Automatic oiling device for shifter

An automatic oil injection and shifter technology, which is applied to engine components, engine lubrication, mechanical equipment, etc., can solve the problems that cannot meet the beat of the assembly line, the amount of oil injection is difficult to control, and there is no oil injection for the shifter, so as to increase surplus labor. Time, meet the production cycle, improve the effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

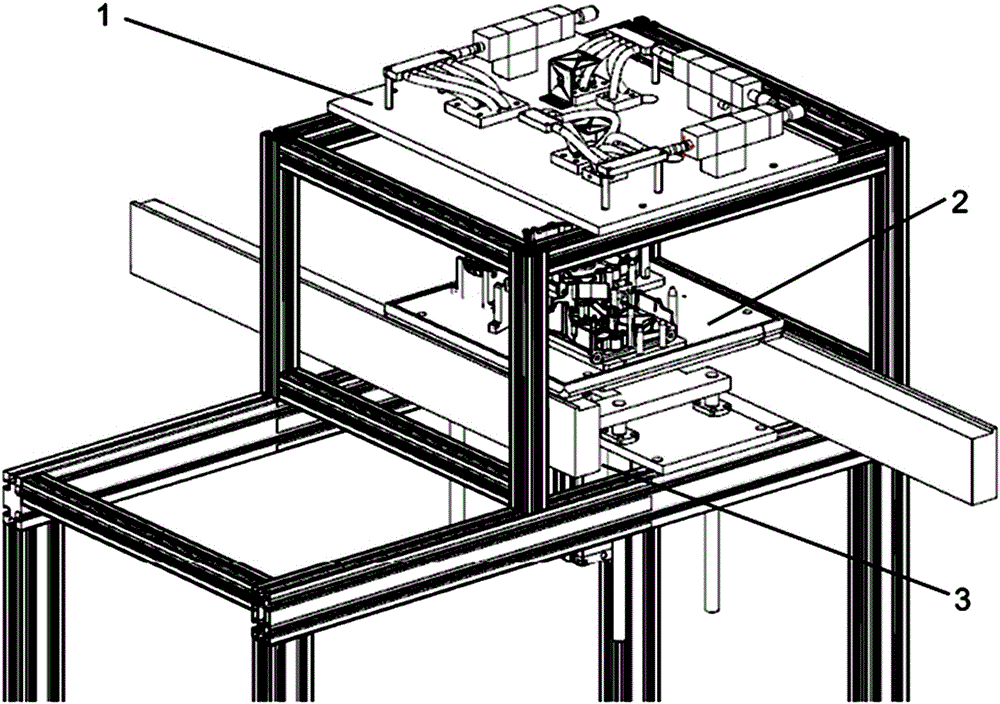

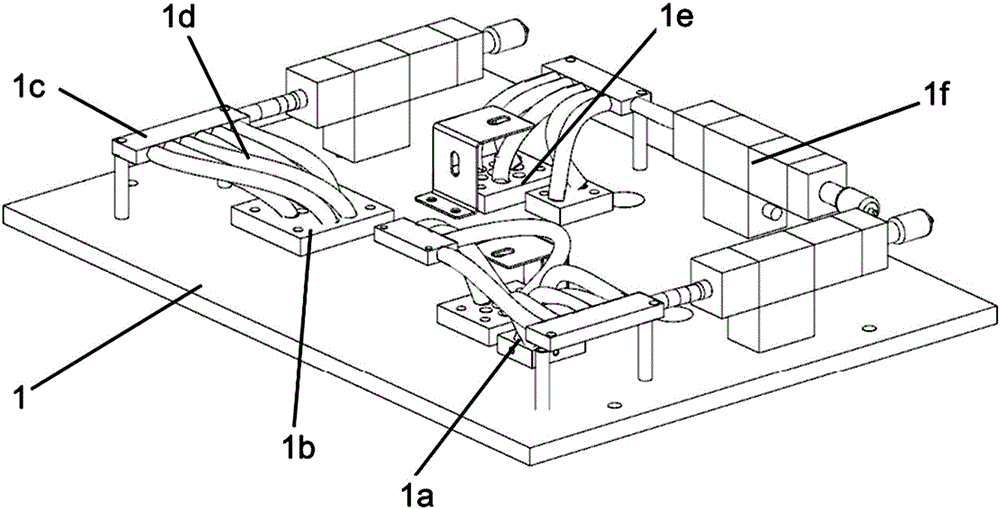

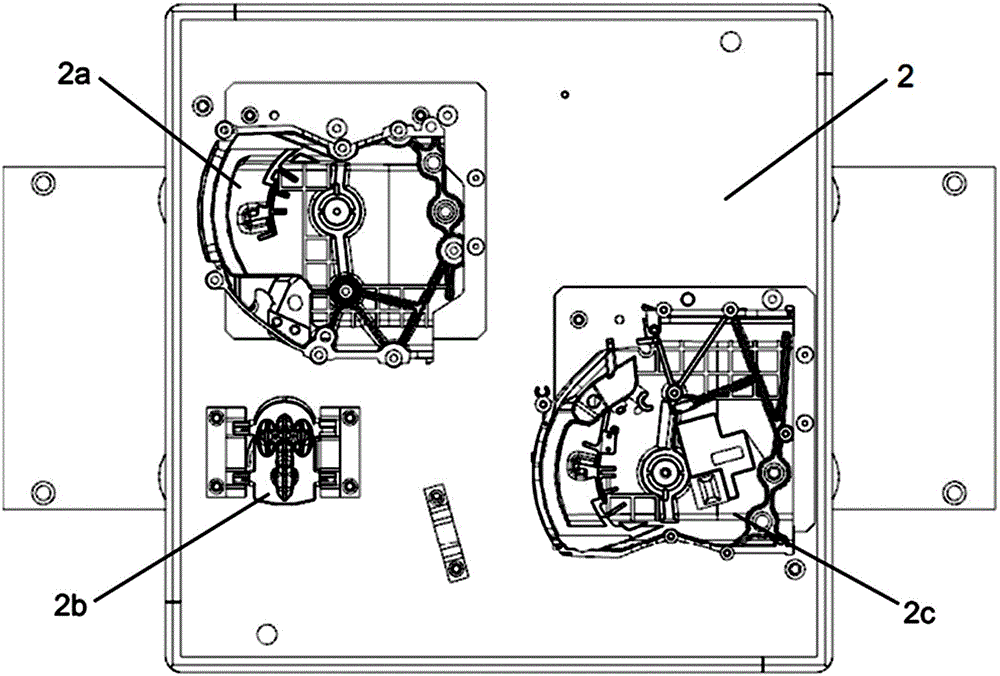

[0036] As shown in the figure, the present invention includes the working platform of the oil filling station of the shifter assembly production line. The main points of the structure are a moving tray below the working platform, a lifting cylinder is arranged under the moving tray, and a shaft housing is arranged on the working platform. The oil injector, the toothed plate oiler and the orifice shell oiler, the oil inlet holes of the shaft shell oiler, the toothed plate oiler and the orifice shell oiler are respectively passed through the oil separator of the pipeline and the oil separator. The oil inlets of each oil separator are connected with their quantitative valves through pipelines; the oil outlets of the shaft shell oiler, the toothed plate oiler and the hole shell oiler are all placed under the working platform .

[0037] The mobile tray is provided with a left casing, a toothed plate and a right casing, the oil filling point of the left casing corresponds to the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com