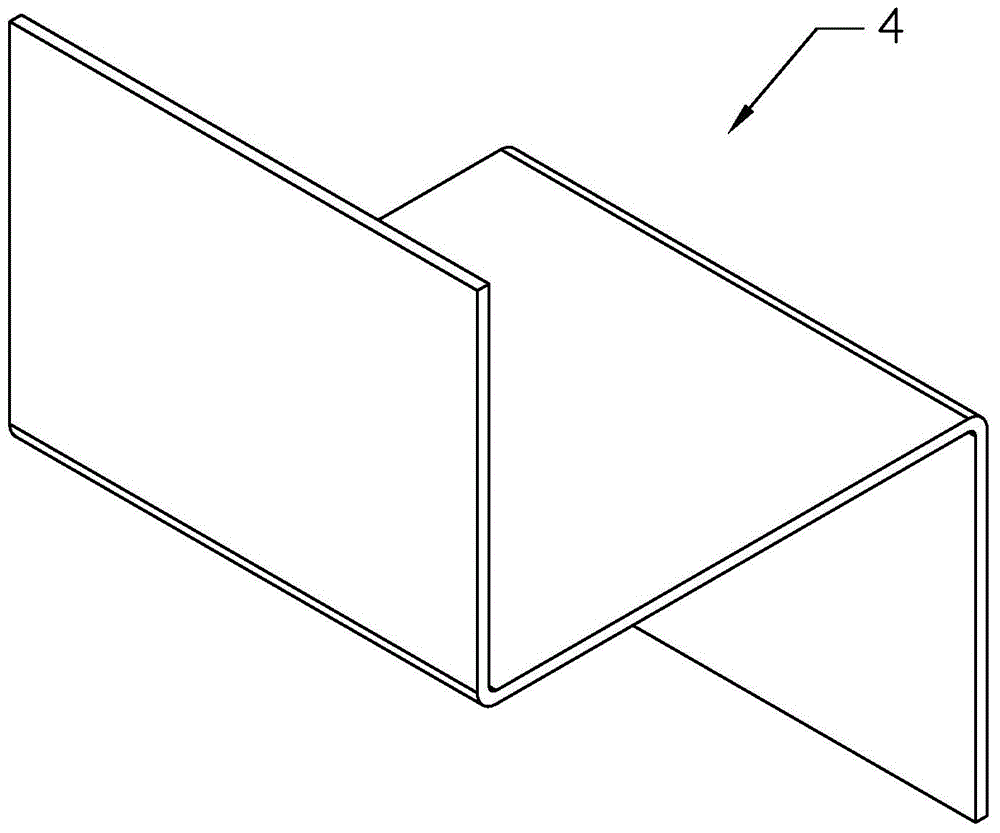

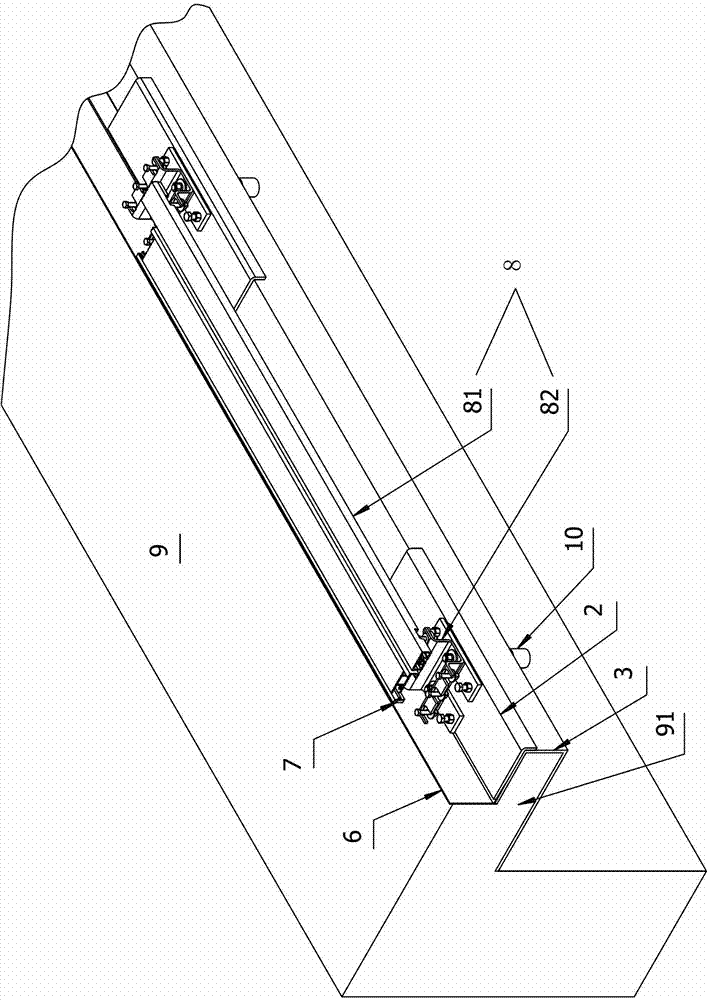

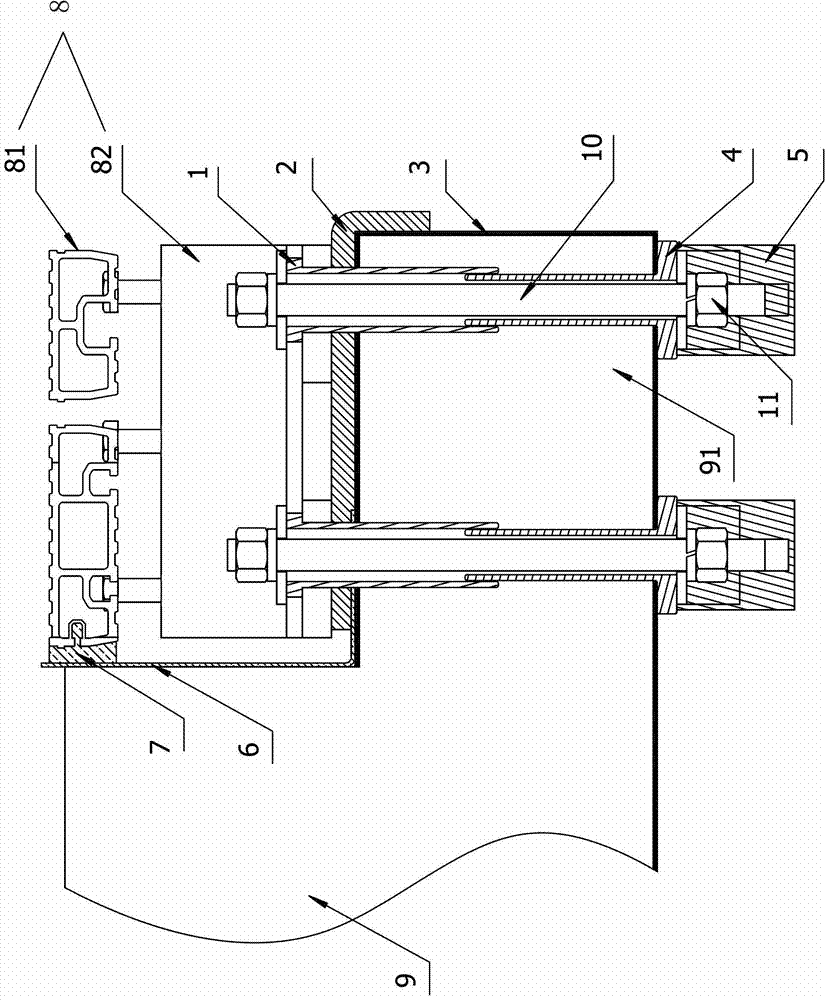

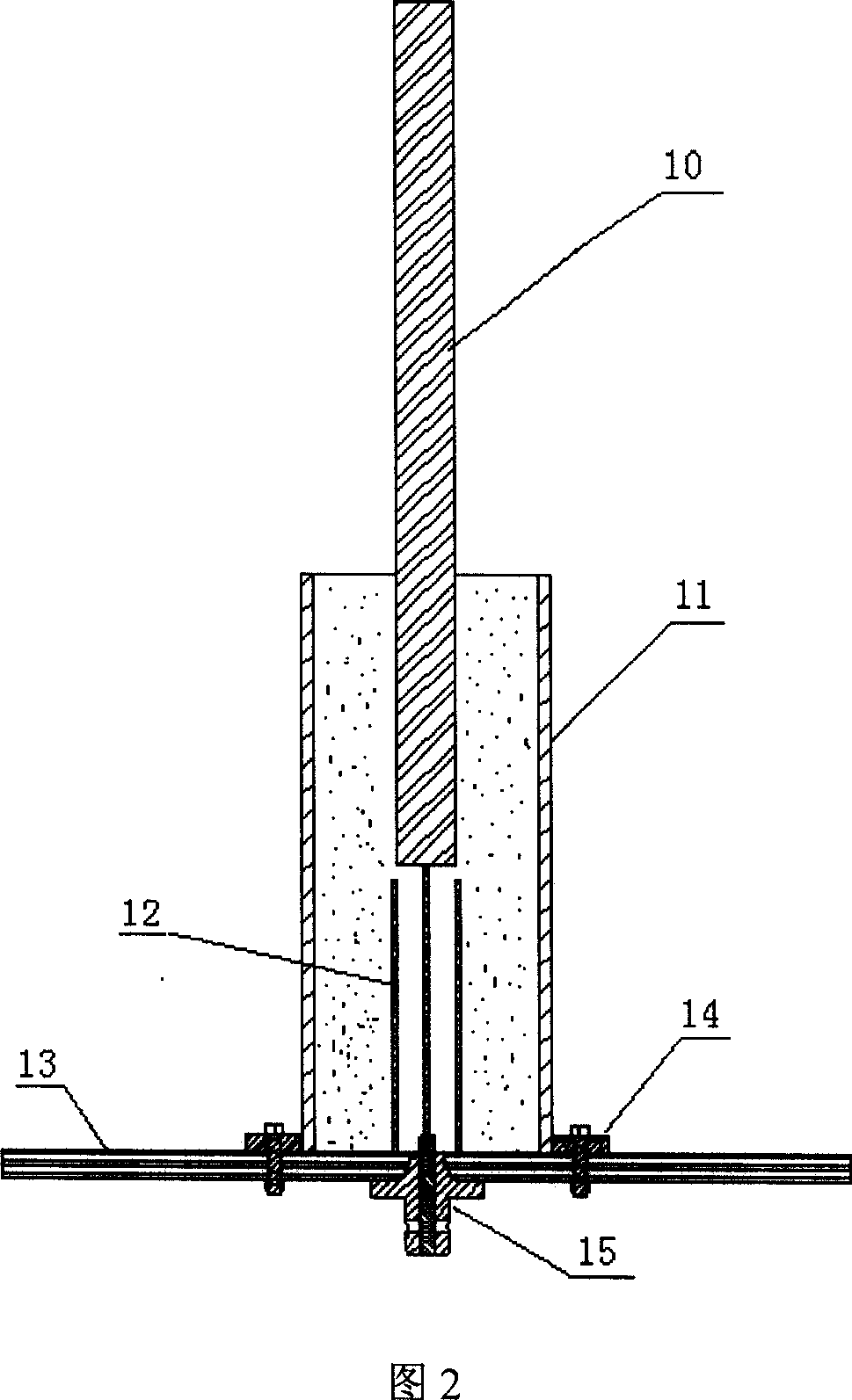

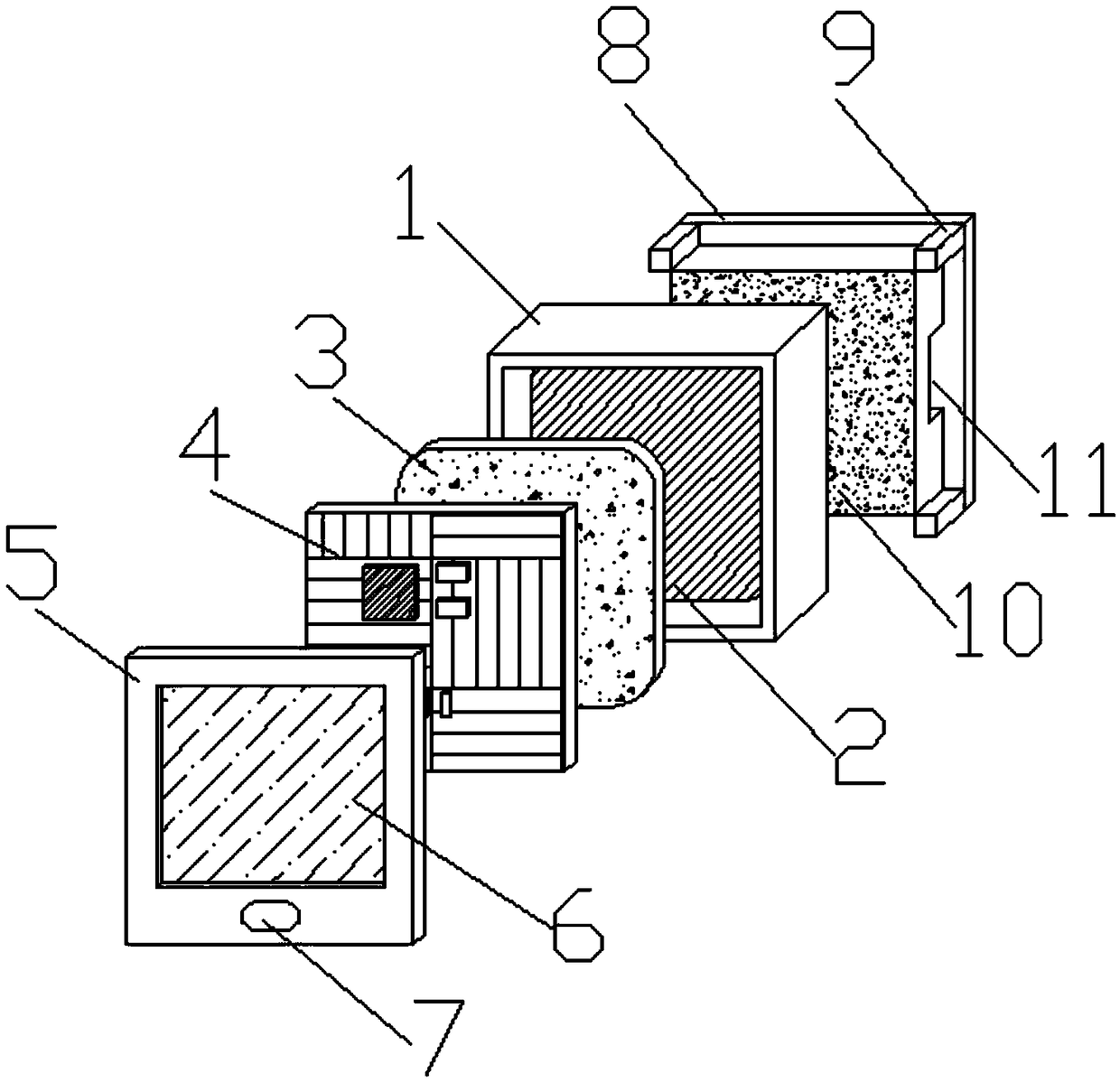

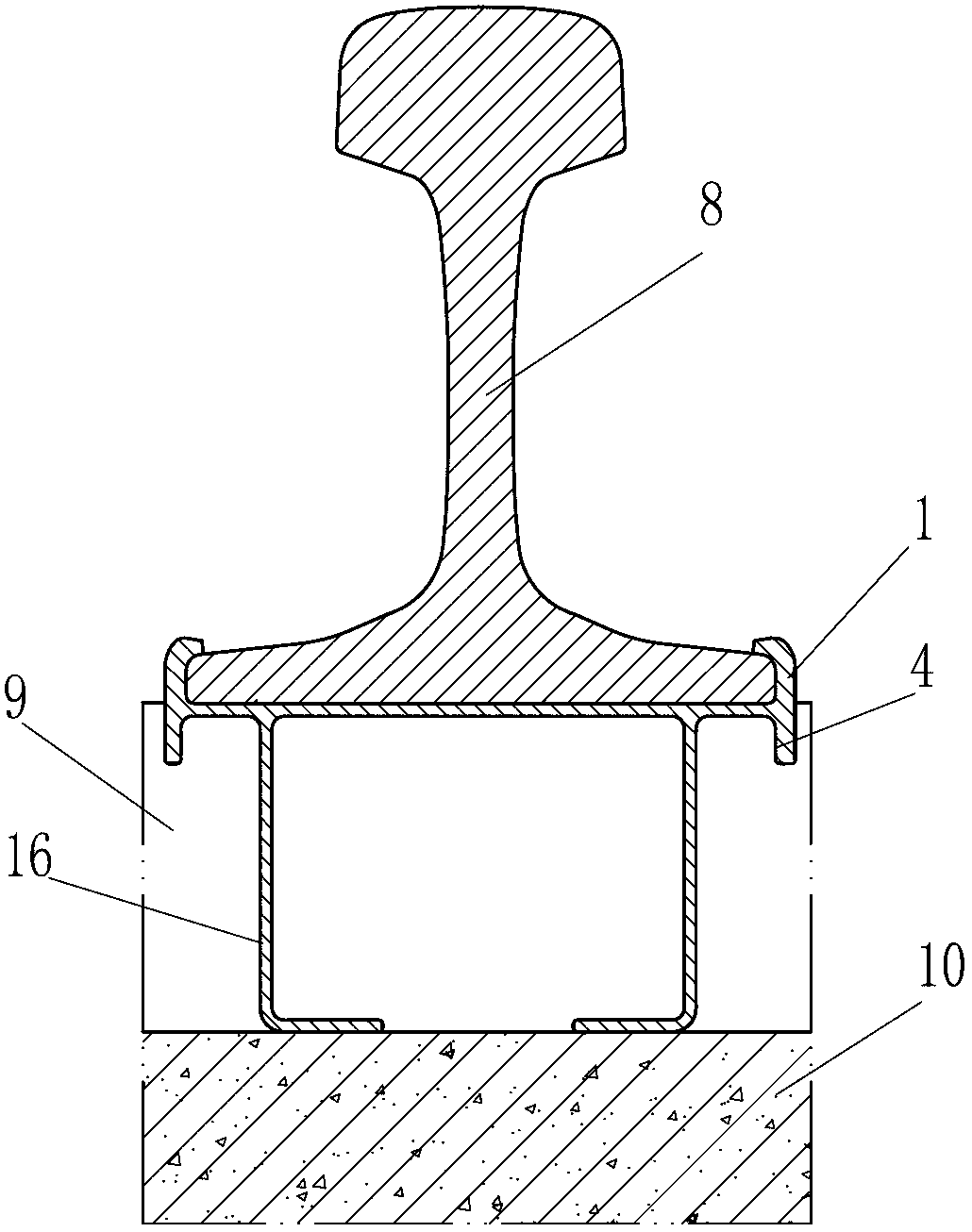

Platform plate insulation structure of subway shielding door

ActiveCN104420420AAvoid insulation failureRefuge islandsDoor/window applicationsAgricultural engineeringBlock structure

The invention provides a platform plate insulation structure of a subway shielding door. A platform protrudes towards the rail side to form a platform plate; the bottom of the shielding door is fixed on the platform plate through a supporting part; the supporting part and the platform plate are fixed together through a penetrating bolt; the cross section of an insulation plate is in a Z shape; the insulation plate covers the surface of the rail side of the platform, the upper surface of the platform plate and the surface of the rail side of the platform plate in an attached mode; an upper insulation sleeve pipe, a lower insulation sleeve pipe and an outer insulation sleeve pipe penetrate and sleeve the penetrating bolt to enable a labyrinth type sealing blocking structure to be formed between the platform plate and the shielding door. According to the platform plate insulation structure of the subway shielding door, the Z-shaped insulation plate wraps the platform and the platform plate, the penetrating bolt which is arranged at the connecting position of the supporting part and the platform plate is insulated through the upper insulation sleeve pipe, the lower insulation sleeve pipe, the outer insulation sleeve pipe and a bolt protection sleeve, and accordingly the conduction area caused by the pollution is avoided and the insulation failure can be effectively avoided.

