Three-position operating mechanism with buffering function

An operating mechanism and three-position technology, applied in the direction of contact vibration/impact damping, etc., can solve the problems of short distance between the isolation knife and the grounding point, insulation faults, etc., and achieve the effect of avoiding insulation faults and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

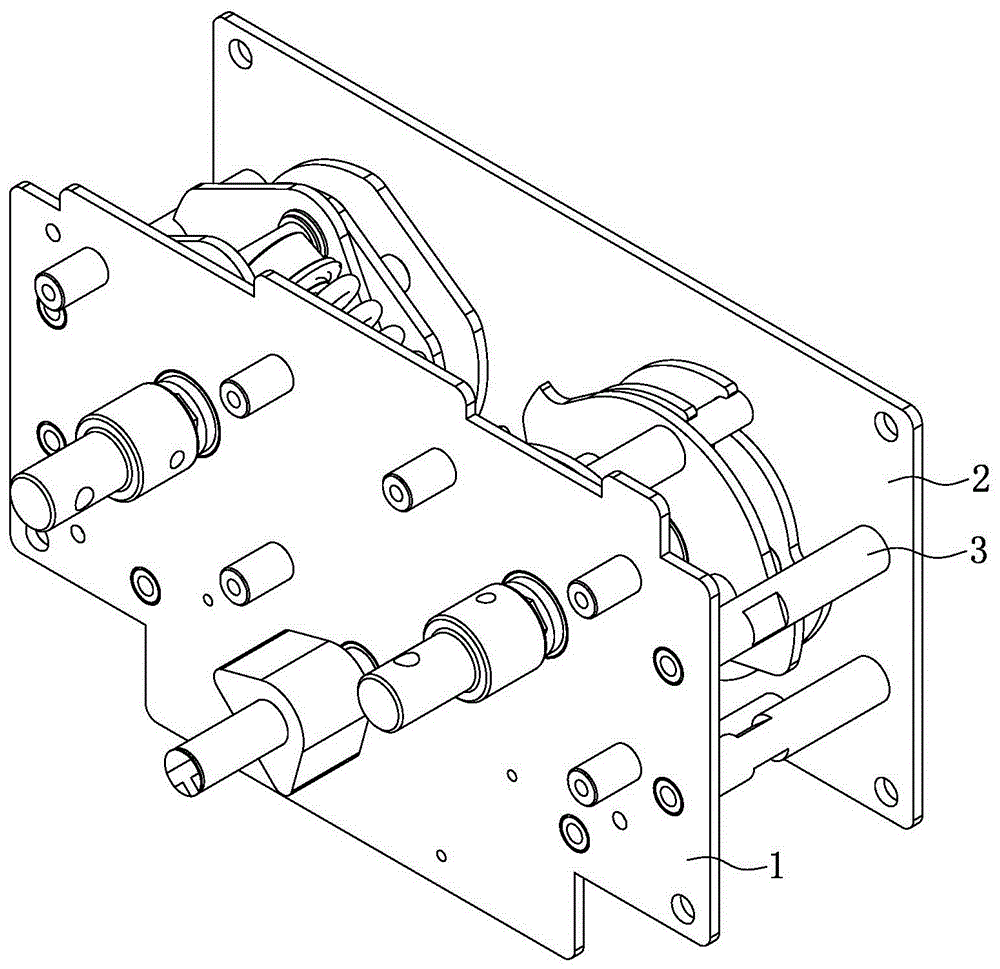

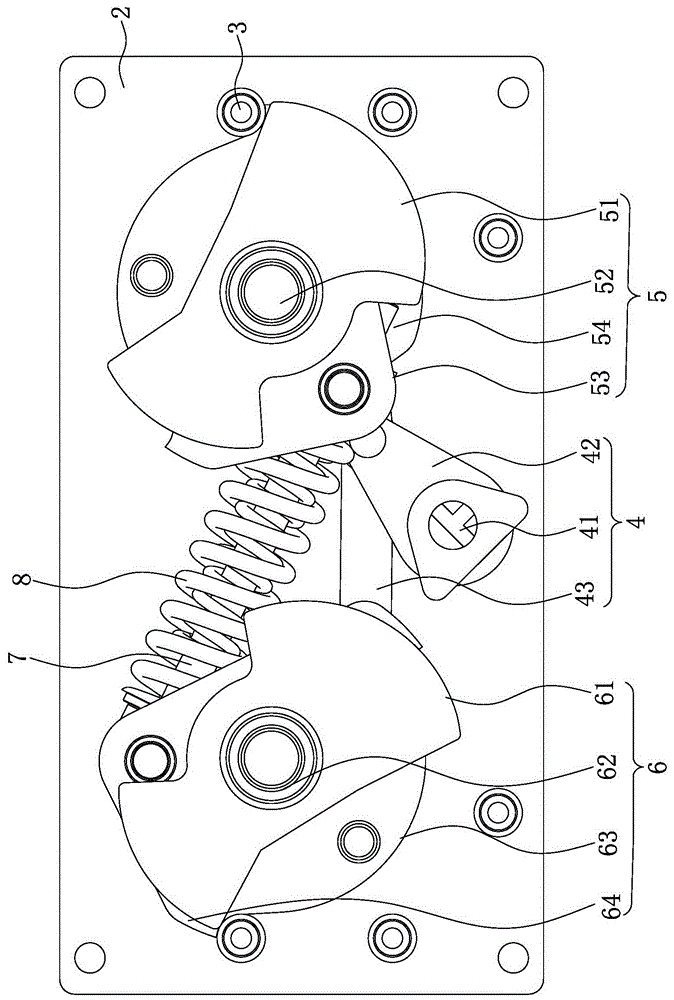

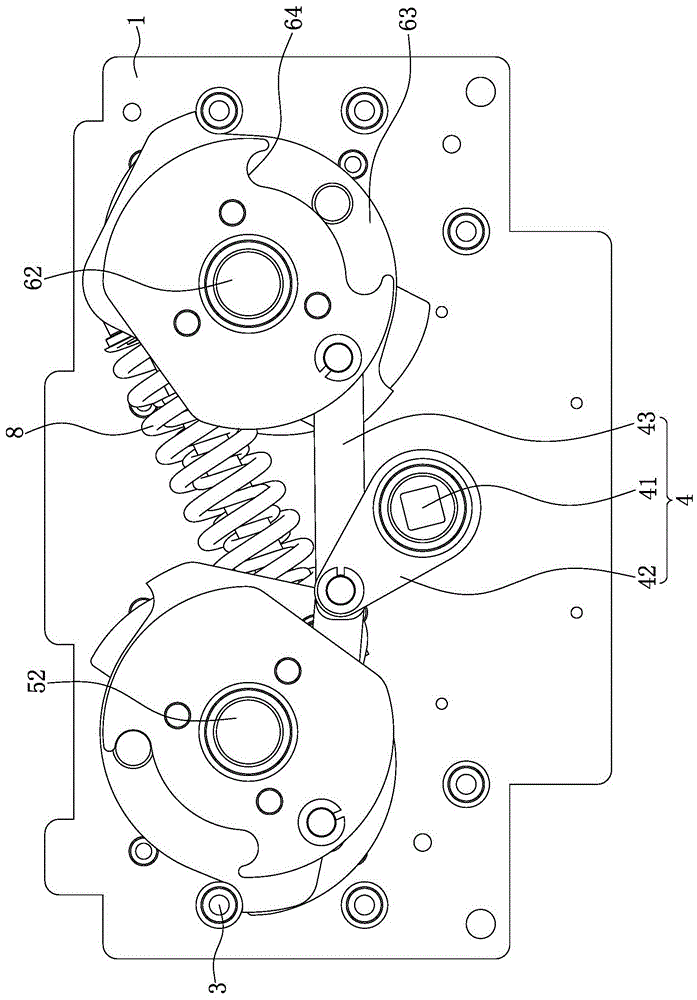

[0025] like Figure 5 to Figure 9 As shown, a three-position operating mechanism with a buffer function disclosed in the present invention includes a mechanism front plate 1, a mechanism rear plate 2, an output shaft module 4, a grounding side closing and opening module 5, and an isolation side closing and opening module. 6. The spring module and buffer module 9, each module is assembled between the front plate 1 of the mechanism and the rear plate 2 of the mechanism; wherein, the output shaft module 4 includes an output shaft 41, an output shaft crank arm 42 and a driving pull rod 43, and the output shaft 41 It is arranged in the middle of the rear plate 2 of the mechanism; the grounding side closing and opening module 5 and the isolation side closing and opening module 6 are centered on the output shaft 41 and distributed on both sides of the output shaft 41; the output shaft crank arm 42 is pivotally connected to the output On the shaft 41, the buffer module 9 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com