Dismountable template system

A technology for dismantling formwork and systems, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., and can solve problems such as inability to simultaneously carry out multi-layer floor slabs, inability to use residential structures, and mismatching construction speeds , to achieve the effect of fast construction speed, flat bottom and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

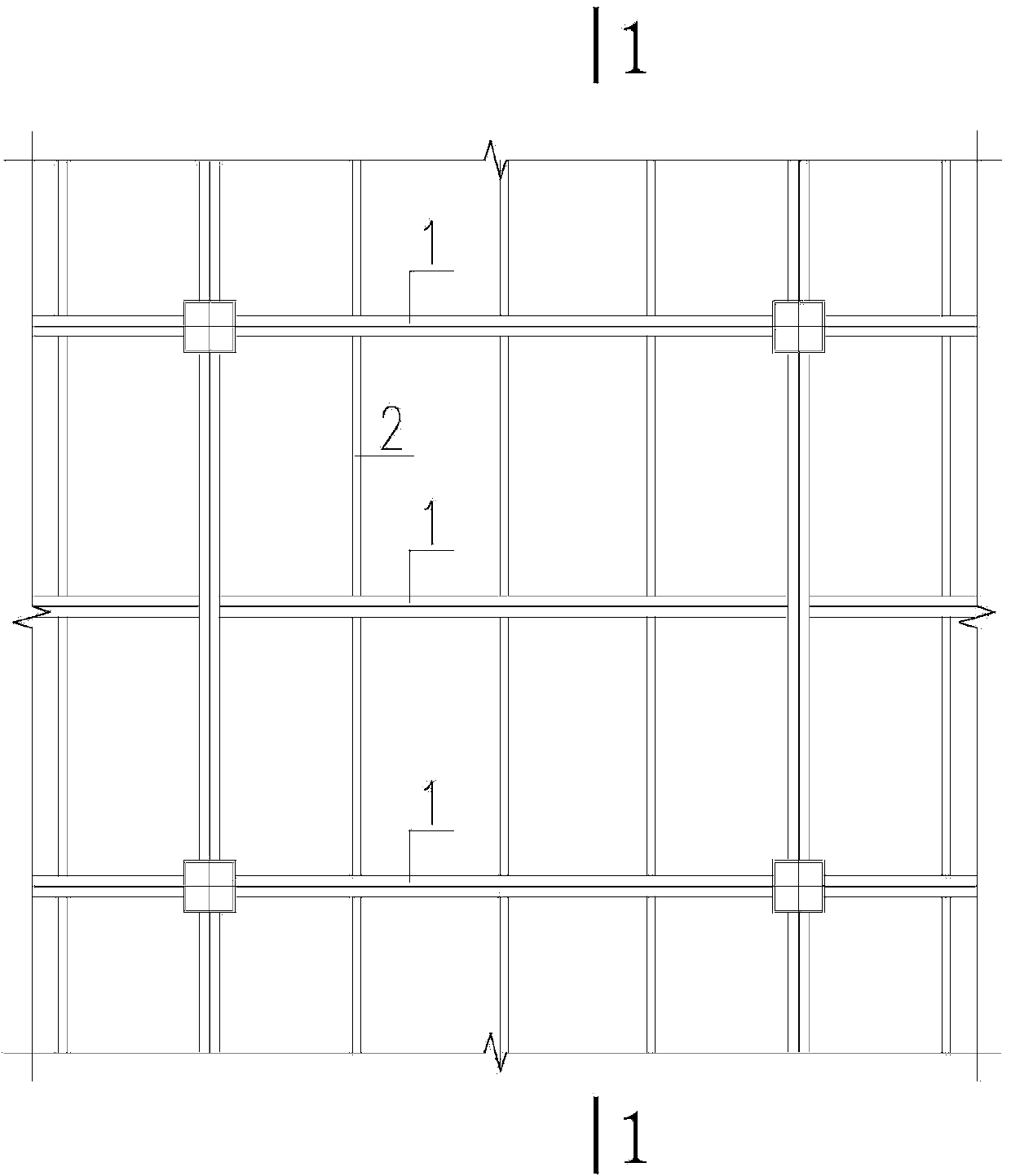

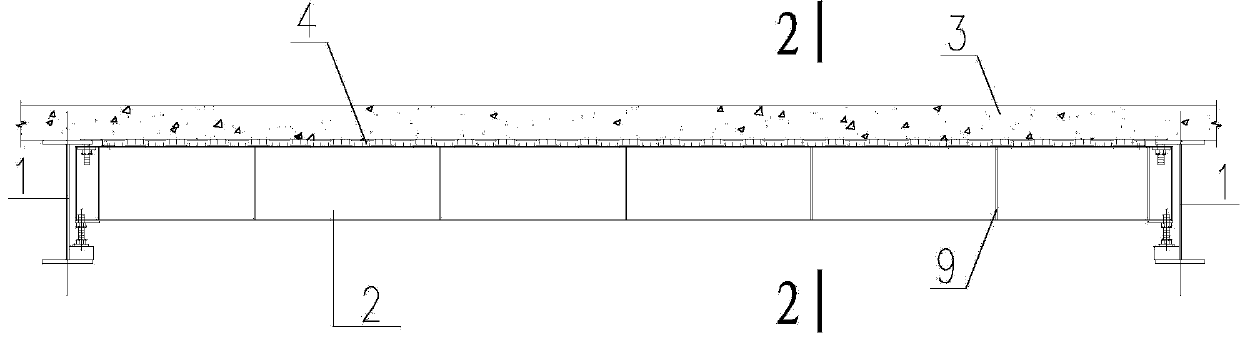

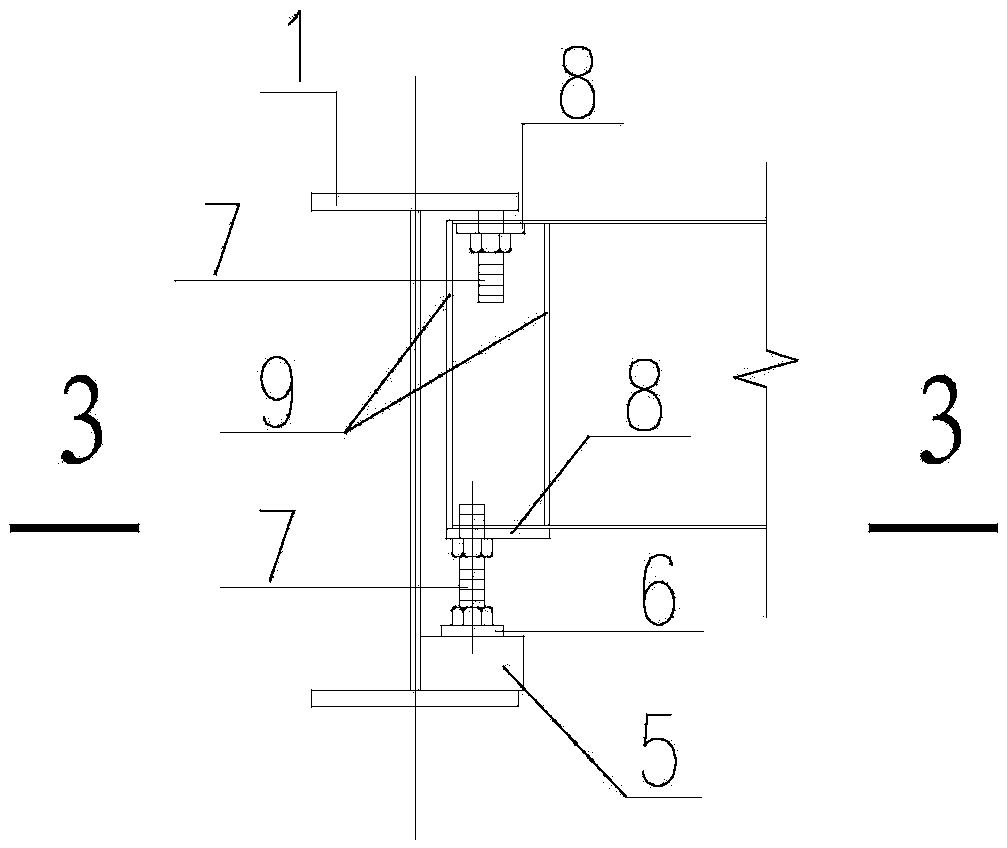

[0032] Refer to attached Figure 1-9 , a detachable formwork system, comprising a fixed-length support frame 2 and a formwork 4, the support frame is processed by C-shaped steel 10, the webs of the C-shaped steel are provided with reinforcing plates 9 at a certain distance, and the ends of the C-shaped steel A first steel plate 8 is respectively welded to the upper and lower flanges. The support frame is fixed on the upper and lower flanges of the steel beam 1 through adjusting bolts 7 , steel backing plates 6 and wooden pads 5 . The formwork is made of a wooden board 15 wrapped with a galvanized steel plate 14, the periphery of the template is wrapped with a second steel plate 11, and the middle part of one direction is attached with a third steel plate 13, the second steel plate 11, the third steel plate 13, the galvanized steel plate 14 and the wooden board 15 They are fixed together by first bolts 12 and second bolts 16 . The screw rod length of the second bolt 16 protru...

Embodiment 2

[0034] Refer to attached Figure 10-18 , a detachable formwork system, including a movable support frame 17 formed by connecting two support frames and a formwork 4. The two support frames are arranged facing away from each other, and the outer ends of the support frames are connected to adjacent steel beams. The C-shaped The inner end of the steel is provided with two rows of round holes 19 at intervals of 50mm, and the inner end of the support frame is fixed by the third bolt 18 passing through the round holes. Described formwork is that bamboo plywood 20 outsources galvanized steel plate 14 to form, and formwork periphery wraps second steel plate 11, sticks the third steel plate 13 outside the middle part in two directions, the second steel plate 11, the 3rd steel plate 13, the galvanized steel plate 14 and plank 15 are fixed together by first bolt 12 and second bolt 16. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com