Corona resistance polyimide film preparing method, corona resistance polyimide film and preparing system of corona resistance polyimide film

A technology of polyimide film and preparation system, applied in flat products, other household appliances, applications, etc., can solve problems such as unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

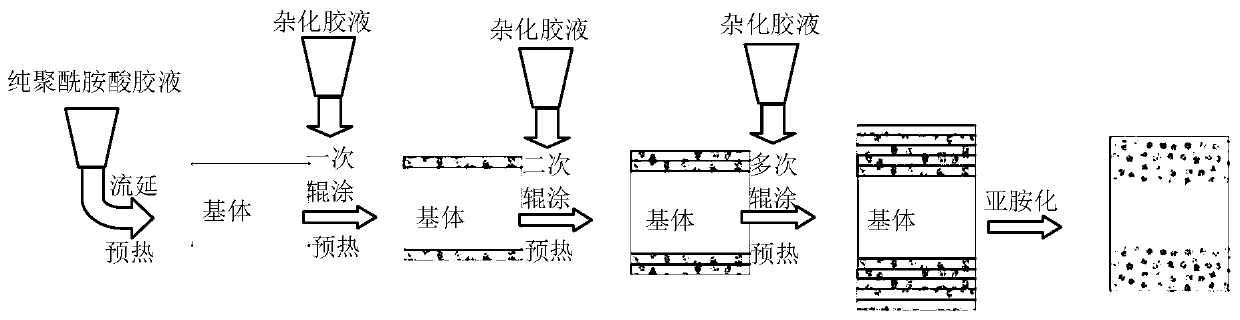

[0045] (1) Add 4,4'-diaminodiphenyl ether (ODA) into the reaction device, and then add N,N-dimethylacetamide (DMAc) so that the solid content is 10%, and add an electric stirrer to fully stir Mix evenly, and the rotating speed is controlled at 500-1500 revolutions per minute. After the ODA is completely dissolved in DMAc, weigh PMDA (pyromellitic dianhydride) in an equimolar ratio to ODA, and add it to the reaction device in batches for multiple times. This feeding process is about 0.5-1 hour, until the phenomenon of "climbing the rod" occurs, the speed is appropriately reduced, controlled at 50-500 rpm, and the stirring is continued for 6-12 hours to ensure that ODA and PMDA are fully polymerized, and finally the product with High molecular weight pure PAA glue;

[0046] (2) Add ODA to the reaction device, then add DMAc, so that the solid content is 10%, add an electric stirrer to fully stir and mix evenly, and the speed is controlled at 500-1500 rpm. After ODA is completely ...

Embodiment 2

[0052] (1) Add ODA in the reaction device, then add a certain amount of DMAc, so that the solid content is 10%, increase the electric stirrer, and the rotating speed is controlled at 500-1500 revolutions per minute, fully stir and mix evenly, until ODA is completely mixed in DMAc After dissolving, weigh the PMDA with the same molar ratio as ODA, and add it to the reaction device several times in batches. The feeding process is about 1 hour, until the phenomenon of "rod climbing" occurs, and the speed is appropriately reduced, controlled at 50-500 rpm , continue to keep stirring for 6-12 hours to ensure that ODA and PMDA are fully polymerized, and finally obtain pure PAA glue with high molecular weight;

[0053] (2) Add ODA to the reaction device, then add a certain amount of DMAc (solid content 10%), add an electric stirrer to fully stir and mix evenly (rotating speed is controlled at 500-1500 rpm), until ODA is completely dissolved in DMAc Finally, add fumed alumina powder wi...

Embodiment 3

[0059](1) Add ODA to the reaction device, then add a certain amount of DMAc, so that the solid content is 10%, add an electric stirrer to fully stir and mix evenly, and the speed is controlled at 500-1500 rpm, until ODA is completely dissolved in DMAc Finally, weigh PMDA with an equal molar ratio to ODA, and add it to the reaction device in batches for several times. The feeding process is about 1 hour, until the phenomenon of "climbing the rod" occurs, and the speed is appropriately reduced, and it is controlled at 50-500 revolutions per minute. , continue to keep stirring for 6-12 hours to ensure that ODA and PMDA are fully polymerized, and finally obtain pure PAA glue with high molecular weight;

[0060] (2) Add ODA to the reaction device, then add a certain amount of DMAc, so that the solid content is 10%, add an electric stirrer to fully stir and mix evenly, and the speed is controlled at 500-1500 rpm, until ODA is completely dissolved in DMAc Finally, add fumed alumina p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com