Patents

Literature

40results about How to "Meet the production takt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

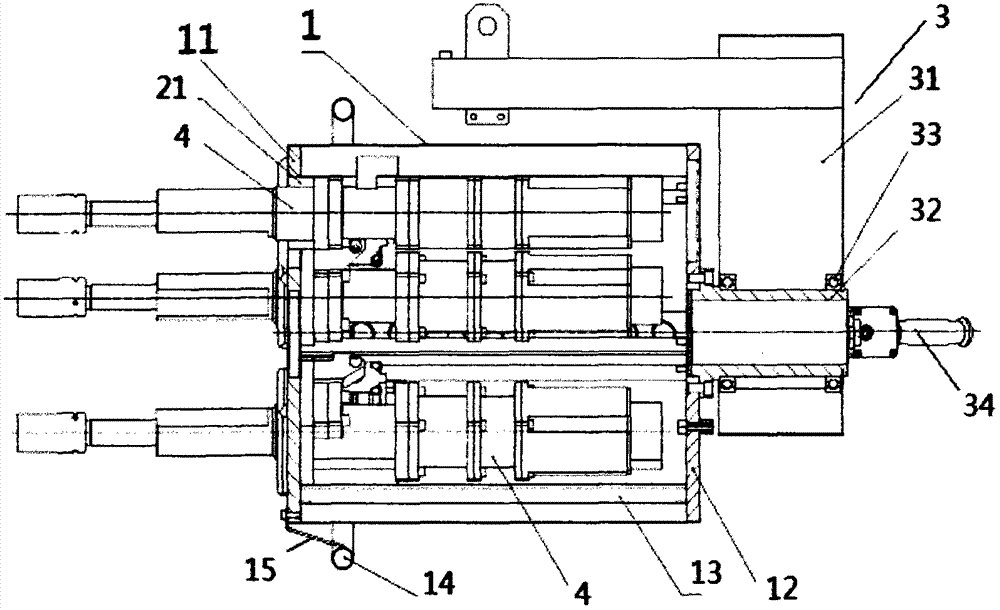

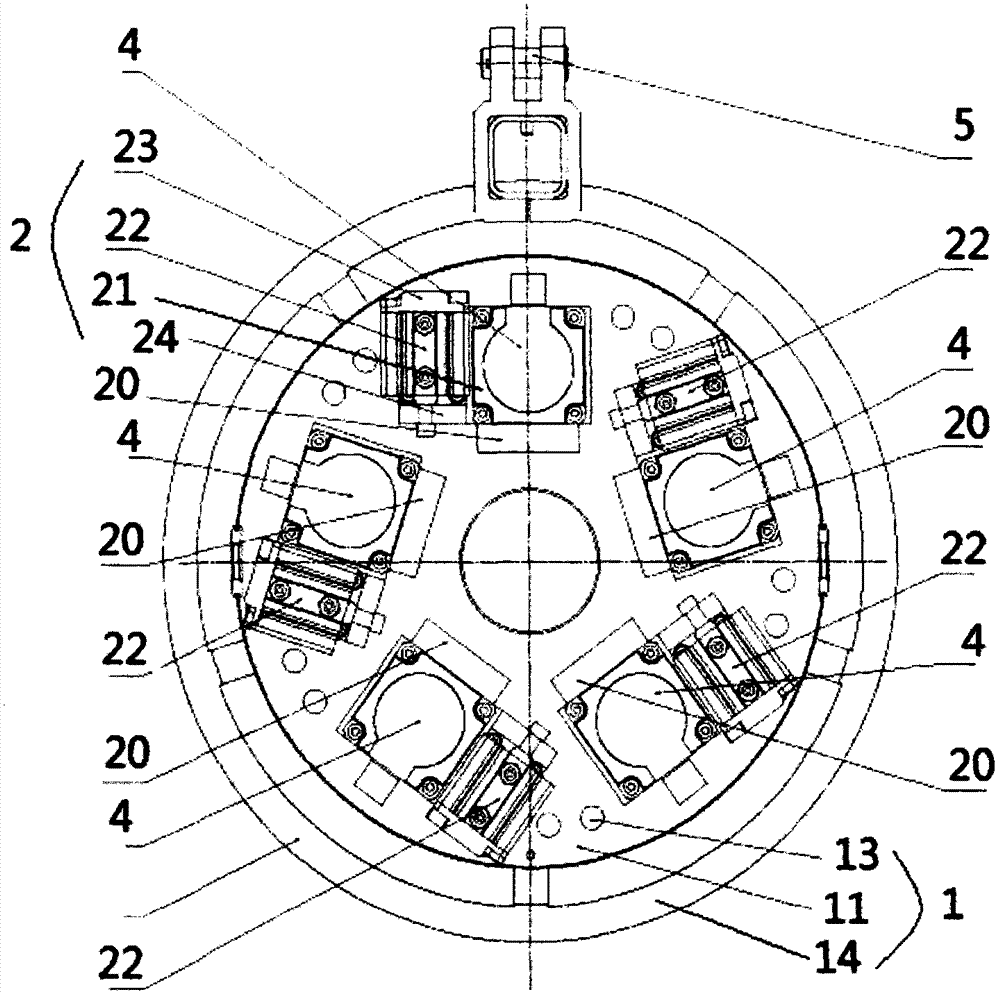

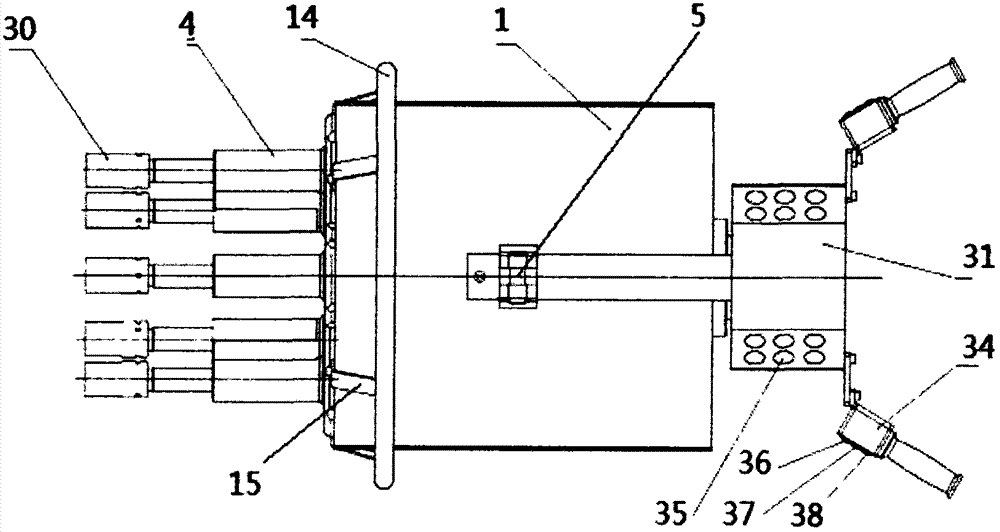

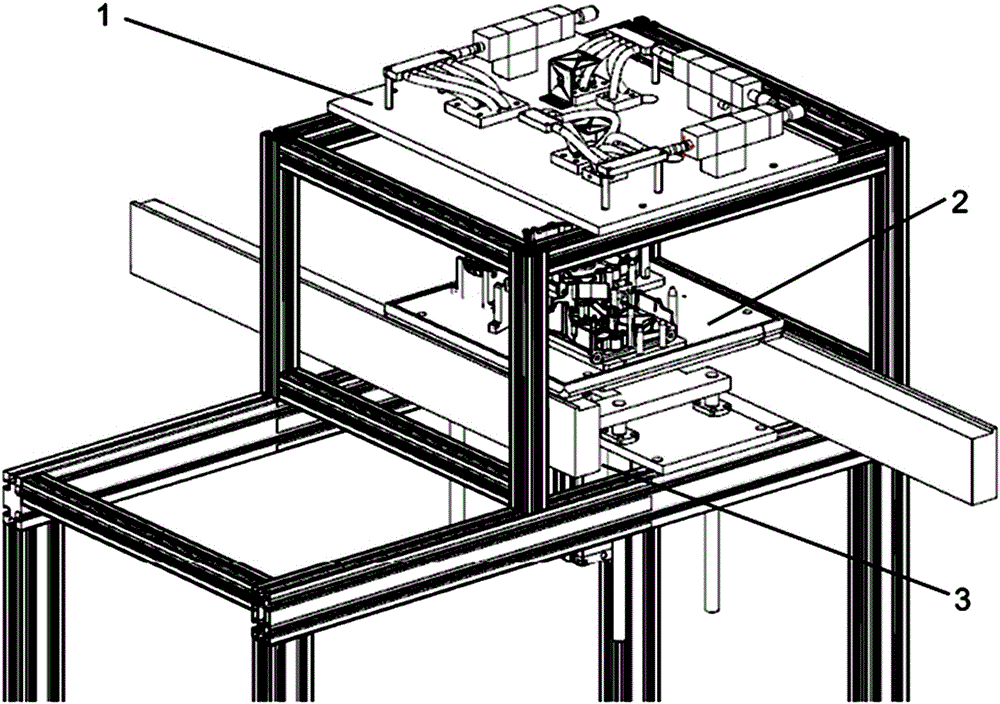

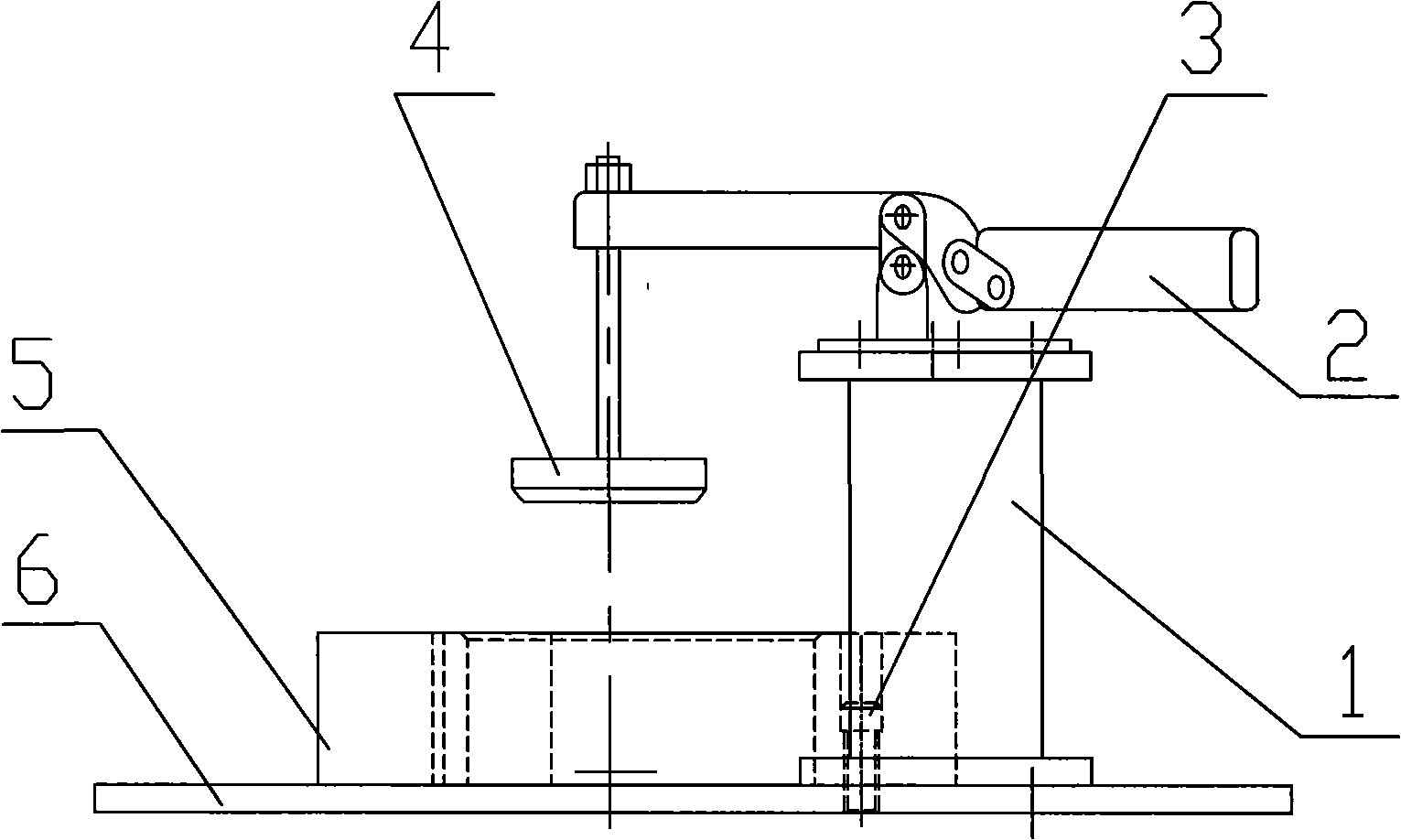

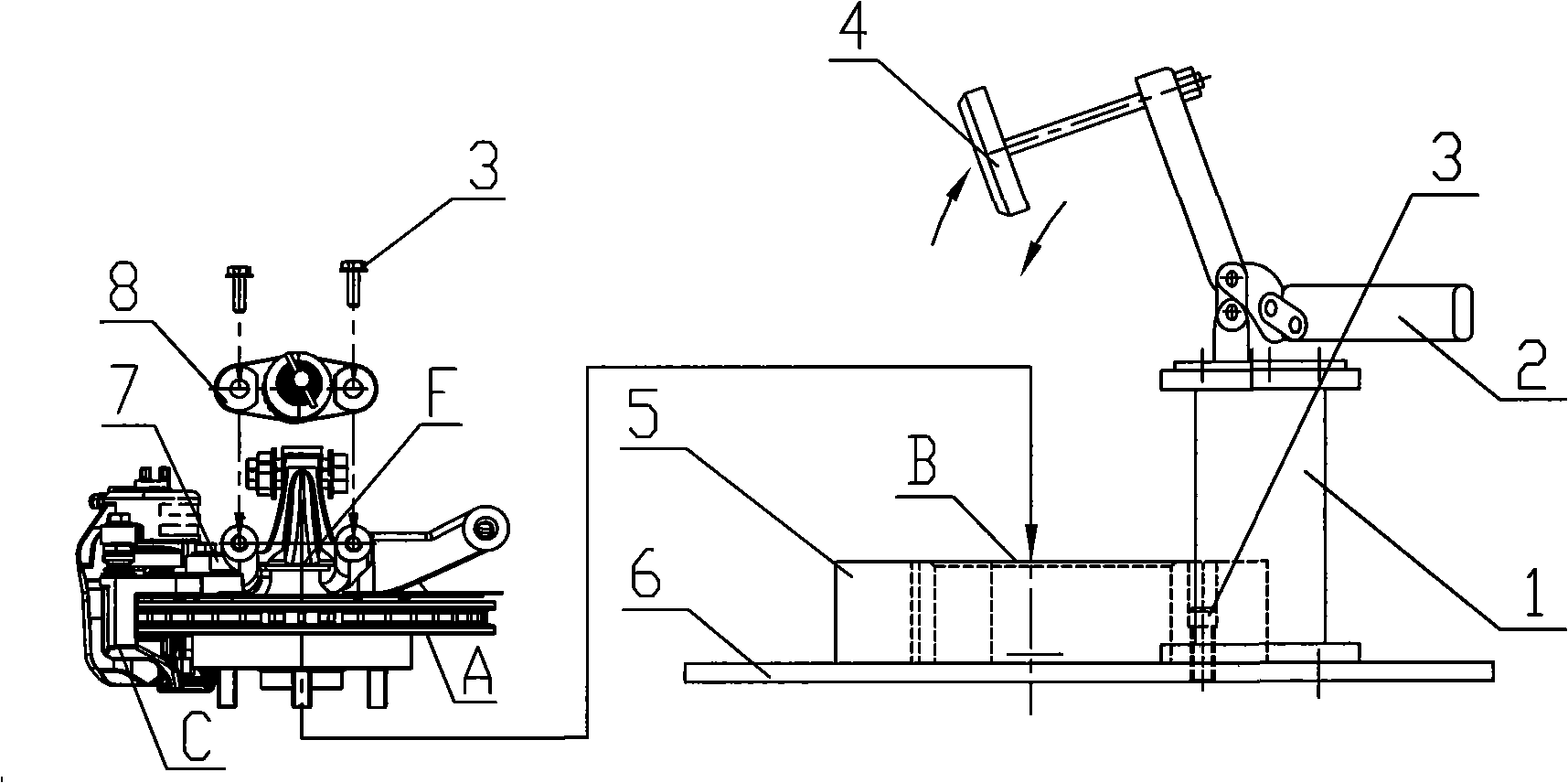

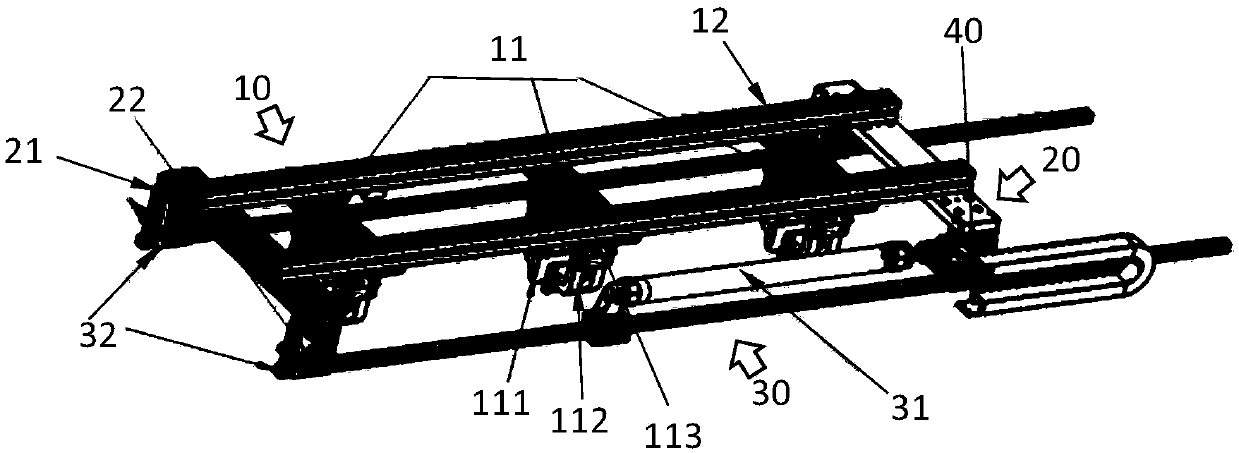

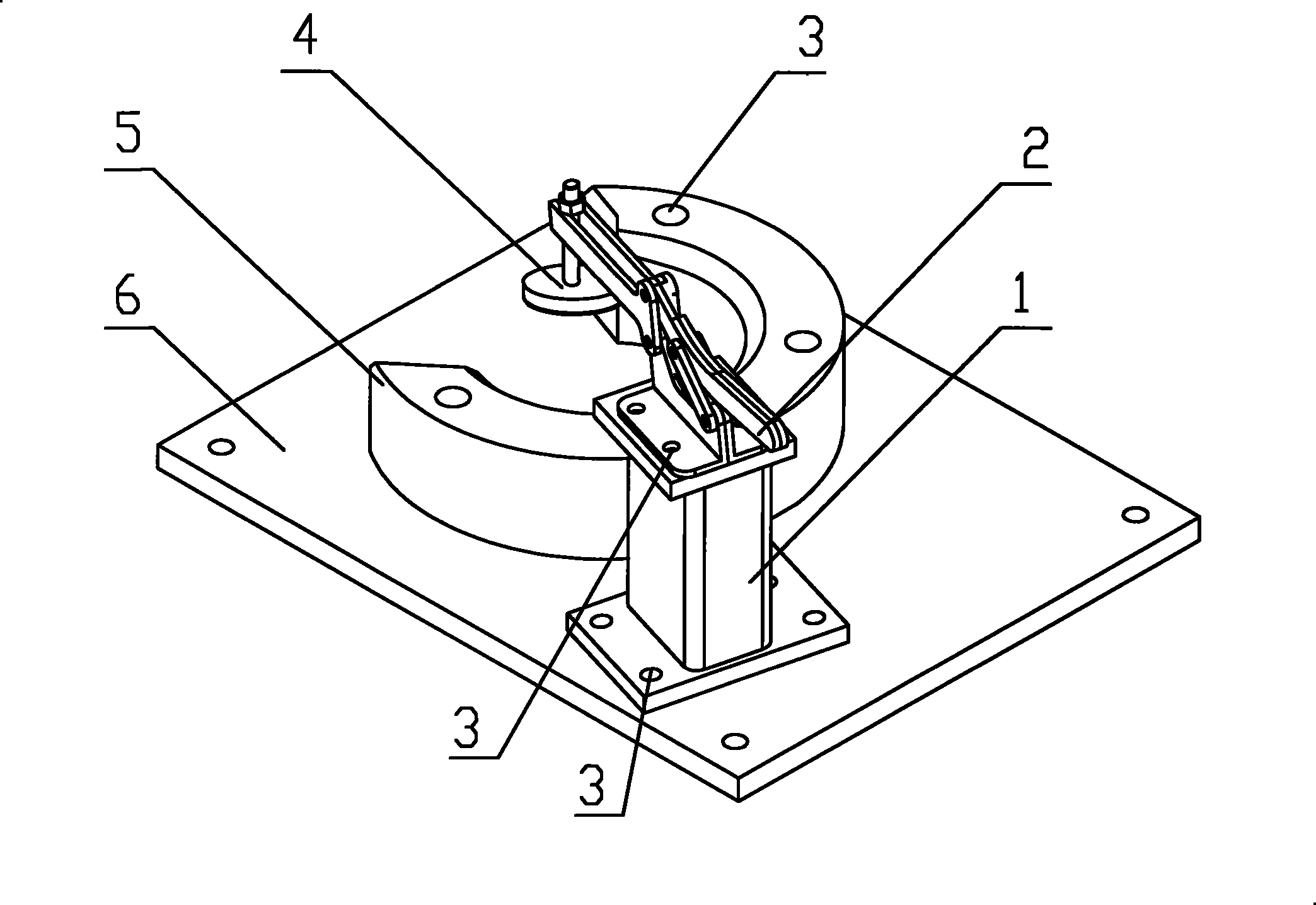

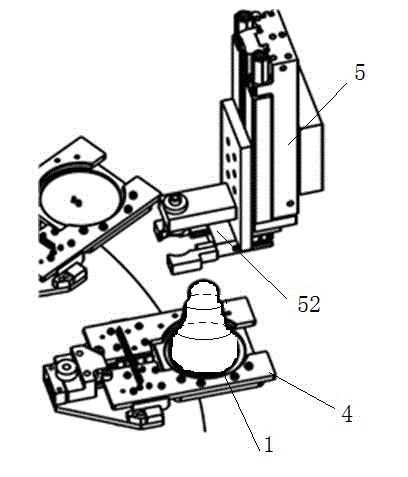

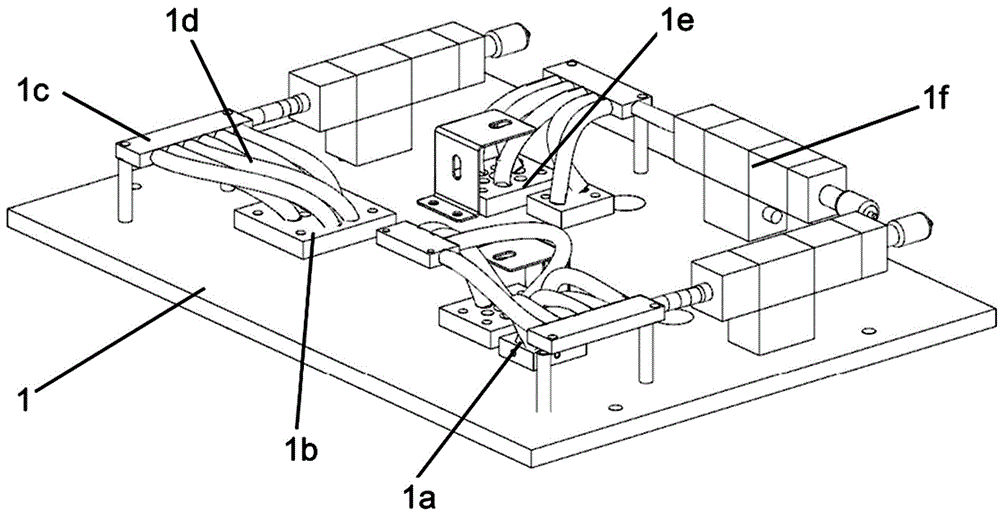

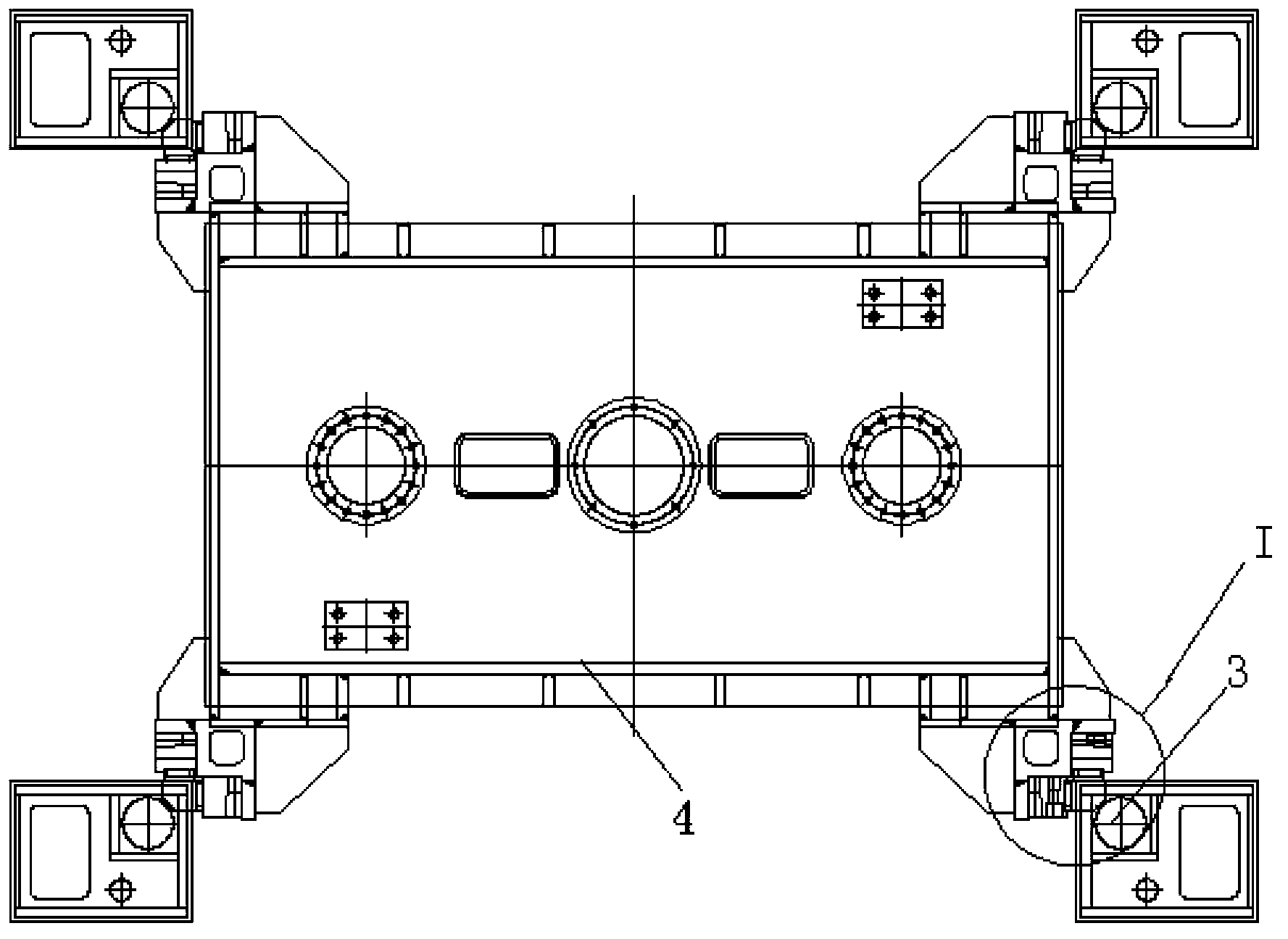

Distribution diameter automatic pitch-control five-axle wheel screwing equipment

ActiveCN102756267AUniform torqueReduce labor intensityMetal working apparatusAssembly linePiston rod

