Sub-rail isolating protective sleeve

A protective sleeve and rail technology, applied in the field of rail transit, can solve electric shock; if the other end of the conductive object is in contact with other equipment, a large current will enter, power supply equipment, communication signals will be affected, and the insulation between the rail and the earth will be damaged. problems, to achieve the effect of eliminating potential safety hazards, good vibration reduction, and strengthening the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

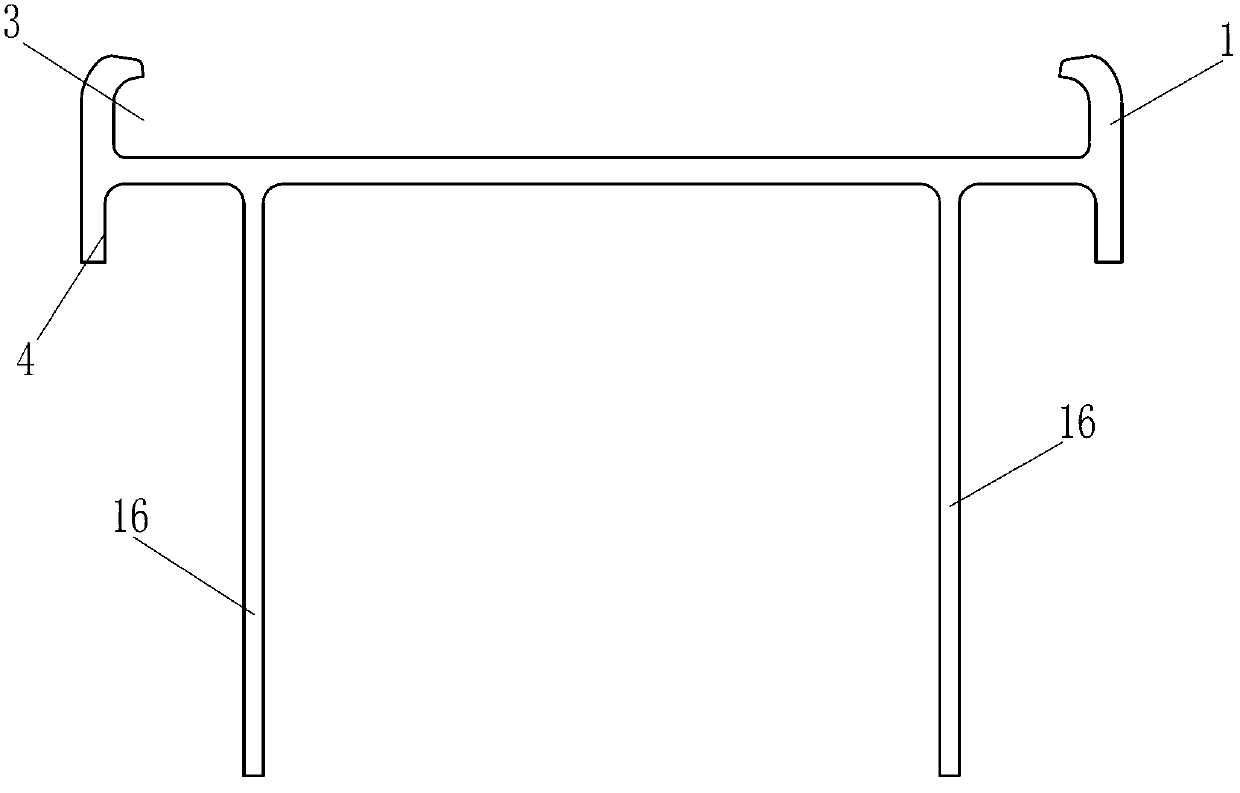

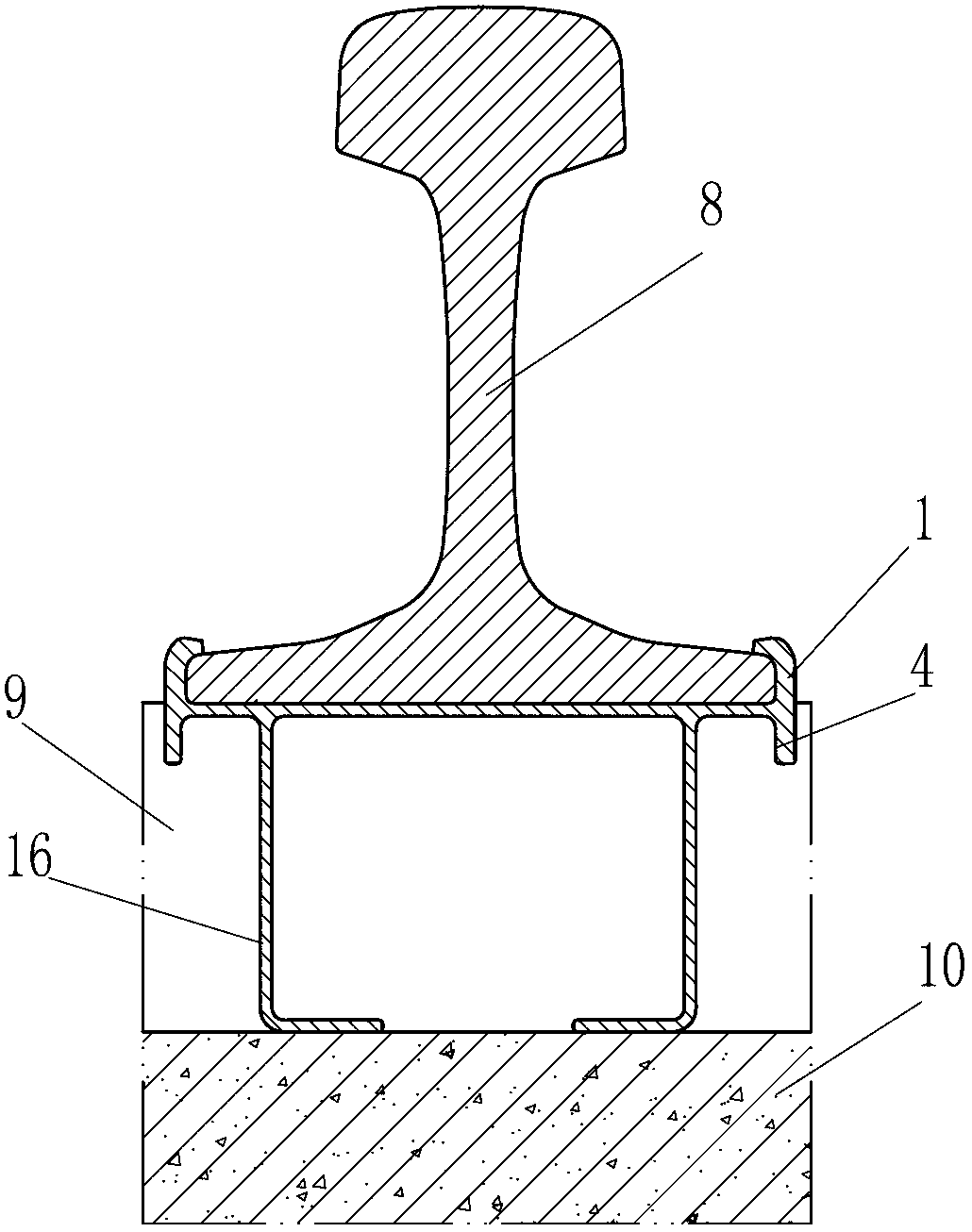

[0038] The structure of the isolation protection cover under the rail of the present invention, such as figure 1shown. The isolation protective cover body includes a fixed support 1 and a skirt, wherein the skirt includes two sub-skirts 16, and the fixed support 1 and the two sub-skirts 16 are integrally made of elastic insulating material, specifically rubber. The upper part of the fixed support 1 is provided with a card slot 3 whose size and shape correspond to the rail bottom of the rail. In addition, the bottom of the fixed support 1 is also provided with a water retaining structure 4. The water retaining structure is specifically a water retaining eaves. The sub-skirt 16 is placed on the inner side of the water retaining structure 4, and is symmetrically arranged on both sides of the bottom of the fixed support along the longitudinal direction of the rail.

