Heavily-loaded vehicle cab rear suspension device

A technology for trucks and cabs, which is applied to the superstructure, vehicle parts, transportation and packaging of trucks, can solve the problems of complex structure, large installation space, damaged spring shock absorbers, etc., to expand maintenance space, Increased installation space and reduced vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

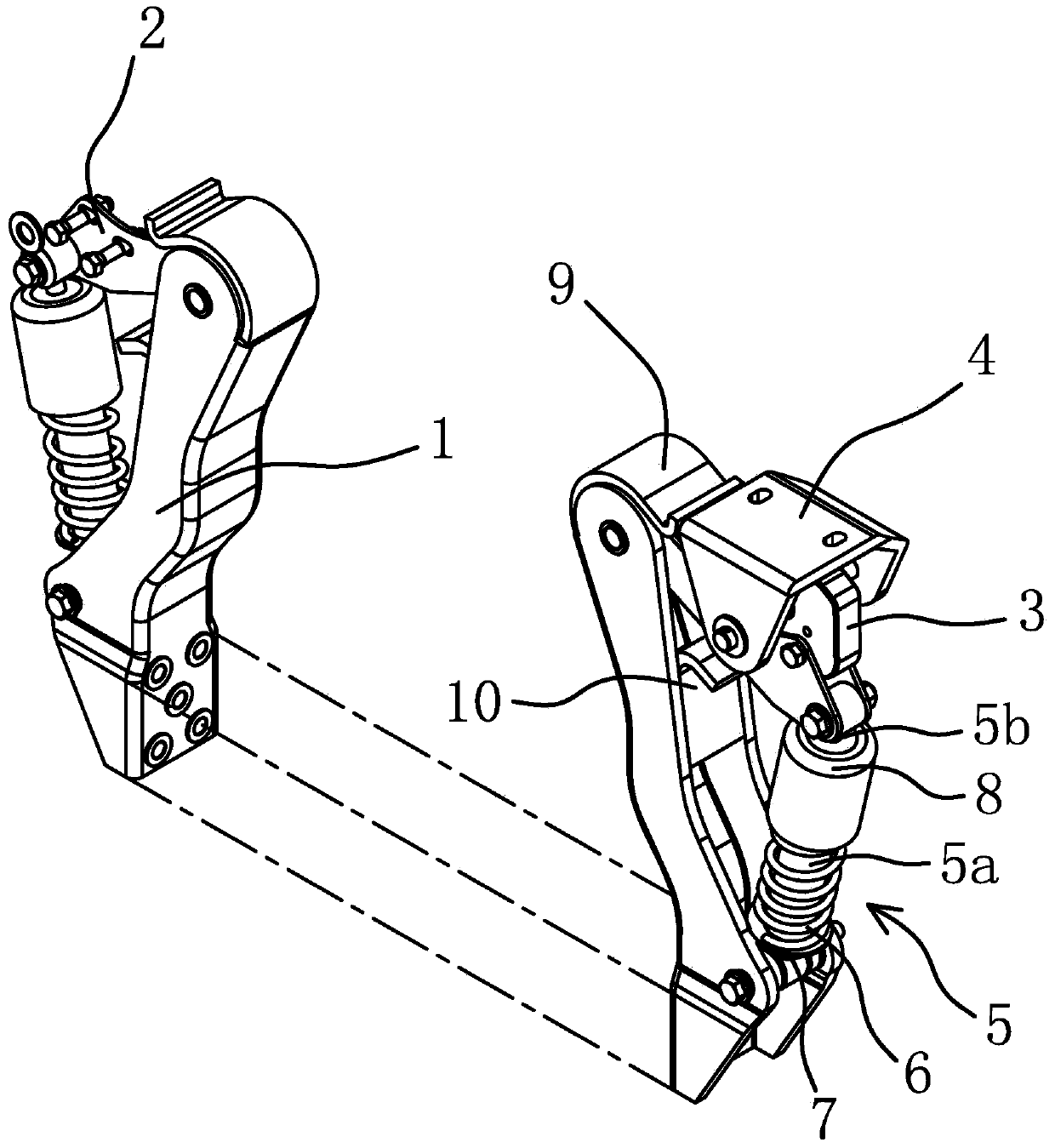

