Method for manufacturing multilayer PCB in plate pressing mode

A technology of PCB board and manufacturing method, applied in the field of multi-layer PCB board press plate manufacturing, can solve the problems of layer and layer offset, PCBA failure, affecting the bonding force between PCB layers and layers, etc., to achieve the effect of fewer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

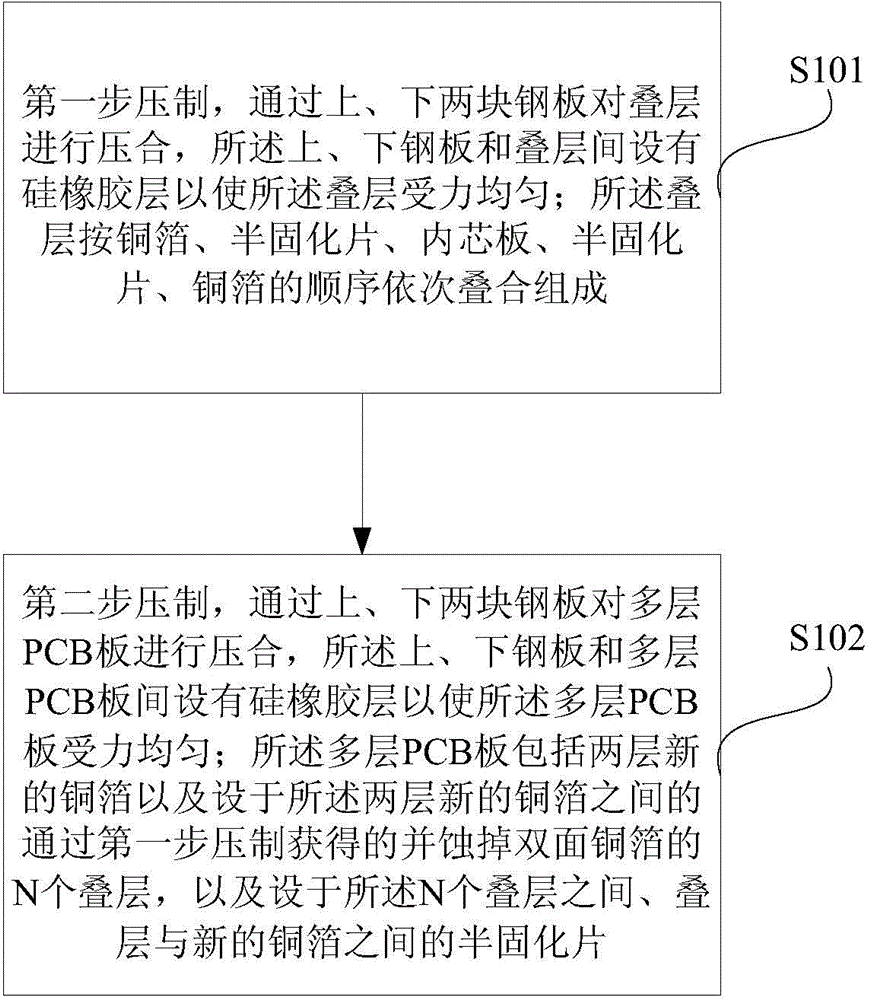

[0023] figure 1 The flow chart of the method for manufacturing a multi-layer PCB plate pressing plate provided by Embodiment 1 of the present invention, the specific steps include:

[0024] S101: the first step is pressing, the lamination is pressed by two upper and lower steel plates, and a silicon rubber layer is provided between the upper and lower steel plates and the lamination so that the lamination is evenly stressed; the lamination It is composed of copper foil, prepreg, inner core board, prepreg and copper foil in sequence;

[0025] S102: the second step is pressing, the multi-layer PCB board is pressed through the upper and lower two steel plates, and a silicon rubber layer is arranged between the upper and lower steel plates and the multi-layer PCB board so that the multi-layer PCB board is stressed Uniform; the multi-layer PCB board comprises two layers of new copper foils and N laminated layers obtained by pressing the first step and etching away the double-sided...

