Liquid crystal display apparatus

A liquid crystal display and equipment technology, applied in the field of liquid crystal display equipment, can solve problems such as inability to display images, degradation of display quality, increase of inductance and resistance at contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

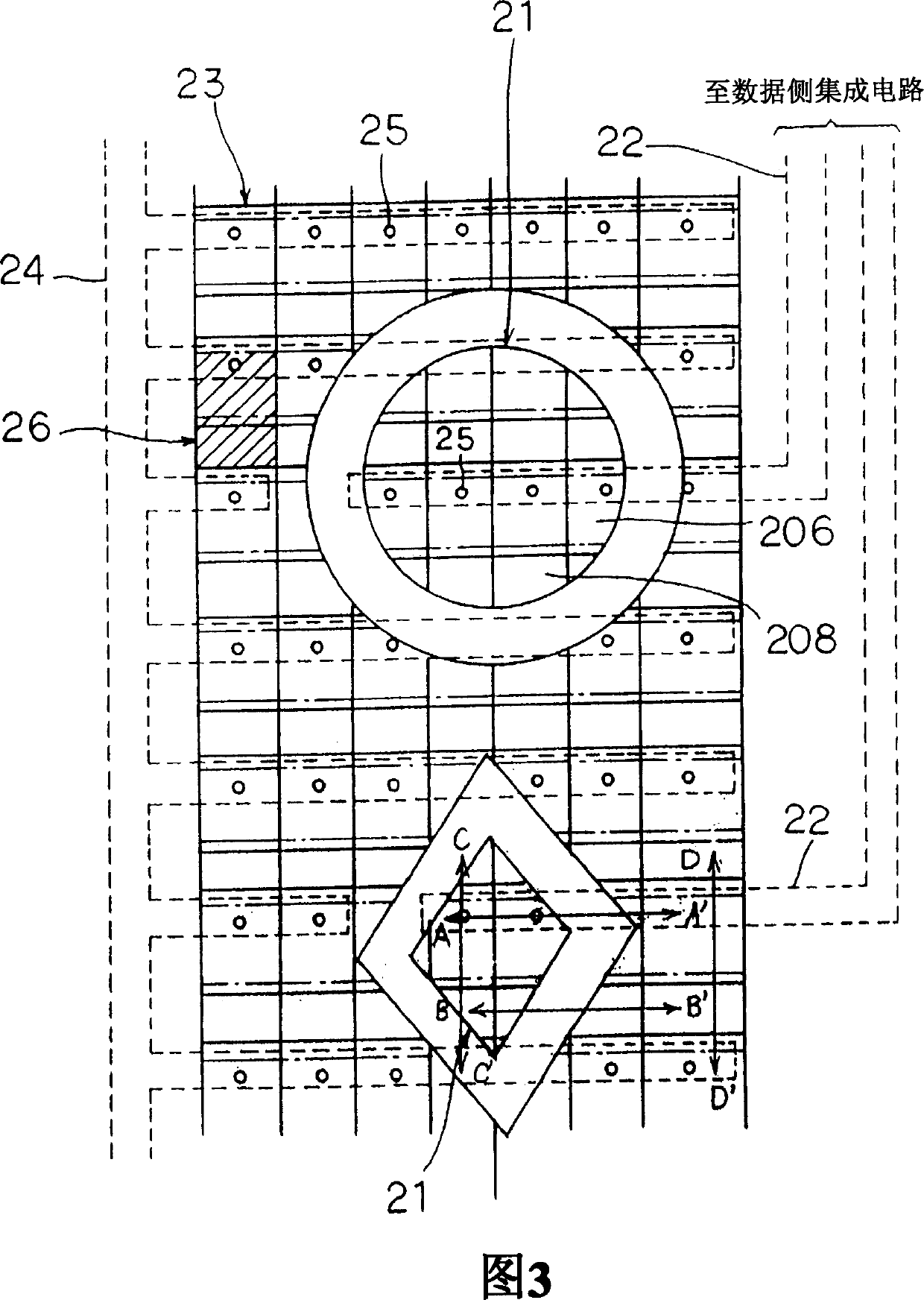

[0072] The third embodiment shows an example of a liquid crystal display device using reflective liquid crystal display elements for the dot matrix display window 6 in FIG. 1 . First, the structure of the reflective dot matrix display window 6 will be introduced with reference to FIGS. 5A and 5B.

[0073] As shown in Figure 5A, the dot matrix display window 6 in the third embodiment includes: dot matrix pixel electrodes 31, which are formed on the component substrate 1 and arranged in a grid structure; dot matrix signal electrodes 32, which straddle the insulating Layer (not shown), is formed under each dot matrix pixel electrode 31; Thin film transistor 33, it uses dot matrix signal electrode 32 as source; And contact hole 34, is used to connect dot matrix pixel electrode 31 and dot matrix signal electrode 32.

[0074] The thin film transistor 33 has a gate and a drain, the gate is connected to the scan-side integrated circuit 5 through a gate wire 35 , and the drain is conn...

no. 5 example

[0090] FIG. 7 shows a top plan view of an exemplary layout of color filters formed on a common substrate in the liquid crystal display device shown in FIG. 1 . 8 and 9 respectively show top plan views of other exemplary layouts of color filters formed on a common substrate in the liquid crystal display device shown in FIG. 1 .

[0091] The liquid crystal display device in the fifth embodiment has R (red), G (green), B (blue) color filters formed in a stripe structure in the dot matrix display window, and the R, G, B color filters are in the The graphic symbol shows that the windows form a triangular structure. Alternatively, as shown in FIG. 8 , the R, G, and B color filters in the dot matrix display window form a strip structure, and the R, G, and B color filters in the graphic symbol display window also form a strip structure. Alternatively, as shown in FIG. 9 , the R, G, and B color filters form a mosaic structure in the graphic symbol display window.

[0092] In the fift...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com