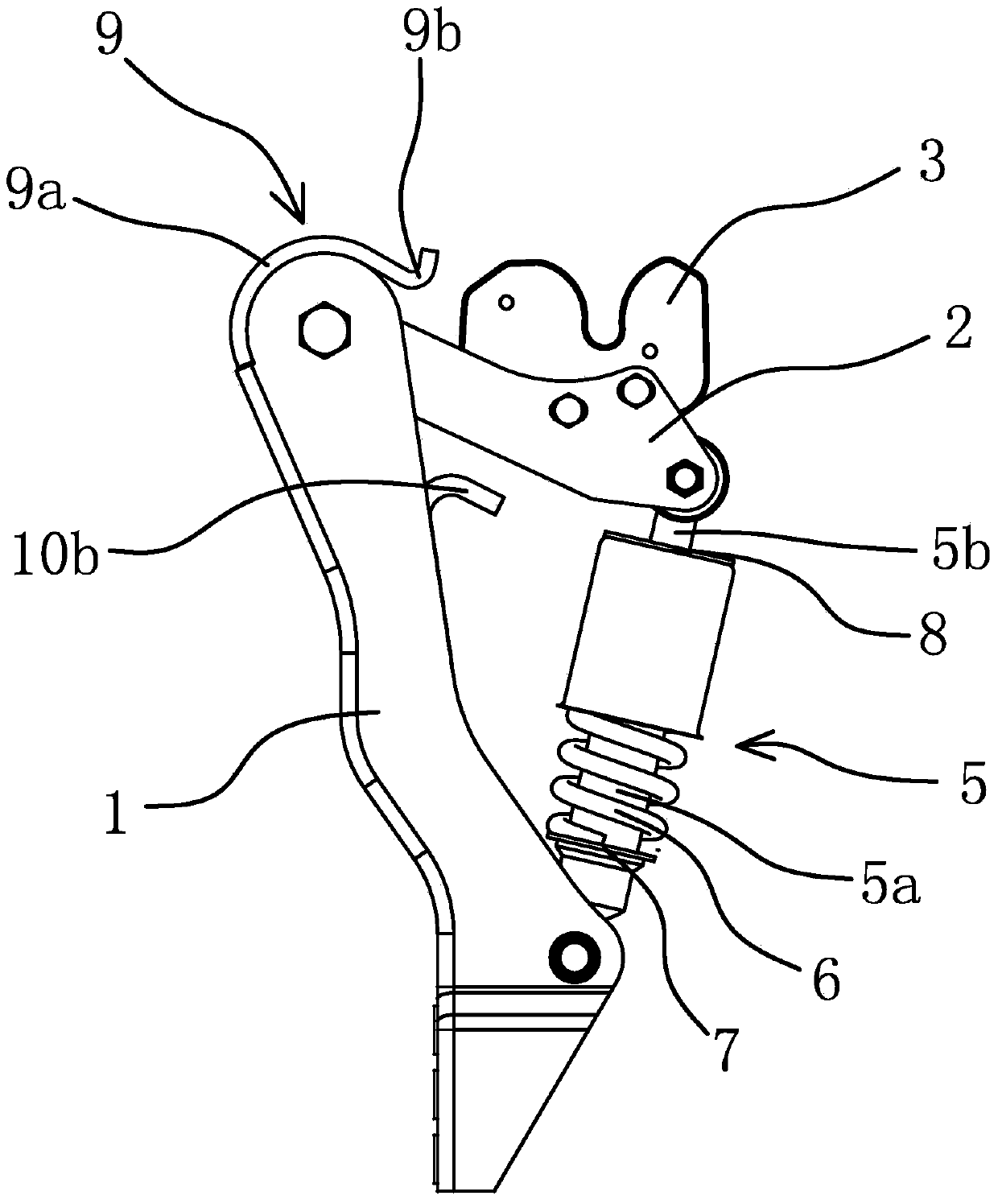

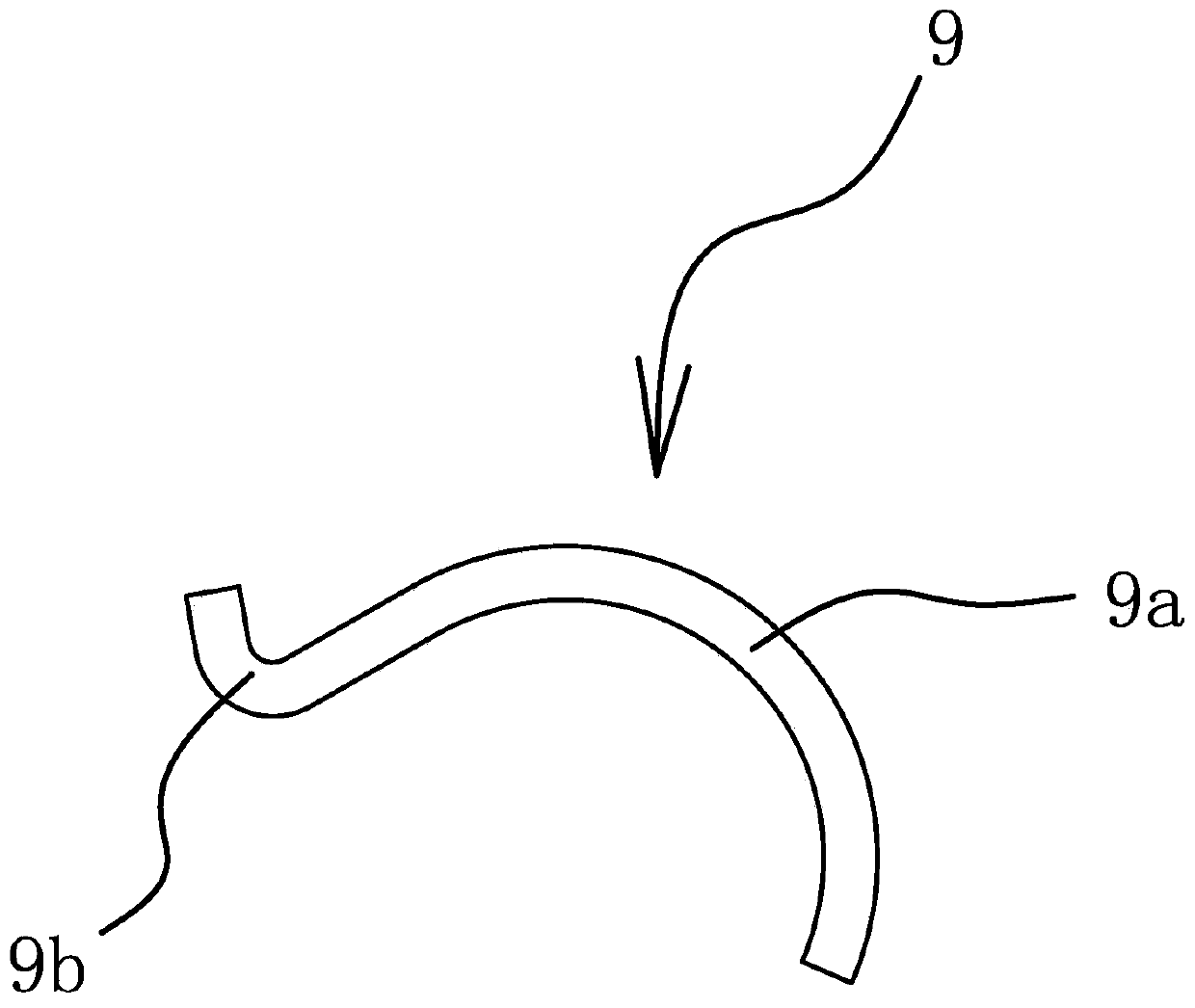

[0027] Such as figure 1 , figure 2 As shown, the truck cab rear suspension device includes a bracket 1, a rocker arm 2, a lock bolt 3, a connecting block 4, a damping shock absorber 5, a spring 6, an upper limit block 9 and a lower limit block 10.

[0028] Bracket 1 is a stamped part, two in number, arranged symmetrically from left to right, and made by stamping, bending, and punching. They are respectively fixed at both ends of the main beam of the car, and the part above the lower end of the bracket 1 is slightly inclined towards the inside as a whole, that is, the distance between the tops of the two brackets 1 is smaller than the distance between the bottoms. The upper end of the bracket 1 has a hinge hole, through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com