Patents

Literature

278results about "Resistive element windings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

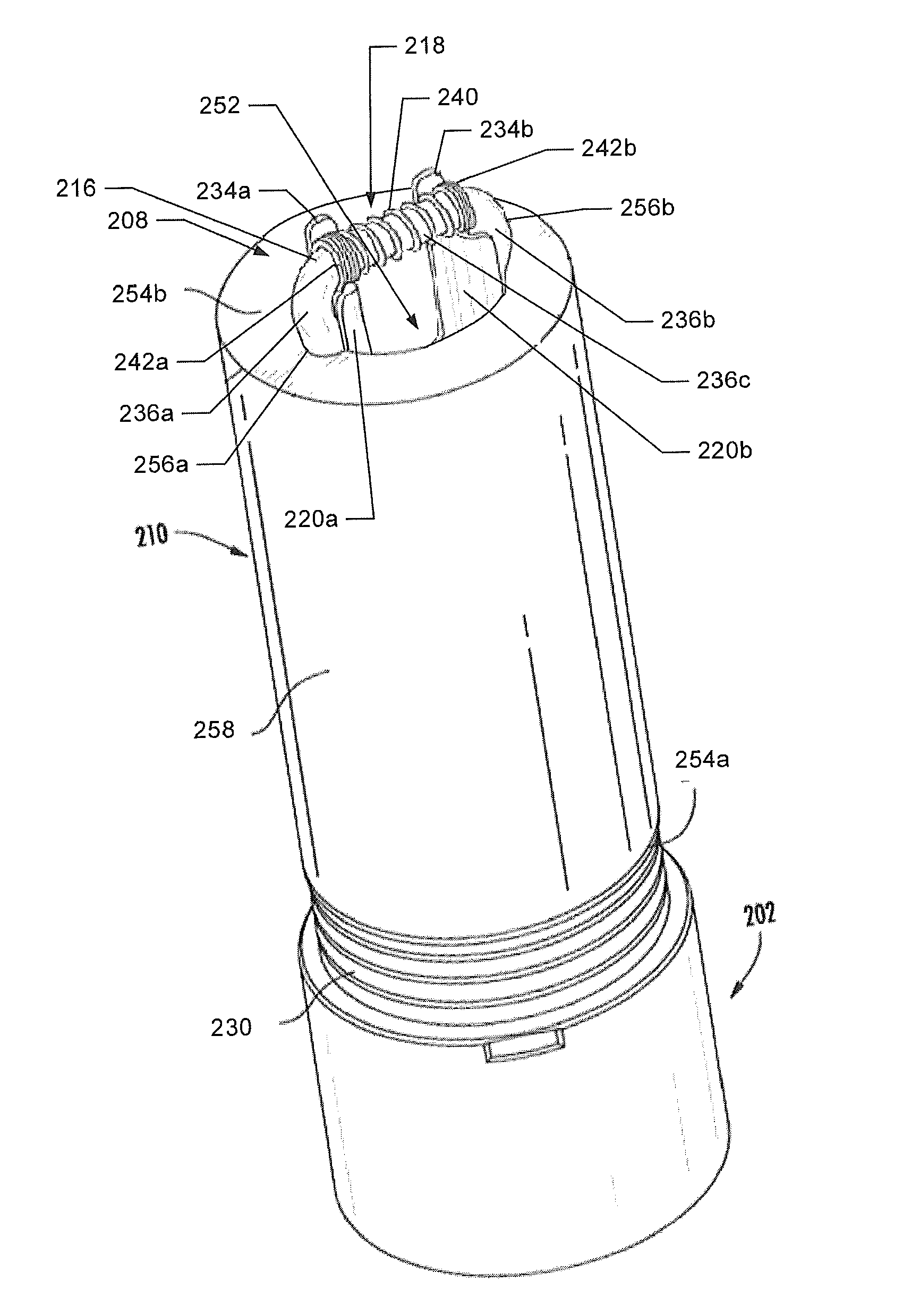

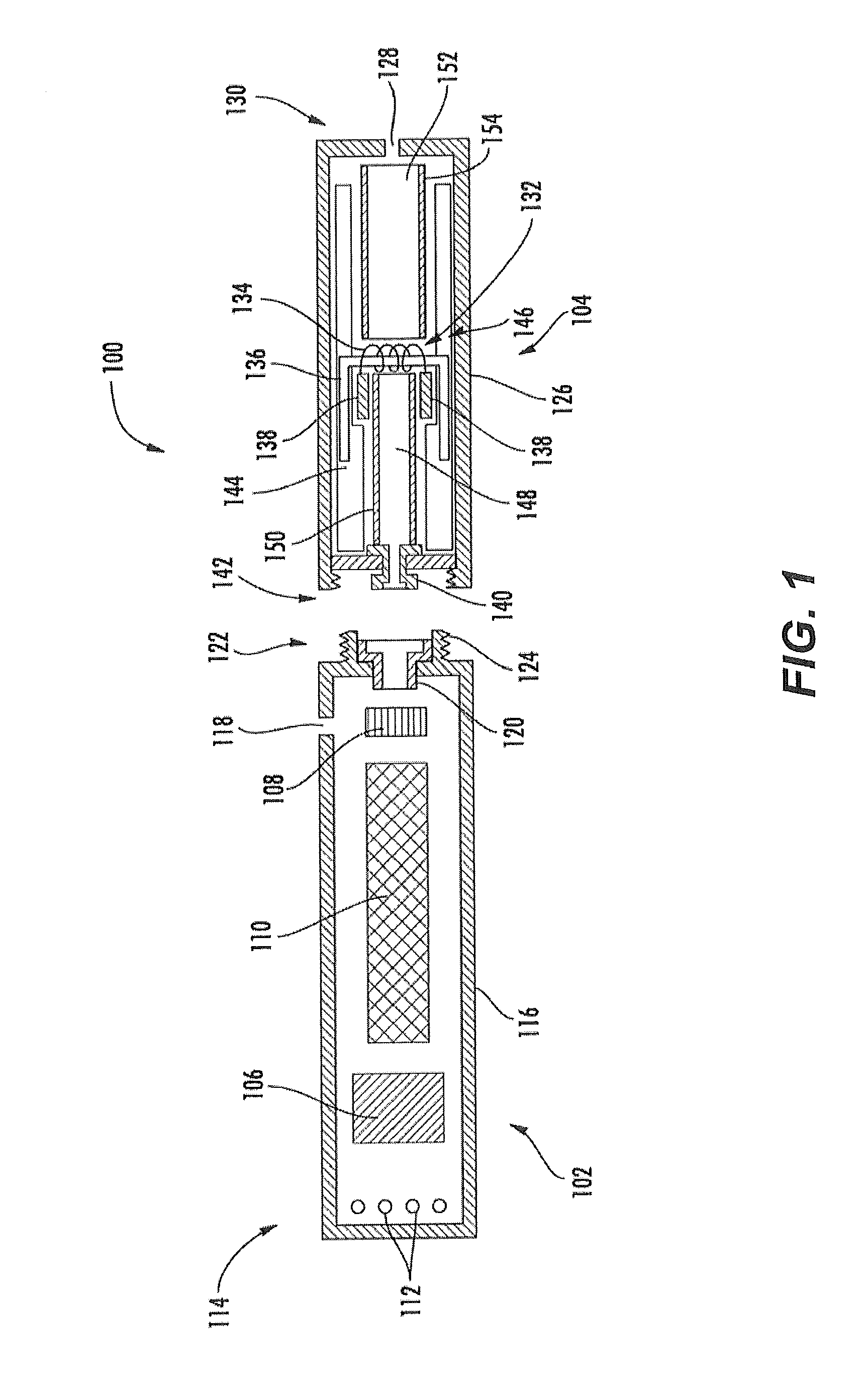

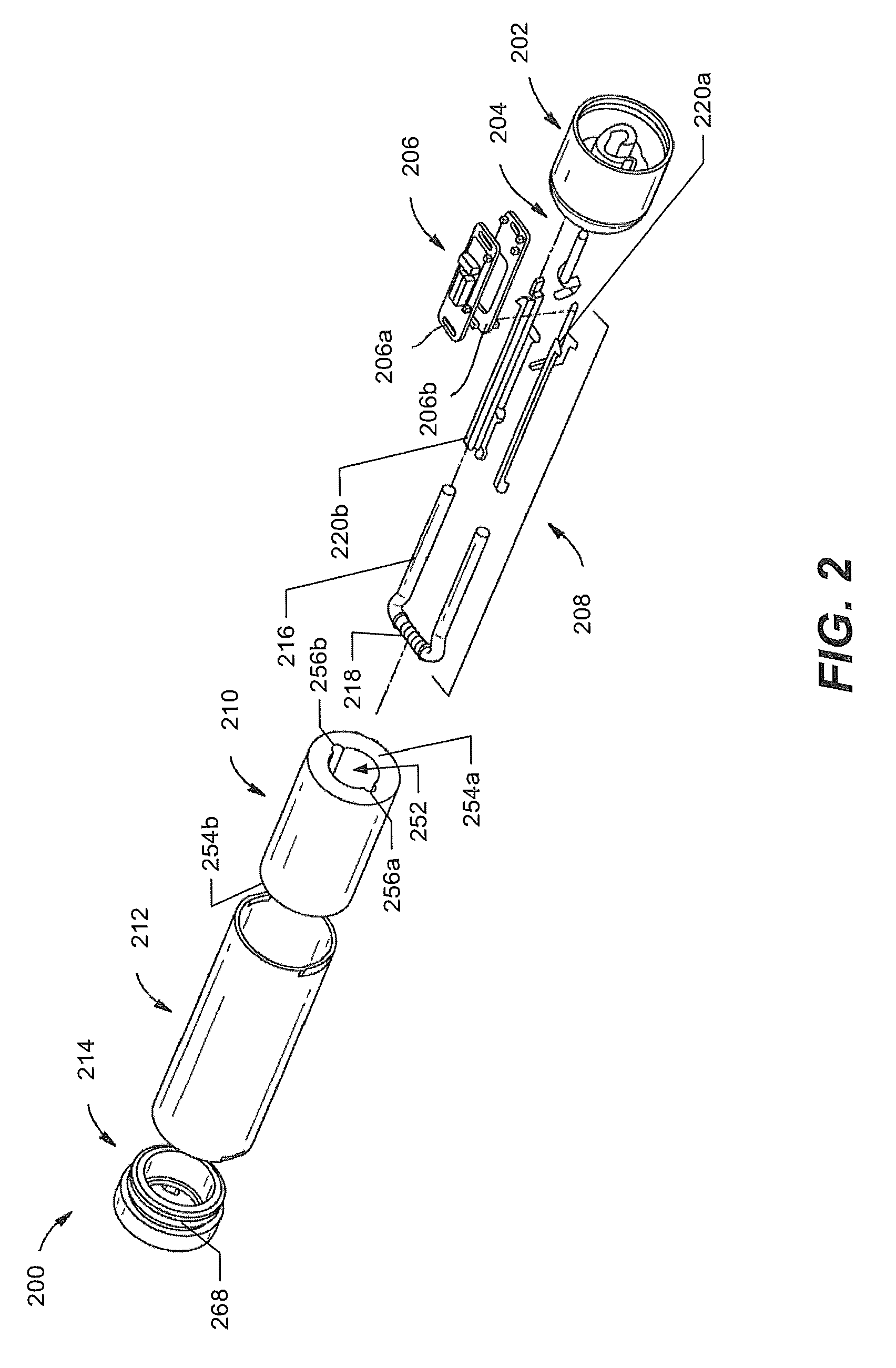

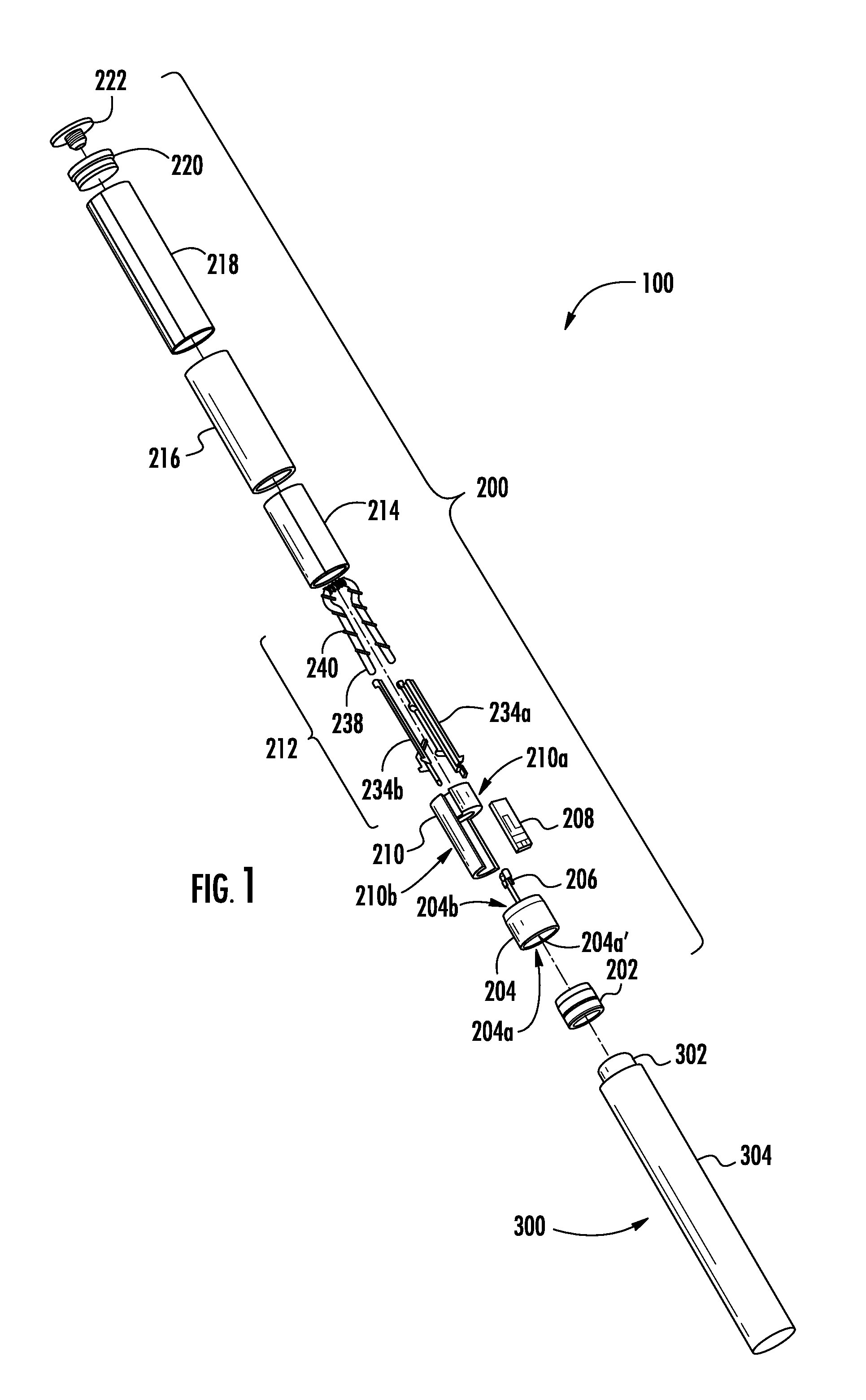

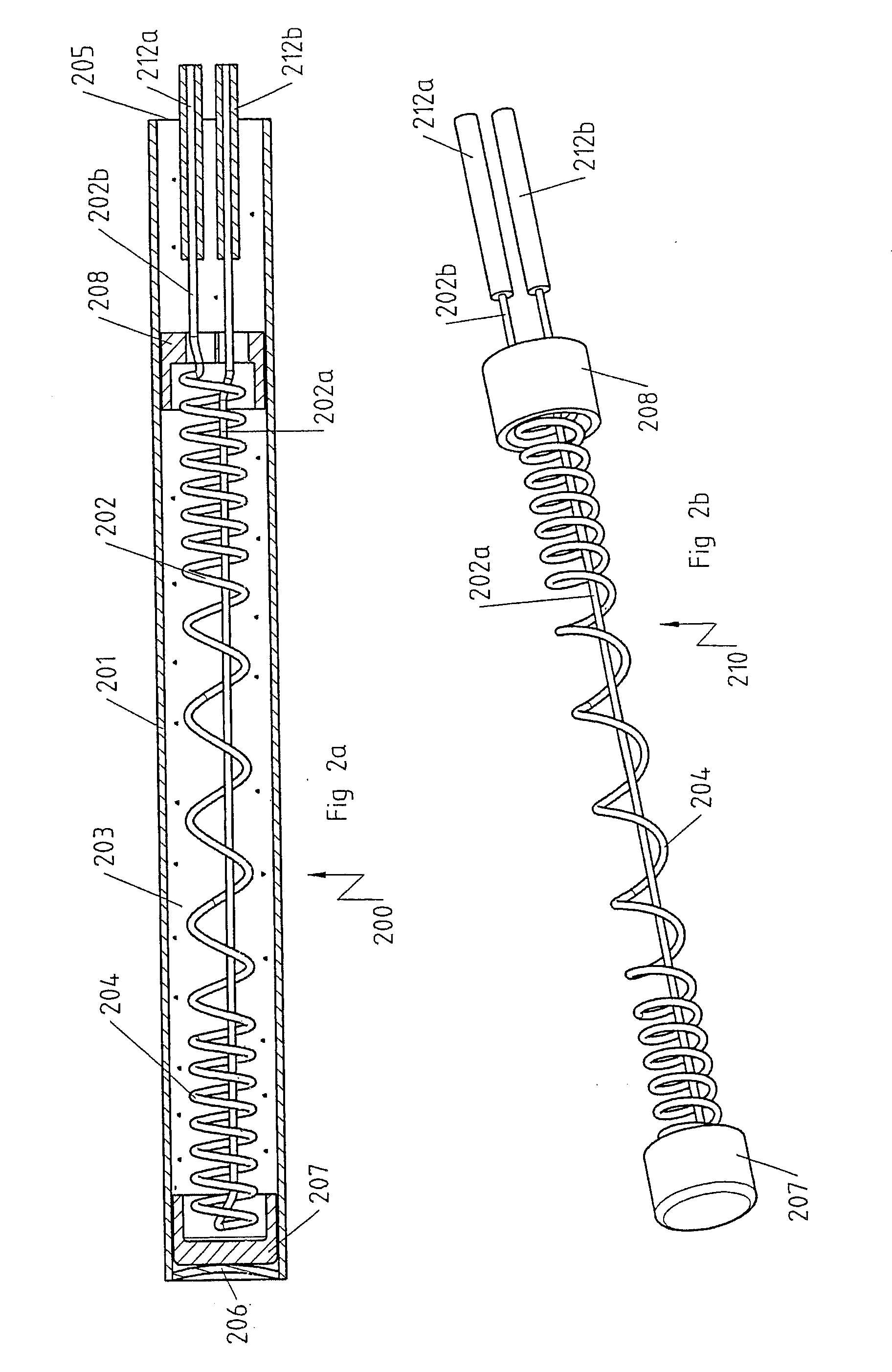

Atomizer for an aerosol delivery device and related input, aerosol production assembly, cartridge, and method

The present disclosure relates to atomizers for an aerosol delivery device such as a smoking article. The atomizer may include a liquid transport element and a wire extending along at least a portion of a longitudinal length thereof. The wire may define contact portions configured to engage heater terminals and a heating portion configured to produce heat. The heating portion may include a variable coil spacing. In other atomizers, the wire may extend at least partially through the liquid transport element proximate the contact portions. Related inputs, cartridges, aerosol production assemblies, and methods of forming atomizers are also provided.

