Patents

Literature

253results about How to "Meet space requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

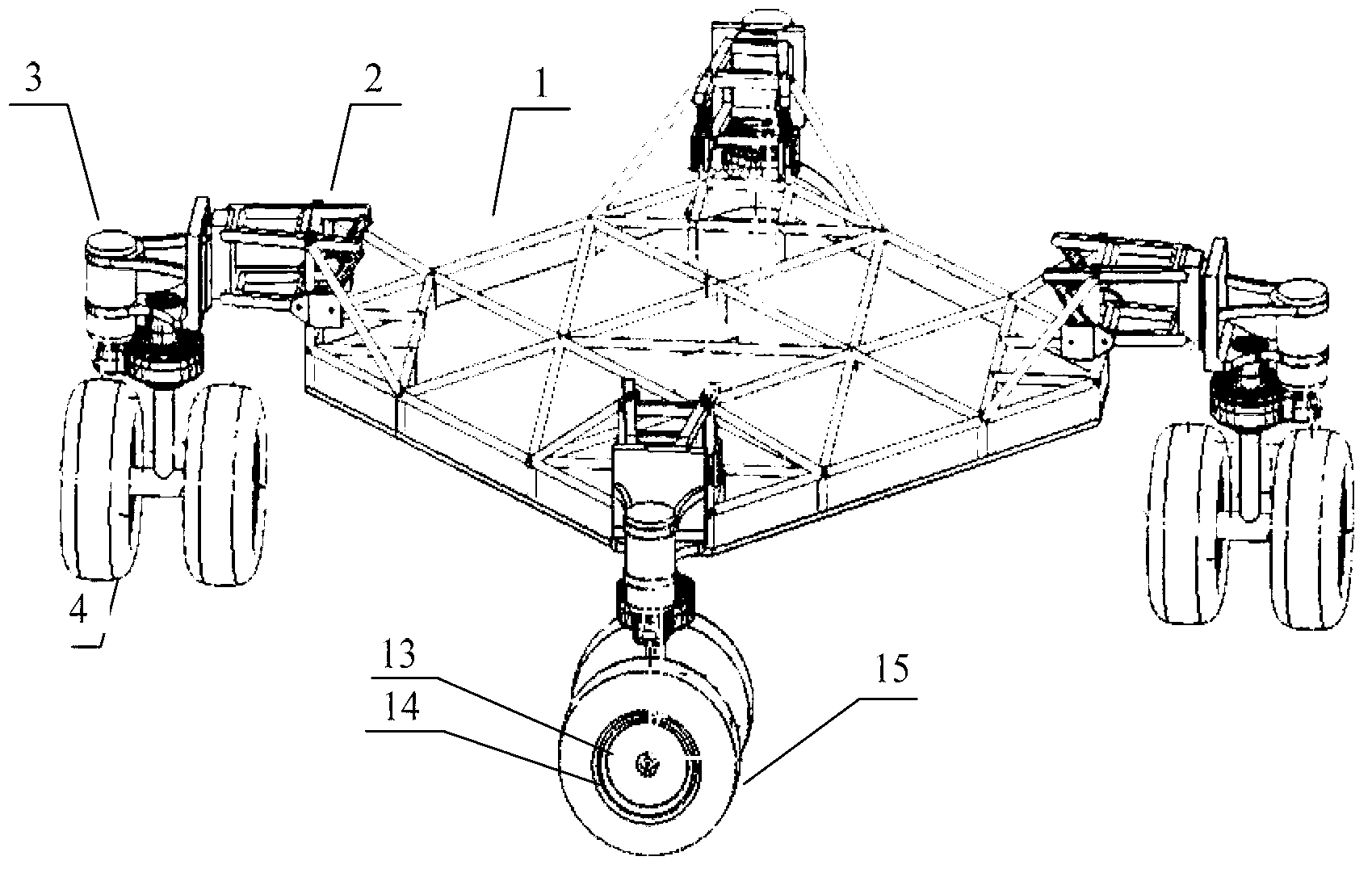

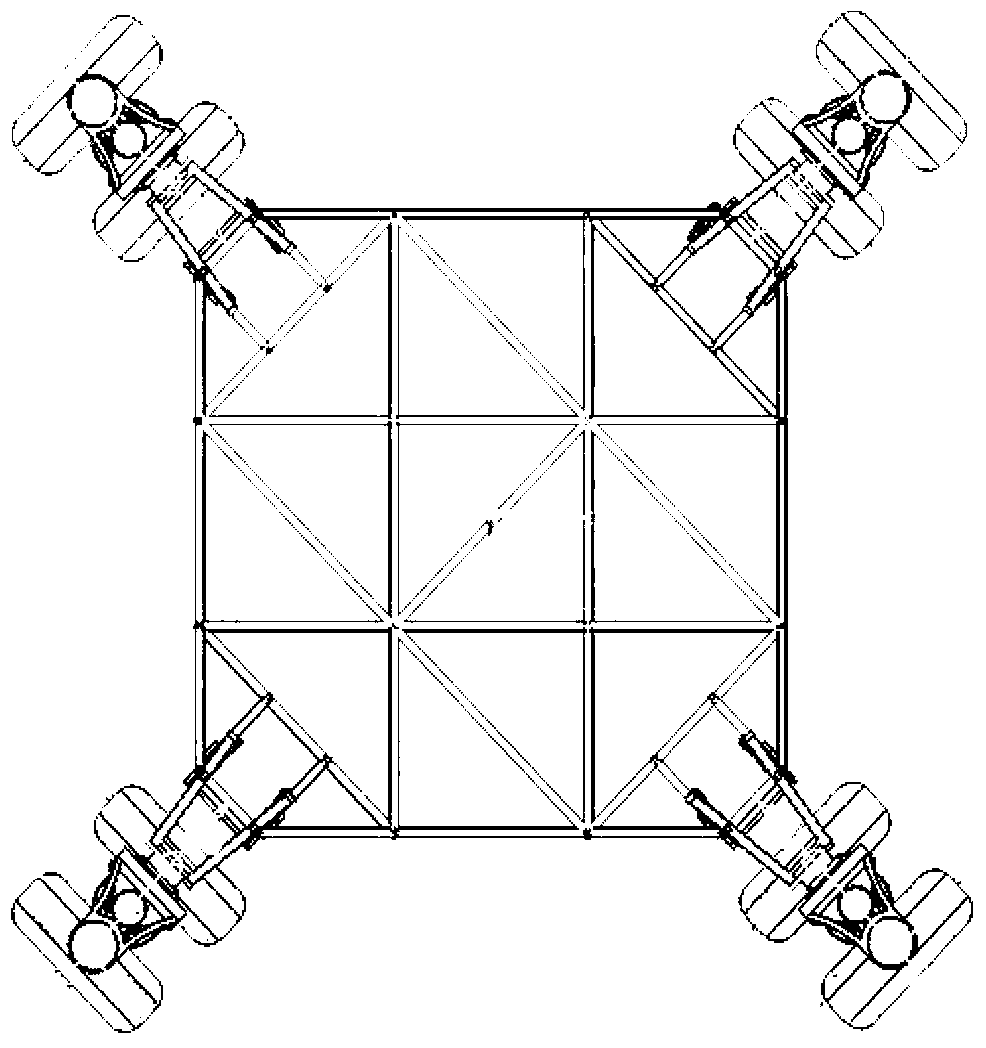

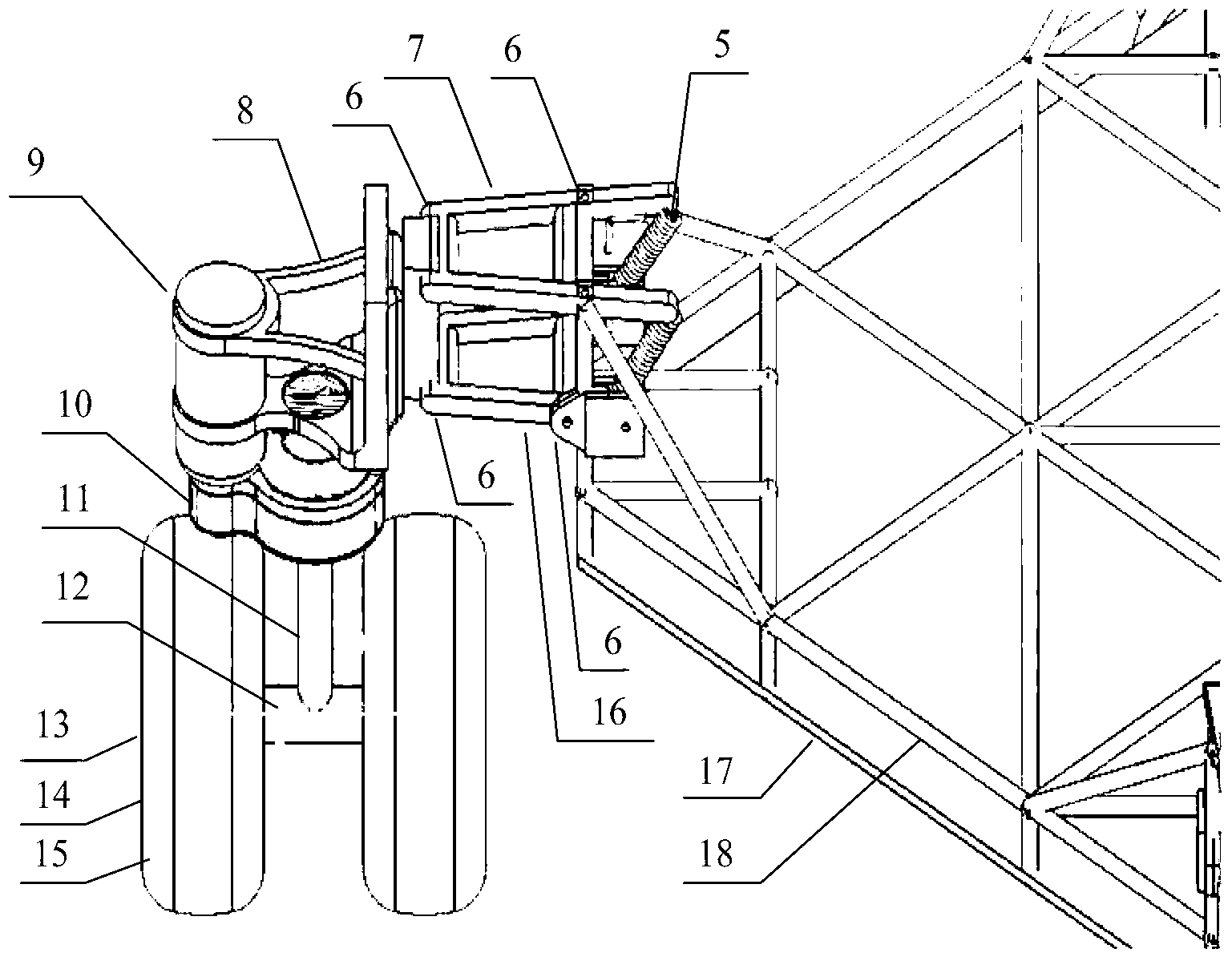

Manned lunar rover

InactiveCN103318423AImprove adaptabilityImprove stabilityExtraterrestrial carsMotor depositionReduction driveDrive shaft

The invention provides a manned lunar rover. The manned lunar rover comprises a vehicle chassis system, four driving systems and a casing which is provided with wire mesh tires; the four driving systems are uniformly distributed on the periphery of the vehicle chassis system; every driving system is in linkage connection with a steering system; the steering systems comprise steering shafts; one ends of the steering shafts are in linkage connection with driving shafts; the other ends of the steering shafts and power output ends of steering motors are fixed through speed reducers; every steering system is connected with the vehicle chassis system through a suspension system. The manned lunar rover has strong driving capability adapting to bad road conditions and can meet the requirements of special road conditions and special environments on the surface of the moon.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

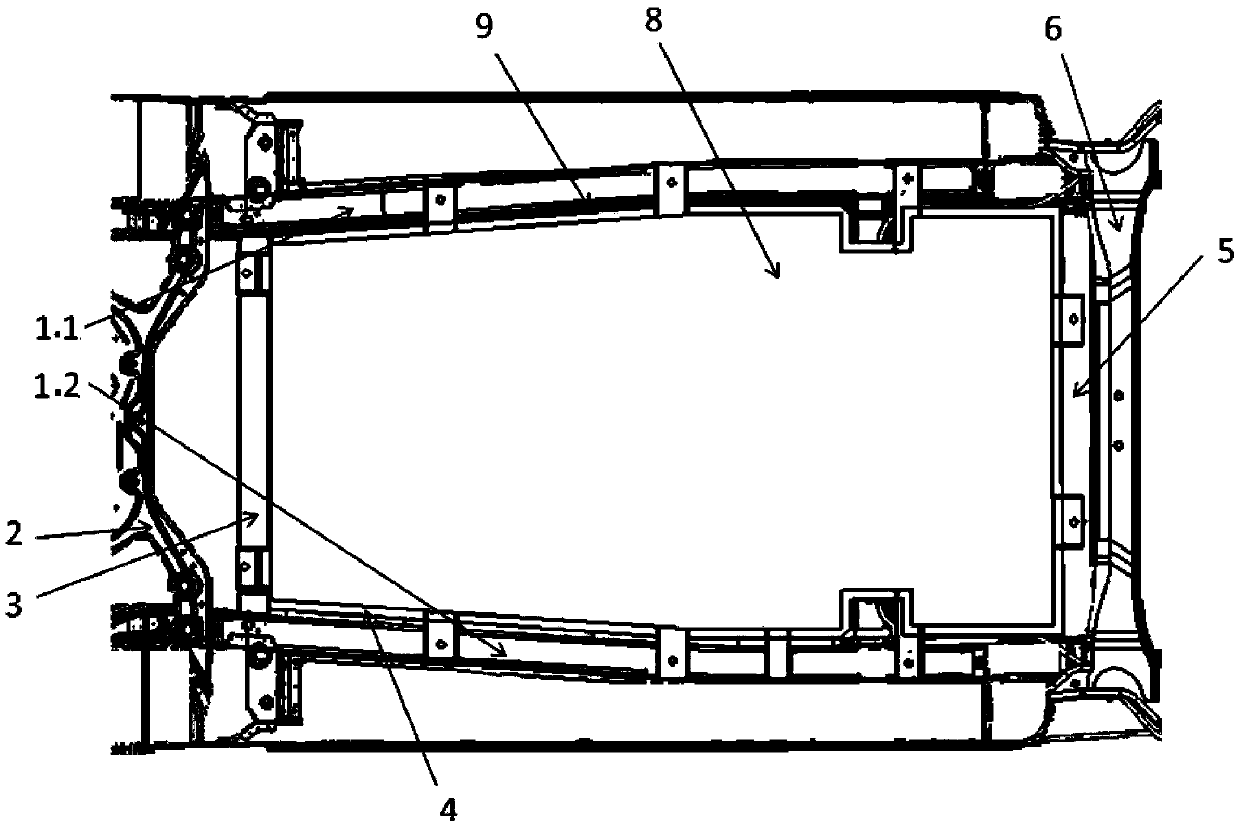

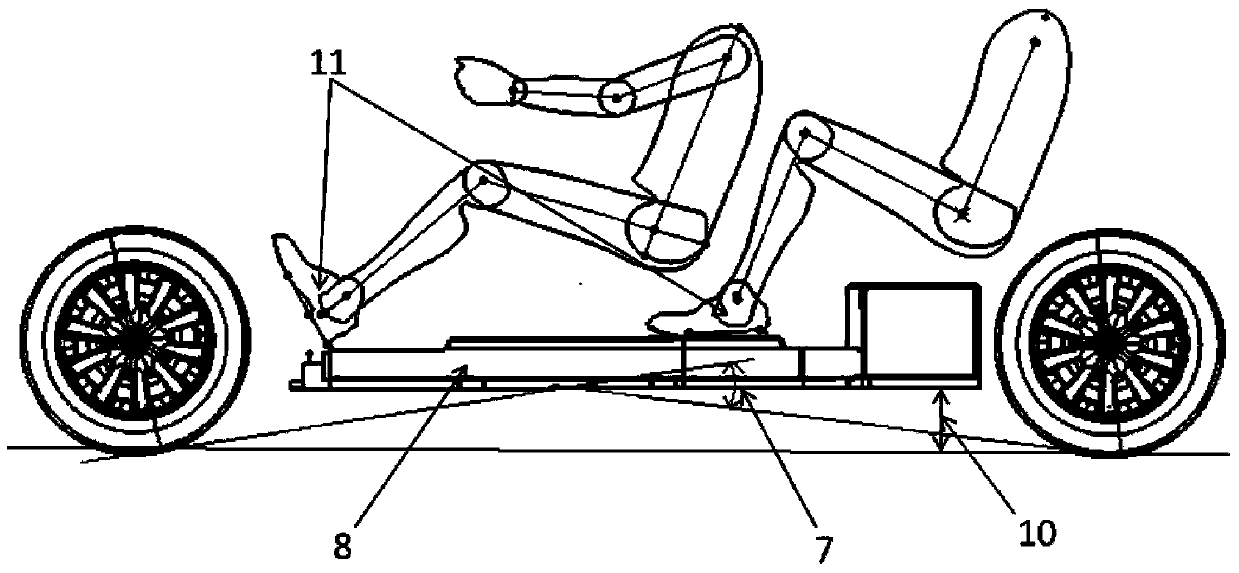

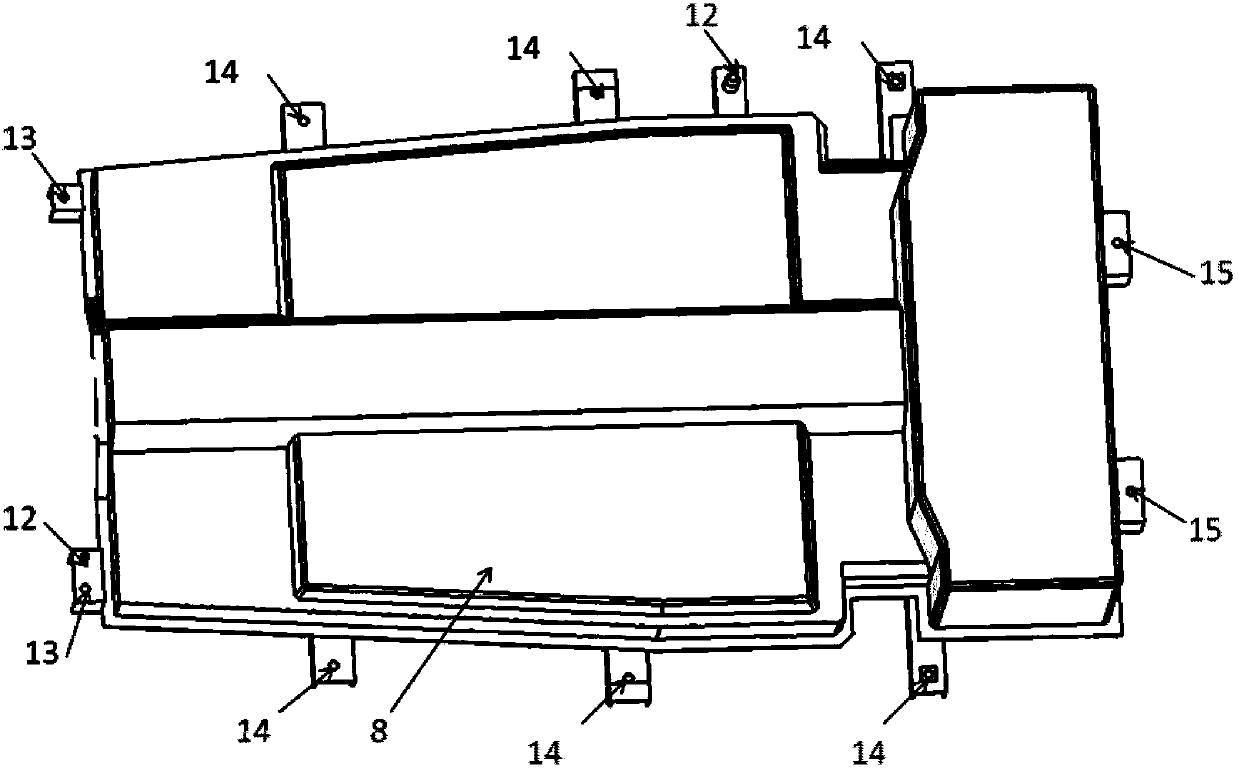

A0-grade pure electric car power battery arrangement scheme

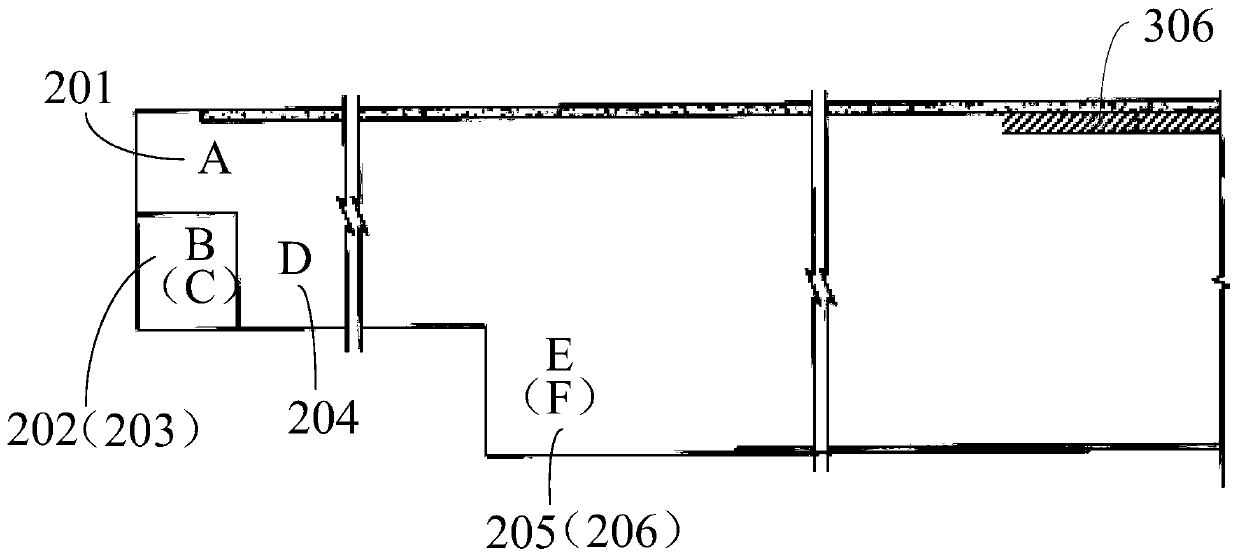

InactiveCN103465763AVolume maximizationImprove battery lifeElectric propulsion mountingPower batteryMan machine

The invention provides an A0-grade pure electric car power battery arrangement scheme. A power battery and an installing structure of the power battery are arranged under a vehicle body floor, are positioned between left and right vertical beams and front and back suspension frames, and maintain reasonable gaps with the left and right vertical beams and the front and back suspension frames, and the space requirements of charging wire harnesses and braking oil pipes are met. According to parameters including the arrangement requirements of the man-machine engineering, the structure of a vehicle body lower floor, an installing structure of a chair, the arrangement requirements of internal battery cells of the power battery and the like, the structure is designed into the step-shaped structure with different heights that the front section of the battery is lower, and the back section of the battery is higher. A lower bottom surface is determined to ensure that the minimum ground clearance and the vertical passing angle of the whole vehicle meet the whole vehicle design relevant requirements. The A0-grade pure electric car power battery arrangement scheme has the advantages that the maximum size of the battery is ensured, the utilization rate of the internal space of the power battery is ensured, and the modification on the prototype vehicle is reduced to the maximum degree. The reasonable axial load distribution of the whole vehicle is ensured through the arrangement position of the power battery on the whole vehicle, so the vehicle has good operation stability, and the running safety of the vehicle is ensured.

Owner:BEIJING ELECTRIC VEHICLE

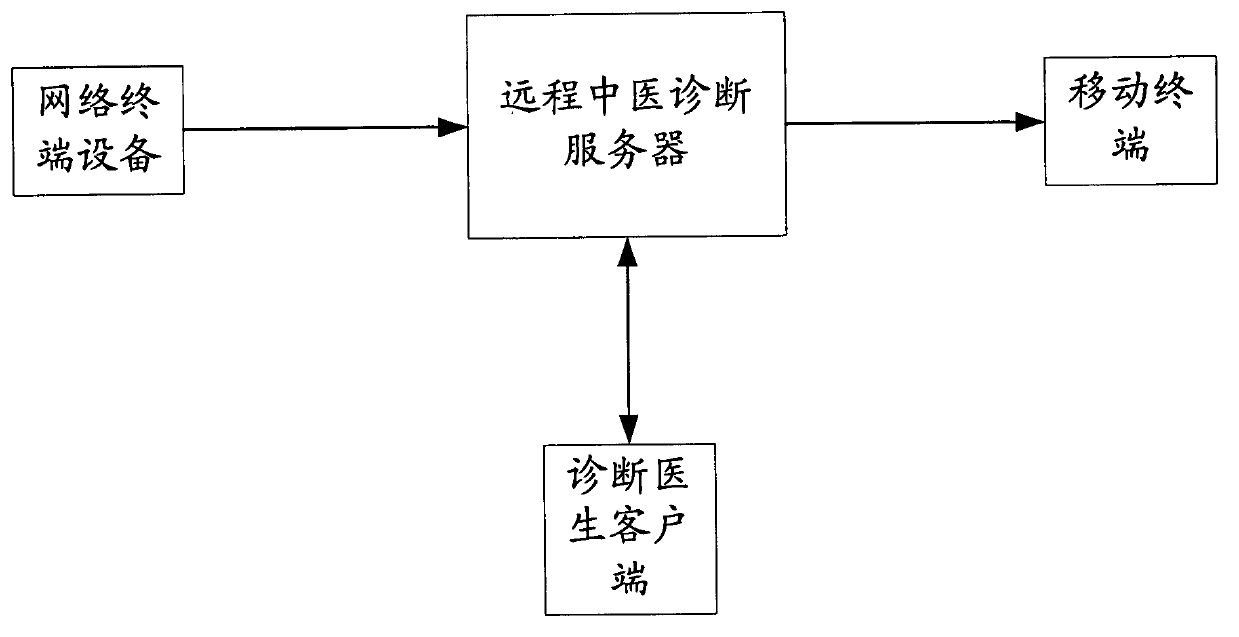

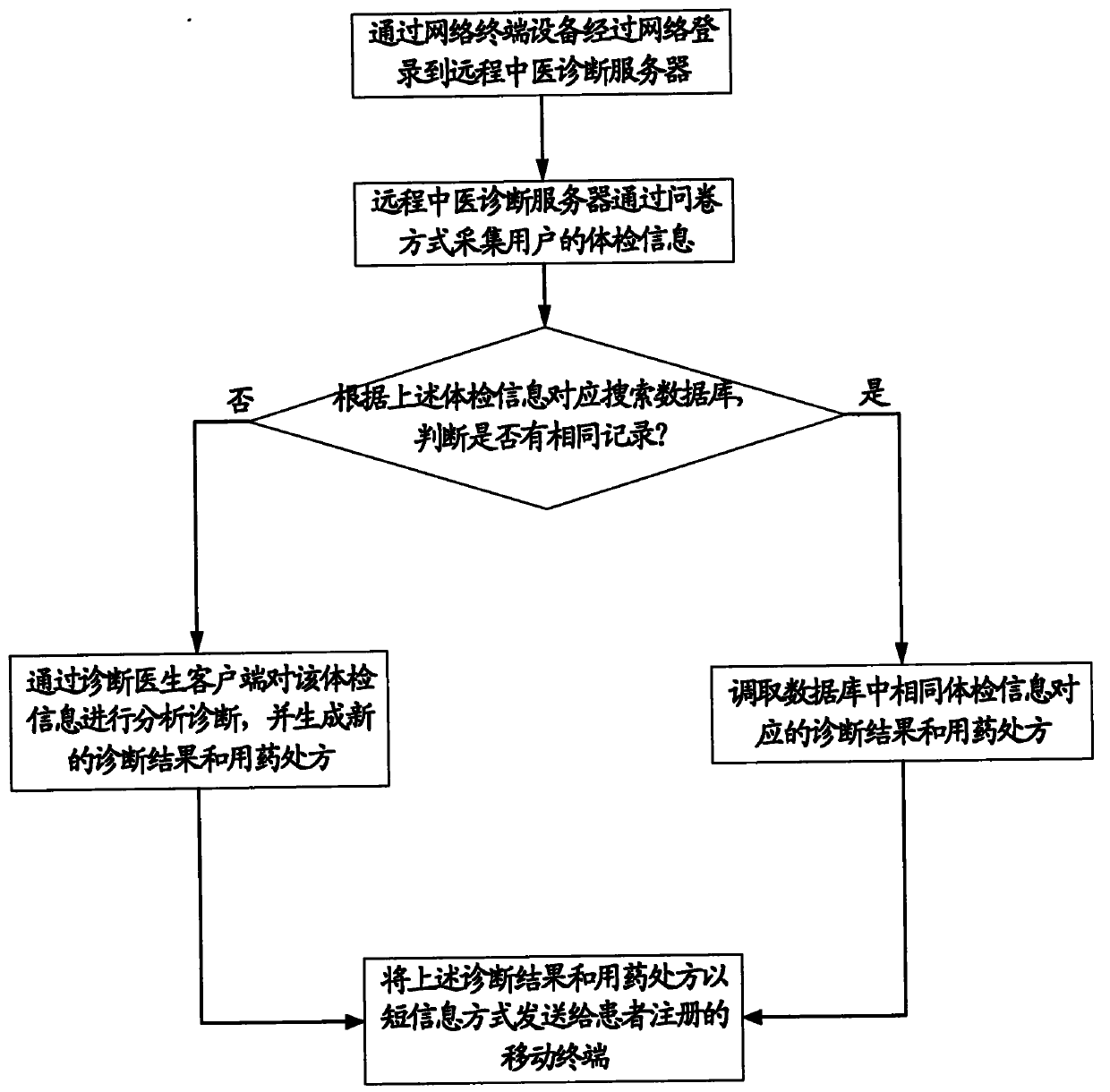

Traditional Chinese medicine remote diagnosis system and method realized by Internet

InactiveCN103136716AMeet the time requirementMeet space requirementsData processing applicationsMessaging/mailboxes/announcementsMedicineTraditional medicine

The invention discloses a traditional Chinese medicine remote diagnosis system and a method realized by Internet. The traditional Chinese medicine remote diagnosis method realized by the Internet comprises the following steps: gathering physical examination information of users by logging on a remote traditional Chinese medicine diagnosis server, and relatively searching and analyzing based on the physical examination information, if the same physical examination information exists, relatively retrieving diagnostic results and drug-taking prescriptions to send to the mobile phones of patients restively through messages; if the same physical examination information dose not exist, the physical examination information is relatively diagnosed through a diagnostic doctor client-side, and the novel diagnostic results are formed and the drug-taking prescriptions are relatively sent to the mobile phones of the patients. The traditional Chinese medicine remote diagnosis system and the method realized by the Internet greatly satisfy the time and spatial requirements of patients for traditional Chinese medicine diagnosis, save time of the diagnosis, are capable of arranging limited medical resources, enabling patients to timely and precisely understand own states of illness, and making a diagnosis and giving treatment in an effective way.