The invention discloses a distribution diameter automatic pitch-control five-axle wheel screwing equipment which comprises a screwing bracket, a hoisting mechanism and five screwing shafts, wherein a screwing shaft fixing plate is fixed at one end of the screwing bracket; five through holes positioned in the same circumference are distributed on the screwing shaft fixing plate; the screwing shafts are fixed on the screwing shaft fixing plate; the hoisting mechanism is fixed at the other end of the screwing bracket; multiple radial pitch-control adjusting mechanisms are arranged on the screwing shaft fixing plate; the radial pitch-control adjusting mechanisms are connected with the screwing shafts in a one-to-one correspondence manner and used for adjusting the radius of the circumference in which each screwing shaft is positioned; each radial pitch-control adjusting mechanism comprises a reducing air cylinder and a sliding block, the cylinder body end of the reducing air cylinder is fixedly connected with the screwing shaft fixing plate through a fixing bracket, and the piston rod end of the reducing air cylinder is connected with the sliding block through a connecting bracket; and the sliding blocks are fixedly connected with the screwing shafts, and each through hole is an elongated sliding chute hole extending along the radial direction of the circumference. The distribution diameter automatic pitch-control five-axle wheel screwing equipment has the advantages of high automation degree, simpleness and convenience in operation, and high efficiency, and is applicable to large-scale flow line production on an automotive assembly line.