Owner:刘春梅

Metro shielding door insulation structure

ActiveCN103921797AAvoid insulation failureRailway componentsSills/thresholdMechanical engineeringPollution

The invention provides a metro shielding door insulation structure. The metro shielding door insulation structure is arranged between a platform and a threshold, wherein a platform plate is protruded from the platform toward a rail side, an insulation glue layer is wrapped around the whole surface of the platform plate, an L-shaped insulation padding plate is arranged on a portion of a U-shaped support of the threshold, connected with the platform plate, an L-shaped insulation support is arranged between the platform plate and a platform side, an insulation glue strip is inlaid between a threshold profile on the upper portion of the threshold and the L-shaped insulation support, a U-shaped support on the lower portion of the threshold is fixed on the platform plate through a penetration bolt, and the penetration bolt is isolated through an upper insulating bush, a lower insulating bush and a bolt protecting bush, and therefore no conductive area generated by pollution exists, and furthermore insulation failure is effectively avoided.

Owner:北京天乐泰力科技发展有限公司

Method for producing self-adhesion compound type enameled aluminium round wire

ActiveCN103000303ASave resourcesLow costMetal/alloy conductorsInsulating conductors/cablesPolyamide-imidePolyamide

A method for producing a self-adhesion compound type enameled aluminium round wire is characterized by comprising the steps of conducting continuous wire-drawing, cleaning and softening on a round aluminum rod, applying primer, an intermediate layer, a finish layer and an self-adhesion layer on a coating of the aluminium round wire after 25-33 times of fine painting and drying, and conducting automatic disc changing and winding up after on-line monitoring and surface lubricating, wherein the primer adopts aromatic polyamide imide paint, the intermediate layer adopts polyesterimide paint, the finish layer adopts polyamide imide paint, and the self-adhesion layer adopts aromatic polyamide self-adhesion paint. The self-adhesion compound type enameled aluminium round wire is wide in temperature-resisting range, resistant to low temperature and resistant to quick temperature variation.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

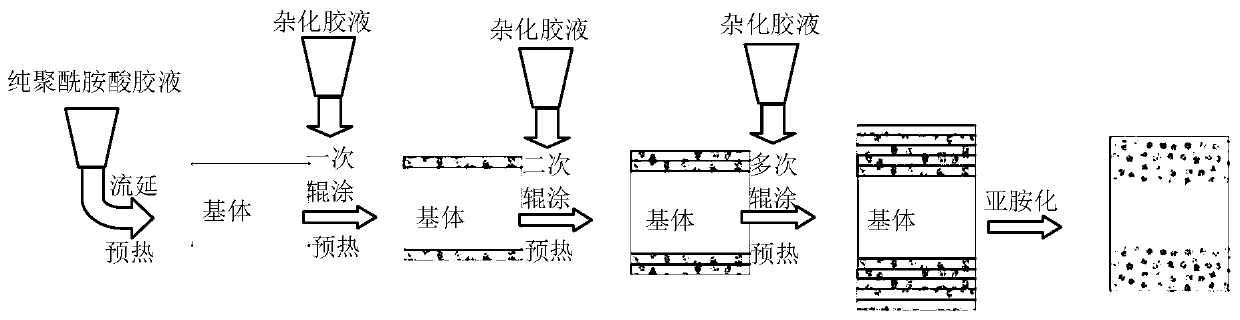

Corona resistance polyimide film preparing method, corona resistance polyimide film and preparing system of corona resistance polyimide film

ActiveCN110744764AImprove mechanical propertiesExcellent dielectric propertiesPretreated surfacesFlat articlesPolymer scienceComposite film

The invention discloses a preparing method of a corona resistance polyimide composite film. A roller coating layer and a middle layer are included. The roller coating layer is formed through aminationafter a polyimide / inorganic particle hybrid glue solution is subjected to one-time or multi-layer roller coating on the two faces of the middle layer, and the middle layer is a polyimide pure layer.According to the prepared polyimide composite film, continuous industrial production of multiple layers of corona resistance polyimide composite films is achieved, on the basis that the corona resistance performance is excellent, the mechanical performance is more excellent, and the preparing method is suitable for large-scale industrial continuous production.

Owner:SUZHOU INST OF INDAL TECH

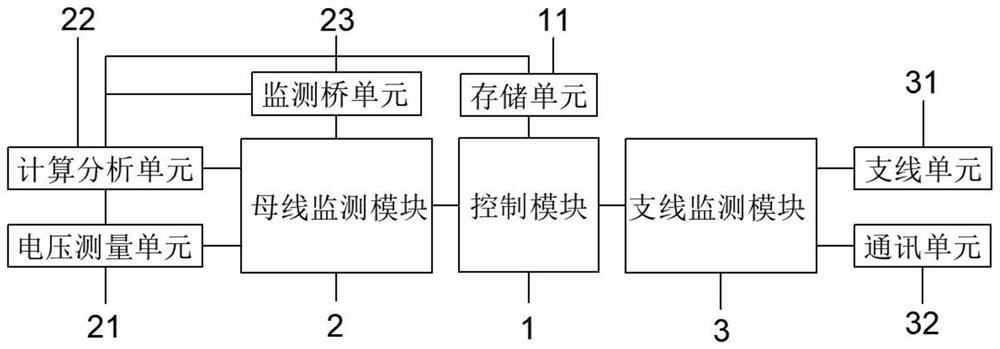

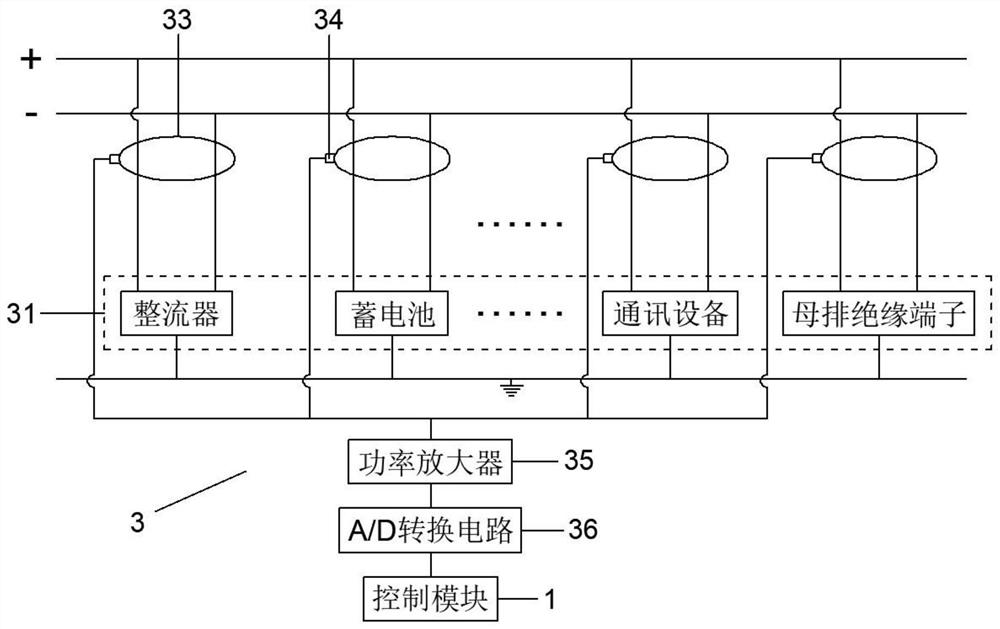

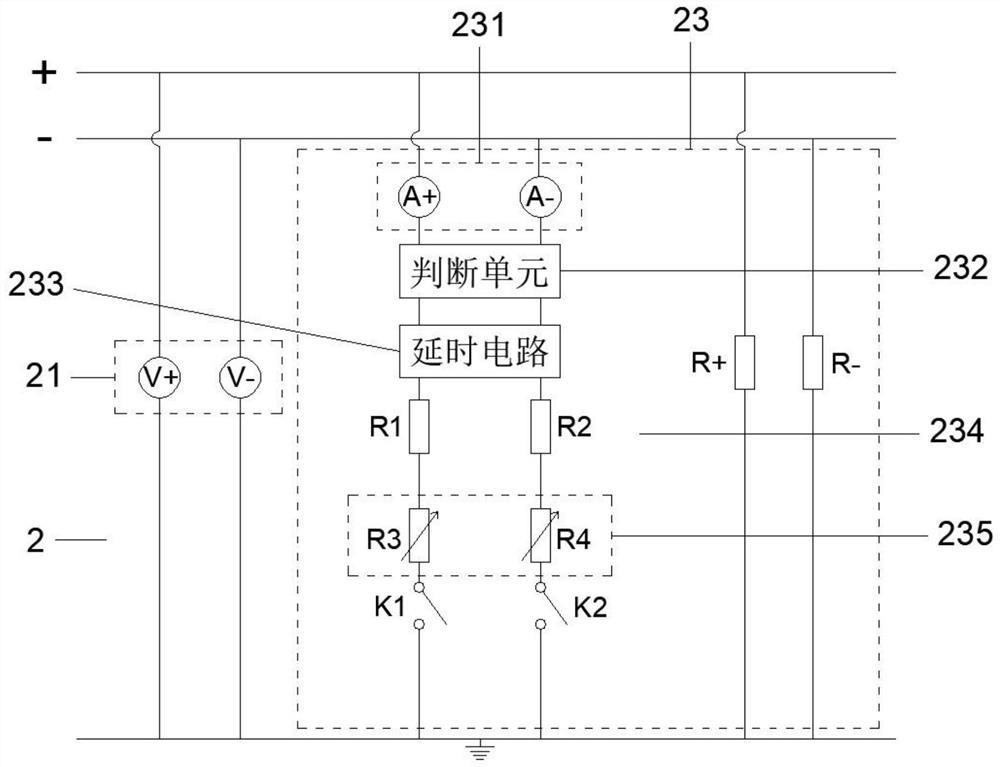

High-voltage direct-current insulation monitoring system and monitoring method

PendingCN113064029AQuick solution to insulation faultsAvoid insulation failureTesting dielectric strengthSatellite radio beaconingOvervoltageDropout voltage

The invention discloses a high-voltage direct current insulation monitoring system and monitoring method. The system comprises a control module, the control module is connected with a bus monitoring module and a branch monitoring module, and carries out insulation monitoring on a bus and a branch, the bus monitoring module comprises a voltage measurement unit, a calculation and analysis unit, and a monitoring bridge unit, the calculation and analysis unit is used for calculating a voltage difference, a current value and an insulation resistance value of a bus anode and a bus cathode, and judging an insulation fault according to the change conditions of the voltage difference and the insulation resistance value, the branch monitoring module is connected with a branch unit and a communication unit, and the branch monitoring module is used for monitoring the insulation condition of the branch unit and transmitting monitoring data through the communication unit. Insulation faults are preliminarily judged through the voltage measurement unit, so that bus faults and branch faults can be distinguished; insulation states are monitored through the bus monitoring module and the branch monitoring module; and switch switching is replaced with potentiometer adjustment, so that voltage-to-ground fluctuation is reduced.

Owner:南京传积兴自动化科技有限公司

Method for rapidly repairing damage of directly-buried cable

ActiveCN112467638ALow costGuaranteed originalityApparatus for repairing insulation/armouring cablesAdhesive beltDirect-buried cable

The invention provides a method for rapidly repairing the damage of a directly-buried cable, which is particularly suitable for repairing the damage of a cable outer sheath or the main insulation of the cable, the insulation sealing performance of the cable is recovered by using a high-voltage waterproof insulation composite adhesive tape in a semi-lapping manner, the mechanical damage resistanceof the cable is recovered by using an industrial armor wrapping tape, and the cable does not need to be cut off. The original main body structure of the cable does not need to be damaged, and only thedamaged part of the cable needs to be repaired to prevent water and moisture from entering the cable to cause insulation faults of the cable. Compared with a traditional repairing method, the high-voltage waterproof insulation composite adhesive tape is used for recovering the insulation sealing performance of the cable in a half-lap wrapping mode, the industrial armor wrapping tape is used for recovering the cable, rapidness and convenience are achieved, and the cost is low; no intermediate joint is generated, the primitiveness of the cable is ensured, and the original electrical insulationperformance of the cable is ensured; and only a fault point needs to be excavated, and the earth excavation amount is reduced.

Owner:西北水利水电工程有限责任公司

Overhead line electricity testing device

PendingCN110231544AImprove detection securityExtended service lifeFault location by conductor typesIndicating presence of current/voltageElectricityComputer module

The invention relates to an overhead line electricity testing device, comprising a shell and an electricity testing module, wherein the shell comprises an induction lantern ring and a mounting seat, the induction lantern ring is arranged at one end of the mounting seat, the induction lantern ring is provided with an accommodating through hole for accommodating an overhead line, a first accommodating space is opened in the induction lantern ring, and a second accommodating space is opened in the mounting seat; and the electricity testing module comprises a coil, a common mode inductor, a voltage stabilizing unit, a rectifying unit and a lamp panel, the coil is arranged in the first accommodating space, the common mode inductor, the voltage stabilizing unit and the rectifying unit are arranged in the second accommodating space, and the lamp panel is arranged at one end of the mounting seat away from the induction lantern ring. The overhead line electricity testing device senses overheadline current into a secondary circuit, can accurately judge whether current flows through the overhead line, requires no external power supply, avoids an insulation fault of the overhead line and thesecondary circuit, and can avoid causing personal injury and equipment damage. Furthermore, the shell is used for protecting the electricity testing module, so that the service life of the overhead line electricity testing device is effectively prolonged.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