Owner:LAUNCH SOFTWARE DEV

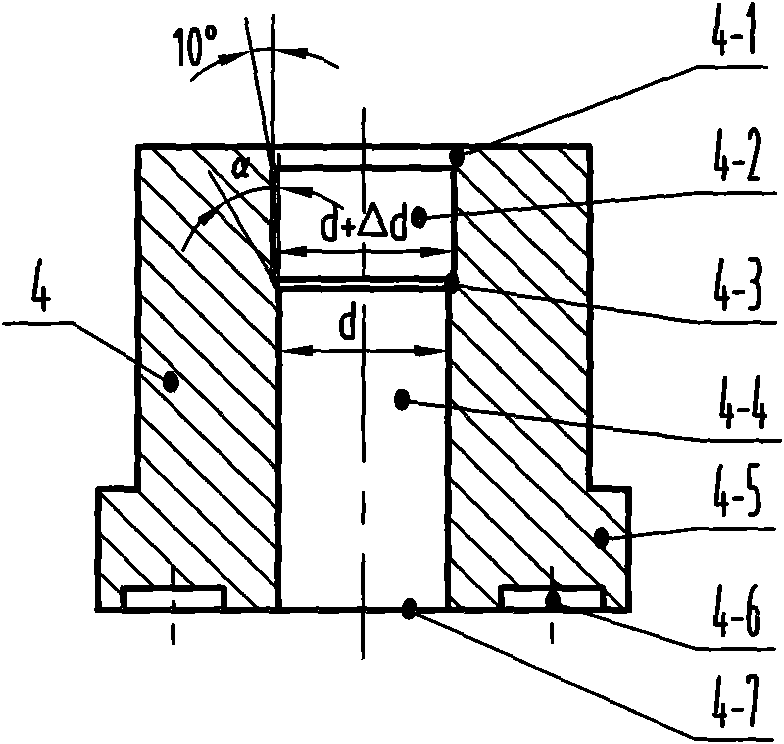

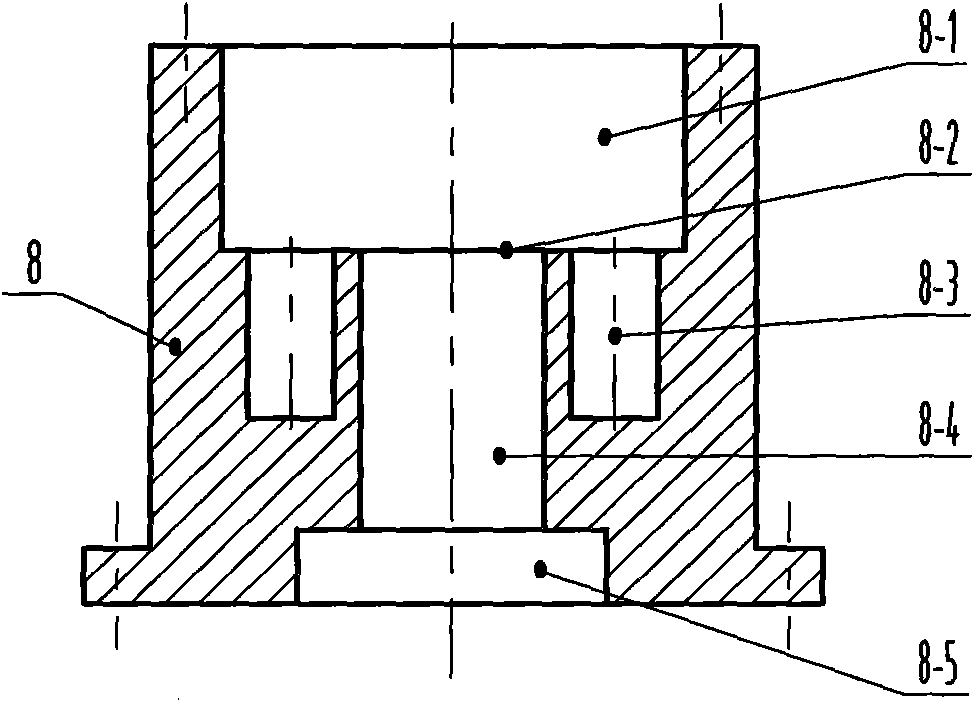

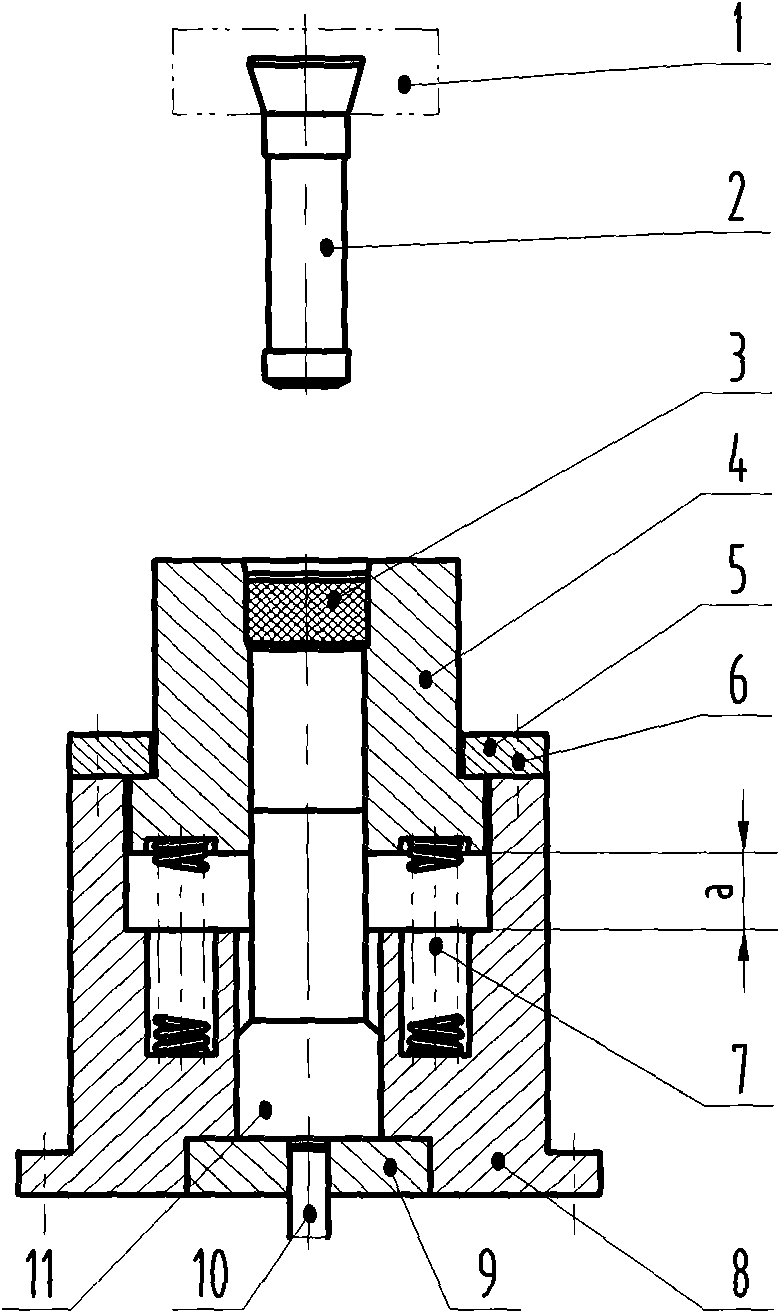

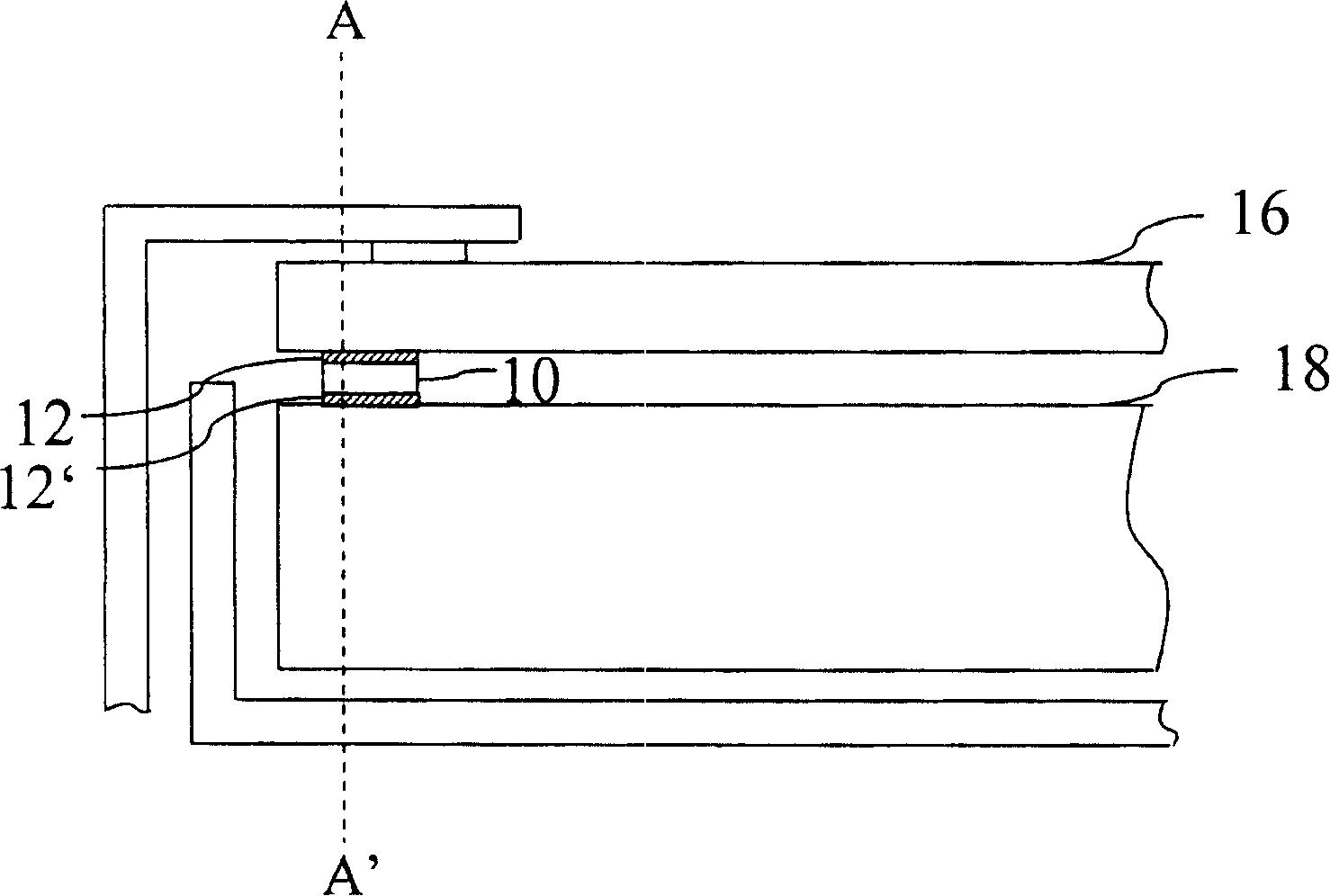

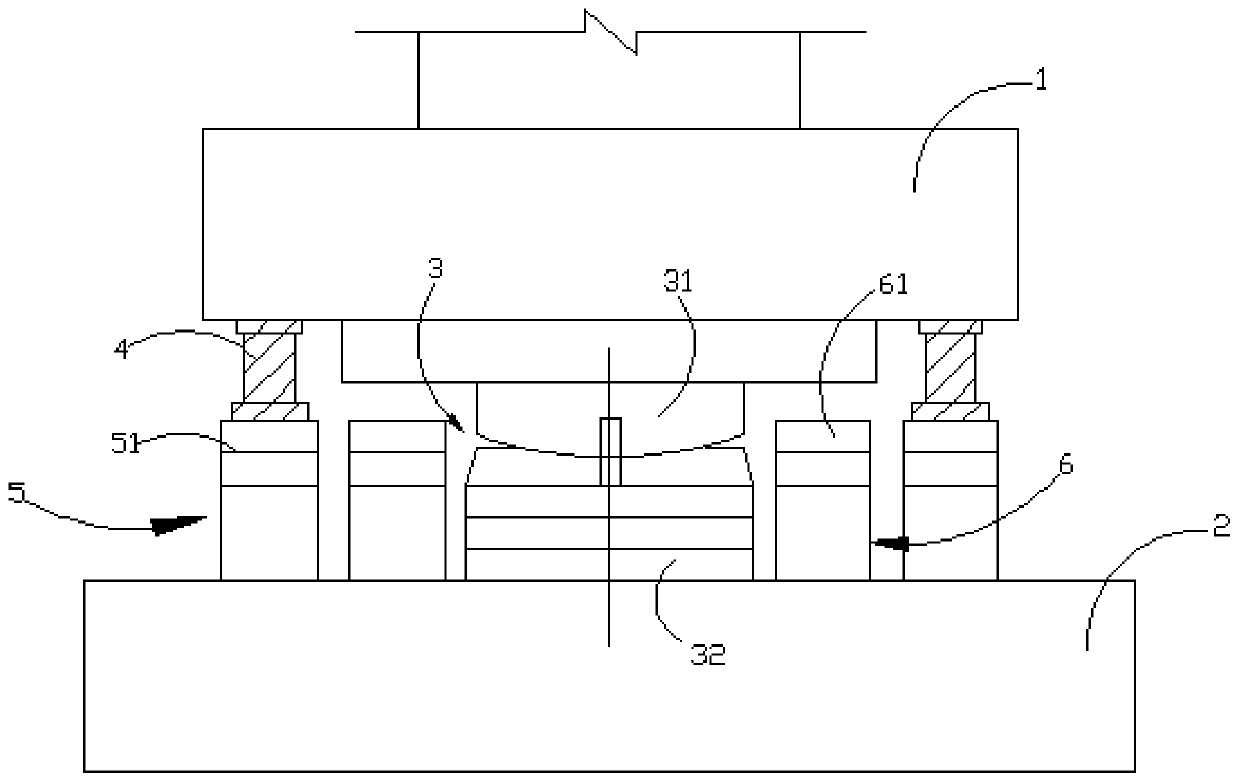

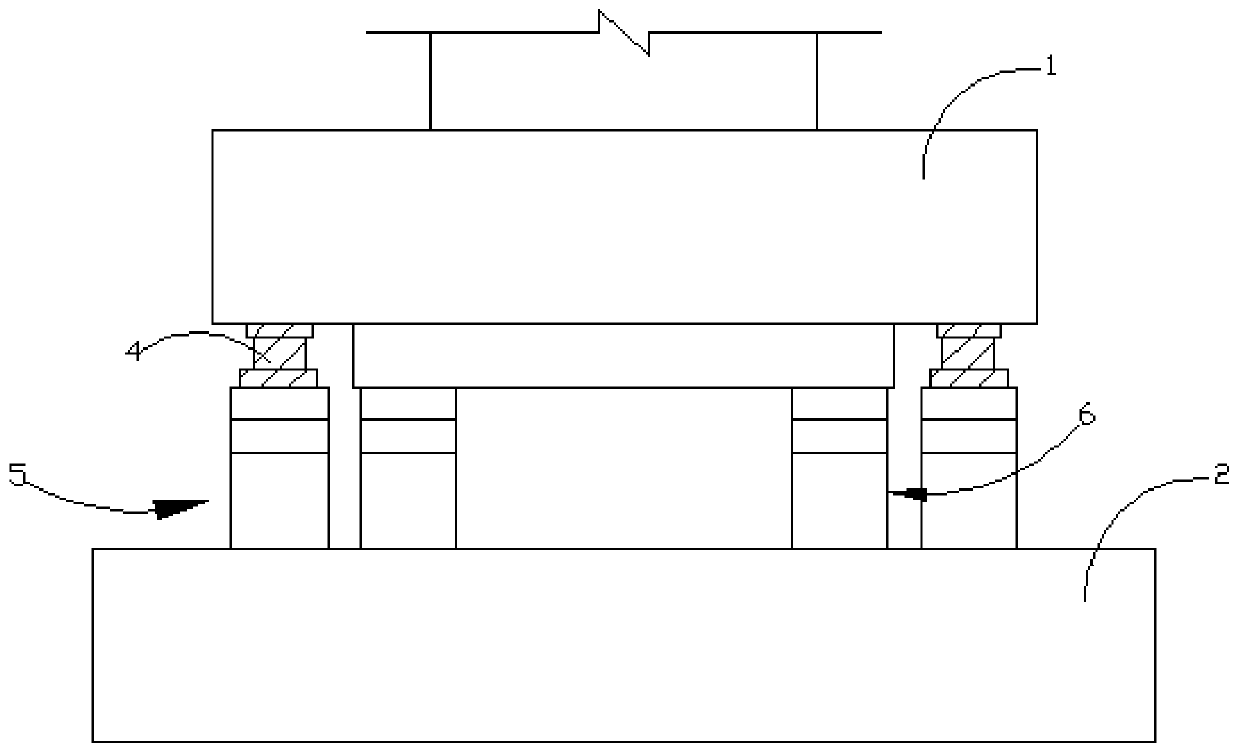

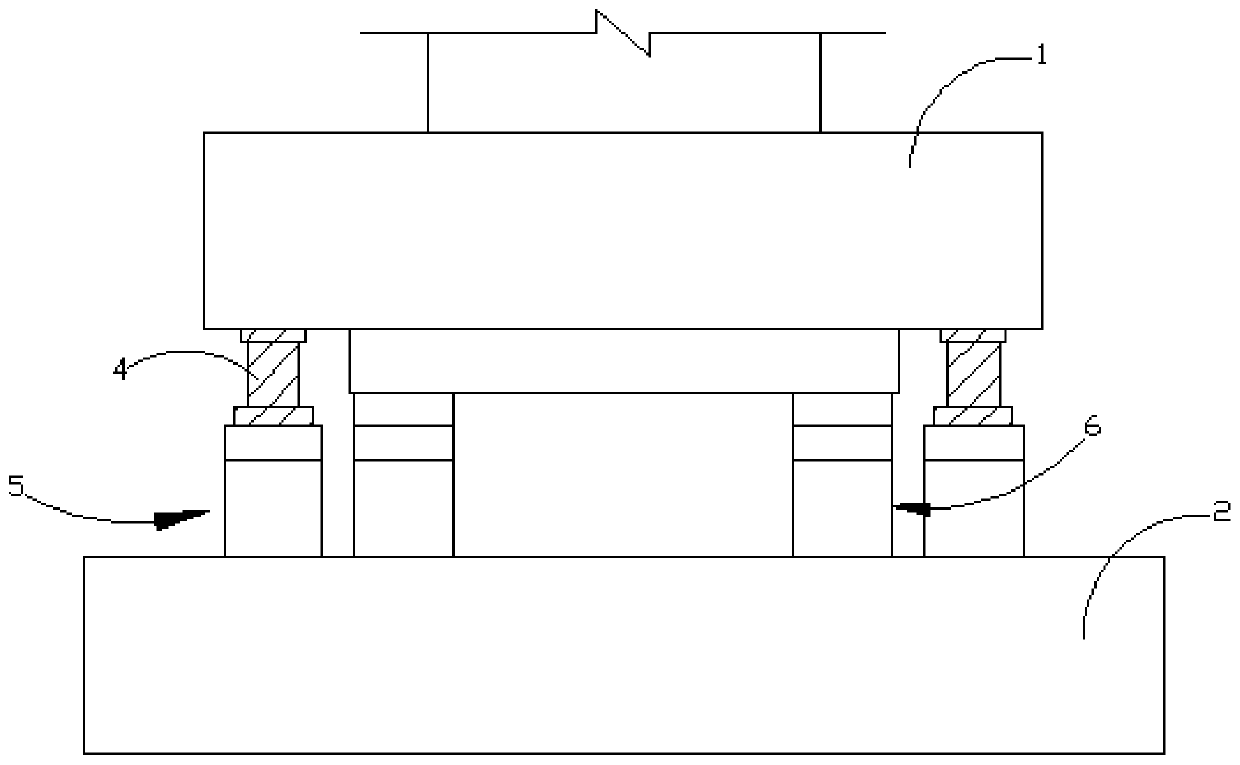

Heat backward extrusion molding process of large-sized cup-shaped piece

ActiveCN102029301AIncrease back extrusion forceReduce the effects of frictionExtrusion diesMaterials scienceForming force

The invention discloses a heat backward extrusion molding process of a large-sized cup-shaped piece, relating to a backward extrusion molding method. By using the invention, the forming force for the heat backward extrusion of the large-sized cup-shaped piece can be reduced and the problem in the prior art that the production efficiency is low is solved. The heat backward extrusion molding process comprises the following concrete steps of: (1) placing a heat blank in a material accommodating cavity; (2) downwards pressing a pressure head to enable a backward extrusion punch head to be contacted with the blank; (3) downwards pressing the pressure head and allowing a backward extrusion cylinder to downwards slide along an inner cavity of a base and compress a spring until the spring contacts with the bottom plane of the inner cavity of the base; (4) downwards pressing the pressure head to enable all blanks to be reduced and extruded to a backward extrusion cavity to be attached to an ejector rod; (5) downwards pressing the pressure head and starting the backward extrusion molding process until the process is finished; (6) backward lifting the pressure head, lifting the backward extrusion cylinder, limiting a stamped part by a stripper plate to separate from the backward extrusion punch head, allowing the ejector rod to upwards eject and then taking out the stamped part after the stamped part is separated from the backward extrusion cylinder; (7) retracting the ejector rod and allowing an ejecting material to fall off and ensuring that a die restores the initial state; and (8) repeating the process steps from (1) to (7) and continuously finishing the heat backward extrusion molding of the large-sized cup-shaped piece.

Owner:NANJING DEV ADVANCED MFG

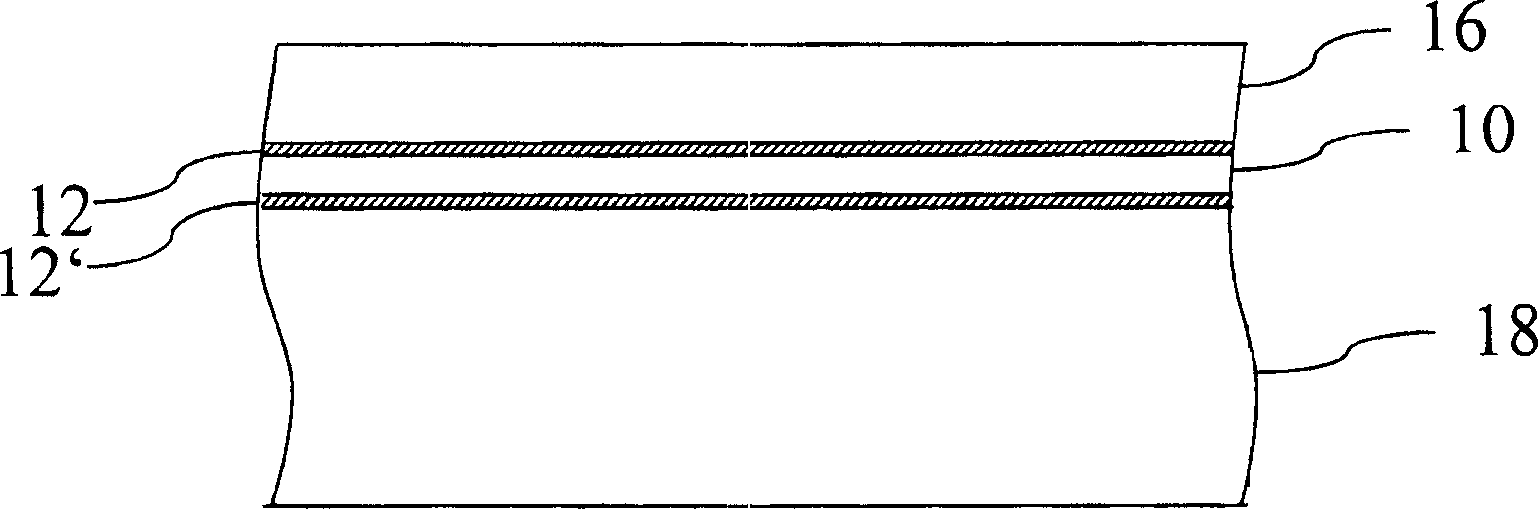

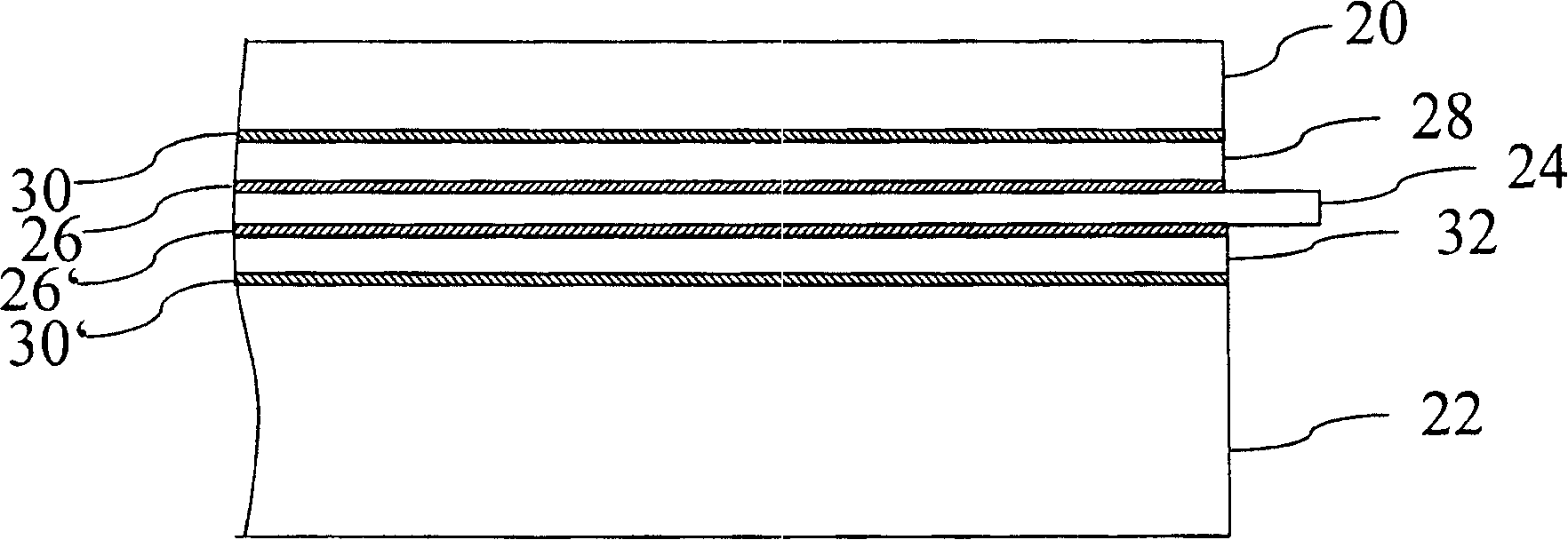

Touch panel assemblage structure

InactiveCN101169695AEasy to separateAvoid damageInput/output processes for data processingCushioningAdhesive

The invention provides a touch panel assembly structure. Based on the existing assembly structure, a long-strip film and a cushioning material layer are added, and the touch panel can be easily separated from a display panel when being disassembled by using the low viscosity of an adhesive tape. The shortcoming that the touch panel cannot be easily separated from the display panel due to the viscosity of a double-sided adhesive tape in the prior disassembly process, the panel has no residual adhesive left after being disassembled, and the touch panel can avoid from being damaged during the disassembly process, so that the touch panel can be repeatedly assembled.

