DC cable connector

A technology of DC cables and shielding layers, applied in cable joints, cable accessories, cable installation, etc., can solve the problems of uneven electric field distribution, electric field distortion at the interface, electric stress concentration, etc., to avoid excessive charge accumulation and reduce electric field. Strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

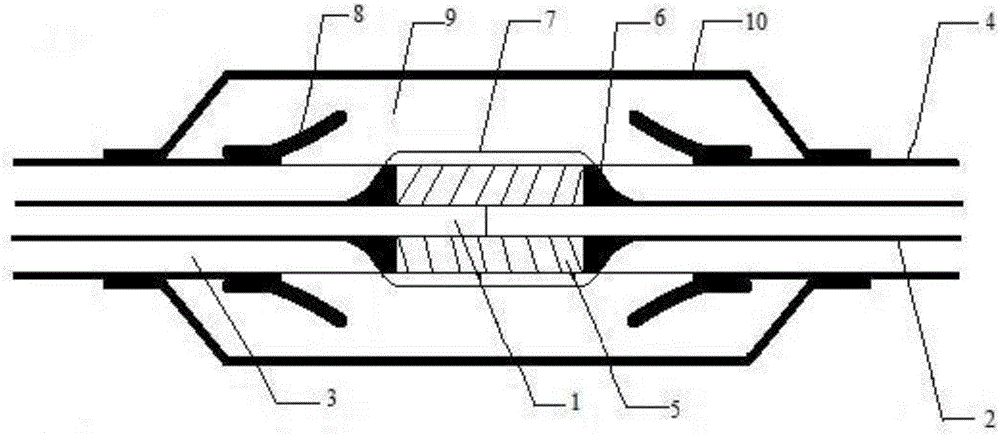

[0052] Such as figure 1 As shown, take the DC cable joint for 320kV XLPE insulated high voltage power cable as an example.