Owner:RAI STRATEGIC HLDG INC

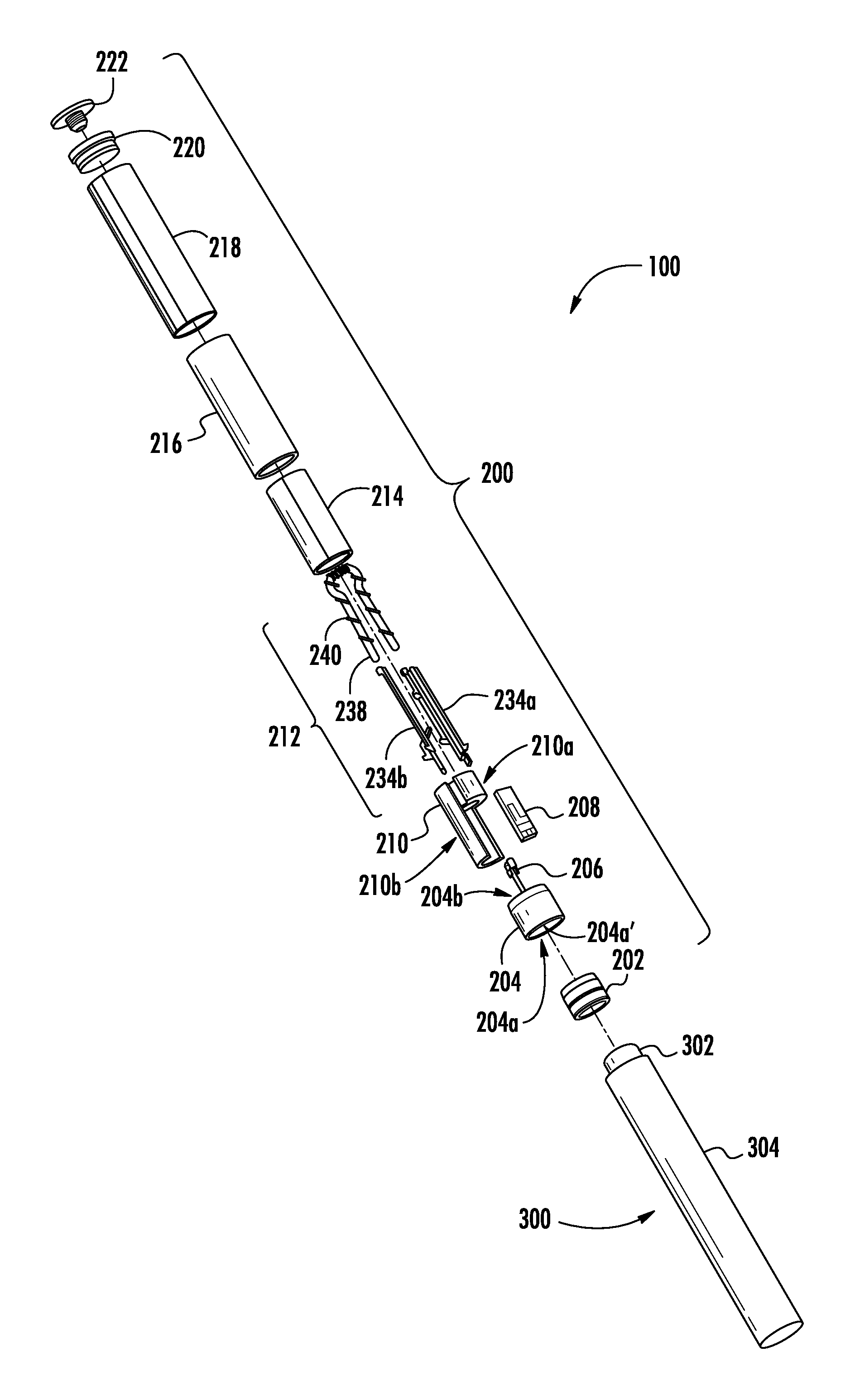

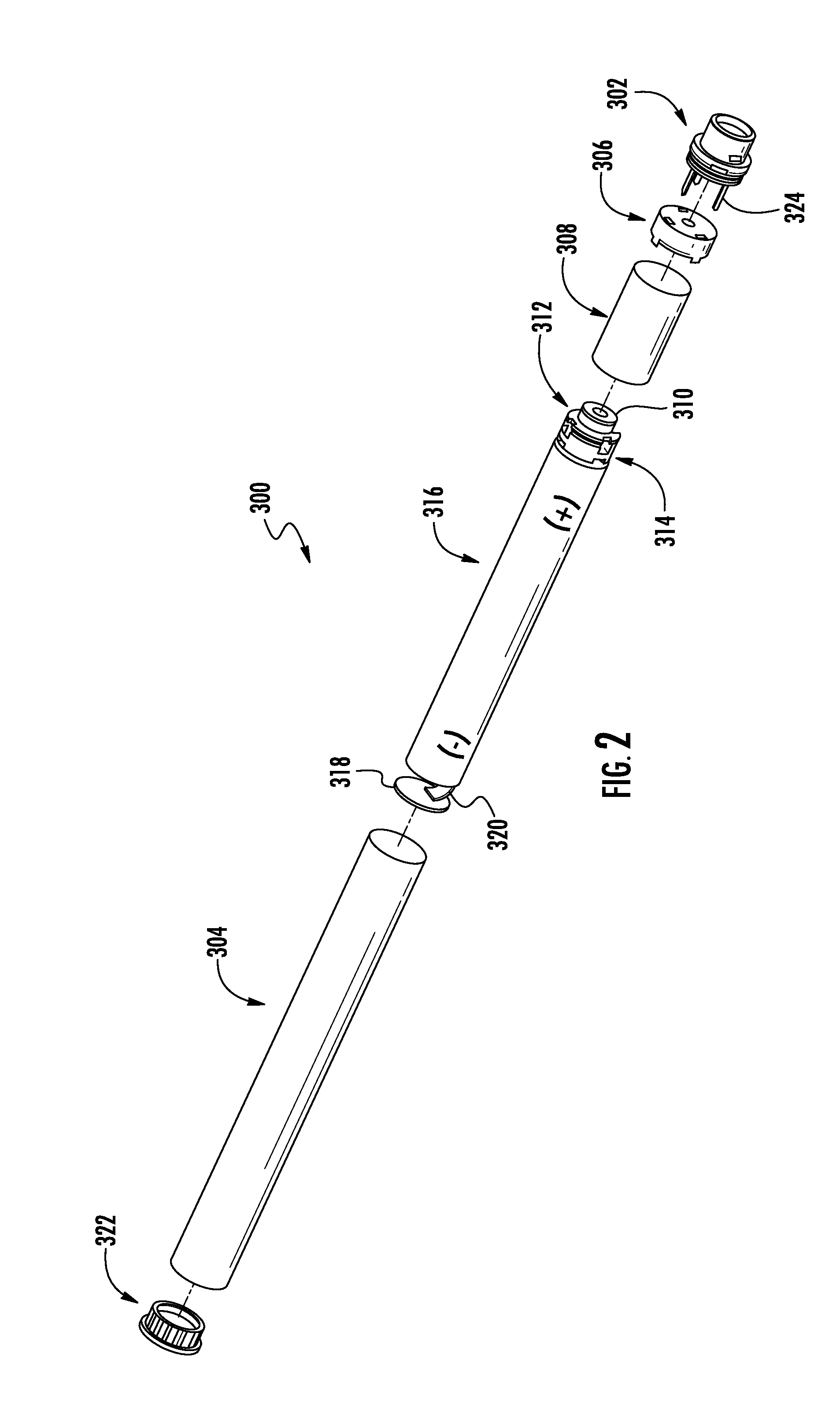

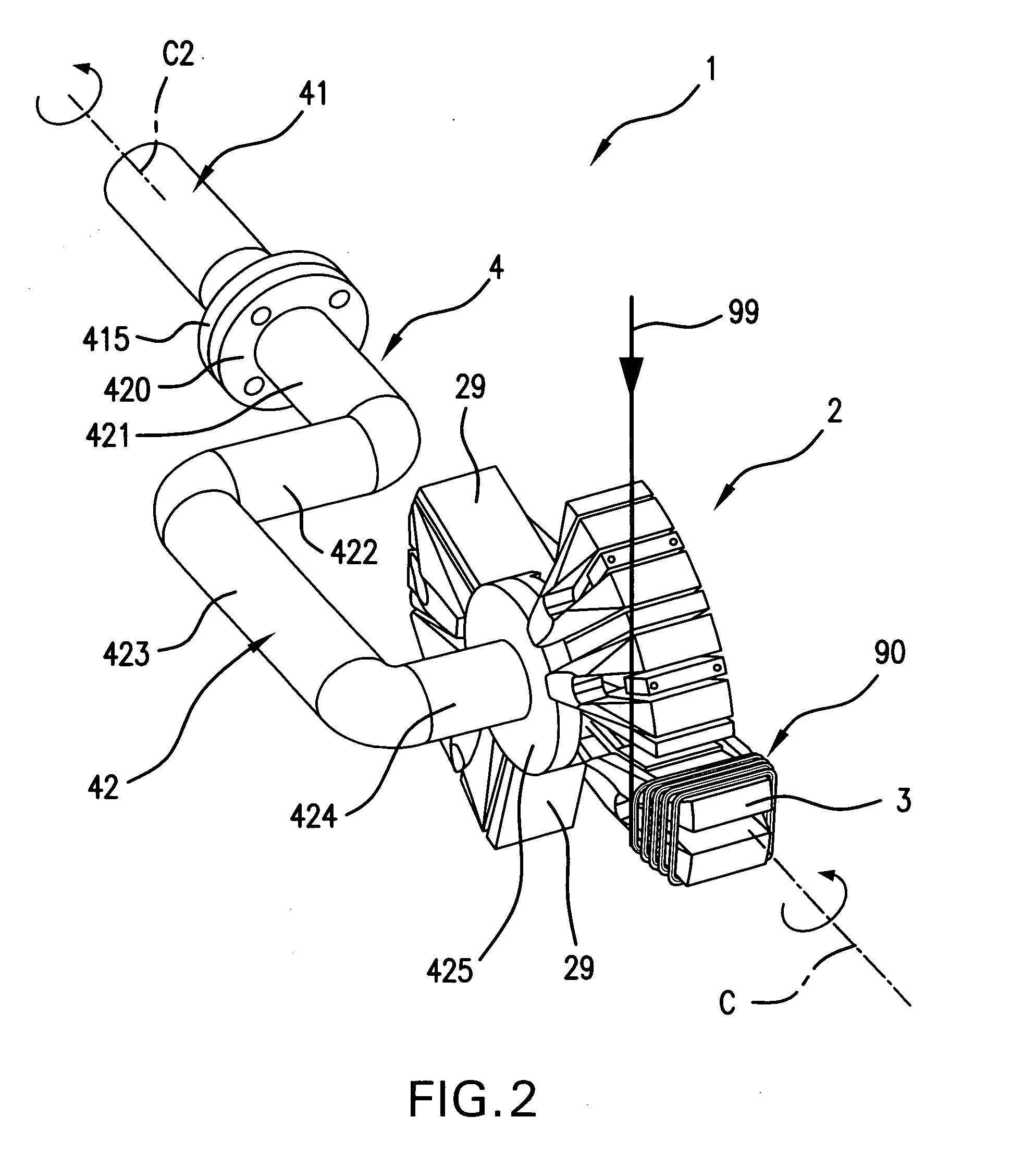

Method for Assembling a Cartridge for a Smoking Article

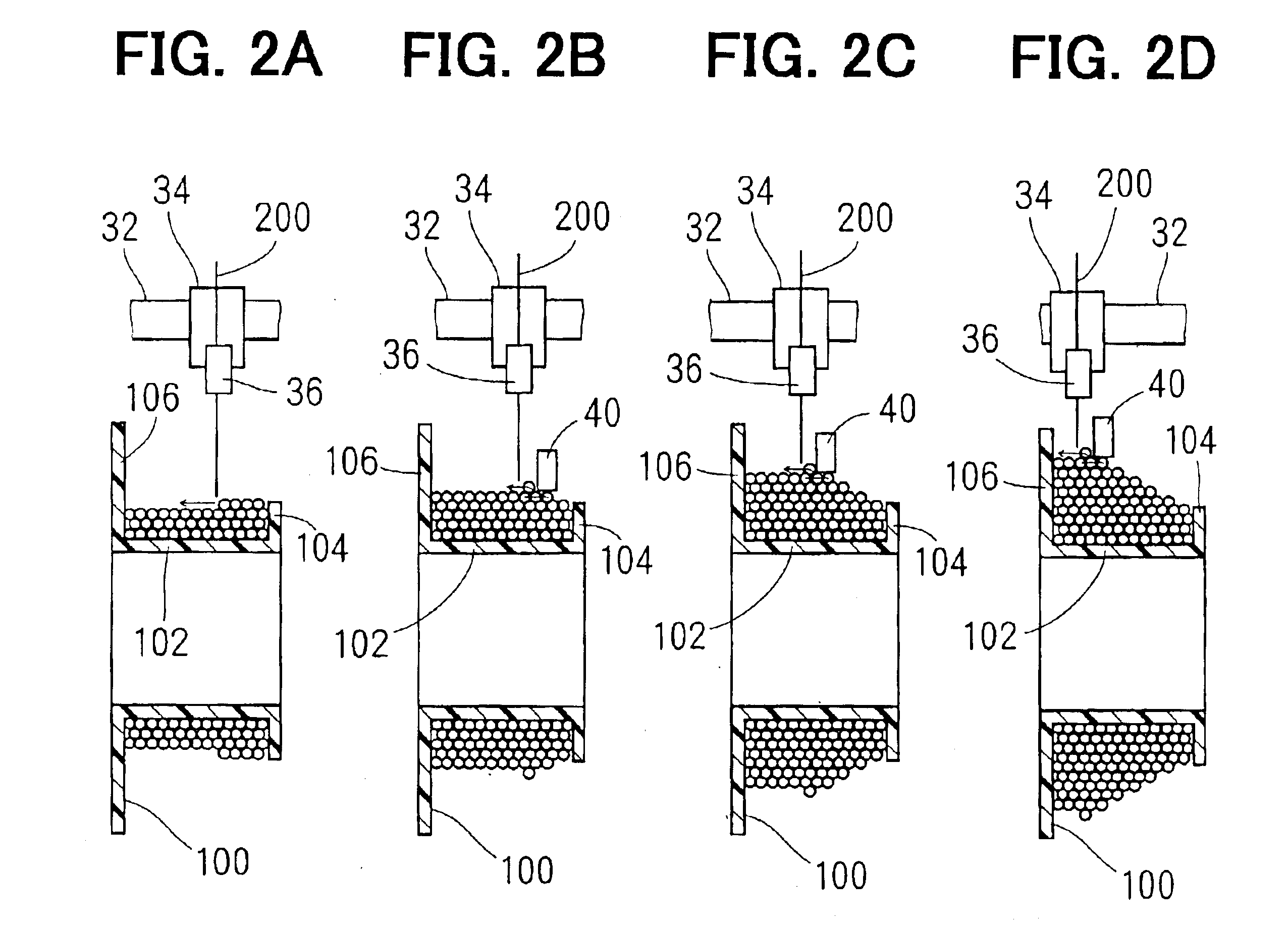

ActiveUS20150223522A1Easy to insertMonorailsCigarette manufactureAerosol deliveryMechanical engineering

The present disclosure relates to systems, apparatuses, and methods for assembling cartridges for aerosol delivery devices. The cartridges may be assembled by transporting carriages between various substations at which parts are added to a base. In another assembly method, the base may be moved between a plurality of robots which direct the base downwardly into contact with components to couple the components therewith. An inspection system may inspect the cartridges at various stages of completion.