Owner:CORETRONIC

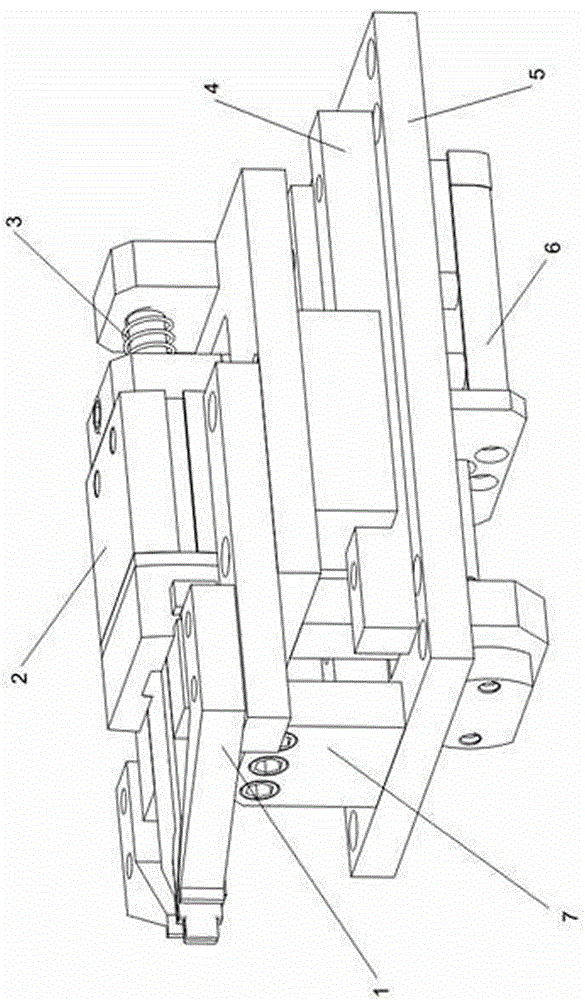

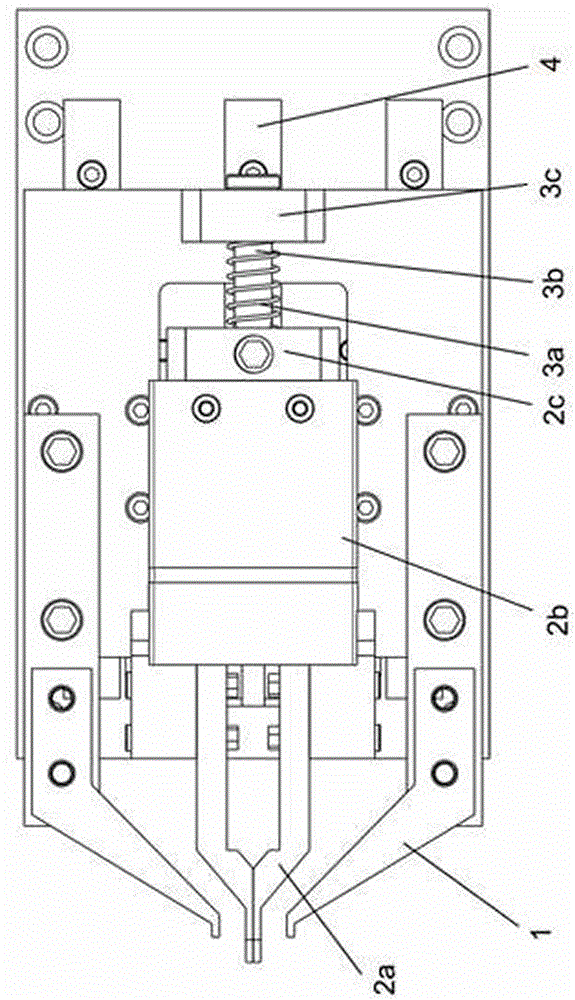

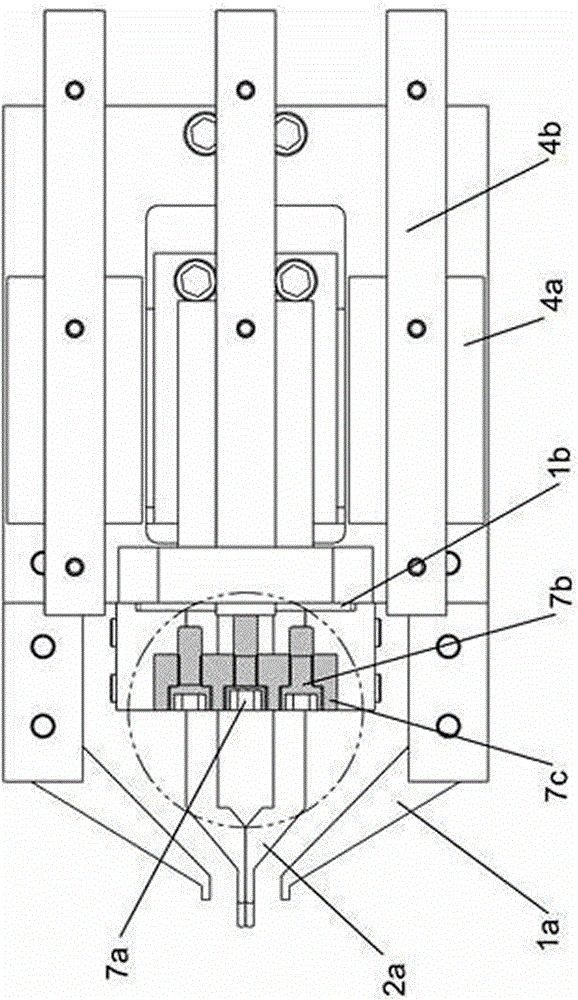

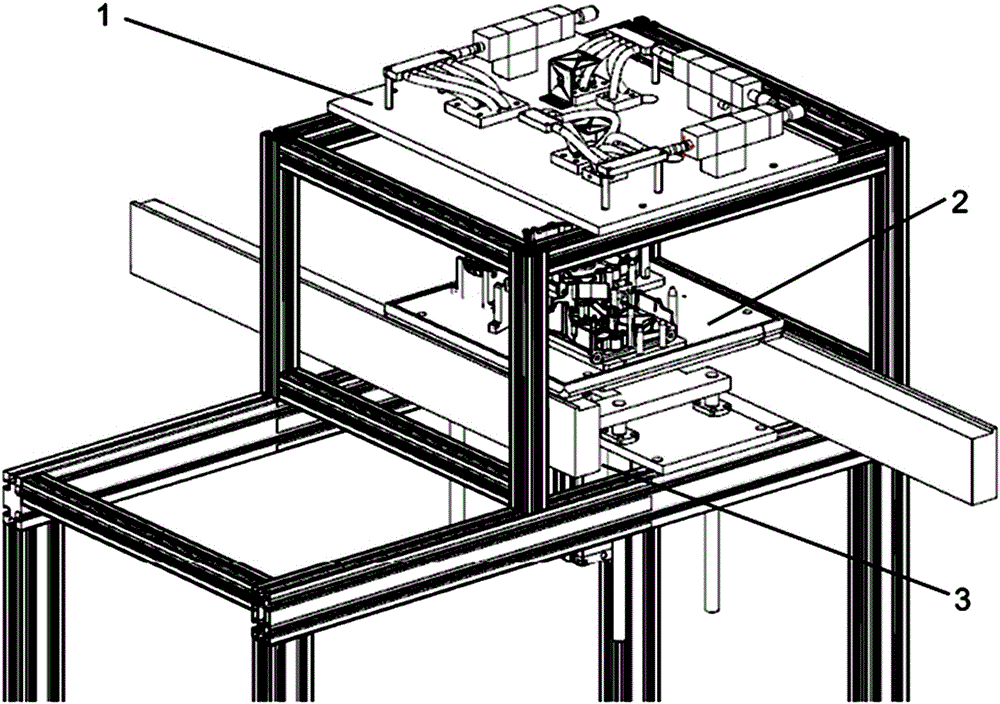

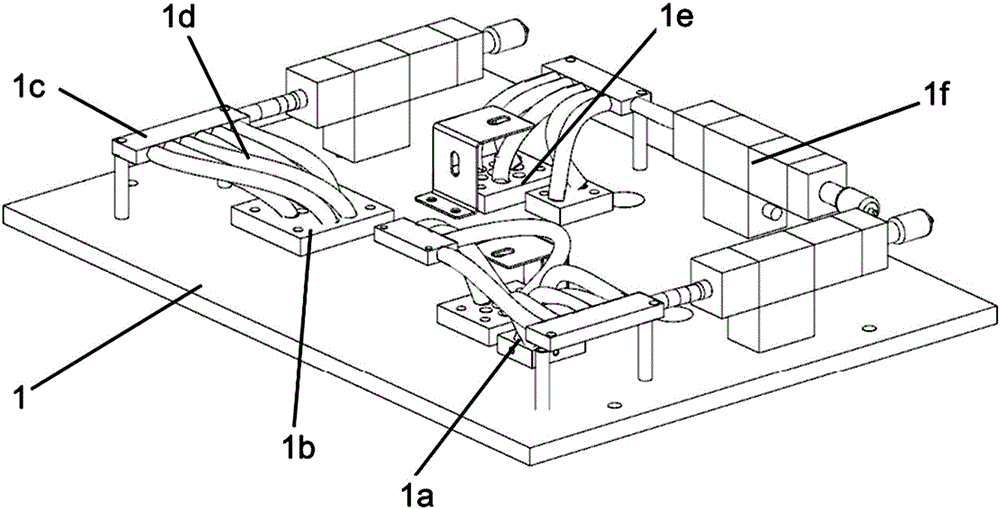

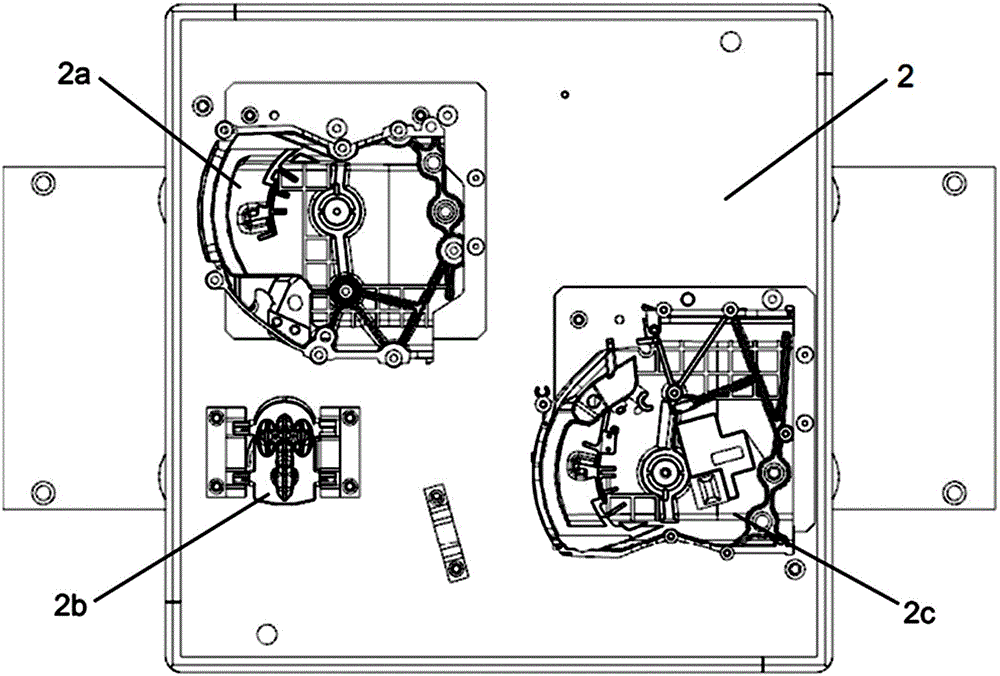

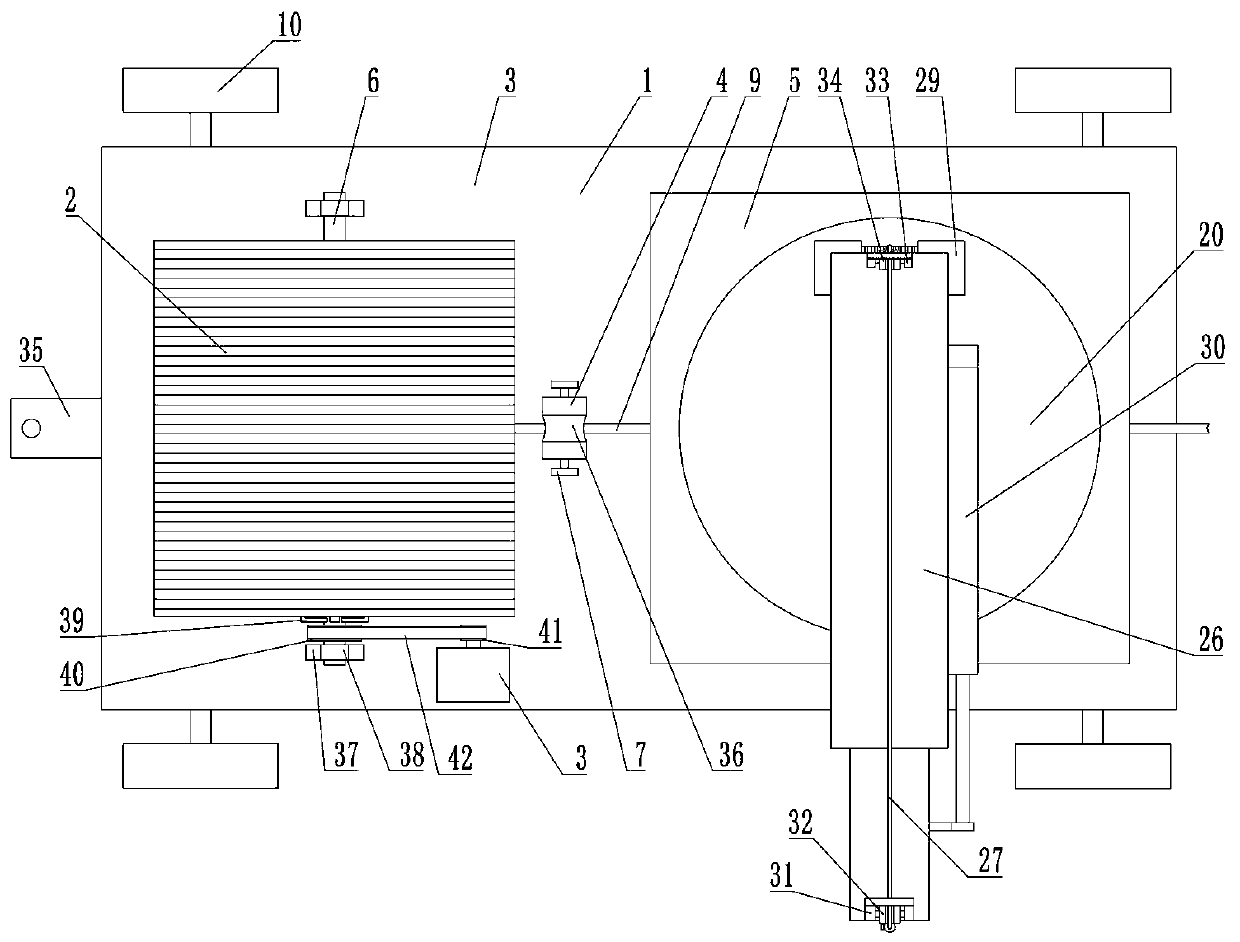

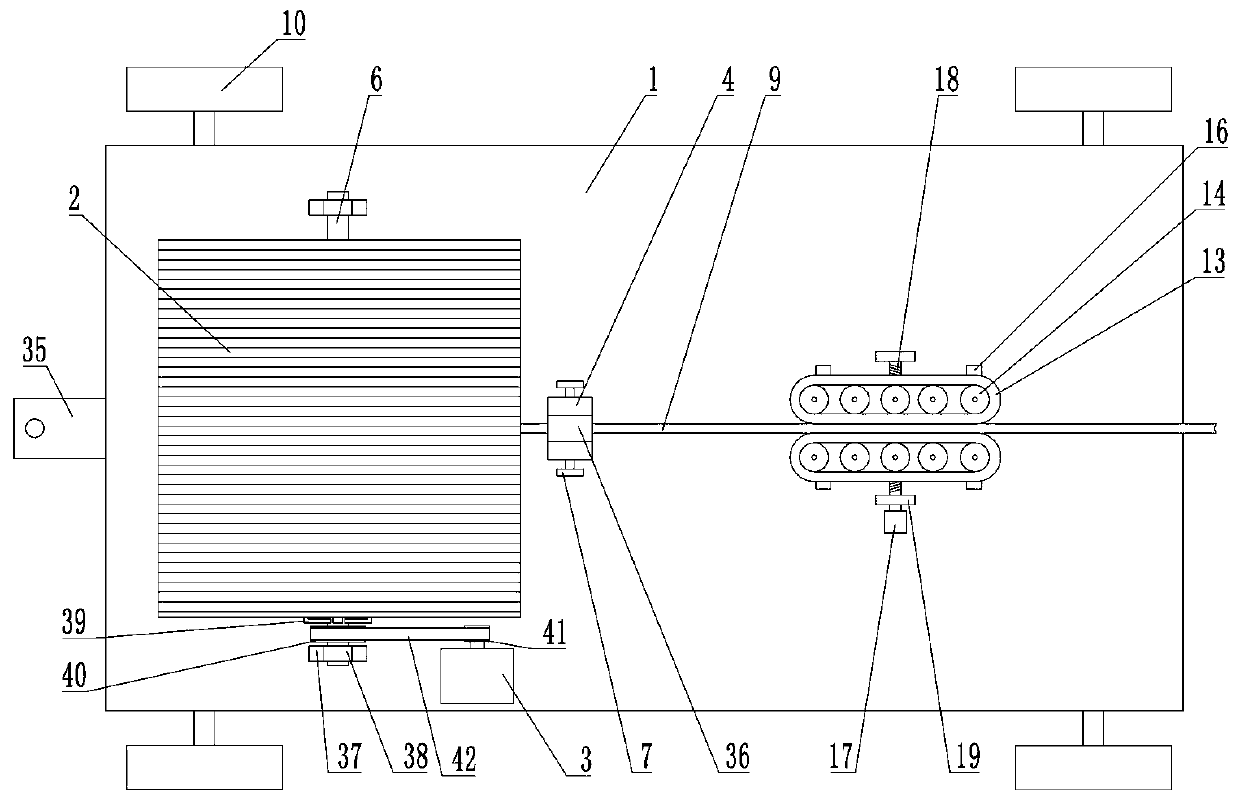

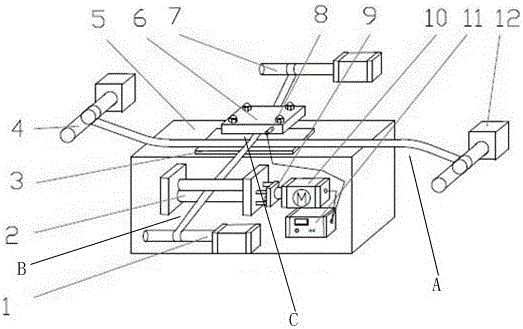

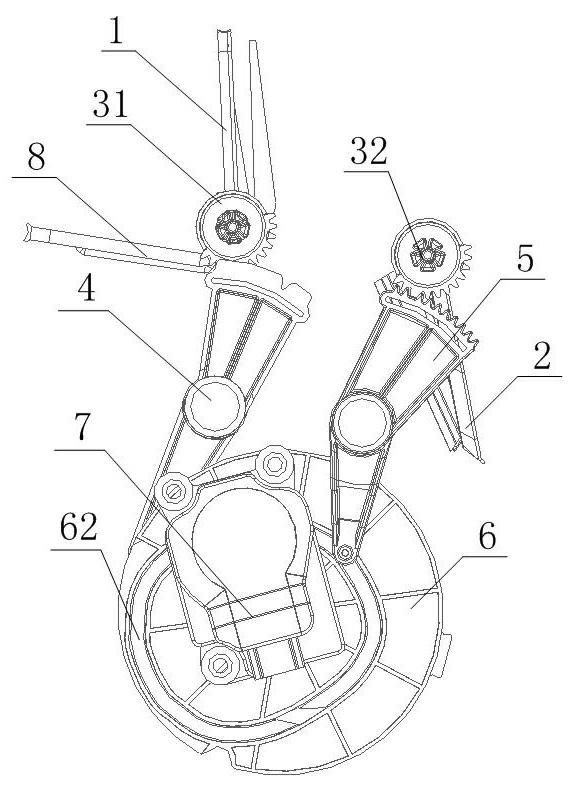

Automatic assembly device for gear shifter O-shaped ring

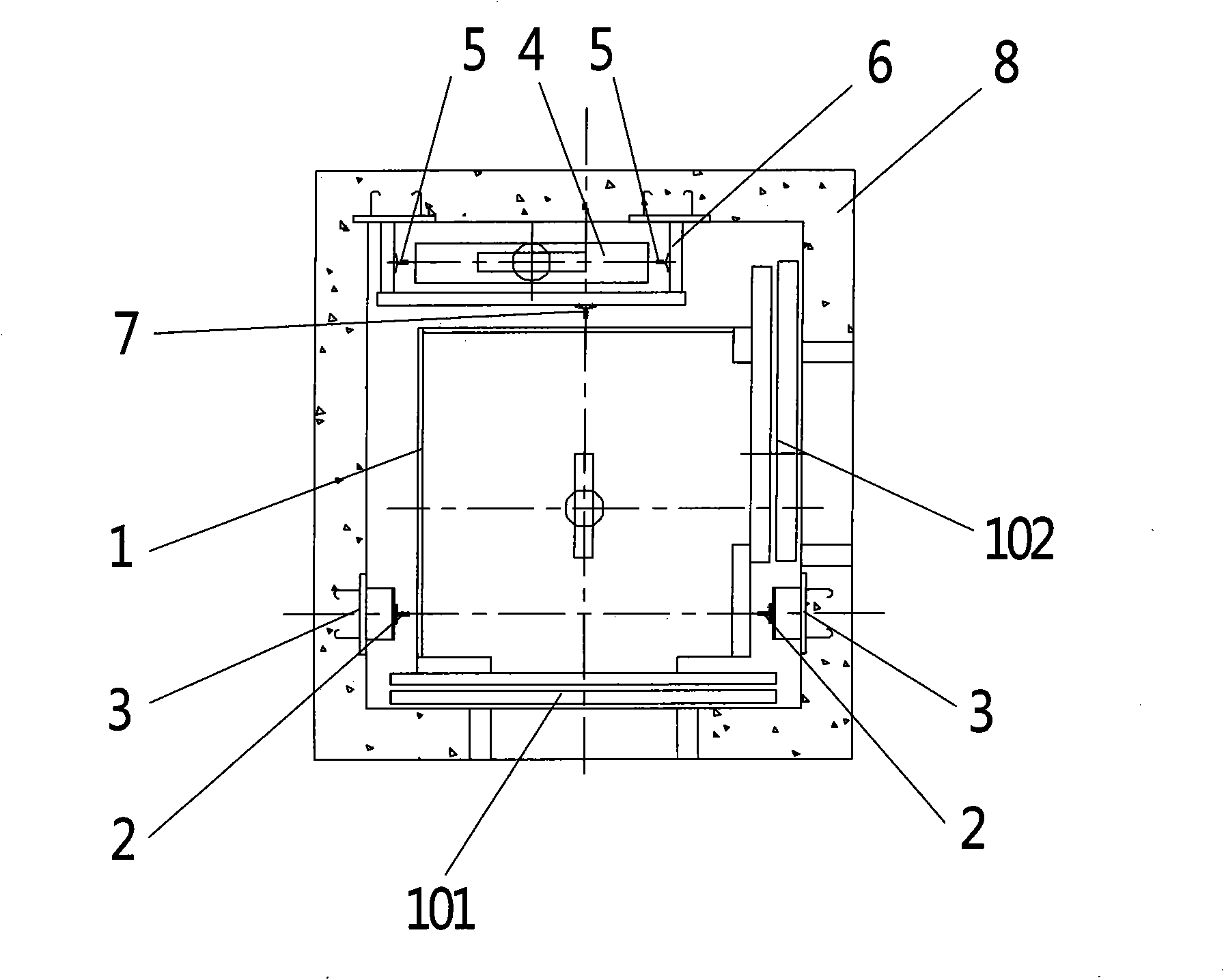

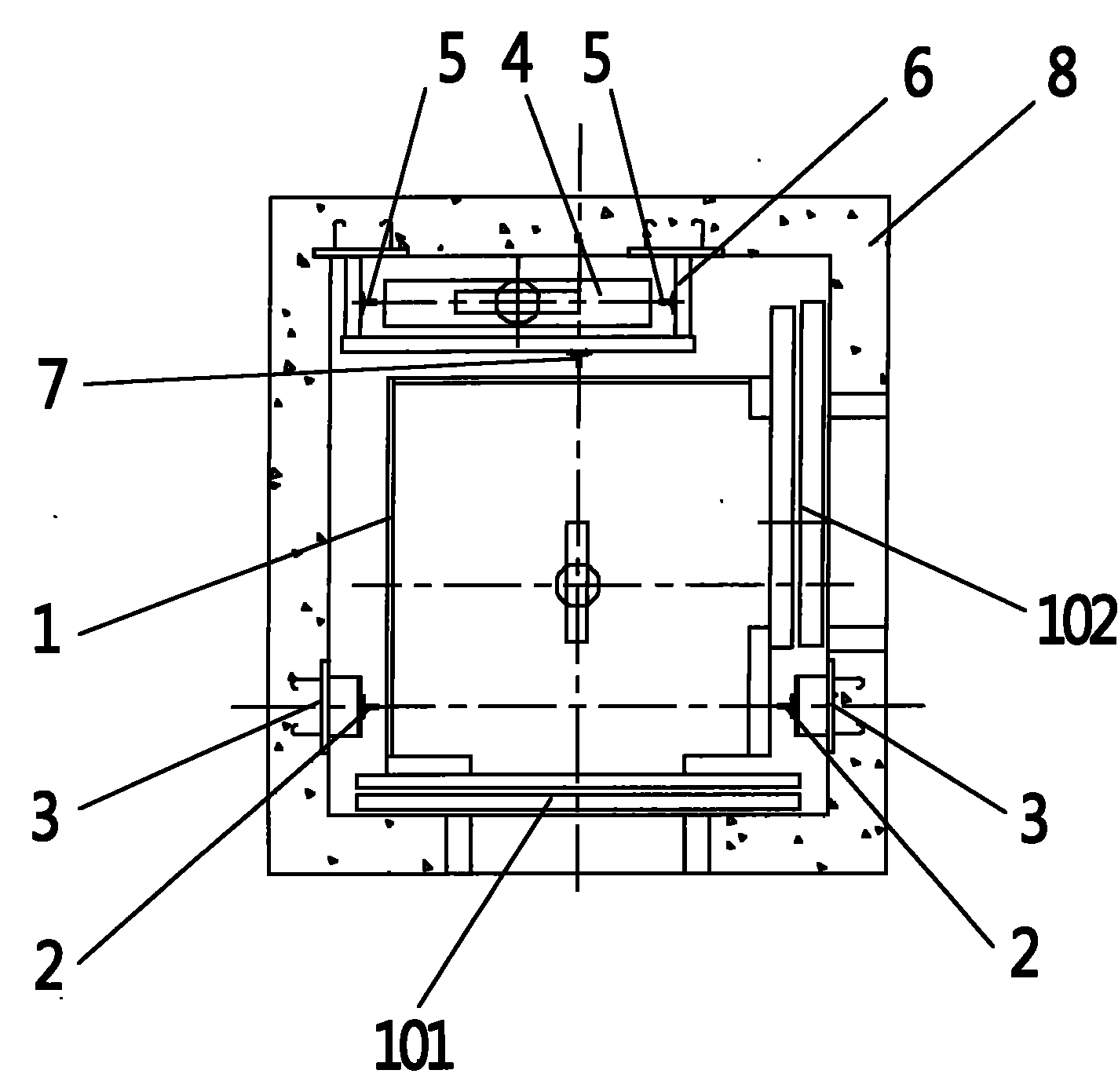

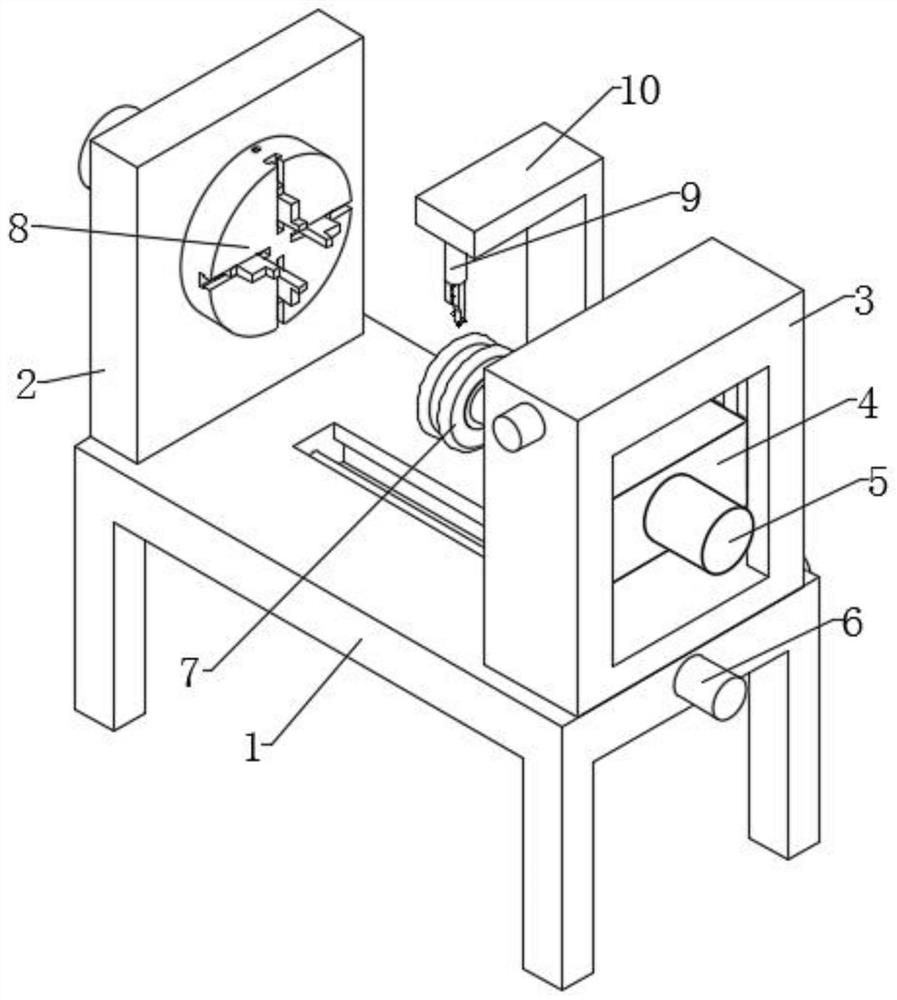

ActiveCN104907799AAssembly precisionImprove assembly pass rateMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic assembly device for a gear shifter O-shaped ring, belongs to the technical field of automatic assembly, and particularly relates to the automatic assembly device of the gear shifter O-shaped ring. The automatic assembly device is high in assembly efficiency and compact in structure. The automatic assembly device comprises a supporting base and is structurally characterized in that a cylinder is horizontally arranged on the rear portion of the lower end of the supporting base, two side guide rails and a middle guide rail are arranged on the two sides and in the middle of the supporting base in the front and back length direction of the supporting base, two side slide blocks are arranged on the two side guide rails, the upper ends of the two side slide blocks are fixed to the lower ends of the two sides of a push jaw fixing plate, push jaws are arranged on the two sides of the front end of the push jaw fixing plate, a pneumatic jaw is arranged at an opening in the middle of the push jaw fixing plate, the lower end of the pneumatic jaw is arranged on the middle guide rail through the middle slide block, the drive end of the front end of the pneumatic jaw is connected with a clamping jaw, the rear end of the pneumatic jaw is connected with the rear end of the push jaw fixing plate through a horizontal elastic thrust mechanism, and a vertical lifting plate is arranged at the front end of the supporting base.

Owner:SHENYANG POLYTECHNIC UNIV

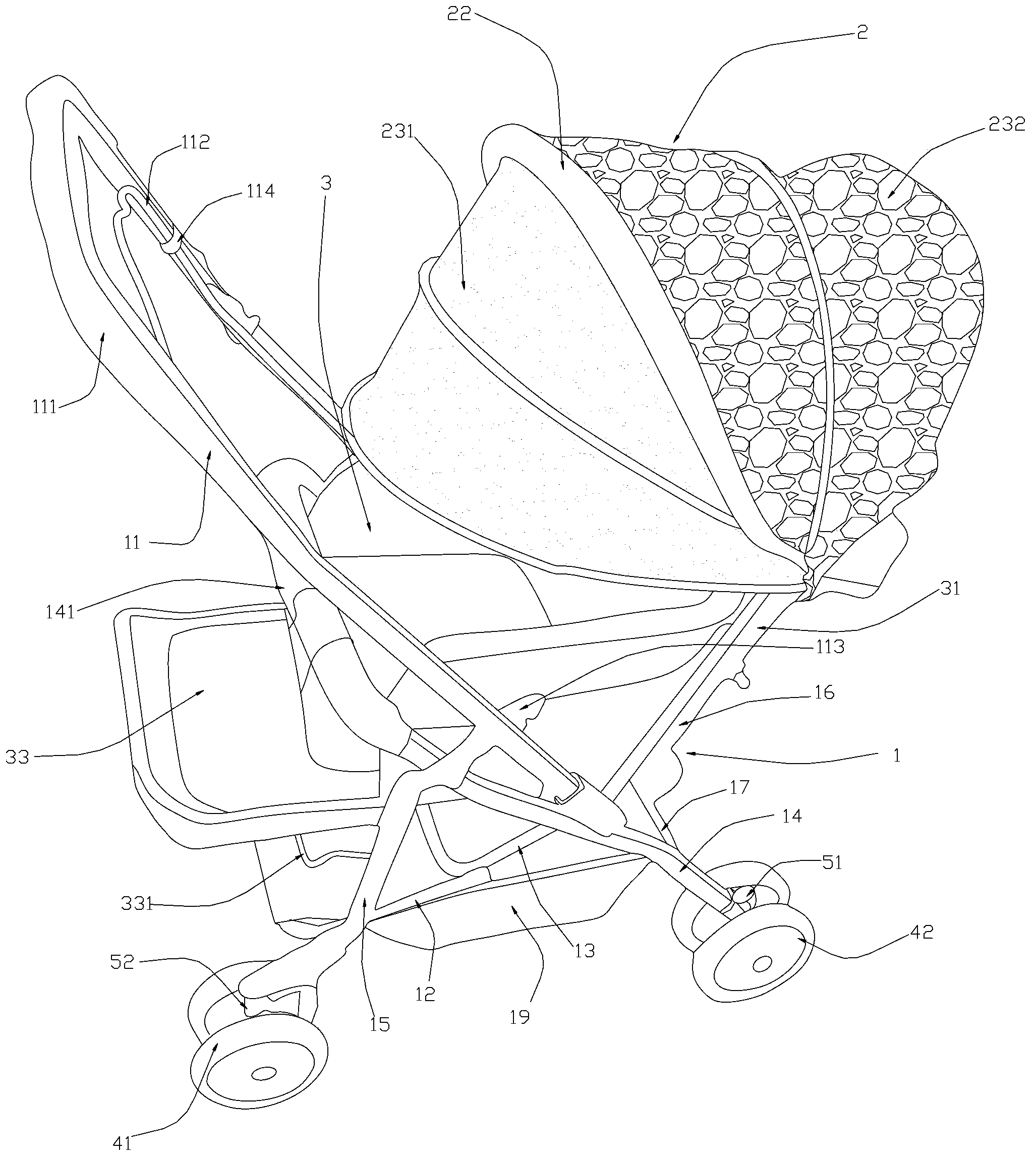

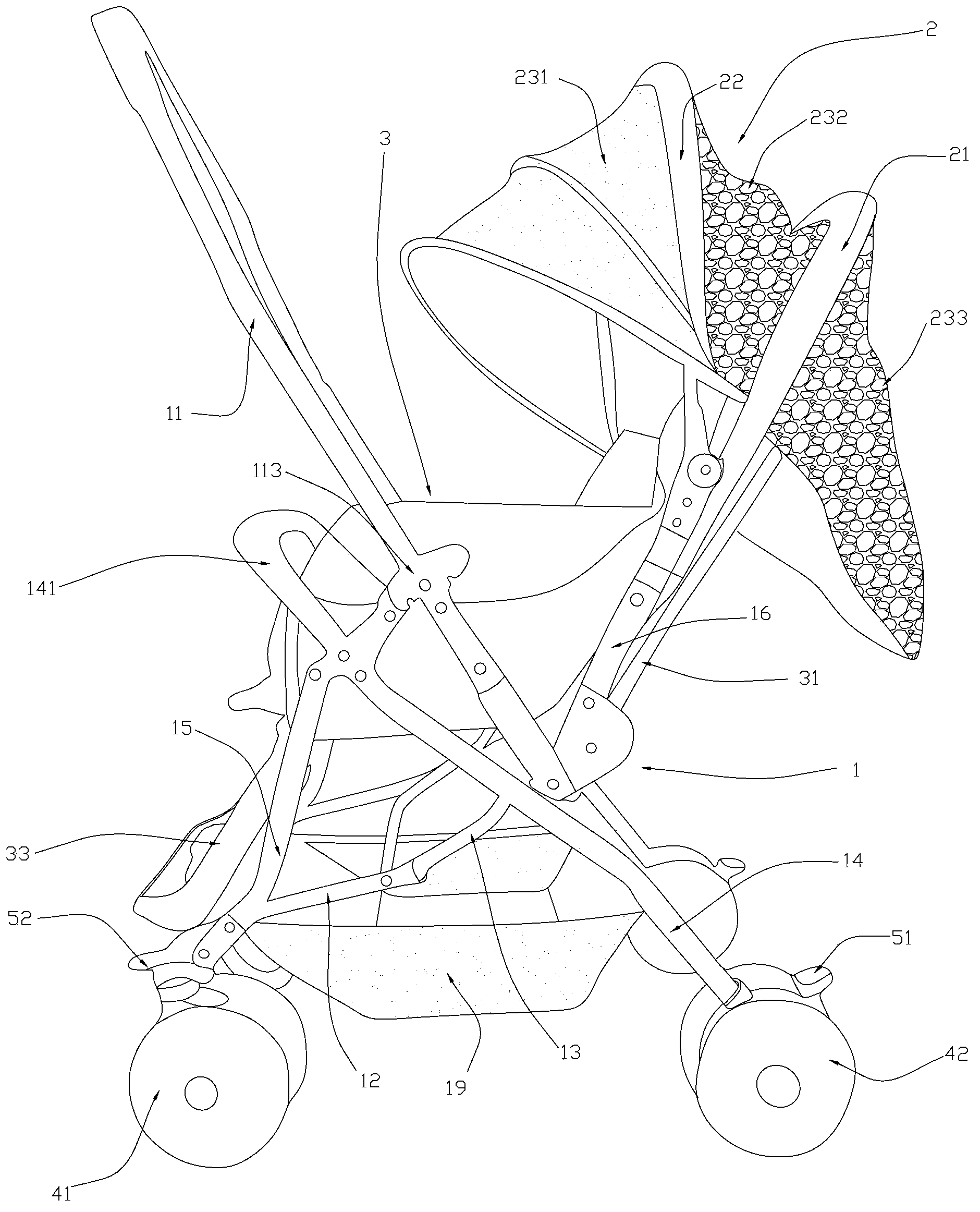

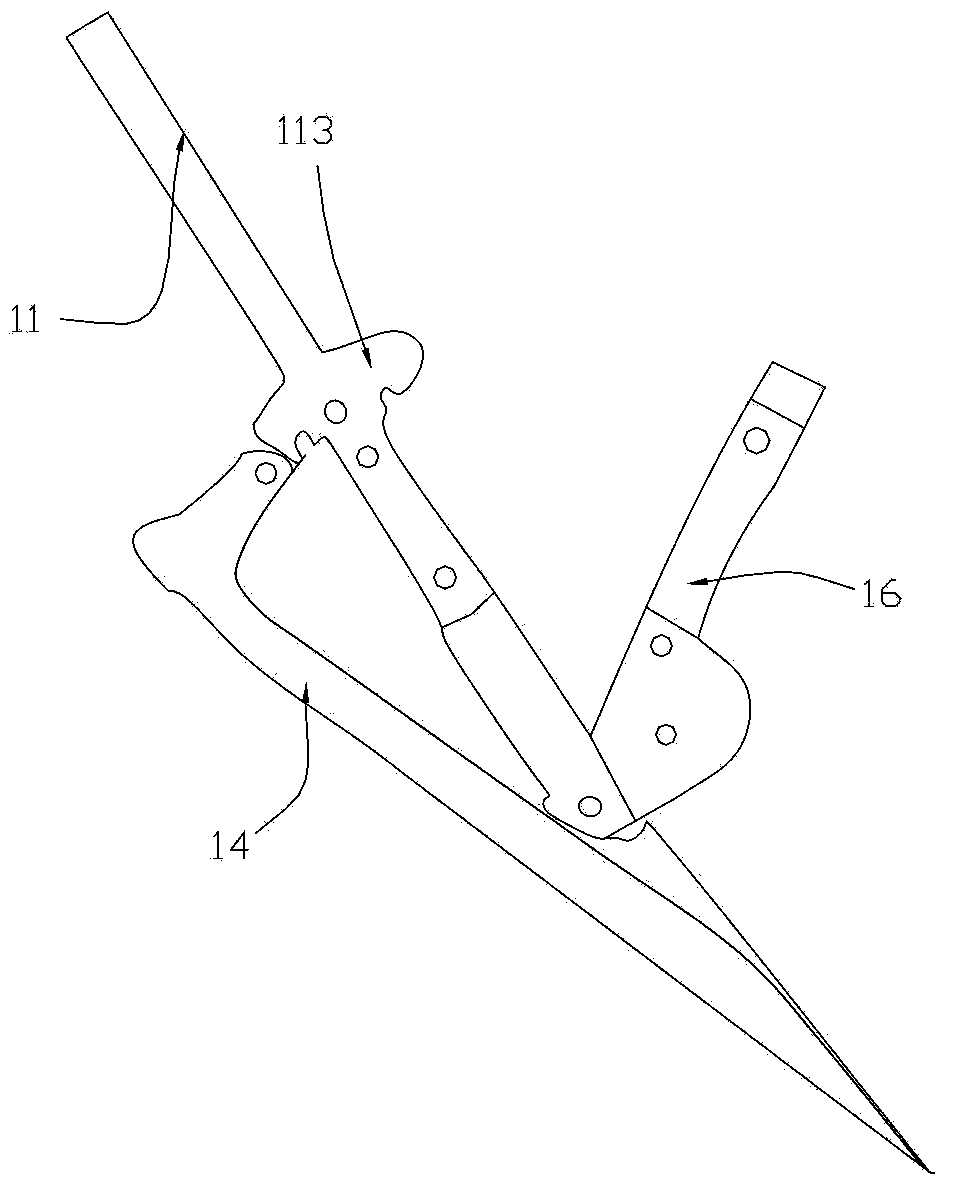

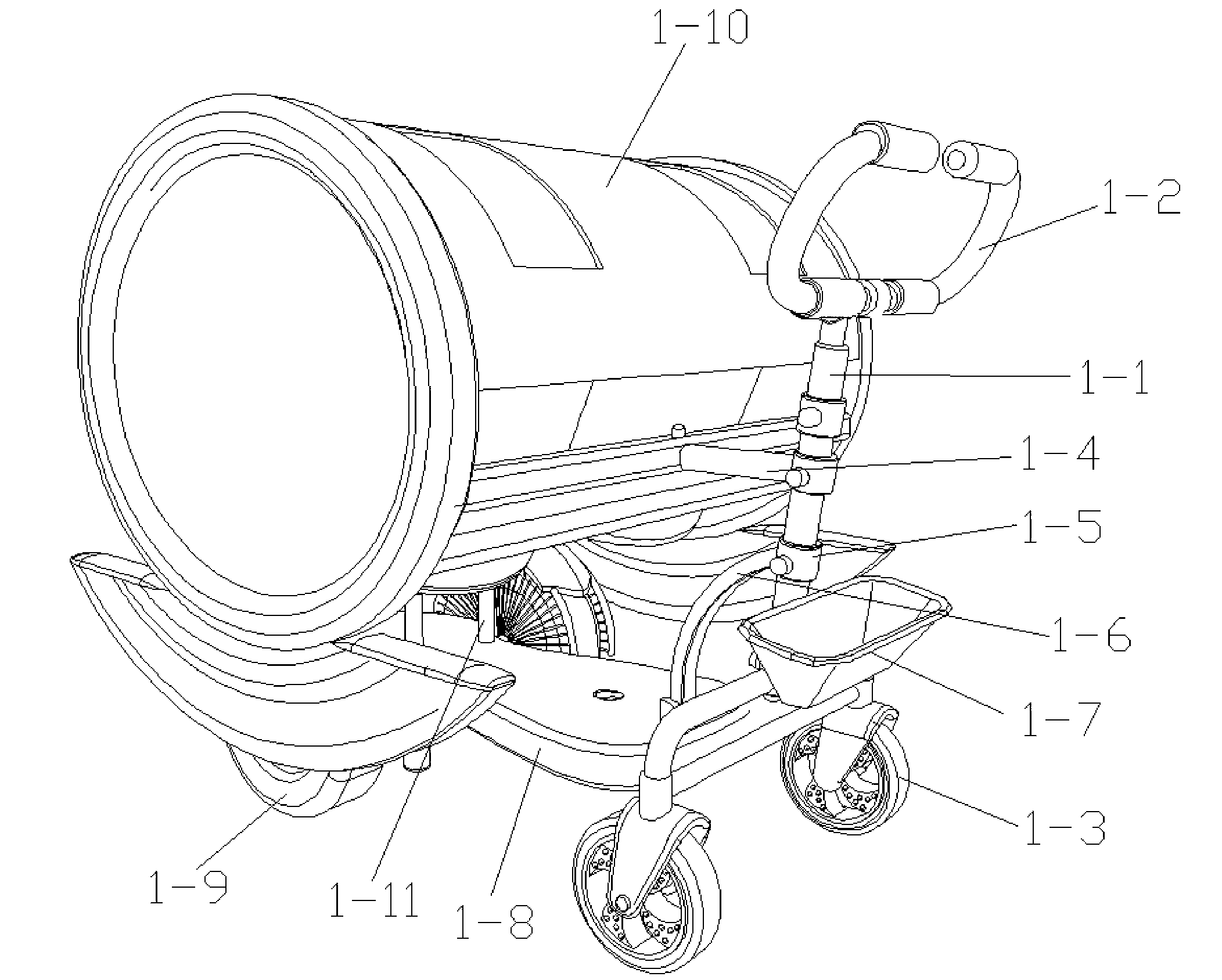

Baby trolley

ActiveCN103407480AReduce volumeEasy to useCarriage/perambulator accessoriesCarriage/perambulator with multiple axesVehicle frameEngineering

