Built-in pre-buried ultrahigh-frequency GIS internal partial discharge monitoring sensor

A monitoring sensor and ultra-high frequency technology, applied in the direction of testing dielectric strength, etc., can solve the problems of reducing the monitoring range and sensitivity to the limit, increasing the hidden danger of air leakage, reducing the insulation margin, etc., to avoid sudden changes in the electric field strength and improve monitoring. Sensitivity, effect of improving insulation margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

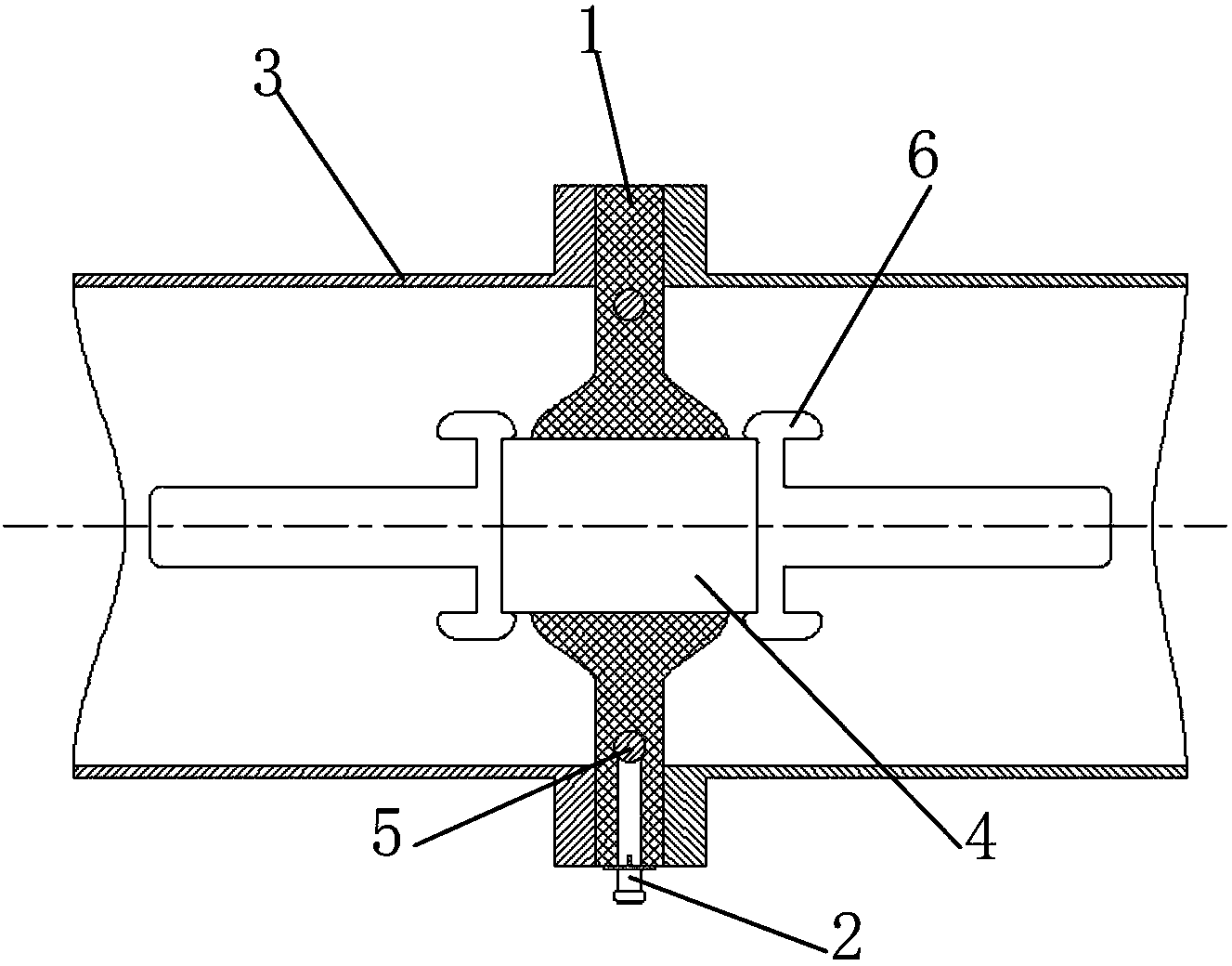

[0009] The present invention will be further described now in conjunction with accompanying drawing, figure 1 It is an embodiment of the present invention, including an insulator 1, a guide device and a radio frequency connector 2. The insulator 1 is disc-shaped, and the guide device is embedded inside the insulator 1. Usually, the guide device is poured on the insulator 1 when the insulator 1 is poured. Inside, the two form one. The insulator 1 is vertically connected to the inside of the grounding shell 3 and divides the grounding shell 3 into two chambers. The circumference of the insulator 1 is connected to the cylinder wall of the shell 3, and its edge extends out of the grounding shell 3, usually A flange is provided at the position where the insulator 1 is connected to the connecting shell 3, so that the connection with the insulator 1 can be facilitated. The guiding device includes a high-voltage conductor 4 and an antenna 5. The high-voltage conductor 4 is cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com