Electric motor

A motor and fan technology, applied in asynchronous induction motors, electric components, electromechanical devices, etc., can solve the problems of easy contact with rainwater and dust, excessive heating of the rotor, and shortened bearing life, etc., to achieve easy combined cooling, high power density, Life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

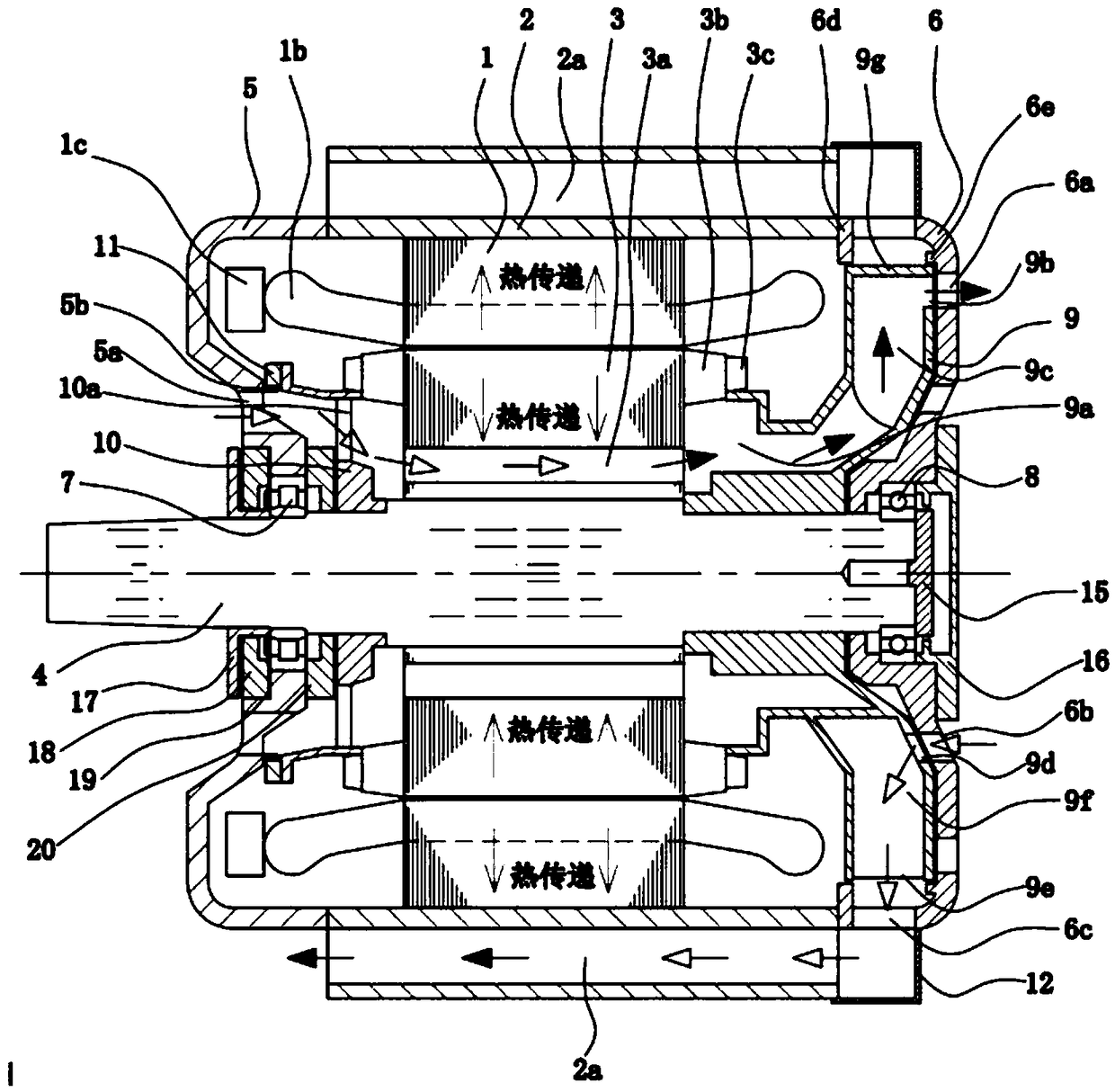

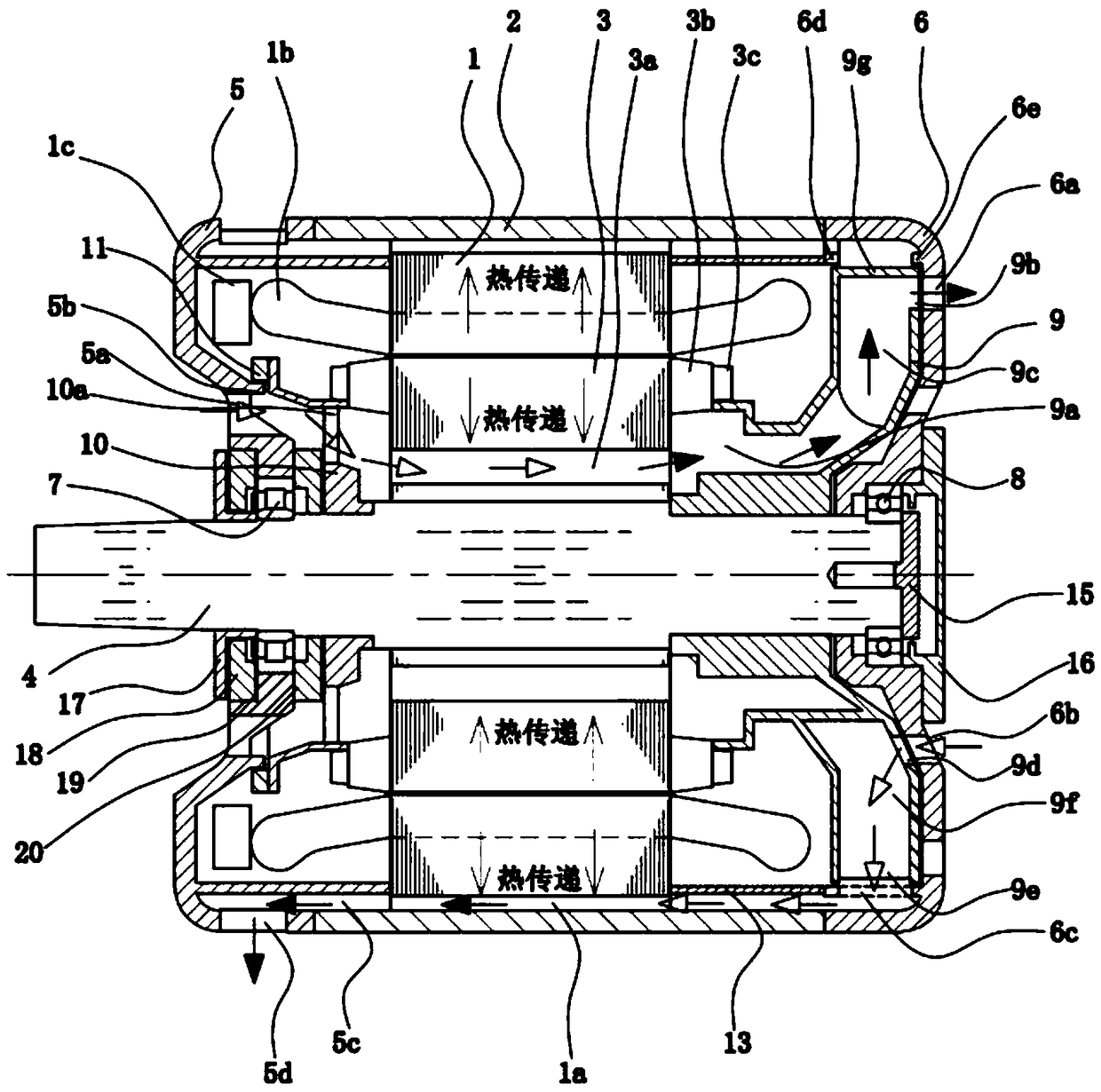

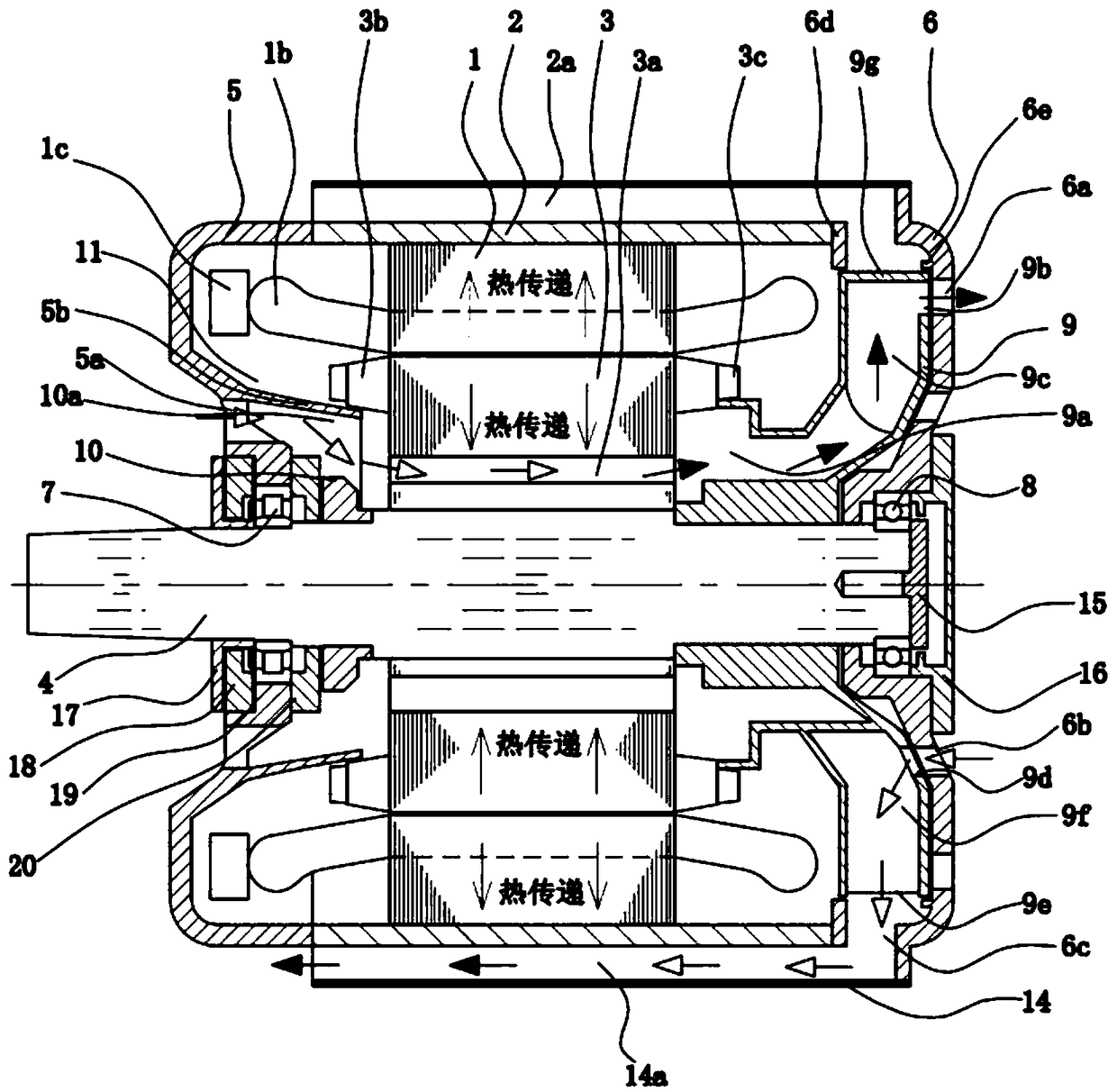

[0085] Referring now to the drawings, wherein like reference numerals indicate like or corresponding parts throughout the several views, in particular the accompanying figure 1 The first embodiment of the present invention has been described.

[0086] figure 1 It is the axial sectional view of the first embodiment of the present invention, refer to below figure 1 Describe the implementation mode:

[0087] Process 1. The stator 1 includes a stator core and a stator coil. There are many slots evenly distributed on the inner circumference of the stator core, and the stator coil is fixed in these slots. Each stator coil is a series connection of multi-turn windings, so the end winding 1b is essential and is arranged at both ends of the stator core. The stator coils need to be grouped and connected regularly, so there are many joints 1c, figure 1 The middle winding connection 1c is arranged at the left drive end. The stator core is fixed on the inner circumference of the shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com