Owner:如东县东广物流有限公司

Elevator

InactiveCN101920890AReasonable internal structure layoutMeet the hoistway space requirementsElevatorsBuilding liftsAutomotive engineeringEngineering

The invention relates to an elevator, which comprises a lift car with two doors, a lift car guide rail, a lift car guide rail support, a counterweight, a counterweight guide rail, a counterweight guide rail support and a lift car auxiliary guide rail, wherein the lift car guide rail is fixed on the lift car guide rail support fixed on a concrete ring beam or a steel frame; the lift car is movably connected on the lift car guide rail or the lift car auxiliary guide rail; the counterweight guide rail is fixed on the counterweight guide rail support fixed on the concrete ring beam or a steel frame; the counterweight is movably connected on the counterweight guide rail; and the two doors of the lift car are respectively distributed on the adjacent two sides of the lift car. By adopting the elevator in the structure, passengers can get in and out of the elevator from different doors when the elevator is installed on the corner of a building, thus avoiding the condition that the elevator can not meet the use requirement for the doors.

Owner:CANNY ELEVATOR

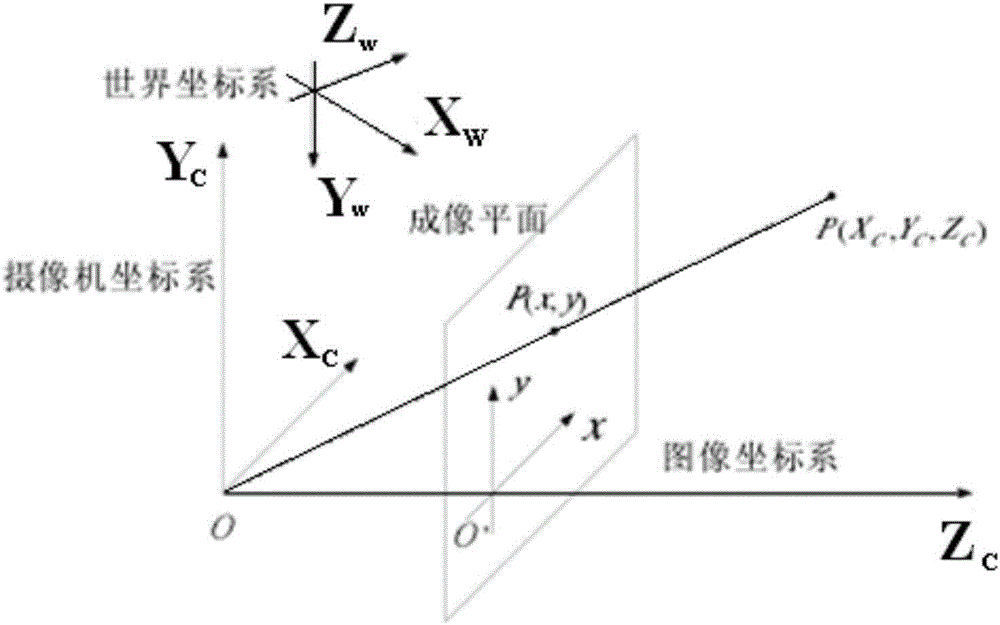

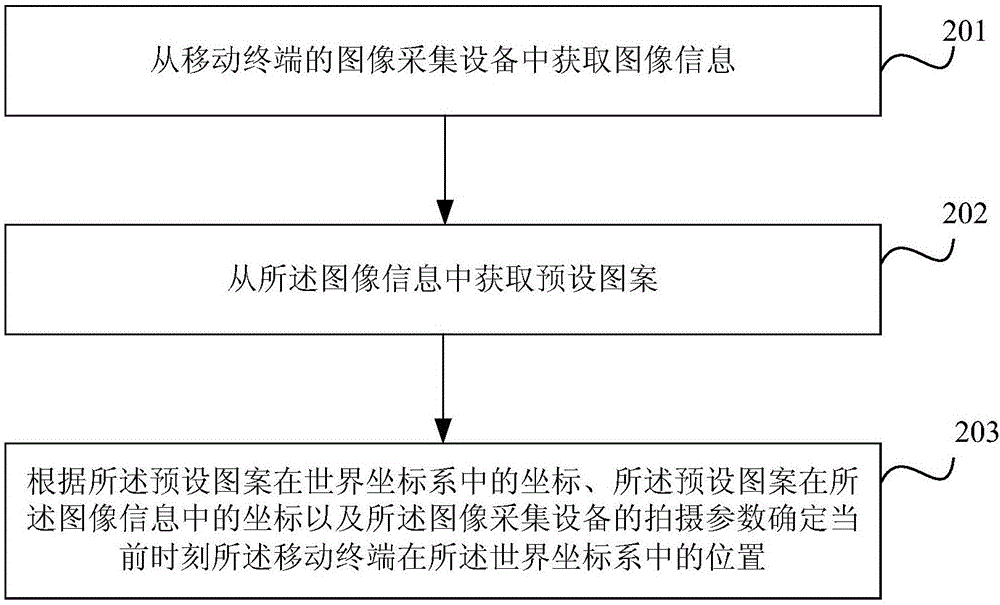

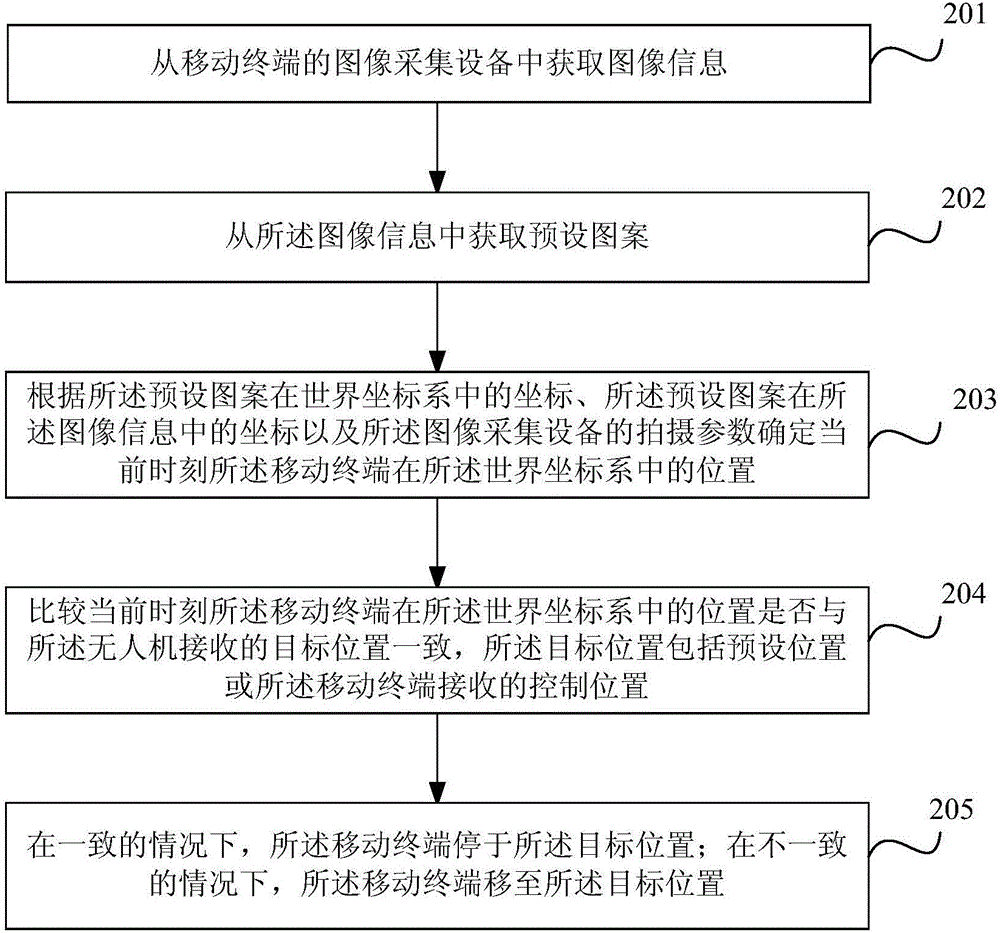

Unmanned aerial vehicle and method and device for positioning and controlling mobile terminal

InactiveCN106444846AHigh positioning accuracyPrecise positioningTarget-seeking controlUncrewed vehicleComputer terminal

The invention relates to an unmanned aerial vehicle and a method and device for positioning and controlling a mobile terminal. The method for positioning the mobile terminal includes the following steps: obtaining the image information from an image acquisition device of the mobile terminal, obtaining a preset mage from the image information, and determining the position of the mobile terminal in a world coordinate system according to a coordinate of the preset mage in the world coordinate system, a coordinate of the preset mage in the image information and a shooting parameter of the image acquisition device.

Owner:杭州零智科技有限公司

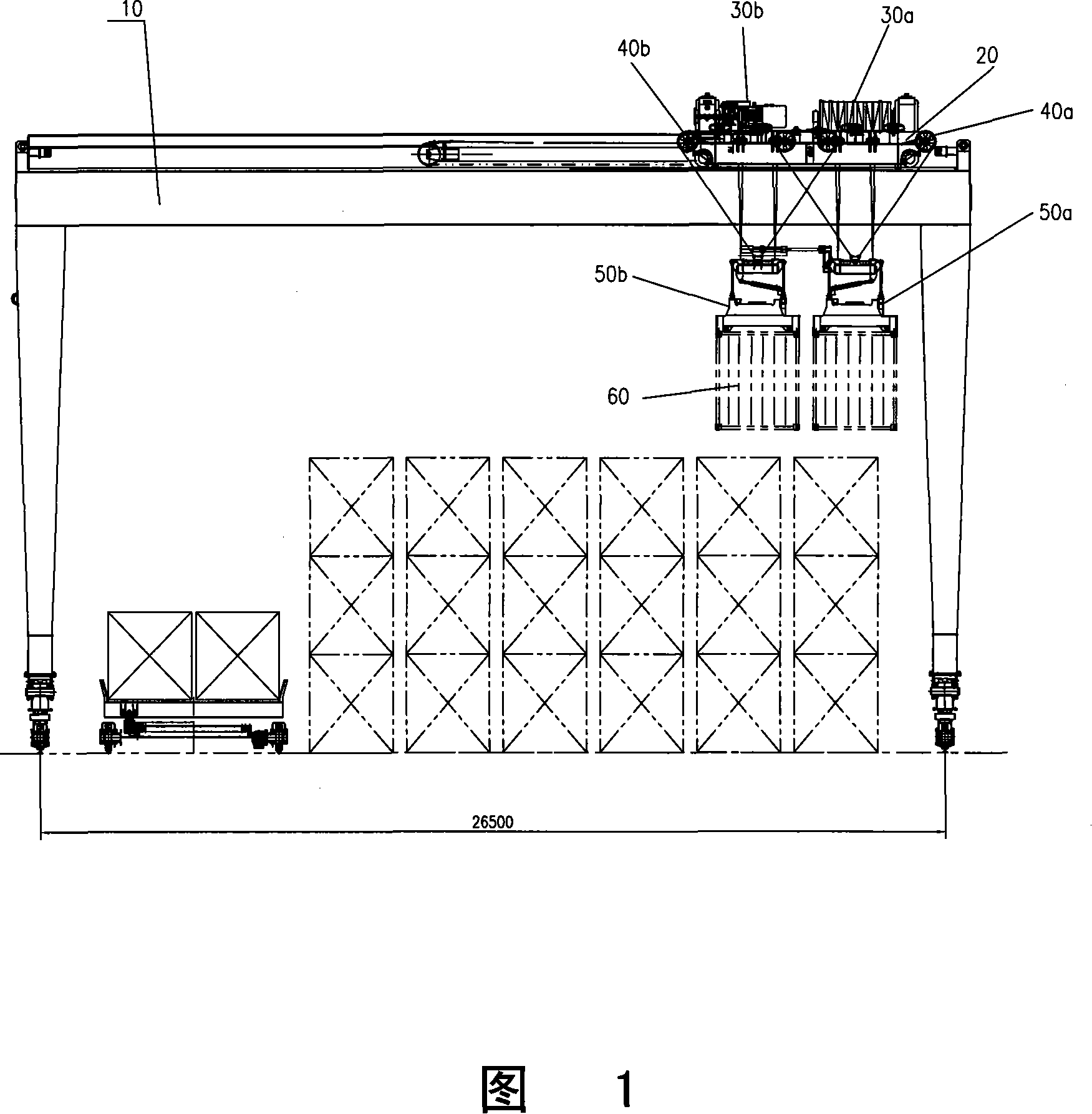

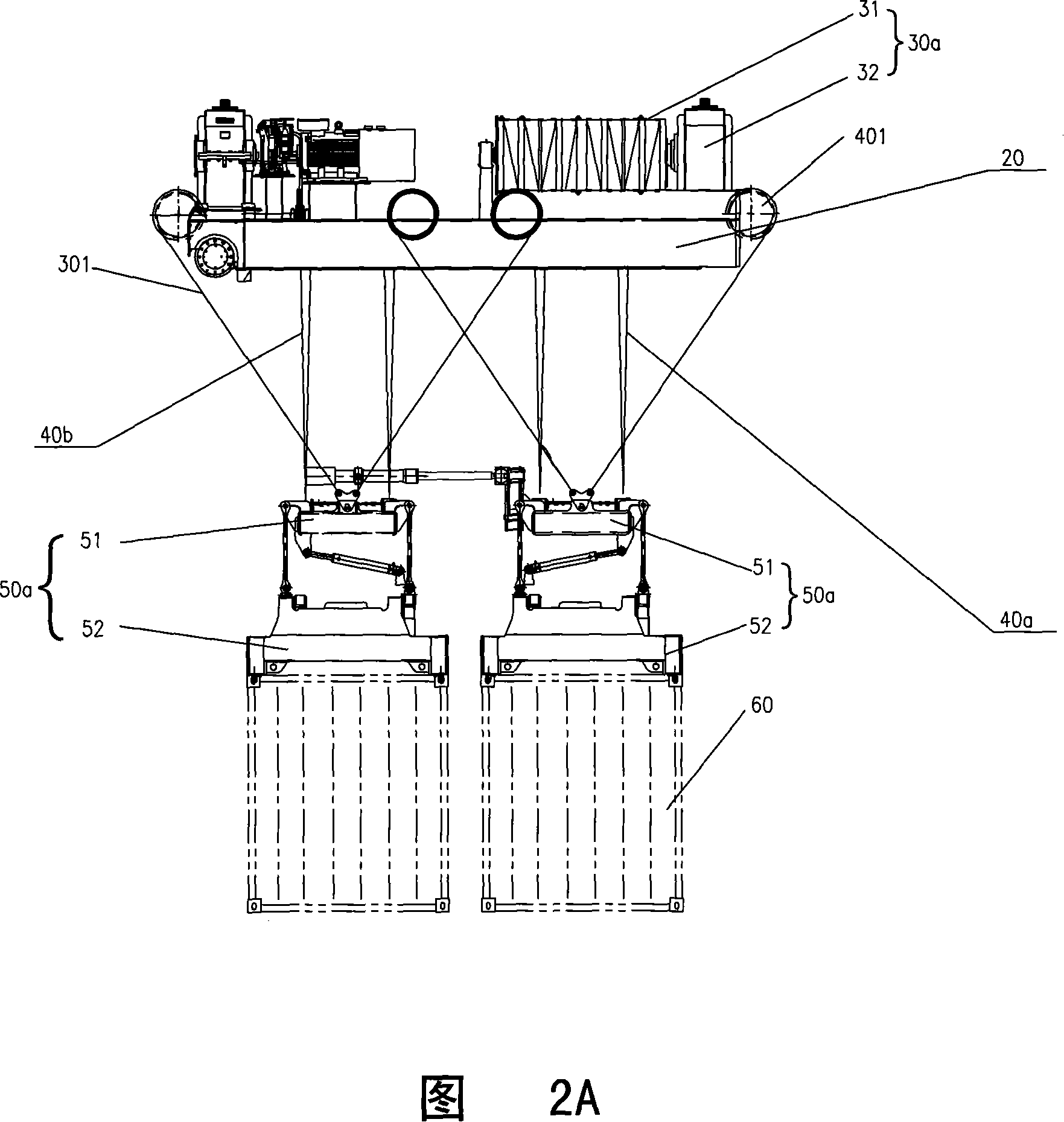

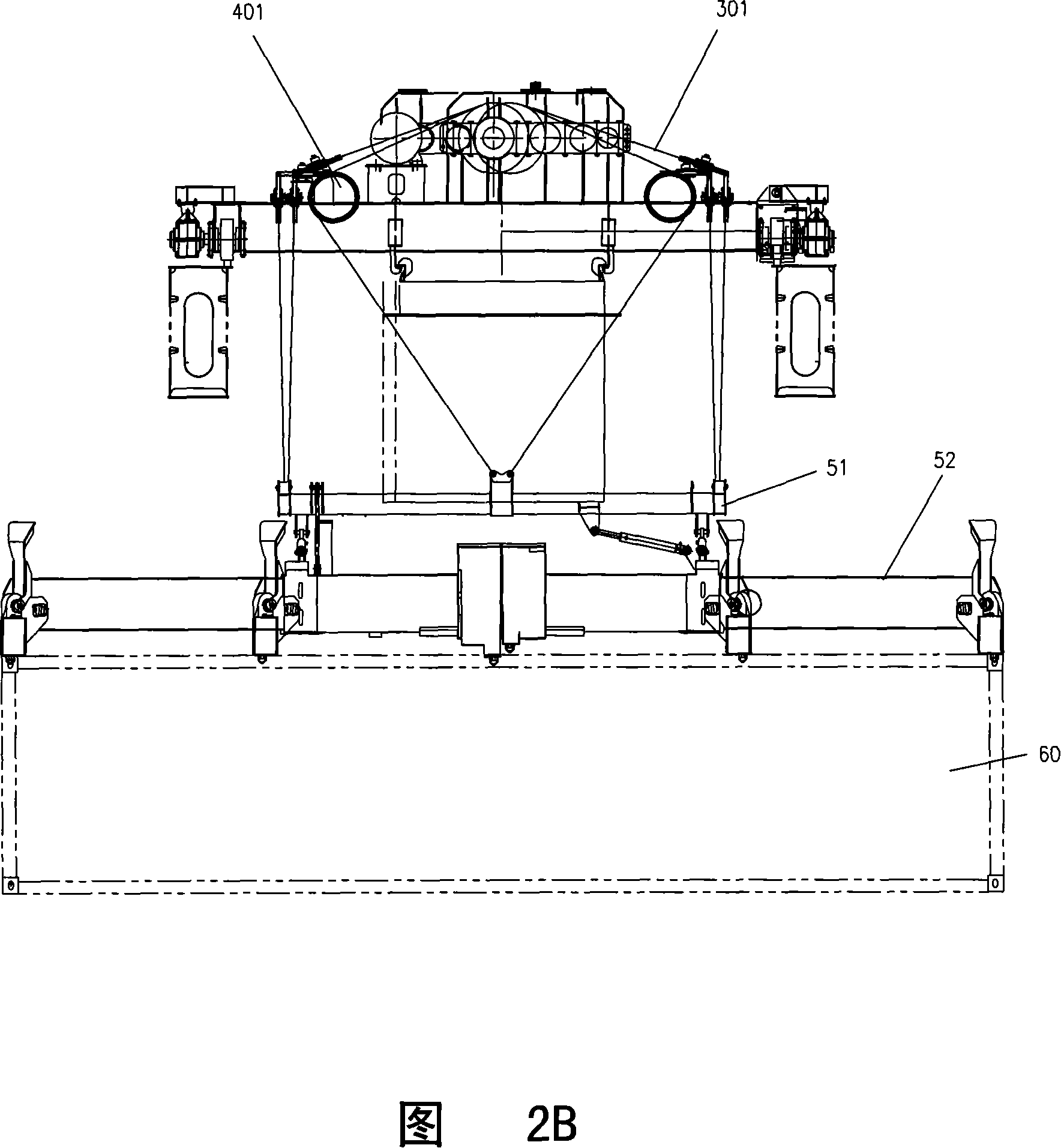

Double 40-feet container yard gantry crane

InactiveCN101070133AImprove work efficiencyMeet space requirementsTrolley cranesLoad-engaging elementsEngineeringYard

The invention discloses a double 40 inches yard gantry crane including the gantry frame and a move dolly set on the gantry crane. The crane includes two sets of the hoisting mechanism, two sets of the steel rope enwinding system and two sets of hanger system; the hoisting mechanism is set on the move dolly which is set with a set of steel rope enwinding system. The steel rope is leaded from the hoisting mechanism and enwinds on the rope enwinding system which the rope cross with each other. A set of hanger system is hanged under the enwinding system which includes up frame and a hanger. The left-right move oil cylinder is set at the bottom of the each up frame and the front-back oil cylinder is set at both sides of the up frame. The hanger is set under the up frame and driven by the left-right move oil cylinder to move to right or left, also the same as the front-back oil cylinder. The two up frames are connected by the oil cylinder to reach the relative separation and combination.

Owner:SHANGHAI ZHENHUA HEAVY IND

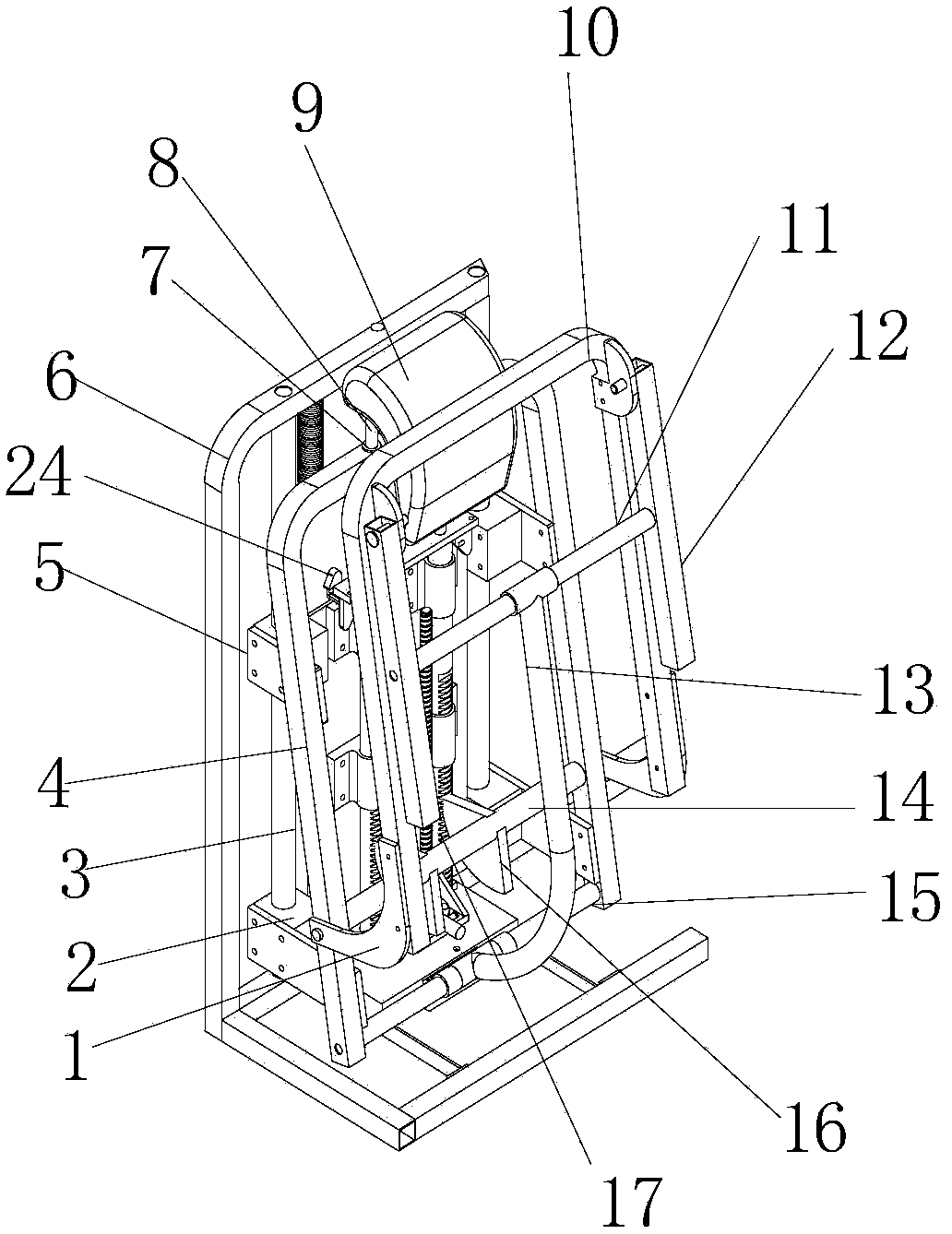

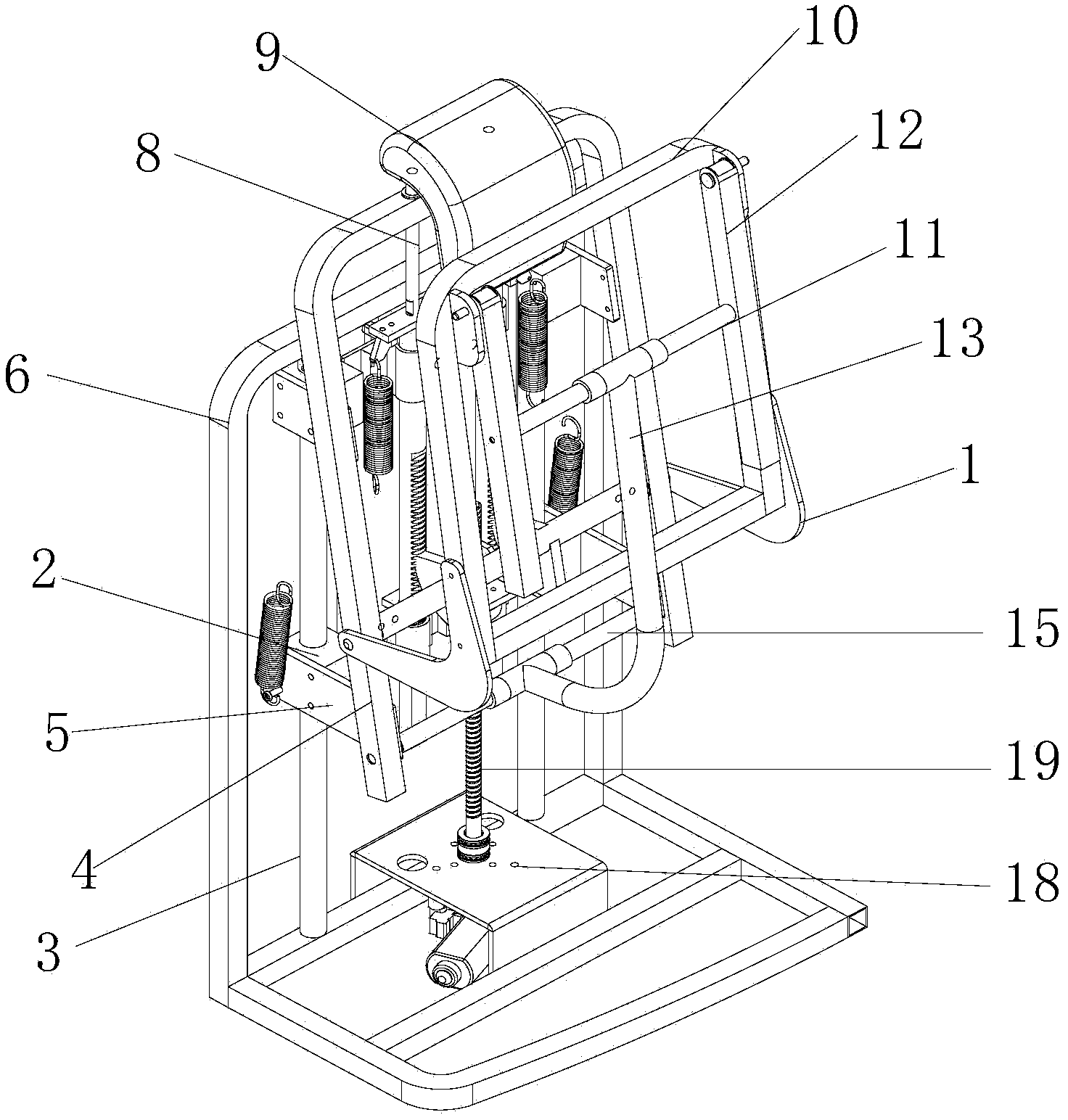

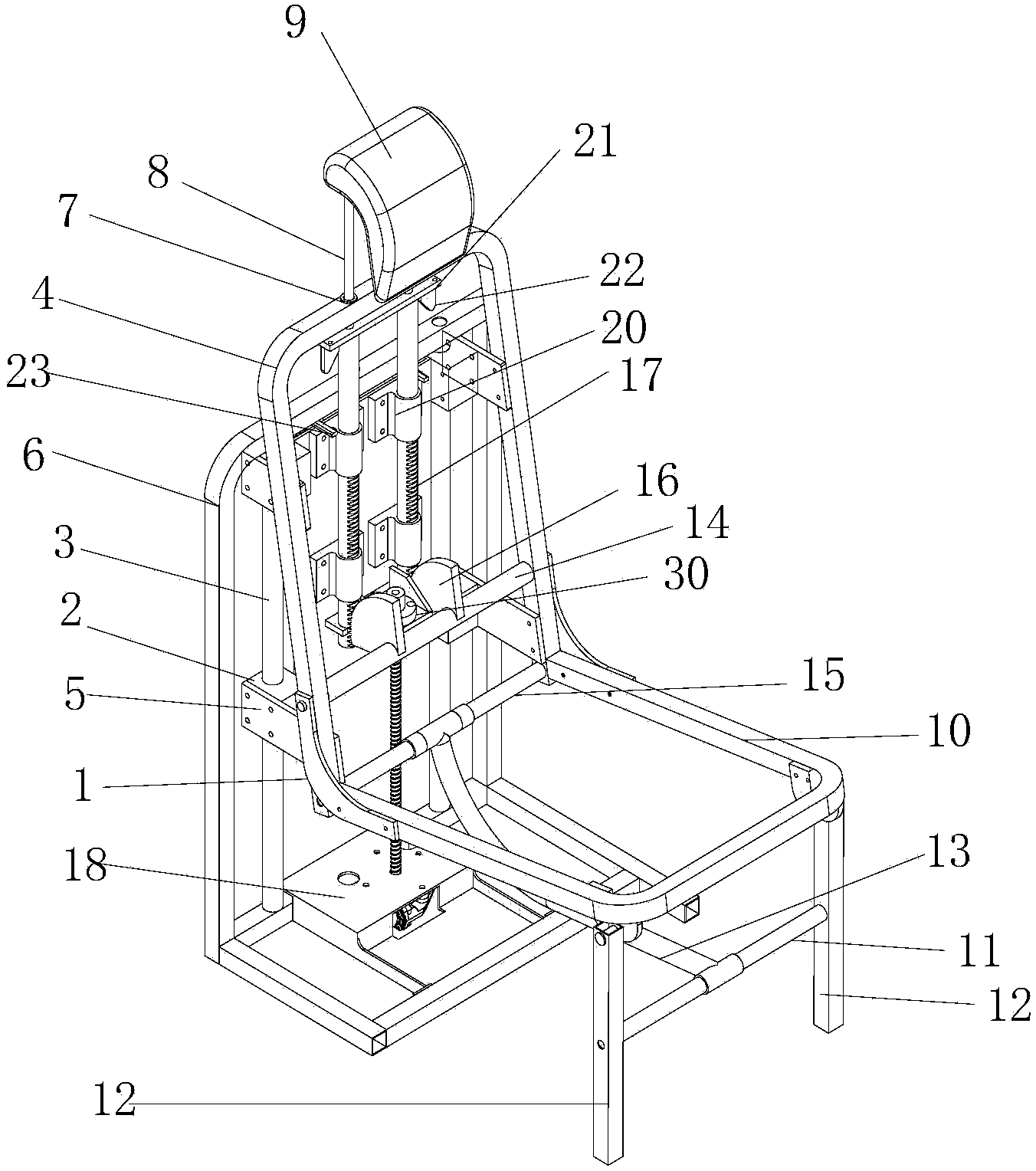

Folding seat

ActiveCN103407389ASmall footprintBig spaceDismountable/non-dismountable seatsEngineeringMechanical engineering

The invention belongs to the field of vehicle accessories, and particularly relates to a folding seat which can be automatically folded and occupies small space after being folded. The folding seat comprises a bracket connected with a bearing device, a vertical sliding mechanism is arranged on the bracket, a folding chair back is connected with the vertical sliding mechanism, the vertical sliding mechanism is provided with a transmission bar capable of sliding vertically, the folding chair back is provided with a rotatable rotating shaft, the rotating shaft is provided with a transmission block which is connected with the transmission bar and can rotate under the action of the transmission bar, two ends of the rotating shaft are connected with two sides of the tail part of a folding stool through arc-shaped overturning plates, the folding stool rotates along with the rotating shaft, the lower end of the transmission bar is provided with a drive connection block, the lower part of the bracket is provided with a drive device, and the drive device is connected with the drive connection block. The invention provides the folding seat which is of two-section type, can be automatically folded and unfolded, and does not need to be manually folded by a user, and the space occupied by the folding seat can be effectively reduced after the folding seat is folded, thus the using space for passengers inside a car is expanded.

