Valve tower for thyristor converter valves

A thyristor converter valve and converter valve technology, which is applied in the direction of converting AC power input into DC power output, output power conversion devices, electrical components, etc., can solve the problems of inconvenient maintenance and small maintenance space, and increase maintenance. Space, compact structure, convenient and quick maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

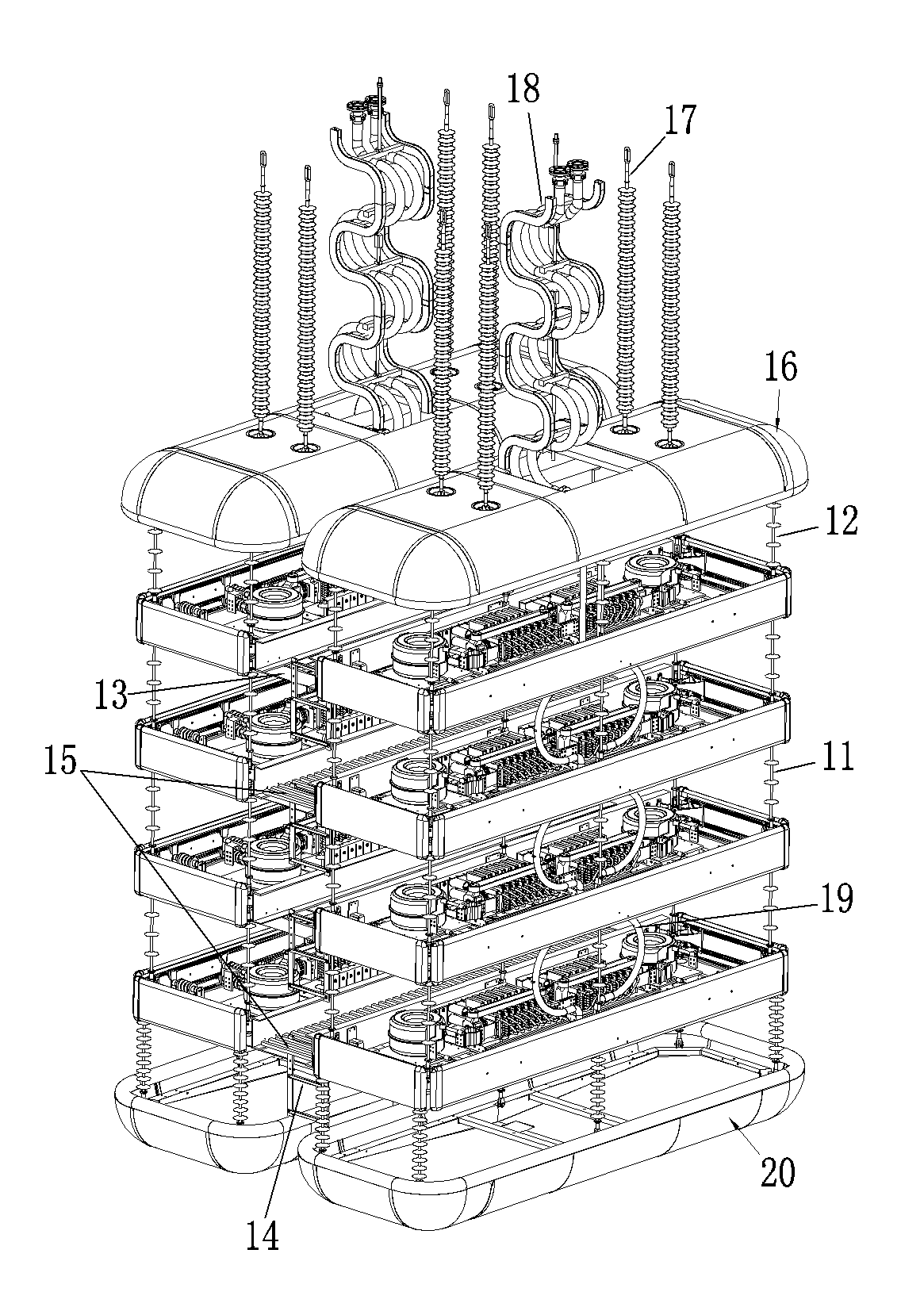

[0014] Embodiments of thyristor valve towers, such as figure 1 As shown, the thyristor converter valve tower includes valve layers. In this embodiment, there are four valve layers stacked from top to bottom, and each valve layer includes two converter valve assemblies 11 arranged side by side at intervals. Two converter valve assemblies on the same valve layer are spaced apart and form a maintenance area between them. The width of the maintenance area is enough for a maintenance person to stand. The maintenance areas on the four valve layers correspond up and down and form a maintenance area together. In the maintenance passage, the upper and lower corresponding converter valve assemblies are fixedly connected together by interlayer hoisting insulators 12. There are aluminum bars 13 at the ends respectively. The aluminum bars 13 are located outside the corresponding converter valve assemblies in the maintenance channel and connect the converter valve components of the same val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com