Insulation structure based on fuel cell

An insulating structure and fuel cell technology, applied in fuel cell components, fuel cells, circuits, etc., can solve the problems of increased humidity inside the stack, stack insulation failure, insulation failure, etc., to reduce the risk of insulation failure, The effect of improving insulation performance and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

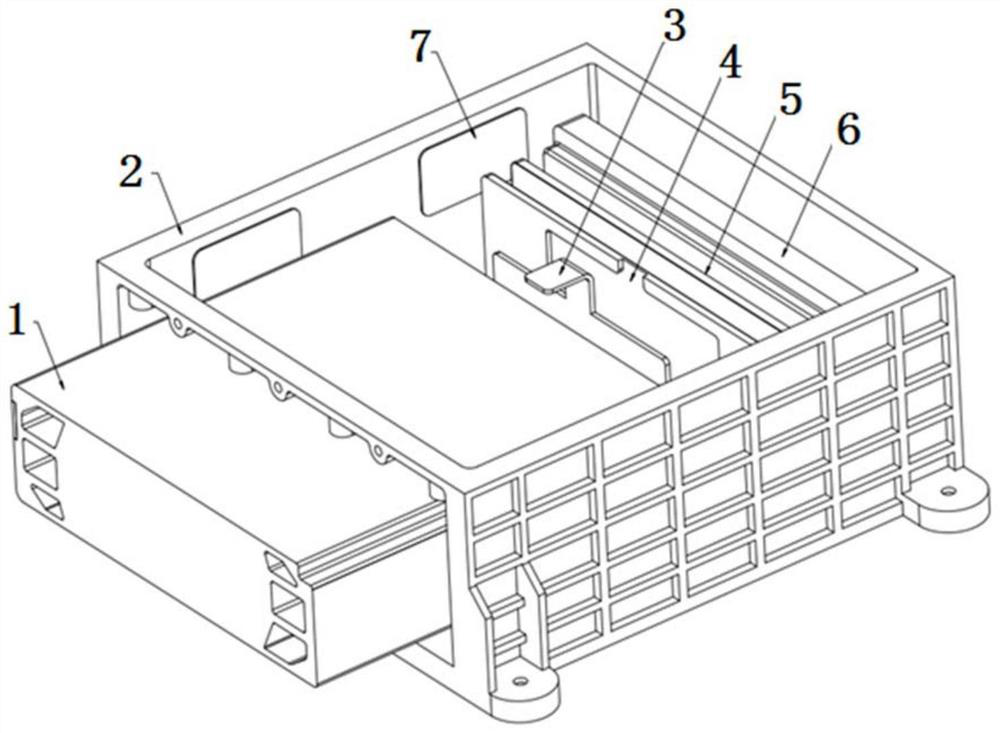

[0026] Such as figure 1 As shown, an insulating structure based on a fuel cell includes a battery body. The battery body includes a battery stack core 1, a battery case 2, a current collector plate 3, an insulating plate 4, and a lower end plate 6. The battery stack core 1 and the current collector plate 3. The insulating plate 4 and the lower end plate 6 are located in the battery case 2, the current collector plate 3, the insulating plate 4 and the lower end plate 6 are arranged in sequence, and an insulating polyester film 5 is provided between the insulating plate 4 and the lower end plate 6.

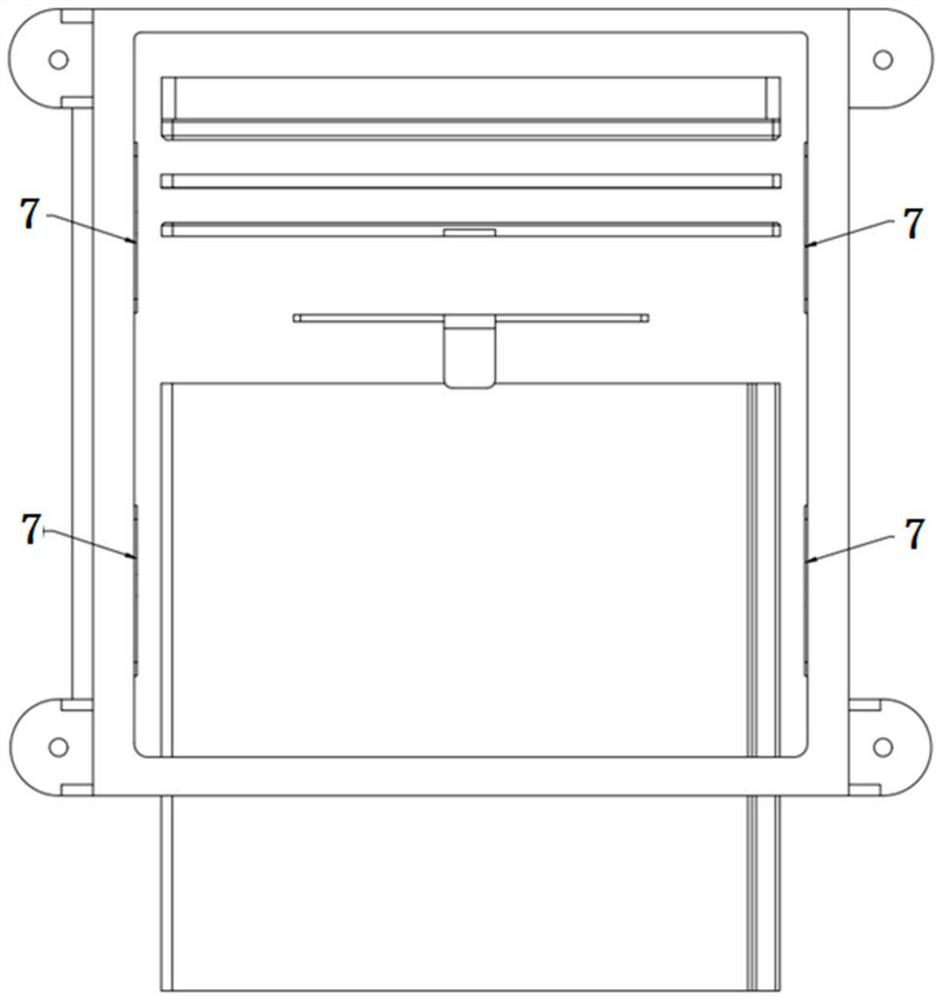

[0027] Such as figure 2 As shown, multiple humidity control sheets 7 are provided on the inner walls of both sides of the motor housing 2. The humidity control sheets 7 have the characteristics of flame retardancy and high and low temperature resistance. In this embodiment, the model of the humidity control sheet 7 is VD -NIPC050-KP03.

[0028] The humidity control sheet 7 is pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com