Owner:肇庆市至立自动化科技有限公司

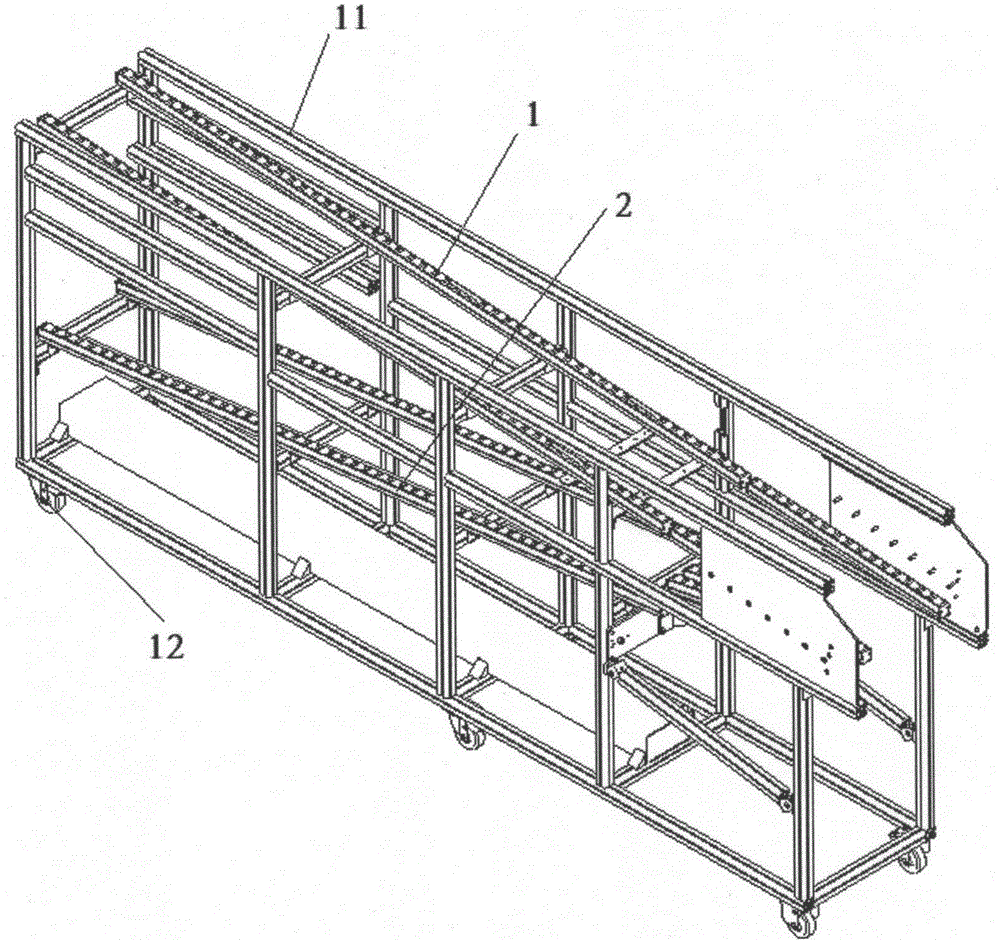

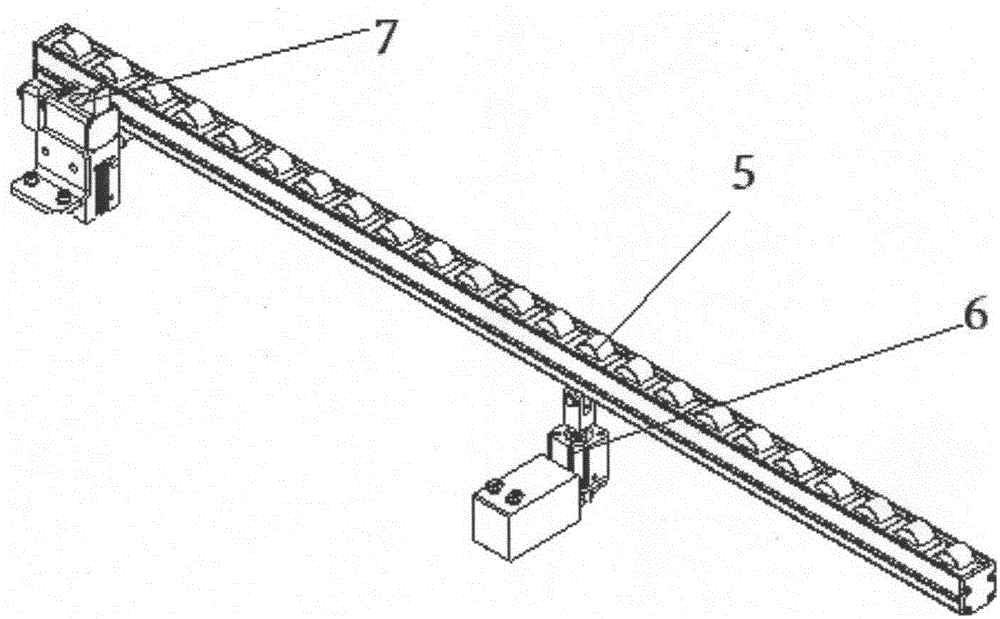

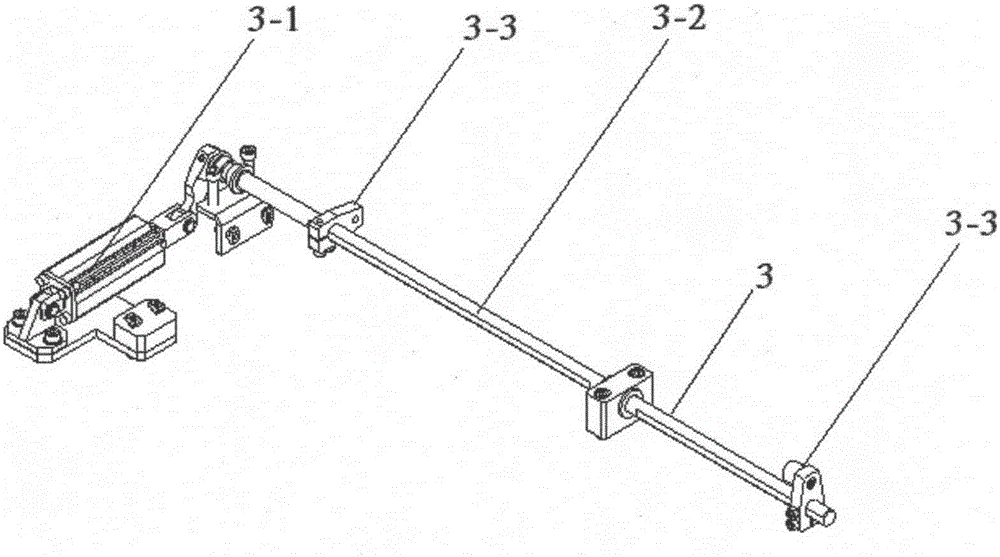

Dynamic line-side rack system

ActiveCN106564739ASolving Ergonomic IssuesReduce labor intensityMechanical conveyorsButt jointEngineering

The invention provides a dynamic line-side rack system. The dynamic line-side rack system is characterized by comprising a material taking slideway assembly, a material discharging slideway assembly located below the material taking slideway assembly, a material stopping and separating mechanism and a movable feeding platform, wherein the movable feeding platform can only contain a single material box and is switched among a material receiving state, a material taking state and an empty material box returning state under the control of a driving mechanism. Through standard design, the height and width of a feeding port of a full material box are consistent with those of a discharging port, and a burden charging carriage can feed the full material box and fetch the empty material box after automatic butt joint through control of a pneumatic element and a sensor. The labor intensity of material burdening personnel is greatly relieved, and production efficiency is improved.

Owner:COMAU SHANGHAI ENG

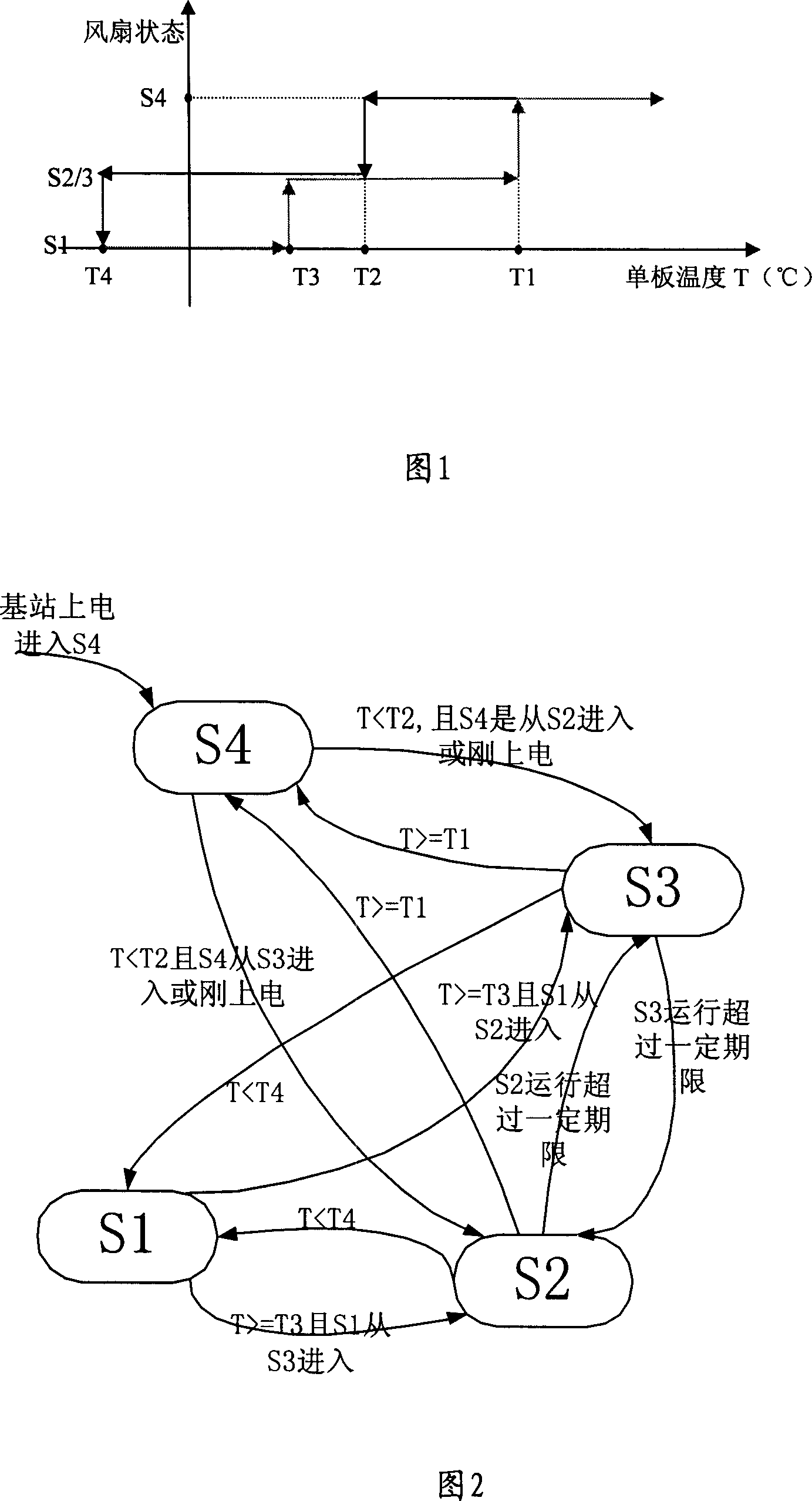

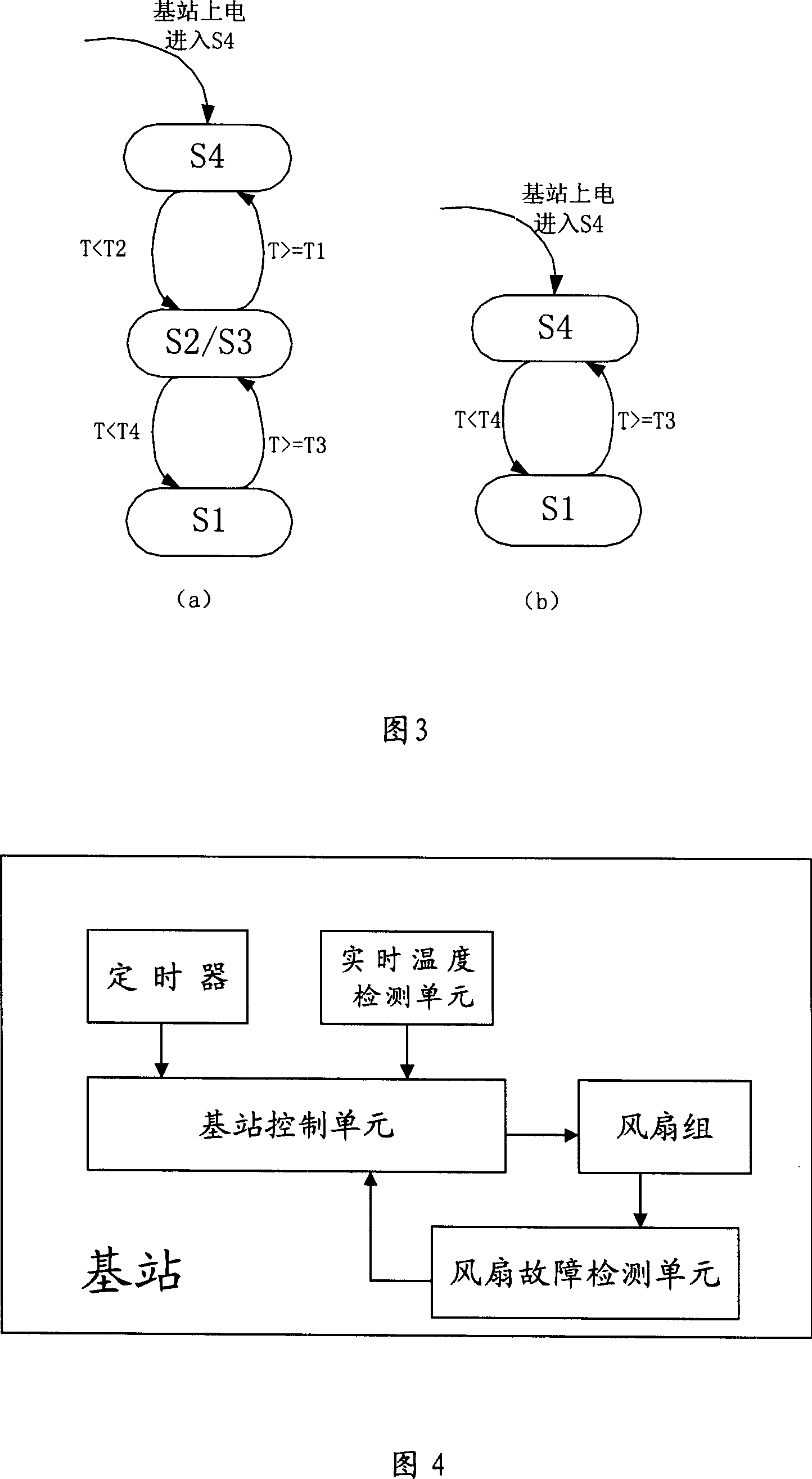

A method and system for the temperature control of the base station

InactiveCN101009874AAvoid frequent switchingEvenly distribute usage timeTemperature control with auxillary non-electric powerRadio/inductive link selection arrangementsTemperature controlTemperature difference

The disclosed BS temperature control system as well as method to heat dispersion problem in minisize BS or distributed BS arranges a fan assembly with at least two mono-body fans to obtain some representative synthesis states according to every fan open and close states, and uses state machine principle to control fan, wherein when switching fan state, setting temperature difference to avoid frequent switch, and adding time factor when switching two fans with same heat dispersion state to average every fan work time and prolong whole fan assembly service time indirectly. This invention can achieve up to well heat dispersion effect, and compensates well the defect in prior art.

Owner:HUAWEI TECH CO LTD

Automatic oiling device for shifter

InactiveCN105090723AImprove efficiencyFacilitate oil filling automationEngine lubricationProduction lineDistributor

The invention belongs to the technical field of automatic assembling, and particularly relates to an automatic oiling device for a shifter. The invention provides the automatic oiling device for the shifter, which can be used for oiling accurately and quantitatively, and can improve the assembly efficiency. The automatic oiling device for the shifter, provided by the invention, comprises a working platform on an oiling station in a shifter assembling production line, and has the structural characteristics that a removable tray is arranged below the working platform, a lift cylinder is arranged below the removable tray, a shaft type housing lubricator, a tooth-shaped lubricator and a hole-type housing lubricator are arranged on the working platform, oil inlets of the shaft type housing lubricator, the tooth-shaped lubricator and the hole-type housing lubricator are connected with oil distributing holes of oil distributors through pipelines respectively, and the oil inlets of all oil distributors are connected with respective proportional valves through pipelines respectively; and oil outlets of the shaft type housing lubricator, the tooth-shaped lubricator and the hole-type housing lubricator are all positioned below the working platform.

Owner:SHENYANG POLYTECHNIC UNIV

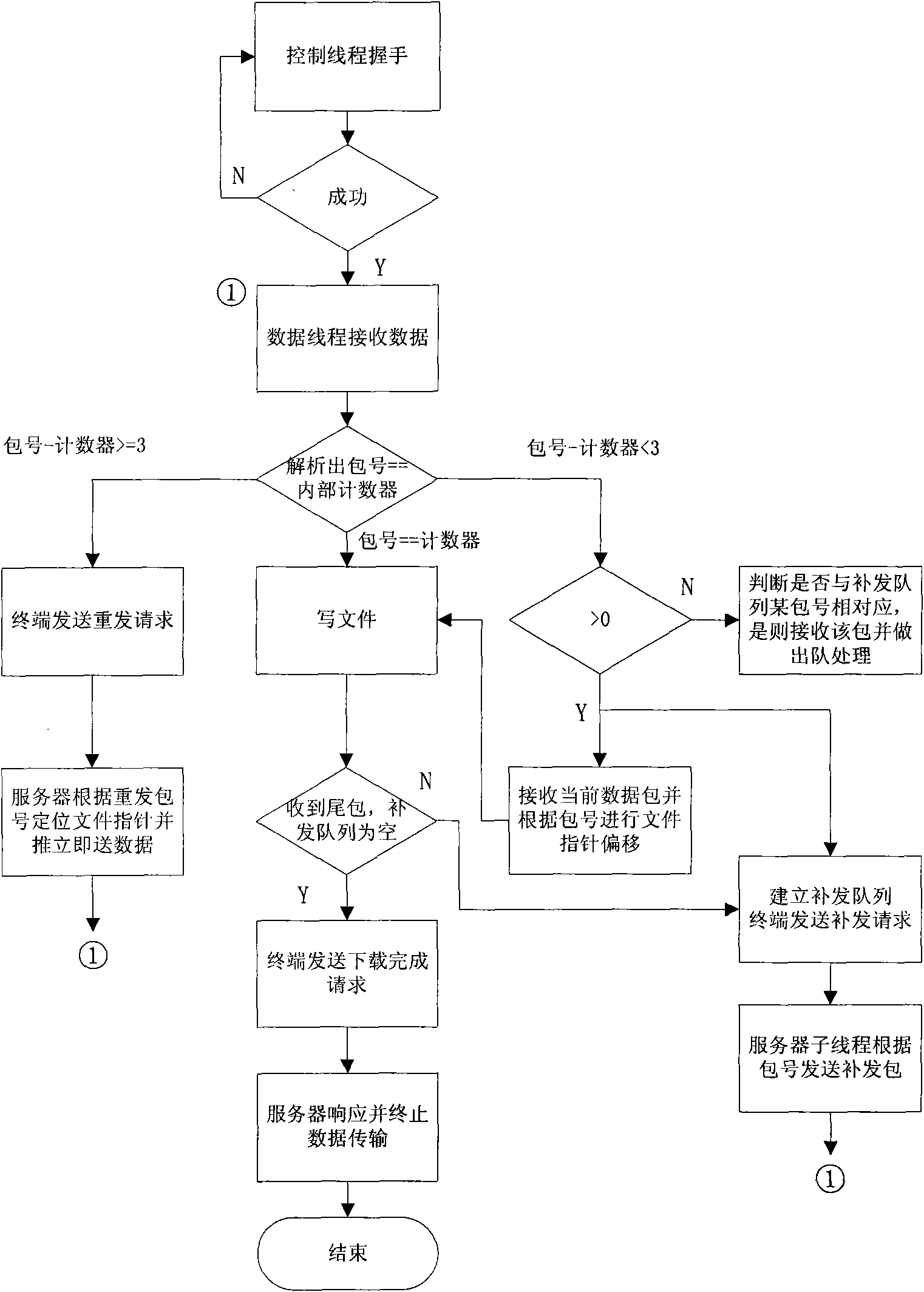

Online download method for large data volume files

InactiveCN101651676ASmall loadReliable and reliableError prevention/detection by using return channelData portData file

The invention provides an online download method for large data volume files. The method relates to a server and a terminal. The server has control threads and data threads; the terminal has control threads and data threads too. The online download method for large data volume files comprises steps of: (1) the server and the terminal operate the control threads for protocol information interactionto realize handshake between control port protocols of the server and the terminal; (2) after the step 1), the server and the terminal operate the data threads to realize handshake between data portprotocols of the server and the terminal; (3) transmitting data files between the data port protocols of the server and the terminal via the data threads; (4) operating the control threads again aftertransmitting the data files. The invention is able to transmit data efficiently and reliably, and is especially suitable for online download of large data volume files.

Owner:中科华影(北京)数字电影院线有限公司 +1

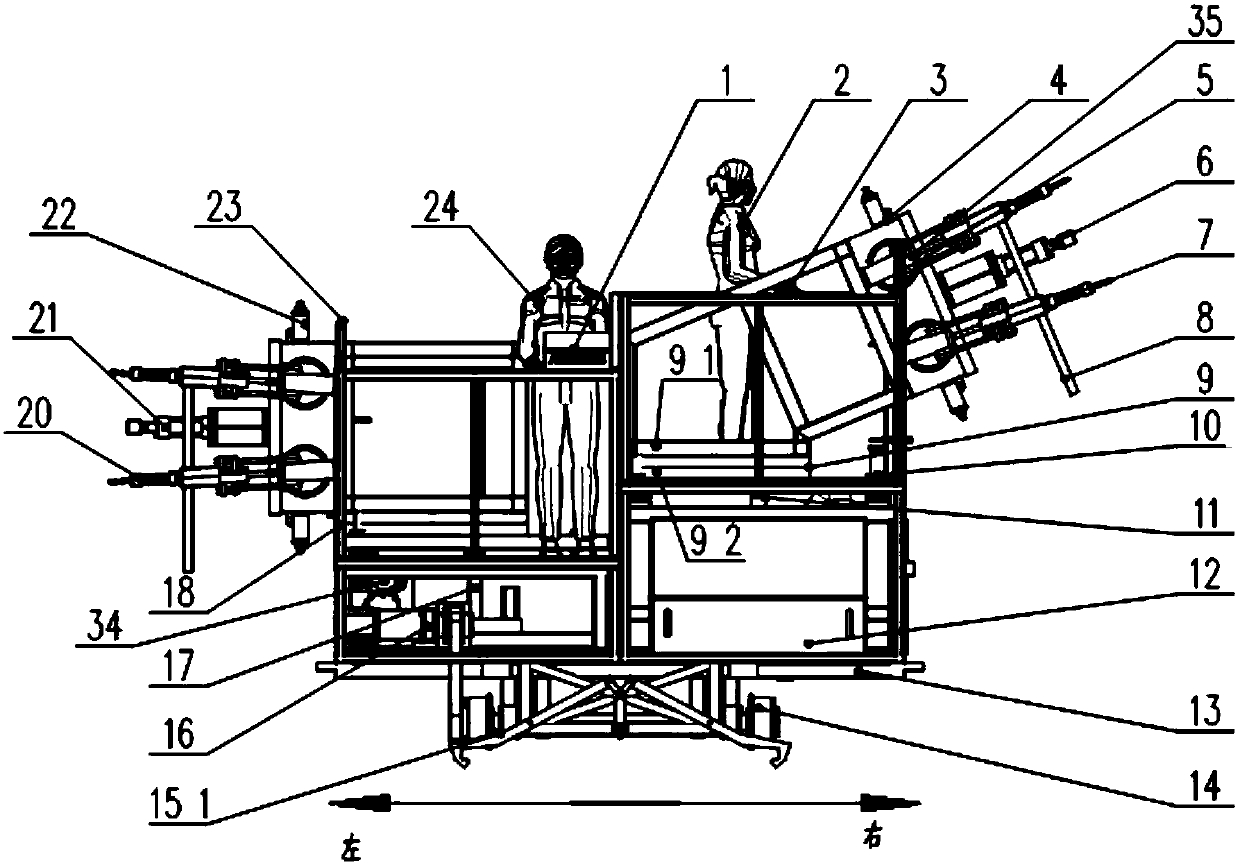

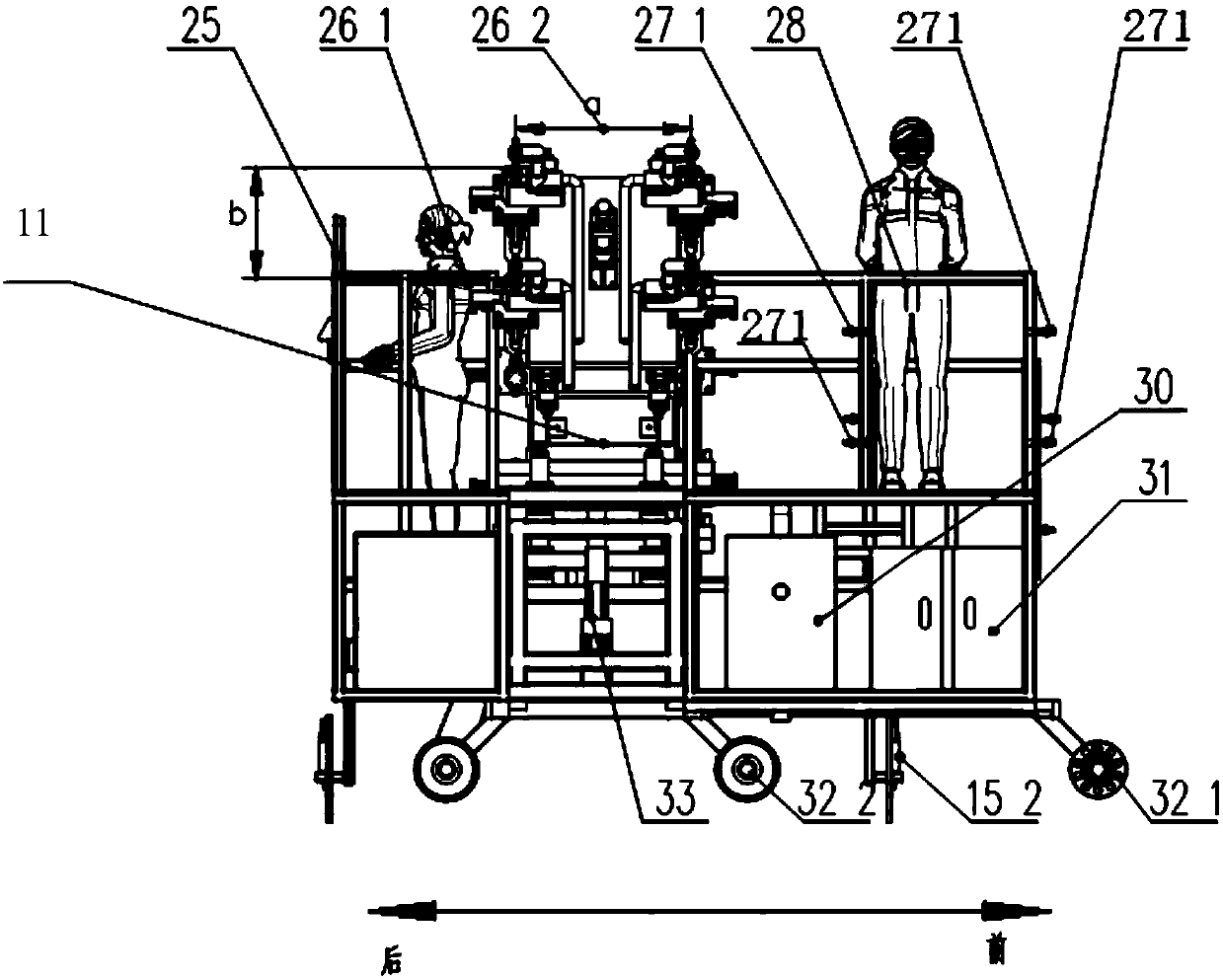

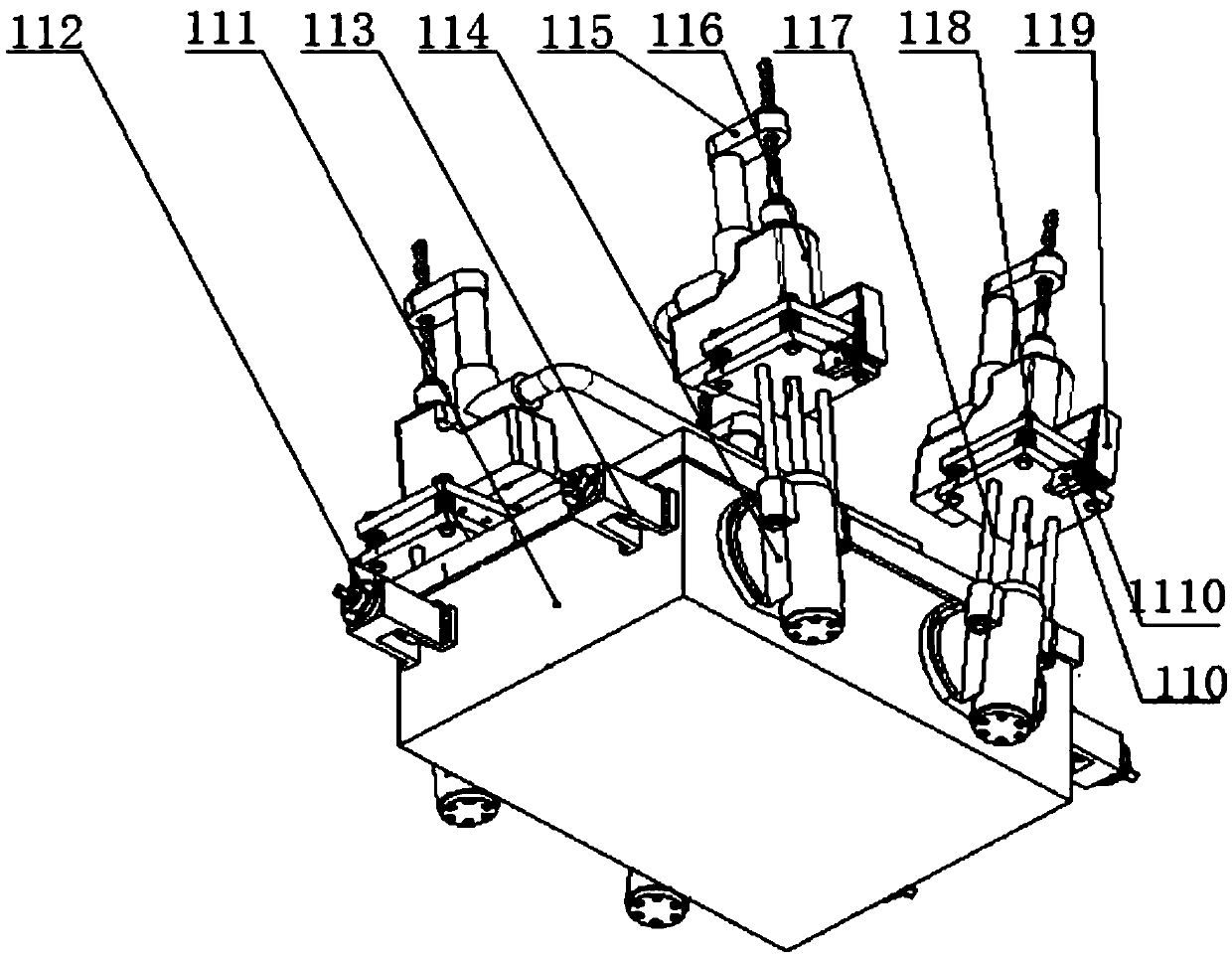

Tunnel drilling robot and construction drilling method thereof

PendingCN109519123AAccurately locate the forward position distanceGuaranteed mounting hole spacingDerricks/mastsDirectional drillingPunchingControl system

