Three-post insulator assembly and GIL

An insulator and three-pillar technology, which is applied to electrical components, gas-filled/oil-filled cable accessories, etc., can solve the problems of high cost, large space occupation, and small insulation margin of legs, etc., to reduce the outer diameter of the cylinder and improve Effect of insulation margin and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

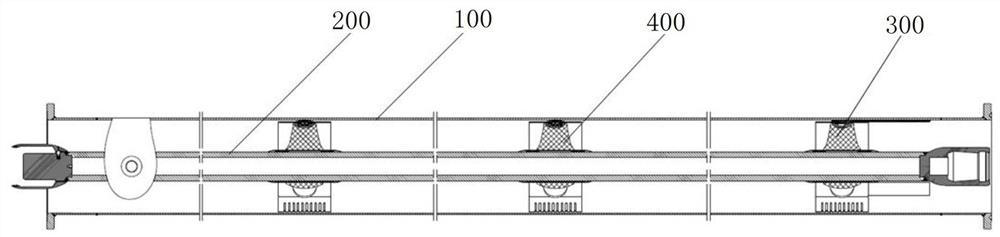

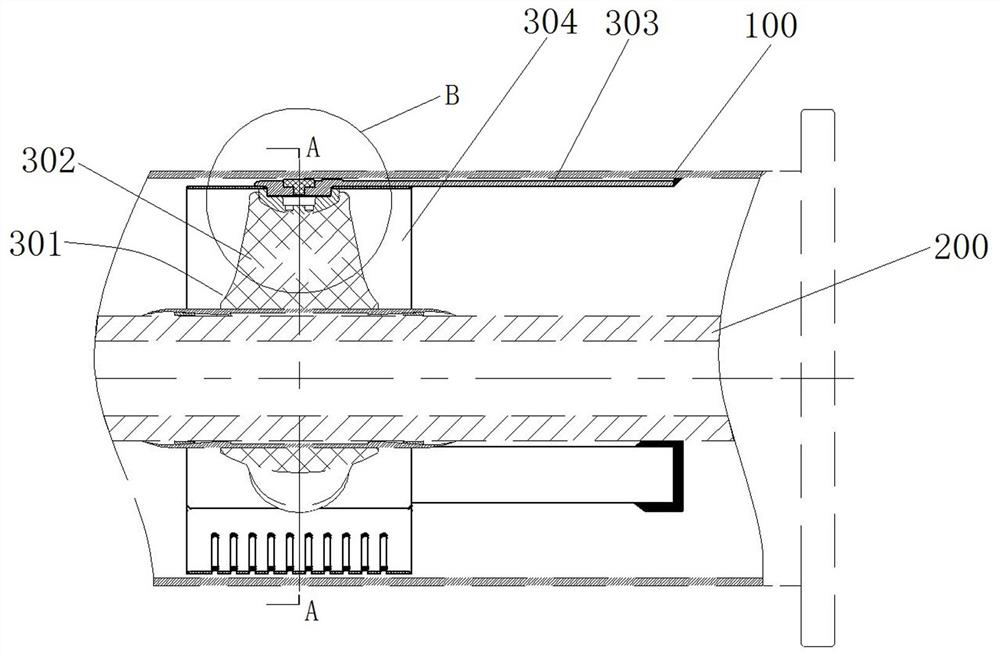

[0033] like Figure 1 to Figure 6As shown, the GIL mainly includes a cylinder body 100, a central conductive tube 200, a fixed three-pillar assembly 300 and a sliding three-pillar assembly 400, wherein the fixed three-pillar assembly 300 is fixedly assembled with the cylinder body 100 and the central conductive tube 200, and the sliding three-pillar assembly The assembly 400 is fixedly assembled with the central conductive tube 200 and can slide relative to the cylinder body 100 . For the convenience of description, the "inner" and "outer" in this embodiment both refer to the radial direction of the cylinder 100, and the ones close to the center are "inner", and the ones facing away from the center are "outer".

