Energy-saving circular weaving machine

A circular loom, energy-saving technology, applied to circular looms, looms, textiles, etc., can solve the problems of high energy consumption and inconvenient maintenance, and achieve the effects of expanding maintenance space, reducing weight, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

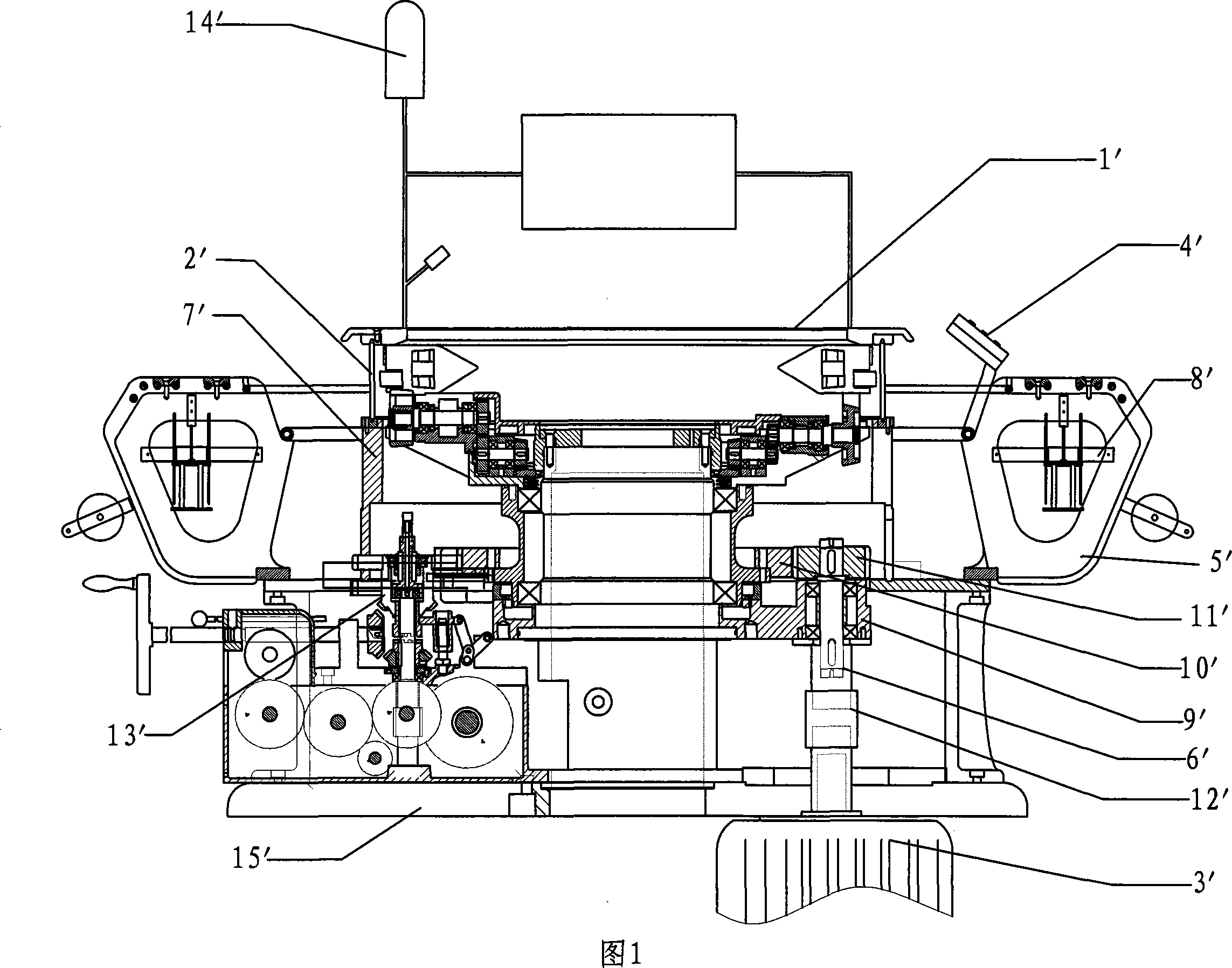

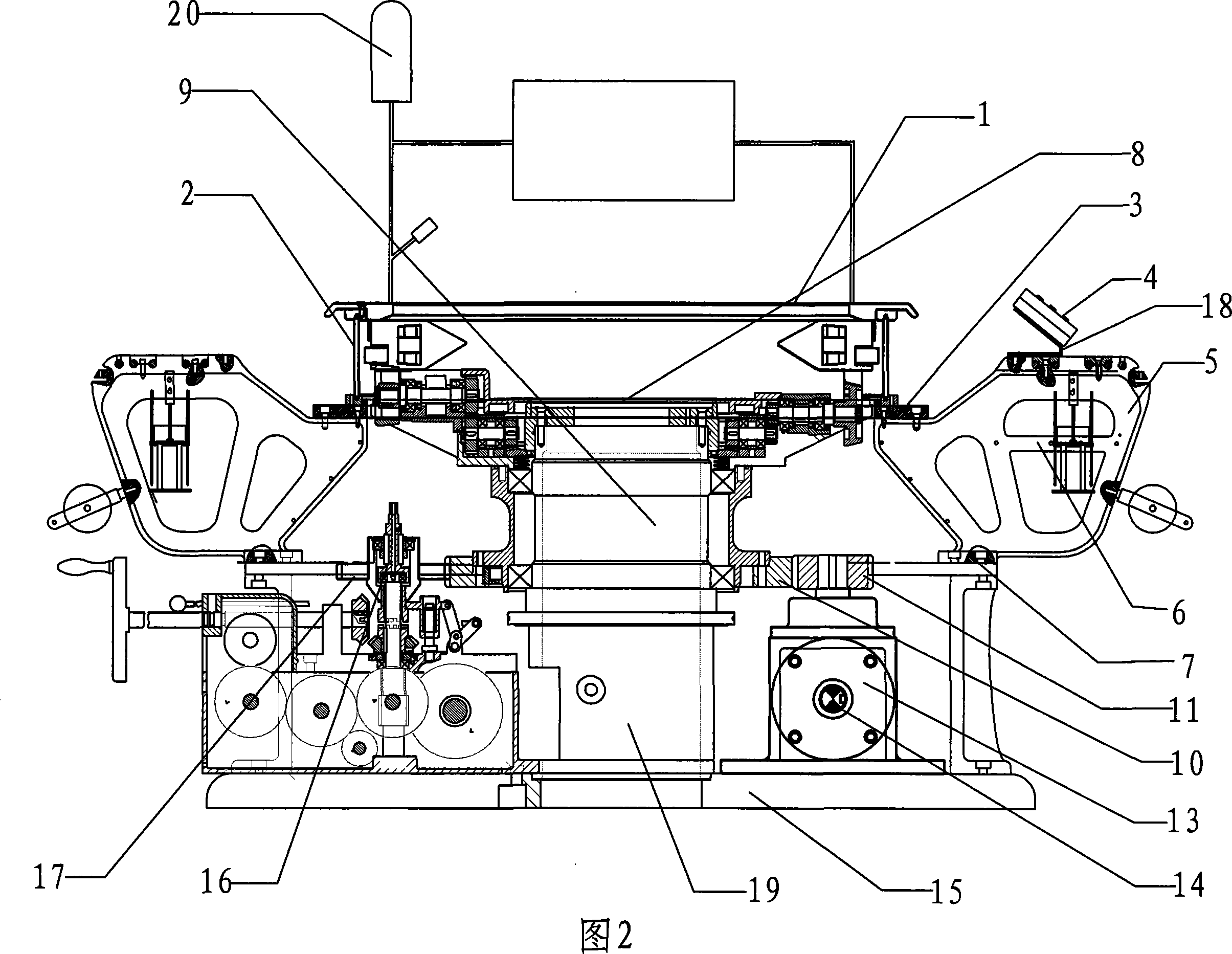

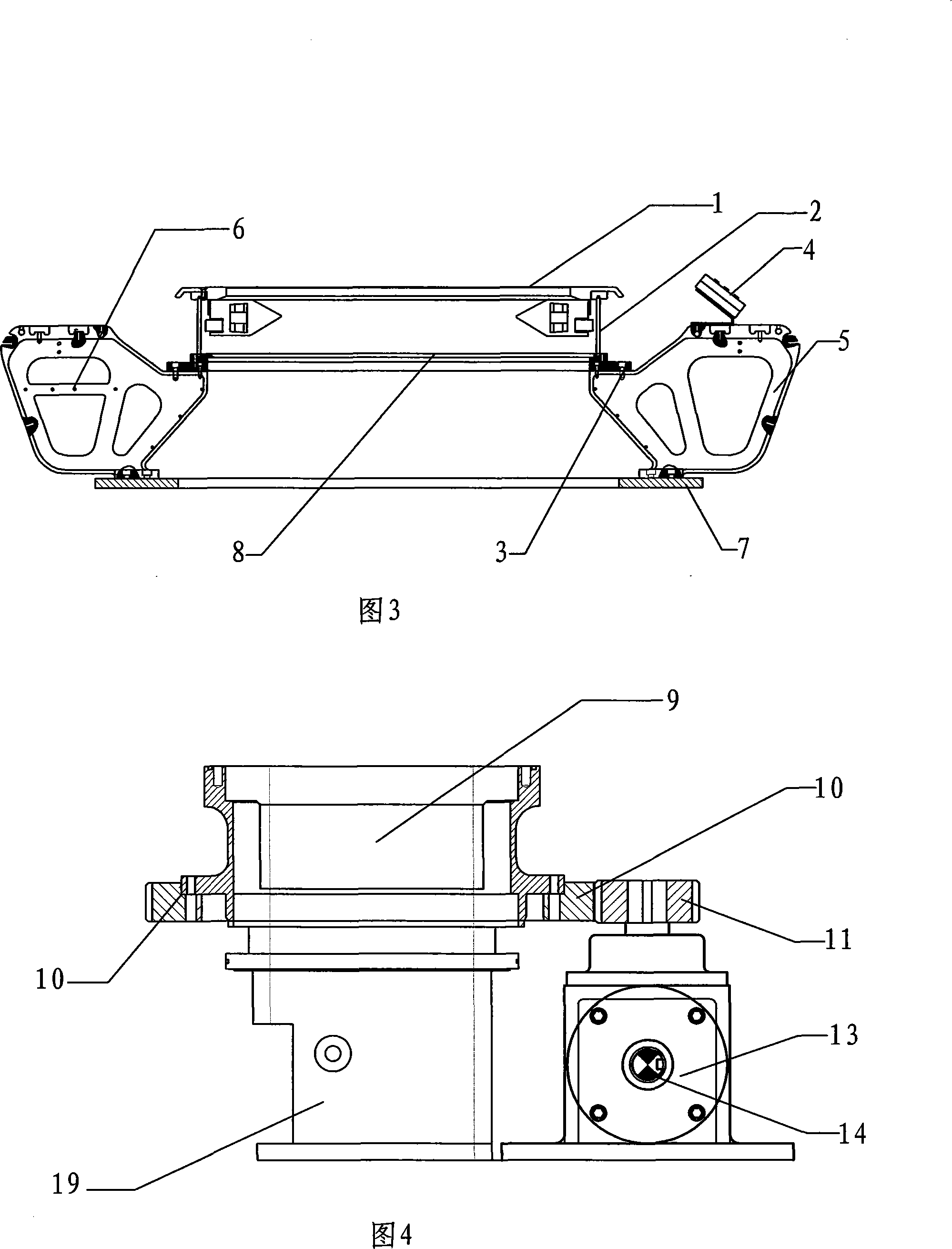

[0023] As shown in Figures 2 to 4, the circular loom of the present invention includes a circular guide rail 1, a shuttle frame 2, a shuttle frame seat 3, a button box 4, a wall panel 5, a horizontal plate 6, a wall panel seat 7, Shuttle bed 8, shuttle bed bearing seat 9, main drive nylon gear 10, driving gear 11, coupling 12, reversing reducer 13, motor 14, large base 15, traction gearbox 16, helical gear 17, V-shaped Support 18, center seat 19 and disconnection alarm indicator light 20.

[0024] In the present invention, the guide shuttle frame 2 is directly fixed on the guide shuttle frame seat 3, the guide shuttle frame seat 3 is then fixed on the wallboard 5, the lower end of the wallboard 5 is fixed on the wallboard seat 7, and the wallboard 5 is precast A horizontal plate 6 is provided, and the button box 4 is installed on the V-shaped support 18, and the V-shaped support 18 is installed on the wallboard 5. The motor 14 is connected horizontally with the reversing redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com