Preparation method of graphene conductive slurry

A technology of conductive paste and graphene, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of difficult dispersion of conductive paste, easy stacking, easy agglomeration, etc., to avoid excessive local temperature and reduce preparation Effect of cost, excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

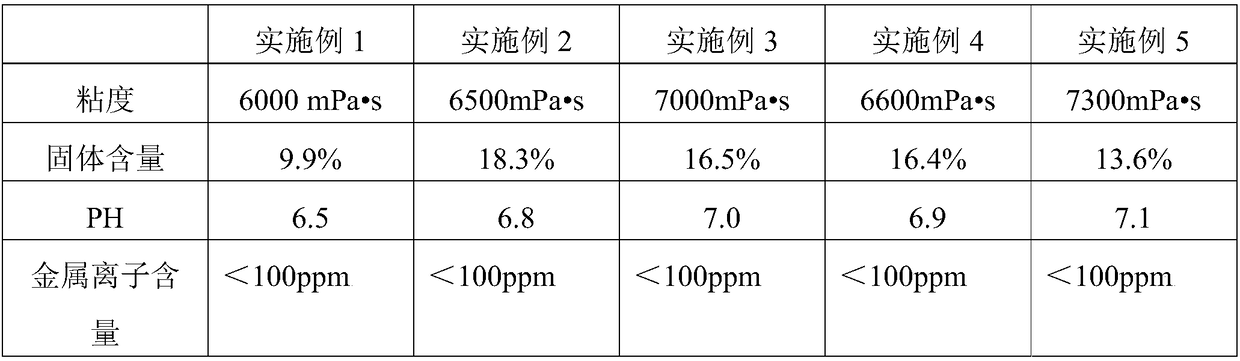

Embodiment 1

[0050] A preparation method for graphene conductive paste, comprising the following steps:

[0051] 1) 5g graphene is mixed with 100gNMP, and ultrasonically dispersed for 60min at an ultrasonic power of 1000W to ensure that graphene is completely dispersed in NMP to obtain a graphene dispersion;

[0052] 2) Add 3 g of multi-walled carbon nanotubes to 50 g of NMP, and perform ultrasonic dispersion treatment at an ultrasonic power of 1000 W for 60 minutes to ensure that the multi-walled carbon nanotubes are completely dispersed in the NMP to obtain a carbon material dispersion;

[0053] 3) After mixing the graphene dispersion obtained in step 1) with the carbon nanotube dispersion obtained in step 2), put it into a high-pressure homogenizer that can be sealed, then add 15g of lithium-ion battery special conductive agent carbon powder and 10g Superconducting carbon black, homogeneously treated for 4 hours under a pressure of 20MPa, and cooling circulating water was connected duri...

Embodiment 2

[0060] A preparation method for graphene conductive paste, comprising the following steps:

[0061] 1) 4g graphene is mixed with 80gNMP, and ultrasonically dispersed for 100min at an ultrasonic power of 1000W to ensure that the graphene is completely dispersed in the NMP to obtain a graphene dispersion;

[0062] 2) Add 25g of carbon black to 50g of NMP, and ultrasonically disperse for 30 minutes at an ultrasonic power of 800W to ensure that the carbon material is completely dispersed in the NMP to obtain a carbon black dispersion;

[0063] 3) after the graphene dispersion that step 1) obtains is mixed with the carbon black dispersion that step 2) obtains, put into a high-pressure homogenizer that can be sealed, then add 18g lithium-ion battery special conductive agent carbon powder and 22g super Conductive carbon black, homogeneous treatment at a pressure of 30MPa for 8 hours, access to cooling circulating water during the treatment process;

[0064] 4) Add 4g of PVDF into 19...

Embodiment 3

[0069] A preparation method for graphene conductive paste, comprising the following steps:

[0070] 1) 3g graphene is mixed with 80gNMP, and ultrasonically dispersed for 60min at an ultrasonic power of 1000W to ensure that the graphene is completely dispersed in the NMP to obtain a graphene dispersion;

[0071] 2) Add 10 g of acetylene black to 50 g of NMP, and perform ultrasonic dispersion treatment for 30 minutes at an ultrasonic power of 800 W to ensure that the carbon material is completely dispersed in the NMP to obtain a dispersion of acetylene black;

[0072] 3) after the graphene dispersion that step 1) obtains is mixed with the acetylene black dispersion that step 2) obtains, put into a high-pressure homogenizer that can be sealed, then add 20g lithium-ion battery special conductive agent carbon powder and 25g super Conductive carbon black, homogeneously treated at a pressure of 30MPa for 3 hours, and connected to cooling circulating water during the treatment process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com