Embodiment 2

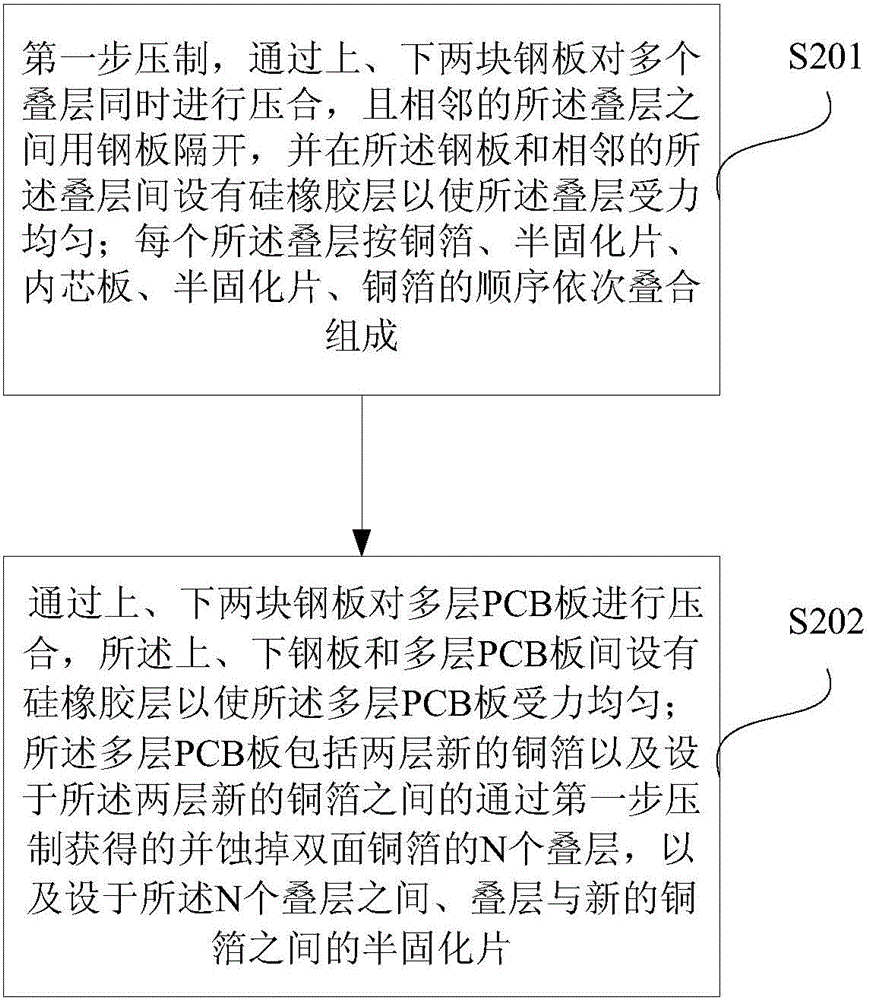

[0036] figure 2 The flow chart of the manufacturing method of the multi-layer PCB plate pressing plate provided by Embodiment 2 of the present invention, the specific steps include:

[0037] S201: The first step of pressing is to simultaneously press a plurality of laminations through the upper and lower steel plates, and the adjacent laminations are separated by steel plates, and between the steel plates and the adjacent A silicone rubber layer is provided between the laminations to make the laminations evenly stressed; each of the laminations is composed of copper foil, prepreg, inner core board, prepreg, and copper foil in sequence;

[0038] S202: the second step is pressing, the multi-layer PCB board is pressed through the upper and lower two steel plates, and a silicon rubber layer is arranged between the upper and lower steel plates and the multi-layer PCB board so that the multi-layer PCB board is stressed Uniform; the multi-layer PCB board comprises two layers of new...

Embodiment 3

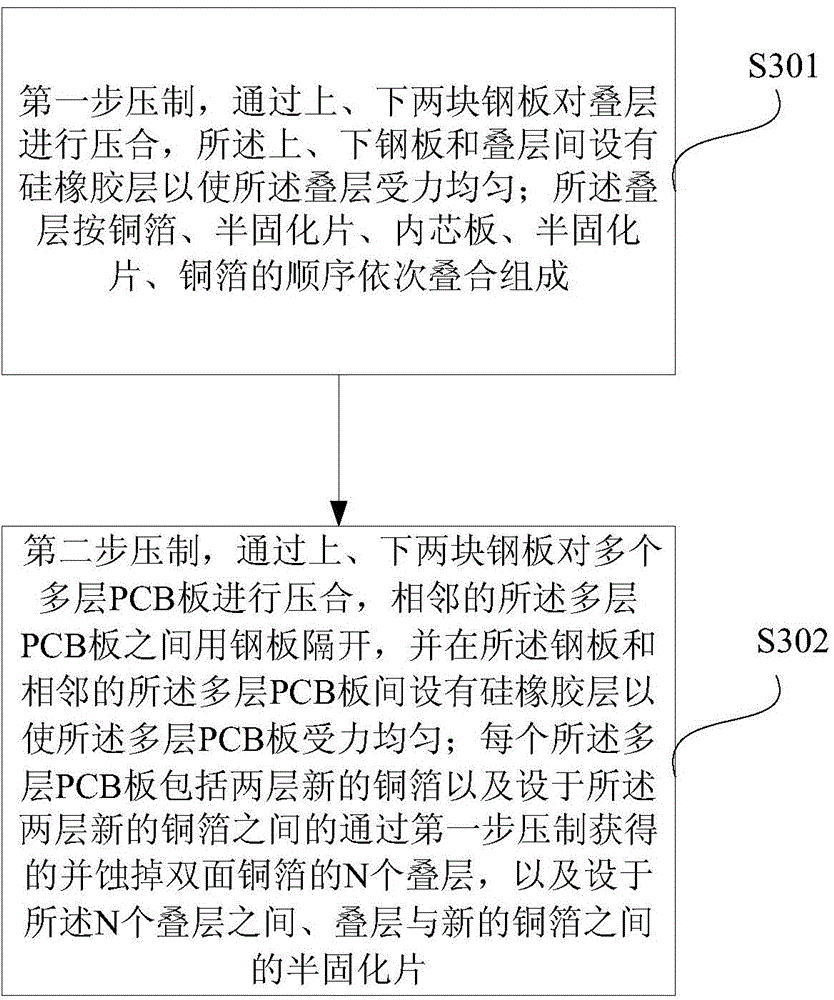

[0049] image 3 The flow chart of the method for manufacturing a multi-layer PCB board press plate provided by Embodiment 3 of the present invention, the specific steps include:

[0050] S301: the first step is pressing, the lamination is pressed by the upper and lower steel plates, and a silicon rubber layer is provided between the upper and lower steel plates and the lamination to make the lamination evenly stressed; the lamination It is composed of copper foil, prepreg, inner core board, prepreg and copper foil in sequence;

[0051] S302: In the second step of pressing, a plurality of multi-layer PCB boards are pressed together by upper and lower two steel plates, and the adjacent multi-layer PCB boards are separated by steel plates, and the steel plates and the adjacent multi-layer PCB boards are separated A silicone rubber layer is provided between the multilayer PCB boards so that the multilayer PCB boards are evenly stressed; each of the multilayer PCB boards includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com