Three-phase sealing structure of oil-cooled motor

A sealed structure, oil-cooled technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of complex structure, increased cost, and high processing precision of the terminal block, so as to reduce the risk of insulation failure, reduce the risk of failure, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

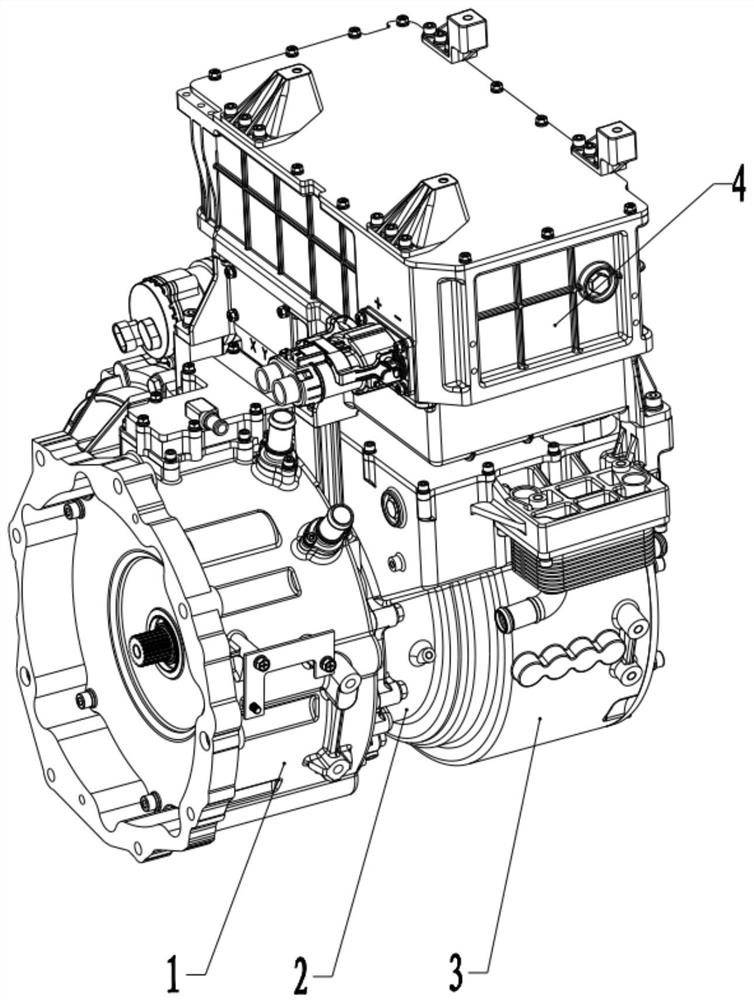

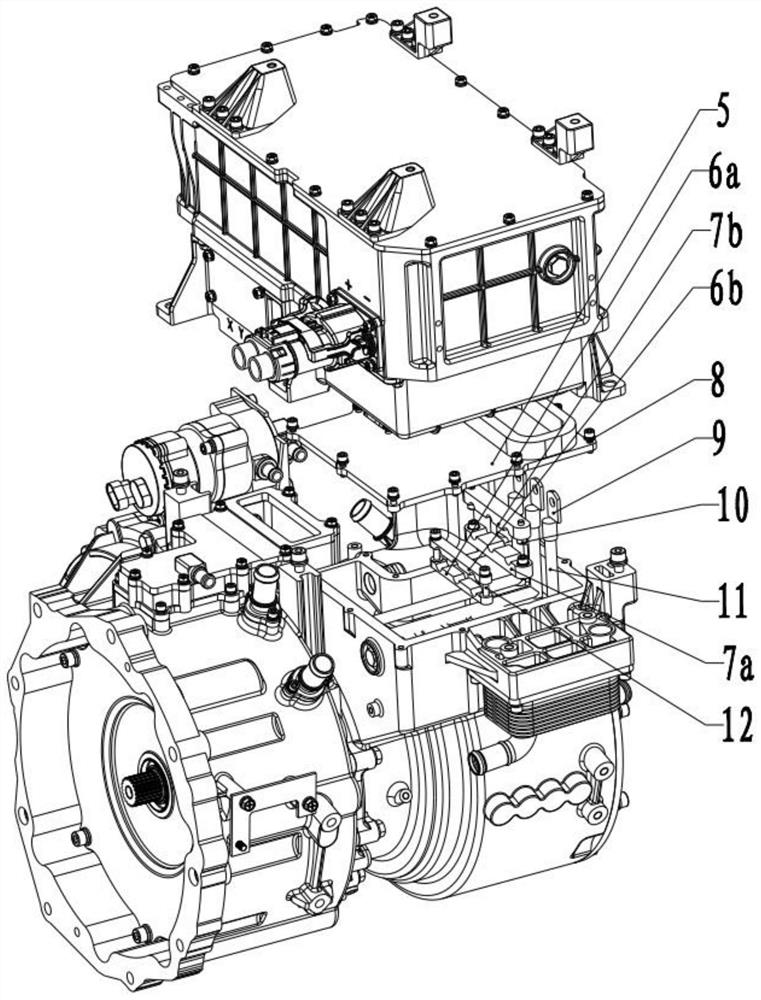

[0027] Embodiment: This application provides a three-phase sealed structure of an oil-cooled motor, including: a generator 1, a reducer 2, an oil-cooled motor 3, and a controller 4; the generator 1 and the oil-cooled motor 3 are distributed in the On both sides, the controller 4 is arranged directly above the oil-cooled motor 3 .