Owner:RAI STRATEGIC HLDG INC

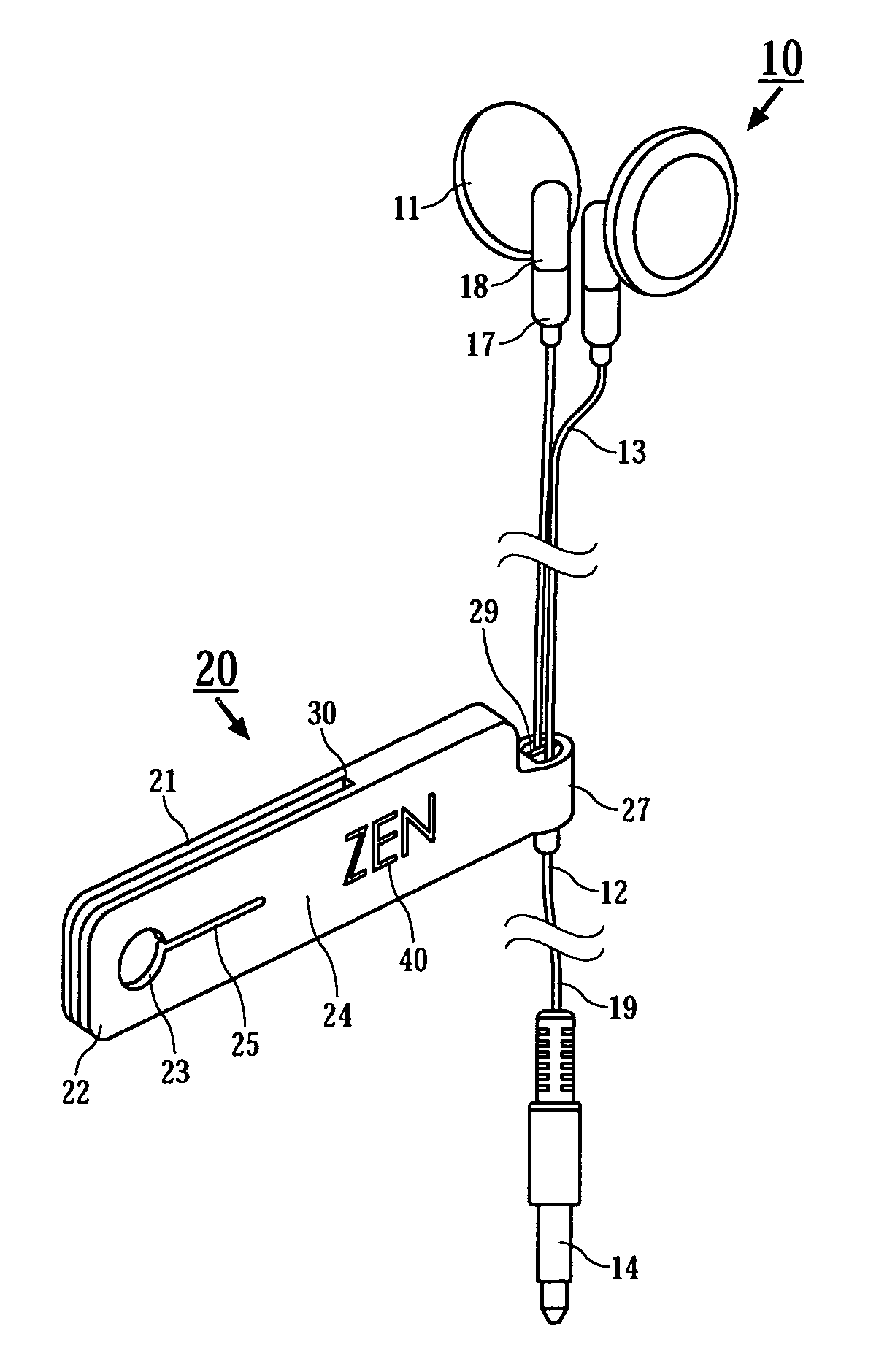

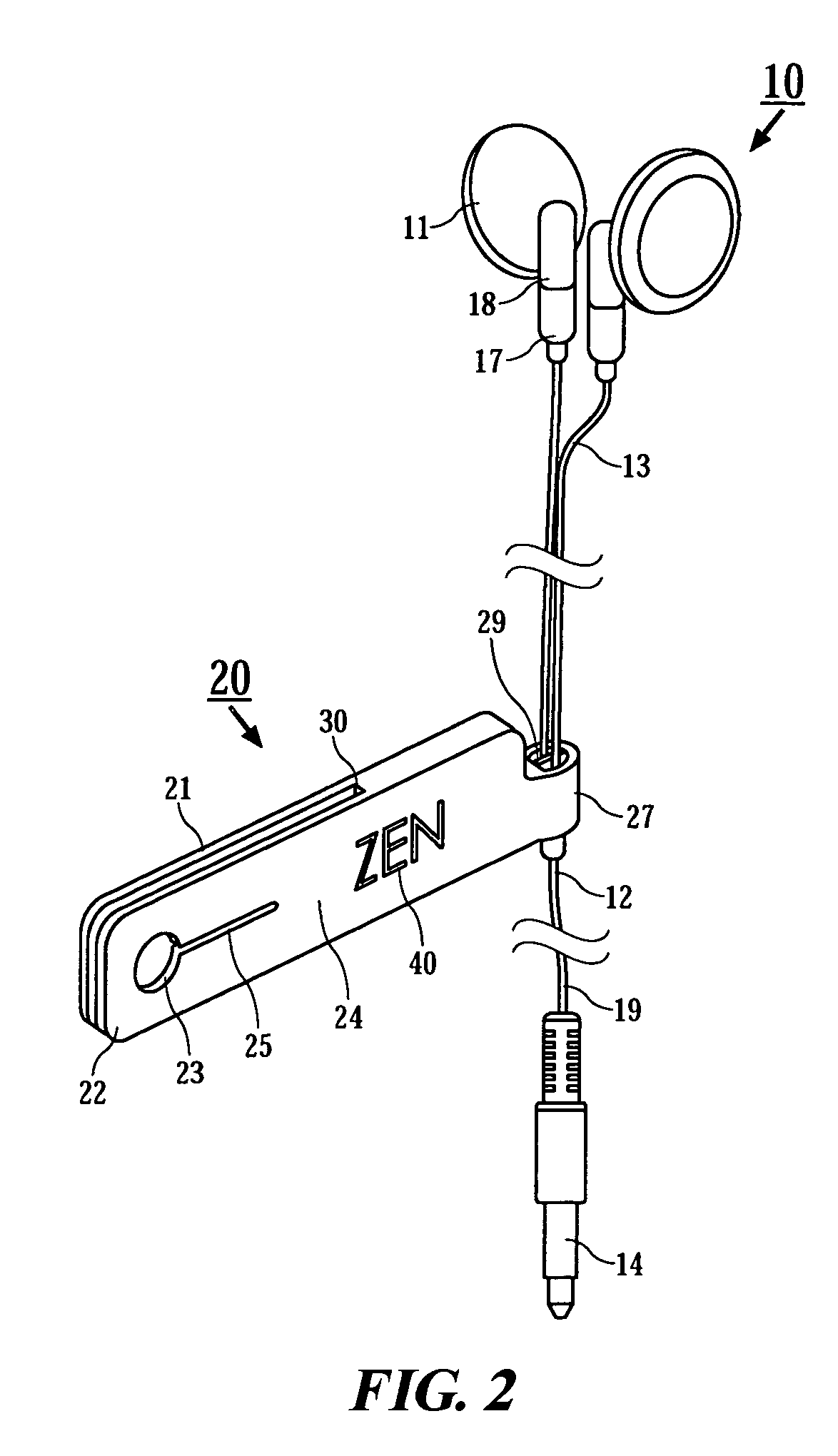

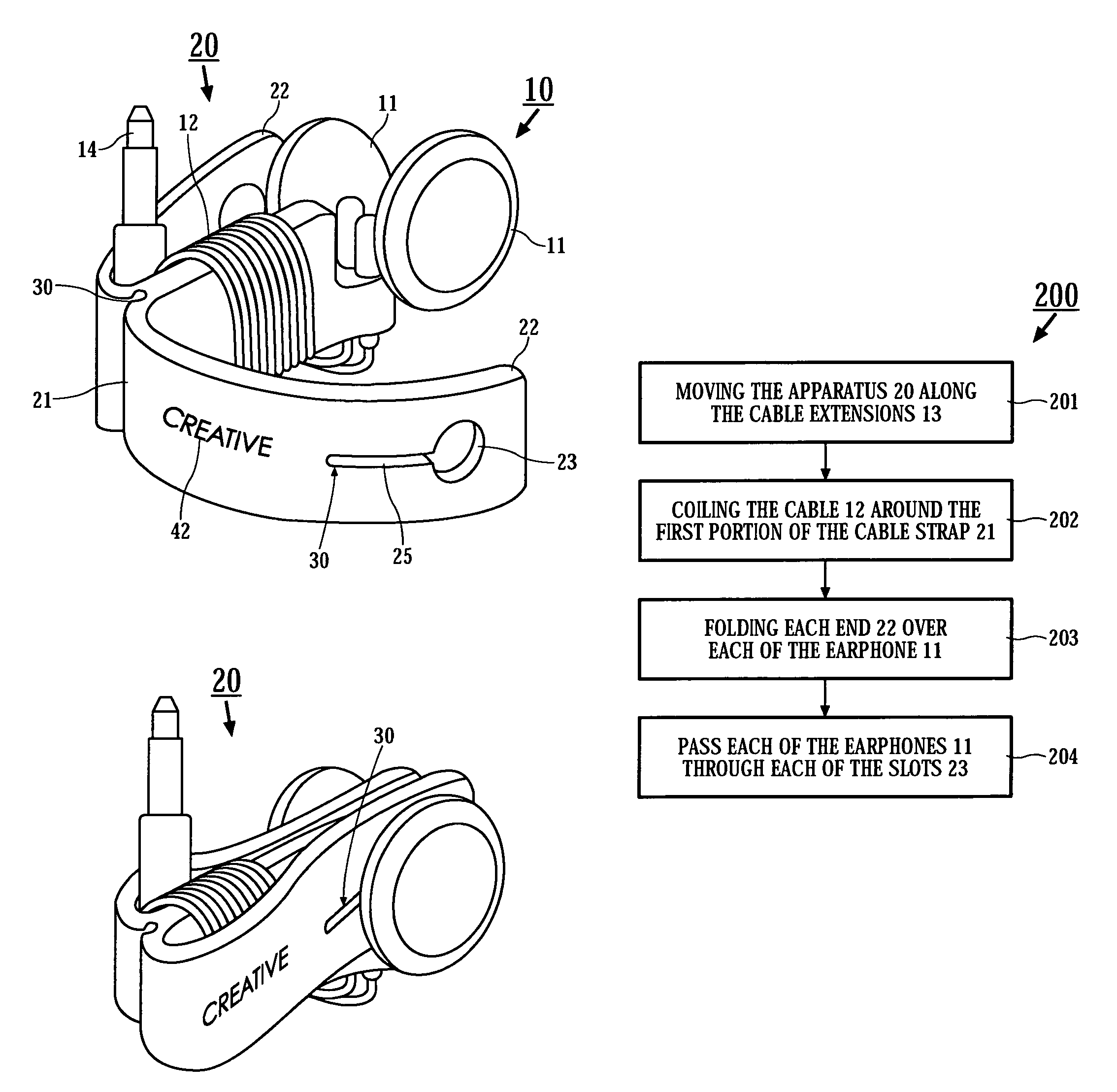