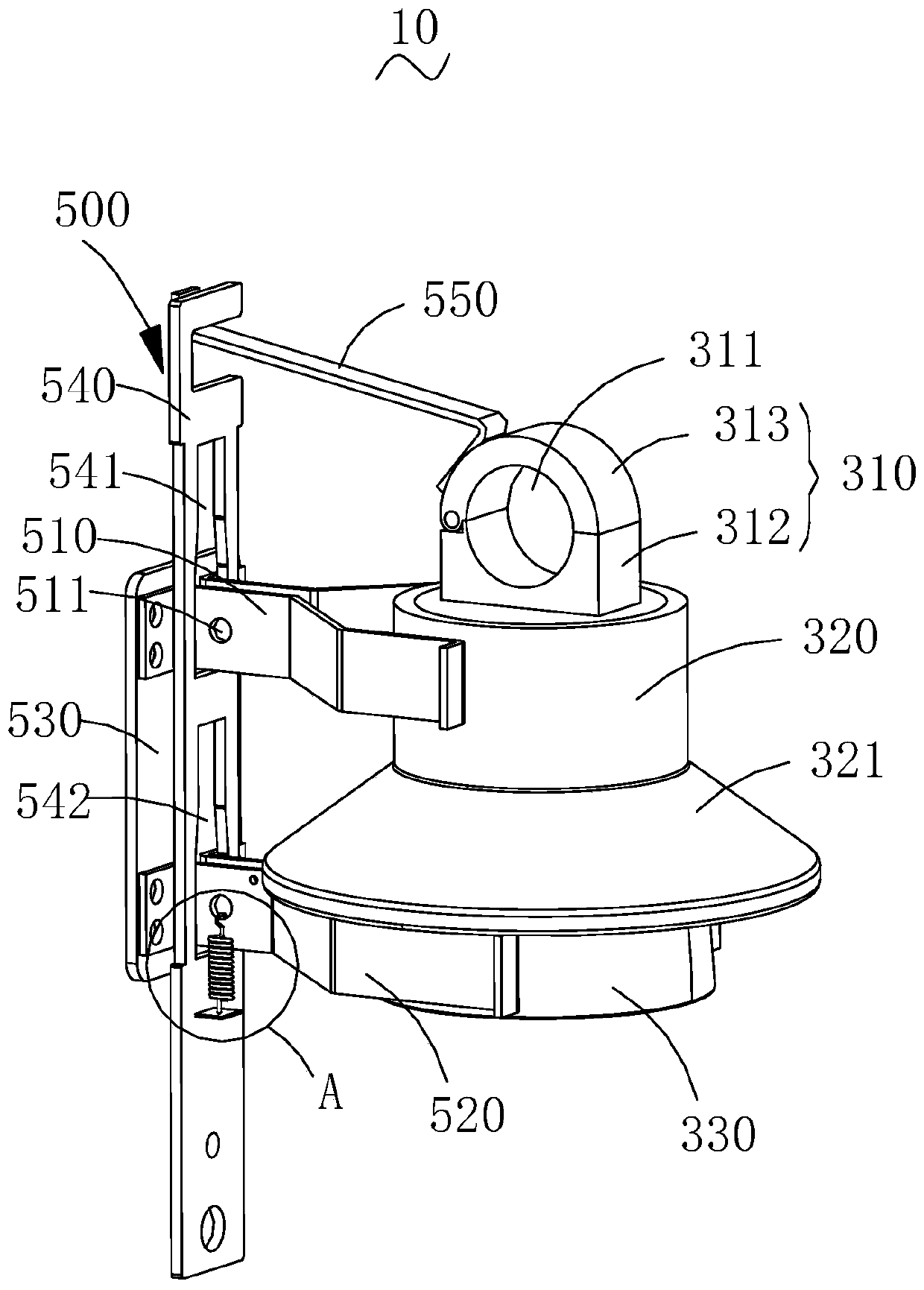

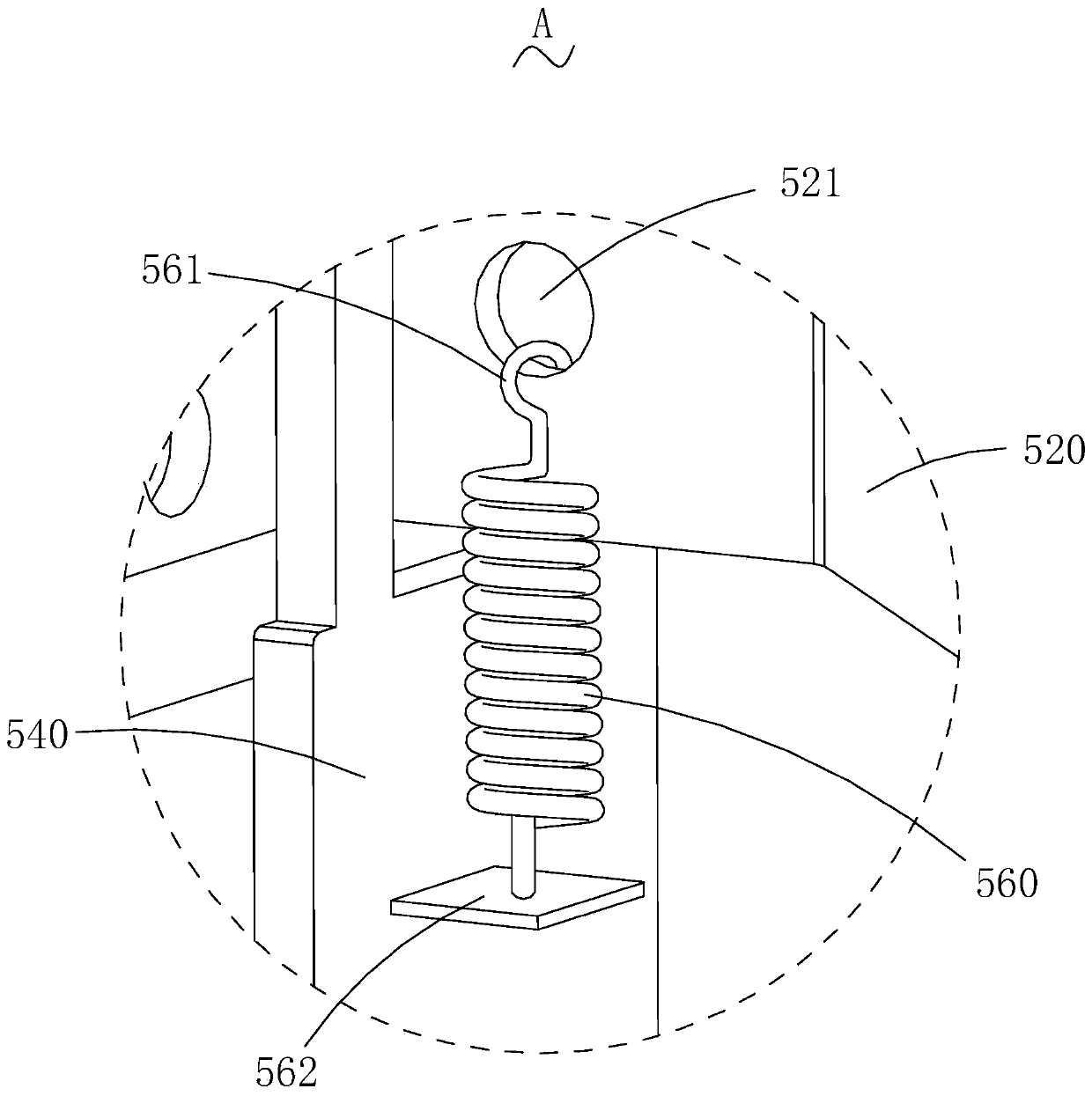

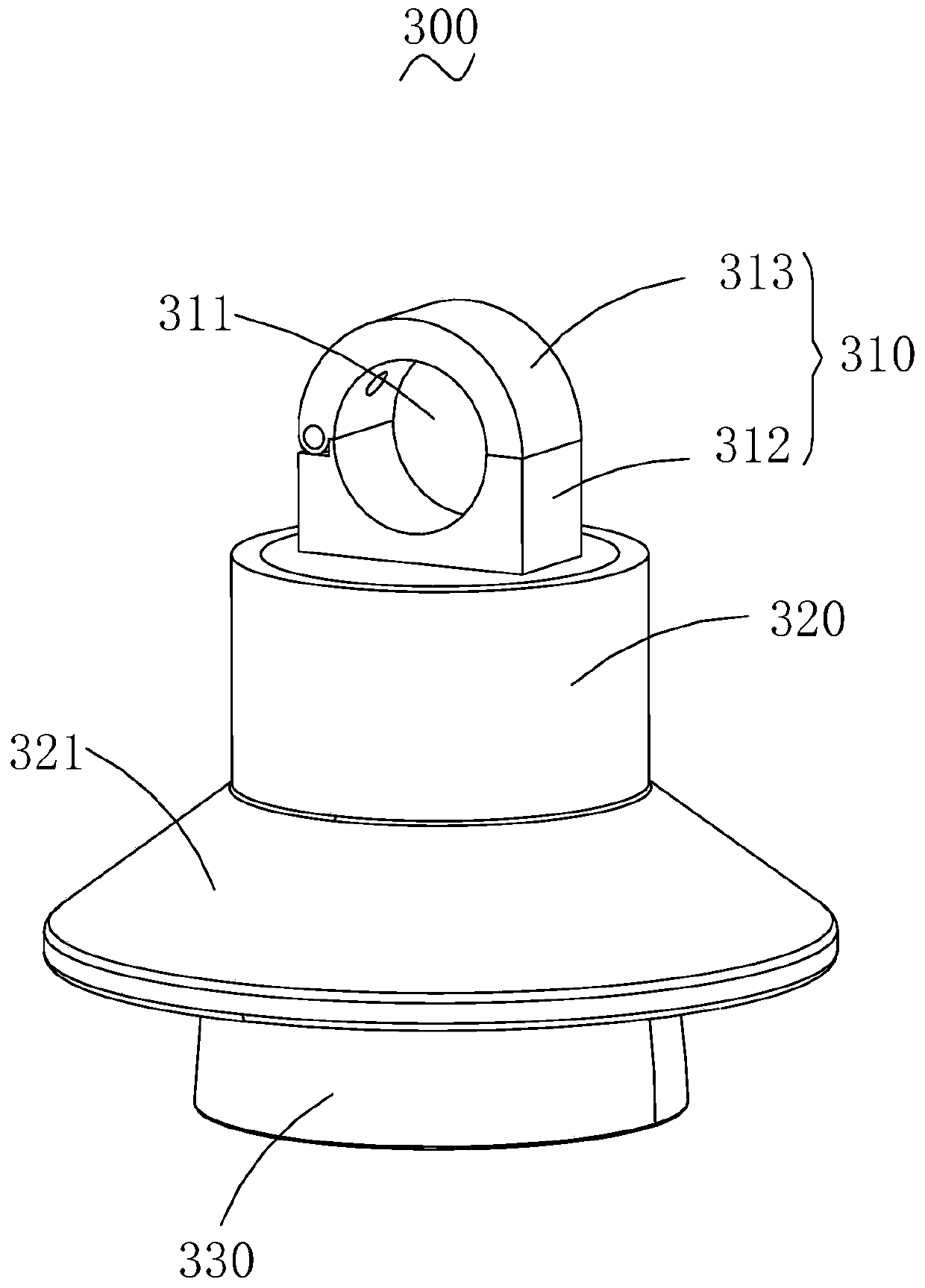

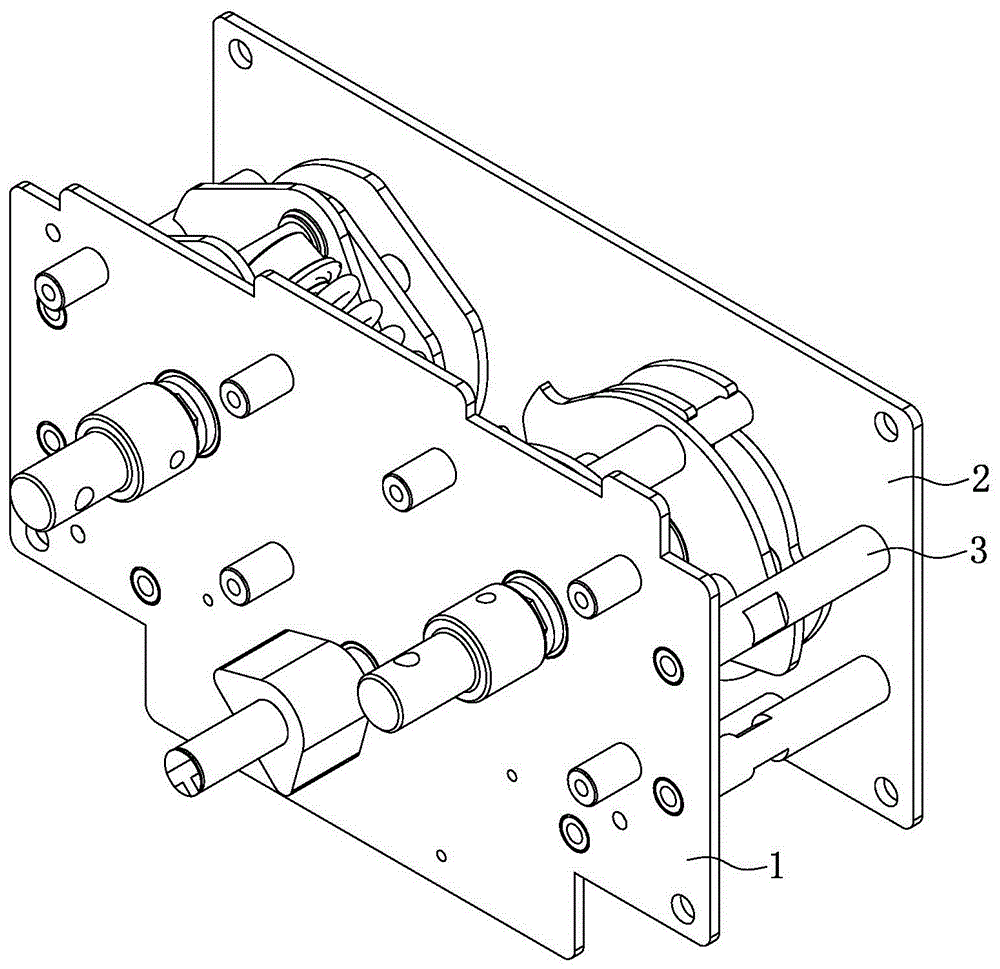

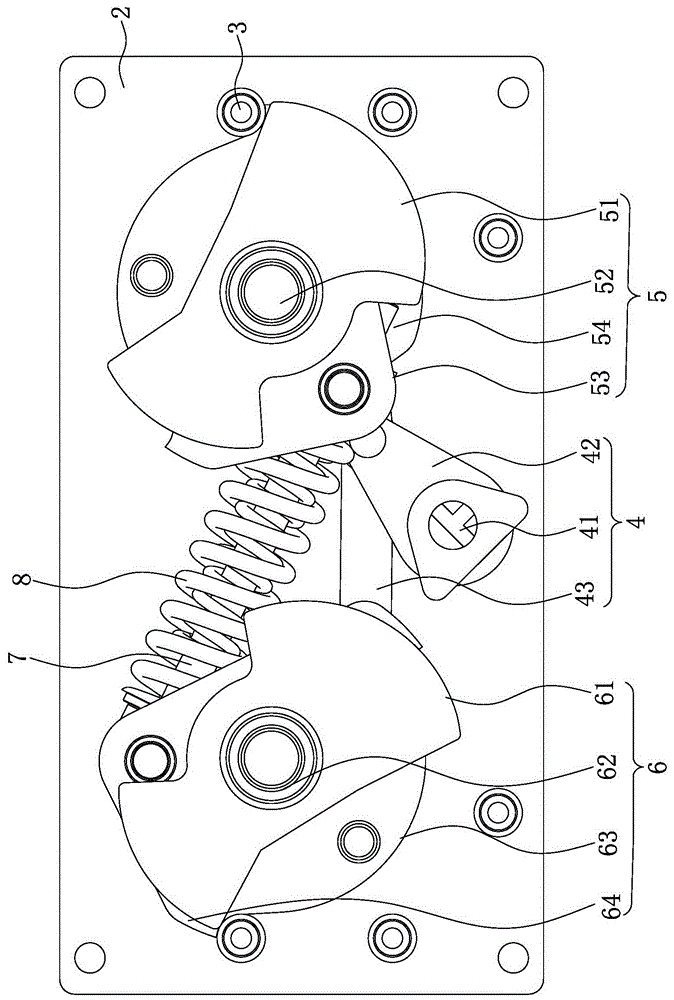

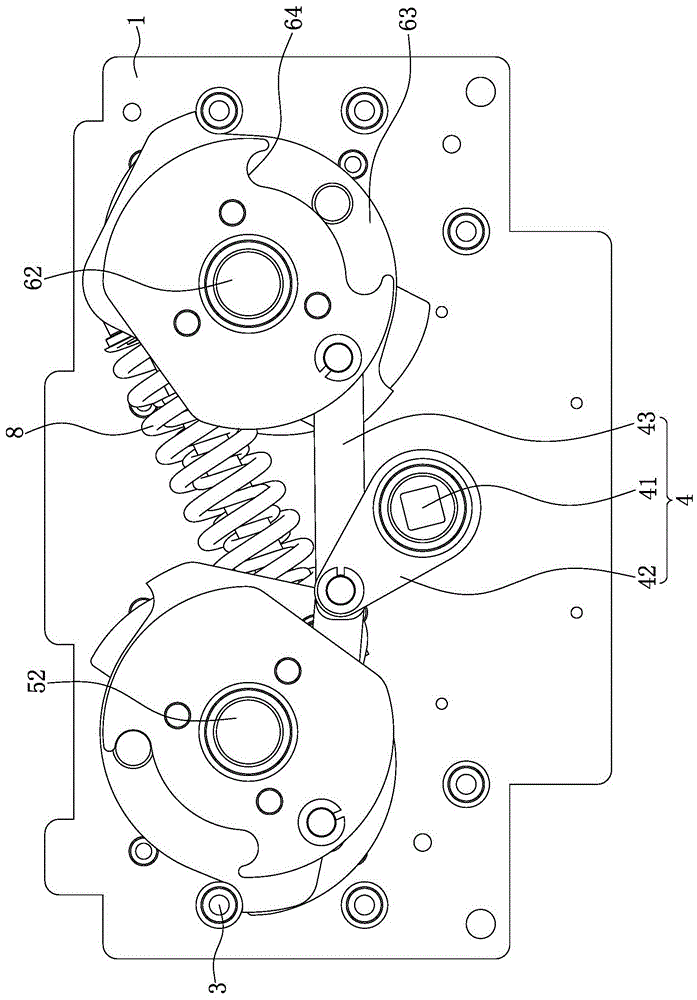

Three-position operating mechanism with buffering function

InactiveCN105977069AAvoid overshootAvoid insulation failureContact vibration/shock dampingEngineeringMechanical engineering

The invention discloses a three-position operating mechanism with a buffering function. The three-position operating mechanism comprises a mechanism front plate, a mechanism rear plate, an output shaft module, a grounding side closing and separating module, an isolation side closing and separating module, a spring module and a buffering module. All the modules are assembled between the mechanism front plate and the mechanism rear plate. The output shaft module comprises an output shaft, an output shaft crank arm and a driving pull rod. The output shaft is arranged on the middle part of the mechanism rear plate. The grounding side closing and separating module and the isolation side closing and separating module are distributed at the two sides of the output shaft with the output shaft acting as the center. The output shaft crank arm is pivotally connected on the output shaft. The buffering module is fixed on the mechanism rear plate. One end of the buffering module abuts against the external side of the output shaft crank arm. An insulation fault caused by overshooting in separating can be prevented so that the safety of operation can be enhanced.

Owner:SOUTH CHINA ELECTRIC DEV XIAMEN

Transformer partial discharge super high frequency detector

InactiveCN1932539AEarly detection of abnormalitiesReduce performanceTesting dielectric strengthHigh-tension/heavy-dress switchesElectricityTransformer

A kind of transformer part turns on electricity an extremely high examination device, belonging to electricity equipments to insulate monitor technique realm. The invention mainly includes the pole sub- antenna of a set of tube list to spread a feeling machine and enlarges a filter, high speed numeral to collect machine and calculator. Set the tube list pole sub- antenna of the invention spreads a feeling machine to be flapped son, metals set a tube by the metals radiation and deliver line and metals scale board and N type of the electric cable with stalk to deal with contact to constitute. Because the invention has a higher intelligent degree and believes a ratio, can examine clear and accurate transformer occurrence part turn on electricity the extremely high electromagnetic wave produced signal, can availably to transform internal occurrence of part on electricity to carry on on-line monitor, so it can be used for the oil immerse type transformer with 110-500 kV extensively.