The invention relates to a tunnel drilling robot and a construction drilling method thereof. The tunnel drilling robot comprises a control system, an automatic walking positioning system, n groups ofsteel bar automatic detection and compensation systems, n groups of drilling systems and a power supply system. The steel bar automatic detection and compensation systems each include a servo laser locator, a steel bar detector, a steel bar yielding bracket and a steel bar yielding bracket driver. The steel bar detector is used for detecting steel bars at a positioning point of the servo laser locator, and sending detection data to the control system, and the control system controls the steel bar yielding bracket driver to drive the steel bar yielding bracket to move according to the detectiondata of the steel bar detector, the drilling systems each include a drilling bracket disposed on the steel bar yielding bracket and an axial drilling system fixed on the drilling bracket, the axial drilling system includes m drilling mechanisms, and the m drilling mechanisms are arranged in the axial direction and circumferential direction of a tunnel. The problems of low punching efficiency, high drill bit rejection rate and complicated devices are solved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

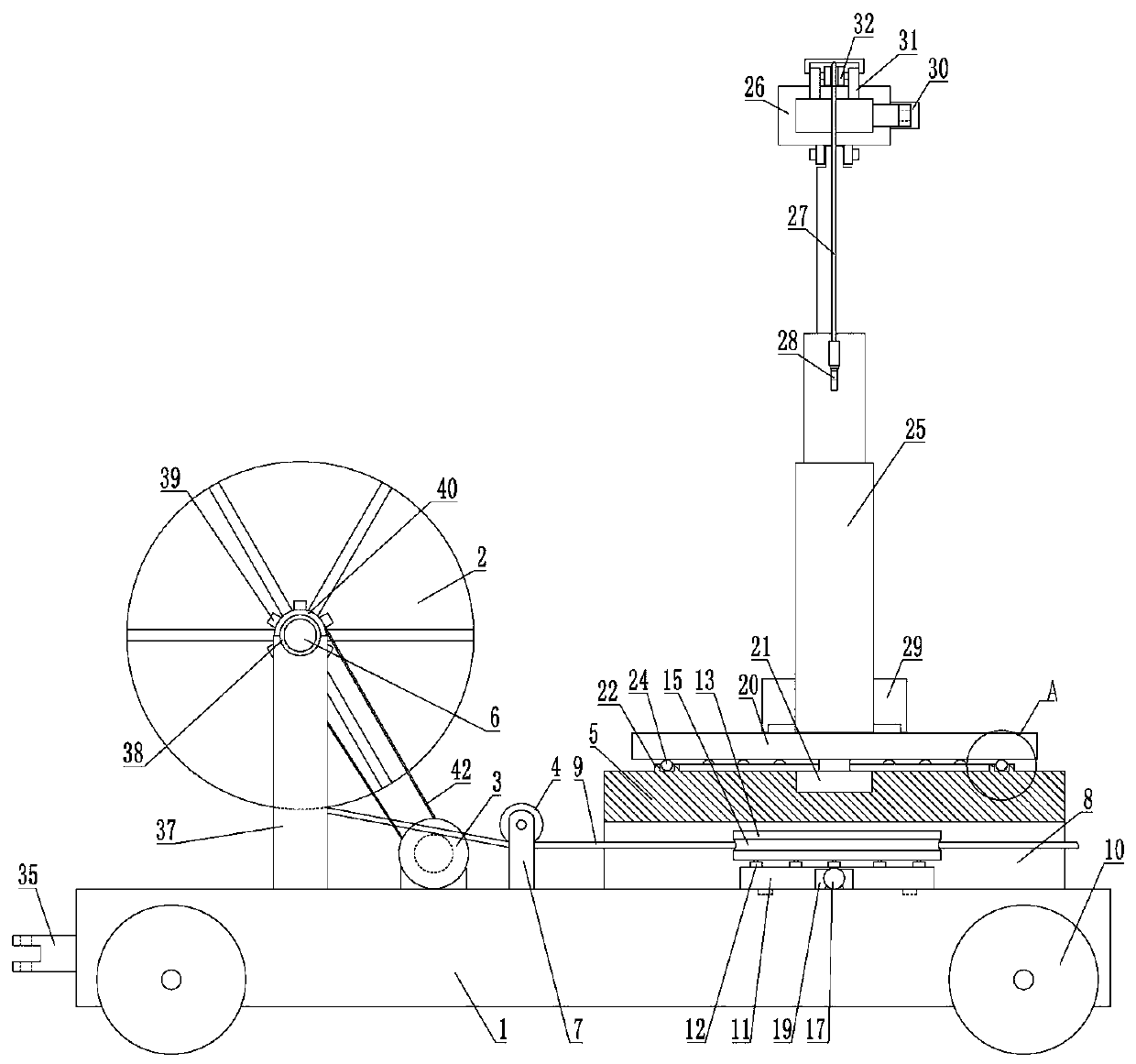

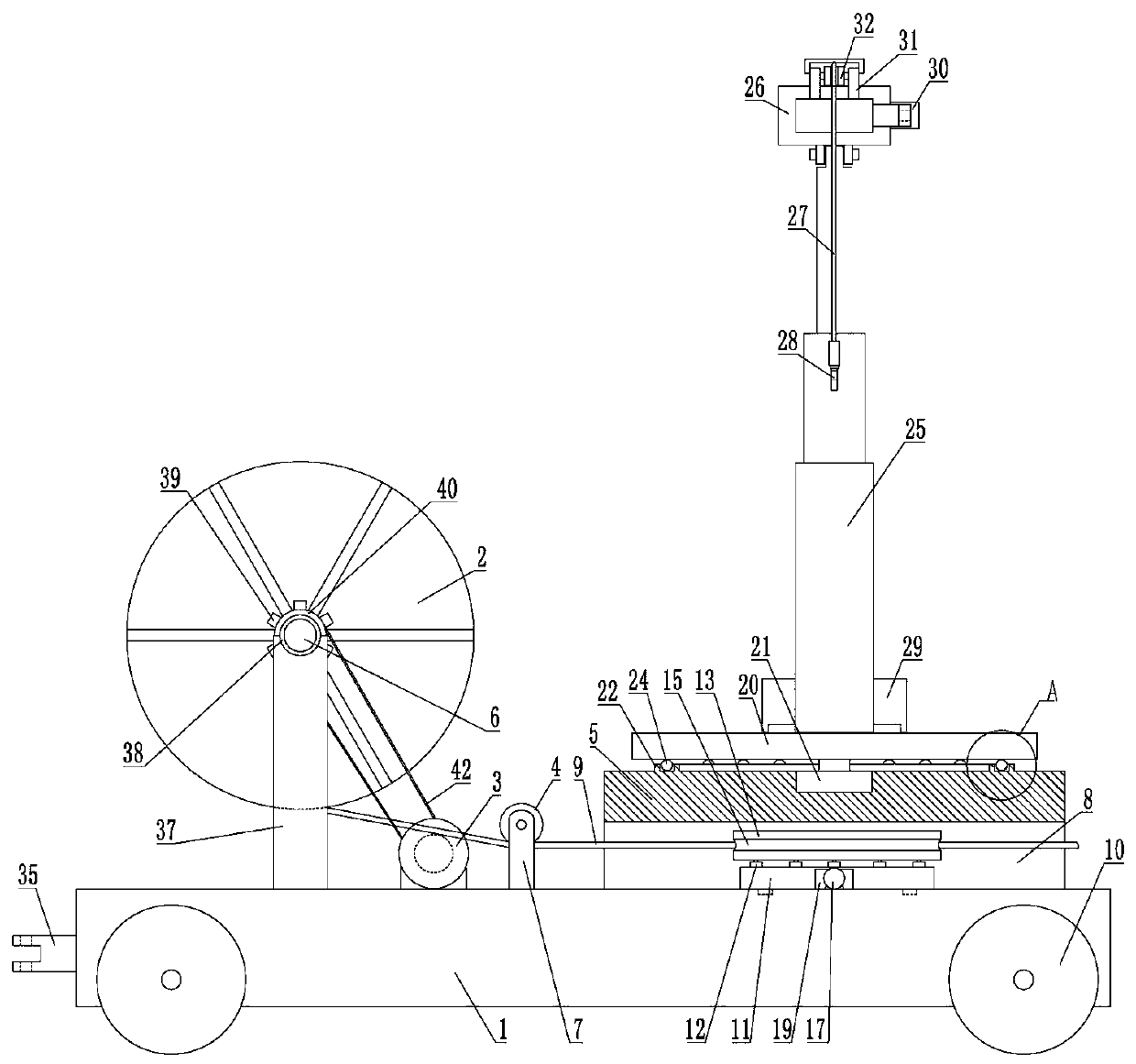

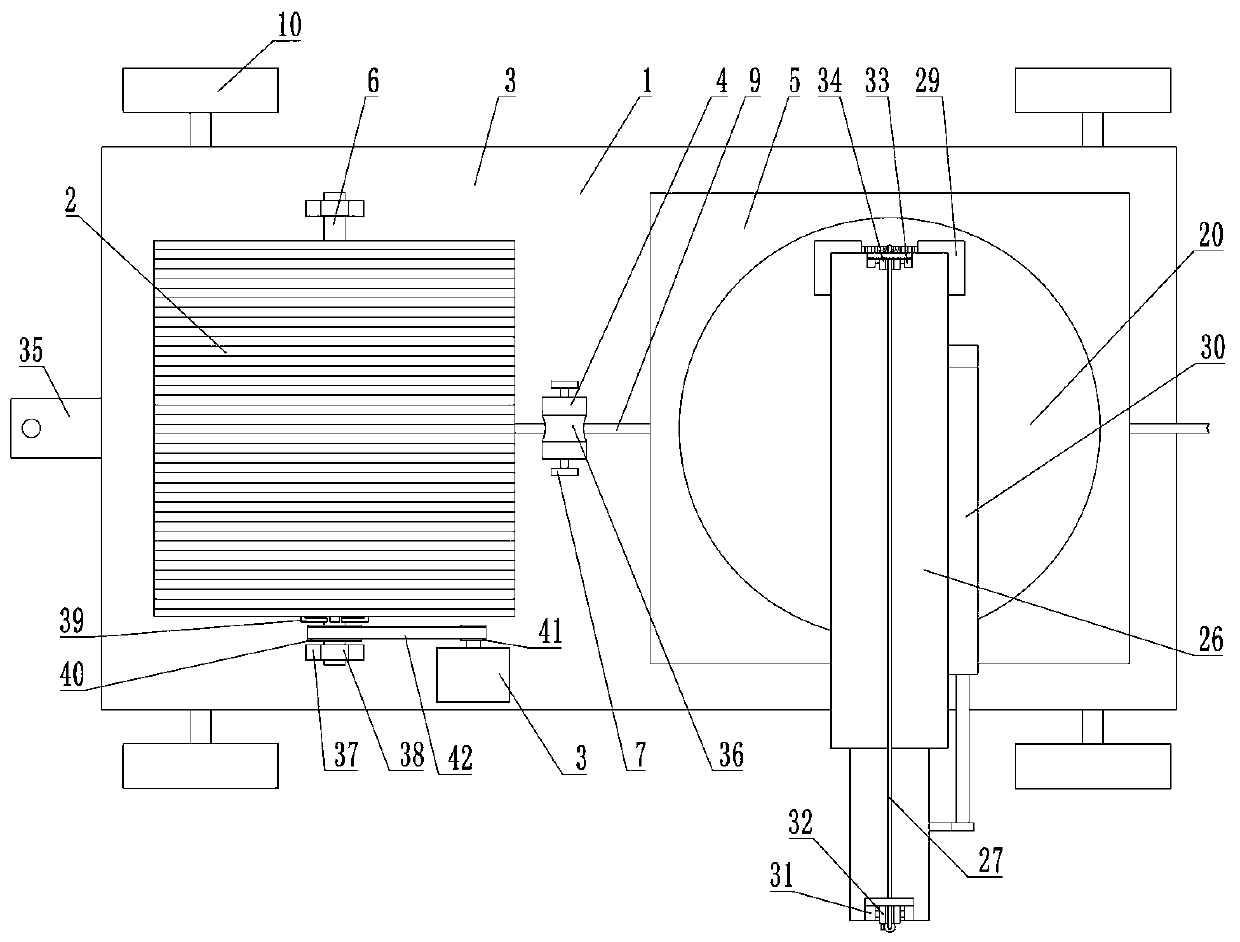

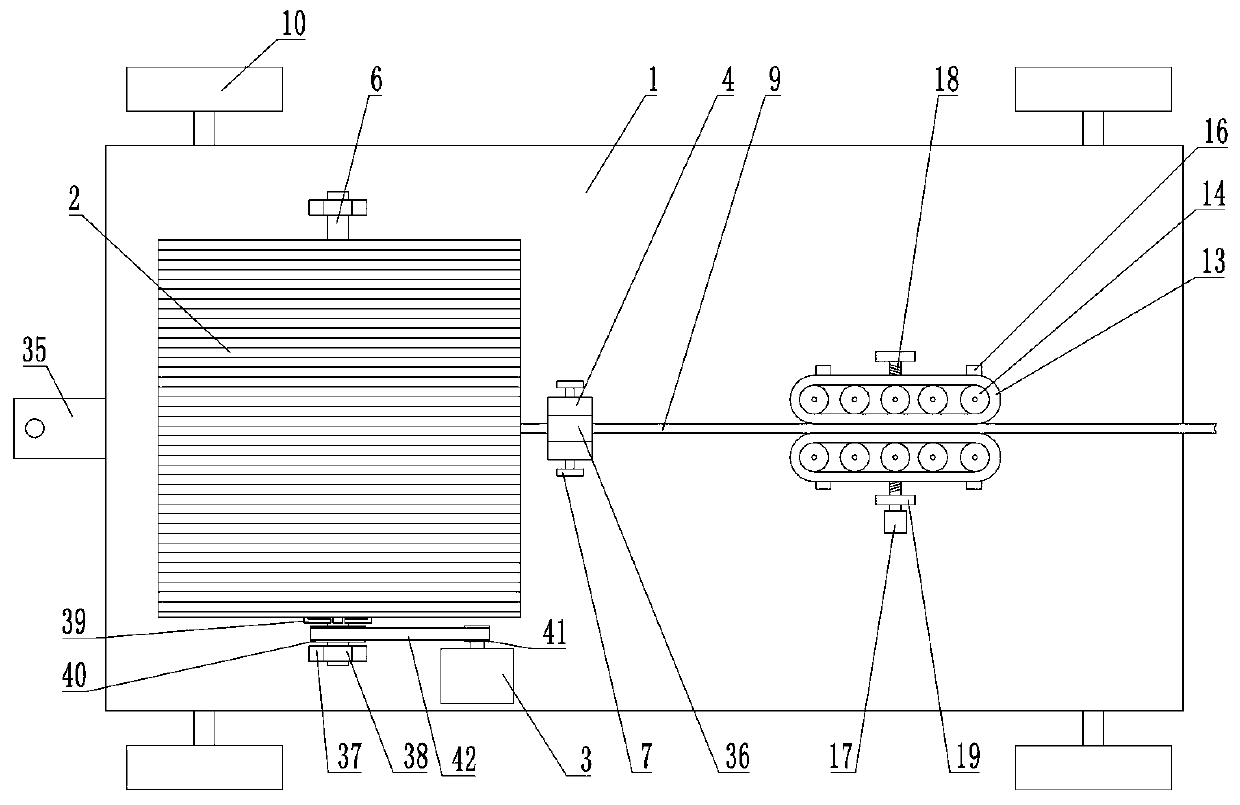

A method of releasing and laying cable from cable reel

InactiveCN110890717AMeet space requirementsApparatus for laying cablesStructural engineeringElectric cables

Owner:国网河南省电力公司鄢陵县供电公司

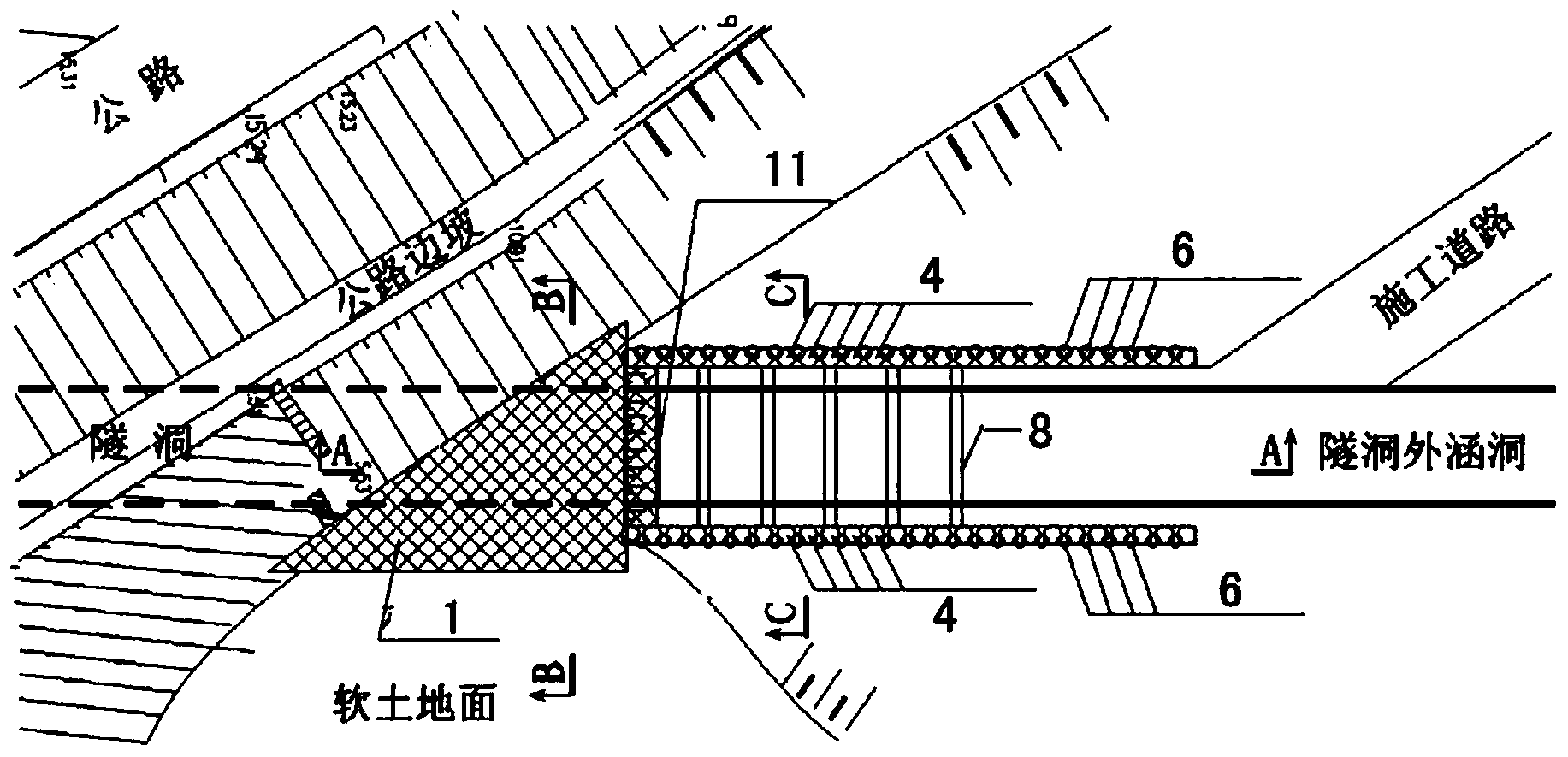

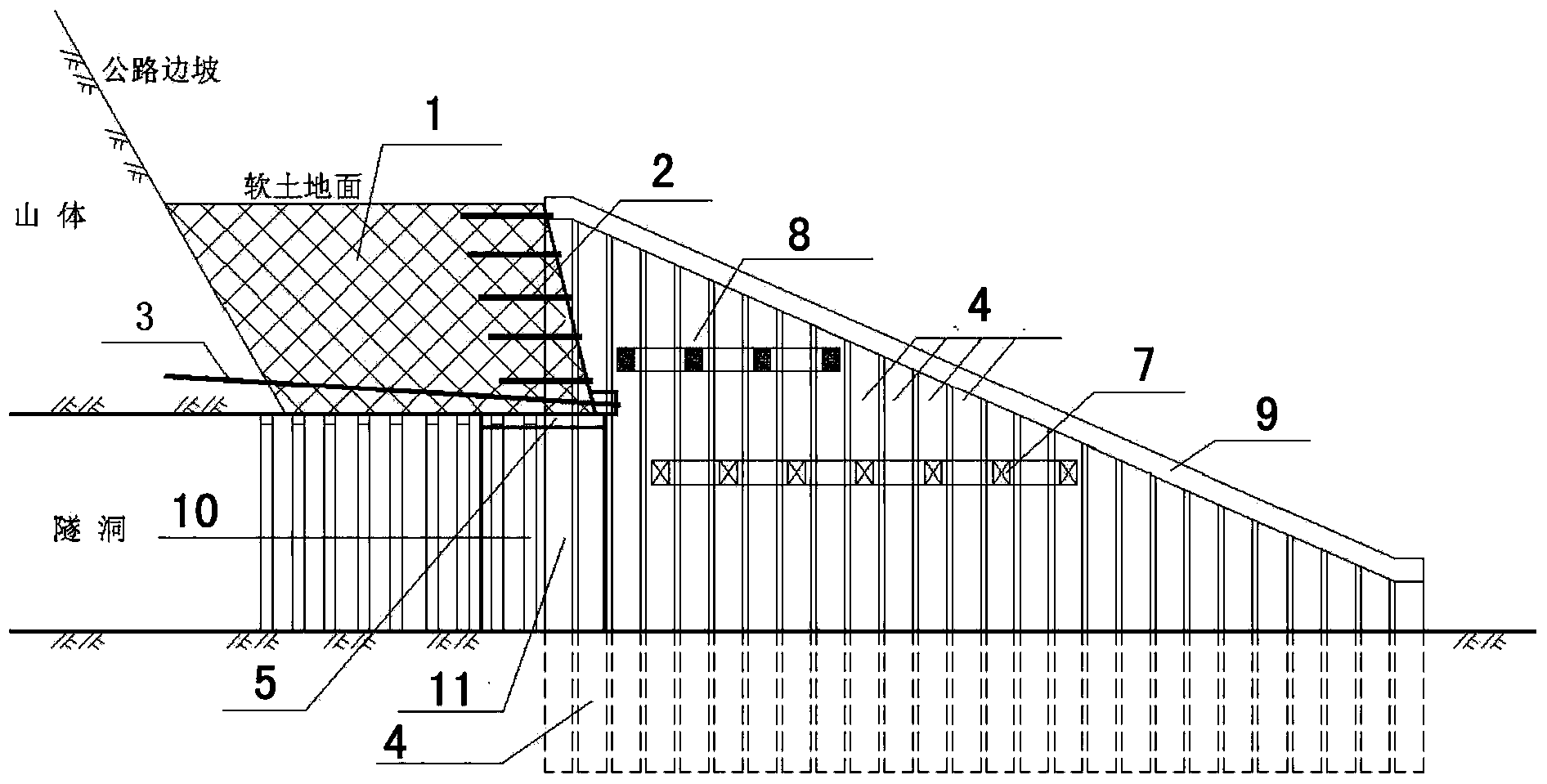

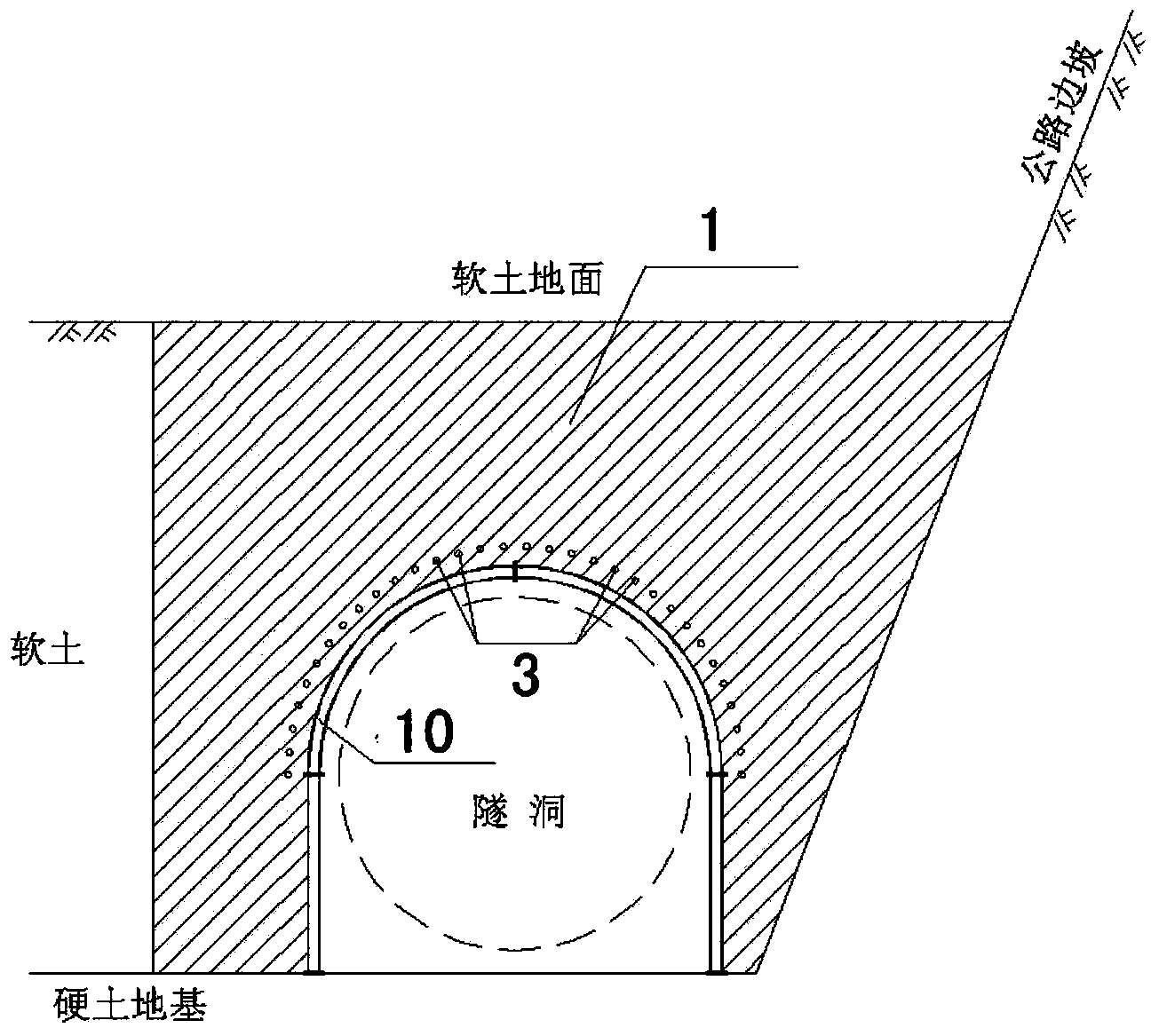

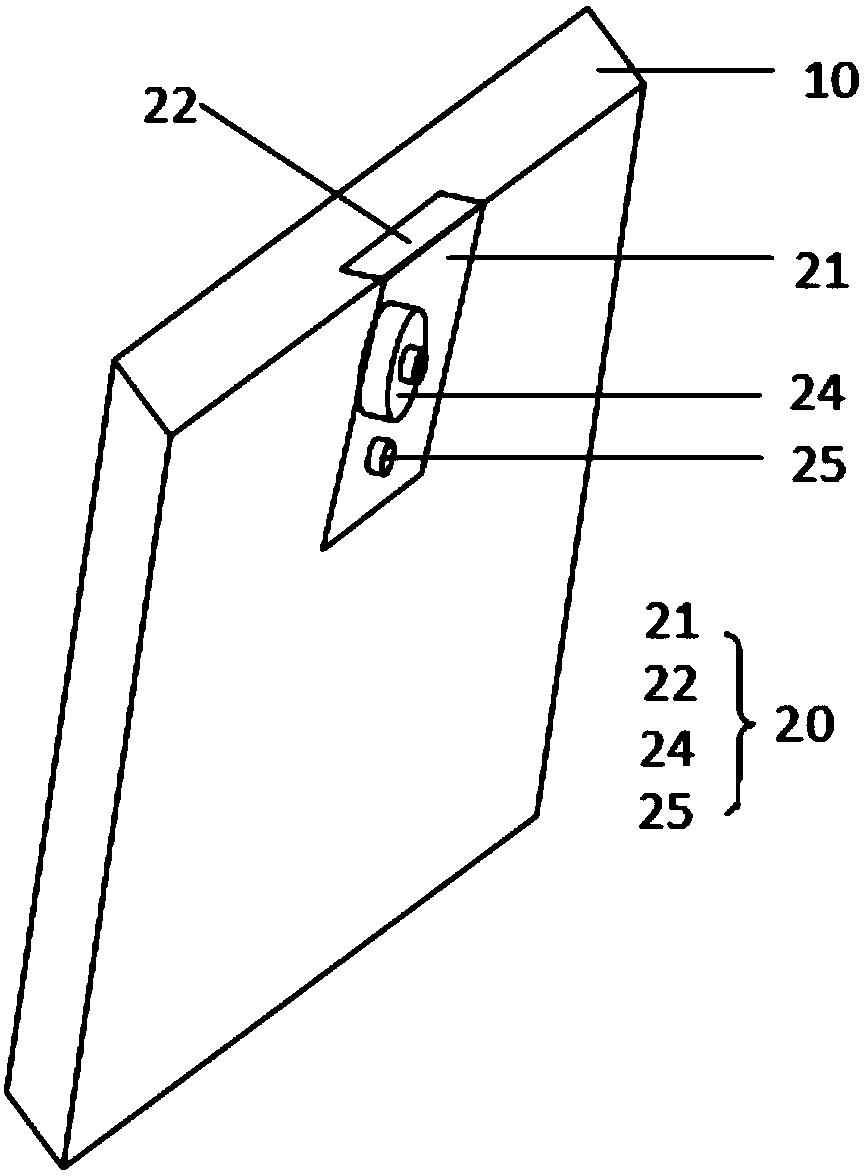

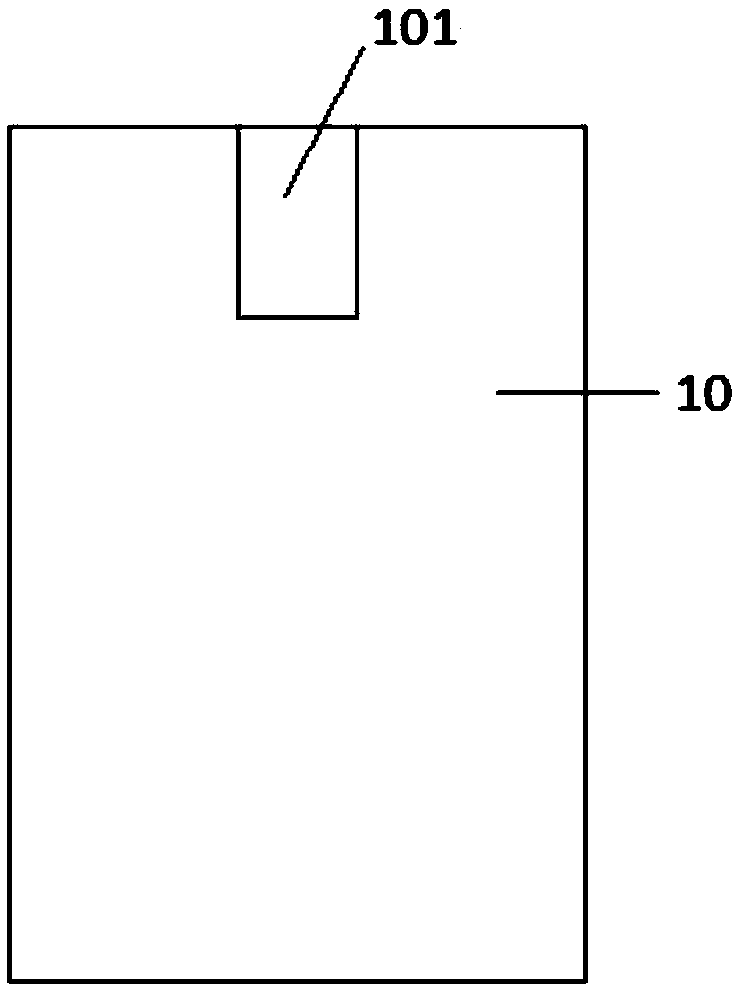

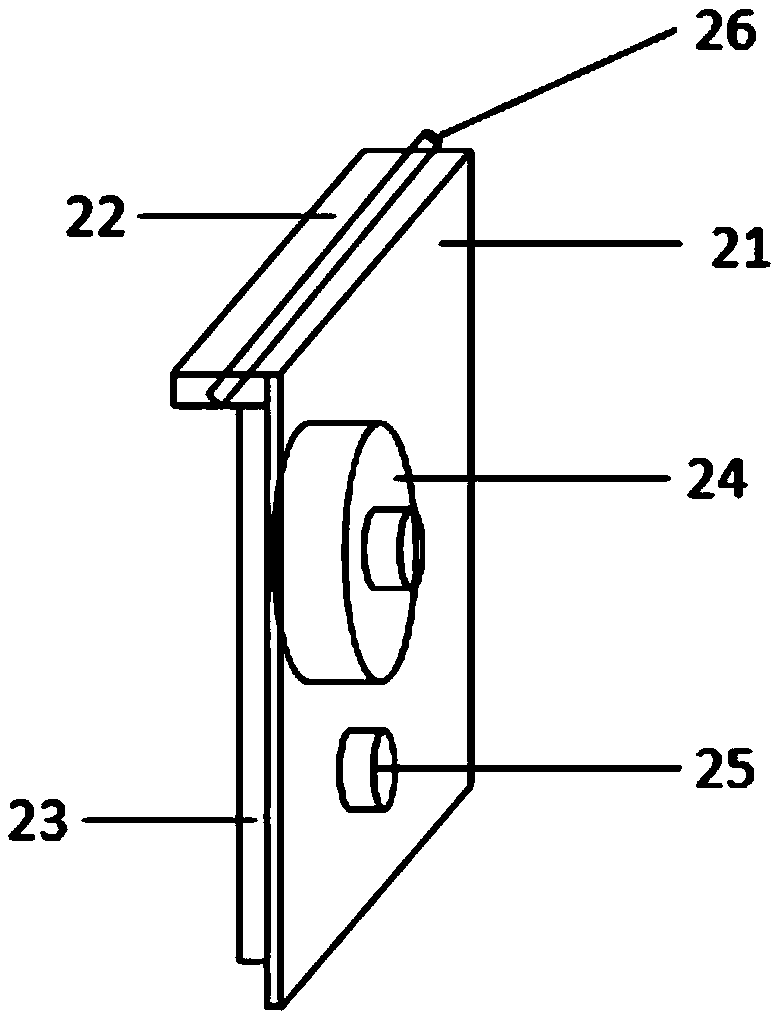

Supporting structure of tunnel opening of power plant circulating water system and construction method