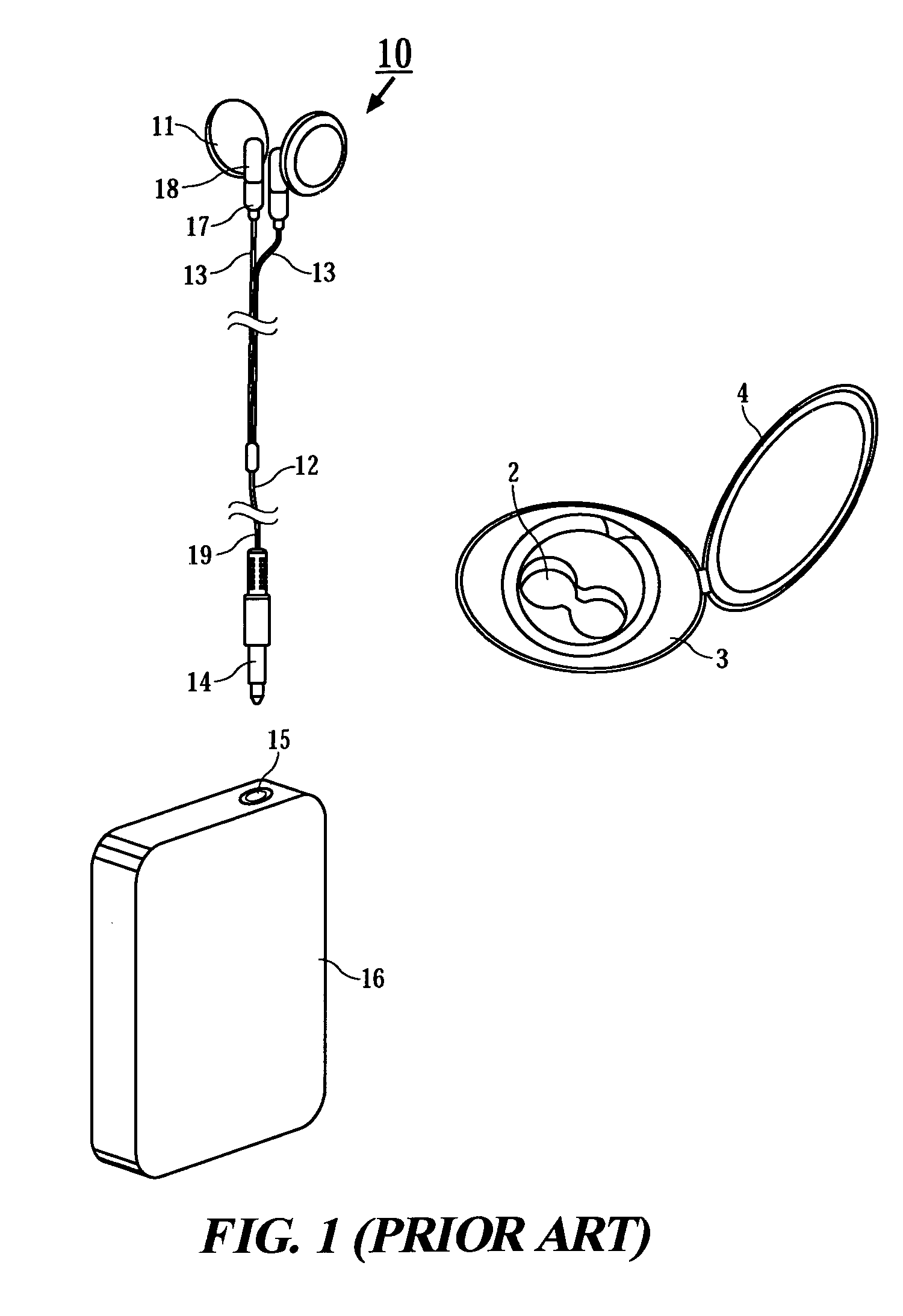

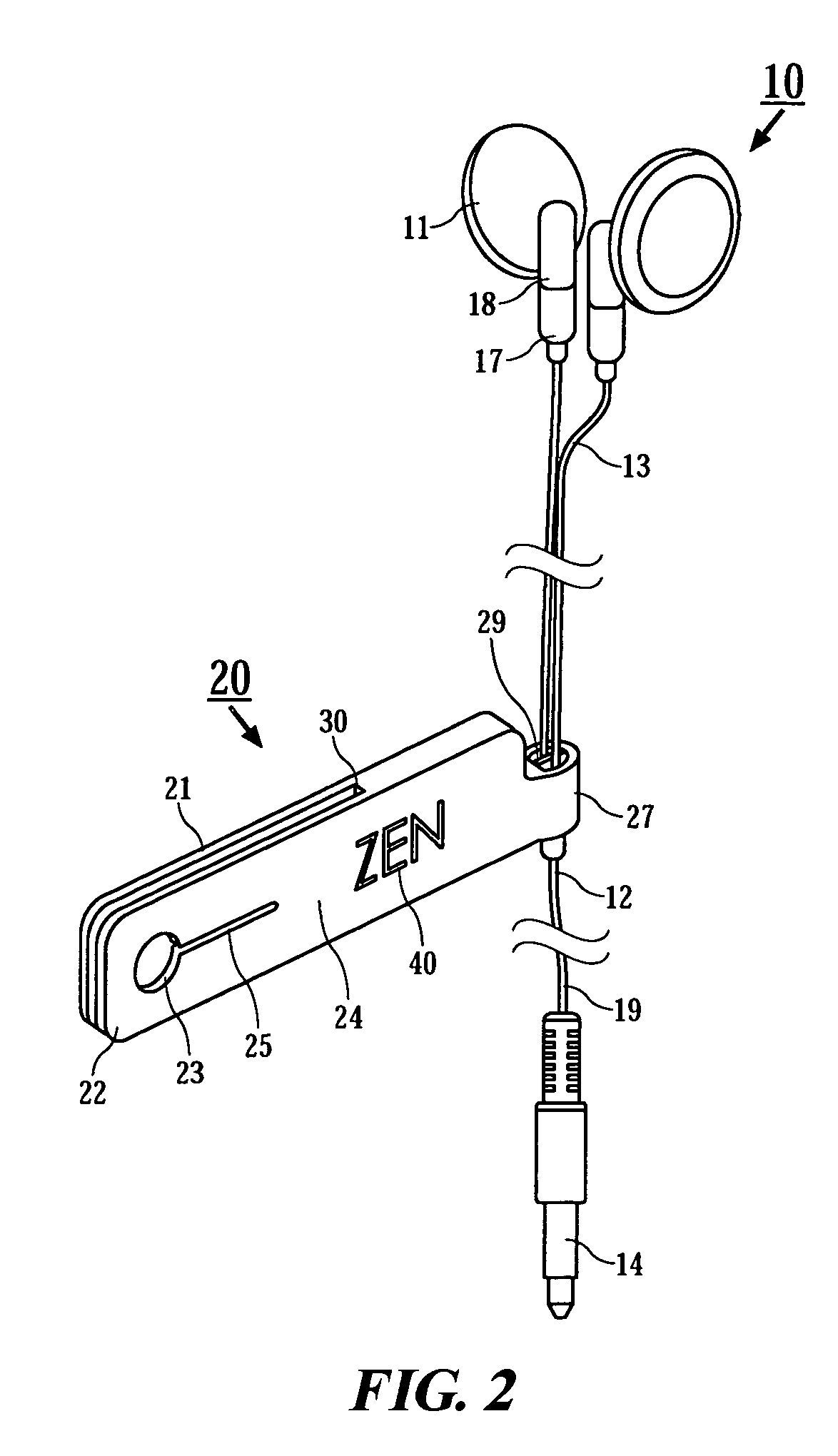

Cable coiling method and apparatus

