Electromotor

A motor and stator technology, applied in the field of fully enclosed self-ventilated motors, can solve the problems of excessive heat generation of the rotor, burning the motor, and cumbersome installation work, and achieve the effects of high power density, simplified structure, and compact appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

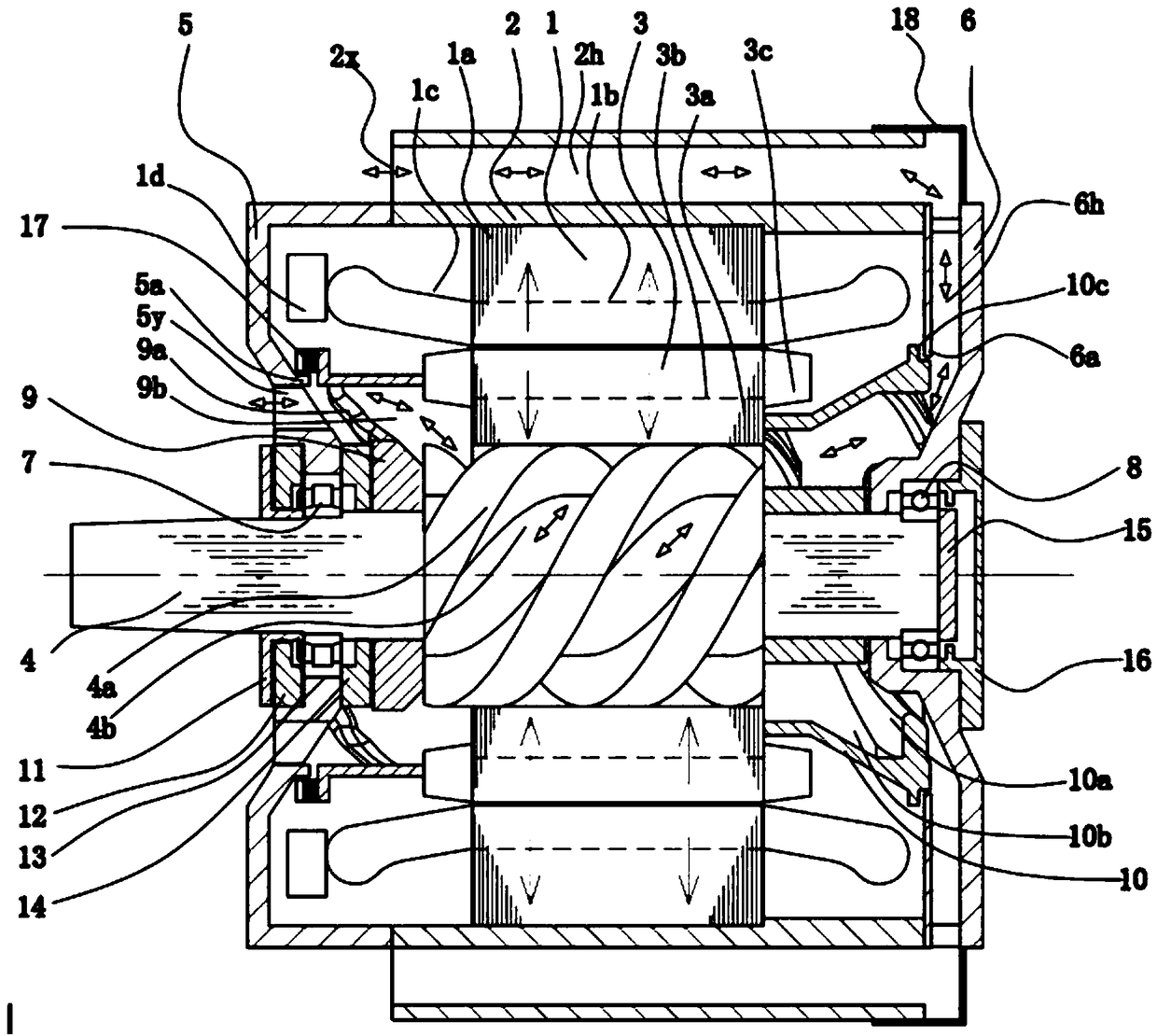

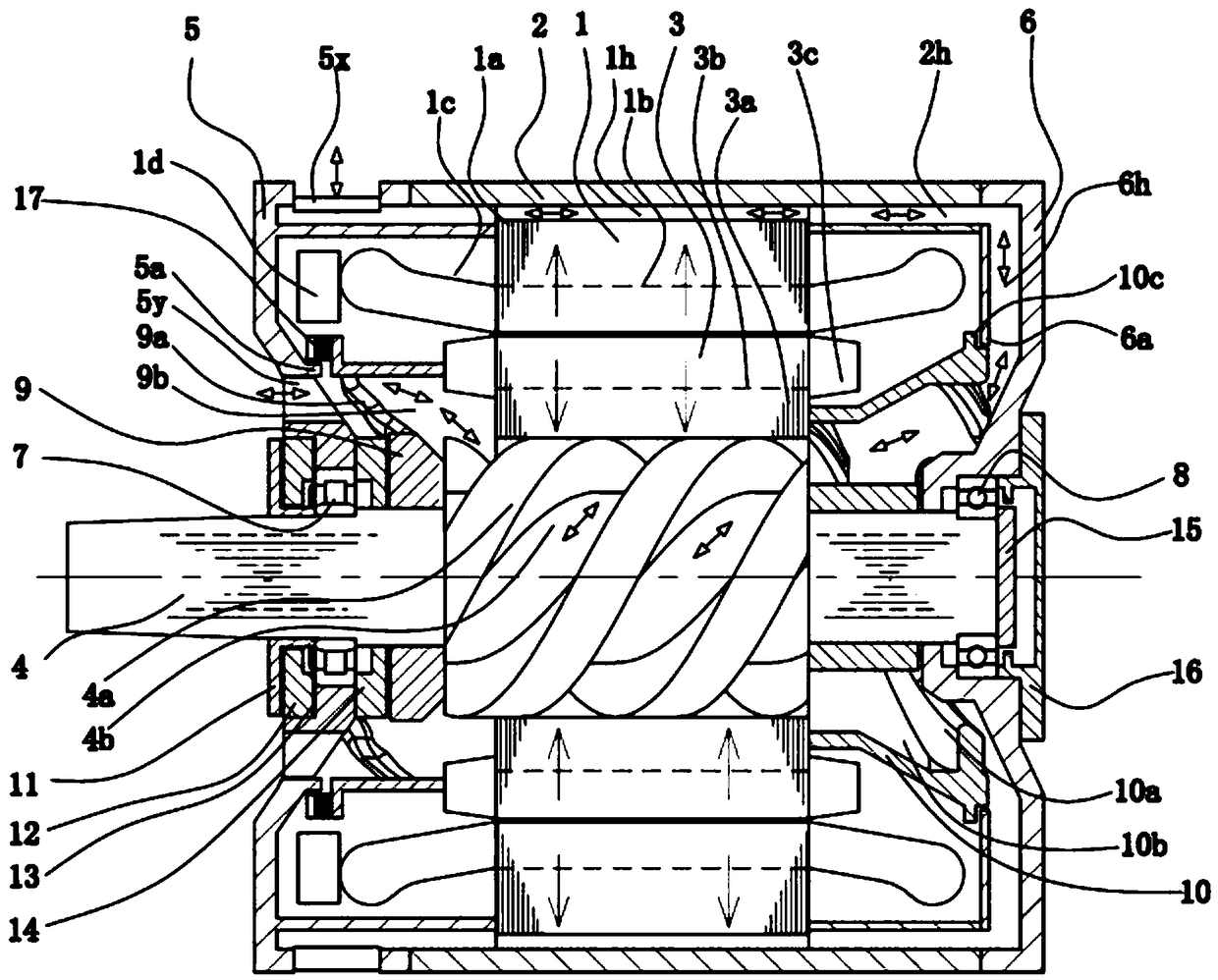

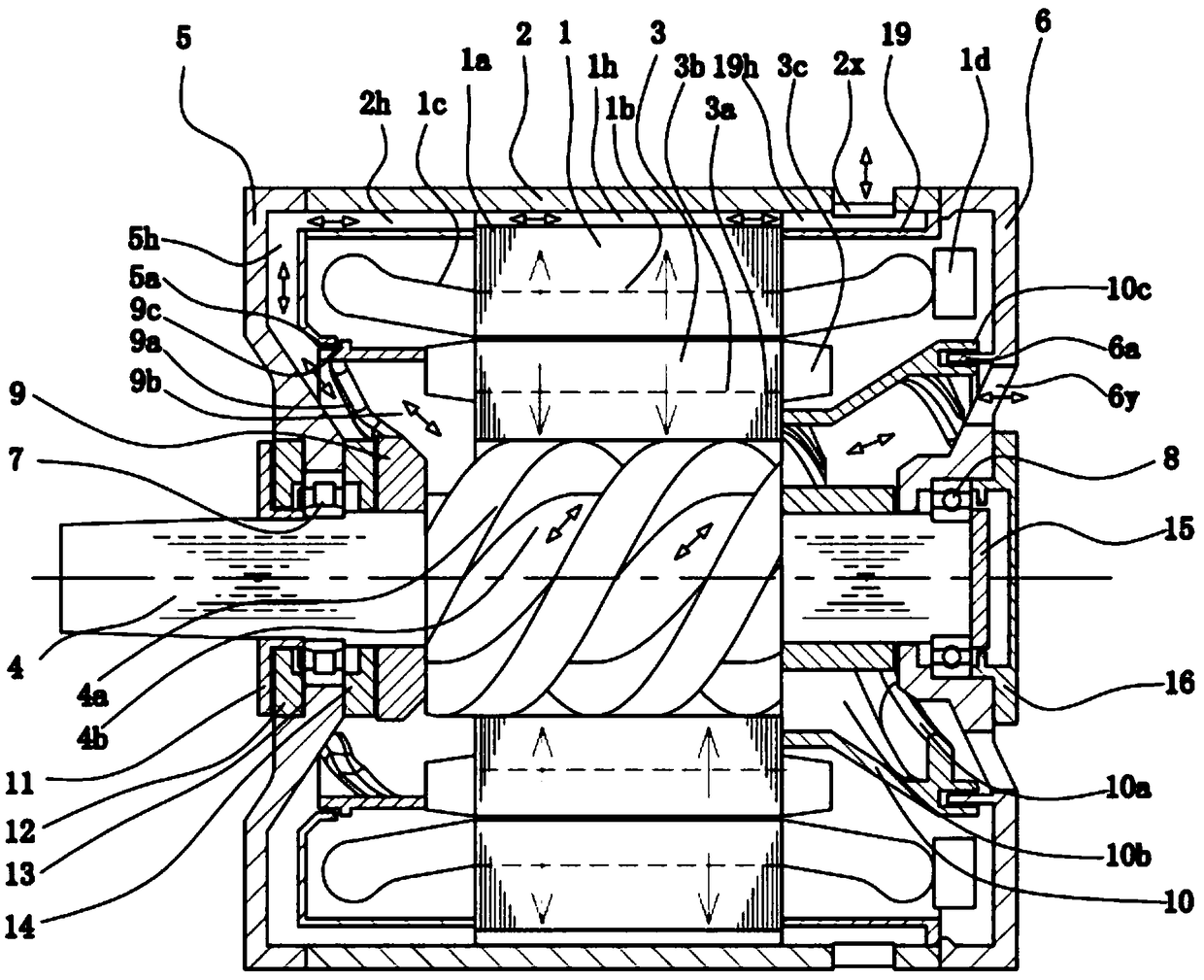

[0099] Referring now to the drawings, wherein like reference numerals designate like or corresponding parts throughout the several views;

[0100] attached figure 1 It is an axial sectional view of the first embodiment of the present invention, referring to the attached figure 1 The implementation manner of the first embodiment is described:

[0101] The feature of the first embodiment is that the stator air passage 2h of the motor casing 2 is located at the four corners of the maximum width and height of the motor body outside, does not occupy the motor circumference size, and reserves the maximum diameter size for the stator and rotor, so that the motor has a higher The power density; two vents are located on the front cover and on the circumference of the casing near the drive end, suitable for electric motors driving subway vehicles;

[0102] Step 1. The stator 1 includes a stator core 1a and a stator winding 1b. There are many slots evenly distributed on the inner circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com