The invention relates to a supporting structure of a tunnel opening of a power plant circulating water system and a construction method. The supporting structure comprises a steel arch, wherein a part of the steel arch is arc-shaped. The supporting structure is characterized in that a plurality of cement stirring piles are arranged around the top and the two sides of the tunnel opening to form a cement grout stirring reinforcing area; the top of the tunnel opening is provided with a plurality of grouting anchor rods, and accordingly a grouting anchor rod reinforcing structure at the top of a tunnel is formed; a plurality of long tubes are arranged on the arc area of the top of the tunnel opening, and a long pipe shed structure is formed; a plurality of soil blocking cast-in-place piles are arranged on the two sides of a tunnel inlet channel outside the tunnel opening, and a soil blocking support of the tunnel inlet channel outside the tunnel opening is formed; the steel arch, the cement grout stirring reinforcing area, the grouting anchor rod reinforcing structure, the long pipe shed structure and the soil blocking support are connected into a whole through concrete, and accordingly the supporting structure of the tunnel opening of the power plant circulating water system is formed. Soft soil is dug in a certain rage of the tunnel opening, the soft soil in a limited range of the tunnel opening is reinforced in special technical measures, and a safe tunnel opening structure is formed; the position of the tunnel opening does not need to be adjusted, the route of the tunnel does not need to be changed, and the supporting structure and the construction method have the advantages that project investment is little and design and construction are convenient to carry out.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Mobile terminal

InactiveCN109495617ASolve the occupation of visible surfaceSolving Manufacturing ComplexityTelevision system detailsColor television detailsCamera moduleComputer science

The application provides a mobile terminal, which comprises a terminal main body and a camera module. The camera module is arranged on the back of the terminal main body, wherein a groove is formed atthe edge position of the back of the terminal main body close to the top of the terminal main body; the camera module fits in with the groove; and one end of the camera module close to the top of theterminal main body is movably connected with the terminal main body.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

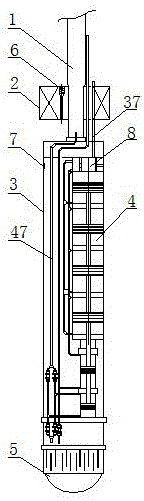

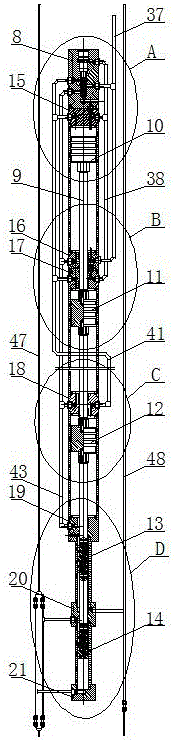

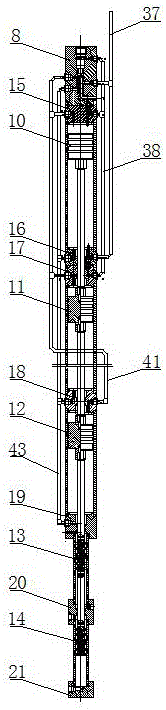

Downhole gas-liquid transduction booster pump

InactiveCN106401925ACompact structureGuarantee smooth developmentPositive displacement pump componentsFlexible member pumpsHigh energySpace requirements

The invention relates to a downhole gas-liquid transduction booster pump and belongs to the technical field of downhole equipment for petroleum and natural gas exploitation. The booster pump comprises an oil pipe, a packer, a housing, a piston component and a filter, wherein the oil pipe is mounted at the top of the housing; the packer is arranged on the oil pipe; the filter is mounted at the bottom of the housing; a reversing valve is eccentrically arranged in the housing; and the piston component is mounted below the reversing valve. The booster pump is compact in structure, can meet the downhole space requirement, does not need additional power during operation, and can greatly pressurize liquid by virtue of energy provided by gas in an oil-gas well, thereby realizing stable and efficient exploitation of low-pressure and low-yield oil-gas wells, coal gas wells and water-producing gas wells. The booster pump solves the problems of high cost and high energy consumption of water draining and crude oil lifting processes of the conventional technology, and is especially applicable to downhole pressurization operation at different depths in low-yield gas wells, gas-containing oil wells and coal-bed gas wells.

Owner:廖嘉炜

Crossed-material-conveyance die cutting machine

ActiveCN106113153AFeeding speed controlIncrease productivityLaminationLamination apparatusEngineeringMechanical engineering

The invention discloses a crossed-material-conveyance die cutting machine comprising a base, a first material conveyance mechanism, a second material conveyance mechanism and a die cutting mechanism. The first material conveyance mechanism and the second material conveyance mechanism are installed on the two sides of the base. The die cutting mechanism is installed in the middle of the base. The material conveyance direction of the first material conveyance mechanism and the material conveyance direction of the second material conveyance mechanism are mutually perpendicular and converge below the die cutting mechanism. The crossed-material-conveyance die cutting machine can conduct die cutting and compounding of materials at the same time and is high in production efficiency and suitable for volume production. Meanwhile, the first material conveyance mechanism and the second material conveyance mechanism achieve asynchronous die cutting, so that the product interval requirement is met, and materials are saved.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

Bridge construction method for combining turning with height regulation

ActiveCN110670485ALower longitudinal slopeReduce project costBridge erection/assemblyStructural engineeringArchitectural engineering

The invention relates to a bridge construction method for combining turning with height regulation. The method comprises the following steps of turning and height regulation, wherein the step of turning comprises the step of carrying out a bridge turning operation above the designed line position of a bridge to be turned, and the step of height regulation comprises the step of lowering the body ofthe bridge to a designed elevation. By use of the bridge construction method provided by the invention, the bridge turning operation is firstly carried out above the designed line position of the bridge to be turned, then, the body of the turned bridge is lowered to the designed elevation so as to be convenient in fully meeting a space requirement in a bridge turning process and avoiding interference with surrounding structures or railway overhead line poles and the like which can not be relocated or modified, meanwhile, the bound limitation of the turned railway / road can be met, the longitudinal slope of the railway / road is effectively lowered, driving comfort is improved, and an engineering construction cost is lowered.

Owner:中铁武汉勘察设计院有限公司

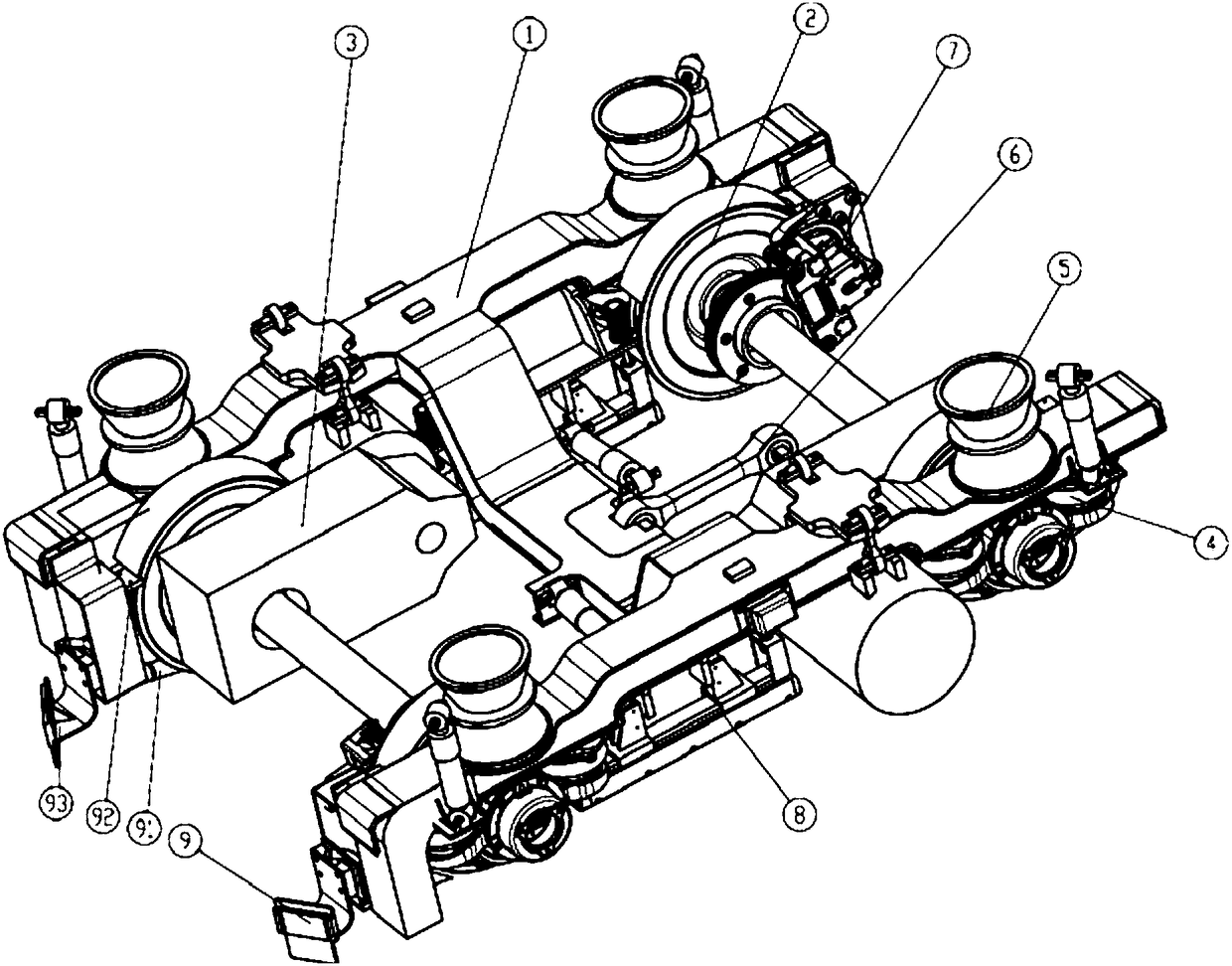

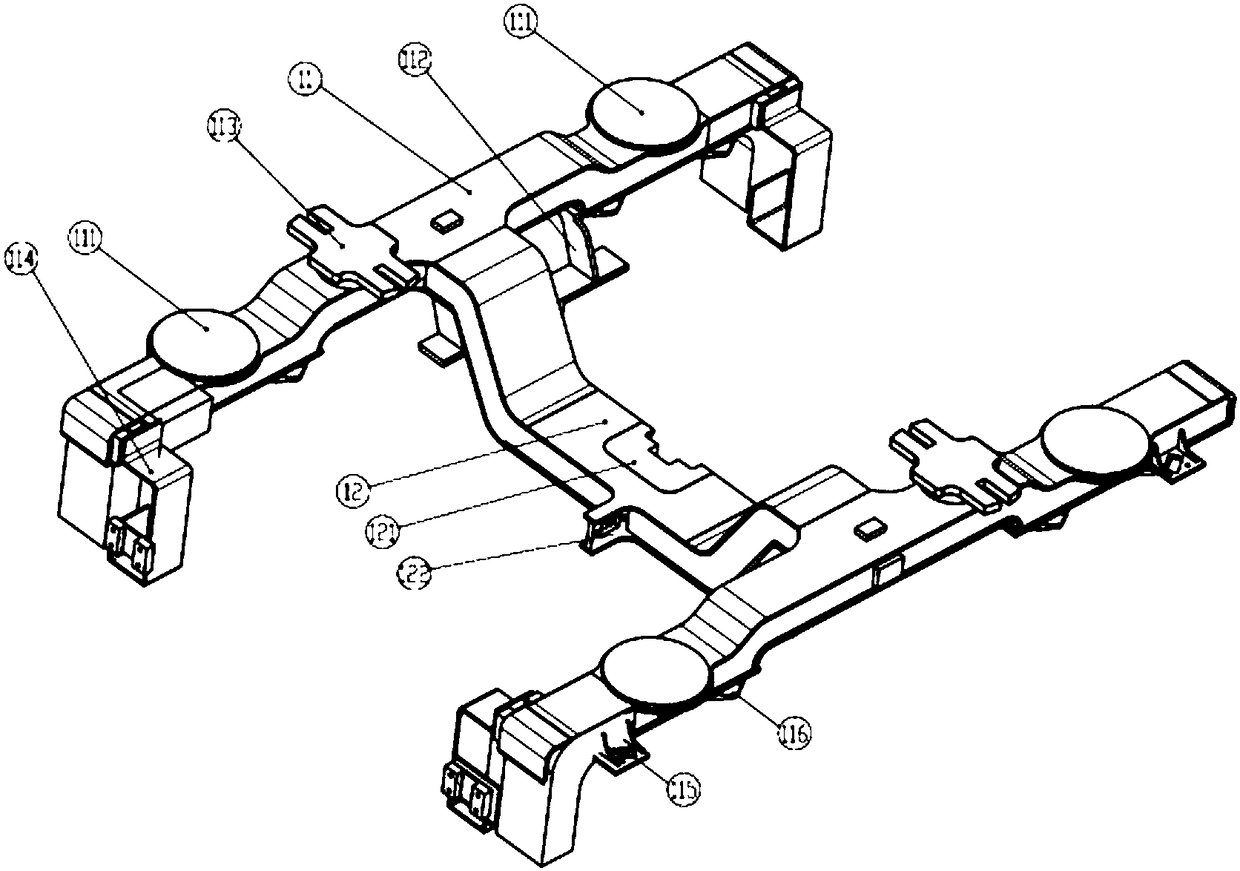

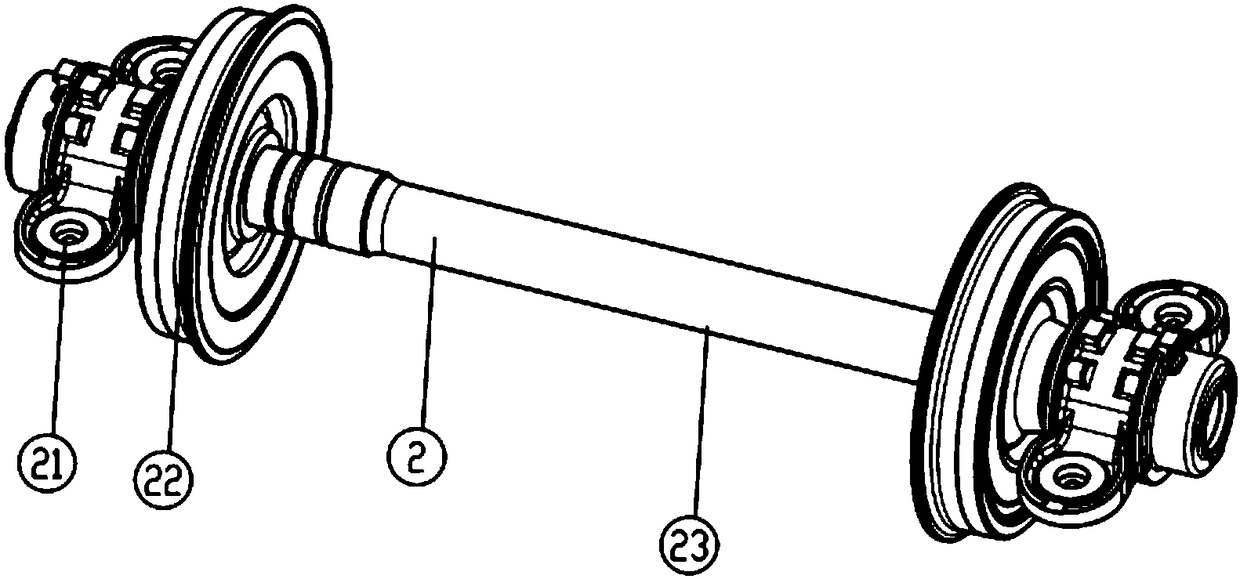

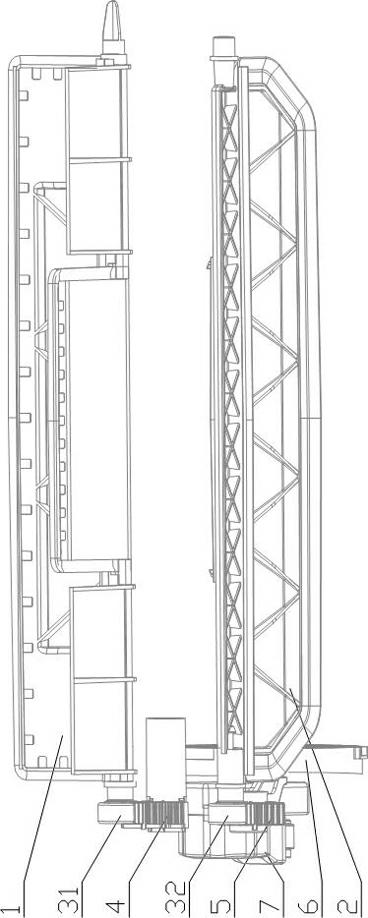

Low-floor tramcar power car bogie

ActiveCN108146461AMeet space requirementsSimple structureBogiesAxle-boxes mountingBogieBraking system

The invention relates to a low-floor tramcar power car bogie. The low-floor tramcar power car bogie is composed of a framework, wheel pairs, driving systems, primary suspension parts, secondary suspension parts, traction devices, brake systems, rim lubricating systems, sand scattering systems, stone removing devices and the like. The low-floor tramcar power car bogie adopts a traditional wheel pair structural mode; the traction devices of the low-floor tramcar power car bogie are arranged on the outer side of the framework in a skew symmetry mode; the driving systems are arranged on the outerside of the framework; and motors are suspended on the upper portions of framework side beams, and each wheel pair is driven by the corresponding motor. The low-floor tramcar power car bogie has the characteristics of simple structure, low manufacturing cost and low casting and welding requirements.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

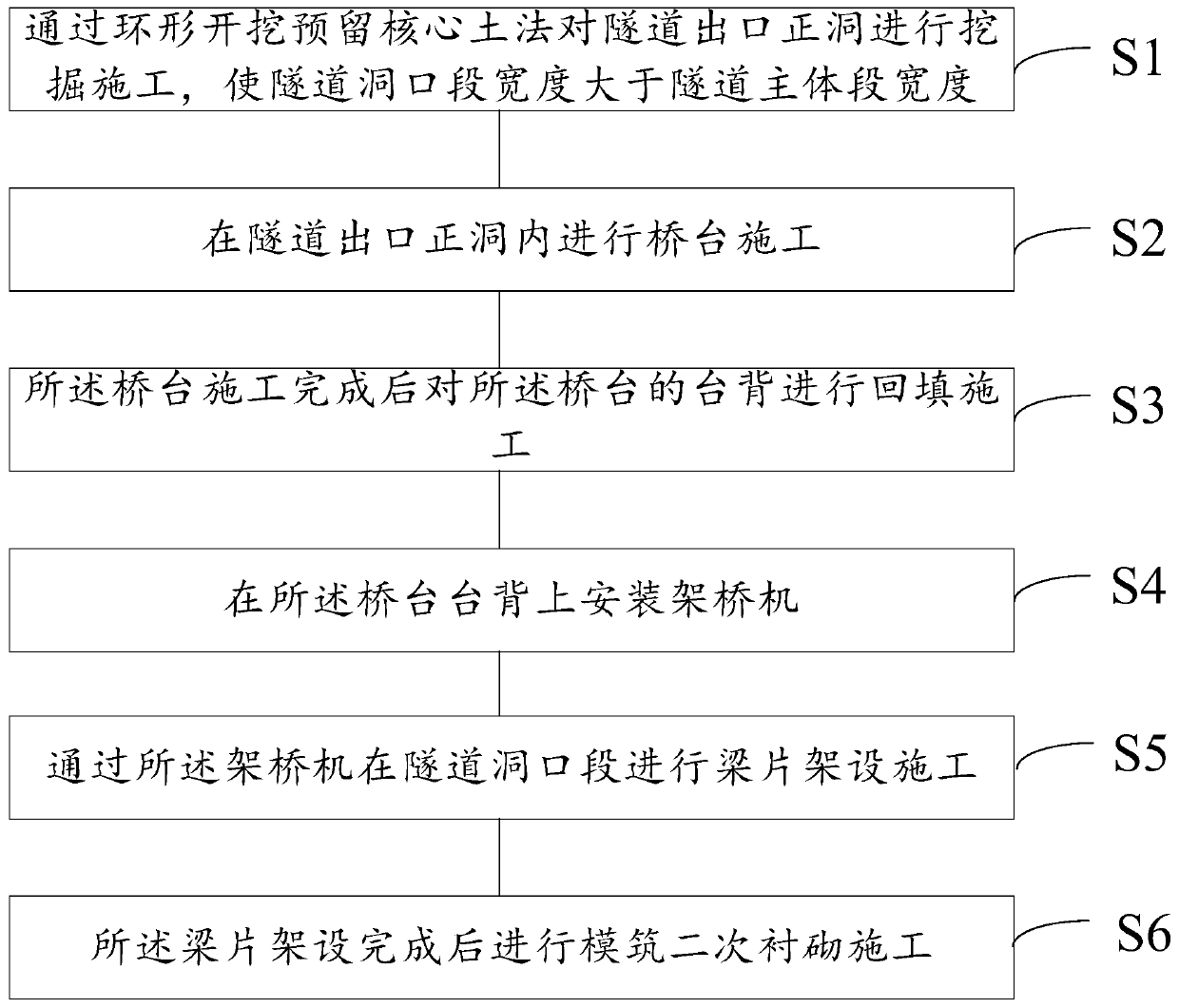

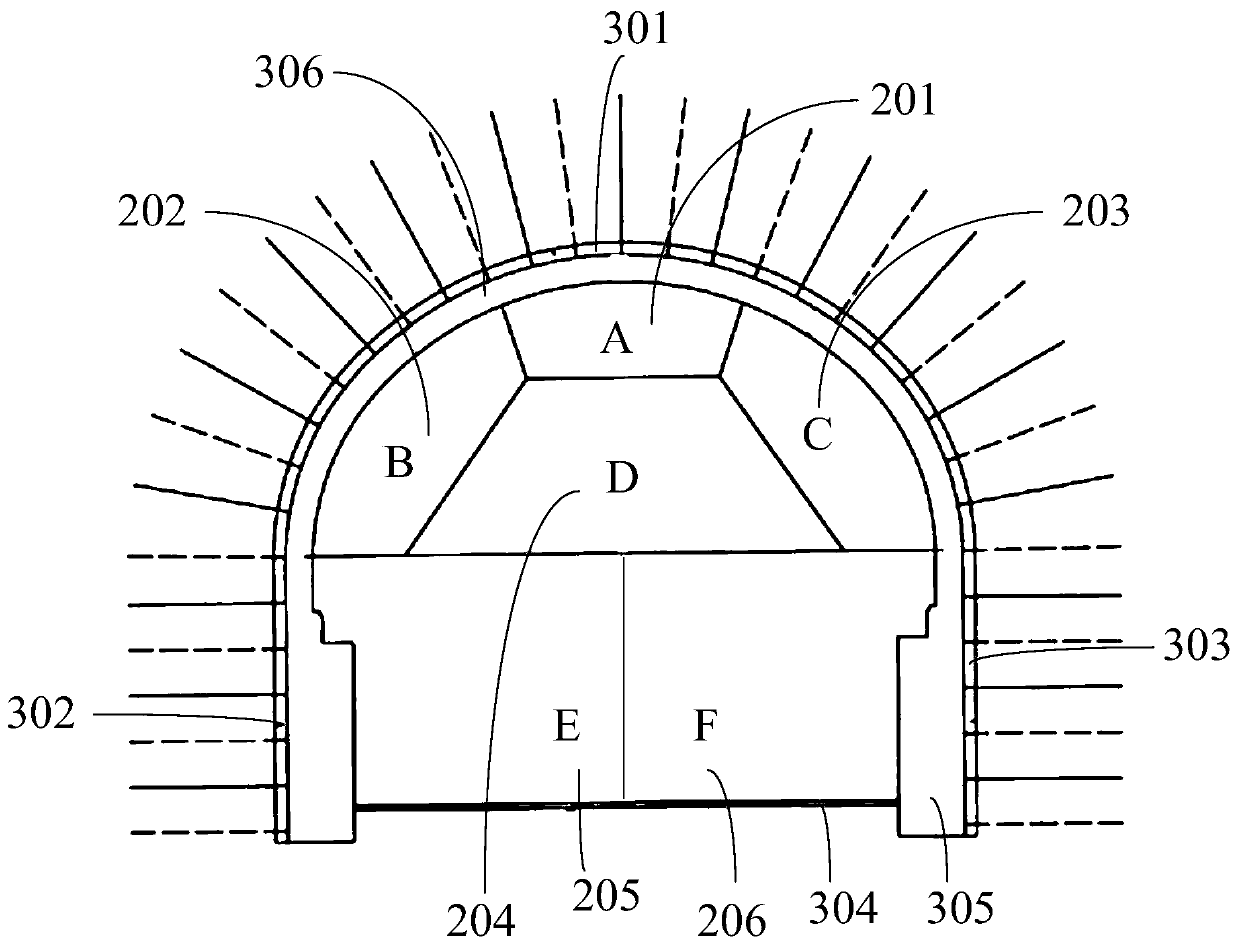

Bridge-tunnel joint tunnel broadening structure and bridging construction method

ActiveCN111270615ASolve the problem of limited connecting spaceEnsure safetyUnderground chambersBridge structural detailsArchitectural engineeringAbutment

The invention discloses a bridge-tunnel joint tunnel broadening structure and a bridging construction method. The method comprises the steps of carrying out excavation construction on a tunnel exit main tunnel through an annular excavation reserved core soil method, and enabling the width of a tunnel portal section to be greater than the width of a tunnel main body section; carrying out bridge abutment construction in the tunnel exit main tunnel; after the abutment construction is completed, carrying out backfill construction on the abutment back of the abutment; mounting a bridge erecting machine on the abutment back; conducting beam piece erecting construction on the tunnel portal section through the bridge erecting machine; and carrying out mold-building secondary lining construction after the beam pieces are erected. According to the invention, the tunnel exit bridge-tunnel joint part is widened, the width of the widened structural section is consistent with the clear width of theconstruction clearance of a tunnel emergency stop area, so that bridge-tunnel joint and bridging construction of the double gird bridge erecting machine are met. Meanwhile, the emergency stop area secondary lining formwork trolley can be comprehensively utilized for constructing a tunnel portal lining, and the cost generated by formwork modification is reduced.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Cable take-up and pay-off and lifting integrated combined vehicle

Owner:国网河南省电力公司鄢陵县供电公司

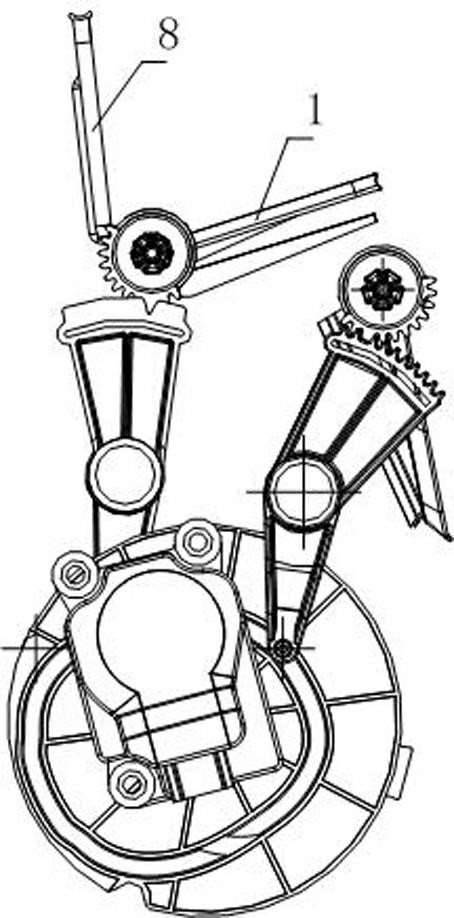

Multi-mode air door regulating mechanism of automotive air conditioner

The invention discloses a multi-mode air door regulating mechanism of an automotive air conditioner. The multi-mode air door regulating mechanism comprises a driving member (7), a disc-shaped transmission member (6), rocker arms, a first air door (8), a second air door (1) and a third air door (2), wherein the disc-shaped transmission member (6) rotates under the action of the driving member (7); a guide rail is arranged on the end face of the disc-shaped transmission member (6); the rocker arm is provided with a first end sliding on the guide rail; the rotating angles of the first air door (8), the second air door (1) and the third air door (2) are controlled by the rocker arms; the first air door (8) is fixedly connected with the second air door (1) and a first gear (31) so as to form a V-shaped air door; the third air door (2) is fixedly connected with the second gear (32); the rocker arms comprise a first rocker arm (4) with a second end meshed with the first gear (31) and a third rocker arm (5) with a second end meshed with the second gear (32). According to the invention, at the same time of adding an air outlet model, the occupied space is smaller, the cost and the mass of an entire car are reduced, and the comfortable level of the entire car is further increased, and the operation is simplified.