Owner:CREATIVE TECH CORP

Cable coiling method and apparatus

Owner:CREATIVE TECH CORP

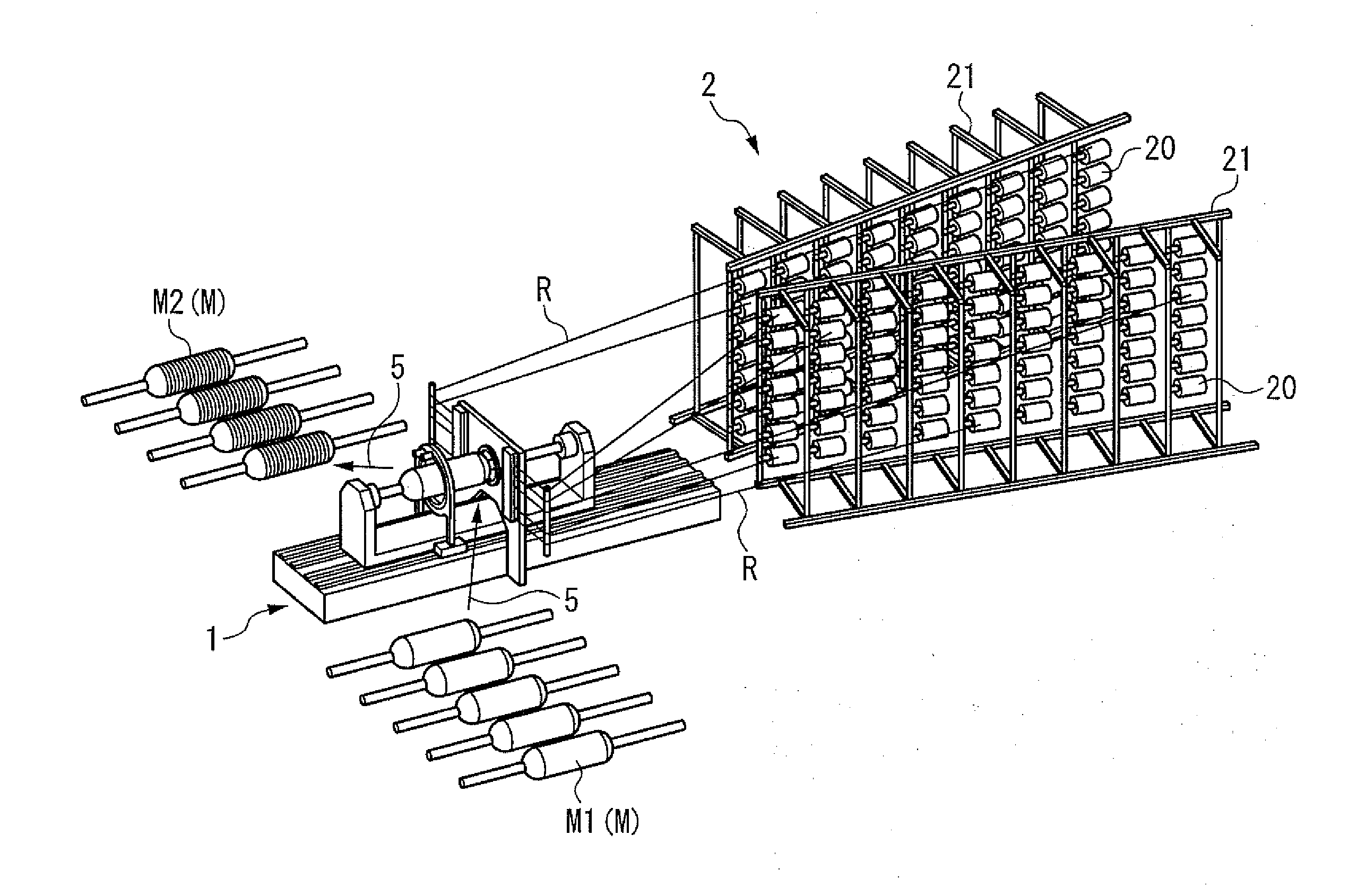