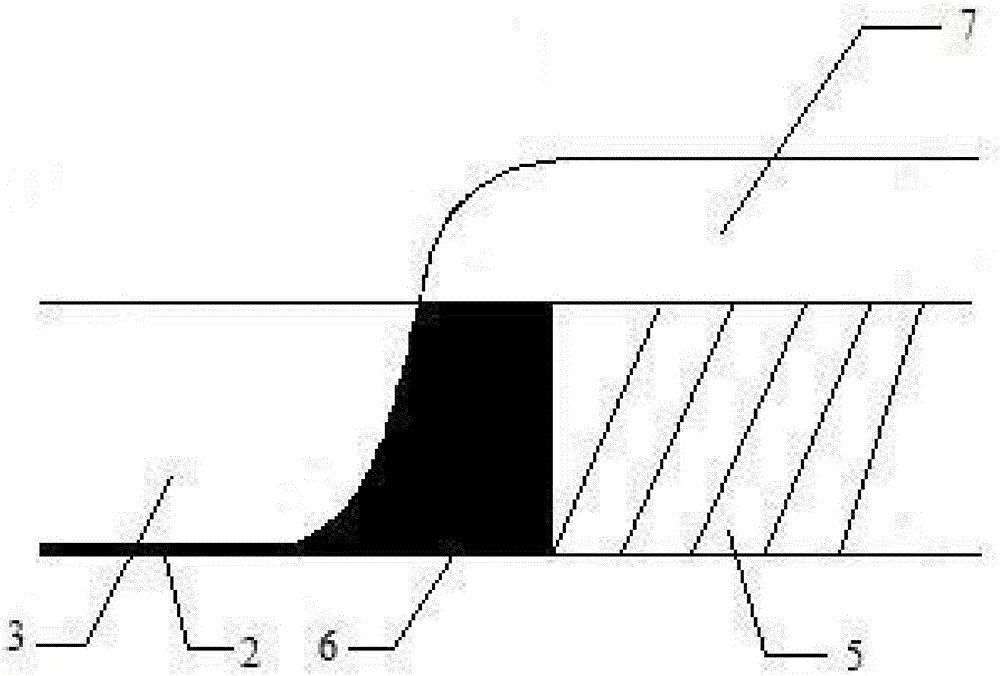

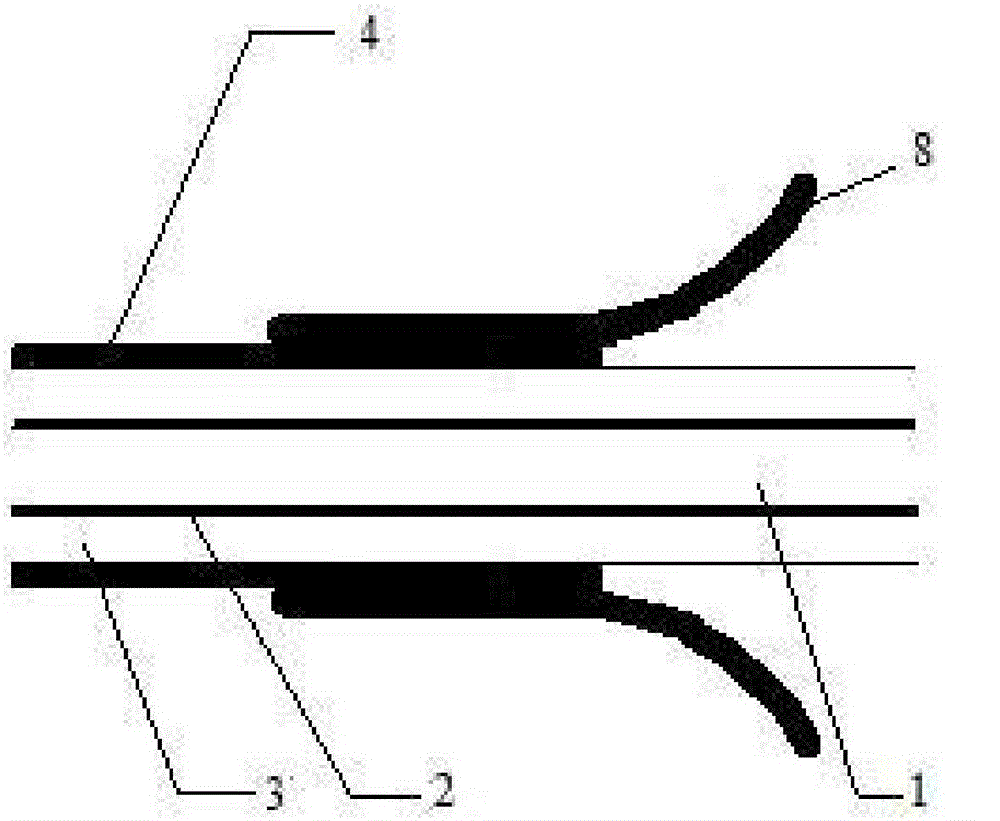

[0053] A DC cable joint, the joint includes a cylindrical high-voltage shielding layer 7, a cylindrical joint insulating layer 9 and a joint shielding layer 10 coaxially arranged in sequence from the inside to the outside, and the joint insulating layers 9 at both ends of the cylindrical high-voltage shielding layer 7 A coaxial symmetrical trumpet-shaped stress cone 8 is embedded on the inner wall, which is symmetrically called two trumpet-shaped symmetry. The trumpet-shaped stress cone 8 includes a cylindrical narrow mouth end and a wide mouth end with a pair of symmetrical arcs in the axial section. The inner wall of the insulating layer 9 is provided with a groove for embedding the narrow end of the stress cone 8 and a protrusion for embedding the high voltage shielding layer 7 .

[0054] The outer diameter of the cylindrical joint insulating layer 9...

Embodiment 2

[0072] Such as figure 1 A DC cable joint is shown, the joint includes a cylindrical high-voltage shielding layer 7, a cylindrical joint insulating layer 9 and a joint shielding layer 10 arranged coaxially from the inside to the outside, and the joint insulation at both ends of the cylindrical high-voltage shielding layer 7 The inner wall of the layer 9 is embedded with a coaxial symmetrical trumpet-shaped stress cone 8, which is symmetrically referred to as two trumpet-shaped symmetry. The trumpet-shaped stress cone 8 includes a cylindrical narrow mouth end and a wide mouth end with a pair of symmetrical arcs in axial section. The inner wall of the joint insulation layer 9 is provided with a groove for embedding the narrow end of the stress cone 8 and a protrusion for embedding the high voltage shielding layer 7 .

[0073] The outer diameter of the cylindrical joint insulating layer 9 is 230 mm, and the two ends of the joint insulating layer 9 are symmetrically arranged circul...

Embodiment 3

[0090] Such as figure 1 A DC cable joint is shown, the joint includes a cylindrical high-voltage shielding layer 7, a cylindrical joint insulating layer 9 and a joint shielding layer 10 arranged coaxially from the inside to the outside, and the joint insulation at both ends of the cylindrical high-voltage shielding layer 7 The inner wall of the layer 9 is embedded with a coaxial symmetrical trumpet-shaped stress cone 8, which is symmetrically referred to as two trumpet-shaped symmetry. The trumpet-shaped stress cone 8 includes a cylindrical narrow mouth end and a wide mouth end with a pair of symmetrical arcs in axial section. The inner wall of the joint insulation layer 9 is provided with a groove for embedding the narrow end of the stress cone 8 and a protrusion for embedding the high voltage shielding layer 7 .

[0091] The outer diameter of the cylindrical joint insulation layer 9 is 200mm, and the two ends of the joint insulation layer 9 are symmetrically arranged round p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com