Small excavator

A kind of excavator, small-scale technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problem of inconvenient maintenance and achieve the effect of shortening the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation will be described below in conjunction with the accompanying drawings.

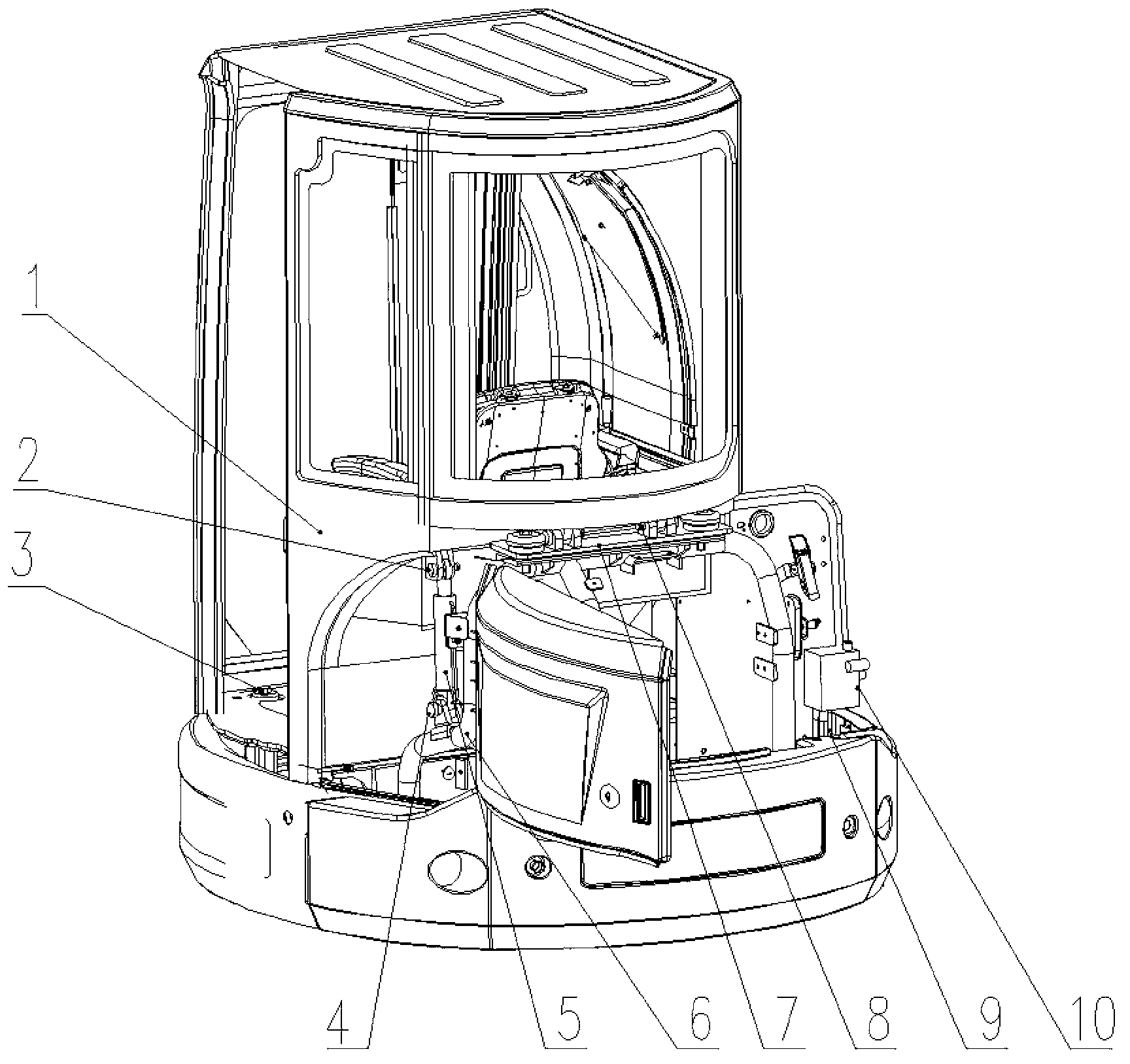

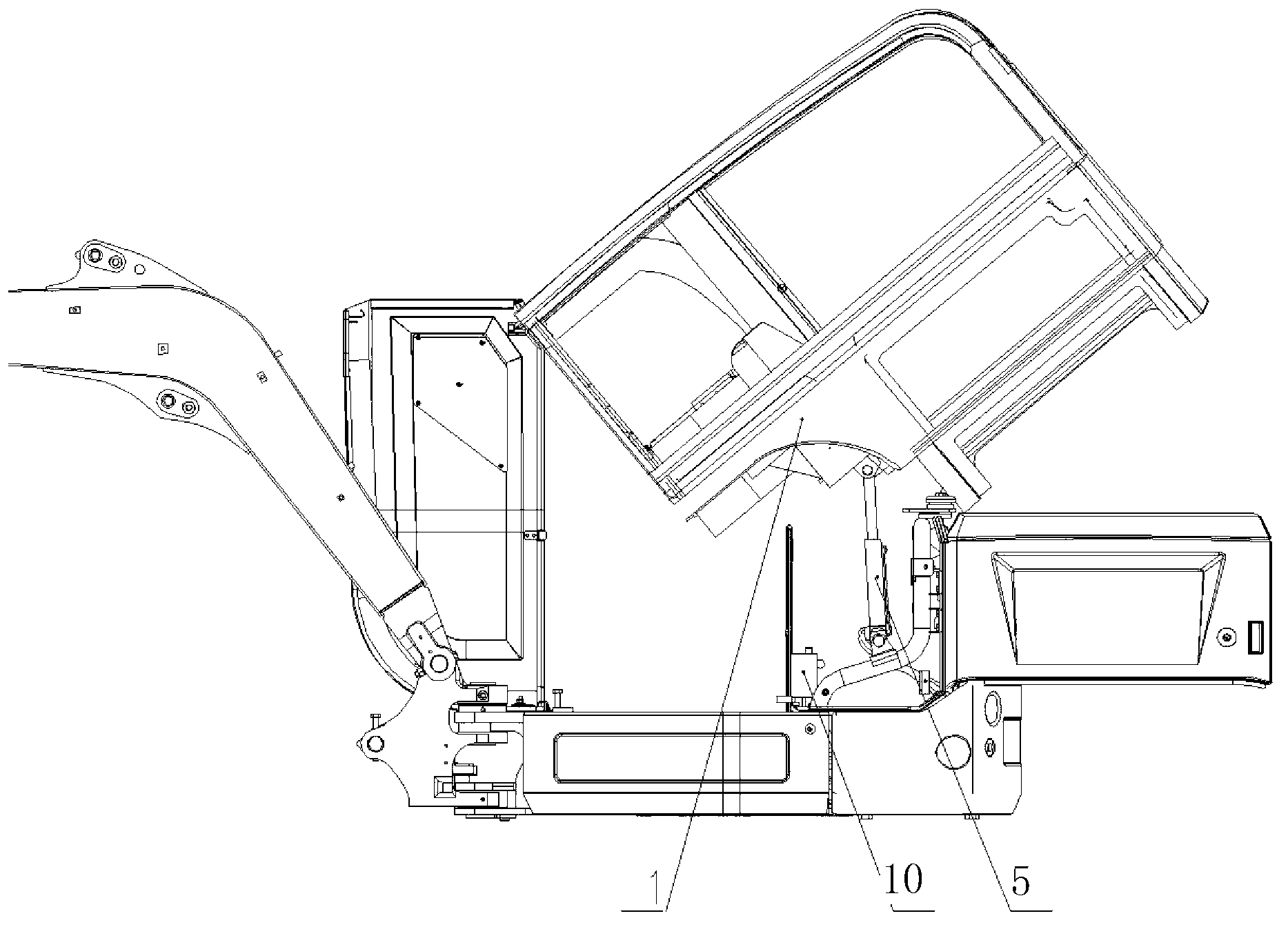

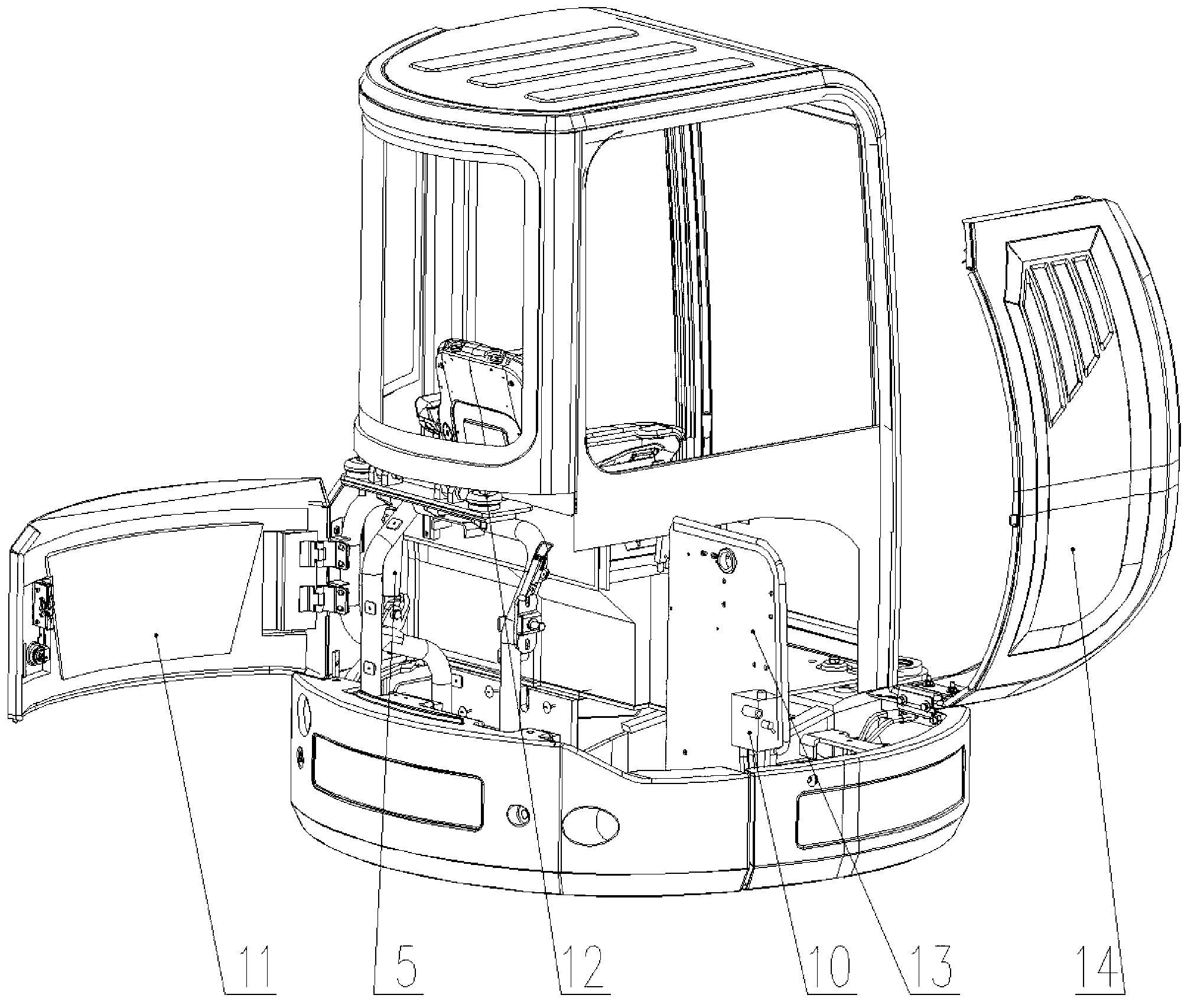

[0016] Such as Figure 1 to Figure 3 As shown, the cab installation platform includes a hinged front hood 14 and a rear hood 11, wherein the hinge axis of the front hood 14 is in a horizontal direction, so that the front hood 14 can turn upwards in the vertical direction around the horizontal hinge axis. The hinge axis of the rear hood is in a vertical direction, so that the rear hood 11 can be horizontally rotated around the vertical hinge axis to open. The rear lower part of the driver's cab 1 is recessed forward, and the depression reaches the middle part of the driver's cab from bottom to top, so that the rear part of the driver's cab presents an inverted stepped shape. There is a bracket 6 protruding upwards to the top of the installation platform on the cab installation platform. The ladder step of the cab 1 forms a hinge through the hinge pin 8 and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com