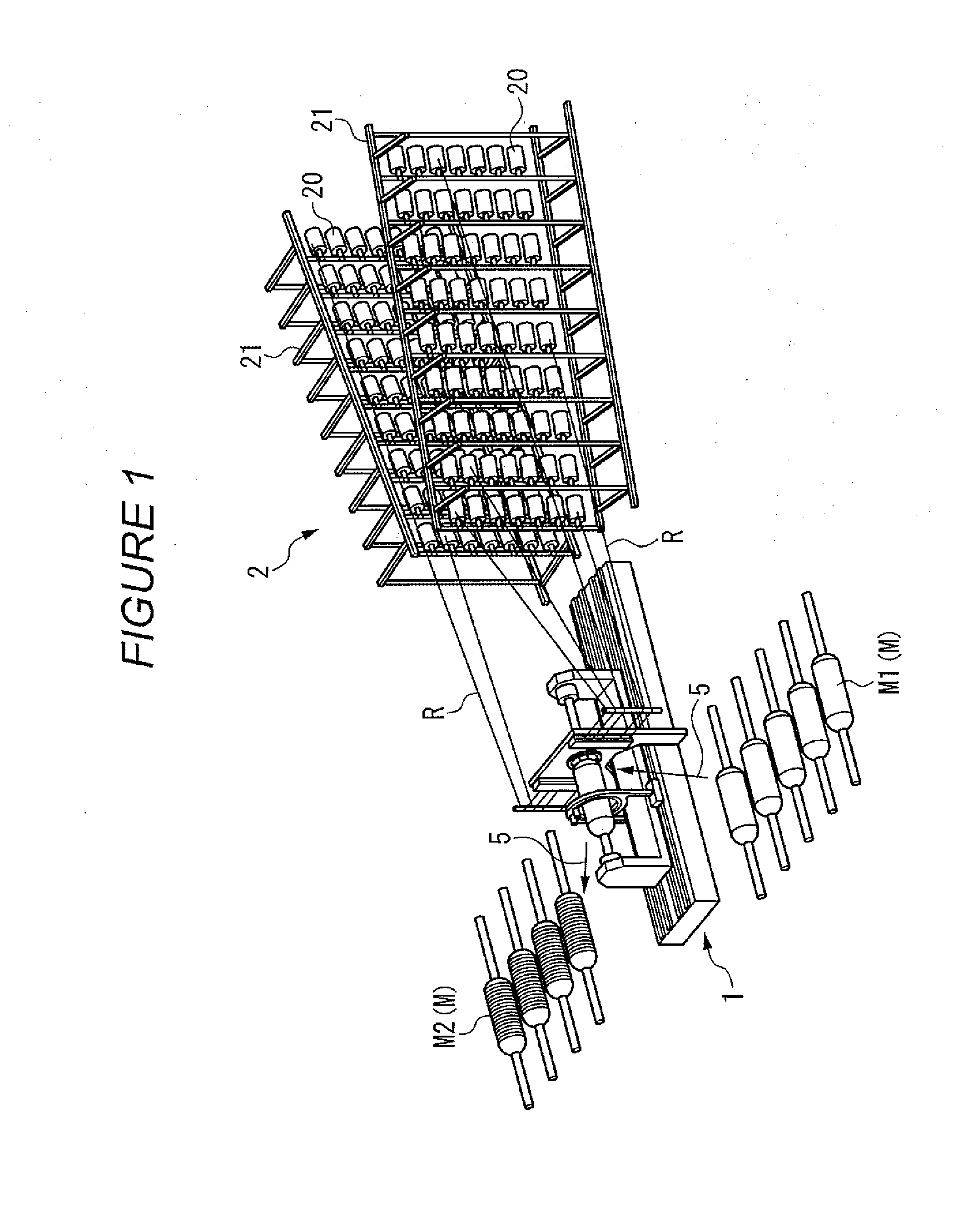

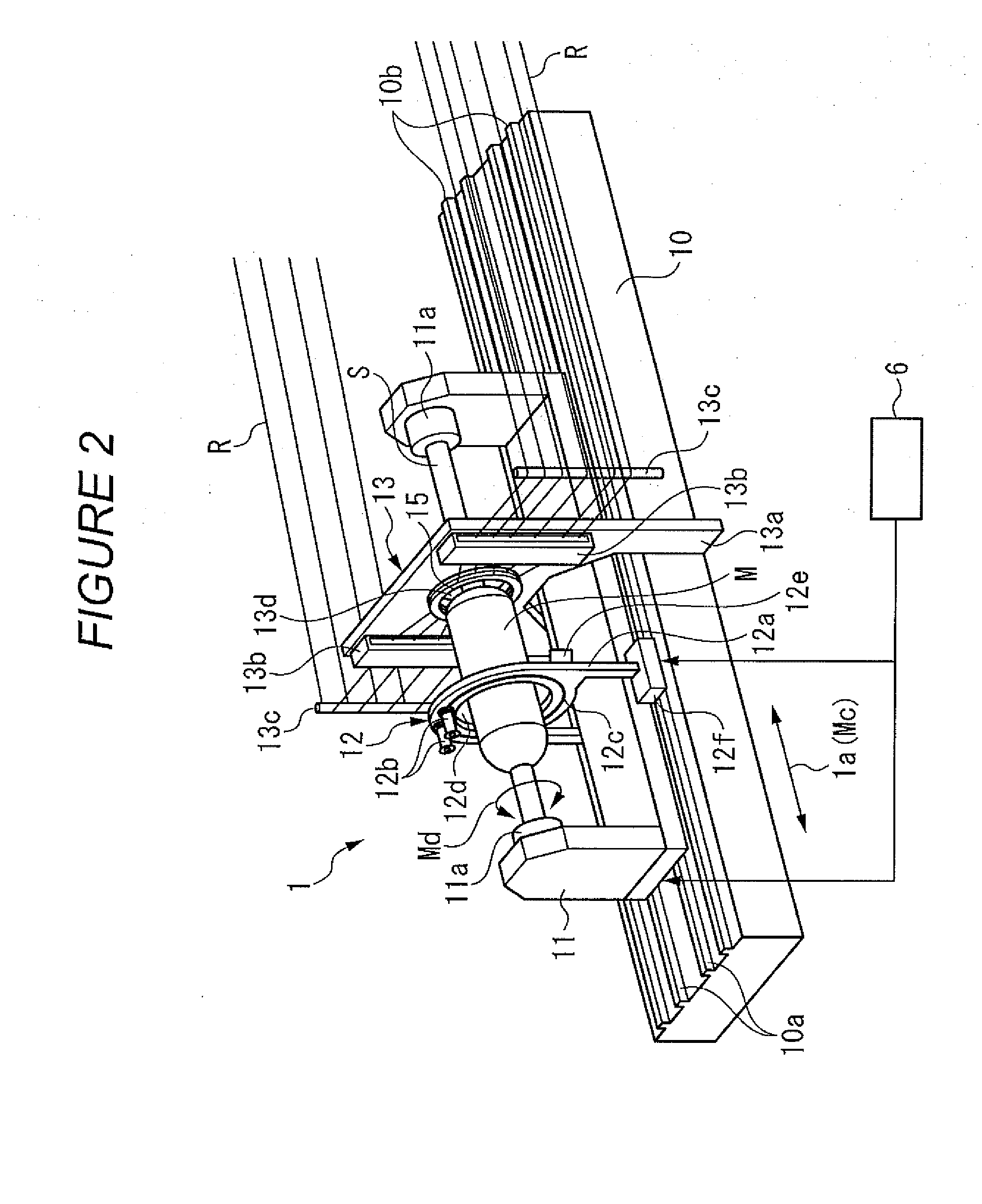

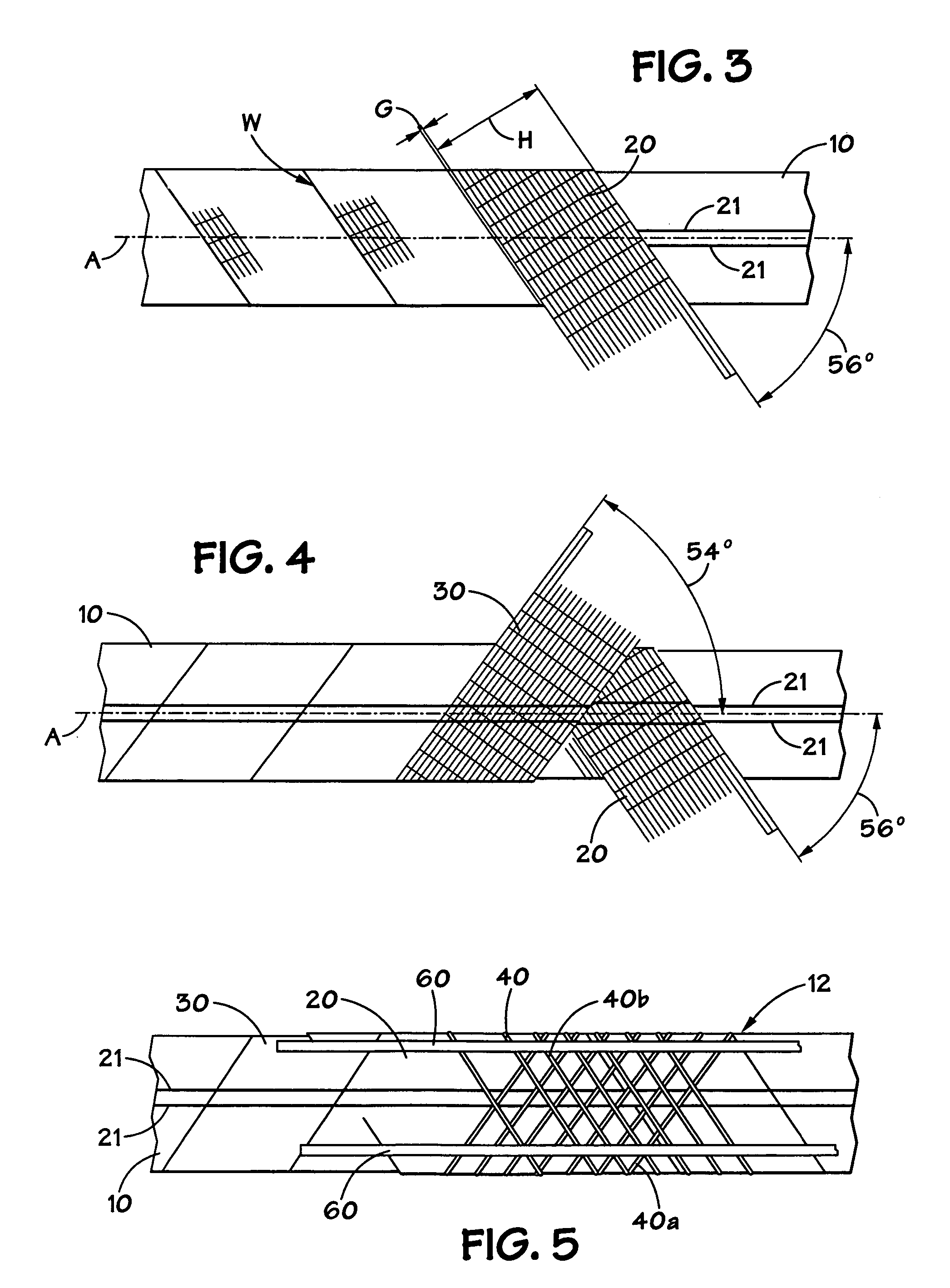

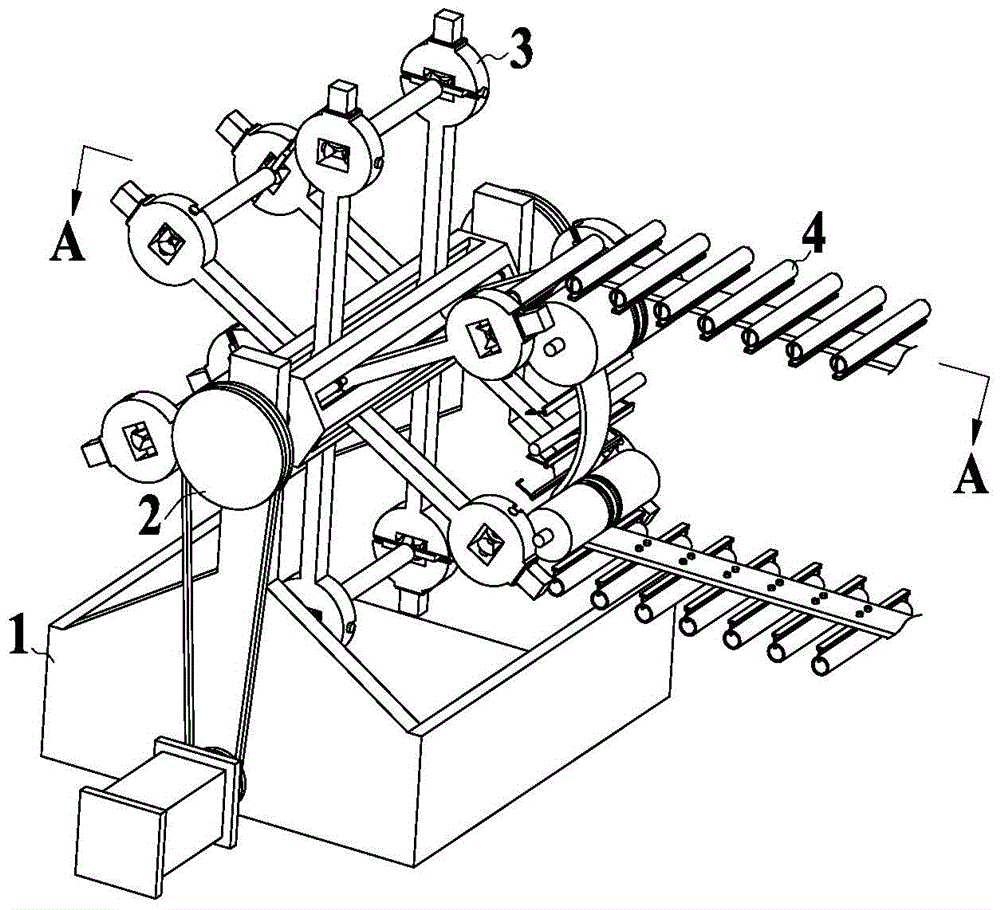