Owner:大连嘉禾自控技术有限公司

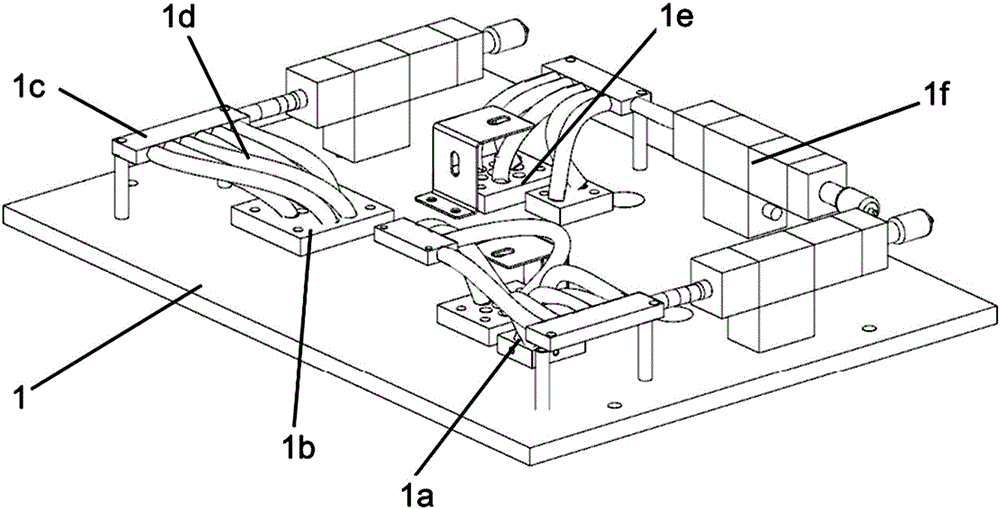

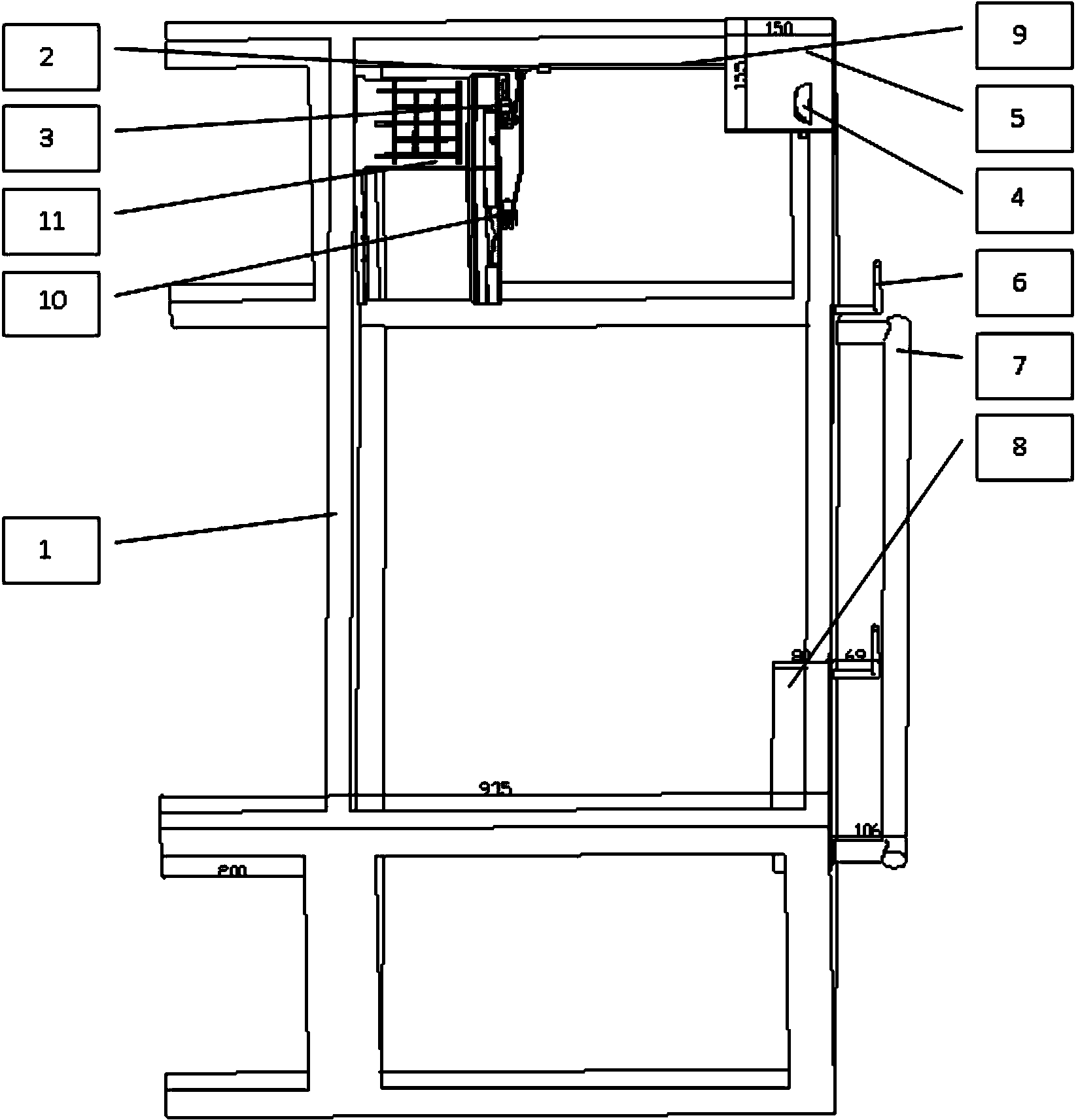

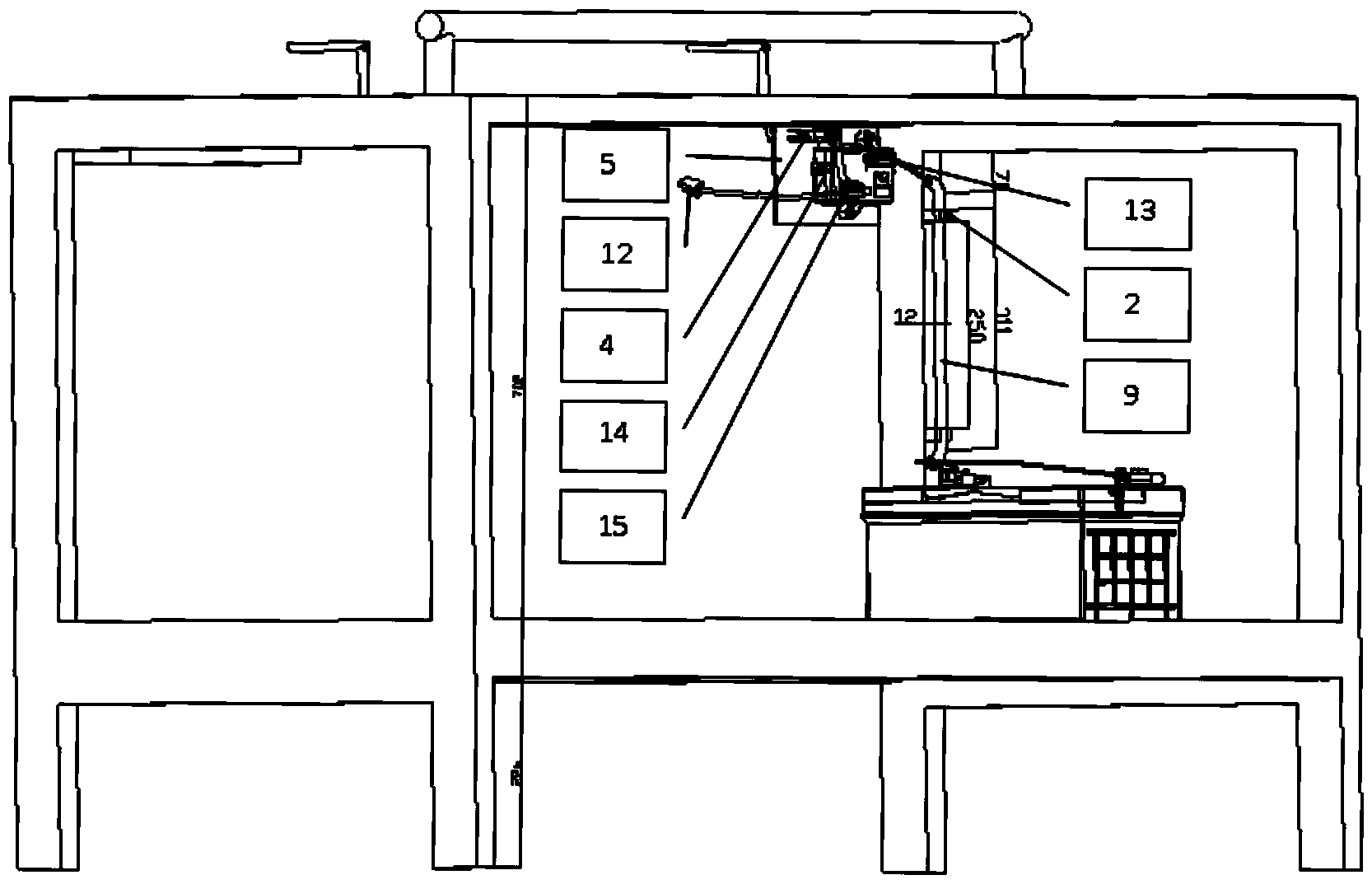

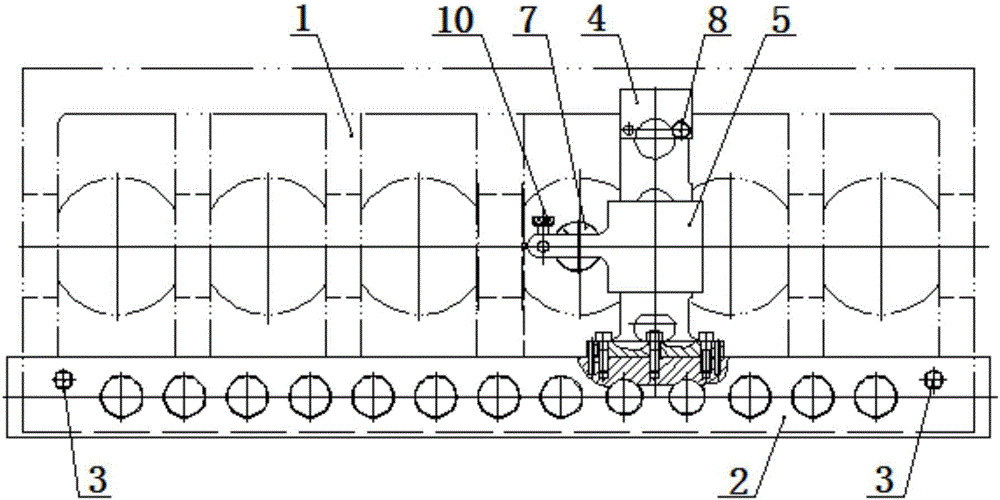

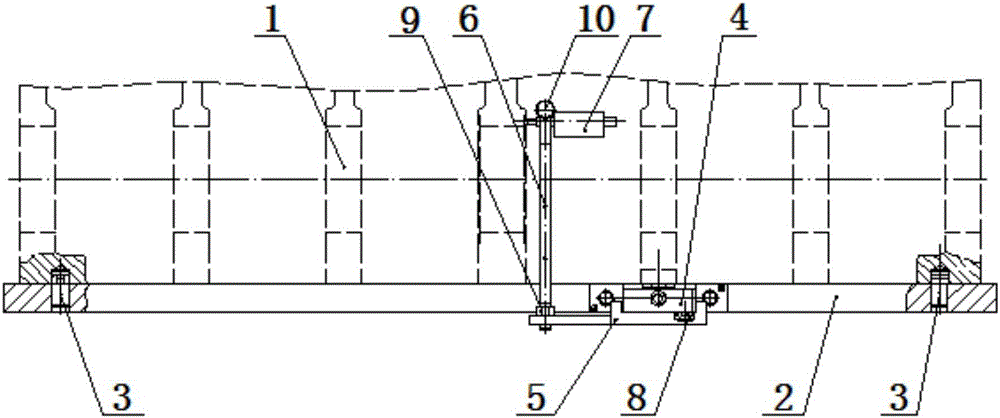

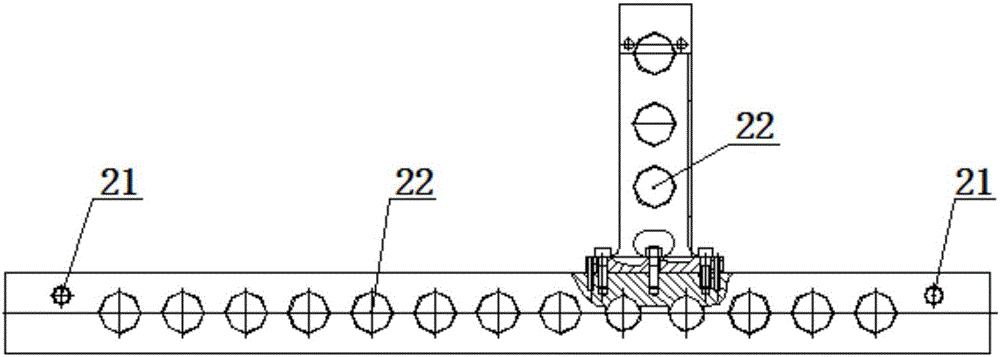

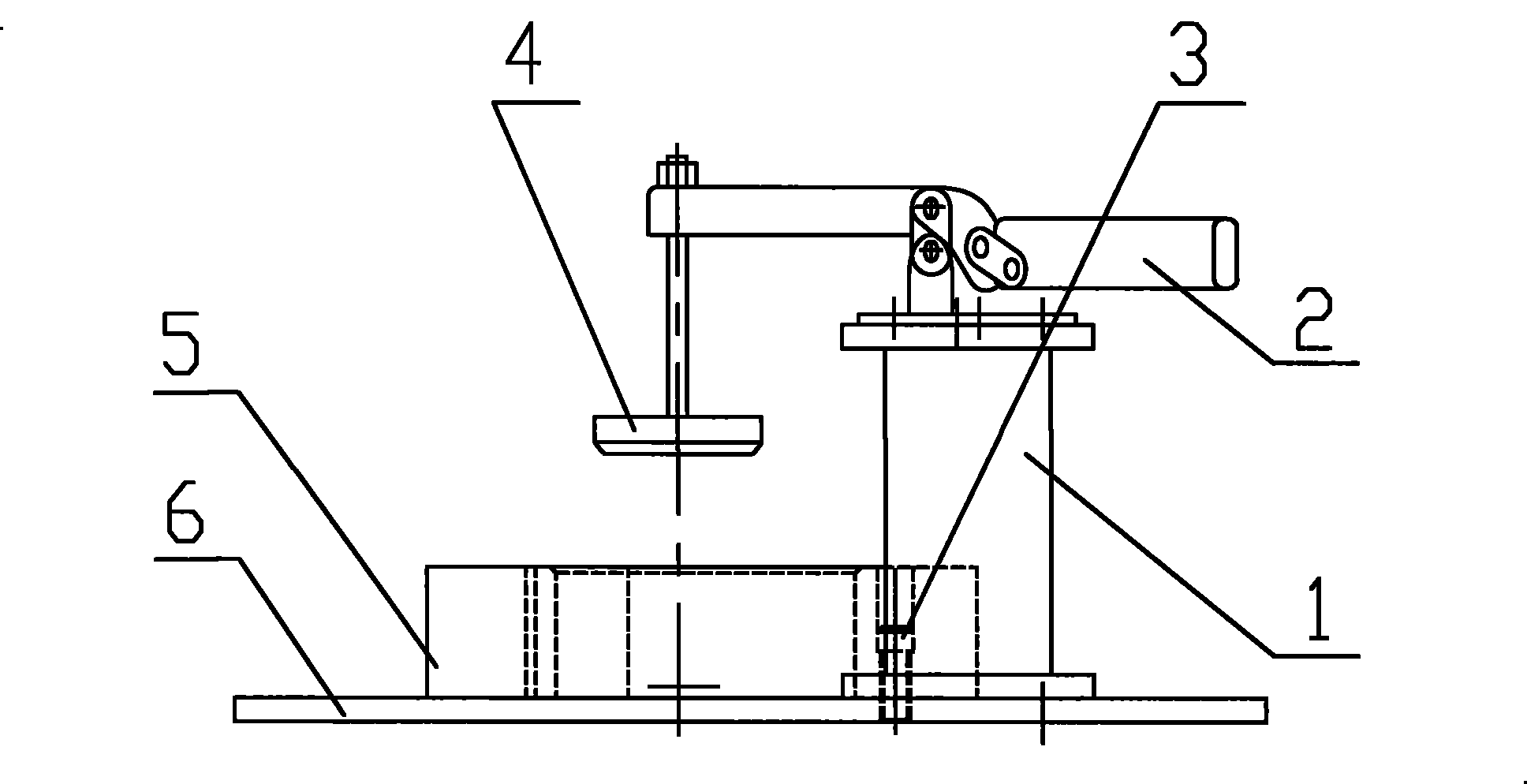

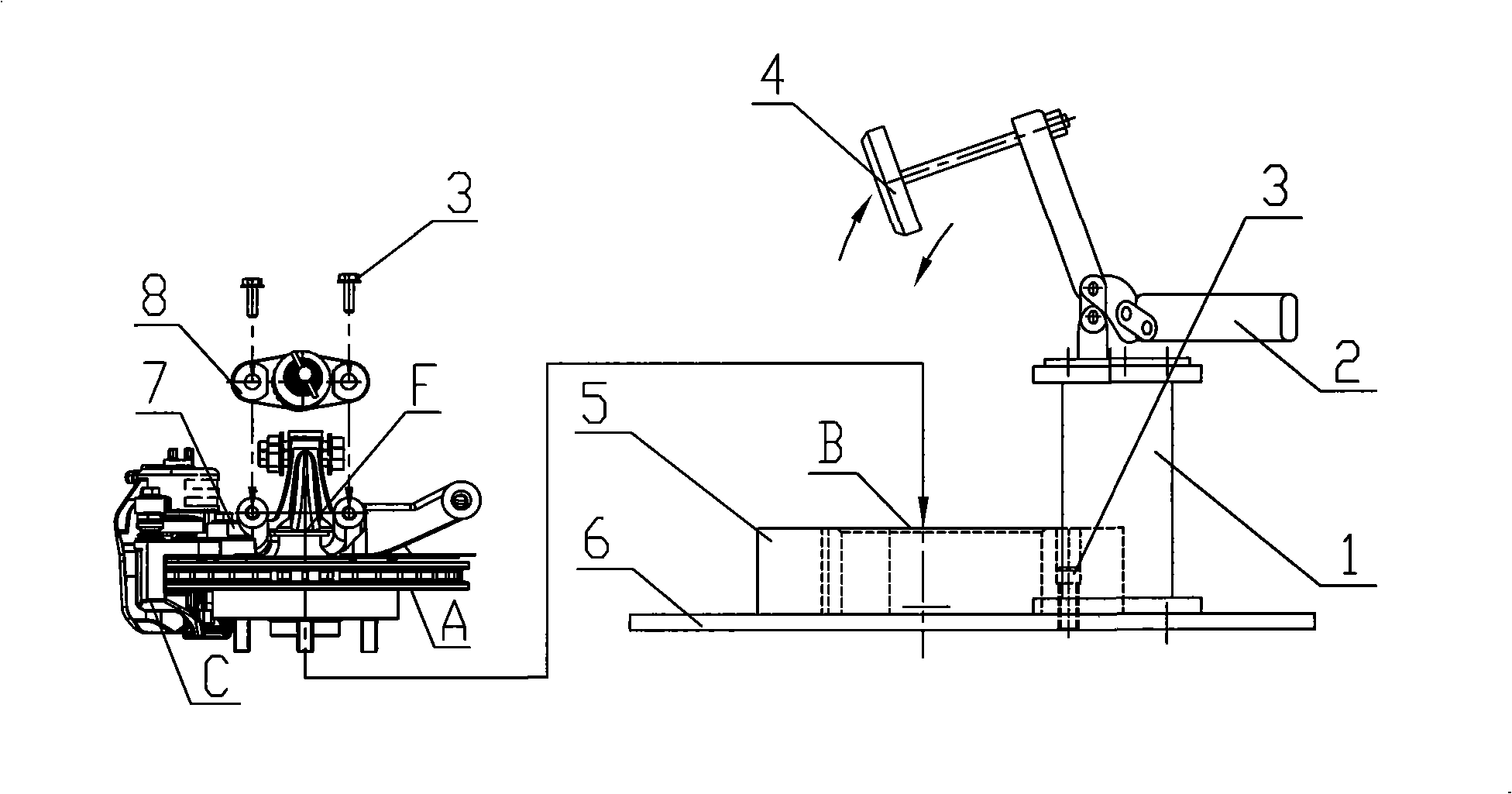

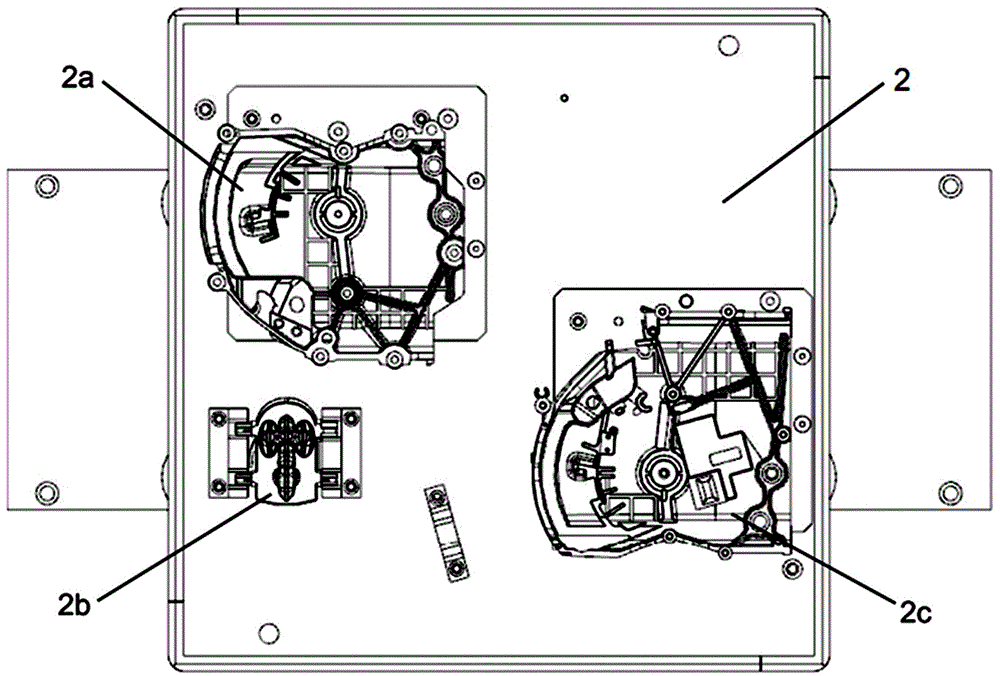

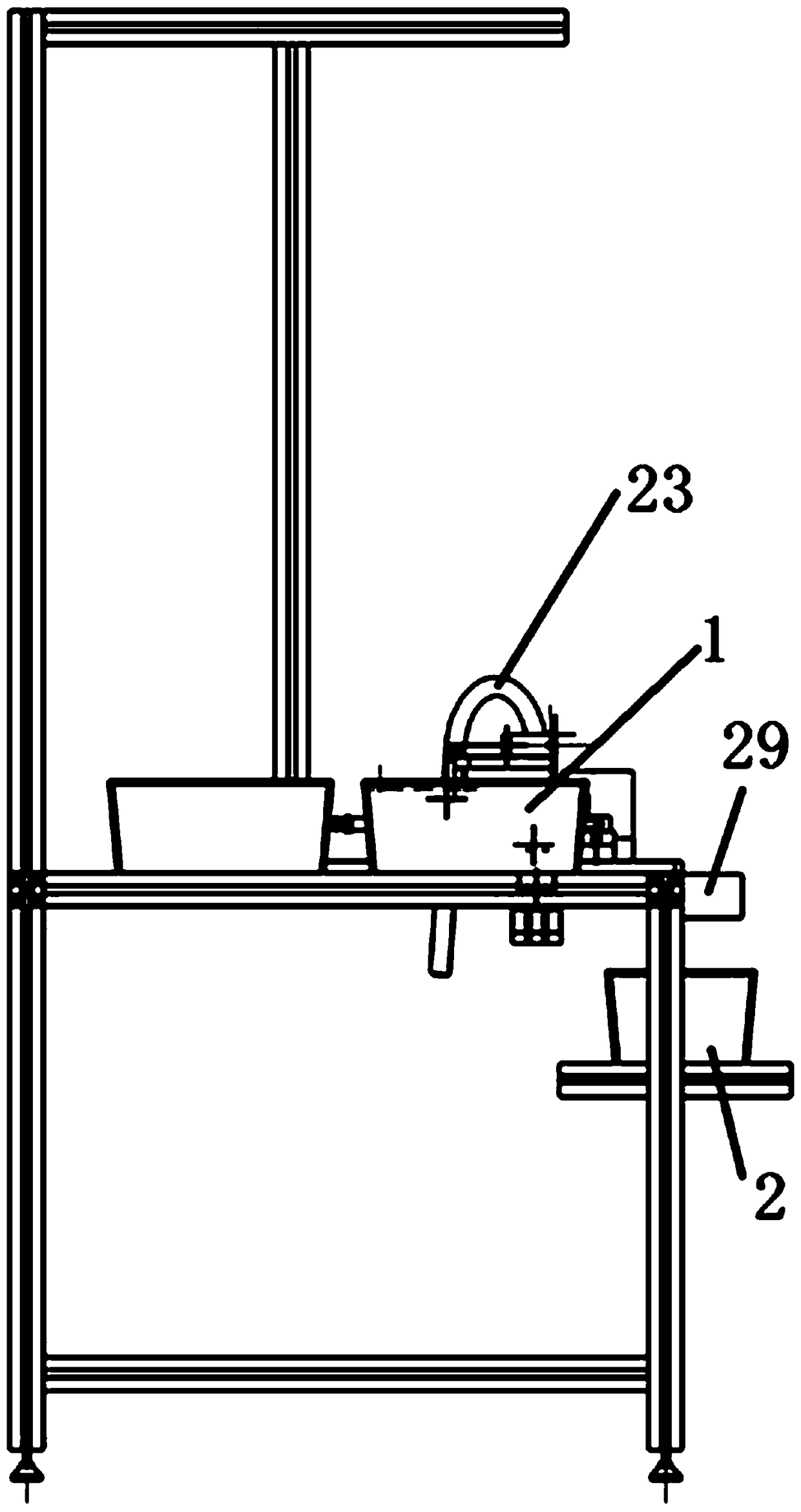

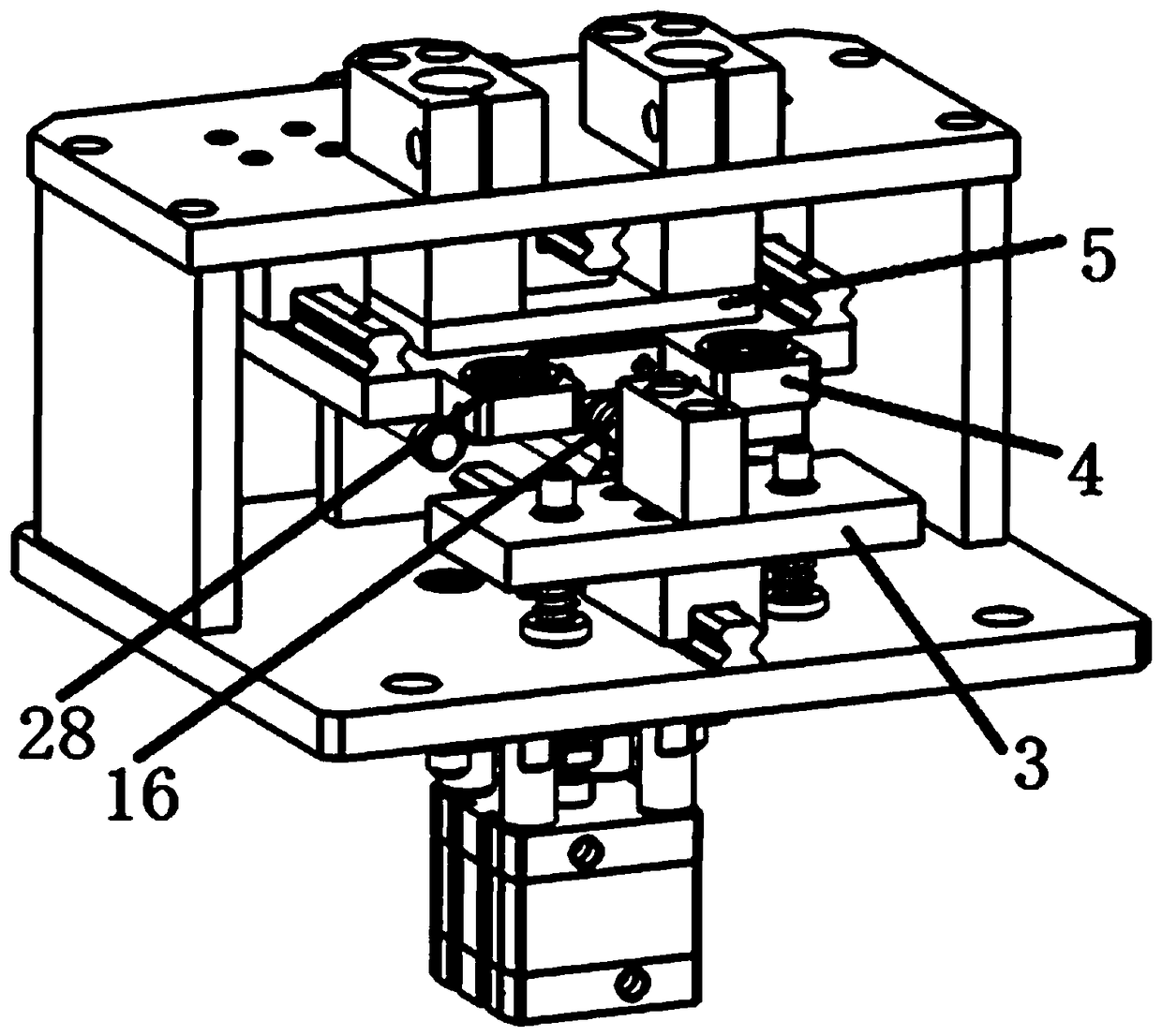

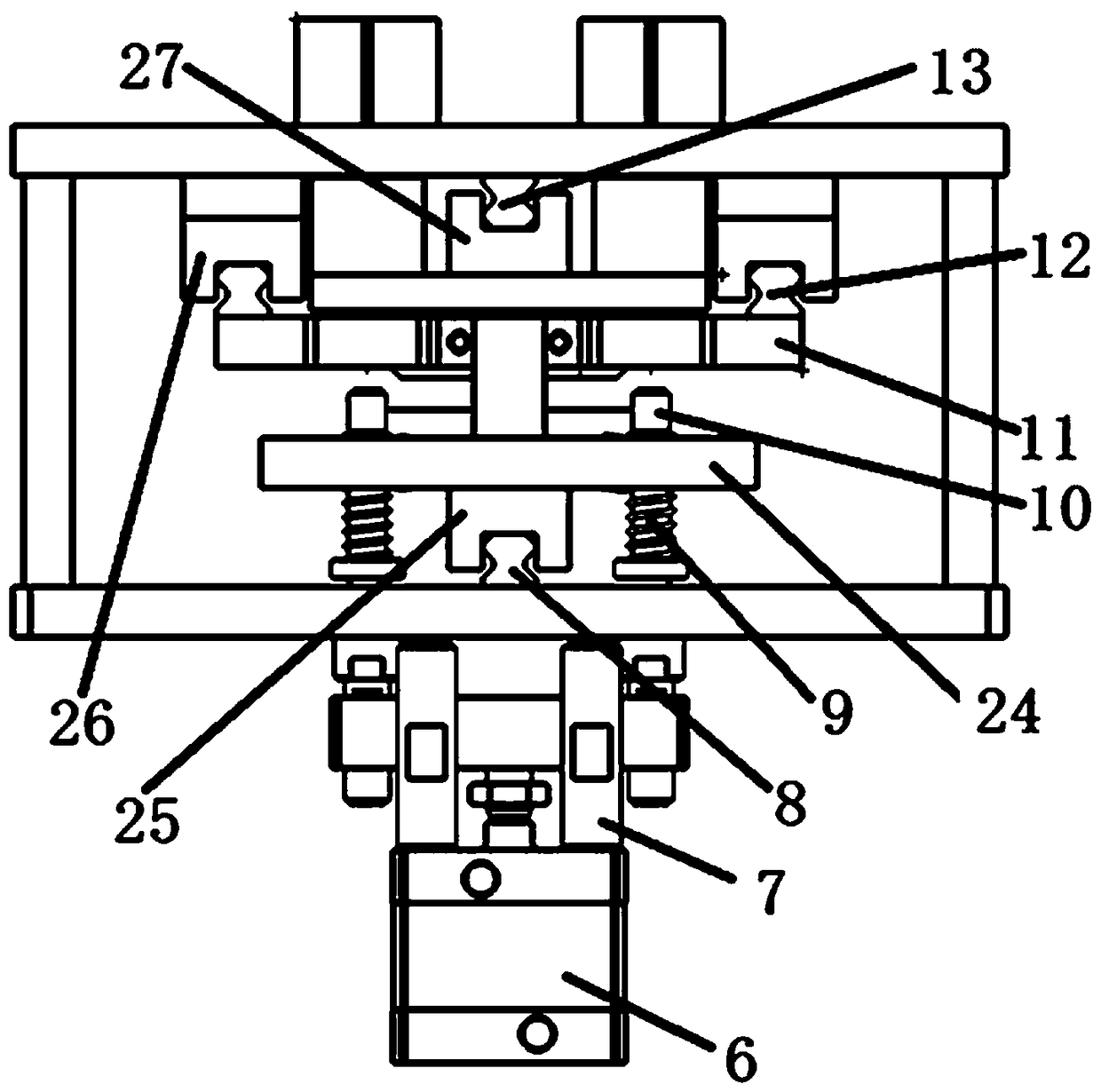

Automatic oiling device for shifter

InactiveCN105090723AImprove efficiencyFacilitate oil filling automationEngine lubricationProduction lineDistributor

The invention belongs to the technical field of automatic assembling, and particularly relates to an automatic oiling device for a shifter. The invention provides the automatic oiling device for the shifter, which can be used for oiling accurately and quantitatively, and can improve the assembly efficiency. The automatic oiling device for the shifter, provided by the invention, comprises a working platform on an oiling station in a shifter assembling production line, and has the structural characteristics that a removable tray is arranged below the working platform, a lift cylinder is arranged below the removable tray, a shaft type housing lubricator, a tooth-shaped lubricator and a hole-type housing lubricator are arranged on the working platform, oil inlets of the shaft type housing lubricator, the tooth-shaped lubricator and the hole-type housing lubricator are connected with oil distributing holes of oil distributors through pipelines respectively, and the oil inlets of all oil distributors are connected with respective proportional valves through pipelines respectively; and oil outlets of the shaft type housing lubricator, the tooth-shaped lubricator and the hole-type housing lubricator are all positioned below the working platform.

Owner:SHENYANG POLYTECHNIC UNIV

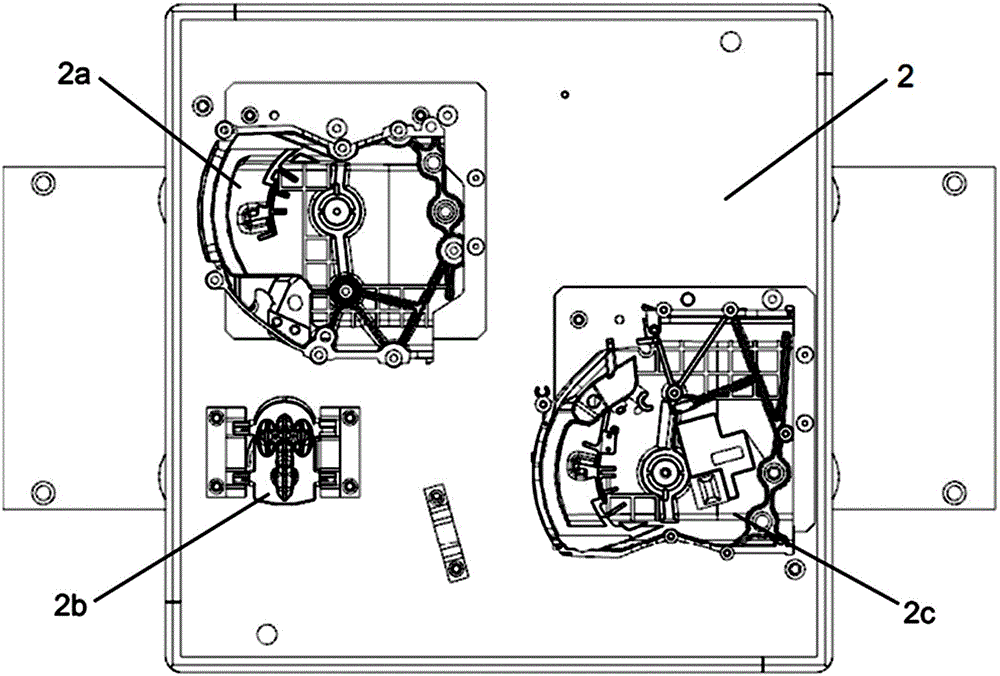

Front brake subassembly clamper for vehicle

ActiveCN101513902AGood positioning accuracyEasy to operateWork holdersVehiclesBaseboardCircular surface

The present invention relates to a front brake subassembly clamper for vehicle, wherein the front brake subassembly clamper comprises a crushing clamper base, a crushing clamper, a crushing clamper head, a positioning ring and a baseboard. The crushing clamper base and positioning ring are respectively fixed on the baseboard. The crushing clamper base is positioned at the outside of positioning ring. The crushing clamper is fixed at the top end of crushing clamper base. The positioning ring is a round table with fracture surface. The inner circular surface of positioning ring is matched with the external step surface of front brake. The fracture surface is provided with an outwards oblique plane and is matched with the size of projection of front brake assembly. The center of the crushing clamper head on the crushing clamper is aligned with the center of positioning ring. The positioning of the front brake assembly is ensured by the clamper positioning ring. The front brake assembly is compressed by a quick manual crushing clamper and the clamper is combined through bolts. The clamper for assembly has the advantages of low manufacturing cost, convenient operation, reliable positioning, ensured assembling quality and production tact satisfaction.

Owner:WANXIANGQIANCHAO CO LTD

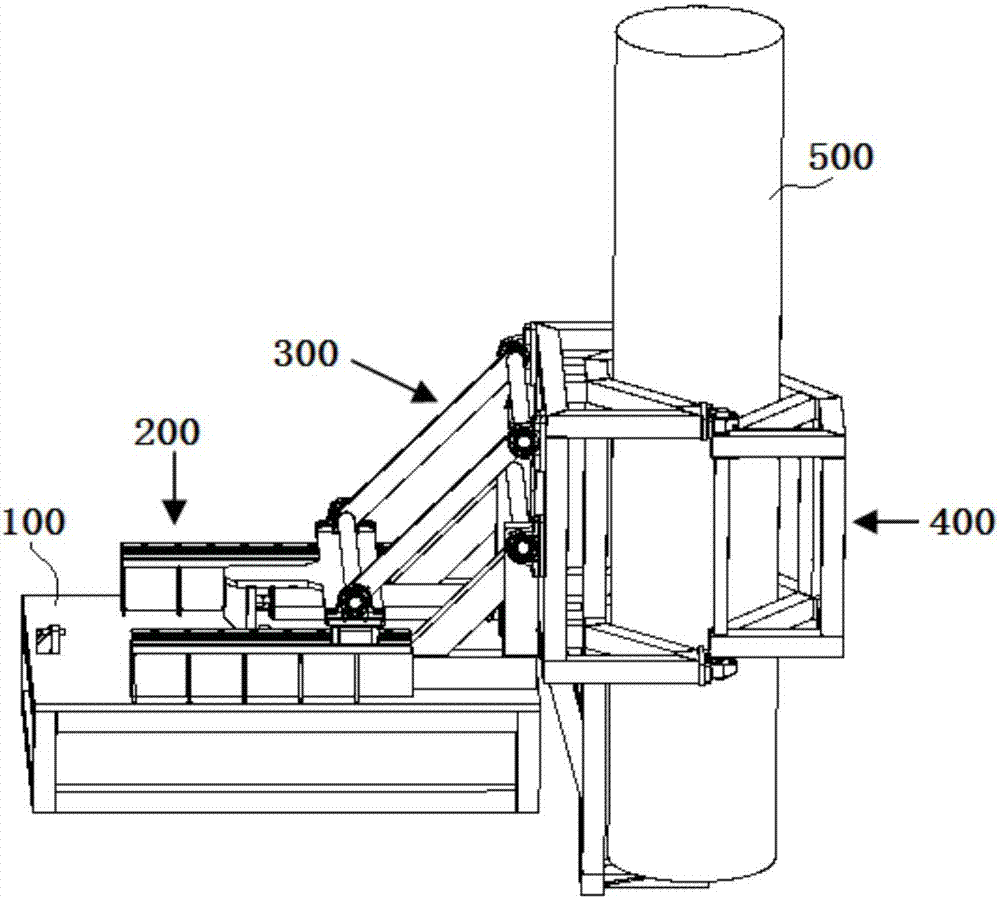

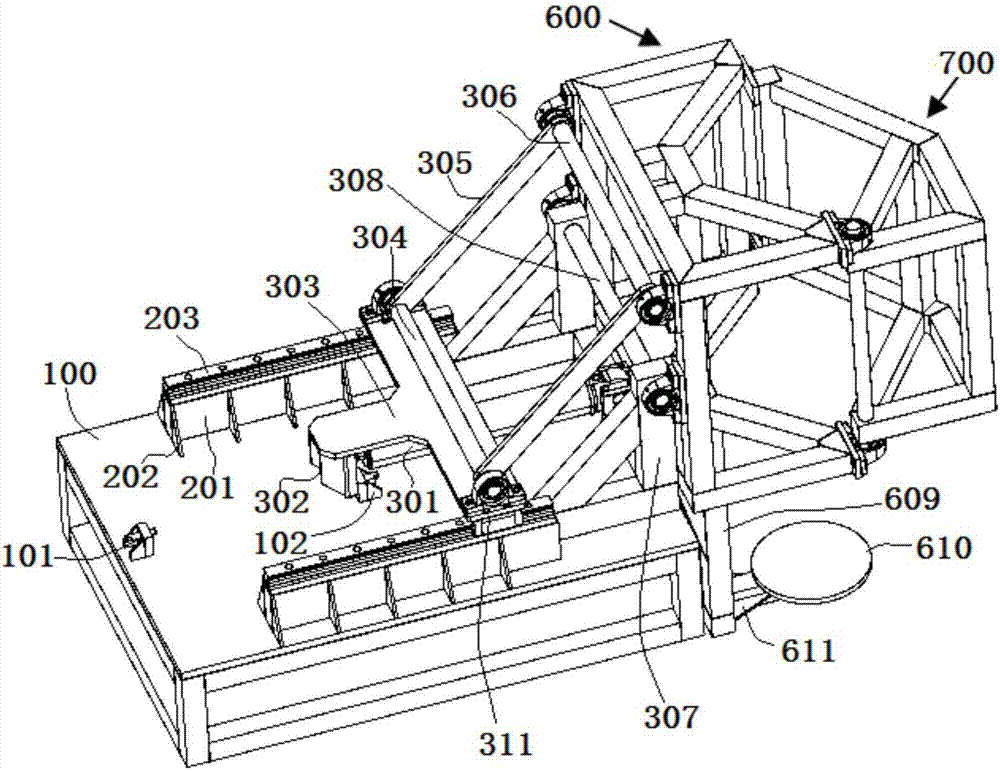

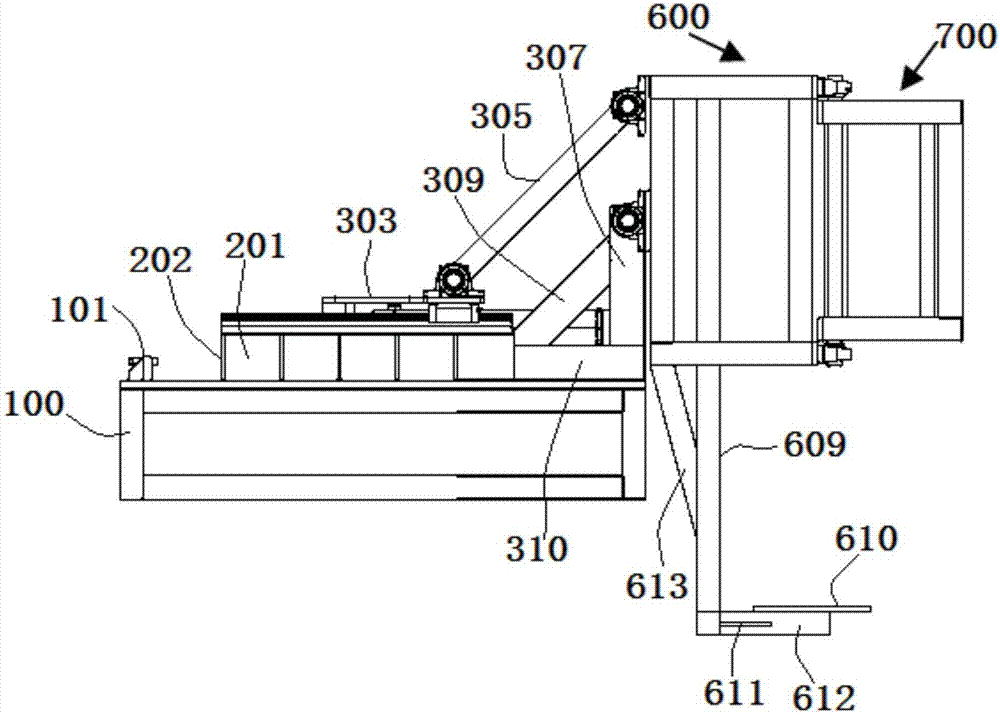

Mobile overturn robot and multistation overturn method thereof

The invention discloses a mobile overturn robot and a multistation overturn method thereof, and belongs to the field of robots. The mobile overturn robot comprises an overturn device, a transfer trolley, and a travelling rail. The overturn device is arranged on the transfer trolley. The transfer trolley transfers the overturn device to different processing stations to perform overturn operation along the travelling rail. The overturn device comprises a power mechanism, an orienteering mechanism, and a locking mechanism. The locking mechanism is used to fix a cylindrical member. The power mechanism comprises an oil cylinder and a pull rod. The pull rod is connected with the locking mechanism. The oil cylinder moves horizontally to drive the pull rod to pull the locking mechanism to overturn. The orienteering mechanism is used to control operation directions of the power mechanism. The mobile overturn robot can perform overturn operation on a workpiece on different stations, and satisfies fast-paced industrial production, and overturn is stable and production security is high.