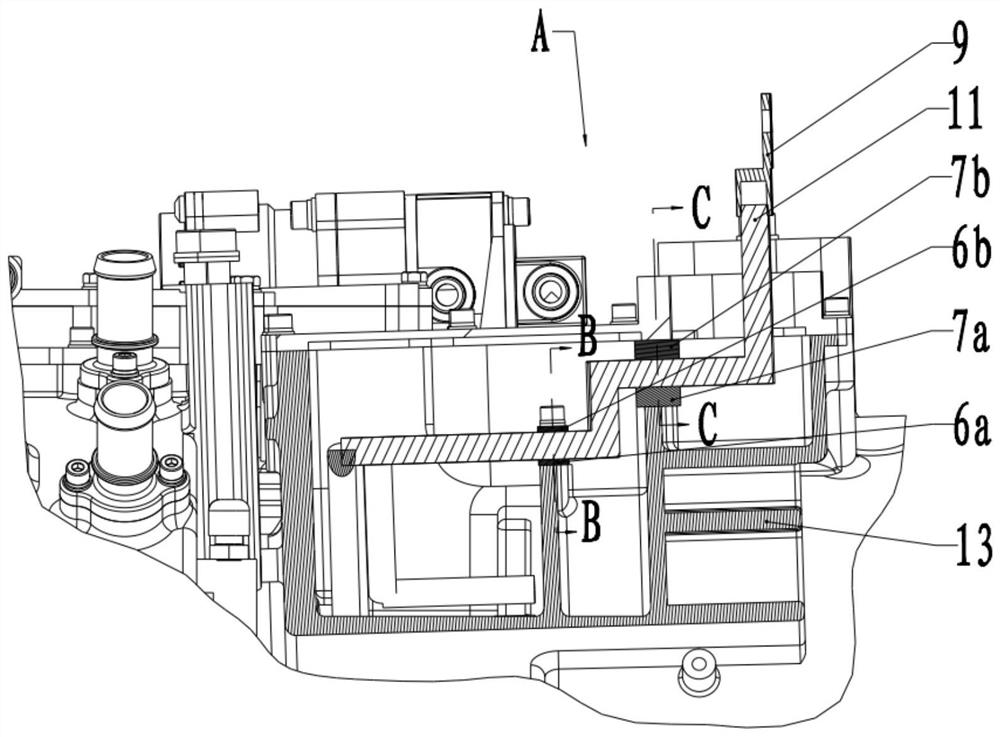

[0028] The oil-cooled motor 3 includes a three-phase cover plate 5, an oil-cooled motor casing 13, a first three-phase buckle 6 and a second three-phase buckle 7; the oil-cooled motor 3 is connected and sealed through the three-phase cover plate 5, and the three-phase The cover plate 5 and the oil-cooled motor casing 13 form a three-phase sealing structure; the first three-phase buckle 6 is used to fix the three-phase line 11 to form a fixed path, and the second three-phase buckle 7 is used to seal the three-phase outgoing line, the purpose is Completely isolate the oil mist inside the motor, prevent the oil mist from contacting the copper nose 9 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com