Method for producing self-adhesion compound type enameled aluminium round wire

A production method and composite technology, applied in the direction of metal/alloy conductors, conductor/cable insulation, electrical components, etc., can solve the poor performance of low temperature resistance and rapid temperature change, and the stability of the quality of enamelled aluminum round wire Influence, uneven coating and other problems, achieve the effect of achieving reliability and stability, maintaining high adhesion, and saving copper resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

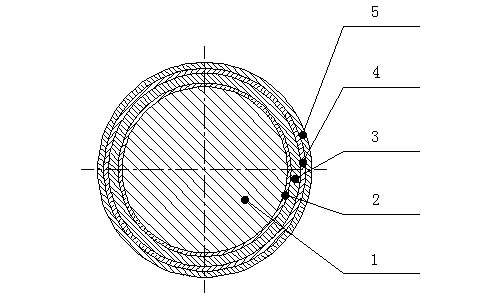

[0032] 1) On the HF456 / 1 enamelling machine with double oven and belt bag produced by MAG Company in Austria, which can operate at high speed, the electrolytic round aluminum rod with a diameter of 3.00mm and a purity of 99.6% (mass percentage) is continuously drawn to 1.000 mm diameter aluminum round wire 1, the drawing speed is synchronized with the baking speed of the enameled wire;

[0033] 2) Use xylene and naphtha each accounting for 50% by weight of solvent combined with 2500Hz frequency ultrasonic waves to carry out negative pressure cleaning on the surface of the conductor, and let the conductor pass through a relatively closed negative pressure container, so that the solvent on the surface of the conductor can be negatively cleaned. pressure sucked away;

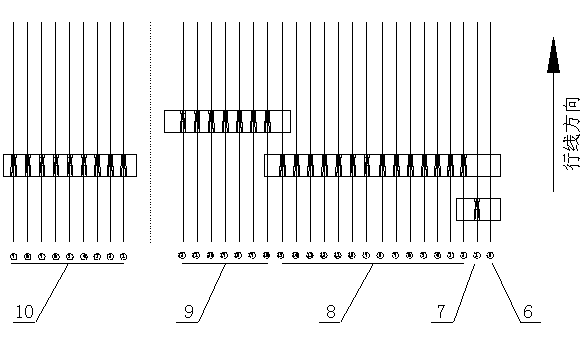

[0034] 3) Directly introduce the cleaned wires into the first oven, and first empty a 6 in the oven to avoid contact with the enameled wire varnish, and use the high temperature of 680±20°C in the first oven to sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com