Owner:安徽佩吉智能科技有限公司

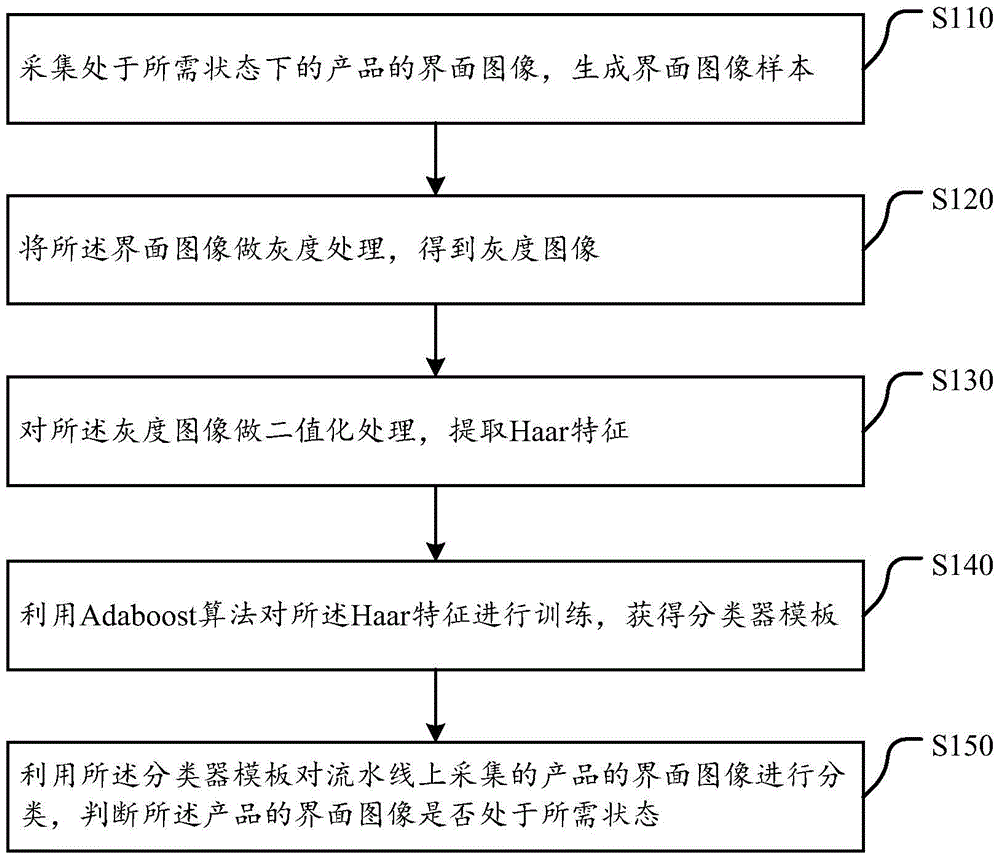

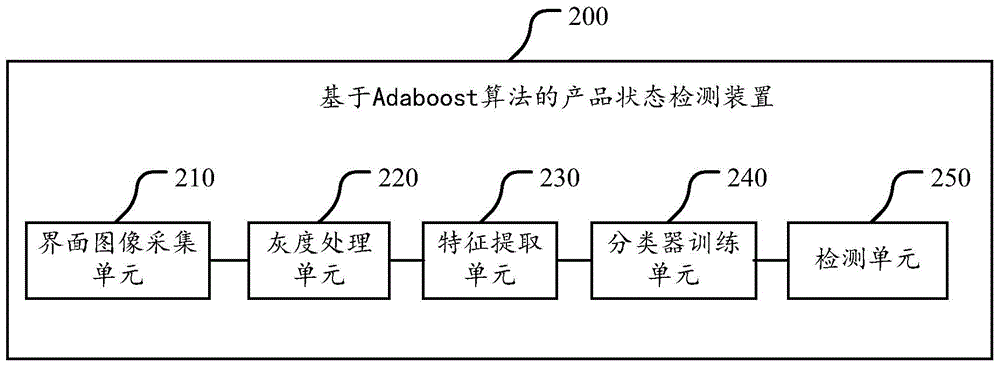

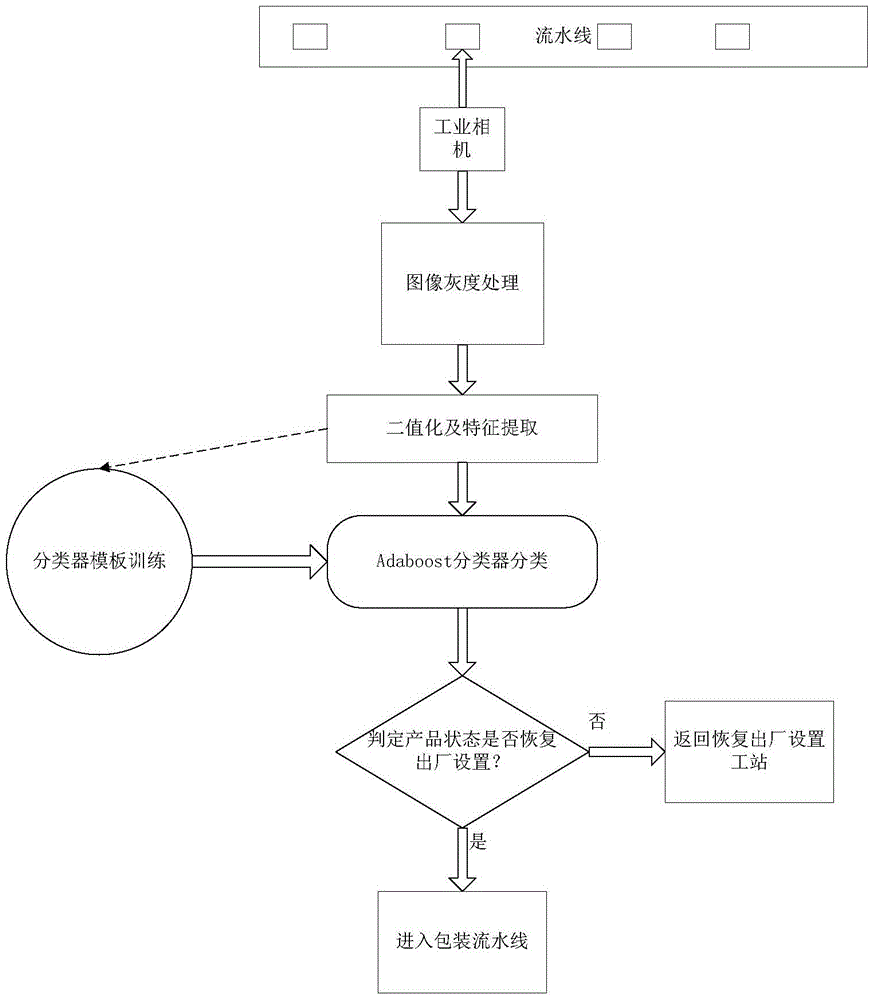

Product state detection method and system based on Adaboost algorithm

InactiveCN105678755AQuick responseImprove classification accuracyImage enhancementImage analysisAssembly lineAdaboost algorithm

The present invention discloses a product state detection method and system based on an Adaboost algorithm. The method comprises the steps of acquiring interface images of products located in the needed state to generate an interface image sample; carrying out the gray processing on the interface images to obtain a gray images; carrying out the binarization processing on the gray images, and extracting an Haar characteristic; utilizing the Adaboost algorithm to train the Haar characteristic to obtain a classifier template; utilizing the classifier template to classify the interface images of the products acquired on an assembly line, and determining whether the interface images of the products are located in the needed states. According to the technical scheme provided by the present invention, the Adaboost algorithm, the image binaryzation and the Haar characteristic are combined to optimize the product image detection, and an optimization algorithm is introduced in the assembly line to detect the products, thereby being able to detect the products automatically, reducing the labor investment, also being able to satisfy the production takt on the production assembly line.

Owner:QINGDAO GOERTEK

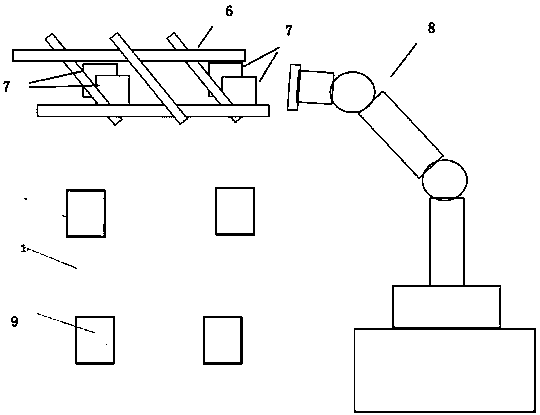

Visual guidance feeding method for automobile manufacturing production line

InactiveCN109015637ASolve the stacking arrangementFast positioningProgramme-controlled manipulatorProduction lineCar manufacturing

The invention discloses a visual guidance feeding method for an automobile manufacturing production line. According to the visual guidance feeding method, a skip is pushed to a feeding station, and acoarse positioning camera installed above the feeding station photographs; coarse deviation of a workpiece on the skip is judged according to the photographed result of the coarse positioning camera;a robot adjusts the position of a gripper according to the coarse deviation result; lasers mounted on the gripper photographs the corresponding feature points in sequence; precision deviation of the workpiece is judged according to the laser photographed results; and the robot adjusts the position of the gripper according to the precision deviation, then grapping is carried out, and feeding is completed. According to the visual guidance feeding method, a two-stage visual guidance method of camera coarse positioning-laser precise positioning is adopted, the stockpiling placement of front floorsof an automobile and the like is solved, the visual guidance feeding of the workpiece fed by the skip is used, the feeding process is highly intelligent and automated, the workpiece positioning speedis high, positioning is accurate, the feeding efficiency is high, the takt of the automobile manufacturing production line is met.

Owner:GUANGZHOU RISONG HOKUTO AUTOMOTIVE EQUIP CO LTD

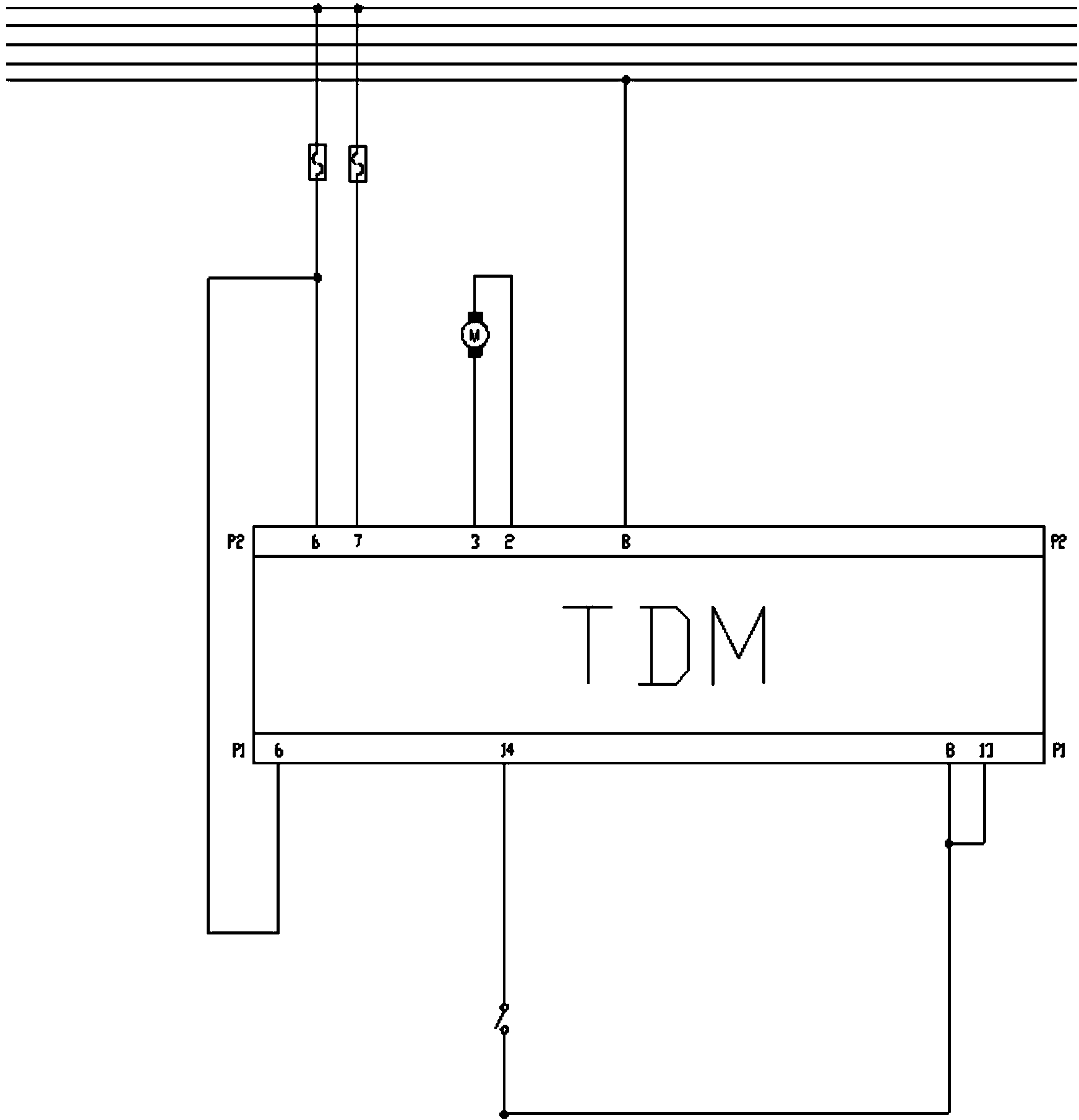

Function test split-mounting table for automobile components

ActiveCN103586852ASmall footprintEasy to learn and understandWork benchesMetal-working hand toolsAppliance componentEngineering

The invention discloses a function test split-mounting table for automobile components. The split-mounting table is provided with an electric appliance component, a support for supporting an electric rear window sunshade is arranged on the table top, the electric appliance component comprises a storage battery, a controller connected with the storage battery, a module P2 connector assembly connected with the controller and supplying power to the electric rear window sunshade to be tested, and a switch connected with the controller and controlling an output power supply to be turned on or off. A problem forward-shifting method is adopted for the function test split-mounting table for automobile components, single components are tested before being mounted in a split mode, and the components can be mounted on an automobile after the functions are tested to be normal. Thus, the adjusting and repairing quality of the whole automobile is guaranteed, the single automobile cost is reduced, work hours are saved, and such problems are thoroughly eliminated.

Owner:CHERY AUTOMOBILE CO LTD

Checking fixture for detecting distance from thrust surface to pin hole of cylinder

InactiveCN106352772ASimple structureEasy to makeMechanical clearance measurementsEngineeringReciprocating motion

The invention discloses a checking fixture for detecting distance from a thrust surface to a pin hole of a cylinder. The checking fixture comprises a locating assembly connected with the cylinder and a measuring assembly connected with the locating assembly and used for detection, wherein the locating assembly comprises a first locating block, a locating pin and a second locating block, the first locating block is matched with the end surface of the cylinder and arranged in the length direction of the cylinder, the locating pin is matched with a process pin hole of the cylinder and locates the first locating block on the cylinder, and the second locating block is fixed at the side part of the first locating block and extends vertically outwards; the measuring assembly comprises a measuring gauge holder which is connected with the second locating block and can reciprocate in the extended axial direction of the second locating block, and the checking fixture further comprises a gauge clamp detachably mounted on the measuring gauge holder and a dial gauge fixed at the extended tail end of the gauge clamp. The checking fixture is simple in structure, convenient to manufacture, high in detection accuracy and easy to operate; the distance from the thrust surface to the pin hole can be detected rapidly, and the work efficiency is effectively improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

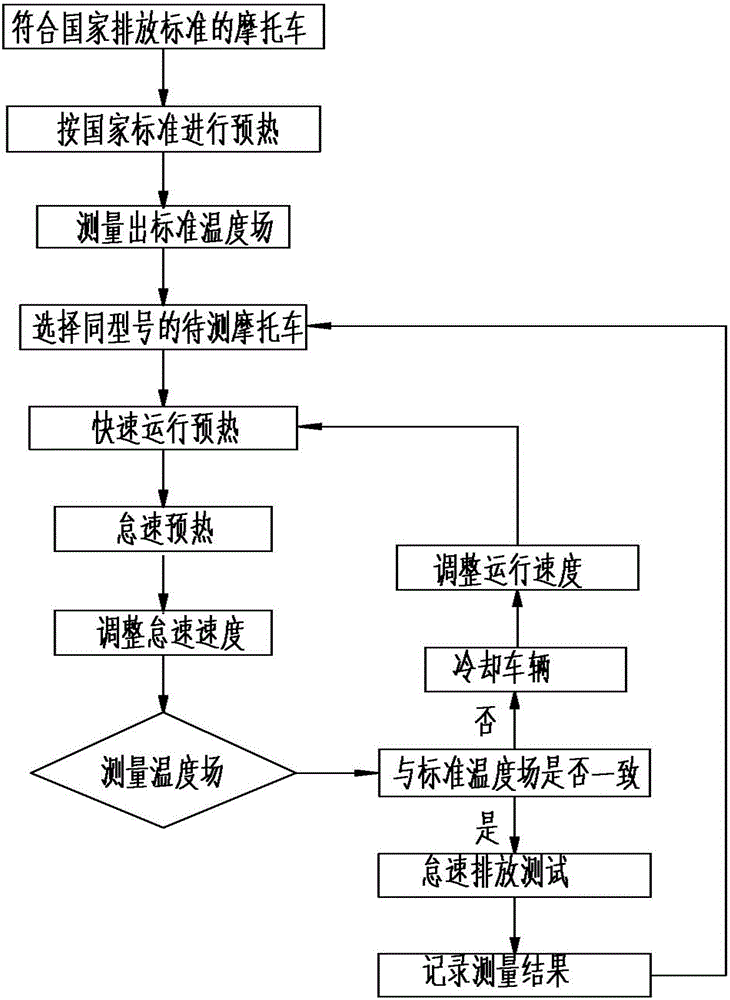

Motorcycle emission measuring method

InactiveCN106323649AGuaranteed accuracyShorten warm-up timeVehicle testingInternal-combustion engine testingEmission standardEngineering

The invention relates to a motorcycle emission measuring method which includes the steps: 1) selecting one motorcycle conforming to emission standards; 2) preheating the motorcycle according to GB14621-2002; 3) measuring a standard temperature field; 4) selecting one motorcycle to be measured; 5) performing rapid running and preheating; 6) performing idle preheating; 7) adjusting idle speed; 8) measuring the temperature field of the motorcycle to be measured, continuing a step 9 if the temperature field is inconsistent with the standard temperature field, and skipping to a step 11 if the temperature field is consistent with the standard temperature field; 9) completely cooling the motorcycle to be measured; 10) returning to the step 5 and adjusting running speed v; 11) measuring the idle speed according to the GB14621-2002; 12) performing numerical value rounding; 13) recording idle speed emission measuring results; 14) returning to the step 4, and measuring emission of a next motorcycle. The motorcycle can be rapidly measured, and accuracy of testing results can be ensured.

Owner:重庆山伦实业有限公司

Taking and delivering device for shoes

ActiveCN109549291ANo mechanical interferenceSo as not to damageShoemaking devicesMechanical engineering

The invention discloses a taking and delivering device for shoes. The device comprises a grasping mechanism, a vertical lifting mechanism and a horizontal transplanting mechanism, wherein the graspingmechanism is used for clamping or releasing shoes on stations; the vertical lifting mechanism is used for lifting up and down the grasping mechanism; and the horizontal transplanting mechanism is used for enabling the vertical lifting mechanism to move to and fro, so that the grasping mechanism can take and place the shoes among the front and rear stations. The device is separated from the stations according to the upper and lower layers, so that no space is occupied on the stations, the demand of clamping shoe trees with different heights and width can be adapted, the production takt also can be satisfied, meanwhile, the control is simple, and the cost is low.

Owner:SHANGHAI FORESIGHT AUTOMATION EQUIP CO LTD

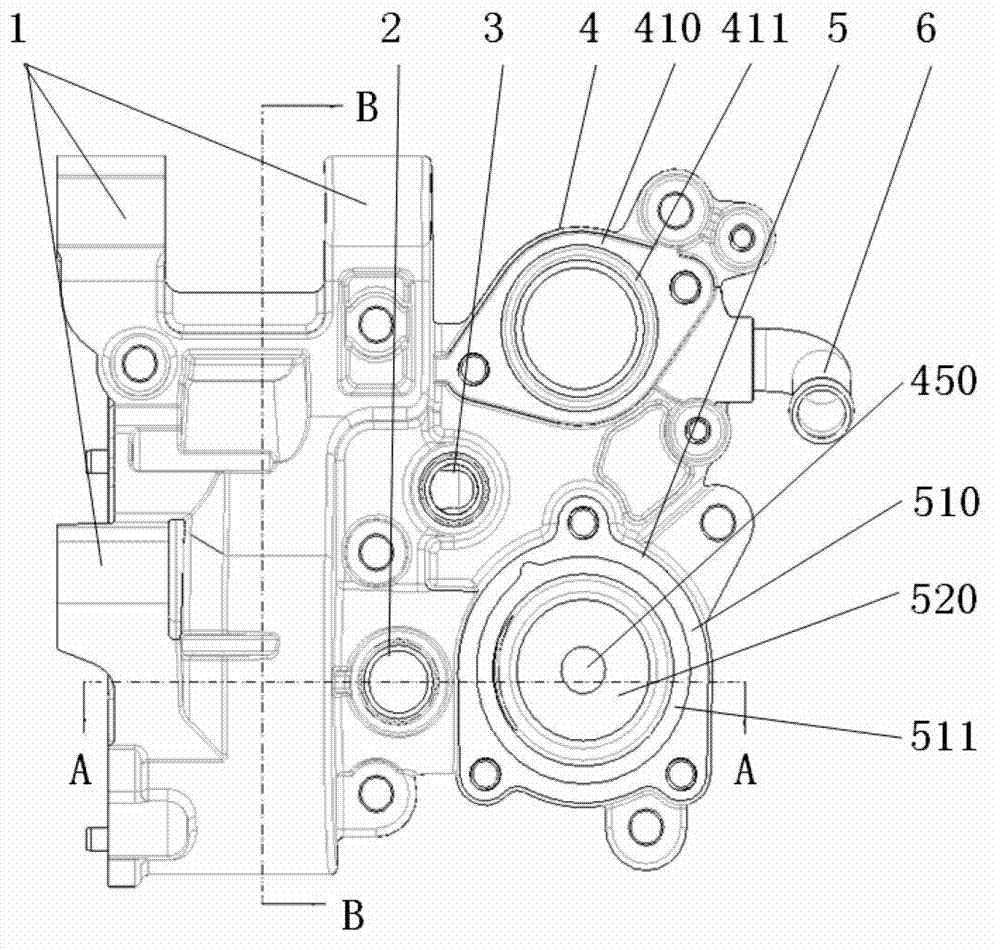

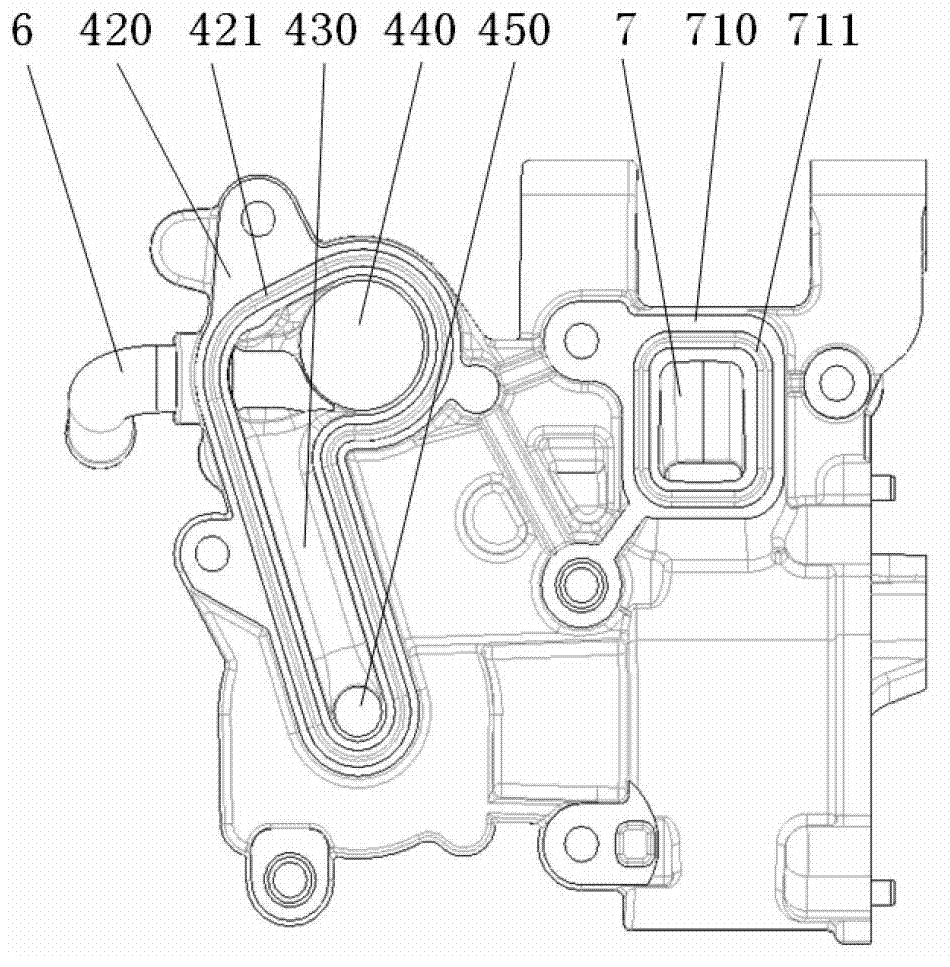

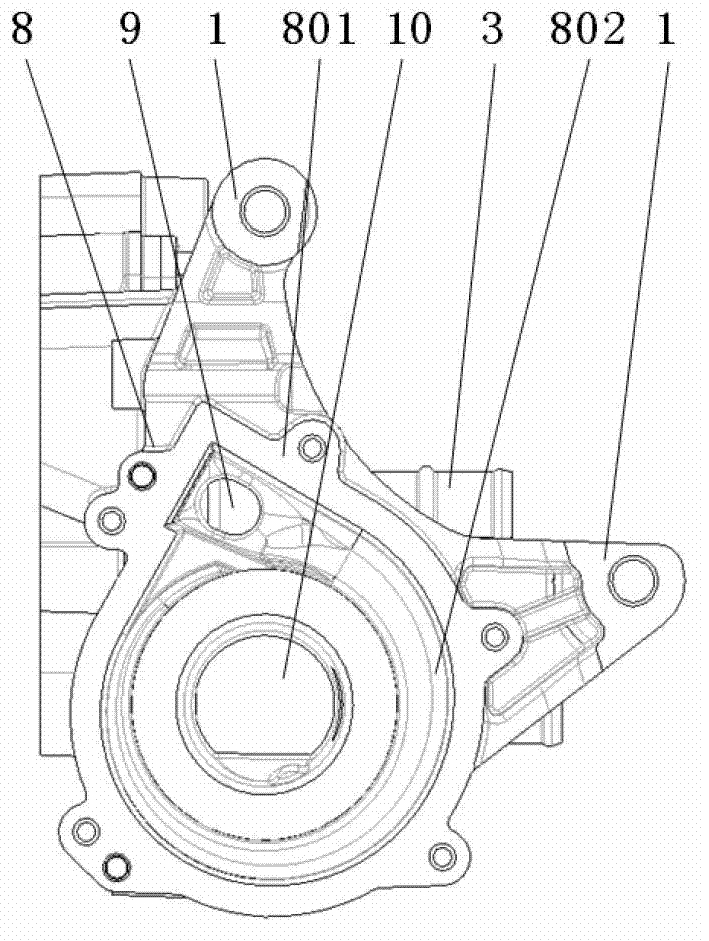

Water pump support where water pump volute is integrated

ActiveCN103195734AReduce casting difficultyIncreased failure ratePump componentsPumpsGasolineEngineering

The invention provides a water pump support where a water pump volute is integrated. The water pump support comprises the water pump volute, a cylinder body water jacket water inflow channel, a thermoregulator accommodating chamber and a cylinder body water jacket water outflow channel. The water pump support further comprises an A steel pipe integrated on the water pump support, a B steel pipe, a C steel pipe and lug parts which are located on the outer edge of the water pump volute and are distributed in a radial mode. The water pump volute is integrated on the water pump support, cylinder casting difficulty is reduced, machining does not need to be performed on the side of a cylinder body, and the reject ratio and increase of cost can be controlled. Connecting lines are fewer, the water pump support is convenient to arrange and compact in structure and integrates various functions, the problem of difficulty in arrangement of a small supercharge direct injection gasoline engine at present is solved, assembling working hours can be reduced simultaneously, and takt time is met.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Front brake subassembly clamper for vehicle

ActiveCN101513902BMeet the total component packaging requirementsMeet packaging requirementsWork holdersVehiclesRound tableBaseboard

The present invention relates to a front brake subassembly clamper for vehicle, wherein the front brake subassembly clamper comprises a crushing clamper base, a crushing clamper, a crushing clamper head, a positioning ring and a baseboard. The crushing clamper base and positioning ring are respectively fixed on the baseboard. The crushing clamper base is positioned at the outside of positioning ring. The crushing clamper is fixed at the top end of crushing clamper base. The positioning ring is a round table with fracture surface. The inner circular surface of positioning ring is matched with the external step surface of front brake. The fracture surface is provided with an outwards oblique plane and is matched with the size of projection of front brake assembly. The center of the crushingclamper head on the crushing clamper is aligned with the center of positioning ring. The positioning of the front brake assembly is ensured by the clamper positioning ring. The front brake assembly is compressed by a quick manual crushing clamper and the clamper is combined through bolts. The clamper for assembly has the advantages of low manufacturing cost, convenient operation, reliable positioning, ensured assembling quality and production tact satisfaction.