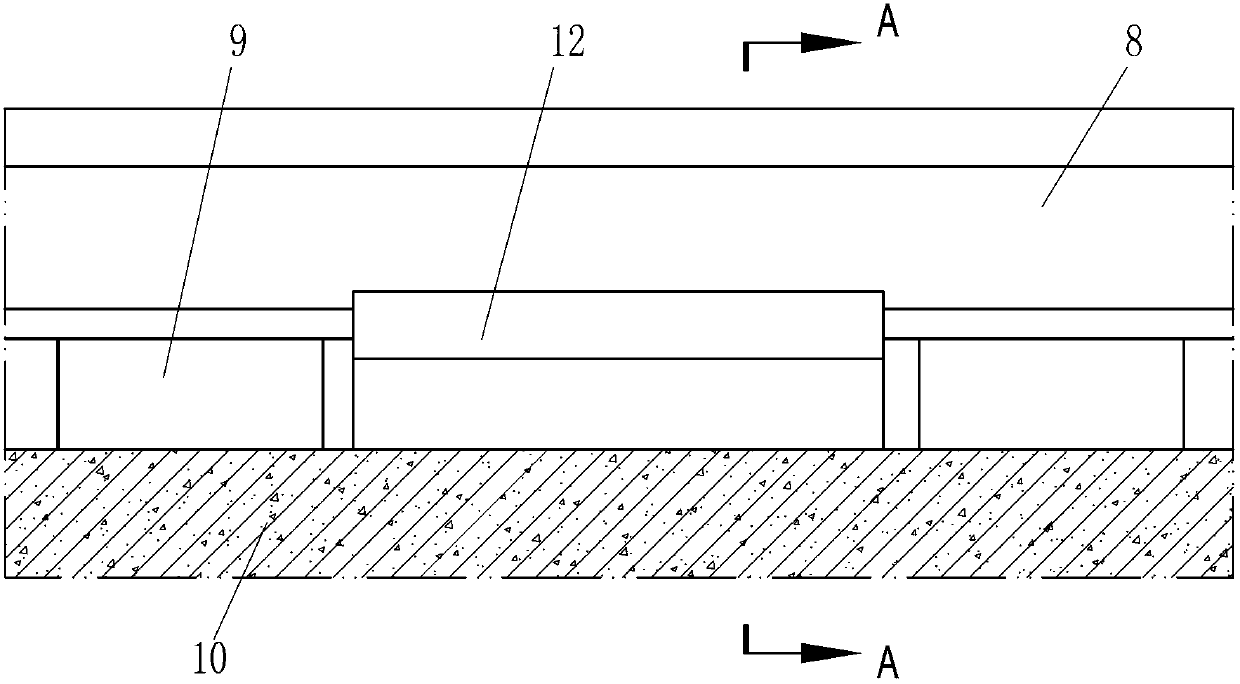

[0039] When applied, such as figure 2 and image 3 As shown, the under-rail isolation protective cover 12 of th...

Embodiment 2

[0045] like Figure 4 The difference between the isolation protection cover under the rail of the present invention and the first embodiment is that the isolation protection cover body includes a fixed support 1 and a skirt 2, and the fixed support 1 and the skirt 2 are made of different materials, wherein the fixed support The seat 1 is made of insulating hard rubber material, the skirt plate 2 is made of high elastic rubber material, and the two are vulcanized and connected into one. In addition, the sound shielding board 14 of the same material is integrated and symmetrically arranged on the fixed support 1, and the sound shielding boards respectively extend upward along both sides of the fixed support and gradually approach the center plane of the fixed support along the longitudinal direction of the rail. A cavity 15 along the longitudinal direction of the rail is formed below the fixed support. In addition, in order to improve the ability of the sound shielding board 14...

Embodiment 3

[0051] like Image 6 The difference between the under-rail isolation protective cover of the present invention and the first embodiment is that the isolation protective cover body includes two parts: an independent fixed support 1 and an apron 2 . The top of the fixed support 1 is provided with a card slot 3, and the bottom is provided with two rows of bosses 5 symmetrically along the longitudinal direction of the rail. The top of the skirt plate 2 is provided with a card slot 6 corresponding to the boss 5 . The cross-sectional profile of the boss 5 is "T" shape, and the shape of the slot 6 corresponds to the boss 5, and the boss 5 can be embedded in the slot 6, so as to realize the connection and limit of the fixed support 1 and the skirt plate 2. Water-retaining structures 4 are arranged on both sides of the skirt plate 2, and the water-retaining structures are specifically water-retaining eaves. Furthermore, a cavity 7 is provided in the apron 2 . The fixed support 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com