Owner:SHANGHAI BEHR THERMAL SYST

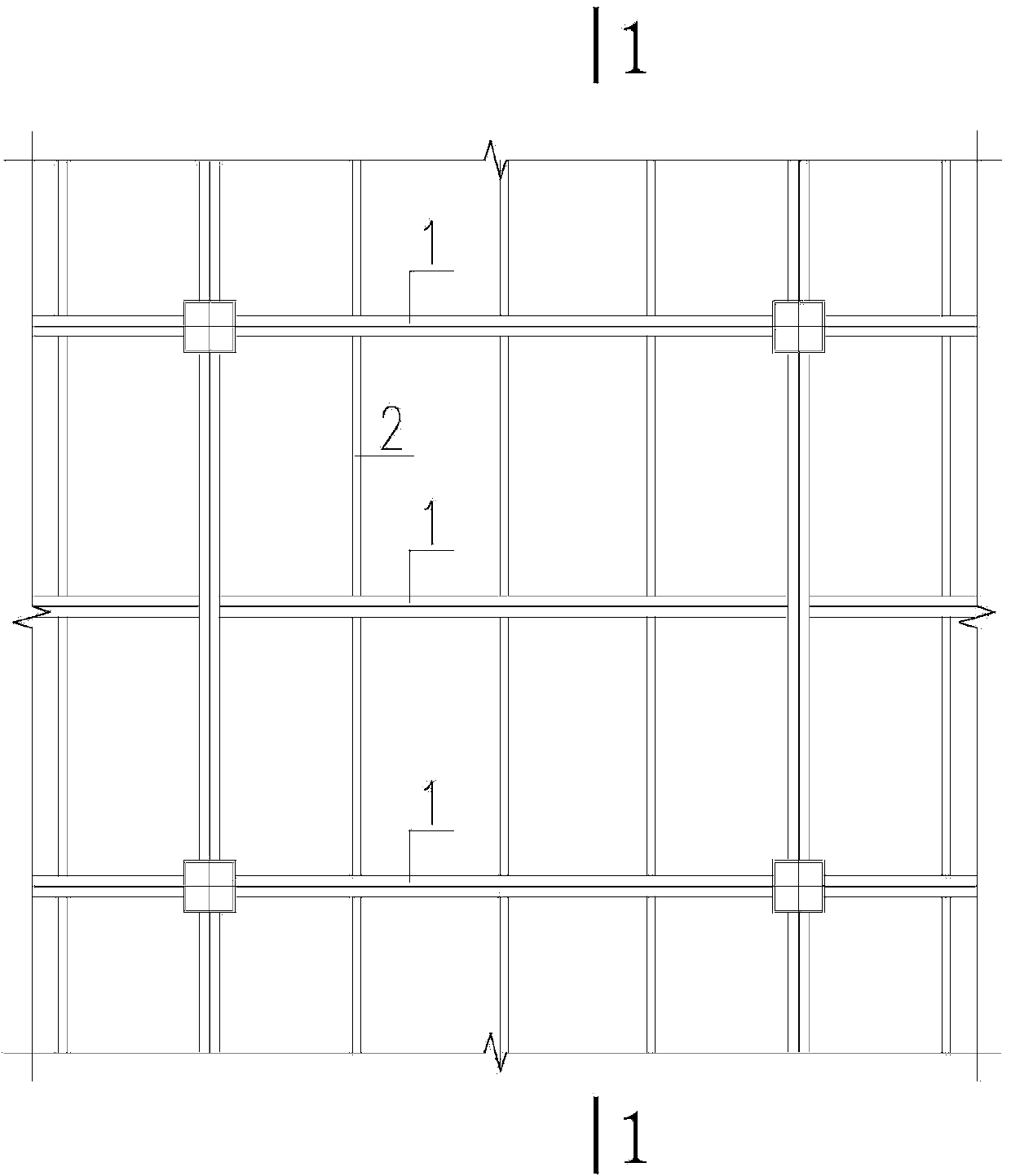

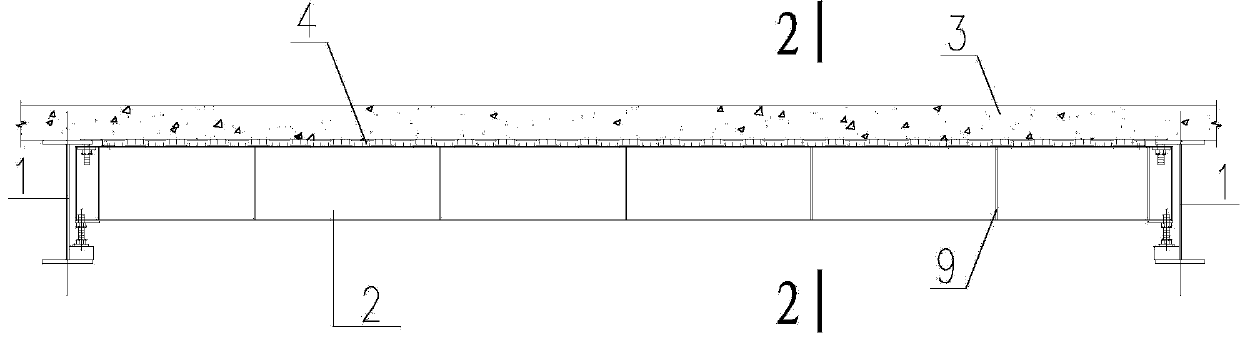

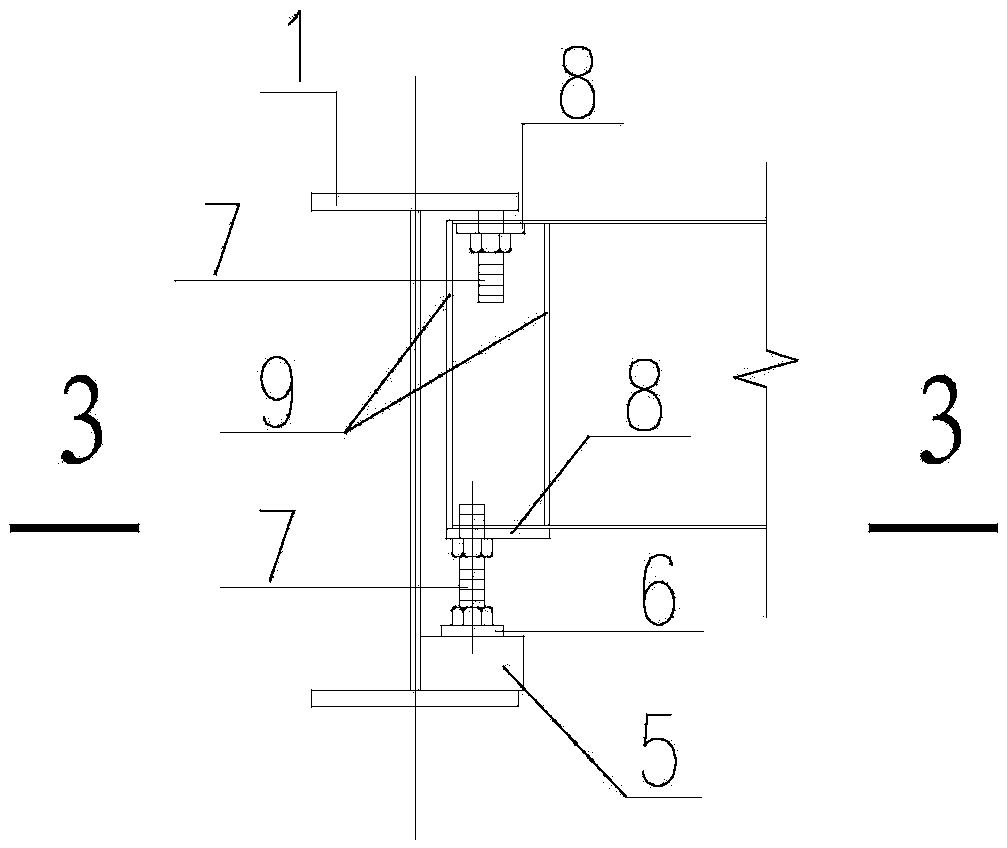

Dismountable template system

ActiveCN104179352AAdaptableMeet space requirementsForms/shuttering/falseworksSheet steelArchitectural engineering

The invention provides a dismountable template system which comprises a support frame and a template, wherein the template is positioned on the upper surface of the support frame; the support frame is perpendicular to a storey steel beam; the two ends of the support frame are respectively positioned on the inner side of the web of the steel beam; a first steel plate is welded on each of the upper wing edge and the lower wing edge of each end part of the support frame; the first steel plates of the support frame are fixed on the upper wing edge and the lower wing edge of the steel beam through adjusting bolts, steel base plates and wood cushion blocks; the template is formed by wrapping a substrate with a galvanized steel sheet; the periphery of the template is wrapped with a second steel plate; a third steel plate is adhered to the external part of the middle of the template in one direction; the second steel plate, the third steel plate, the galvanized steel sheet and the board are fixed together through first bolts and second bolts. The dismountable template system is convenient to construct, the whole-room steel pipe scaffold is not required and decoration is facilitated.

Owner:杭州市城建设计研究院有限公司

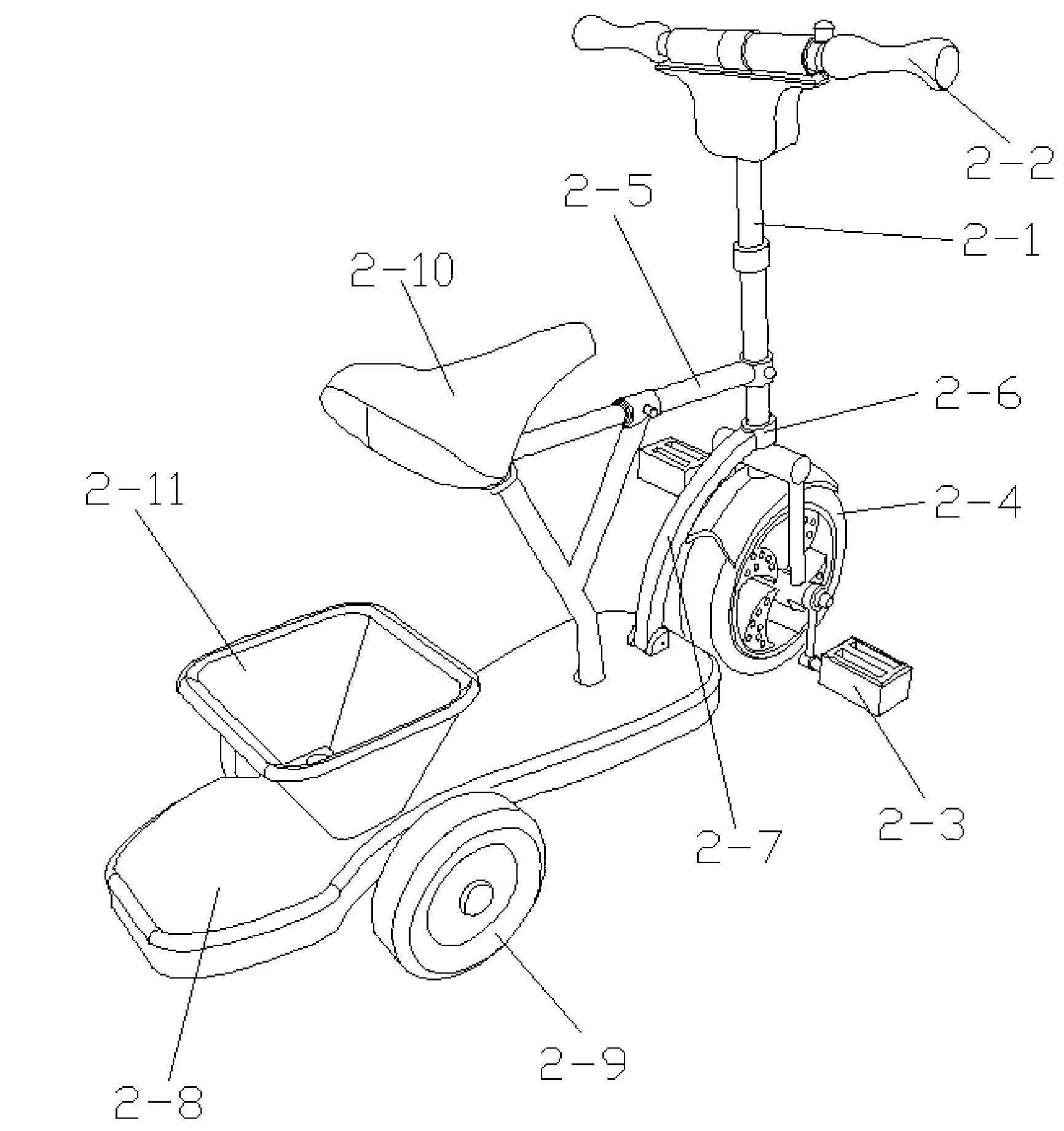

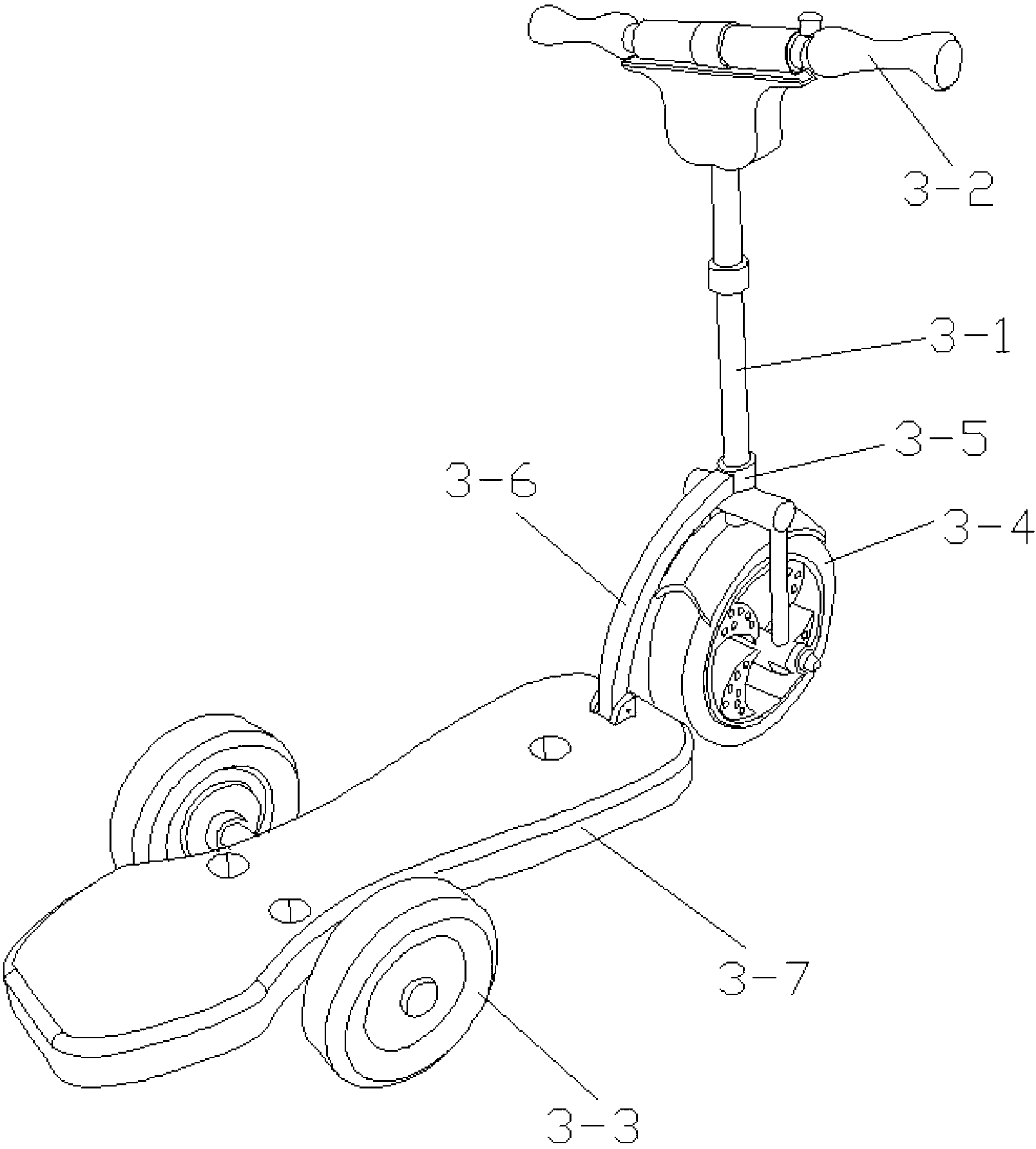

Detachable combined stroller

InactiveCN103318360AMeeting timeMeet space requirementsCarriage/perambulator with multiple axesConvertible cyclesEngineering

The invention discloses a detachable combined stroller comprises two sets of handlebar assemblies, one set of stroller plate assemblies, one set of bicycle frame and one set of stroller seat which are all detachable. The detachable combined stroller can be detached and combined as a stroller, a child's bicycle, a scooter, a wheelbarrow, or a child rocking chair. The detachable combined stroller is simple in structure and convenient to produce, and functional practicality and convenience of combination and deformation are concentrated; the detachable combined stroller is convenient to assemble, disassemble, combine and deform, is simple in operation, high in practicality and easy to promote, and the detachable combined stroller further has the advantages of multifunction, low cost, convenience in assemble and disassemble and comfort. Meanwhile, space occupation and material waste are avoided.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

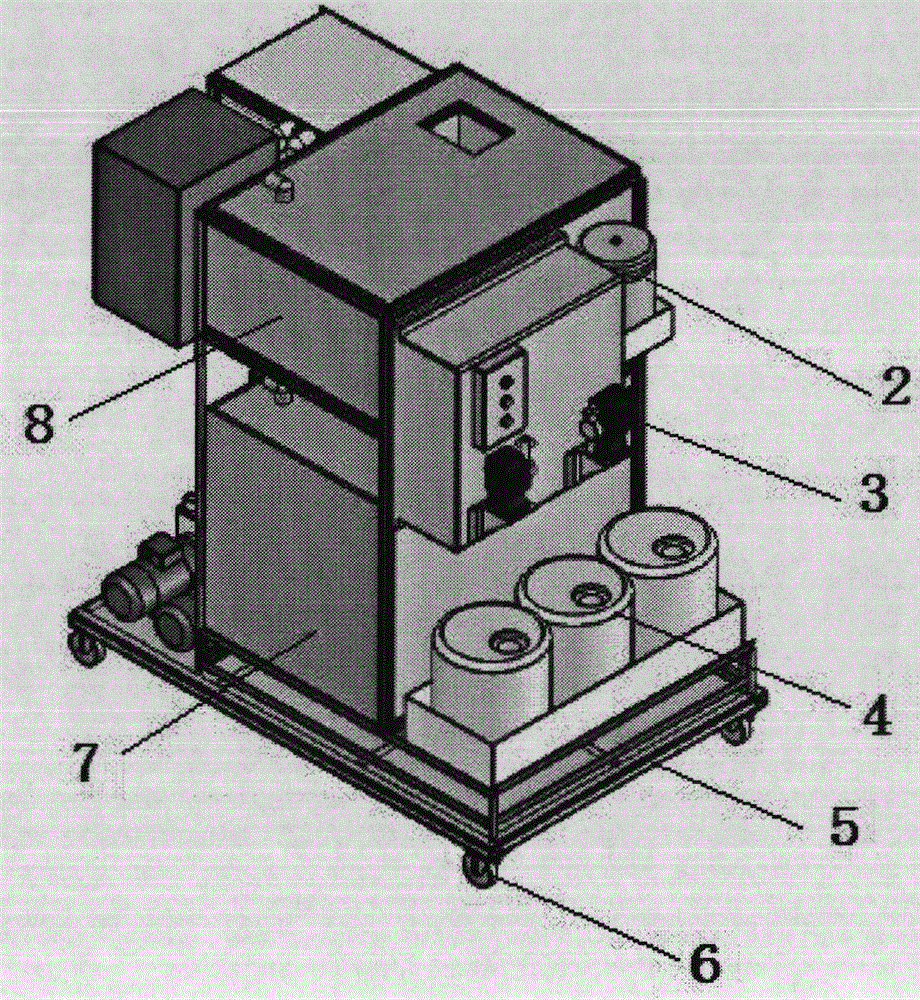

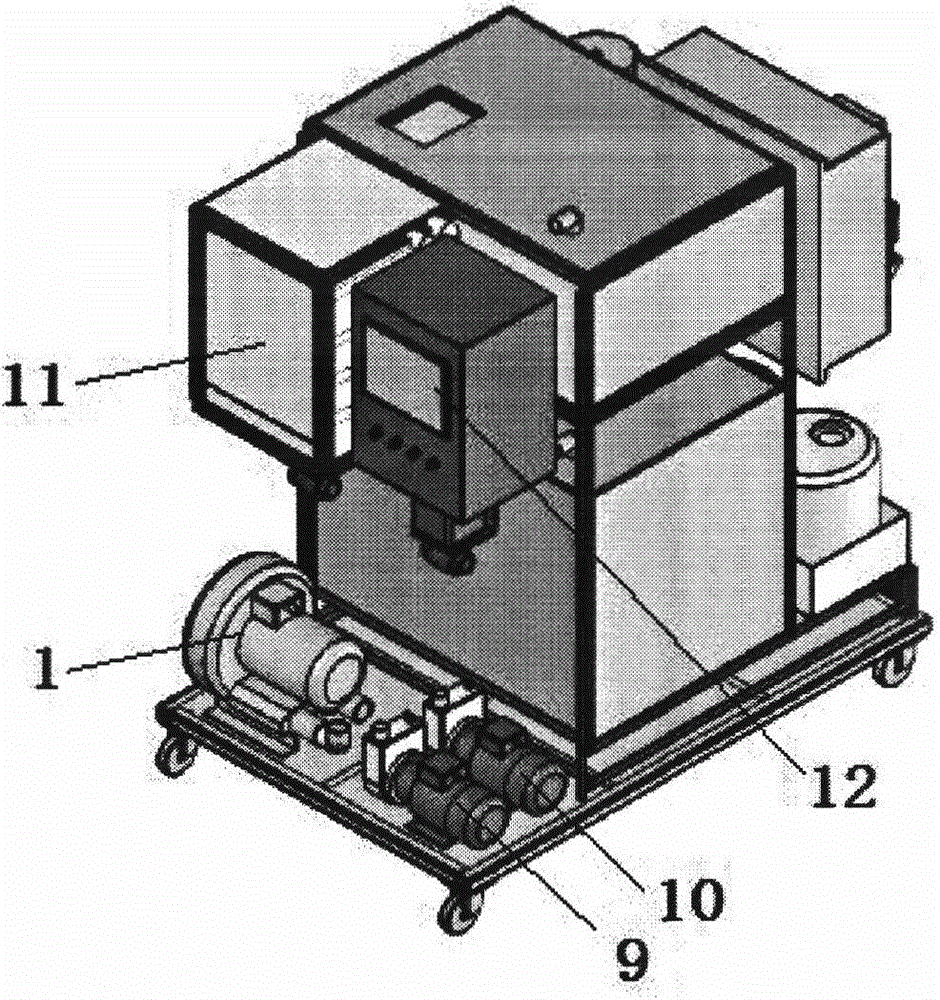

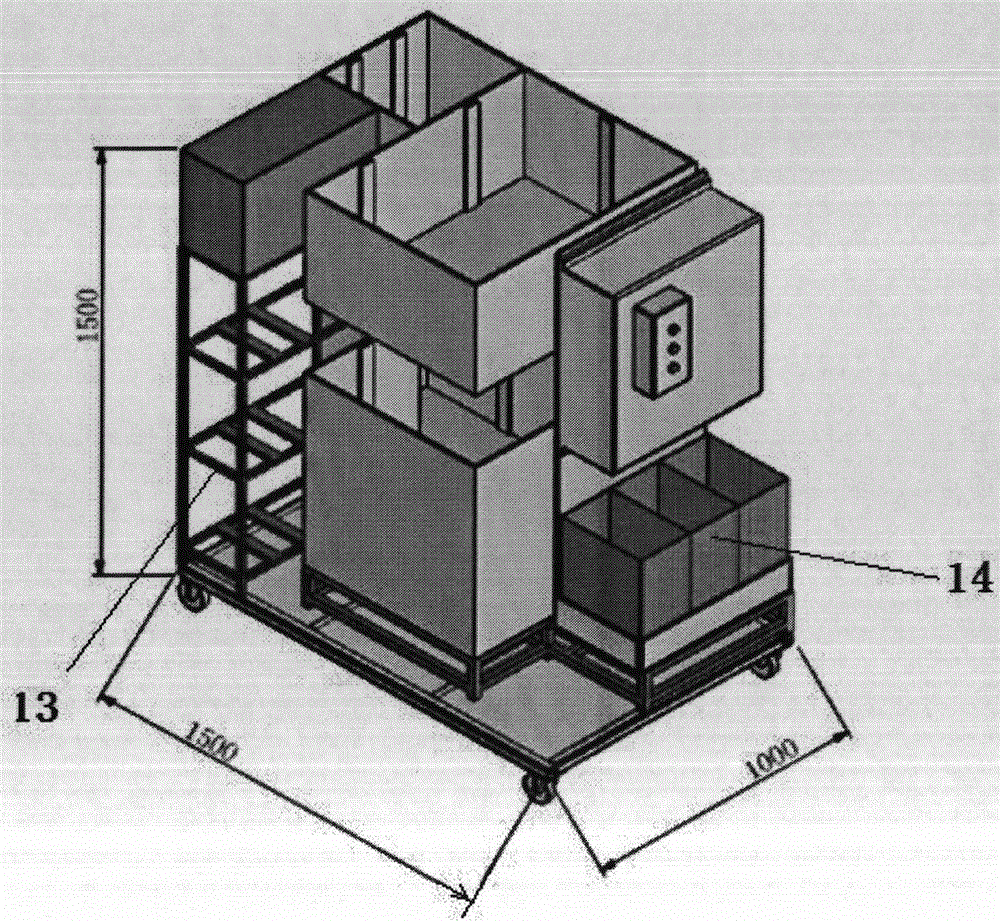

Metalworking fluids filtration system

ActiveCN103555411ASuitable for different environmentsEasy to useLubricant compositionMetalworking fluidFiltration

The invention relates to a metalworking fluids filtration system. The filtration system comprises a box body, equipment arranged in the box body and a bottom support, wherein the equipment in the box body includes a vacuum filtration system, a precision filtration system, a fluid storage system, a pumping system and an intelligent control system; the fluid storage system comprises a first fluid storage box and a second fluid storage box; the pumping system comprises a first pumping system and a second pumping system; the first fluid storage box is connected with a first drug bucket by fluid purification and sterilization equipment; the second fluid storage box is connected with a second drug bucket; sterilization drugs are filled in the second drug bucket and are finally output by the second pumping system to be recycled. The filtration system can purify cutting fluid periodically and continuously, not only better maintain the usability of the cutting fluid but also prolong the service life of the cutting fluid by many times, carry out quick filtration and efficient operation and achieve the aims of safety, environment-friendliness, saving and emission reduction at minimal cost.

Owner:昆山辰芳环保科技有限公司

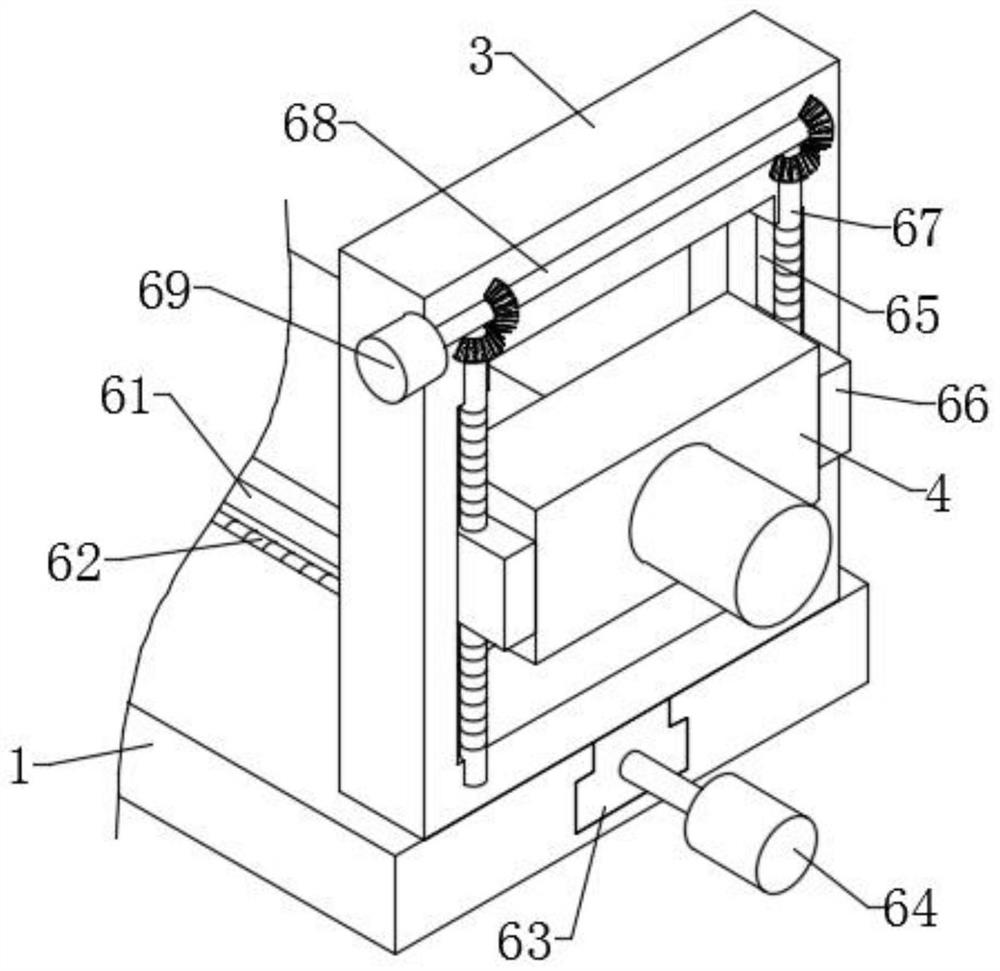

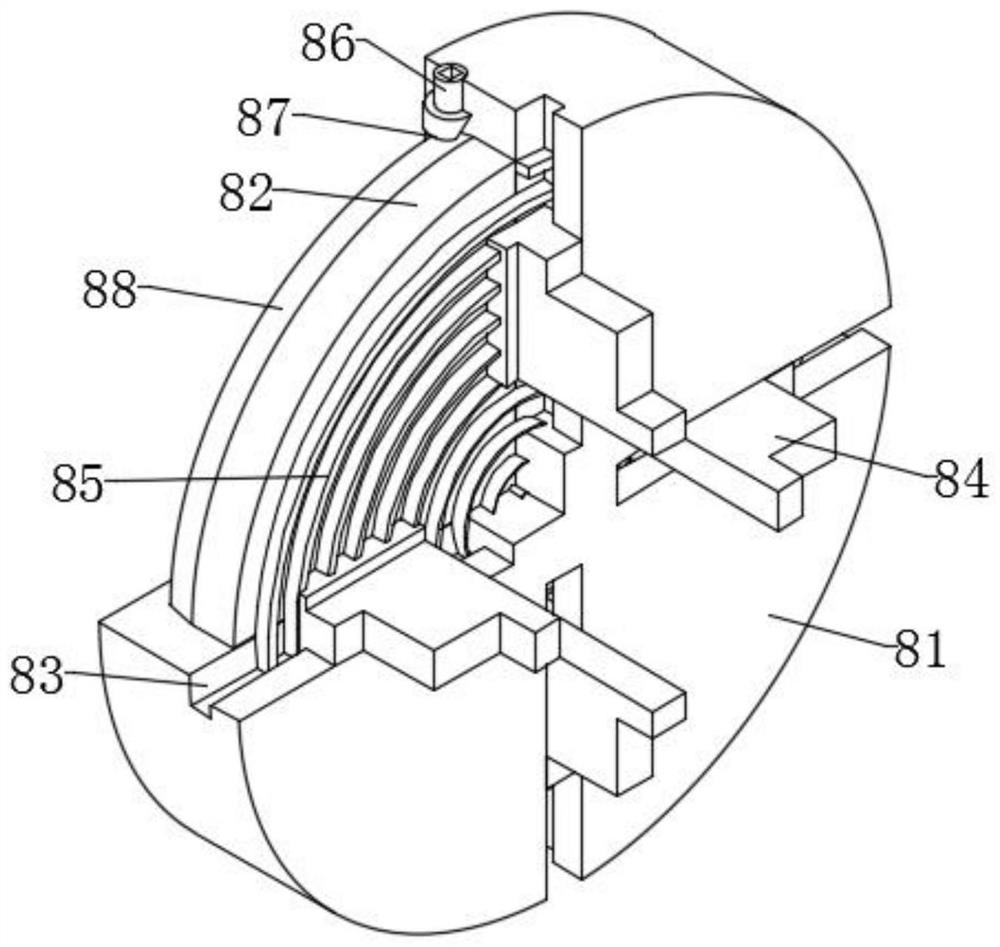

Bearing outer ring double-groove one-time grinding process and equipment

PendingCN113927416AGuaranteed coaxialityKeep the position fixedGrinding drivesGrinding machinesElectric machineryStructural engineering

The invention discloses a bearing outer ring double-groove one-time grinding process and equipment, and belongs to the technical field of bearing machining. The defects that in existing bearing outer ring double-groove grinding machining, as the positions of two grooves are asymmetric, equipment needs to be adjusted after one groove is ground, then another groove is machined, the machining efficiency si low, and the relative accuracy of the two grooves cannot be guaranteed are overcome. According to the scheme, the equipment comprises a machine frame, a fixed plate is installed at the top of one end of the machine frame, a chuck is installed on the fixed plate, a movable frame is installed at the top of the other end of the machine frame, a movable seat is clamped between the inner walls of the movable frame, a cutter feeding assembly is installed among the movable seat, the machine frame and the movable frame, a grinding motor is installed on the movable seat, an output shaft of the grinding motor penetrates through the movable seat and is provided with a double-grinding-wheel mechanism, a hanging bracket is fixedly installed on the machine frame between the fixed plate and the movable seat, and a dresser is installed on the hanging bracket. Two grinding wheel discs are dressed before grinding, it is ensured that the distance meets the requirement for the distance between double grooves, the machining efficiency is improved through one-time grinding, and the machining precision is ensured.

Owner:HANGZHOU RENBEN AUTOMOBILE BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com