Owner:CHONGQING UNIV

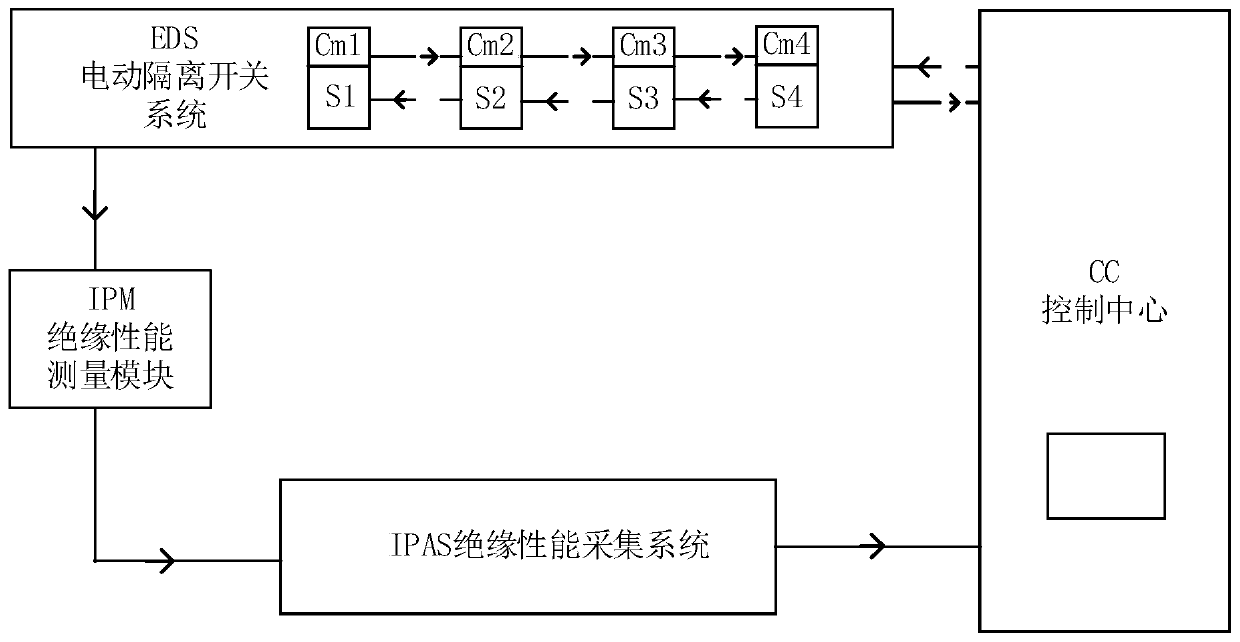

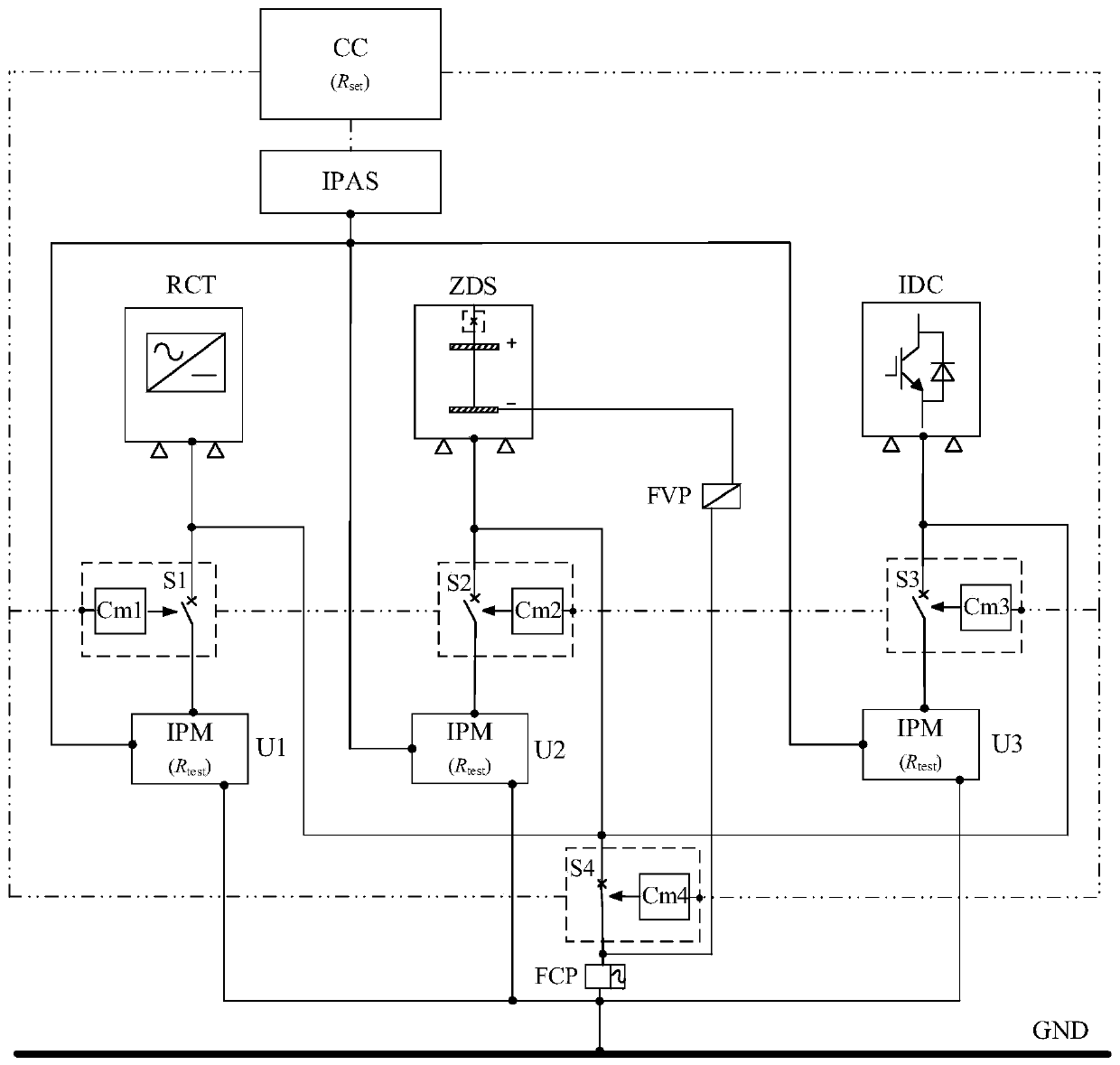

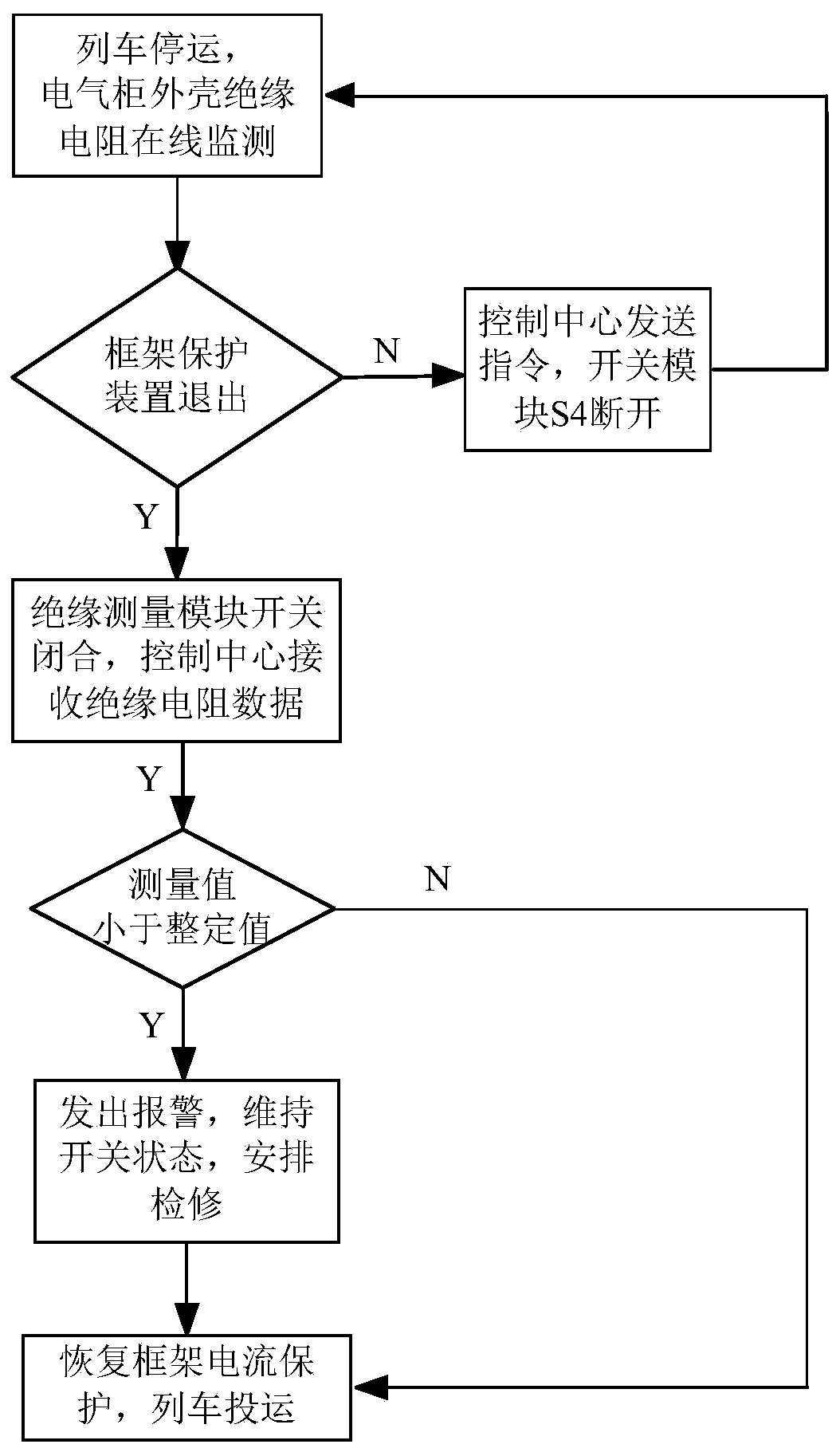

On-line insulation performance monitoring system for urban rail transit direct current equipment and control method

ActiveCN110780120AImprove system reliabilitySave operating investmentVery high resistance measurementsInsulation resistanceBusbar

The invention discloses an on-line insulation performance monitoring system for urban rail transit direct current equipment and a control method. The system comprises an insulation performance measuring module, an insulation performance collecting system, a switch module and a control center, wherein the insulation measuring module is installed between an equipment frame of a rectifier cabinet, adirect-current switch cabinet and an inverter feedback device cabinet and a grounding busbar and is connected to the insulation acquisition system; an electric isolating switch between a cabinet shelland the insulation measuring module is in a normally open state; a switch between a centralized grounding point of a frame protection element and the grounding busbar is in a normally closed state; the insulation measuring module is used for measuring the insulation resistance data of the cabinet body and sending the insulation resistance data to the control center through the insulation acquisition module; and the control center is regularly sending a monitoring signal for maintaining the state of the switch module, continuously receiving insulation resistance data, performing logic judgmentand acting on the switch module. According to the system, the insulation performance of the urban rail transit direct current equipment can be monitored online, the misoperation of a frame protectiondevice can be avoided, and the reliability is high.

Owner:SOUTHWEST JIAOTONG UNIV

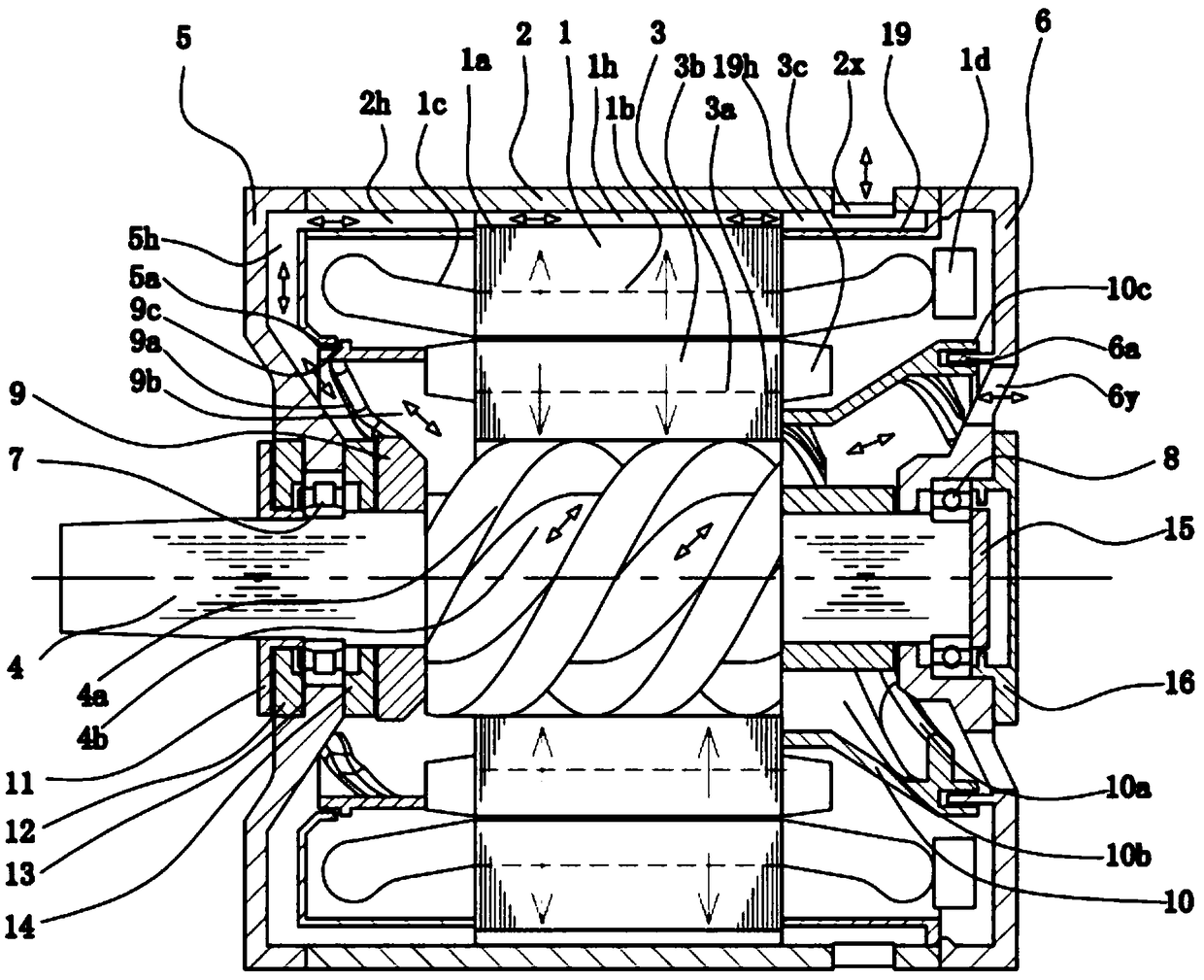

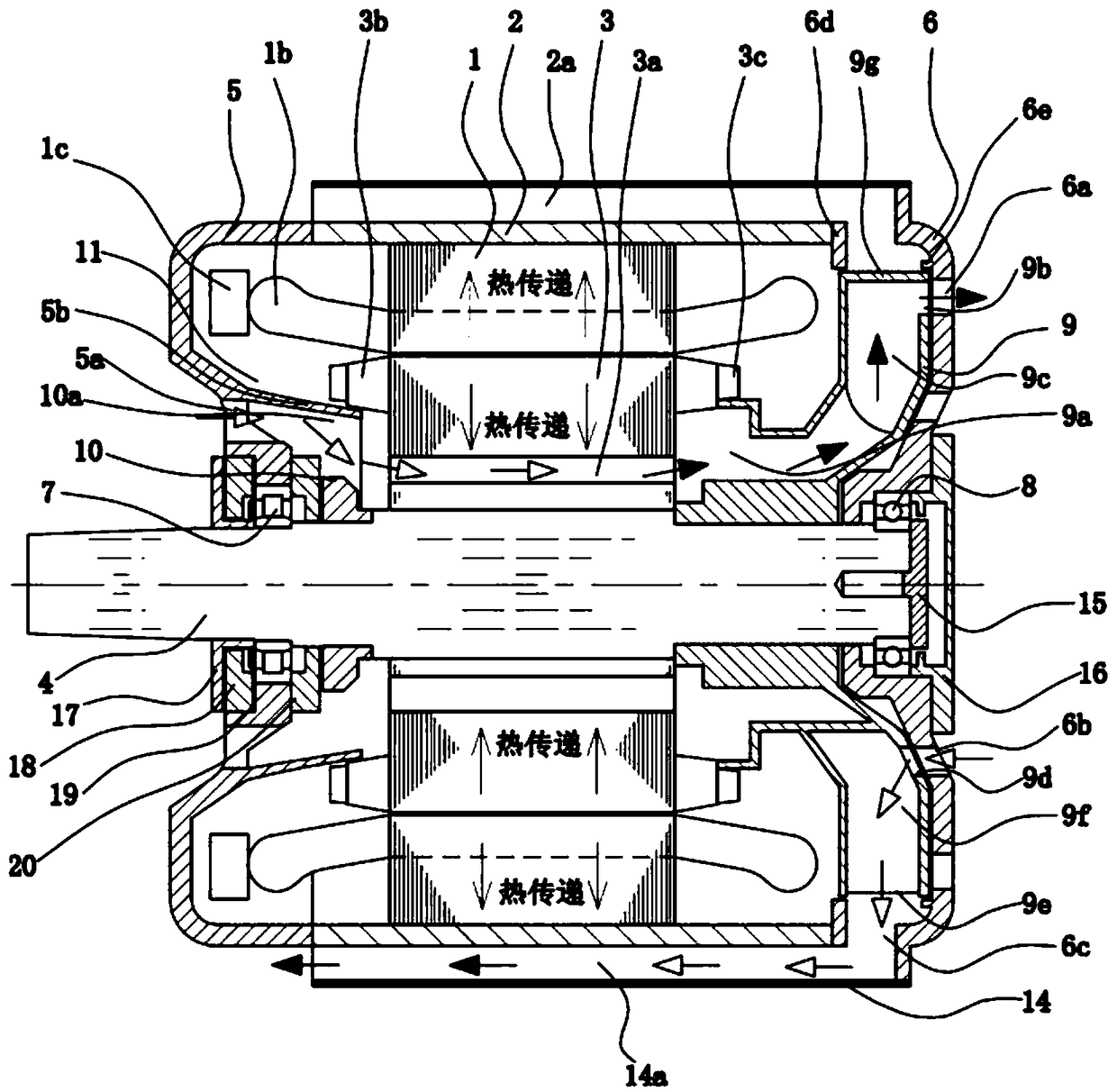

Electromotor

ActiveCN108808986AGuaranteed cooling effectImprove working environmentMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineEngineering

The invention discloses an electromotor for realizing stator sealing and rotor opening ventilation manners by adopting axial flow ventilation. An adopted shaft is provided with an external circumference spiral groove and is matched with an axial flow fan with two ends clinging to each other and same spiral direction so as to form an axial flow combination ventilation device; the devices are arranged on the inner part of a rotor and two ends of the rotor so as not to occupy an extra motor axial space, so that the electromotor is compact in structure; due to different steering directions, the air flow direction is also different, but the motor can be cooled; by matching with labyrinth seal, a cooling manner combining stator seal type ventilation cooling with rotor open type ventilation cooling of the electromotor is realized, so that the stator insulation reliability and the rotor heat radiation capacity are ensured through the combined cooling manner, and the motor efficiency is improved; a stator cooling air flue is formed by (2x), (2h) and (6h); a rotor cooling air flue is formed by (5y), (9b), (4b) and (10b); the two cooling air flues are connected with each other in series and is jointly supplied with air pressure by the spiral combination device.

