Axle sleeve automatic assembly detection device

A technology of automatic assembly and detection device, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of poor assembly reliability and low work efficiency, avoid direct damage, occupy less space, and improve the degree of automated assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

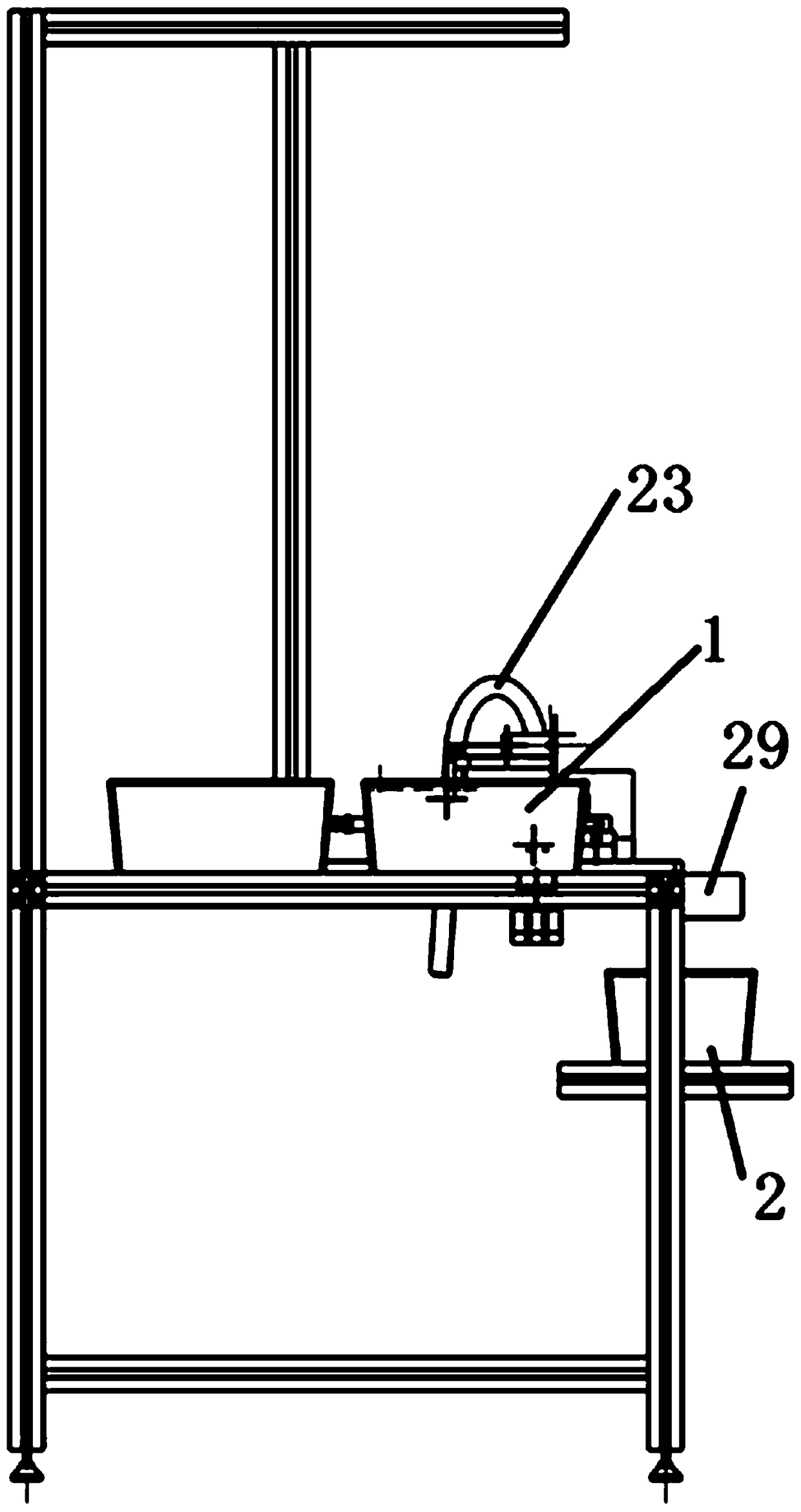

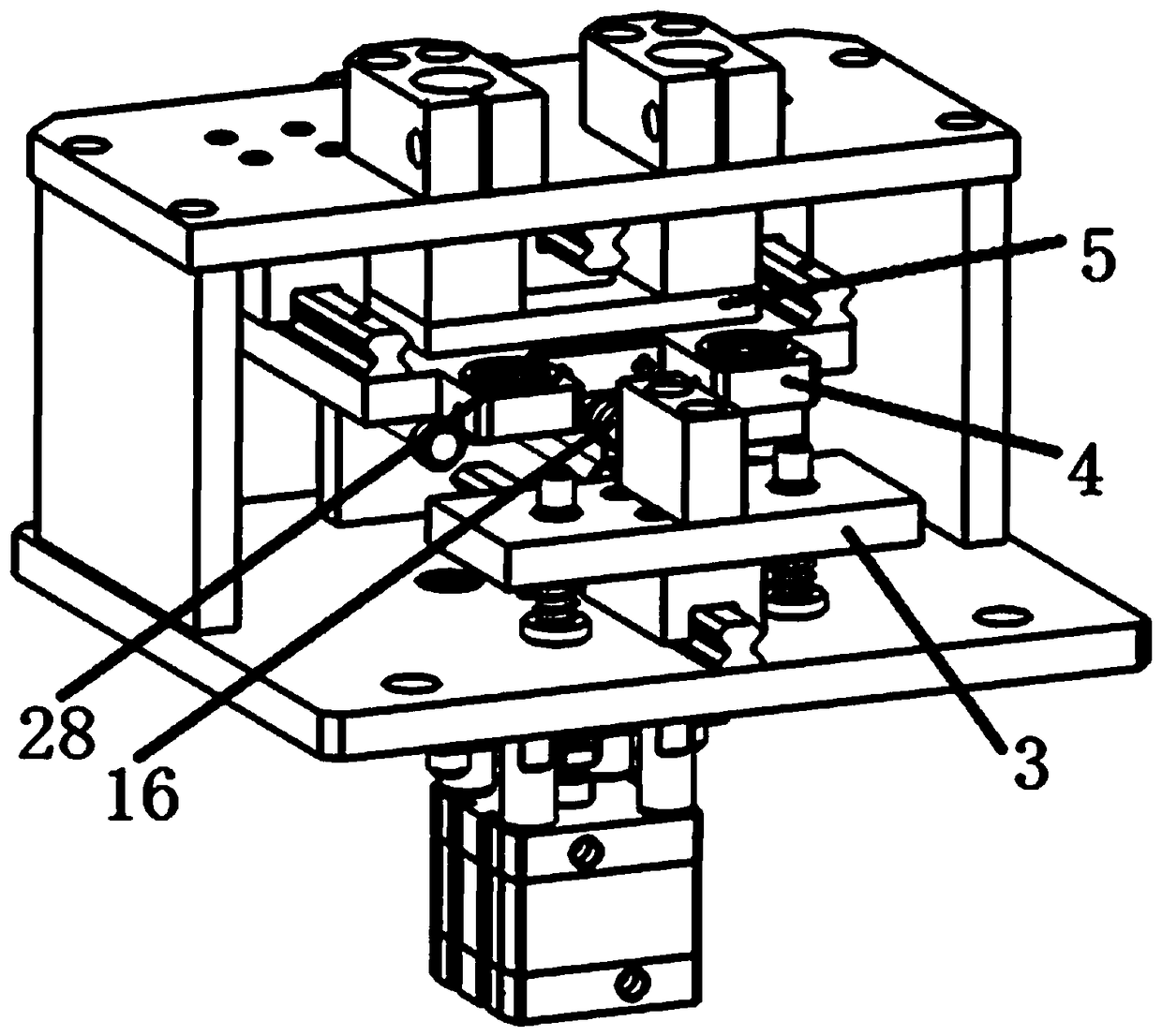

[0028] As shown in the accompanying drawings, the invention is a shaft sleeve automatic assembly detection device, which is characterized in that: it includes a shaft sleeve automatic assembly work platform 1, an inner shaft sleeve and an elastic body arranged on the shaft sleeve automatic assembly work platform 1 The moving device 3 and the outer shaft sleeve moving device 4 are provided with a receiving device 2 under the shaft sleeve automatic assembly work platform 1, and a position detection device is provided at the right side of the shaft sleeve automatic assembly work platform 1 Sensor 29 ; the shaft sleeve automatic assembly detection device also includes an air pipe 23 for collecting the assembled shaft sleeves into the receiving device 2 .