Owner:WANXIANGQIANCHAO CO LTD

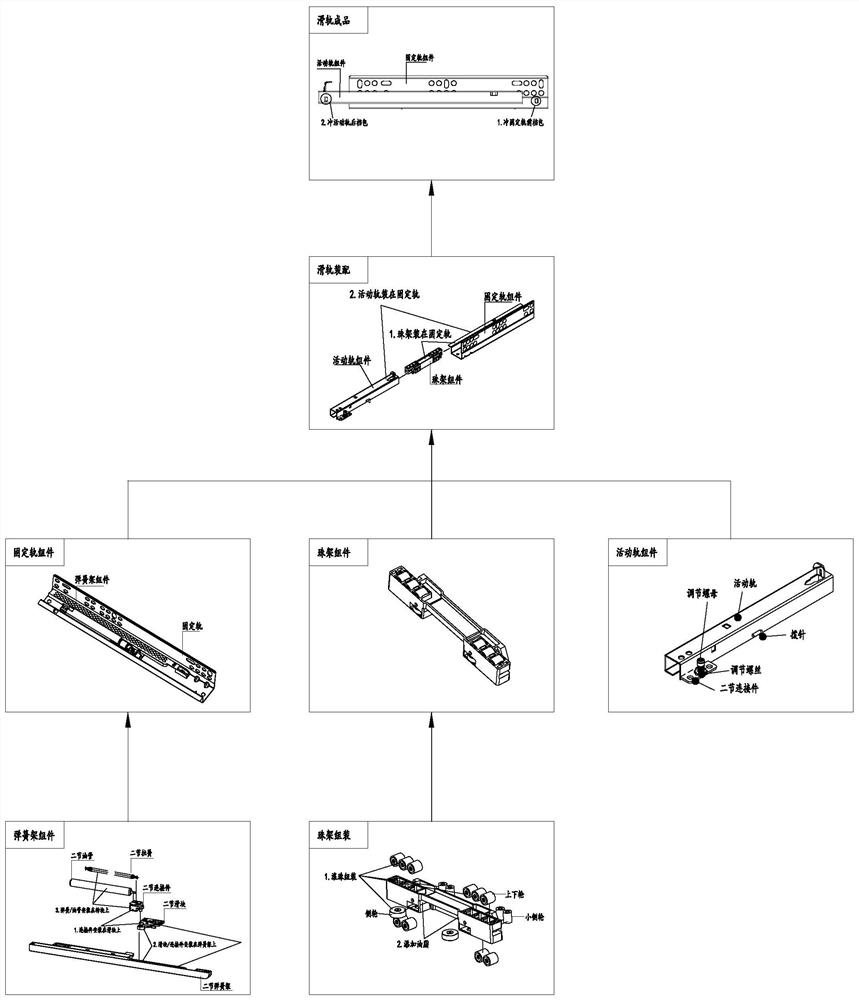

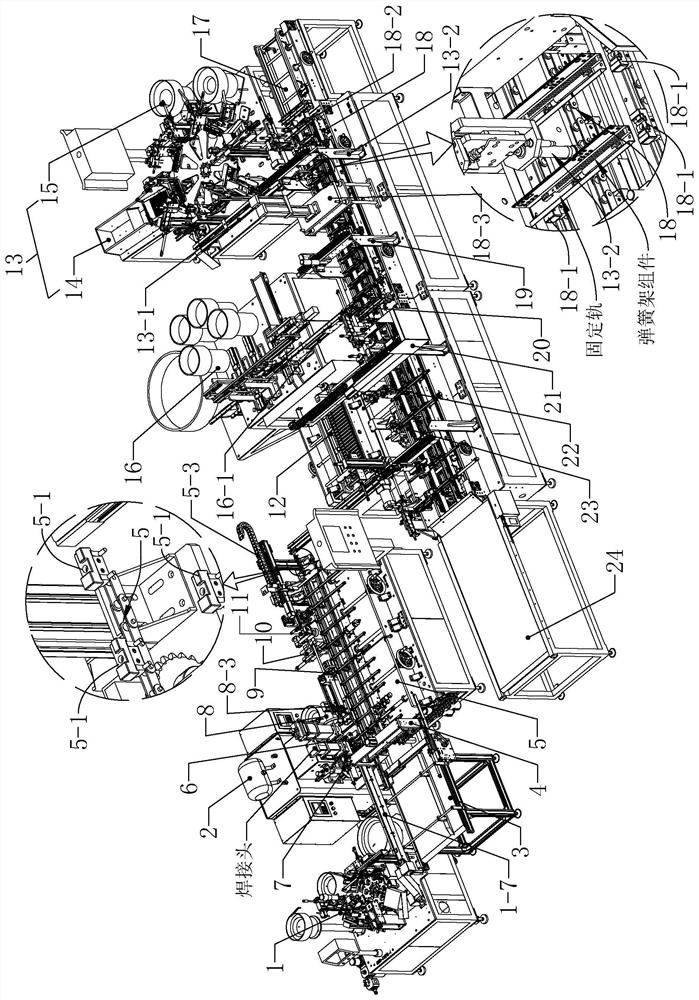

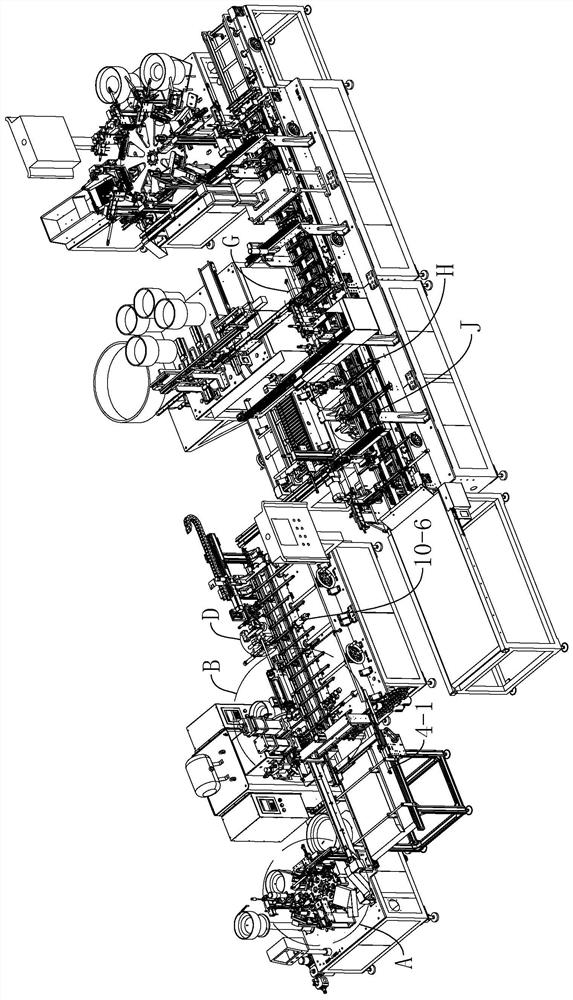

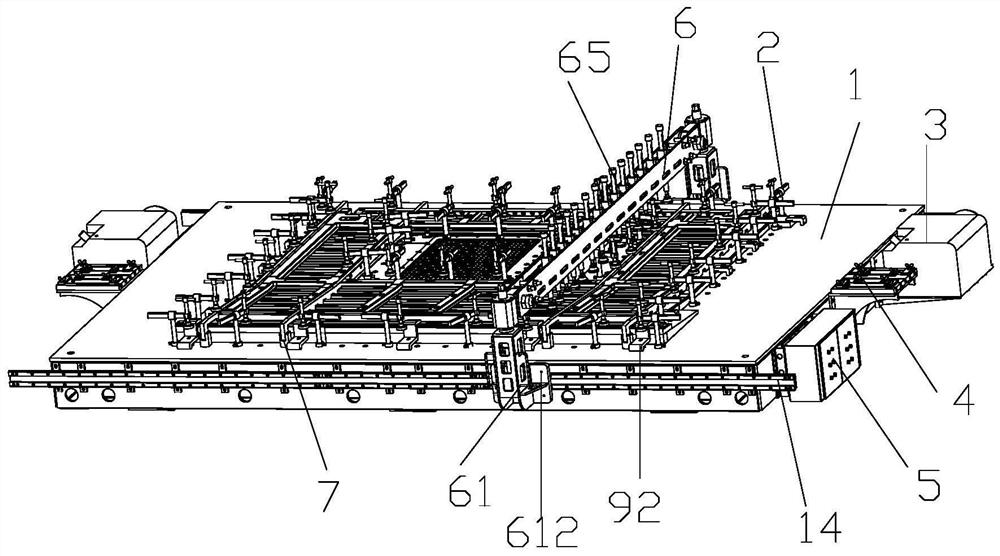

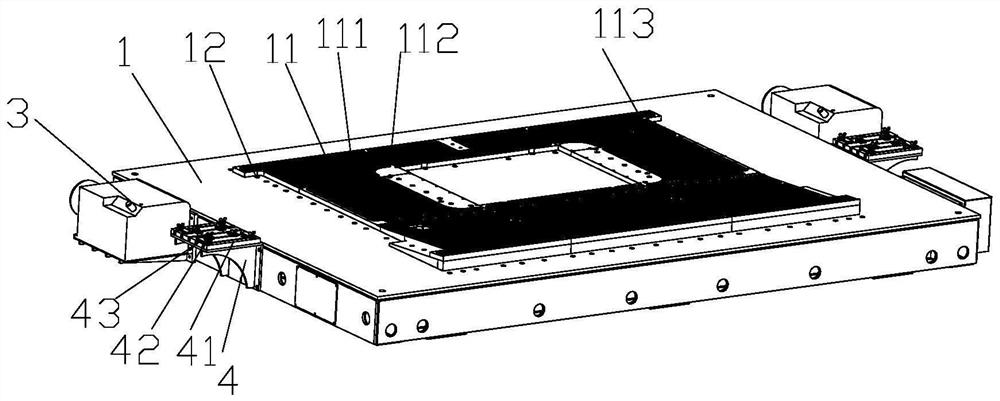

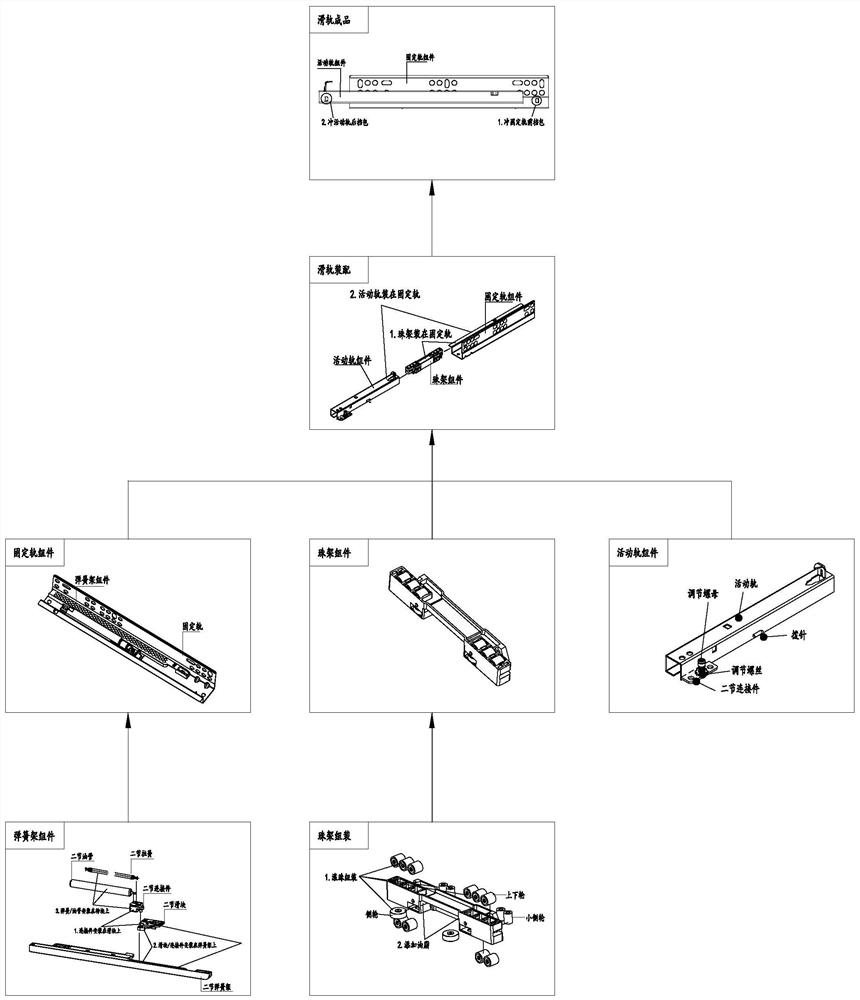

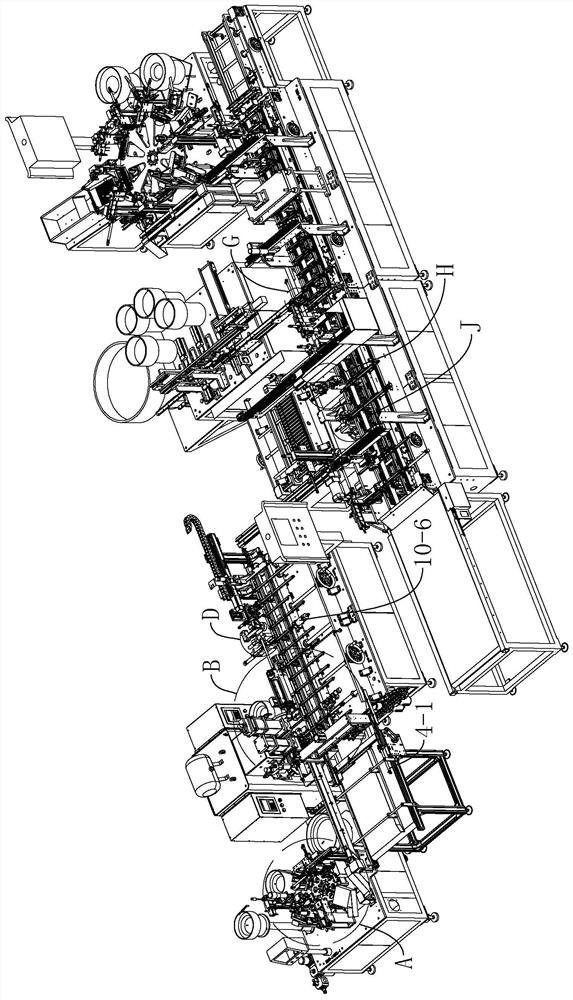

Production assembly line of two-section hidden rails

PendingCN112296626ATo achieve the role of mutual cooperationReduce the chance of falling outAssembly machinesOther manufacturing equipments/toolsAssembly lineManufacturing engineering

The invention discloses a production assembly line of two-section hidden rails. The production assembly line comprises a movable rail component assembly machine, a spring frame assembly machine, a ball frame assembly machine and a fixed rail assembly machine. The movable rail component assembly machine is used for intelligently producing and assembling to form movable rail components to be storedon a movable rail component storage machine, then in the process of conveying a fixed rail through a finished product assembly conveying belt of the fixed rail assembly machine, spring frame components obtained by production of the spring frame assembly machine and ball frame components obtained by production of the ball frame assembly machine are installed one by one, and finally the movable railcomponents stored on the movable rail component storage machine are installed, so that pre-installation of whole sliding rail finished products is achieved, and finally, qualified slide rail productsare obtained after an adjustment test. Therefore, automatic installation operation of the two-section hidden rails is achieved, and the production assembly line has the advantages of improving production efficiency, relieving labor intensity of staff, and improving the product percent of pass at the same time.

Owner:佛山市本吉智能科技有限公司

Block side wall installing and welding tool and process for laser welding structure

PendingCN111790981AAchieve Compatible SolderingQuality improvementAxle-box lubricationLaser beam welding apparatusCarbon steelWall plate

The invention provides a block side wall installing and welding tool and process for a laser welding structure. The block side wall installing and welding process comprises the following steps that S1, an installing and welding frame and an aluminum plate profiling working tread are adopted as a tool main body; S2, an exhaust groove and a sealing groove are milled in the aluminum plate profiling working tread, and a vacuum pump is used for adsorbing a wallboard to the working tread through the sealing groove; S3, a corrugated plate is pre-spotted on the wallboard through a single-face pre-spotted technology, and the corrugated plate is positioned through profiling pressing positioning; S4, a layer of insulating paint is sprayed on the surface of the tool to prevent the wallboard and the tool from generating electric sparks to burn a strong board during pre-spotting; and S5, a gantry is assembled on the tool, and pressing and spot fixation of a framework and the wallboard on the tire position is achieved through the gantry. According to the block side wall installing and welding tool and the process for the laser welding structure, the wallboard is installed on a carbon steel installing and welding foundation platform in an adsorption mode, and laser automatic welding can be achieved under the condition that the tool is not pressed or positioned; compared with the spot welding,and after automatic laser welding is achieved, the quality of the exposed face is obviously improved.