Owner:胜利油田顺天节能技术有限公司

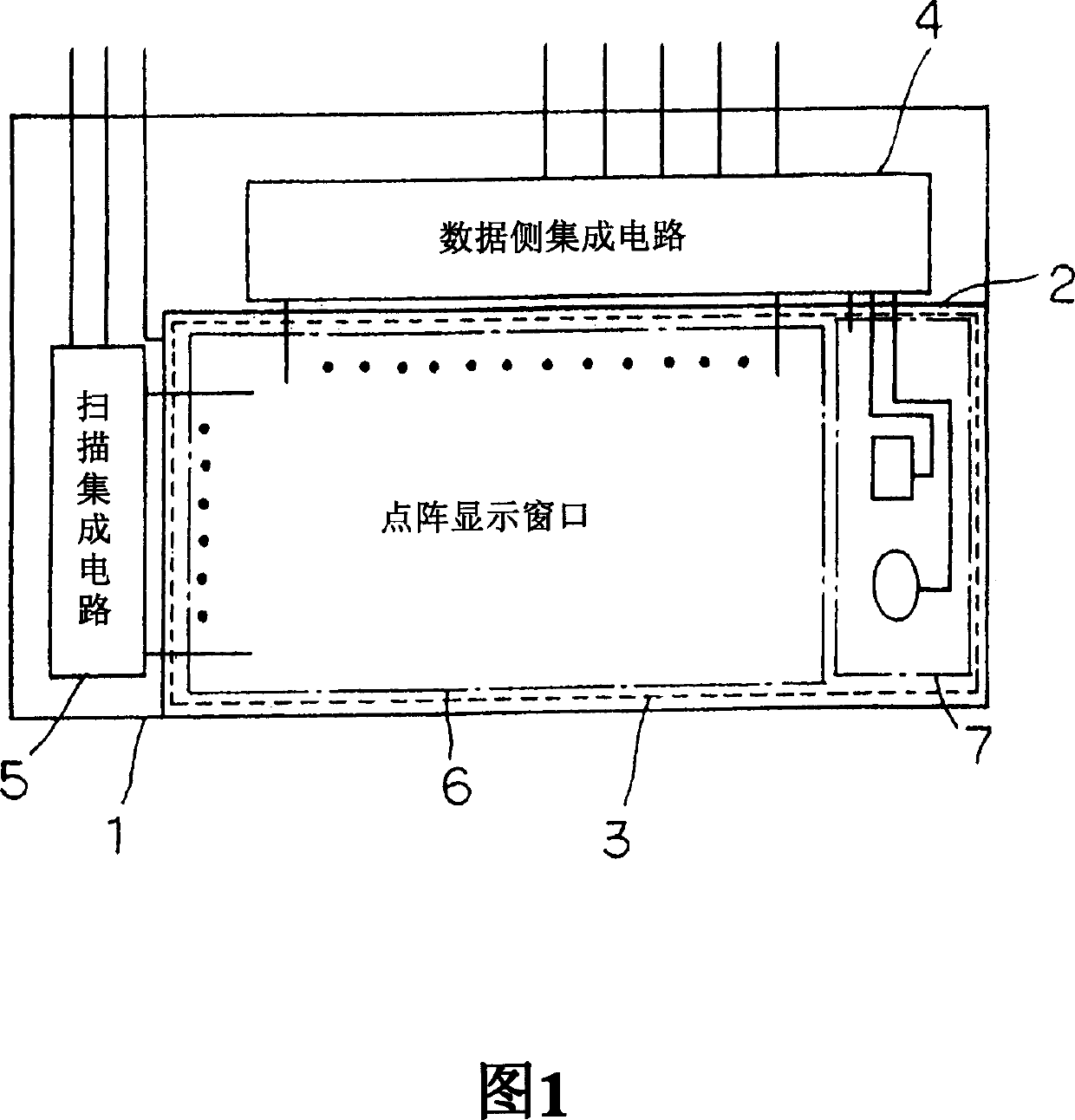

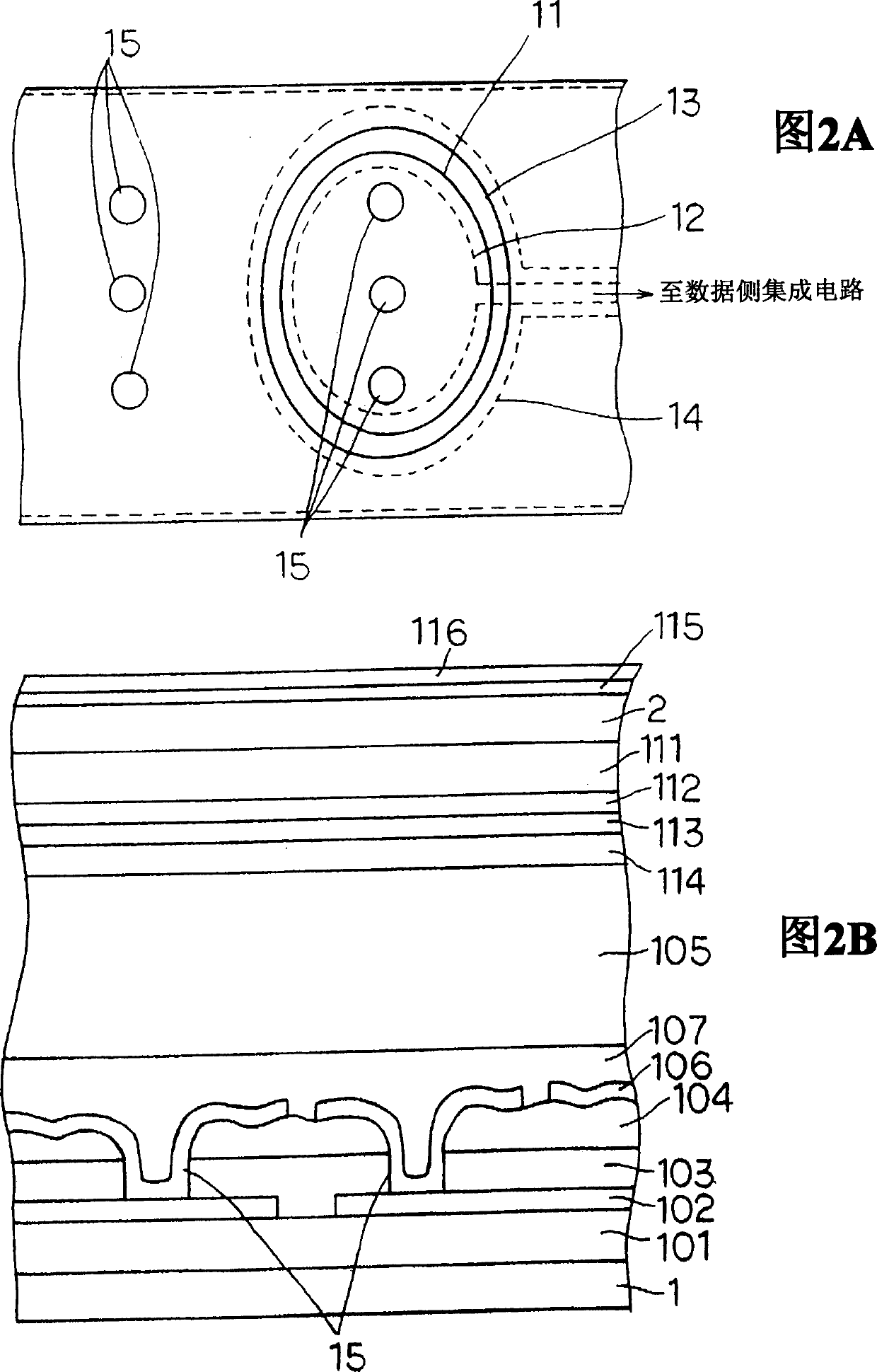

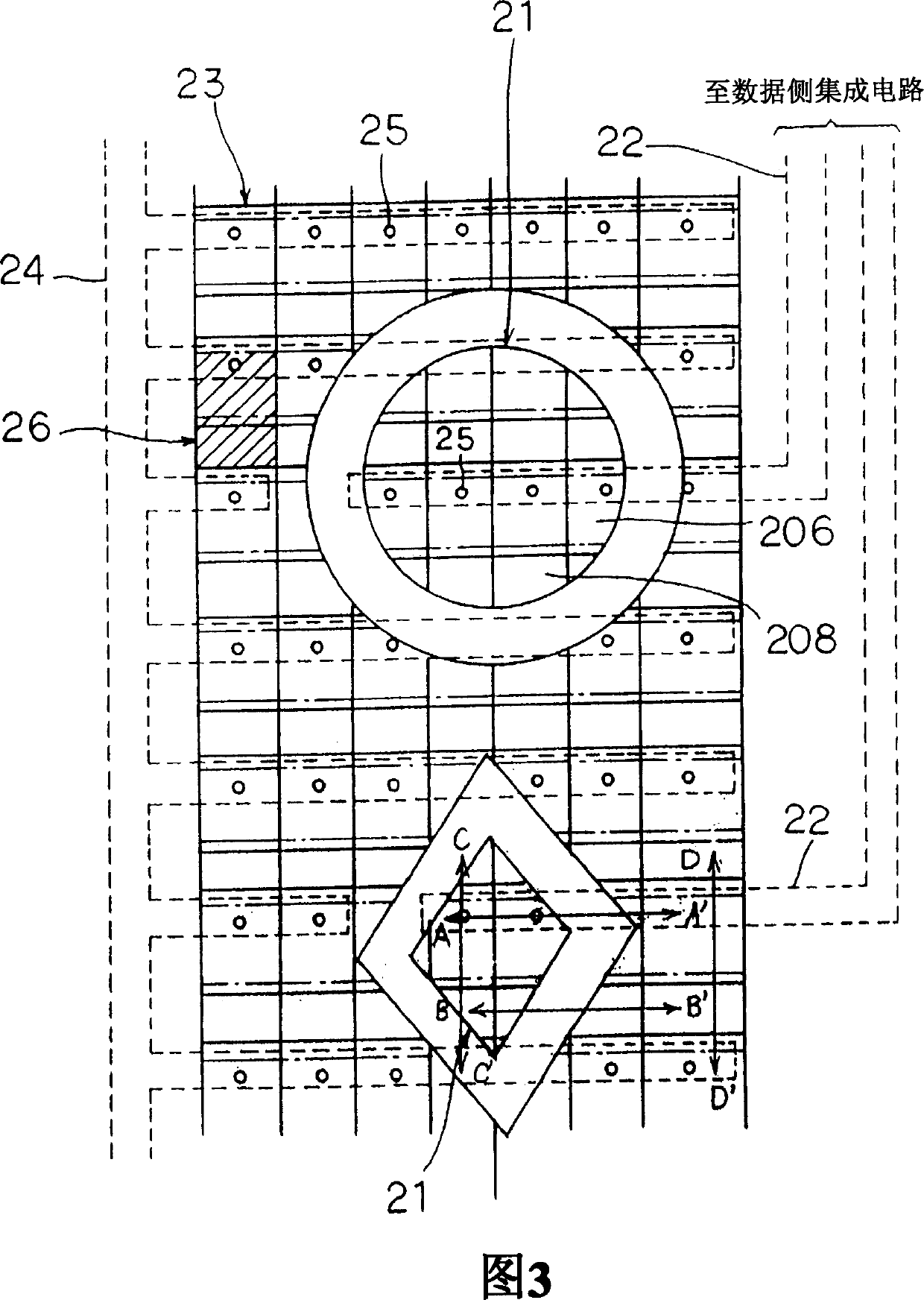

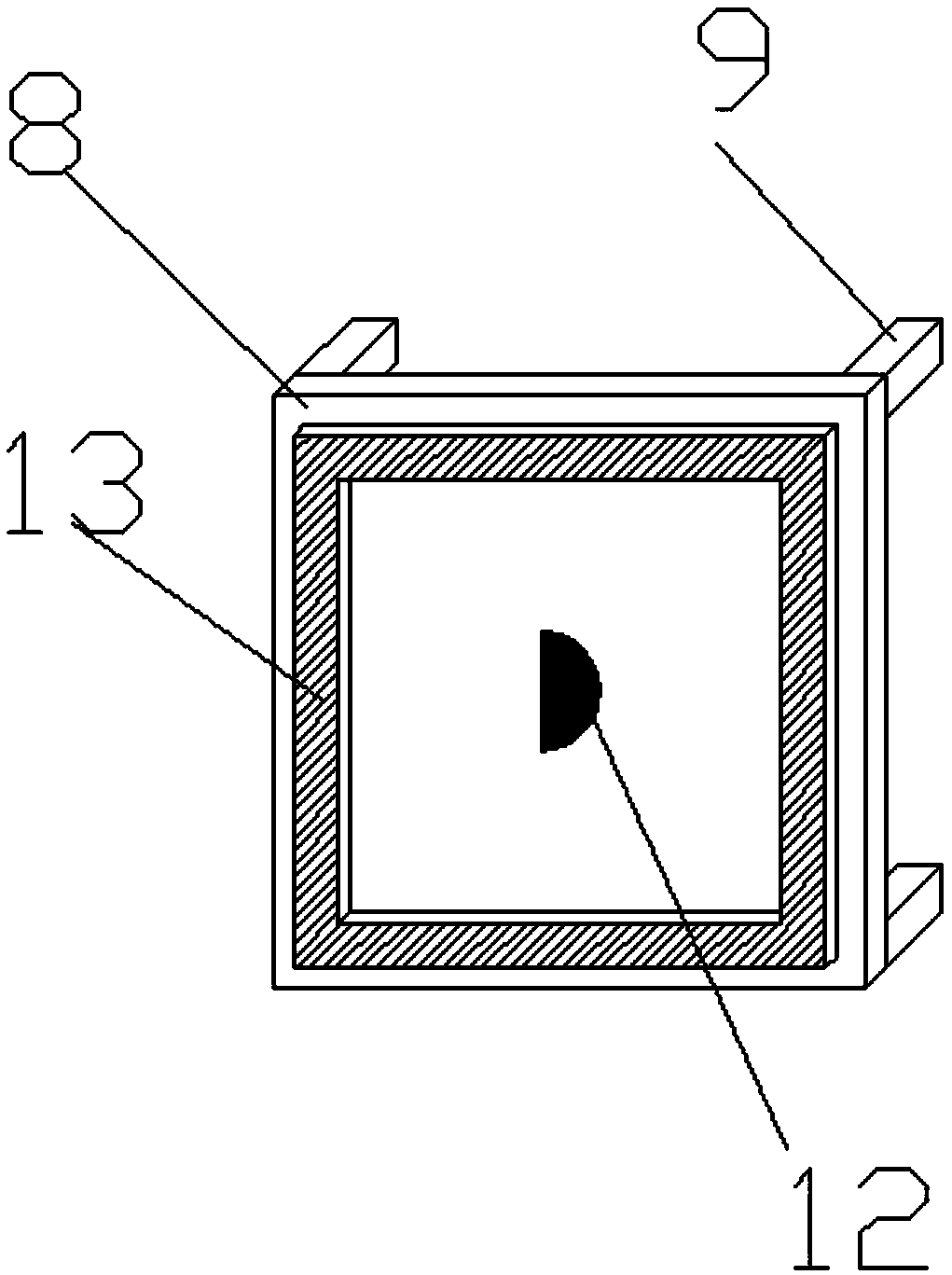

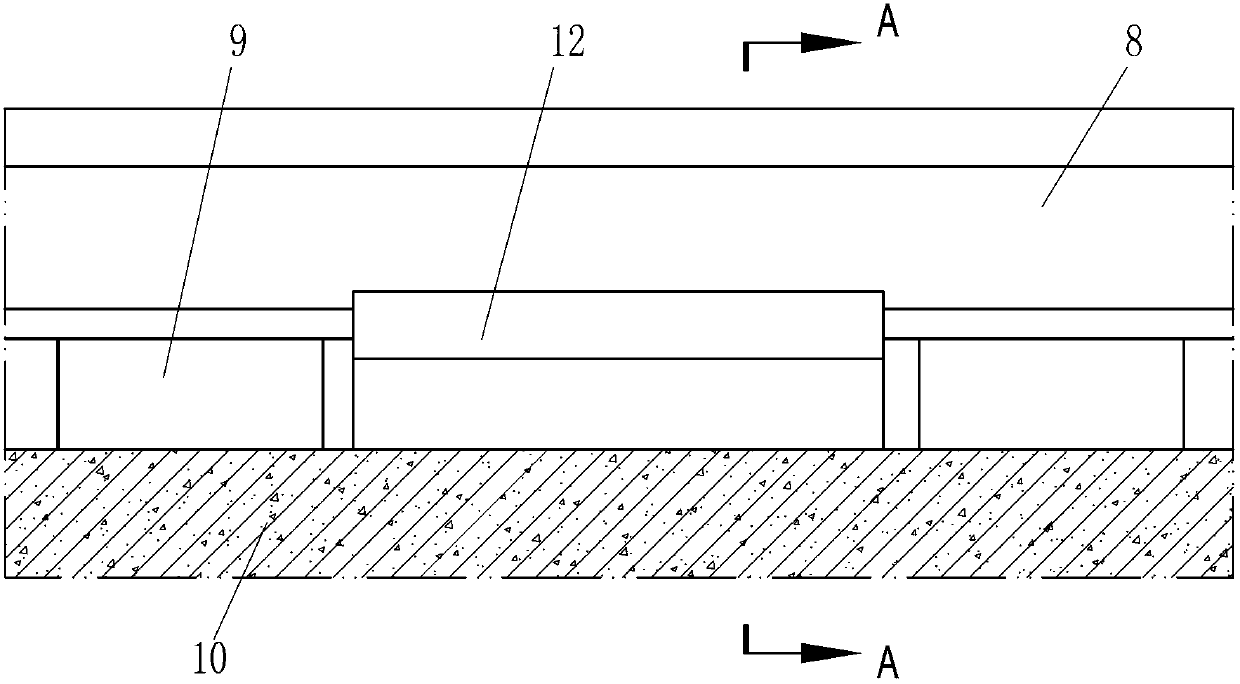

Liquid crystal display apparatus

InactiveCN1451995AImprove insulation performanceAvoid insulation failureStatic indicating devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayLiquid crystal

A liquid crystal display device has a first substrate, a second substrate and a liquid crystal layer. Wherein the first substrate has graphic symbol pixel electrodes for displaying graphic symbols represented by fixed patterns; the second substrate has a common electrode opposite to the graphic symbol pixel electrodes; the liquid crystal layer is sandwiched between the first substrate and the second substrate. The graphic symbol pixel electrode is formed on the interlayer insulating film, and is connected with the graphic symbol signal electrode through a plurality of contact holes, the contact holes penetrate the interlayer insulating film, and the graphic symbol signal electrode is formed under the interlayer insulating film.

