Return yoke folding screen supporting structure for electric reactor

A technology of support structure and reactor, applied in the direction of transformer/inductor magnetic core, circuit, electrical components, etc., can solve the problems of increasing field strength in oil, easily damaged ground screen, small bending radian, etc. The effect of field strength value in oil, simple manufacturing process and uniform oil gap distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

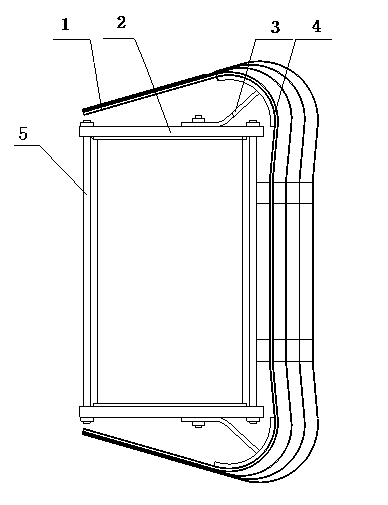

[0009] A side yoke screen supporting structure for a reactor, as shown in the figure, includes a side yoke 5, a side yoke pull plate 2 and a side yoke screen 1, supports are provided at the upper and lower corners of the side yoke 5, and the side yoke screen is wound Before 1, fix the support on the side yoke pull plate 2 to support the outside side yoke enclosure. The support is welded by the support arm 3 and the arc arm 4, and one end of the support arm 3 is fixed on the side yoke pull plate by bolts. On the board 2, the other end is welded to the middle position of the arc arm 4. The radian of the arc arm 4 is designed according to the actual field strength requirement of the reactor at the corner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com