Owner:天津中车唐车轨道车辆有限公司 +1

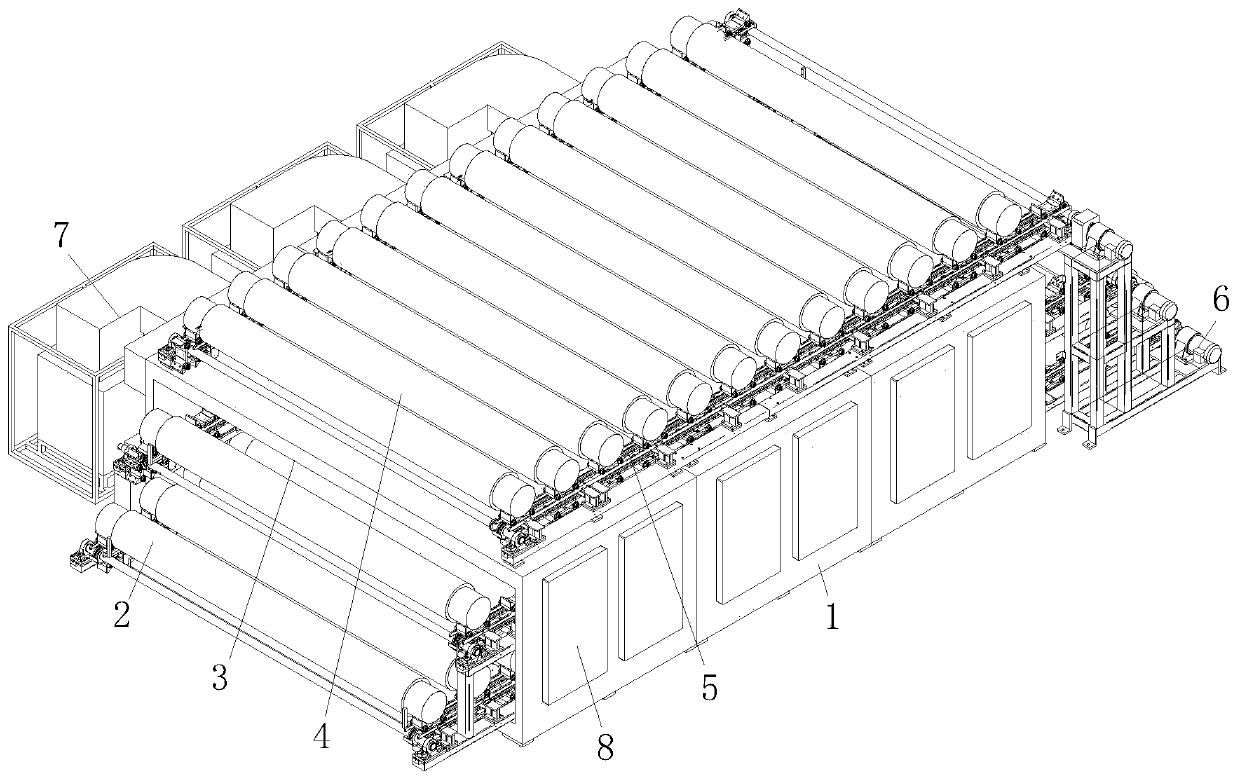

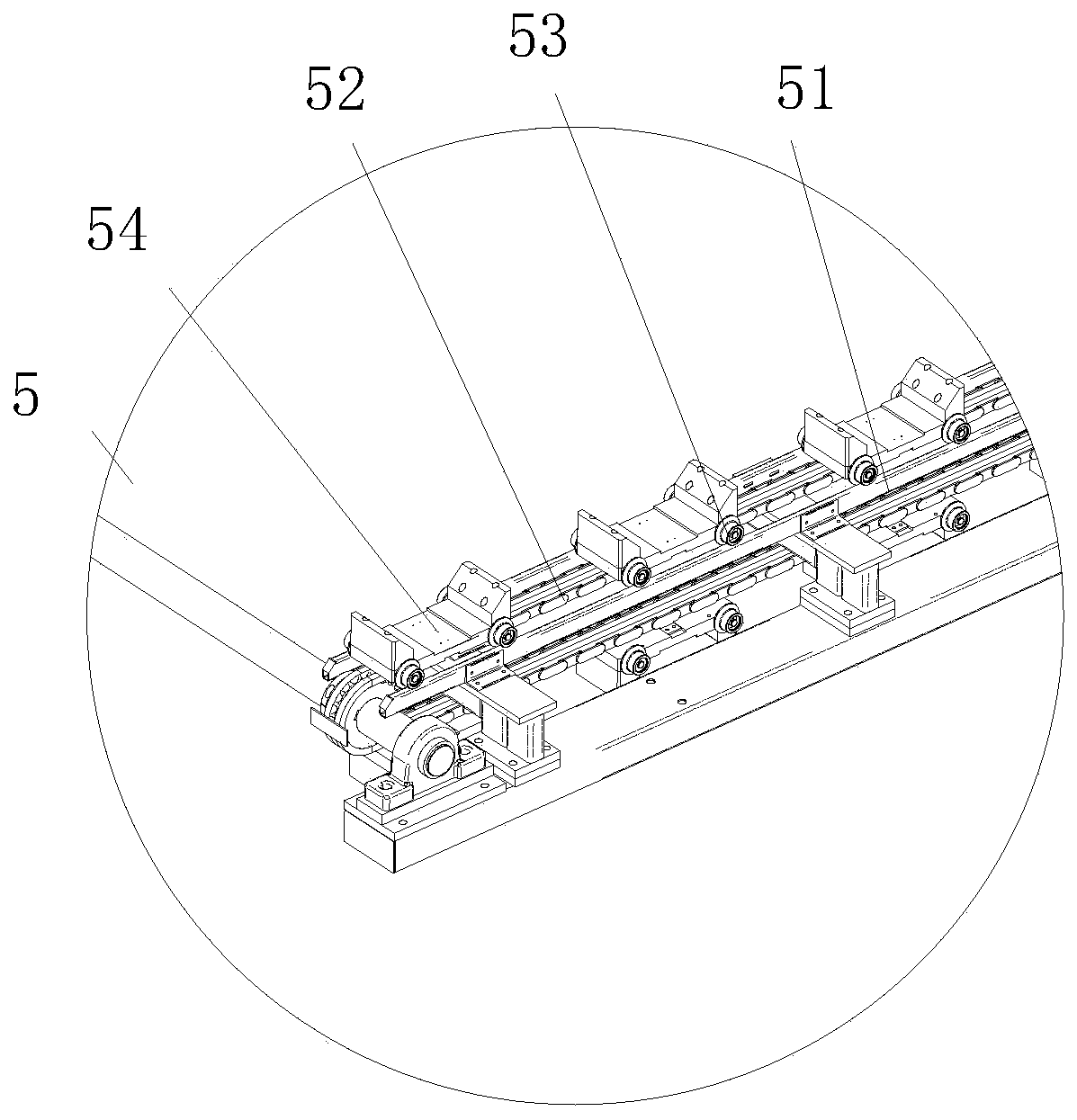

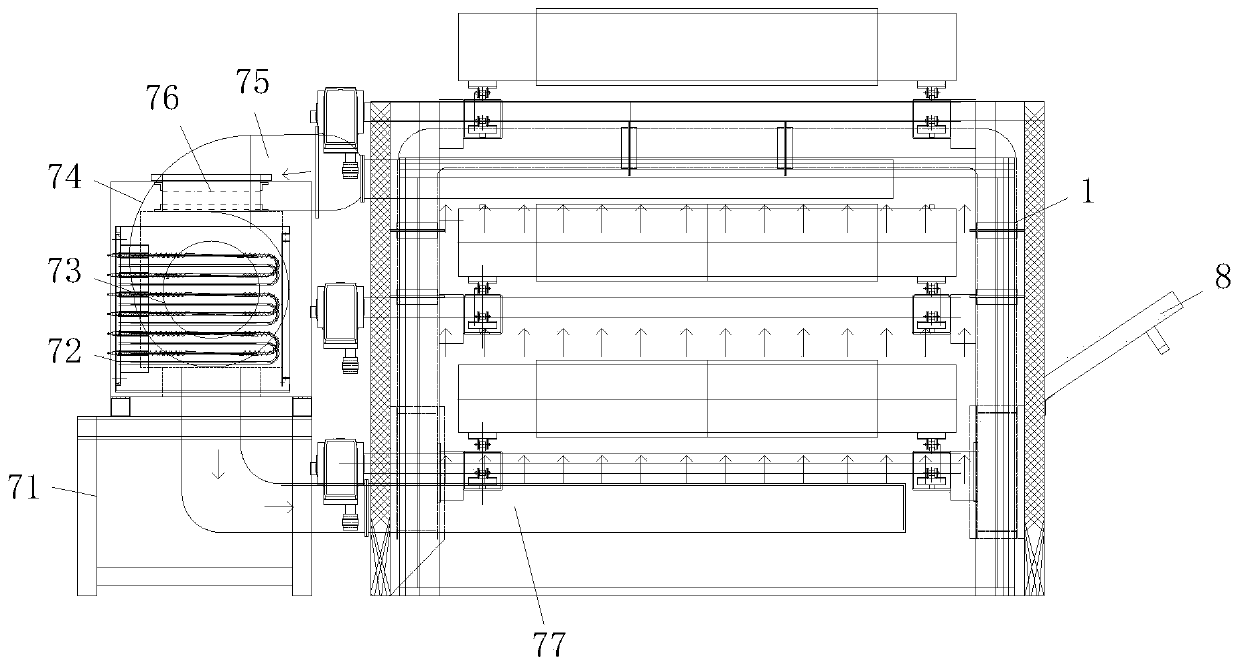

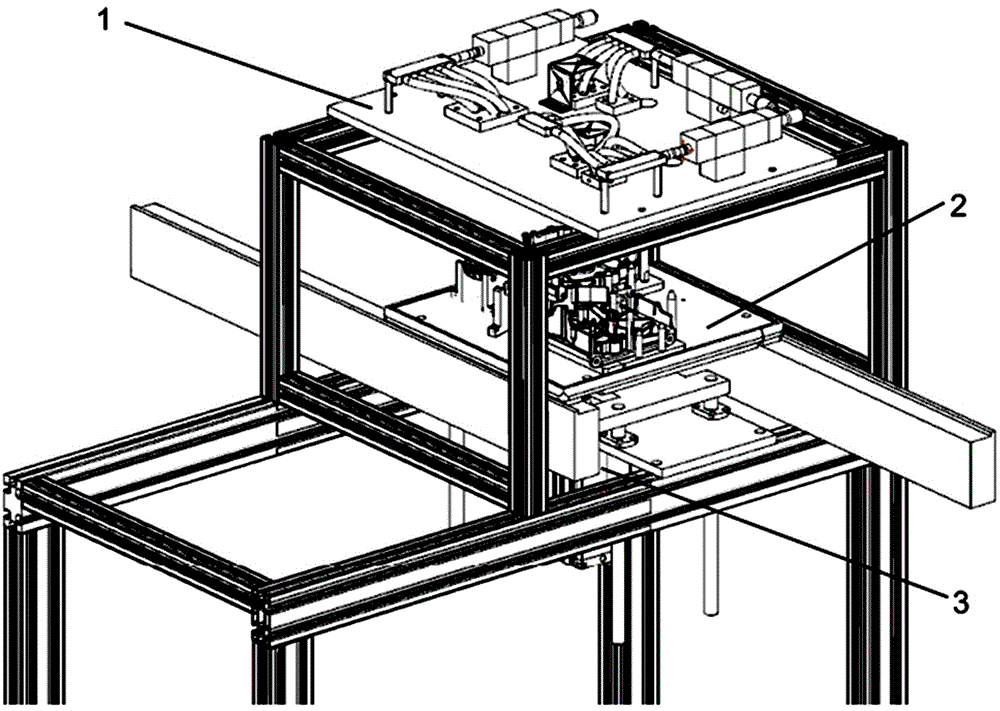

Lithium battery separator drying production line

InactiveCN110986546AImprove drying efficiencyUninterrupted drying operationDrying gas arrangementsDrying machines with progressive movementsProduction lineThermodynamics

The invention relates to the technical field of lithium battery production, in particular to a lithium battery separator drying production line. The lithium battery separator drying production line involves a rack, a first-layer drying channel, a second-layer drying channel, a top storage area, a bearing mechanism, a driving motor, a drying mechanism and an opening and closing bin door, the lithium battery separator drying production line is formed by the mode that the rack is matched with the first-layer drying channel, the second-layer drying channel and the top storage area in combination with one another, wherein the first-layer drying channel and the second-layer drying channel are main drying chambers, and a conveying device provides conveying capability for the first-layer drying channel, the second-layer drying channel and the top storage area. According to the lithium battery separator drying production line, the purpose of rapidly and uniformly drying a separator roll is achieved, uninterrupted drying operation can be carried out on a separator, and therefore, the drying efficiency of the lithium battery separator is greatly improved, the site is saved, the arrangement ofthe top storage area is matched at the same time, a product can be naturally cooled while the product is stored, and the functionality of the whole device is improved.

Owner:深圳市标王工业设备有限公司

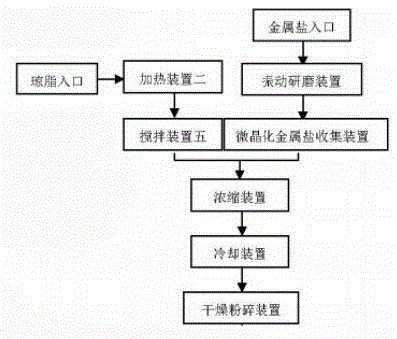

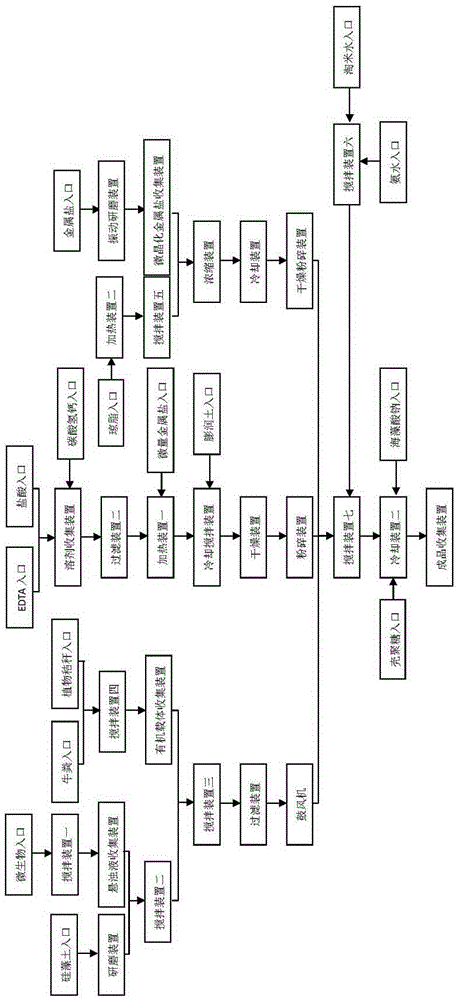

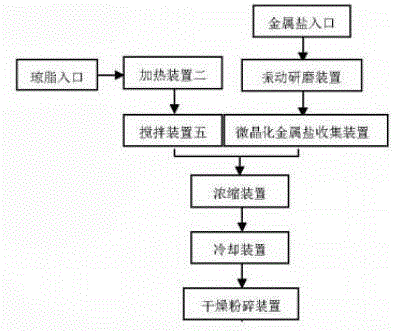

Intelligent preparation method for slow-release micro-crystallization metal salt mineral powder

InactiveCN105418210AIncrease productivityMeet the production taktFertilizer mixturesEngineeringAutomation

The invention discloses an intelligent preparation method for slow-release micro-crystallization metal salt mineral powder. The method includes the steps that a sensing module senses whether the weight of added raw materials reaches a certain preset value or not, and according to all sensing values, through internal analysis and computation, a PLC controls a heating module, a prompting module, a vibrating module, a grinding module, a stirring module, a concentrating module, a cooling module, a drying module and a smashing module to perform related operation. According to the method, through accurate control over various parameters, the stability of the slow-release micro-crystallization metal salt mineral powder can be effectively improved, and the release speed of the slow-release micro-crystallization metal salt mineral powder applied into soil can be reduced; production efficiency is high, the production tact is met, labor intensity is reduced, and detection is accurate and reliable; preparation efficiency can be effectively improved, the automation degree is high, operation is convenient, and resources are saved.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

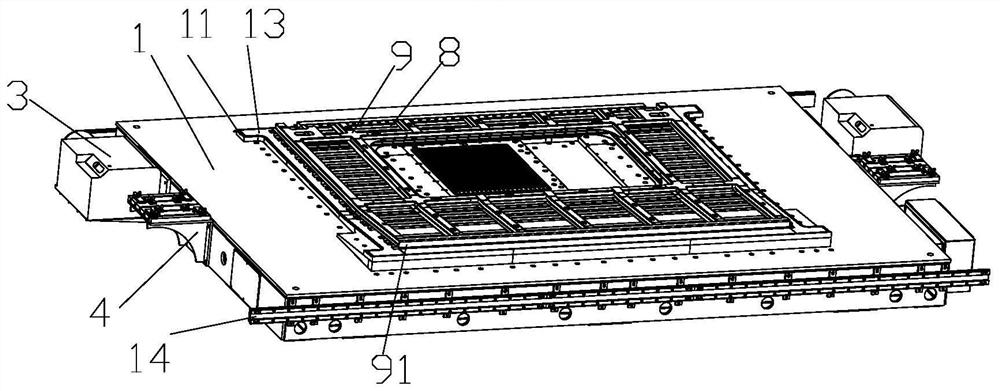

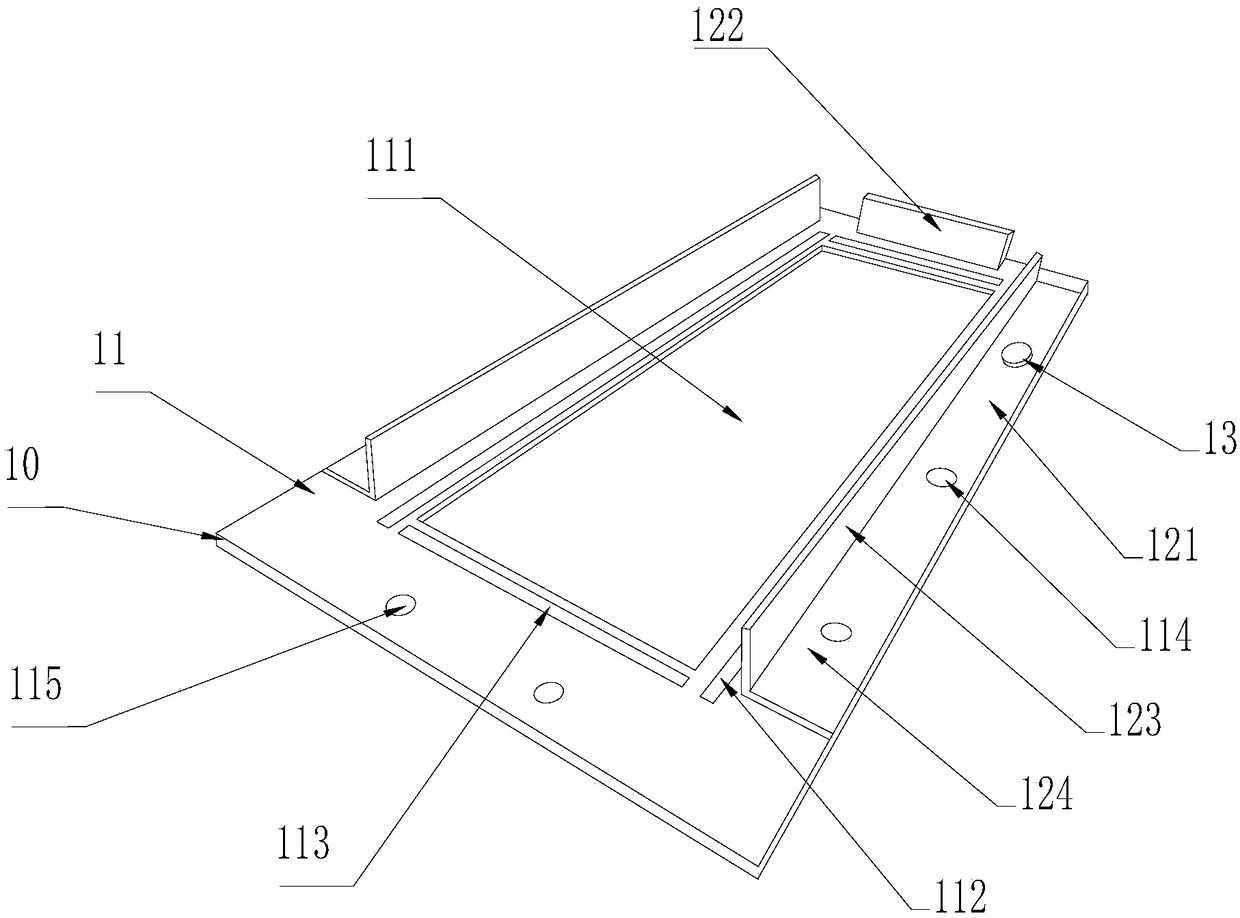

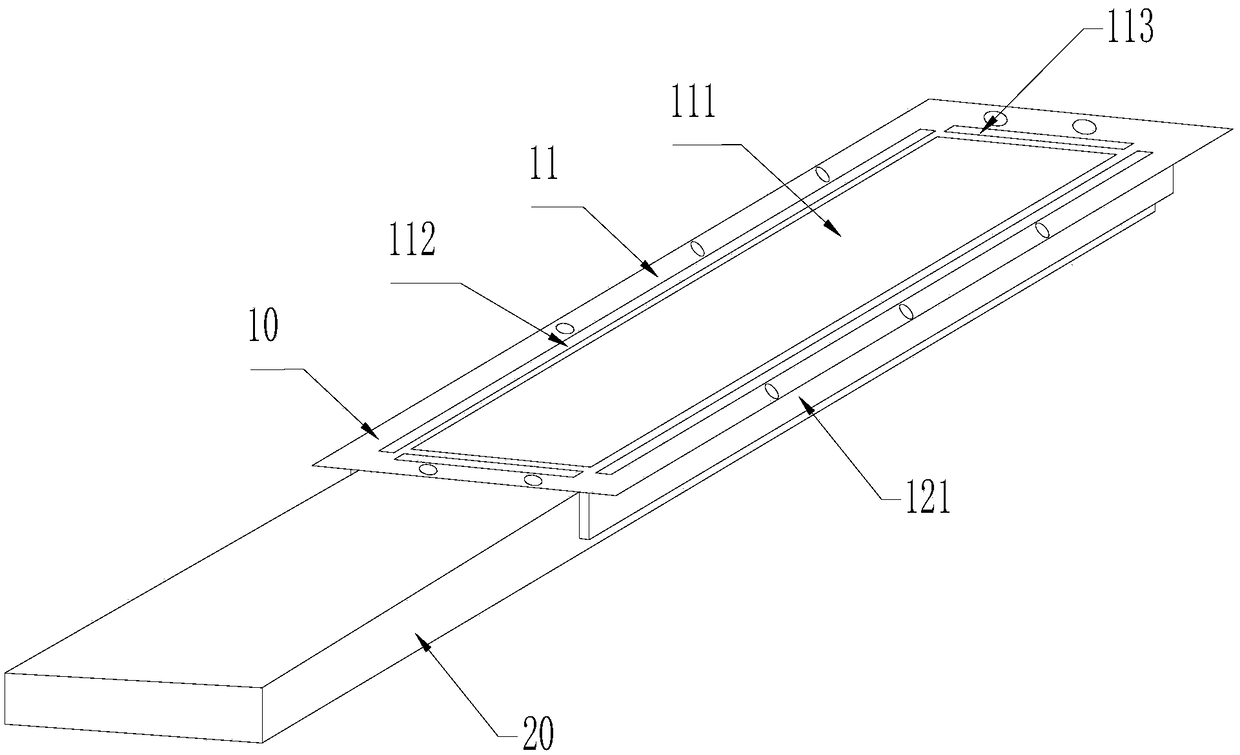

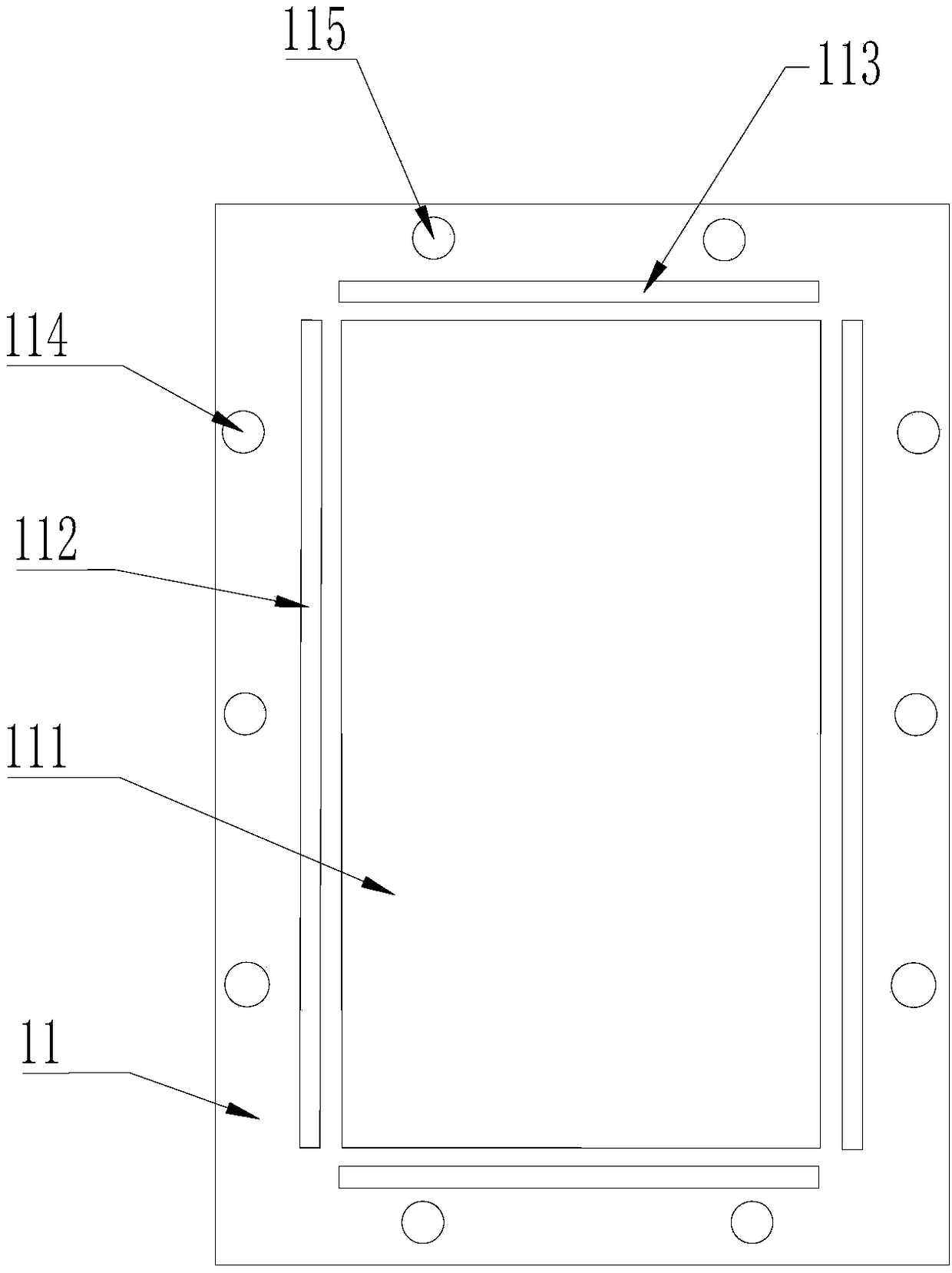

Auxiliary marking tool used for glass base plate grinding workbench

The invention relates to an auxiliary marking tool used for a glass base plate grinding workbench. The auxiliary marking tool comprises a main body part and a positioning part connected with the mainbody part, wherein a marking slot hole is formed in the main body part; and the positioning part comprises a positioning part which is matched with the glass base plate grinding workbench. With the adoption of the technical scheme, the auxiliary marking tool provided by the invention can mark out the same vacuum slot in table cloth.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

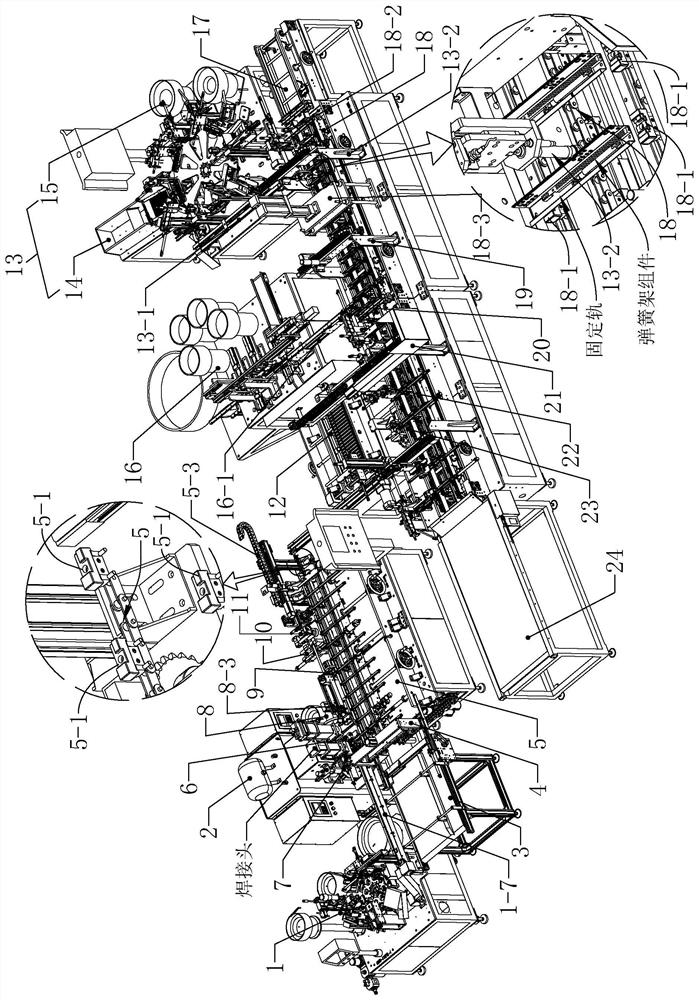

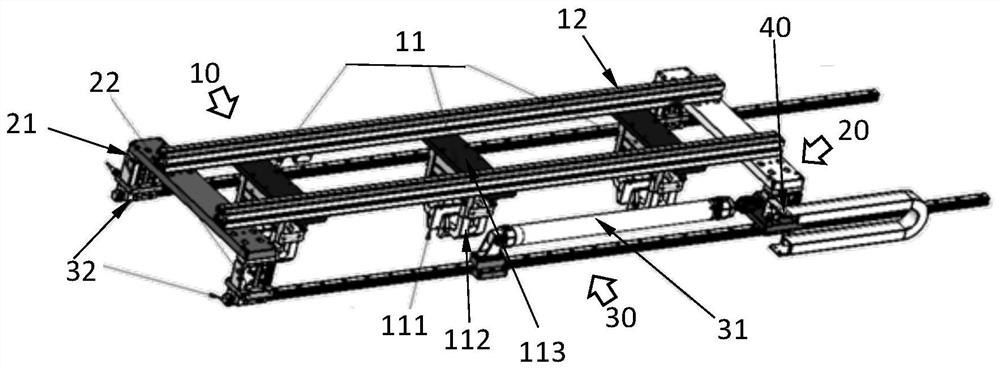

Movable rail component assembly line of two-section hidden rail production assembly line

PendingCN112222826AImprove pass rateConvenient welding operationWelding/cutting auxillary devicesAssembly machinesMultiple deviceAssembly line

According to a movable rail component assembly line of a two-section hidden rail production assembly line, connecting pieces, nuts and adjusting screw assembling machines are intelligently assembled to form connecting piece accessories; the connecting piece accessories are connected to bayonets of welding clamps in an inserted mode under the pushing effect of movable rail positioning cylinders, and therefore, the positioning effect is achieved, and the welding position is more accurate; the connecting piece accessories and pull needles are moved to the corresponding welding positions of the movable rail at the bayonets through connecting piece clamping pieces and the pull needle clamping pieces respectively; and finally the connecting piece accessories and the pull needles are welded through a welding head of a movable rail welding machine, so that the effects of installing and fixing the connecting piece accessories and the pull needles are achieved; and finally, the assembled movablerail component is stored on a movable rail storage machine through a movable rail conveying belt so as to be matched with a fixed rail, and therefore full-automatic mounting operation of the movablerail component is achieved. The production rhythm of the production line is coordinated through multiple devices, so that labor is saved, and the production efficiency and the product percent of passcan be improved.