Owner:NEC LCD TECH CORP

Built-in pre-buried ultrahigh-frequency GIS internal partial discharge monitoring sensor

InactiveCN104316853AImprove insulation marginLarge monitoring areaTesting dielectric strengthElectrical conductorMechanical engineering

The invention relates to a device for monitoring GIS internal partial discharge, in particular to a built-in pre-buried ultrahigh-frequency GIS internal partial discharge monitoring sensor. The sensor comprises an insulator, a guiding device and a radio-frequency connector, wherein the insulator is perpendicularly connected to the interior of a grounding shell, the circumferential portion of the insulator is connected with the cylinder wall of the shell, the edge of the insulator extends out of the shell, the guiding device comprises a high-voltage conductor and an antenna, the high-voltage conductor is arranged along the axis of the grounding shell and penetrates through the insulator, the two ends of the high-pressure conductor extend out of the insulator, the antenna is annular, the section of the antenna is in the shape of a circle or a long circle, the antenna is embedded into the insulator, one end of the radio-frequency connector is connected with the antenna, and the other end of the radio-frequency connector extends out of the edge of the antenna. The sensor has the advantages that monitoring position is flexible, monitoring range is wide, monitoring sensitivity is high, the uniform electric field of an original coaxial cylindrical structure is not changed, original insulation margin is increased, and cost is low.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

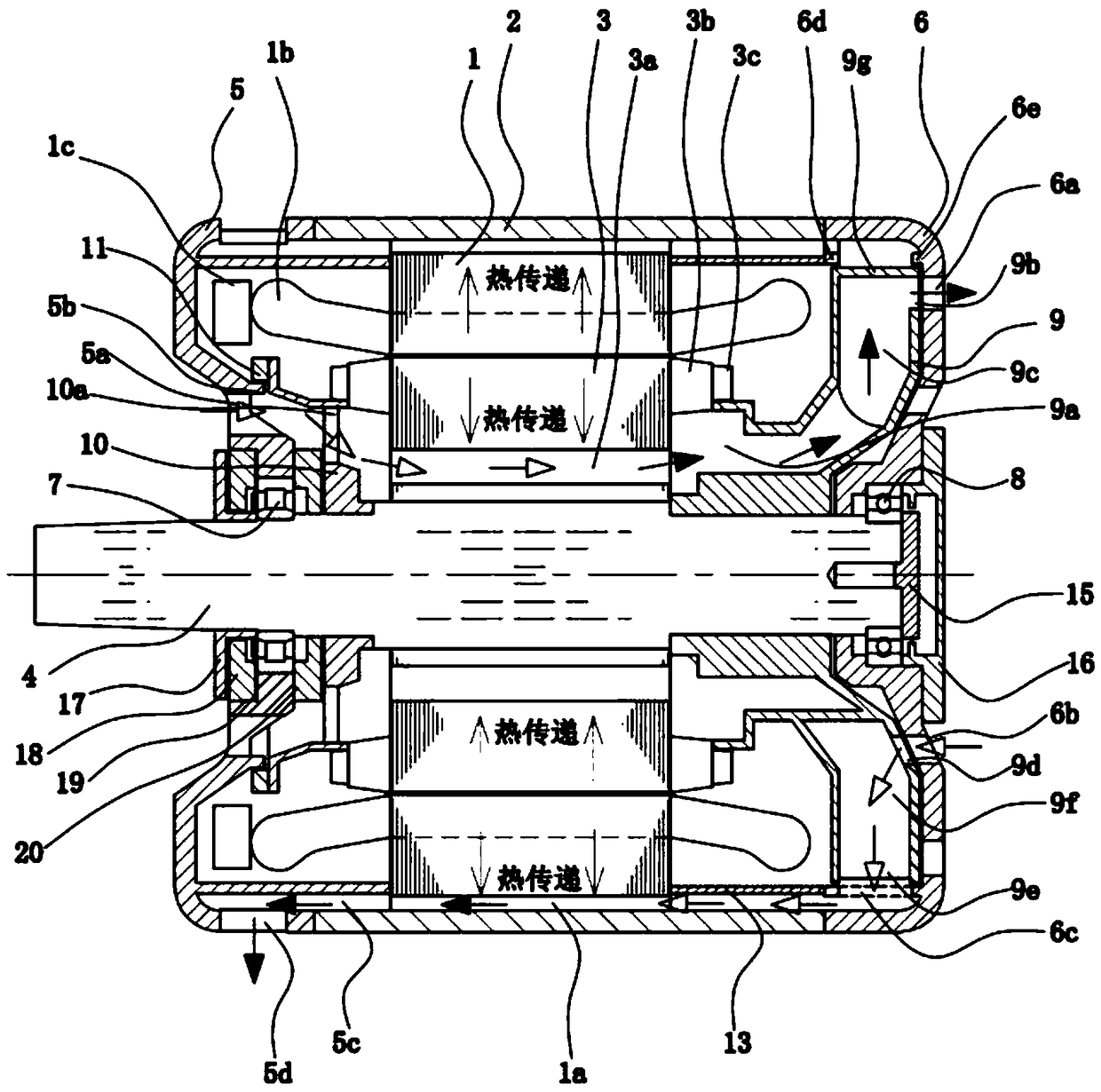

Electric motor

InactiveCN109274216AGuaranteed cooling effectAvoid insulation failureMagnetic circuit rotating partsAsynchronous induction motorsElectric machineThree phase asynchronous motor

The invention discloses a fully enclosed motor which adopts a dual-channel fan to realize stator-rotor separate cooling, and adopts a unique dual-channel fan 9 with a motor structure to realize a combined cooling mode of stator enclosed ventilation cooling and rotor open ventilation cooling of a three-phase asynchronous motor. This combined cooling method ensures the reliability of stator insulation and the heat dissipation ability of rotor, and improves the efficiency of the motor. The dual-channel fan 9 is capable of functioning as two fans, so that the motor structure is compact. The bladesof the two-channel fan 9 are divided into two groups 9c and 9f, which are circumferentially staggered. The air ducts 5a, 10a, 3a, 9a, 9c, 9b, 6a form independent rotor cooling ducts; The air ducts 6b, 9d, 9f, 9e, 2a form separate stator cooling ducts. The protrusion 5b forms a labyrinth seal with the toothed disk 11; Fan out circle 9g cooperates with small clearance of convex 6d and 6e to isolatethat stator and rotor spaces.

Owner:高建鑫

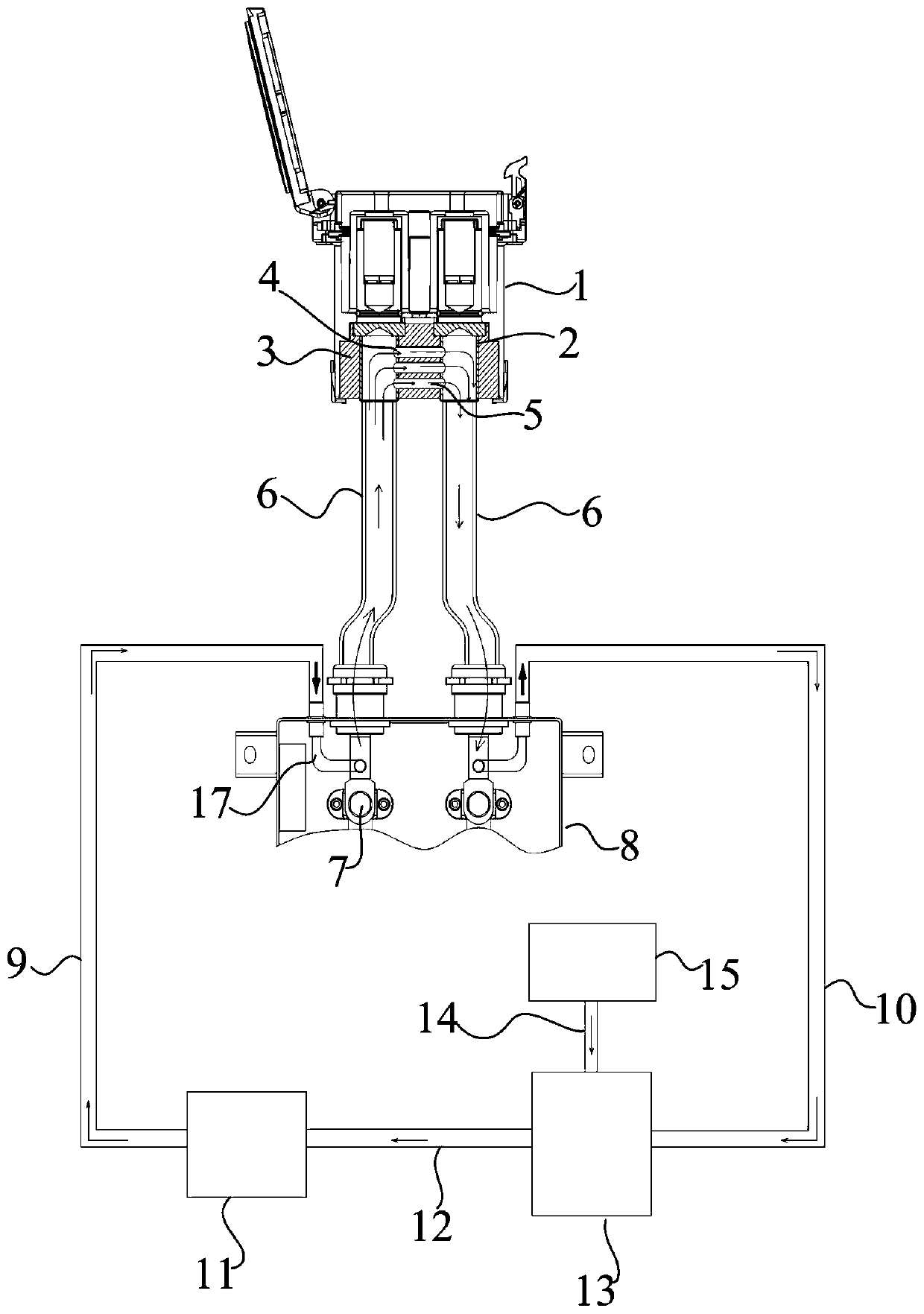

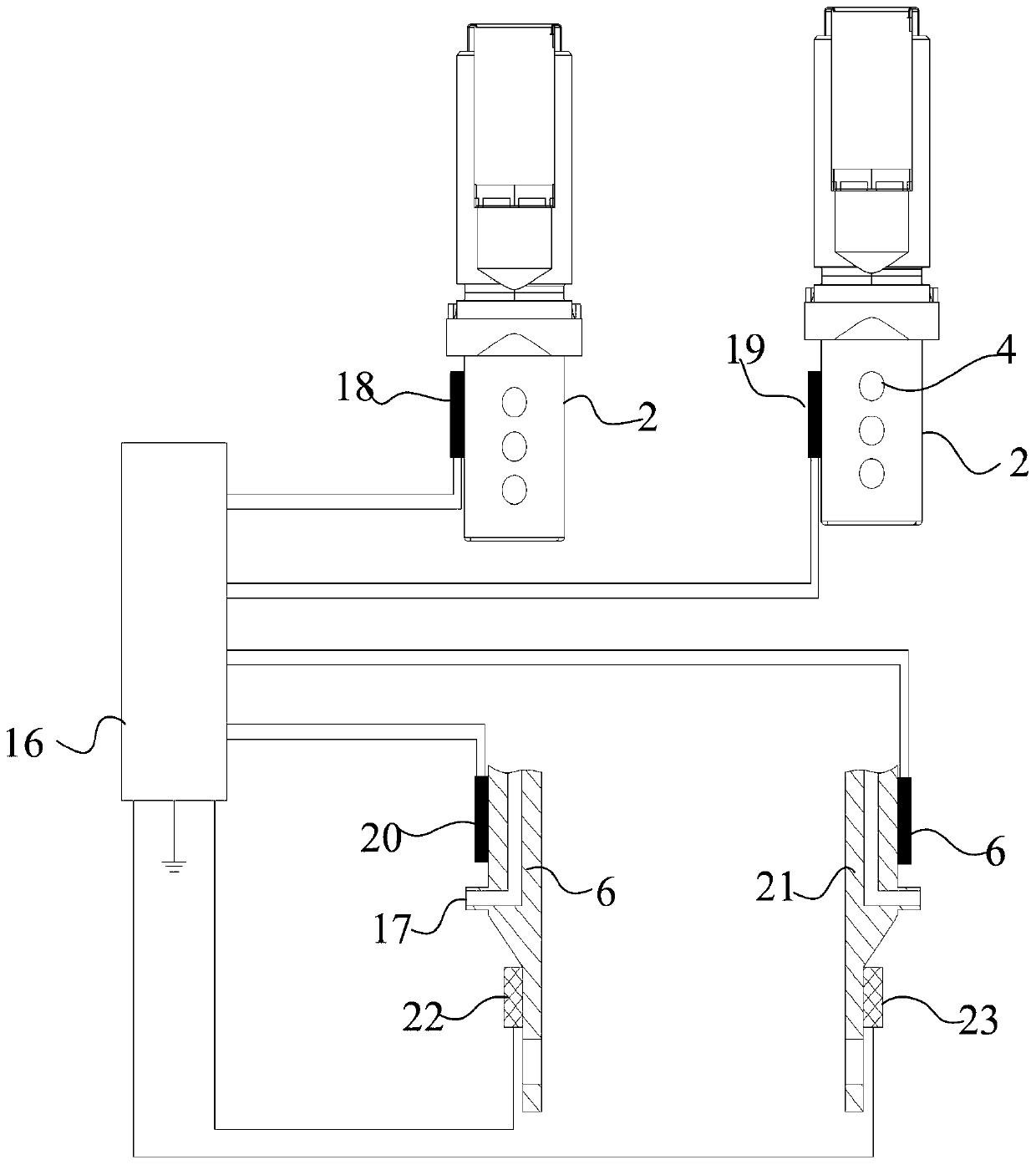

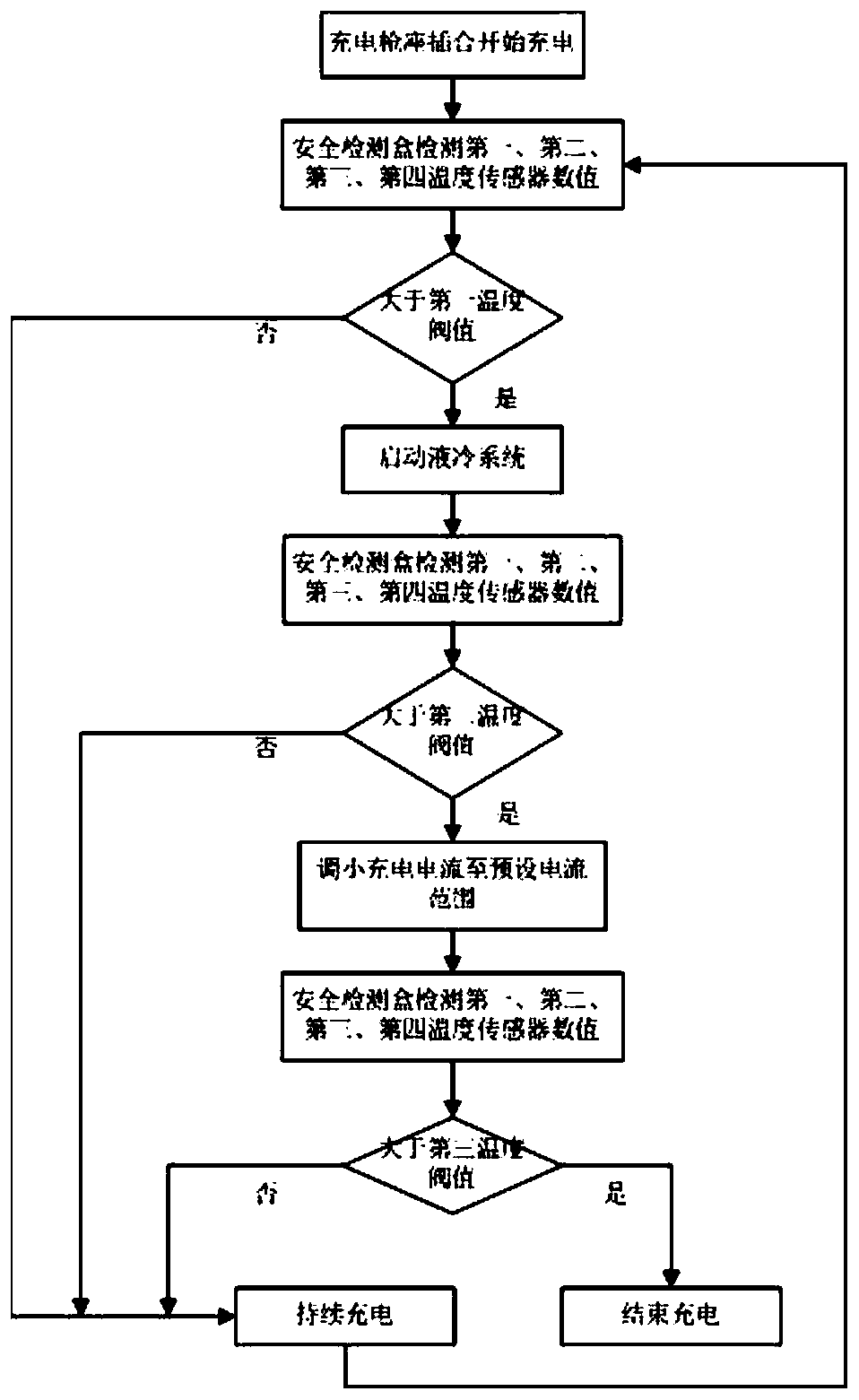

Liquid cooling charging system for new energy automobile and control method

ActiveCN110758140AImprove cooling effectEnsure safetyVehicle connectorsCharging stationsThermodynamicsNew energy

The invention belongs to the technical field of charging of new energy vehicles, and particularly relates to a liquid cooling charging system for a new energy vehicle and a control method. The systeminvolves a charging socket, a water pump, a water inlet pipe, a water outlet pipe, a connecting water pipe, a heat dissipation water tank, a power distribution unit and a safety monitoring box, wherein the water pump and the heat dissipation water tank are connected through the connecting water pipe, the water inlet pipe is arranged at the end, away from the connecting water pipe, of the water pump, and the water outlet pipe is arranged at the end, away from the connecting water pipe, of the heat dissipation water tank. According to the liquid cooling charging system for the new energy vehicleand the control method, through the reasonable structural arrangement, the cooling effect of the liquid cooling charging system is effectively improved; through temperature sensors arranged on a charging liquid cooling terminal and a liquid cooling terminal, temperature monitoring is carried out, and the safety of the charging process is guaranteed; and meanwhile, through the arrangement of a cooling liquid insulation detection module, the insulation failure problem due to the long-term use of cooling liquid is avoided.

Owner:ZHONGTONG BUS HLDG

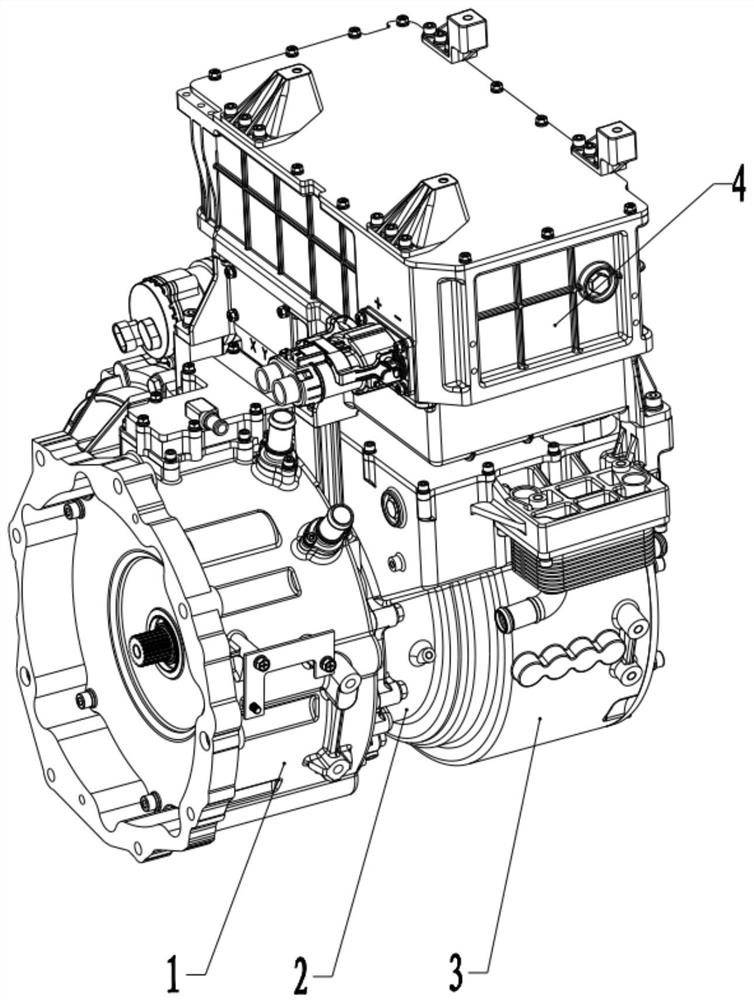

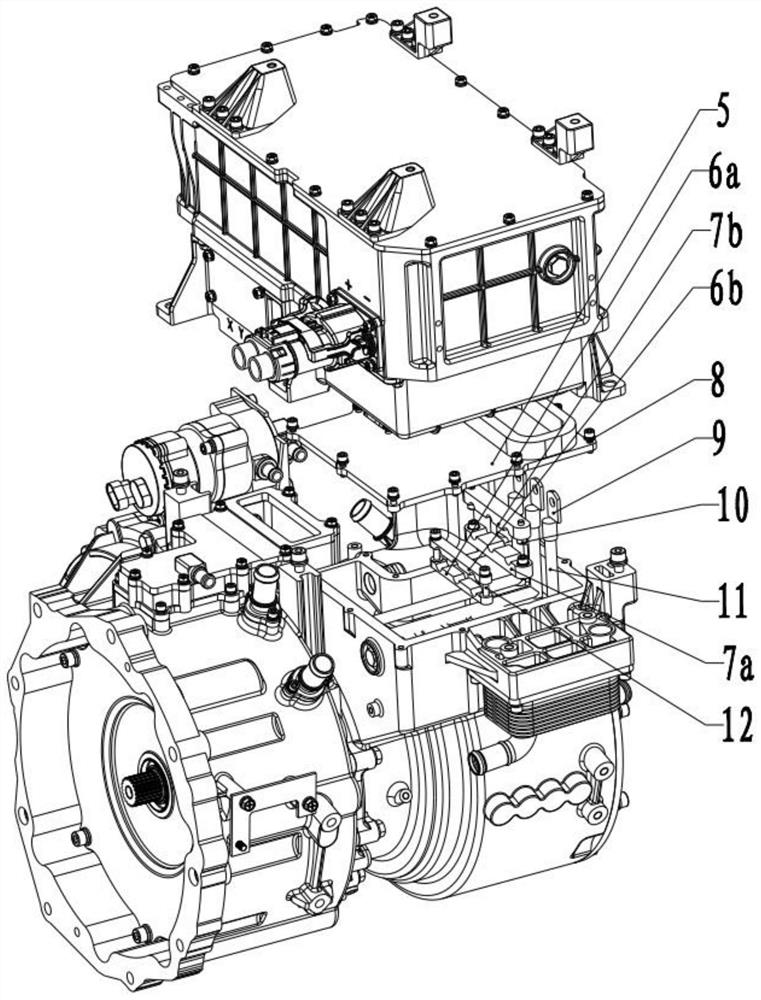

Three-phase sealing structure of oil-cooled motor

InactiveCN112615466AReduced risk of insulation failureAvoid exposureCooling/ventillation arrangementSupports/enclosures/casingsElectric machineReduction drive

