A method of releasing and laying cable from cable reel

A technology for laying cables and cable reels, applied in the direction of cable laying equipment, etc., which can solve problems such as large manpower, single function of cable laying devices, and difficult operation of lifting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

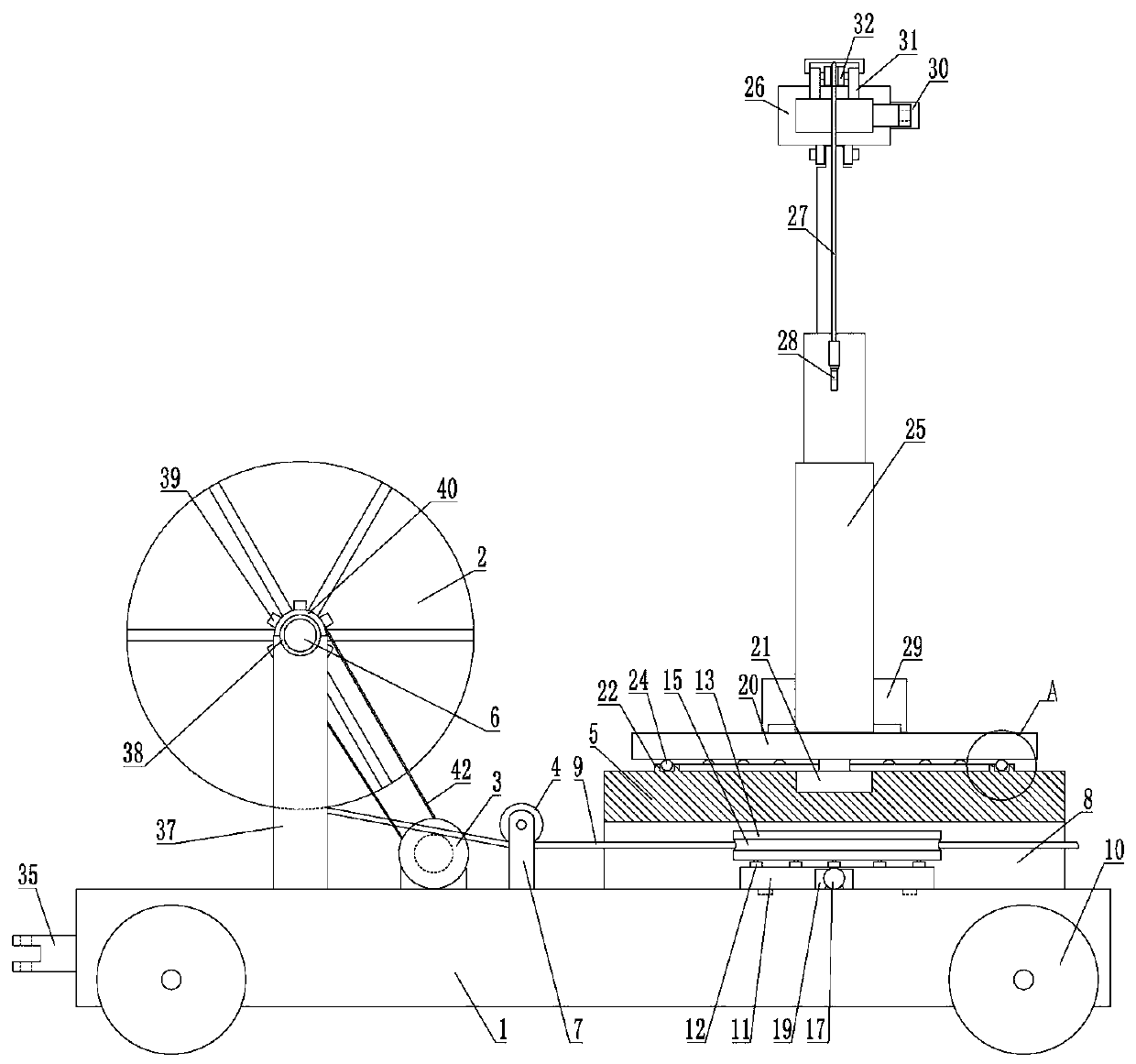

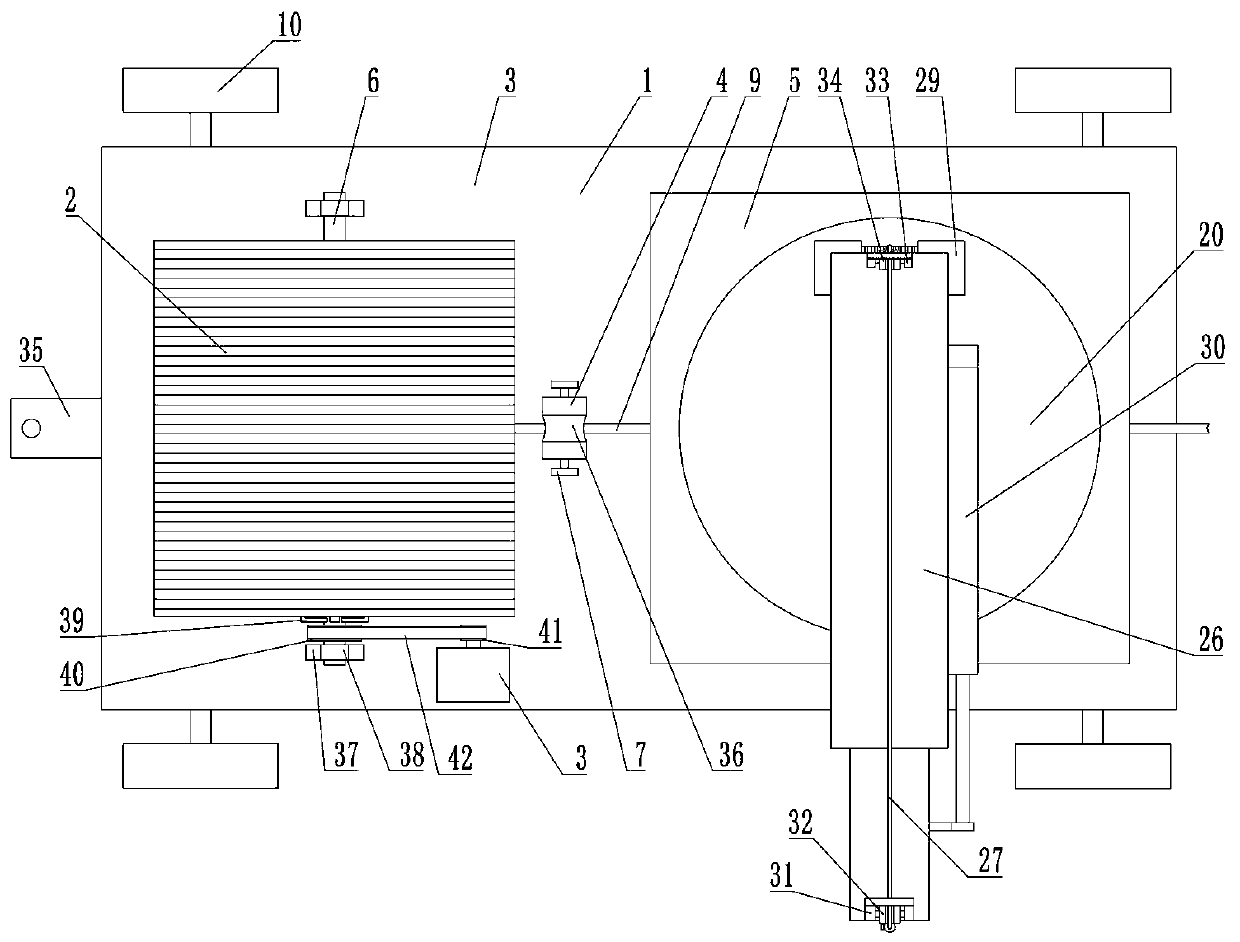

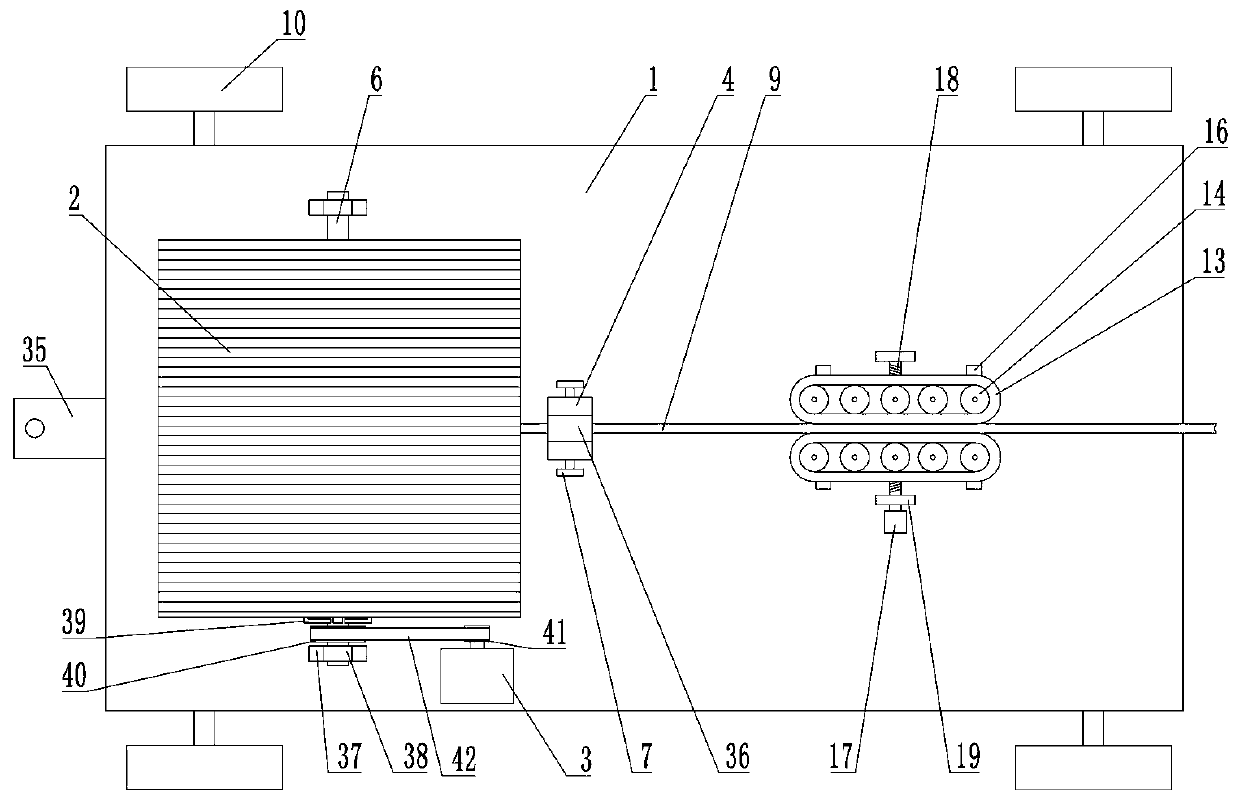

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] Such as Figure 1-6 As shown, a method of releasing and laying cables from a cable drum includes the following steps:

[0033] (1) Manipulate the integrated cable retracting and lifting vehicle to hoist the cable reel 2 full of cables to the integrated cable retracting and lifting vehicle;

[0034] (2) Connect the power locomotive to the cable retractable and lifting integrated vehicle, and the powered locomotive pulls the cable retractable and lifting integrated vehicle to drive to the side of the cable trench where the cable is to be laid;

[0035] (3) Manipulate the cable retracting and lifting integrated vehicle, release the cable on the cable reel, and place the released cable next to the cable trench along the length direction of the cable trench;

[0036] (4) Manually lay the cables on the installation frame inside the cable trench, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com