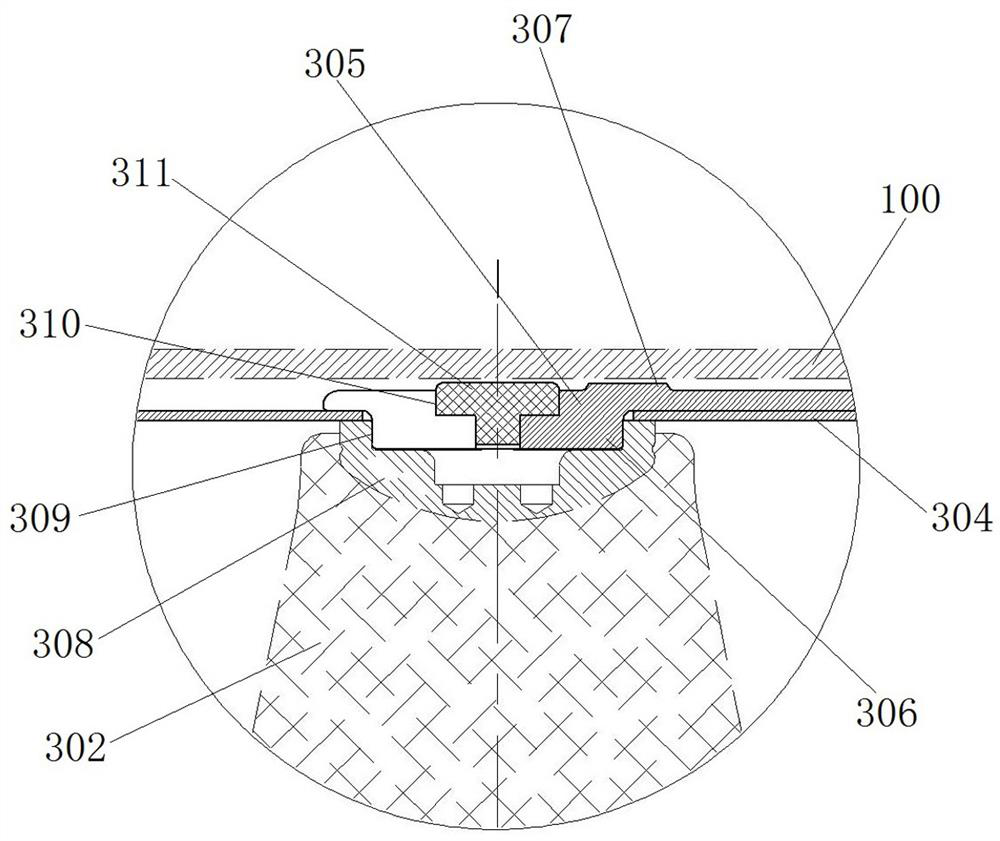

[0034] The structure of the fixed three-pillar assembly 300 is as Figure 2 to Figure 6 As shown, the fixed three-pillar assembly 300 includes a three-pillar insulator 301. The three-pillar insulator 301 includes a central conductor and three legs 302 arranged at int...

specific Embodiment 2

[0043] The difference from Embodiment 1 is that in Embodiment 1, the boss fits into the groove, and the groove is used to position the boss. In this embodiment, the size of the boss is smaller than the fit of the groove, and the positioning cannot be achieved after the boss is embedded in the groove, but because the boss and the insert will be fastened by screws at last, even if the boss cannot be in the groove The positioning in the groove will not affect the subsequent fixed connection.

specific Embodiment 3

[0045] The difference from Embodiment 1 is that in Embodiment 1, a stepped hole extending to the boss is provided on the connecting end of the insert, and a non-metal buffer gasket is embedded in the stepped hole. In this embodiment, the stepped holes are replaced with equal-diameter through holes. In other embodiments, the hole on the connecting end of the insert is eliminated, and the non-metallic buffer gasket is directly pasted on the connecting end of the insert. In other embodiments, the material of the non-metallic buffer gasket can be replaced, for example, it can be rubber. In other embodiments, the non-metallic cushioning gasket is omitted, and a soft material coated on the fixing plate is additionally added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com