The invention discloses a three-phase sealing structure of an oil-cooled motor. The three-phase sealing structure comprises a generator, a speed reducer, the oil-cooled motor and a controller, wherein the generator and the oil-cooled motor are distributed on the two sides of the speed reducer, and the controller is arranged over the oil-cooled motor; the oil-cooled motor comprises a three-phase cover plate, an oil-cooled motor casing, a first three-phase buckle and a second three-phase buckle; the oil-cooled motor is connected and sealed through a three-phase cover plate, and the three-phase cover plate and the oil-cooled motor shell form a three-phase sealing structure; the first three-phase buckle is used for fixing a three-phase line to form a fixed path, and the second three-phase buckle is used for sealing a three-phase outgoing line. A three-phase line is led out from a motor stator winding, is fixed through a first three-phase buckle, is sealed through a second three-phase buckle and enters a three-phase chamber, and a three-phase line copper nose extends into the controller. The three-phase line and the copper nose are completely isolated, the risk of insulation failure of the motor is reduced, motor oil mist is prevented from entering the controller in a high-temperature environment, and the risk of failure of electrical components is reduced.

Owner:HEFEI JUYI POWER SYST CO LTD

Stator coil of DC motor and DC motor

ActiveCN108288884BImprove temperature riseExtended service lifeWindings insulation shape/form/constructionWindings conductor shape/form/constructionDC - Direct currentStator coil

The invention provides a stator coil of a direct current motor and a direct current motor, and relates to the technical field of a direct current motor. The stator coil of the direct current motor includes: a copper bus bar with a plurality of turns, an insulation paper tape and a silicone rubber insulation tape. The multi-turn copper bus bar is configured as a coil profile of the stator coil of the direct current motor. The insulation paper tape is placed between two adjacent turns of the copper bus bar. The outer side of the multi-turn copper bus bar is wrapped with the silicone rubber insulation tape. The direct current motor comprises the above stator coil of the direct current motor. The stator coil of the direct current motor can effectively improve the temperature rise without changing the size and voltage of the direct current, the service life is ensured, and the output power and the torque is improved for better use.

Owner:NEW UNITED RAIL TRANSIT TECH

DC cable connector

InactiveCN106486959AEasy to install on siteGuaranteed uptimeCable junctionsInsulation layerEngineering

The invention provides a DC cable connector which comprises a cylindrical high voltage shielding layer 7, cylindrical joint insulation layers 9 and a joint shielding layer 10 which are coaxially arranged from inside to outside. Coaxial symmetrical horn-shaped stress cones 8 are embedded to the inner walls of the joint insulation layers 9 of two ends of the cylindrical high voltage shielding layer 7, and two horn openings are symmetrical. Each of the horn-shaped stress cones 8 comprises a cylindrical narrow port end and a wide port end whose axial section is a pair of symmetrical arcs. The inner wall of each of the joint insulation layers 9 is provided with a groove for embedding the narrow ends of the stress cones 8 and a convex block for embedding the high voltage shielding layer 7. According to the DC cable connector, the connector structure design is optimized, the electric field intensity in a stress cone root, a high voltage shielding layer root and the joint insulation layers is reduced, the field intensity distribution in the joint is uniform, and the joint insulation space charge excessive accumulation and electric field breakdown caused by high field intensity are avoided.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

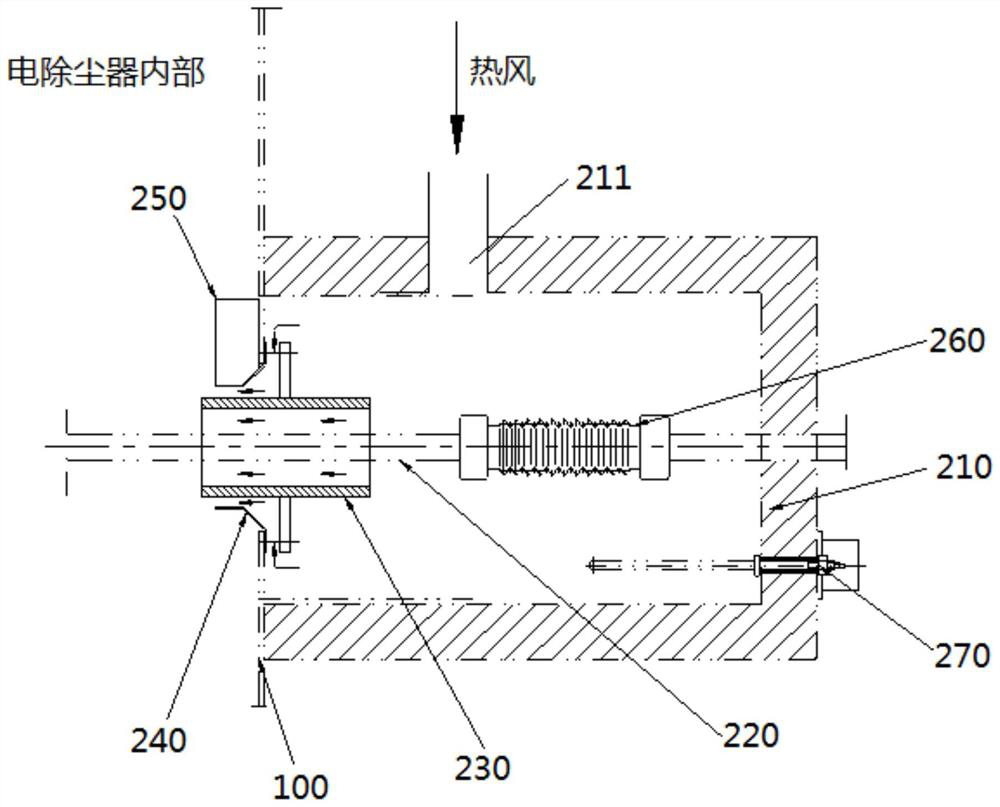

Electric dust remover and cathode rapping insulation device thereof

PendingCN114433360AAvoid accumulationAvoid stickingElectric supply techniquesElectrodes cleaningEngineeringLantern

The invention discloses an electric dust remover and a cathode rapping insulation device thereof.The cathode rapping insulation device comprises a rapping shaft and a rapping box, and the rapping shaft penetrates through a wall plate of an electric dust remover shell and extends into the electric dust remover; the device further comprises an insulating pipe, a lantern ring and a hot air source. The vibrating shaft is sleeved with the insulating pipe, the insulating pipe and the vibrating shaft are not in contact, one end of the insulating pipe is located in the vibrating box, and the other end of the insulating pipe is located in the electric dust remover; the lantern ring is sleeved outside the insulating pipe, the lantern ring and the insulating pipe are not in contact, one end of the lantern ring is fixedly connected with the wall plate in a sealing manner, and the other end of the lantern ring extends into the electric dust remover; an air inlet is formed in the rapping box, and the hot air source is communicated with the air inlet, so that hot air enters the rapping box, and air curtains are formed between the insulating pipe and the rapping shaft and between the lantern ring and the insulating pipe. The device can ensure the insulation effect of the cathode rapping shaft.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD +1

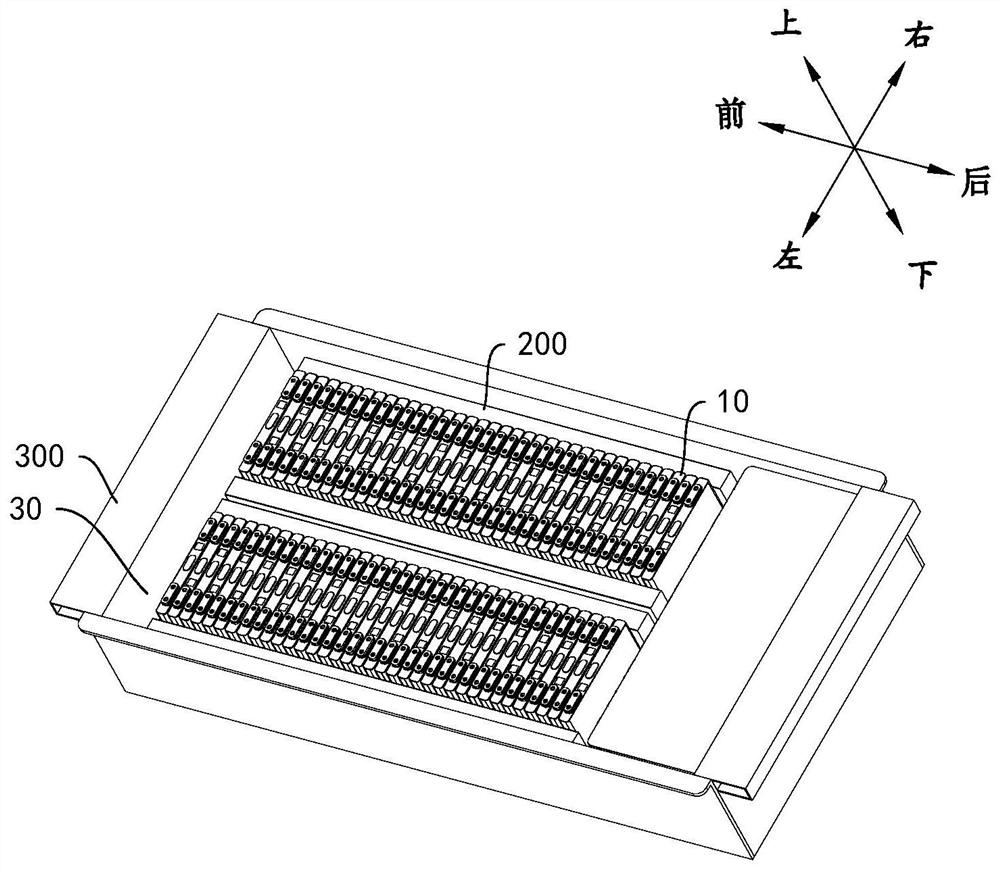

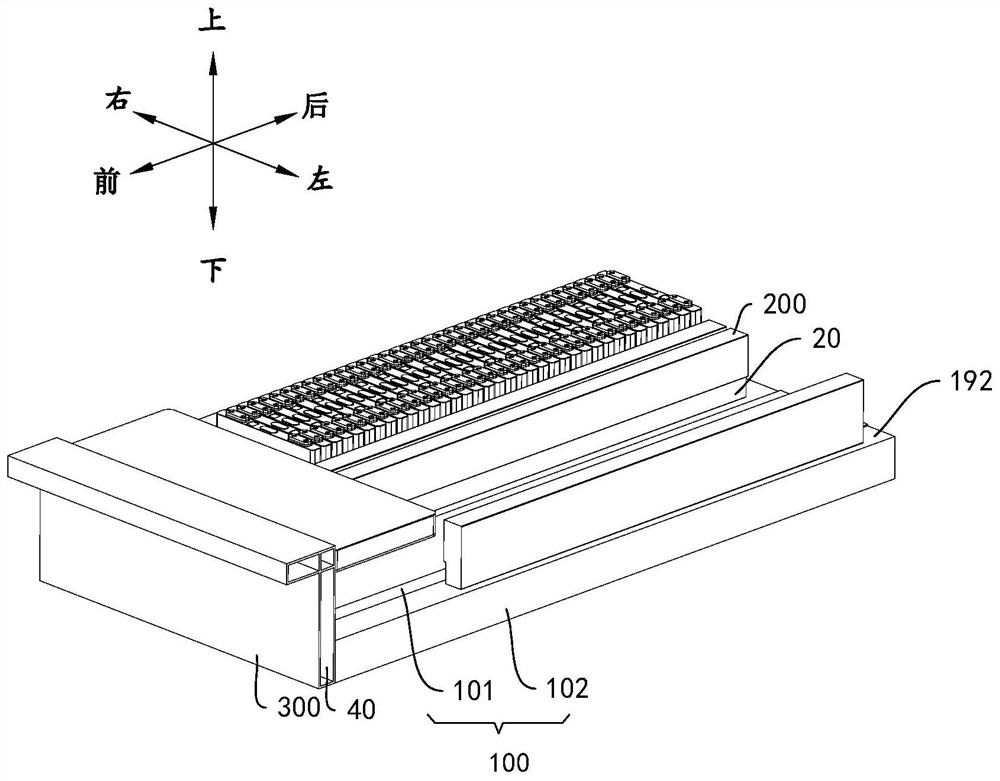

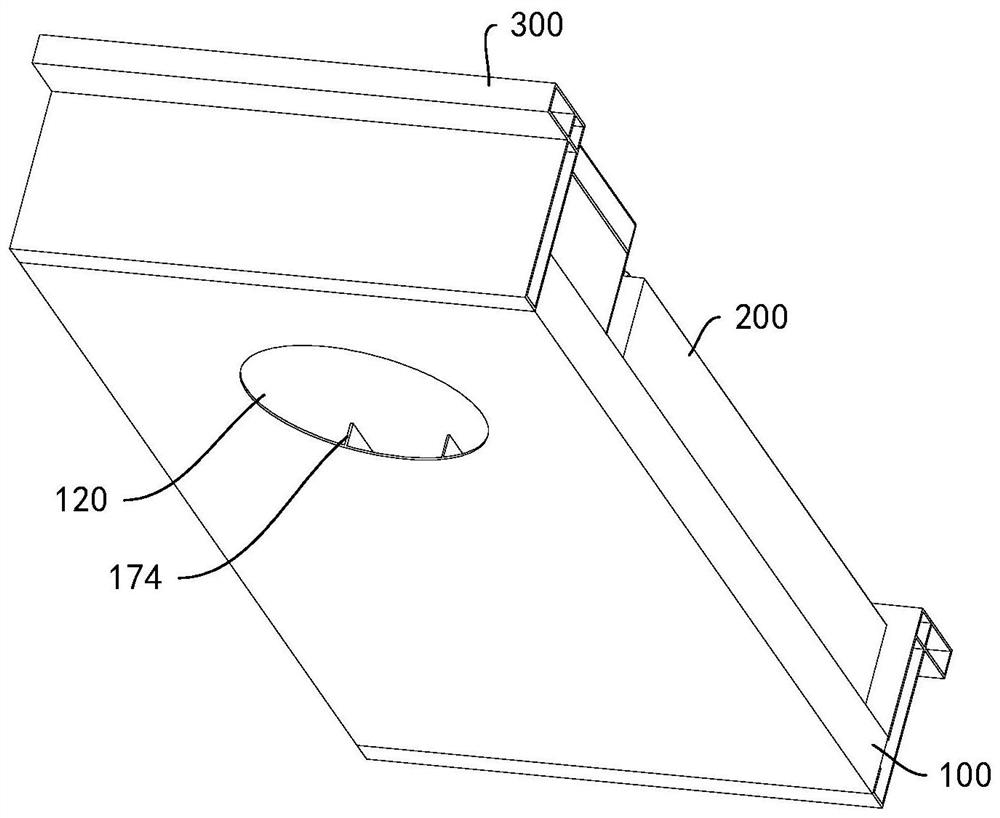

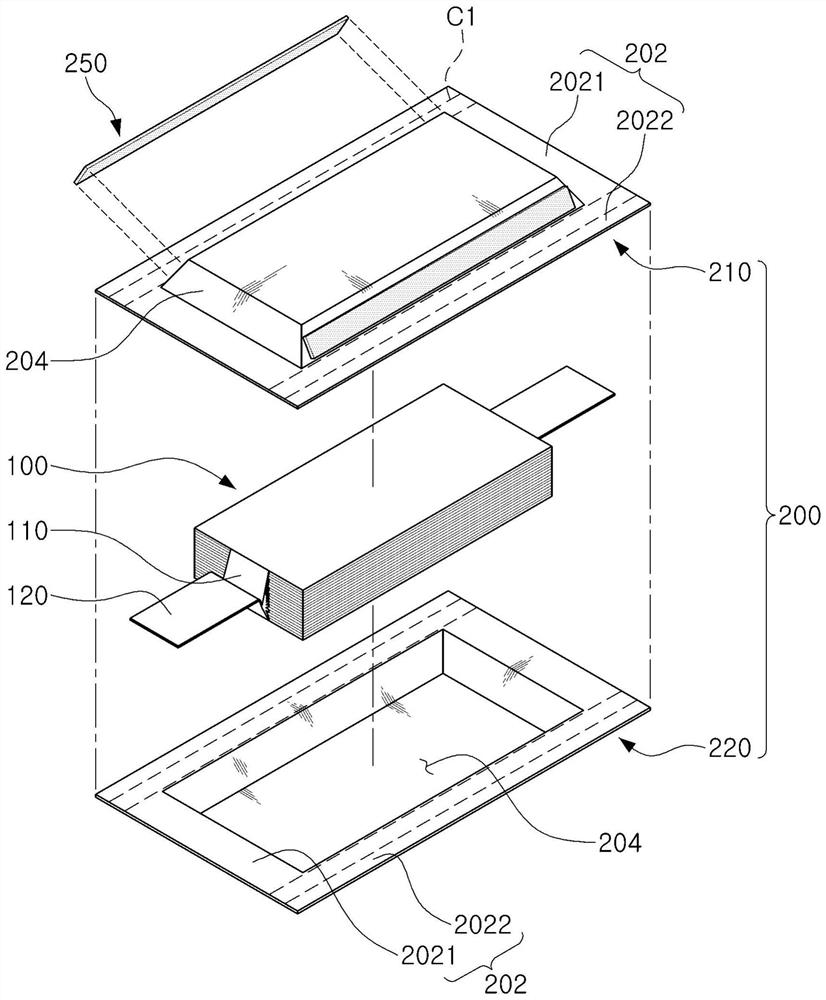

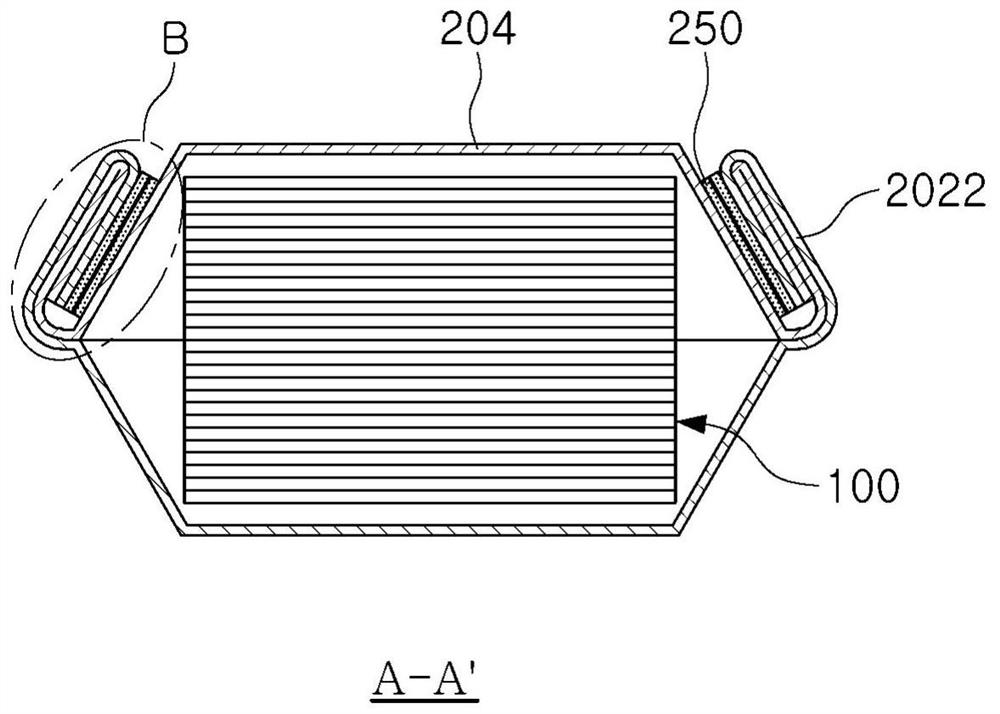

Battery cell module and electric vehicle

PendingCN113097636AAvoid insulation failureSecondary cellsCell component detailsSurface coolingCooling chamber