Owner:佛山市本吉智能科技有限公司

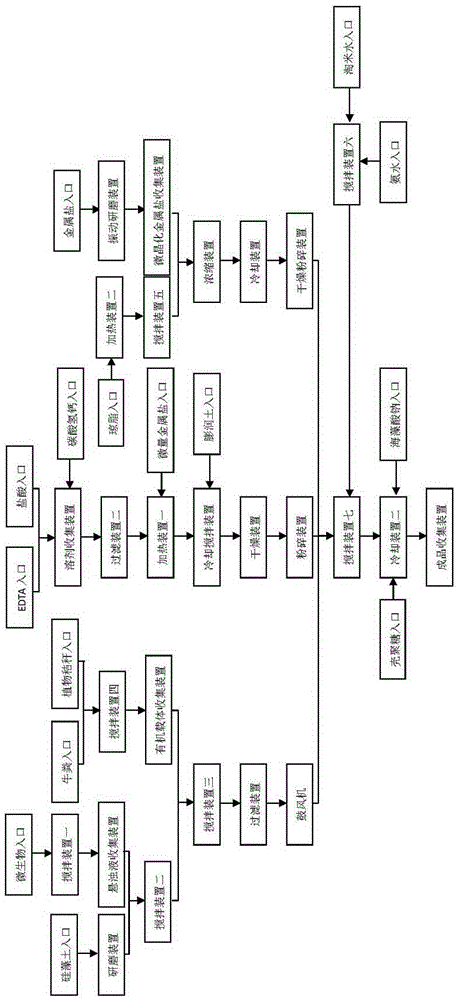

Intelligent preparation system and intelligent preparation method of liquid slowly-controlled-release fertilizer

InactiveCN105669293AIncrease productivityMeet the production taktFertilizer mixturesSolenoid valveIndustrial engineering

The invention discloses an intelligent preparation system and an intelligent preparation method of a liquid slowly-controlled-release fertilizer. A sensing module senses whether adding weights of raw materials reach preset values or not. A temperature detection module detects the temperature in a fourth stirring apparatus. A ventilation detection module detects the ventilation degree in the fourth stirring apparatus. A pH detection module detects the pH value of a solution. A PLC, according to the sensed values, the temperature value, the ventilation degree and the pH value, controls an electromagnetic valve, a grinding module, a stirring module, a sugar / water proportion module, an air blowing module, a temperature control module, the ventilation detection module, a reminding module, a heating module, a material module, a refrigerating module, a drying module, a crushing module, a filter module, a vibration module, a concentration module and a cooling module to execute related operations through internal analysis and calculation. By accurate control on various parameters, the intelligent preparation method effectively improves stability of a slow-release microelement chelating agent and a slow-release micro-crystallized metal salt mineral powder, so that the method is high in production efficiency, satisfies production demand, reduces labor intensity and provides accurate and reliable detection.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

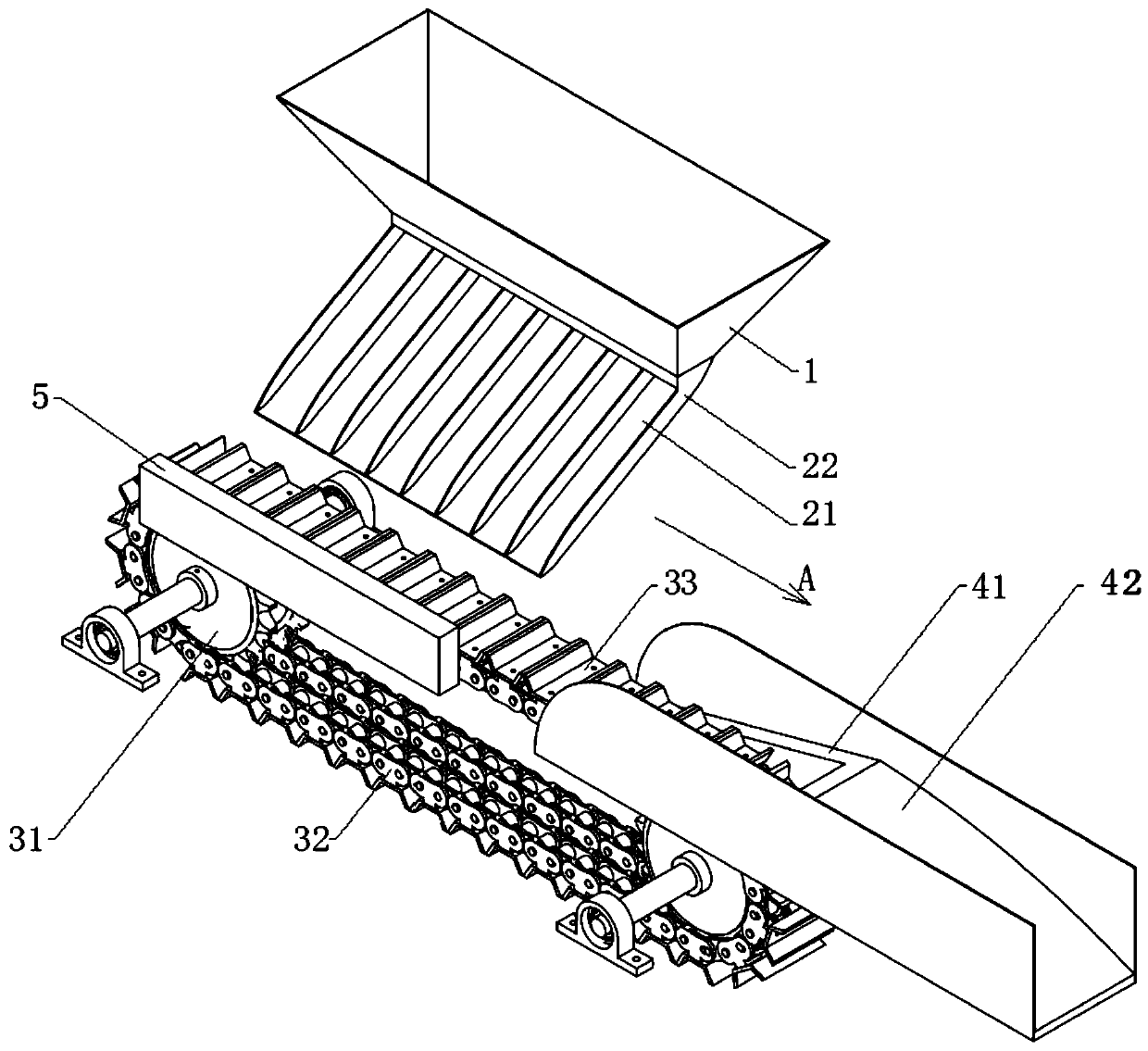

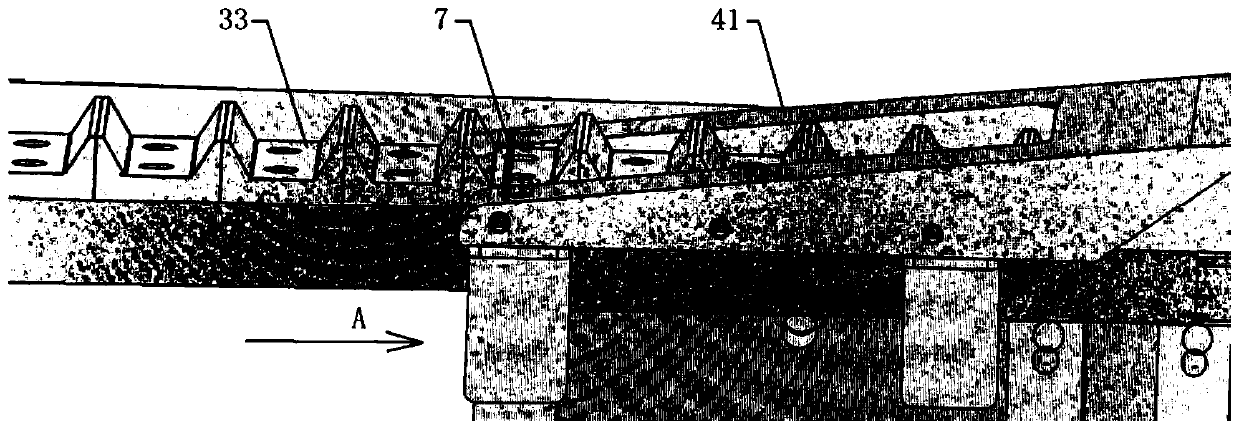

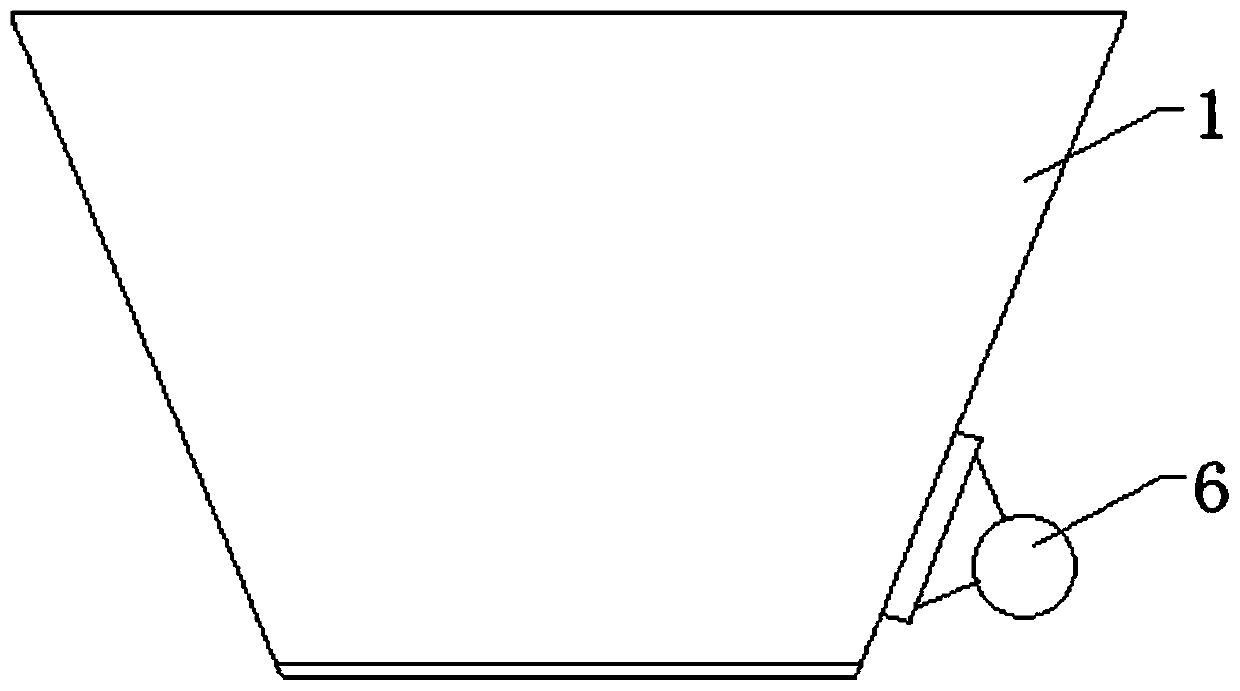

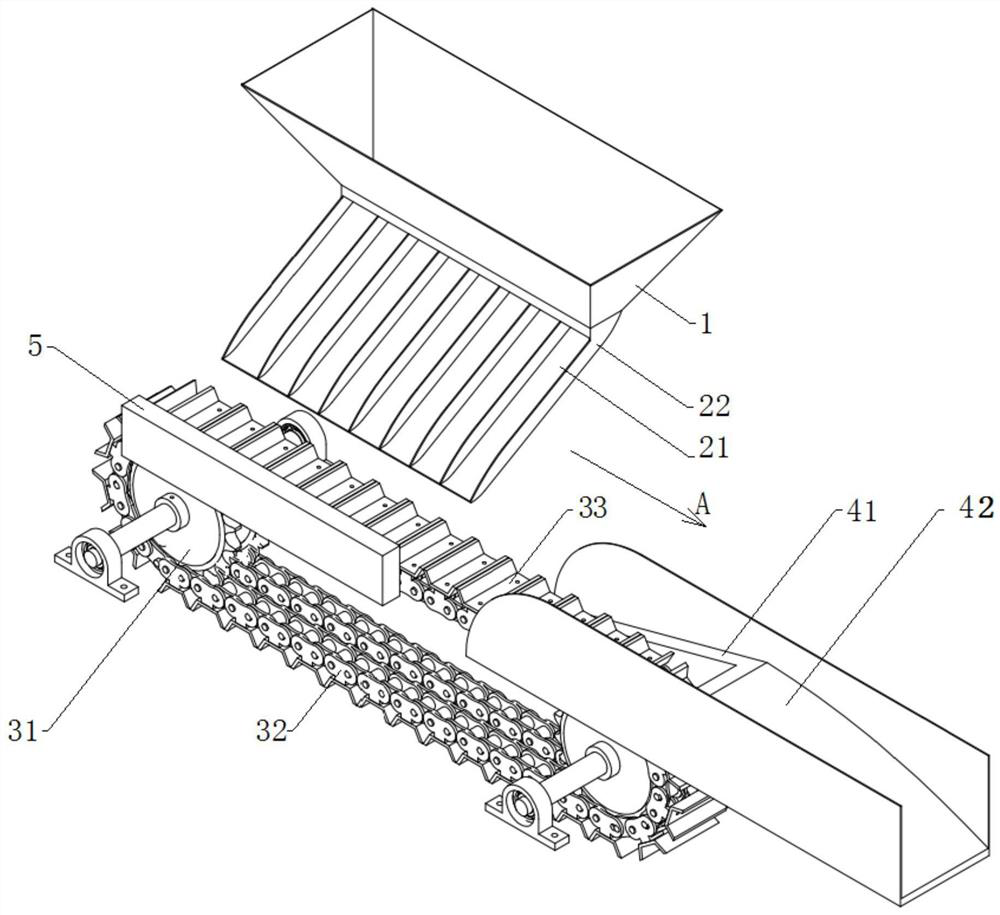

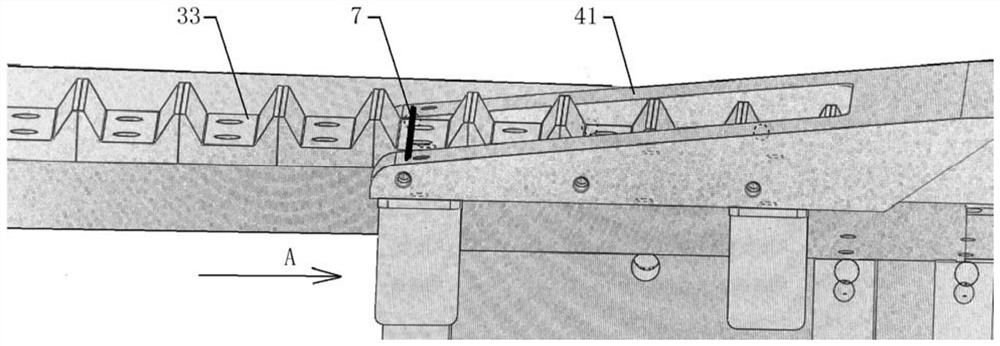

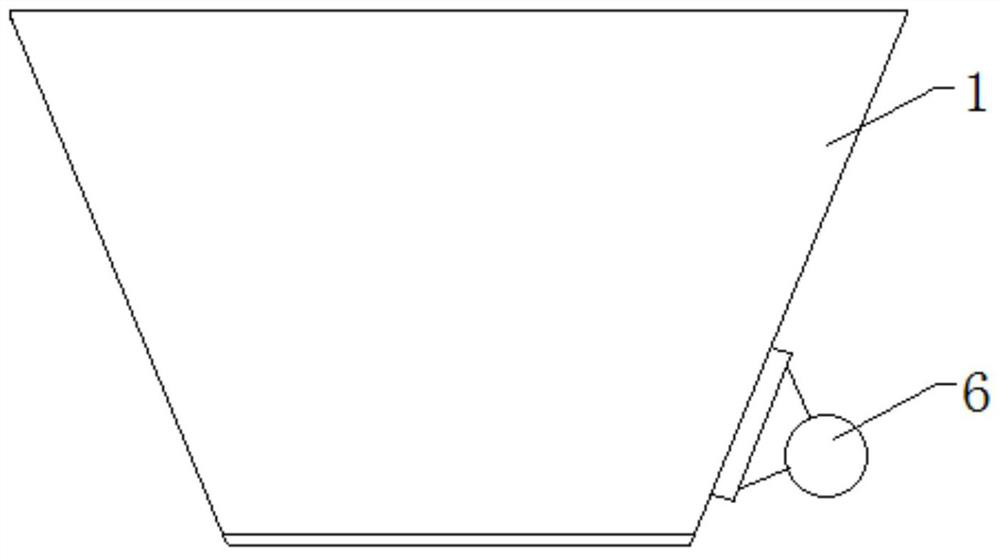

Automatic ice cream stick feeding system

ActiveCN111332742ARealize automatic feeding functionPrecise arrangementConveyorsConveyor partsChain linkIce cream

The invention discloses an automatic ice cream stick feeding system. The automatic ice cream stick feeding system comprises a feeding bin, a feeding slide way, a conveying part and a feeding part, wherein the feeding bin is in a funnel shape. ice cream sticks are put into the feeding bin from the upper portion of the feeding bin, and the ice cream sticks slide out of a long and thin outlet in thebottom of the feeding bin; the feeding slide way is obliquely arranged so that the ice cream sticks can slide down under the action of gravity; the conveying part comprises chain wheels, a chain and amaterial carrying plate, the material carrying plate is fixed to the chain, and the starting end of the conveying part is positioned below the feeding slide way; the feeding part comprises a materialreceiving plate and a discharging slide way; and the material receiving plate comprises two supporting plates, the two supporting plates are arranged on the two sides of the tail end of the conveyingpart correspondingly, and the material receiving plate is connected with the discharging slide way. The ice cream sticks are put into the feeding bin and then transferred to the material carrying plate of the conveying part through the feeding slide way, when the ice cream sticks are conveyed to the tail end of the conveying part by the conveying part, the two ends of the ice cream sticks are lapped on the material receiving plate, and the ice cream sticks are lifted from the material carrying plate and pushed to the discharging slide way along with continuous movement of the material carrying plate and enter an ice cream stick processing production line.

Owner:内蒙古佰邦科技股份有限公司

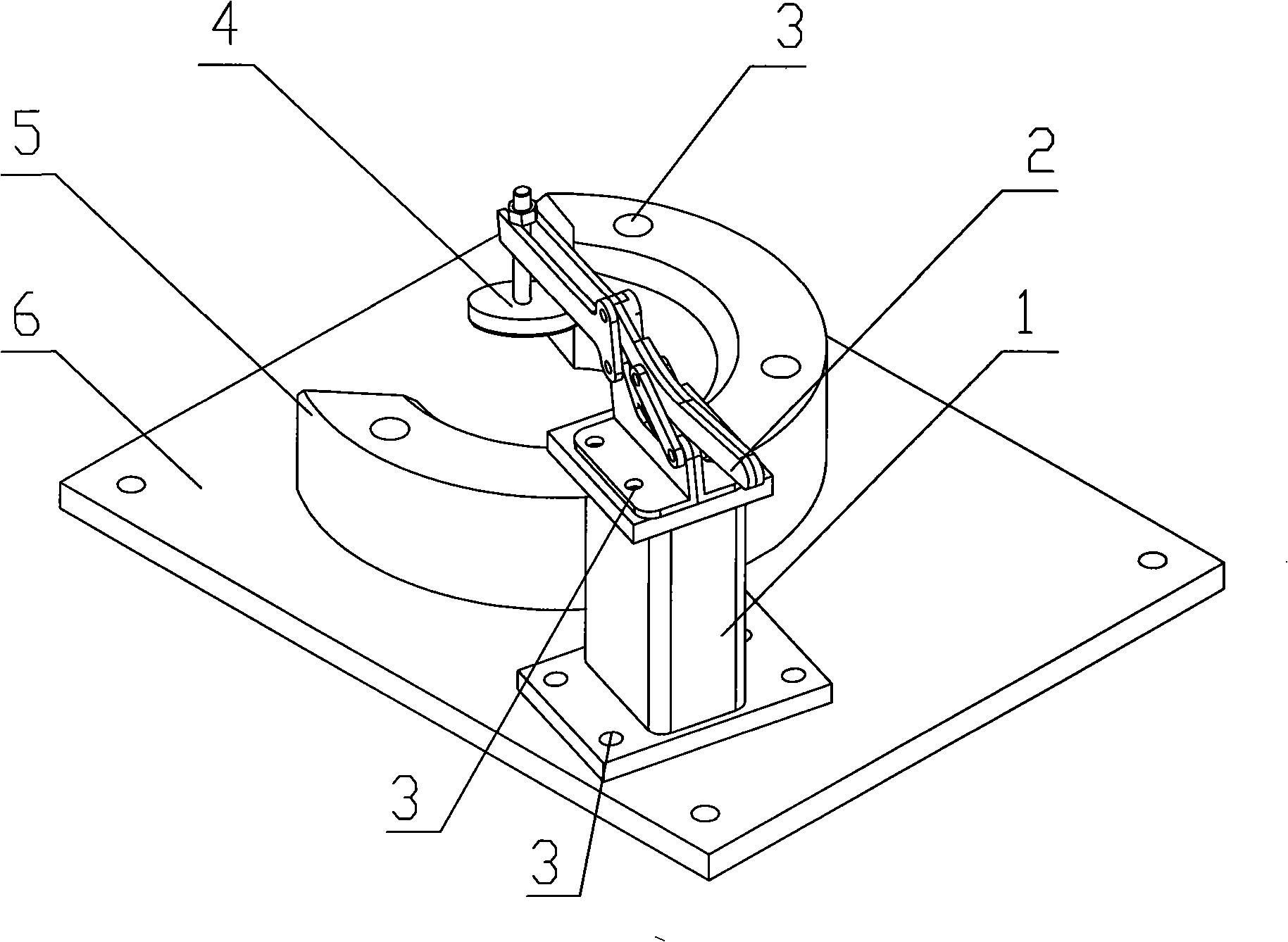

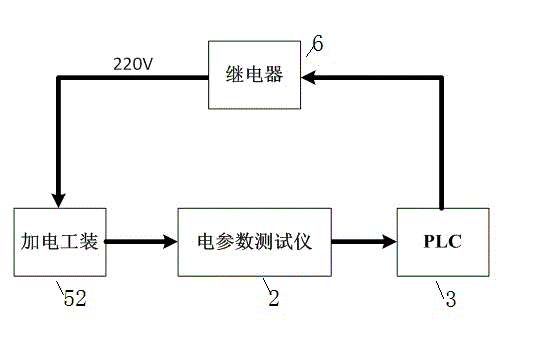

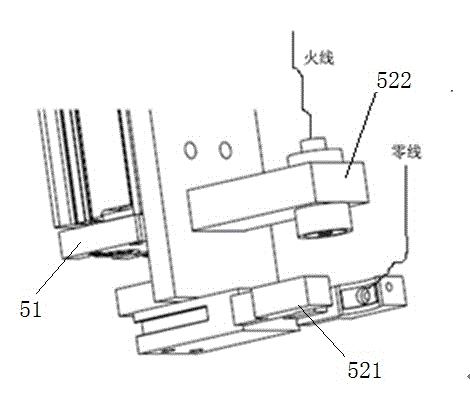

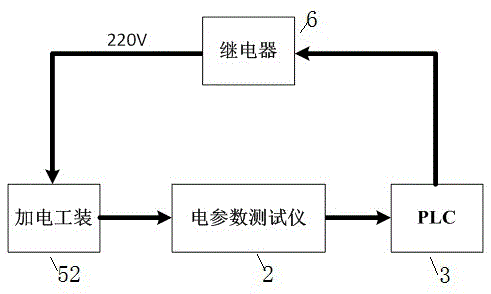

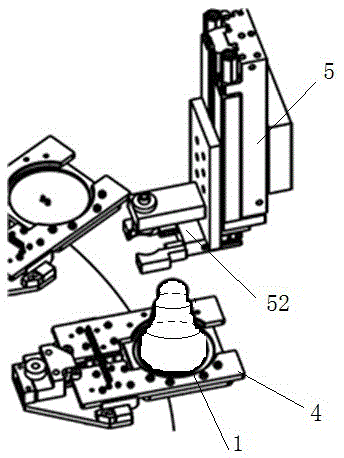

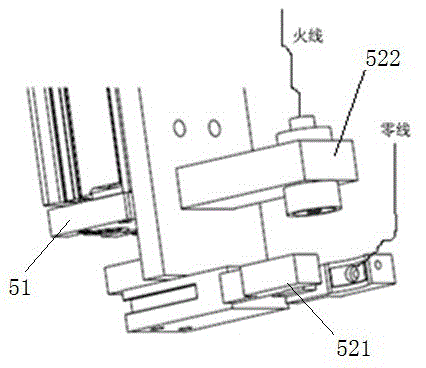

Bulb lamp on-line automatic rapid electrical parameter detecting device and method

The invention discloses a bulb lamp on-line automatic rapid electrical parameter detecting device and method which are used for detecting electrical parameters of a bulb lamp. The bulb lamp is provided with a bulb lamp live line electrode and a bulb lamp null line electrode, the detecting device comprises an electrical parameter tester, a PLC connected with the parameter tester through a bus, a rotary table station, a power-on tool manipulator and a relay. The power-on tool manipulator is connected with the rotary table station and comprises a straight-line motion mechanism and a power-on tool installed on the straight-line motion mechanism, and the output end of the power-on tool is connected with the electrical parameter tester. The input end of the relay is connected with the PLC, and the output end of the relay is connected with the input end of the power-on tool. The bulb lamp on-line automatic rapid electrical parameter detecting device and method can avoid problems brought by manual testing, also automatically perform electrical parameter testing and result judging on the bulb lamp and achieve rapid detection on the electrical parameters to meet the production takt of an overall assembling line.

