Bearing outer ring double-groove one-time grinding process and equipment

A bearing outer ring and grinding technology, which is applied in the field of bearing processing, can solve problems such as low processing efficiency, inability to guarantee relative accuracy, and inability to guarantee product quality, so as to achieve the effect of ensuring processing accuracy and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

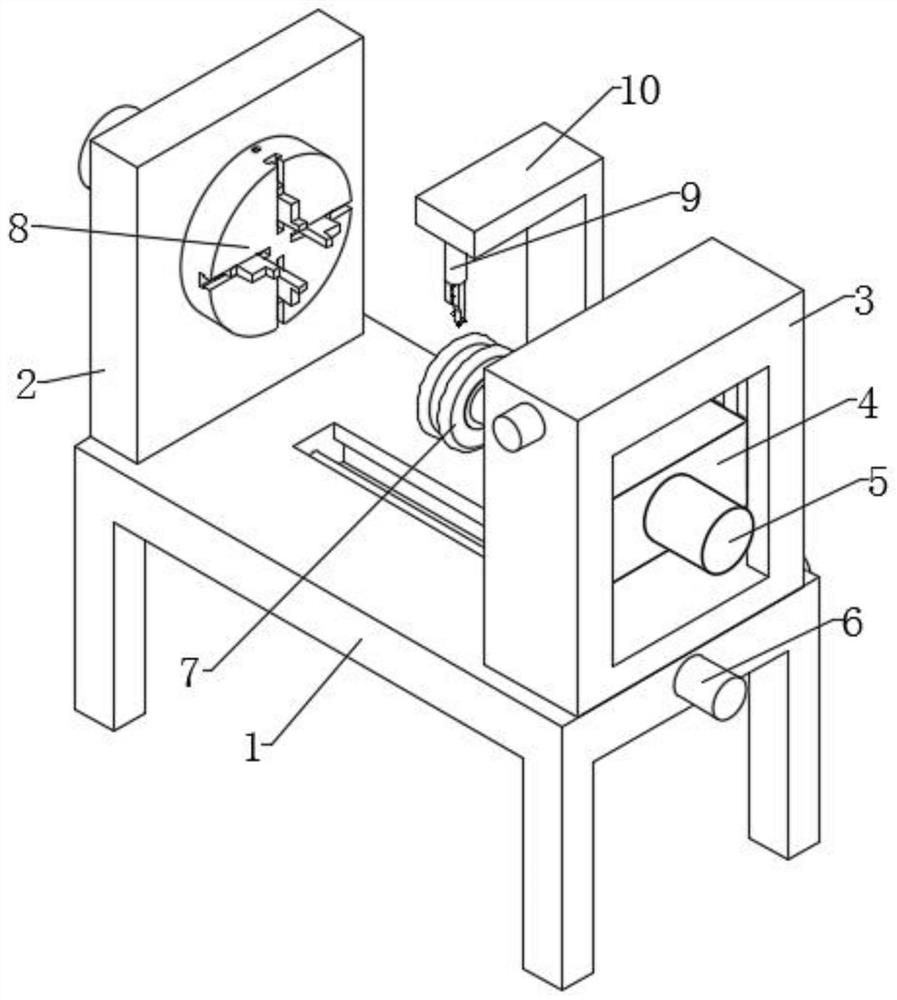

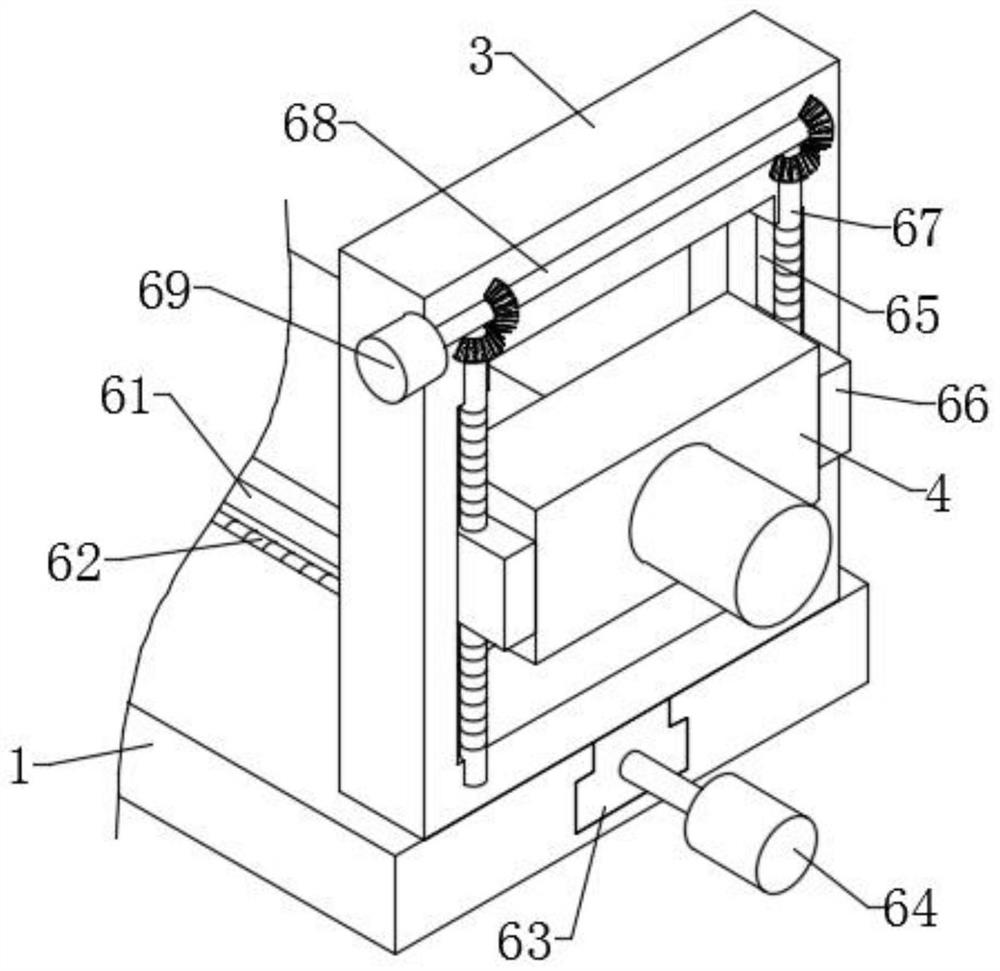

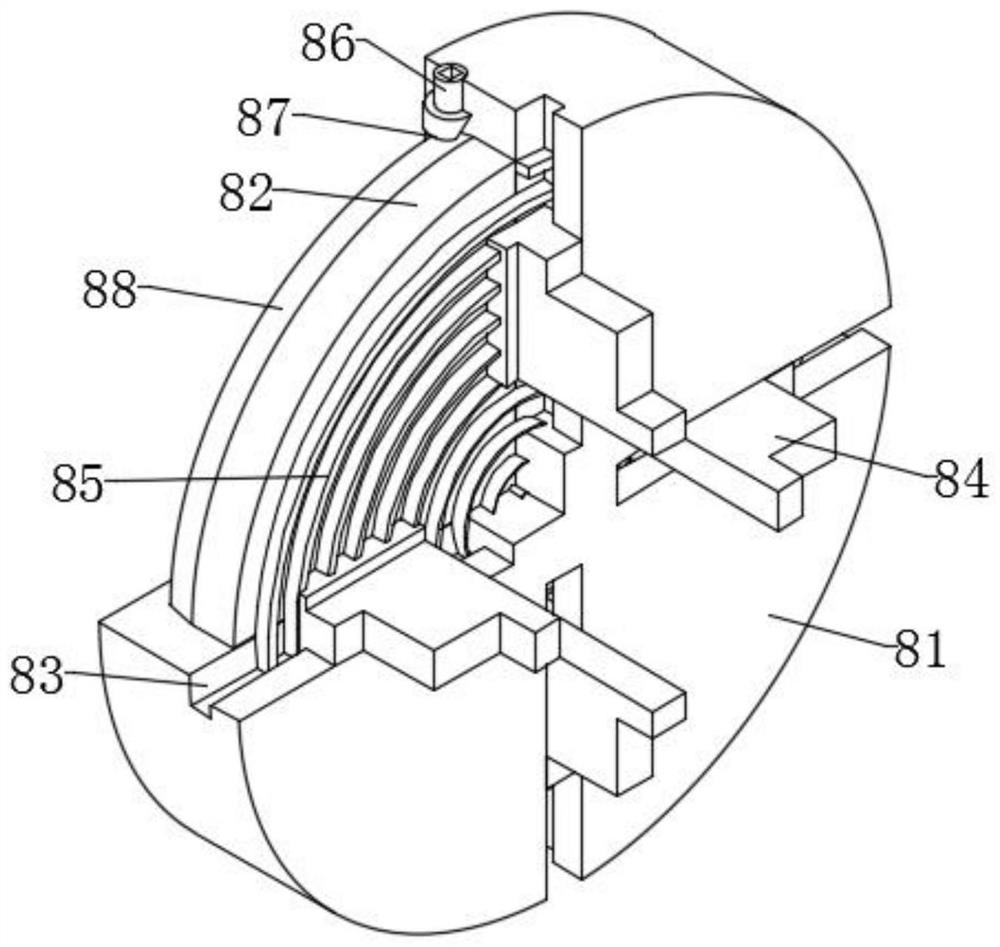

[0032] Example: such as Figure 1 to Figure 6 As shown, the present invention provides a double-groove primary grinding equipment for bearing outer rings, comprising a frame 1, a fixed plate 2 is fixedly installed on the top of one end of the frame 1, a chuck 8 is installed on the fixed plate 2, and the top of the other end of the frame 1 Install the moving frame 3, the inner wall of the moving frame 3 slides and clamps the moving seat 4, the moving seat 4 and the frame 1 and the moving frame 3 install the knife assembly 6, and the end of the moving seat 4 away from the fixed plate 2 is fixedly installed with a grinding motor 5. The output shaft of the grinding motor 5 runs through the movable base 4 and a double grinding wheel mechanism 7 is installed. The hanger 10 is fixedly installed on the frame 1 between the fixed plate 2 and the movable base 4, and the dresser 9 is installed on the hanger 10.

[0033] Further, the chuck 8 includes a fixed disc 81, the fixed disc 81 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com