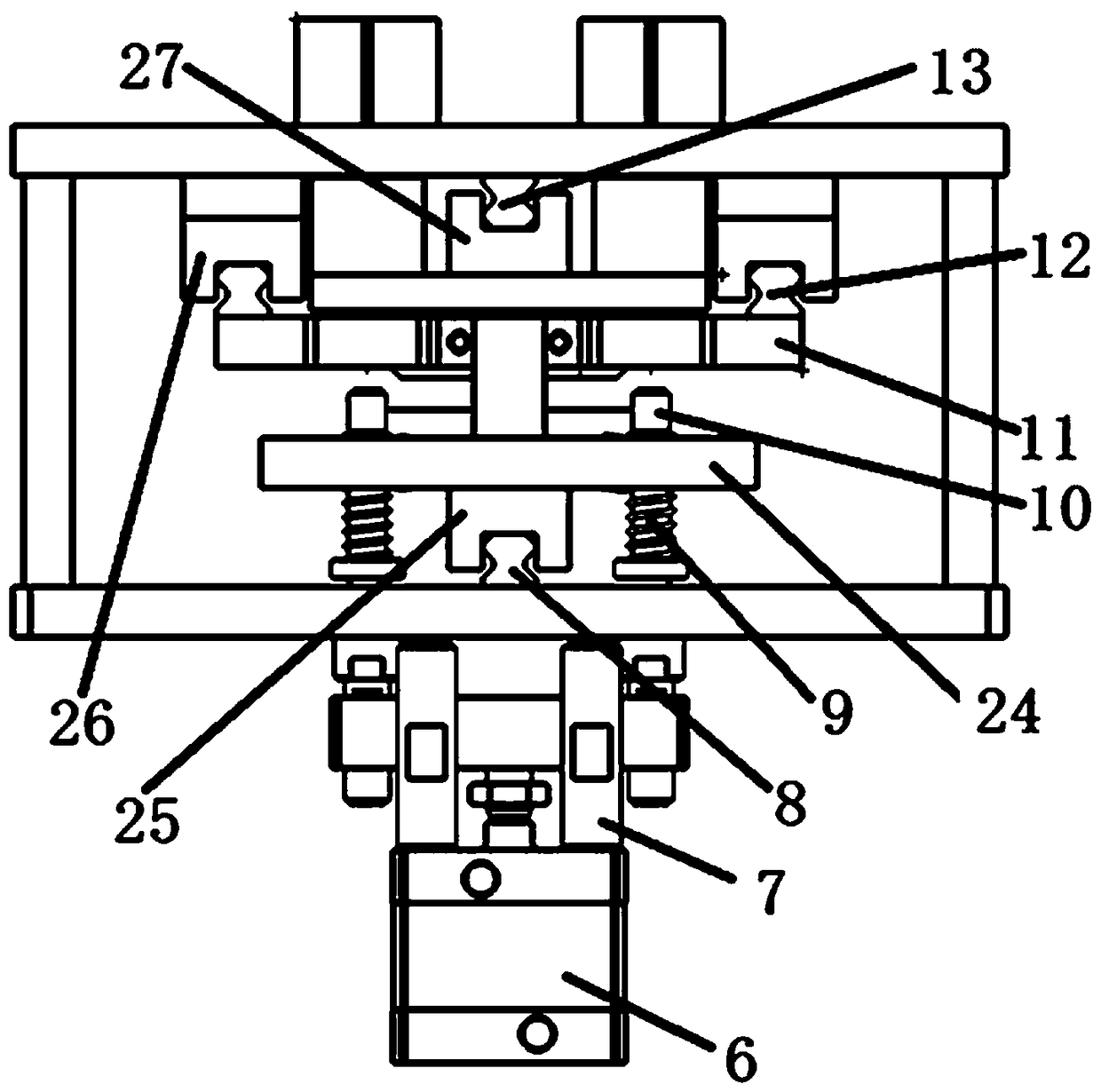

[0029] As a preferred solution of the present invention, the inner shaft sleeve and elastic body moving device 3 include a bottom panel 24, a compression spring 9, a shaft 10, a return spring 16, a hollow shaft 7, a compression c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com