Owner:SHANGHAI RADIO EQUIP RES INST

Intelligent preparation method of liquid slowly-controlled-release fertilizer

InactiveCN105669292AIncrease productivityMeet the production taktProgramme control in sequence/logic controllersFertilizer mixturesTemperature controlControl release

The invention discloses an intelligent preparation method of a liquid slowly-controlled-release fertilizer. A sensing module senses whether adding weights of raw materials reach preset values or not. A temperature detection module detects the temperature in a fourth stirring apparatus. A ventilation detection module detects the ventilation degree in the fourth stirring apparatus. A pH detection module detects the pH value of a solution. A PLC, according to the sensed values, the temperature value, the ventilation degree and the pH value, controls an electromagnetic valve, a grinding module, a stirring module, a sugar / water proportion module, an air blowing module, a temperature control module, the ventilation detection module, a reminding module, a heating module, a material module, a refrigerating module, a drying module, a crushing module, a filter module, a vibration module, a concentration module and a cooling module to execute related operations through internal analysis and calculation. By accurate control on various parameters, the intelligent preparation method effectively improves stability of a slow-release microelement chelating agent and a slow-release micro-crystallized metal salt mineral powder, so that the method is high in production efficiency, satisfies production demand, reduces labor intensity and provides accurate and reliable detection.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Shifter automatic oil filling device

InactiveCN105090723BImprove efficiencyFacilitate oil filling automationEngine lubricationProduction lineDistributor

Owner:SHENYANG POLYTECHNIC UNIV

Ice cream stick automatic feeding system

ActiveCN111332742BRealize automatic feeding functionPrecise arrangementConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses an automatic feeding system for ice cream sticks, which comprises a feeding bin, which is funnel-shaped, and ice cream sticks are put in from above the feeding bin, and the ice cream sticks slide out from an elongated outlet at the bottom of the feeding bin; Feeding chute, the inclined arrangement of the feeding chute makes the ice cream stick slide down by gravity; the transmission part includes a sprocket, a chain and a loading plate, the loading plate is fixed on the chain, and the starting end of the transmission part is located at the feeding The bottom of the material slideway; the feeding part, including the receiving plate and the discharging slideway; the receiving plate includes two support plates, which are arranged on both sides of the end of the conveying part, and the receiving plate is connected with the discharge slide road. After the ice cream stick is put into the feeding bin, it is transferred to the loading plate of the conveying part through the feeding chute. When the ice cream stick is transported to the end of the conveying part by the conveying part, the two ends of the ice cream stick rest on the receiving plate Along with the continuation of motion of the loading plate, the ice cream sticks are lifted from the loading plate and pushed onto the discharge chute to enter the ice cream stick processing line.

Owner:内蒙古佰邦科技股份有限公司

Axle sleeve automatic assembly detection device

ActiveCN106392631BGuaranteed total assembly timeAutomatic assembly is fastAssembly machinesAssembly lineEngineering

Owner:SHENYANG POLYTECHNIC UNIV

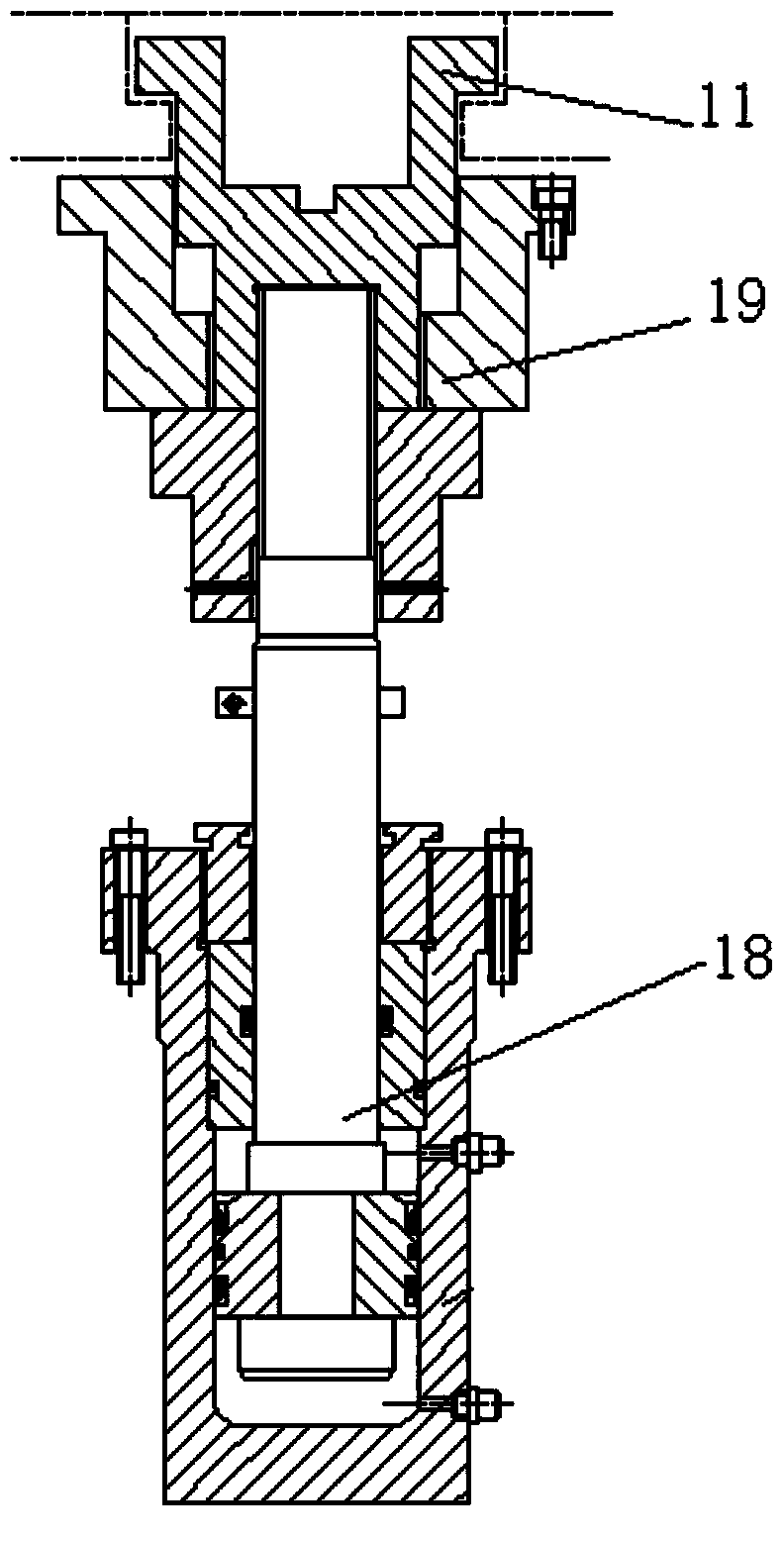

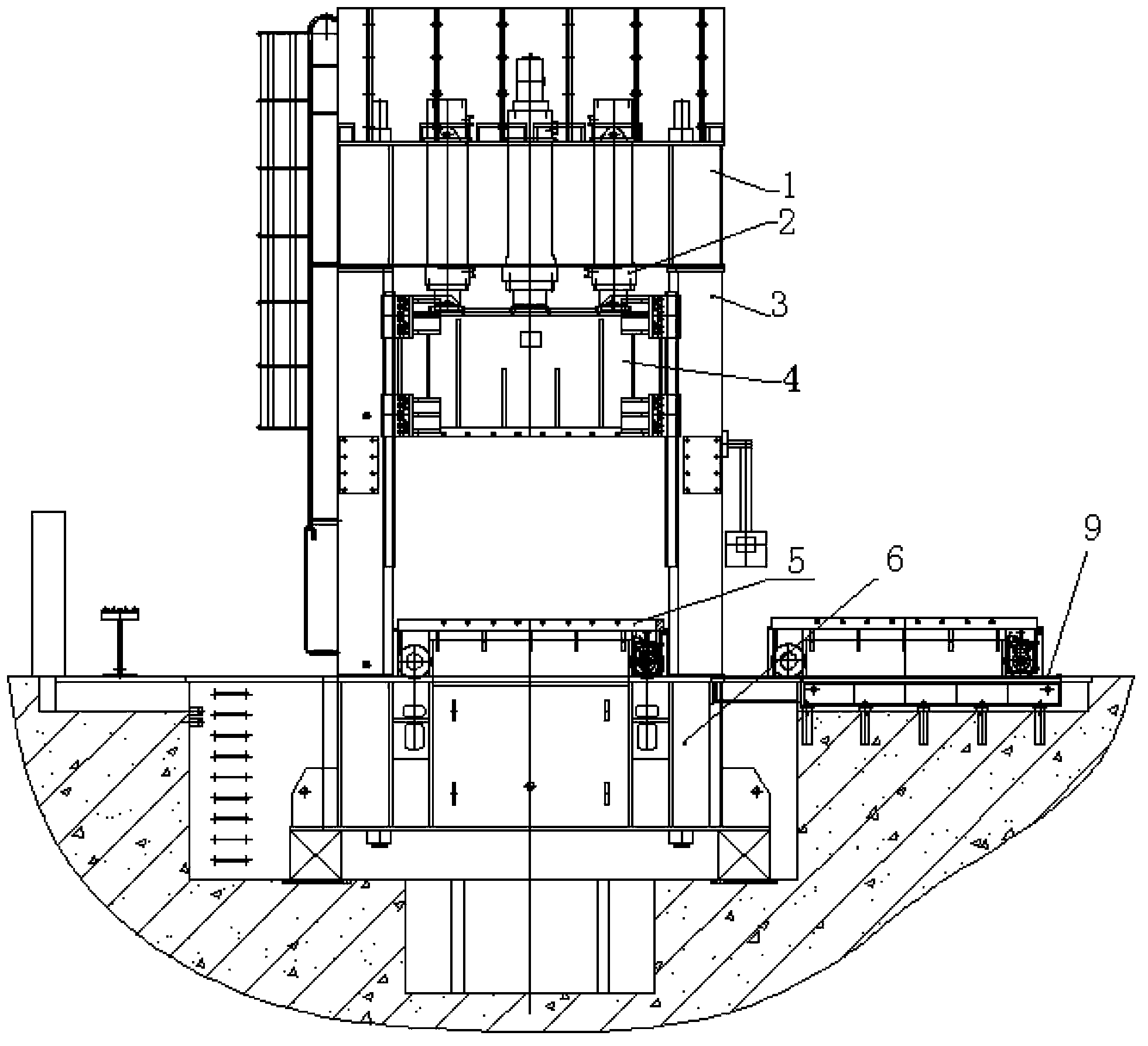

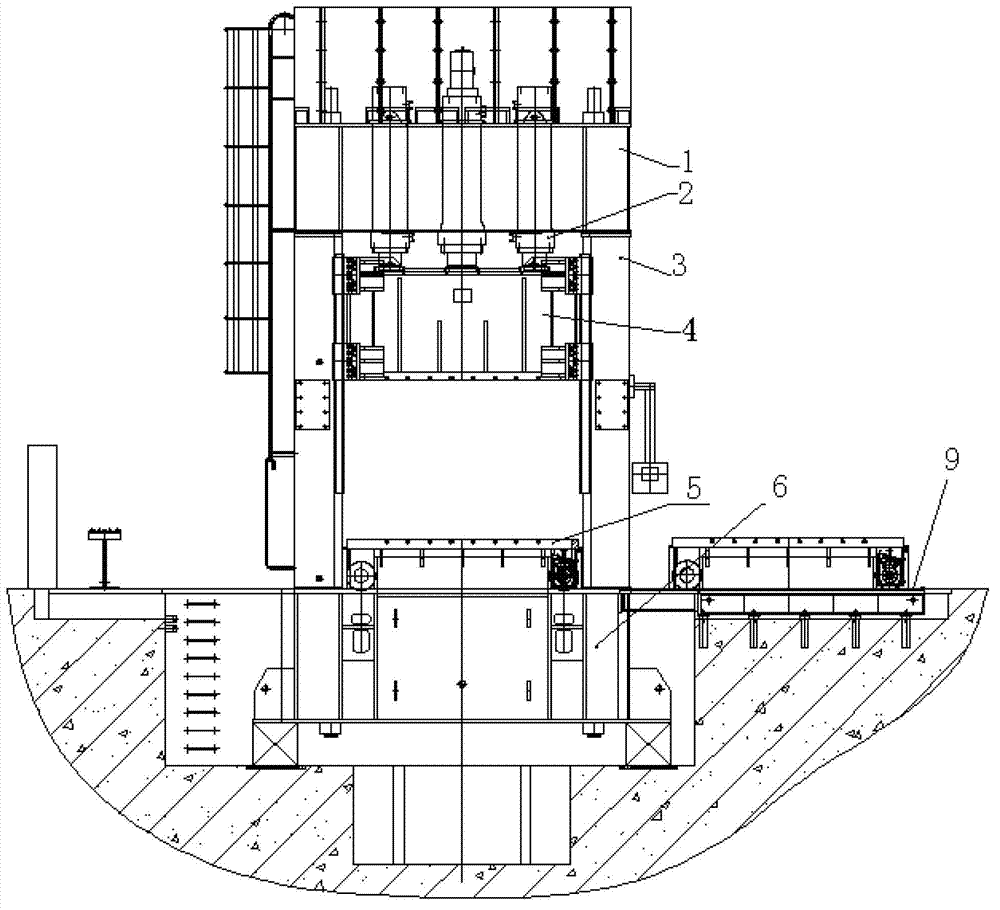

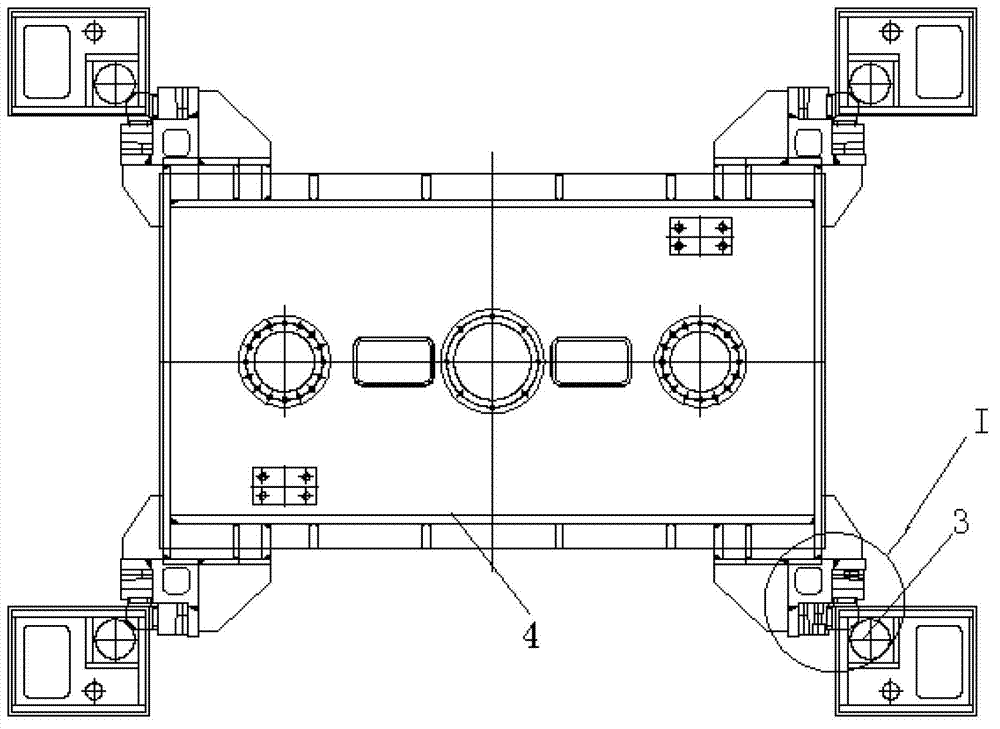

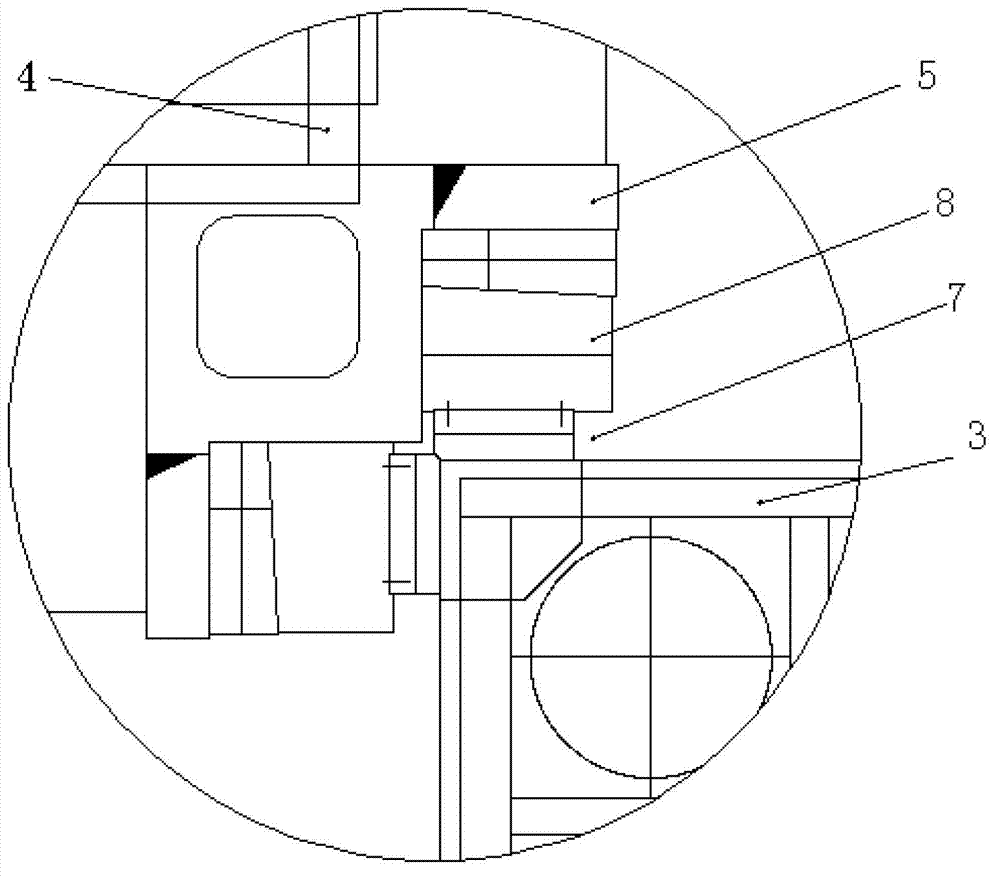

High-speed hydraulic machine

ActiveCN102873247BMeet the production taktReduce frictionForging/hammering/pressing machinesForging press drivesIdler-wheelPiston rod

The invention discloses a high-speed hydraulic machine which comprises a stand column and a frame-type bracket which is formed between and by an upper cross beam and a lower cross beam. A main oil cylinder with a downward piston rod is fixedly installed on the upper cross beam; a slide block is installed at a lower end of the piston rod of the main oil cylinder; the slide block is in slide and guide fit with the stand column through an adjustable guide rail guide mechanism; the adjustable guide rail guide mechanism comprises a slide block guide plate, an adjustable guide plate with a slant angle and a guide plate; the slide block guide plate is welded on the slide block; the guide plate is in slide fit with the stand column; the adjustable guide plate with the slant angle is fitly installed between the slide block guide plate and the guide plate; a sideway-type working table is erected on the lower cross beam; a bottom end of the sideway-type working table is provided with idler wheels; positioning holes matched with the idler wheels are distributed on the lower cross beam; lifting clamping mechanisms which push the idler wheels to move up and down are respectively installed below the positioning holes. The high-speed hydraulic machine can perform high-speed pressing on the hydraulic machine in production, the production efficiency of the high-speed hydraulic machine is about three times of that of an ordinary press, and the high-speed hydraulic machine satisfies continuously developing production rhythm.

Owner:HEFEI METALFORMING MACHINE TOOL

Smart preparation system and method of slow-release microcrystallization metal salt mineral powder

InactiveCN105330418AIncrease productivityMeet the production taktFertilizer mixturesEngineeringMetal salts

The invention discloses a smart preparation system and method of slow-release microcrystallization metal salt mineral powder. The smart preparation system comprises a heating module, a vibration module, a grinding module, a prompt module, a stirring module, a concentration module, a cooling module, a drying module, a PLC, a crushing module and a sensing module. The sensing module is used for sensing whether the raw material feeding amount reaches a certain preset value or not; the PLC controls the heating module, the prompt module, the vibration module, the grinding module, the stirring module, the concentration module, the cooling module, the drying module and the crushing module to execute related operation after internal analysis and calculation according to all sensing values. According to the smart preparation system and method of slow-release microcrystallization metal salt mineral powder, through accurate control over all parameters, the stability of the slow-release microcrystallization metal salt mineral powder can be effectively improved, and the releasing speed of the slow-release microcrystallization metal salt mineral powder after being applied to soil is reduced; the smart preparation system and method have high production efficiency, meet the production tact, lower labor intensity and are accurate and reliable in detection; the preparation efficiency can be effectively improved, the automated degree is high, operation is convenient, and resources are saved.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

High-speed hydraulic machine

ActiveCN102873247AMeet the production taktReduce frictionForging/hammering/pressing machinesForging press drivesSlant angleEngineering

The invention discloses a high-speed hydraulic machine which comprises a stand column and a frame-type bracket which is formed between and by an upper cross beam and a lower cross beam. A main oil cylinder with a downward piston rod is fixedly installed on the upper cross beam; a slide block is installed at a lower end of the piston rod of the main oil cylinder; the slide block is in slide and guide fit with the stand column through an adjustable guide rail guide mechanism; the adjustable guide rail guide mechanism comprises a slide block guide plate, an adjustable guide plate with a slant angle and a guide plate; the slide block guide plate is welded on the slide block; the guide plate is in slide fit with the stand column; the adjustable guide plate with the slant angle is fitly installed between the slide block guide plate and the guide plate; a sideway-type working table is erected on the lower cross beam; a bottom end of the sideway-type working table is provided with idler wheels; positioning holes matched with the idler wheels are distributed on the lower cross beam; lifting clamping mechanisms which push the idler wheels to move up and down are respectively installed below the positioning holes. The high-speed hydraulic machine can perform high-speed pressing on the hydraulic machine in production, the production efficiency of the high-speed hydraulic machine is about three times of that of an ordinary press, and the high-speed hydraulic machine satisfies continuously developing production rhythm.

Owner:HEFEI METALFORMING MACHINE TOOL

A shoe pick-up and delivery device

ActiveCN109549291BNo mechanical interferenceSo as not to damageShoemaking devicesSimulationMechanical engineering

The invention discloses a pick-up and delivery device for shoes, which comprises: a grabbing mechanism for clamping or loosening shoes at a work station; a vertical lifting mechanism for raising and lowering the grabbing mechanism; A planting mechanism is used to make the vertical lifting mechanism move back and forth, so that the grabbing mechanism can pick and place shoes between the front and rear stations. The device of the present invention is separated from the work station according to the upper and lower layers to ensure that no space is occupied on the work station. It can not only meet the needs of shoe last clamping with different heights and widths, but also meet the production rhythm, and the control is simple and the cost is low. .

Owner:SHANGHAI FORESIGHT AUTOMATION EQUIP CO LTD

Bulb lamp online automatic fast electric parameter detection device and detection method

The invention discloses a bulb lamp on-line automatic rapid electrical parameter detecting device and method which are used for detecting electrical parameters of a bulb lamp. The bulb lamp is provided with a bulb lamp live line electrode and a bulb lamp null line electrode, the detecting device comprises an electrical parameter tester, a PLC connected with the parameter tester through a bus, a rotary table station, a power-on tool manipulator and a relay. The power-on tool manipulator is connected with the rotary table station and comprises a straight-line motion mechanism and a power-on tool installed on the straight-line motion mechanism, and the output end of the power-on tool is connected with the electrical parameter tester. The input end of the relay is connected with the PLC, and the output end of the relay is connected with the input end of the power-on tool. The bulb lamp on-line automatic rapid electrical parameter detecting device and method can avoid problems brought by manual testing, also automatically perform electrical parameter testing and result judging on the bulb lamp and achieve rapid detection on the electrical parameters to meet the production takt of an overall assembling line.

Owner:SHANGHAI RADIO EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com