The invention discloses a battery cell module and an electric vehicle. The battery cell module comprises a box body, a plurality of side boxes and a plurality of battery cells, the box body is provided with a first mounting surface, a second mounting surface, a main cooling chamber and a cooling medium outlet, the side boxes are provided with side cooling chambers, the side cooling chambers are bidirectionally communicated with the main cooling chamber, the side boxes are arranged on the second mounting surface, the bottom surfaces of the square battery cells are attached to the first mounting surface, and the two opposite side surfaces abut against the surfaces of the side boxes. A cooling medium enters the side cooling chambers through the main cooling chamber, then returns to the main cooling chamber through the side cooling chambers, and finally leaves the box body through the cooling medium outlet. The bottom of the battery cell is attached to the first mounting surface, and the two sides of the battery cell abut against the side surface of the side box, so that when the cooling medium flows in the battery cell module, the cooling medium does not make contact with the battery cell, the purpose of cooling the square battery cell can be achieved, and the insulation failure of the battery cell is avoided.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

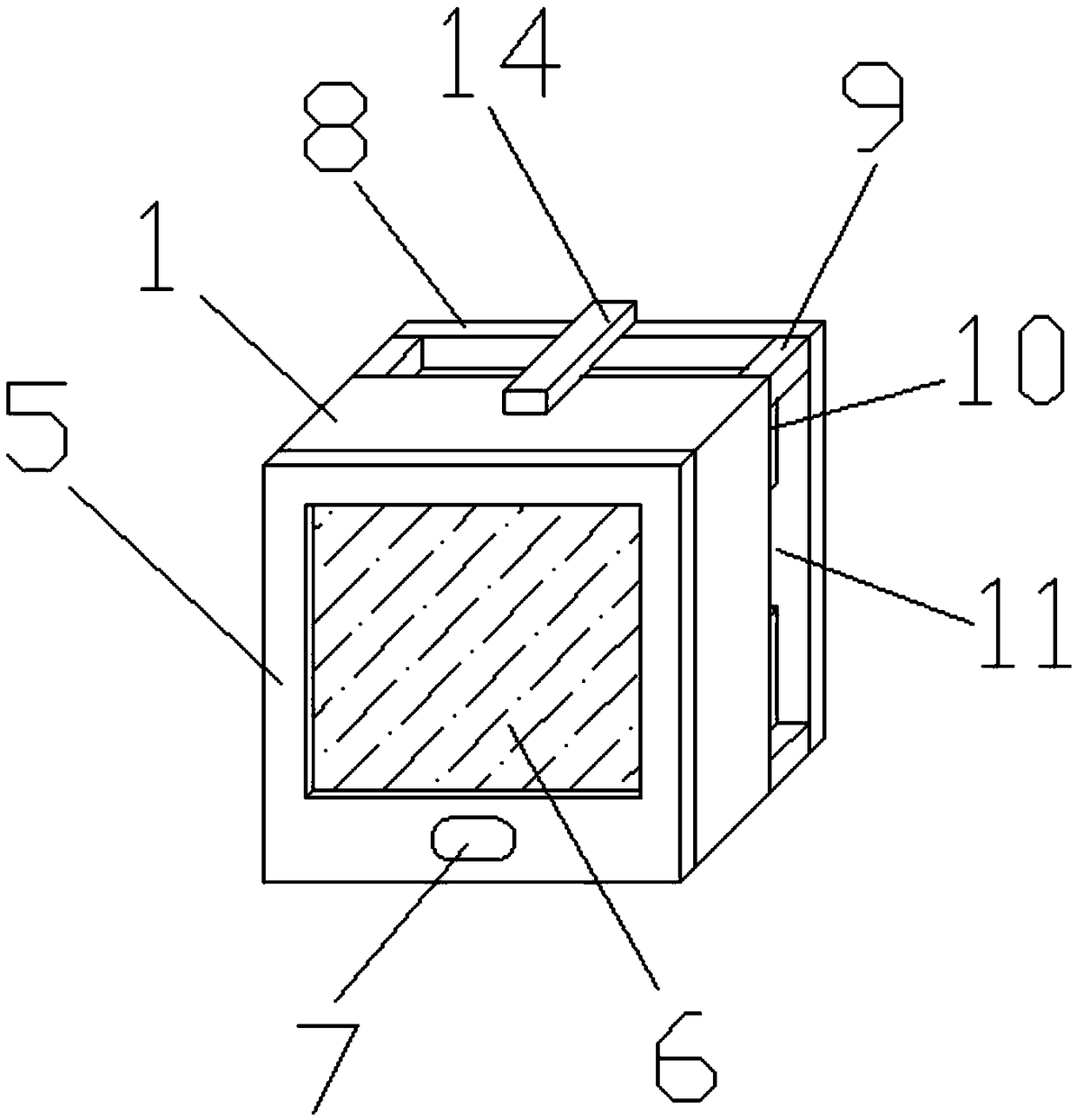

Micro-visual temperature measuring device

InactiveCN109489861ACompact connectionEasy to useThermometer applicationsInformation processingMagnet

The invention discloses a micro-visual temperature measuring device. The micro-visual temperature measuring device comprises a shell, a storage battery, a rubber plate, a circuit board, a panel, a display screen, a button, an installing plate, a supporting column, a heat insulation block, a fixed opening, a sensor, a magnet and a connecting bridge. The micro-visual temperature measuring device hasthe advantages that the insulation and deformable rubber plate is padded between the storage battery and the circuit board, it is avoided that the circuit board is in contact with the storage batteryto cause an insulation fault, heat generated when the circuit board works can also be isolated, and it is avoided that the temperature of the surface of the storage battery is over high; space between the shell and the installing plate is filled with the heat insulation block made from a heat insulation material, the measuring part devices are separated from the temperature displaying and information processing device parts, and it is avoided that due to the high temperature precision equipment such as the display screen and the circuit board is damaged. The micro-visual temperature measuringdevice is small and exquisite in using and convenient to check, and is particularly suitable for temperature measurement of some narrow areas.

Owner:ZHENGZHOU HAIWEI OPTOELECTRONICS TECH CO LTD

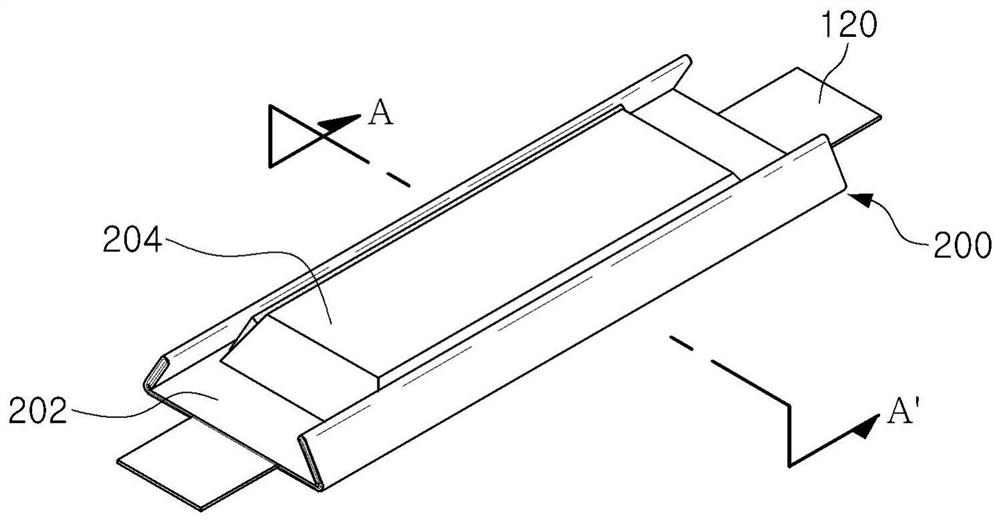

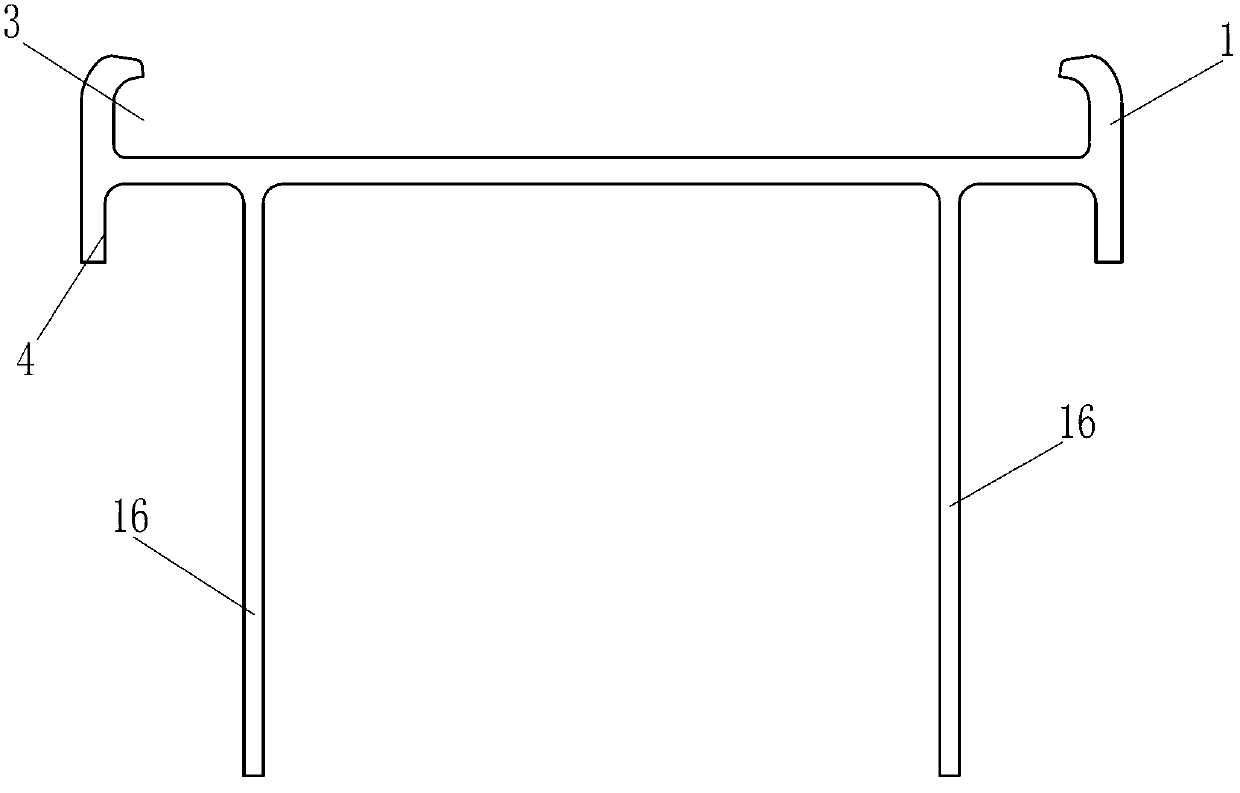

Battery cell and method for manufacturing same

PendingCN111712939AMaximize Volumetric EfficiencyAvoid excessive diffusionLarge-sized flat cells/batteriesFinal product manufactureMechanical engineeringBattery cell

A battery cell according to an embodiment of the present invention comprises an electrode assembly; a case including a reception part for receiving the electrode assembly and a sealing part formed along the periphery of the reception part; and a fixing member interposed between the reception part and the sealing part and bonding the reception part and the sealing part to each other, wherein the fixing member includes a core layer and adhesive layers staked on both surfaces of the core layer, respectively.

Owner:SK ON CO LTD

Sub-rail isolating protective sleeve

ActiveCN103088728ASimple structureCompact structureRailway tracksForeign matterStructural engineering

The invention relates to a sub-rail isolating protective sleeve. The sub-rail isolating protective sleeve comprises an isolating protective sleeve body, wherein the isolating protective sleeve body comprises a fixed support and a skirt plate; a clamping groove structure is arranged on the upper part of the fixed support and corresponds to the bottom of a steel rail; the skirt plate comprises two sub skirt plates; the two sub skirt plates are arranged on two sides of the lower part of the fixed support along the longitudinal direction of the steel rail respectively, or a cavity is formed in the skirt plate along the longitudinal direction or the vertical direction of the steel rail; and the skirt plate is arranged below the fixed support. The sub-rail isolating protective sleeve has the characteristics of diverse structure, convenience in installation and maintenance, high economic efficiency and wide application range; and after the sub-rail isolating protective sleeve is assembled at the bottom of the steel rail, the space between the steel rail between two sleepers and a ballast bed is relatively closed, so that foreign matters are prevented from entering the lower part of the steel rail, potential safety hazards are eliminated, and the market prospect is very wide.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +1

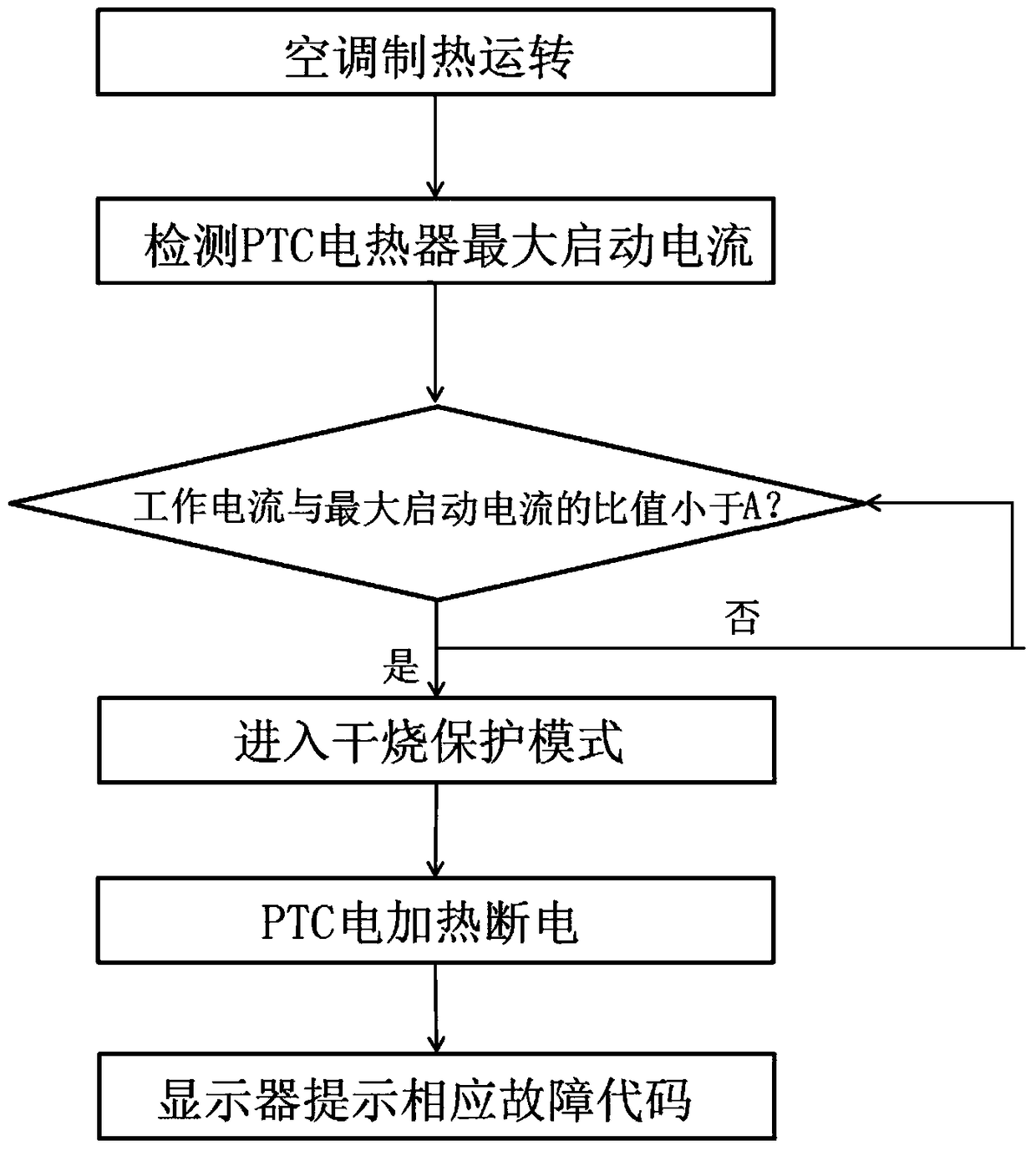

A PTC electric heater dry burning protection method and device and household appliances

ActiveCN105357780BAvoid Accelerated DecayAvoid insulation failureOhmic-resistance heating detailsPower flowEngineering

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com