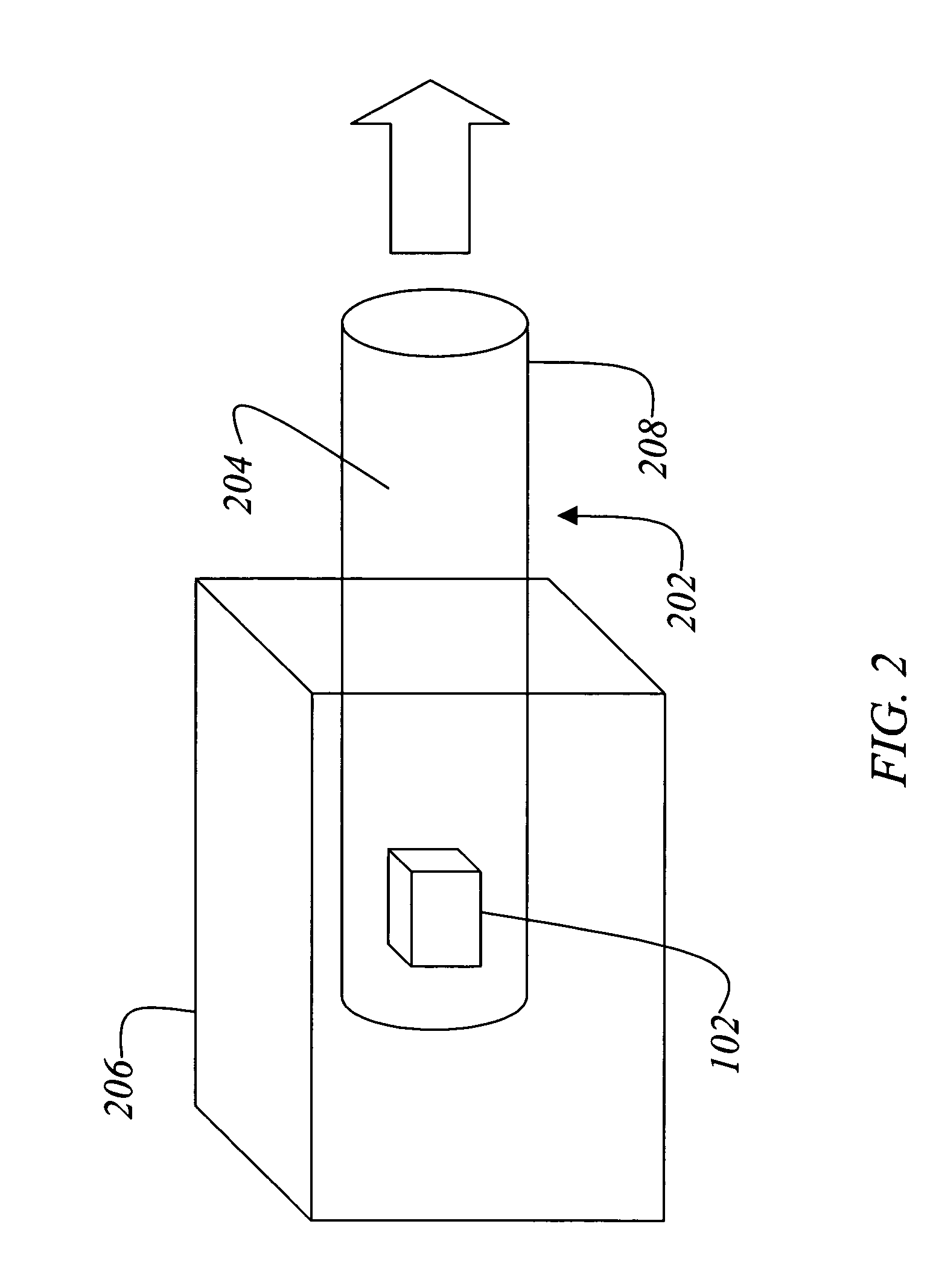

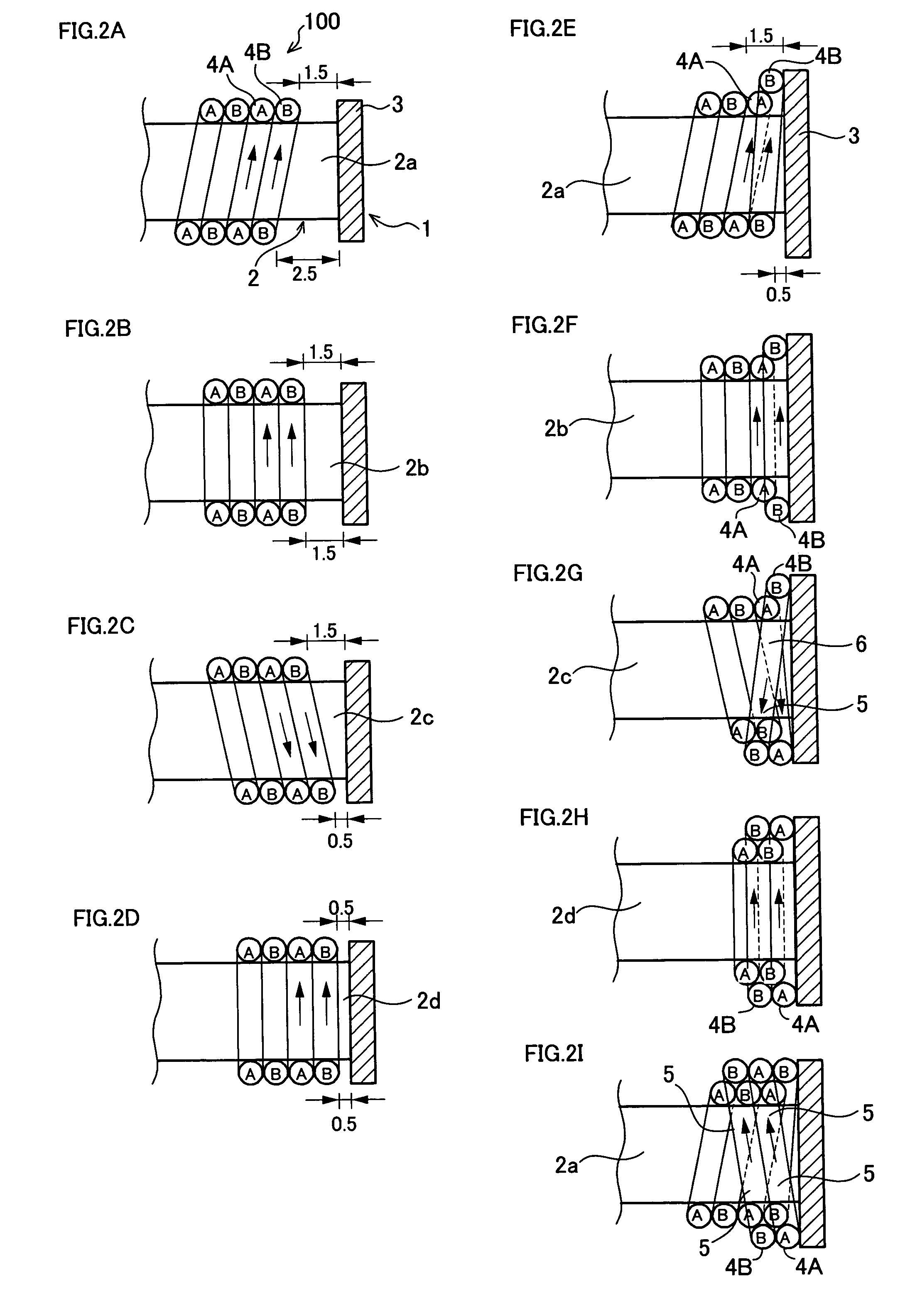

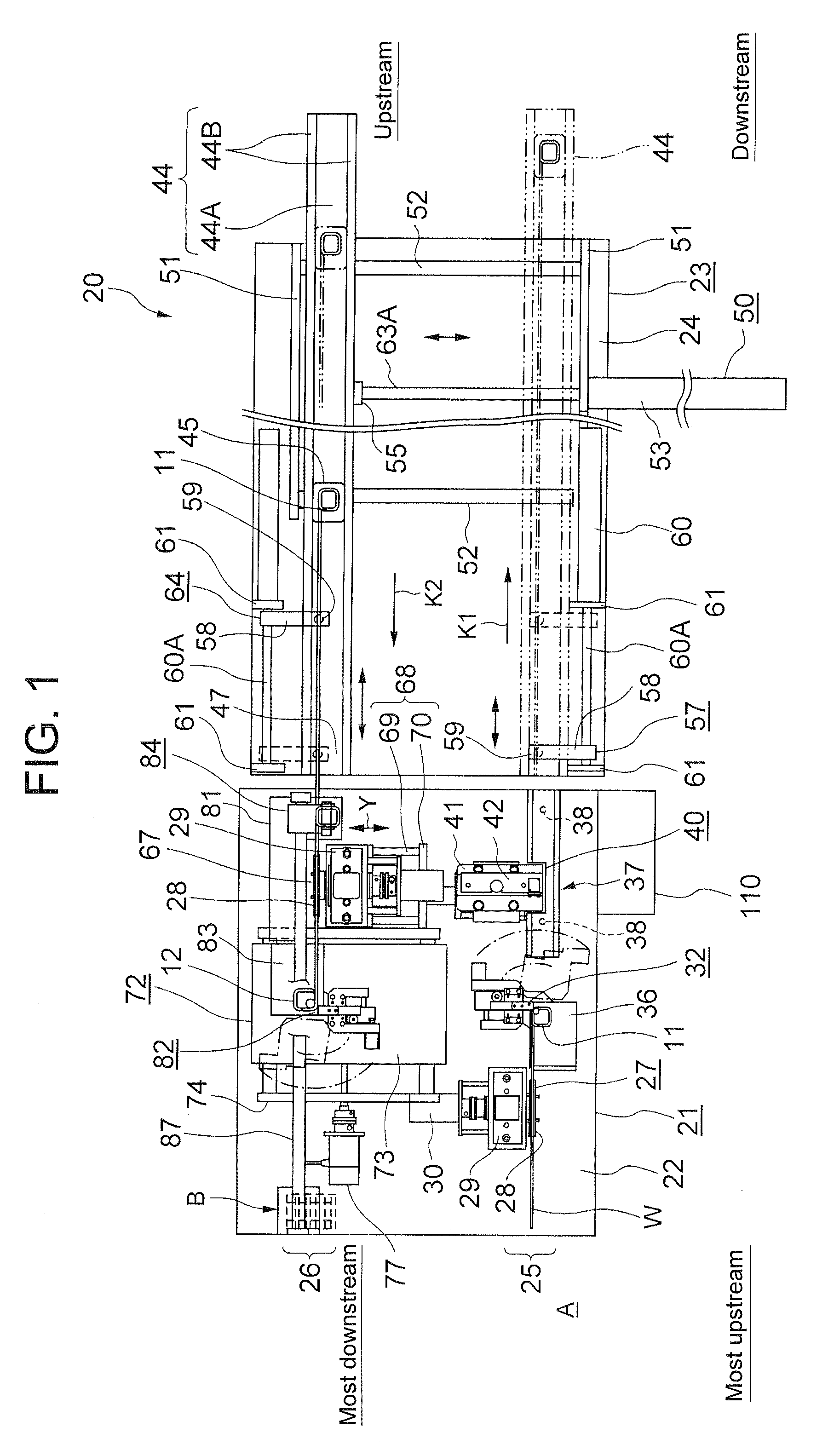

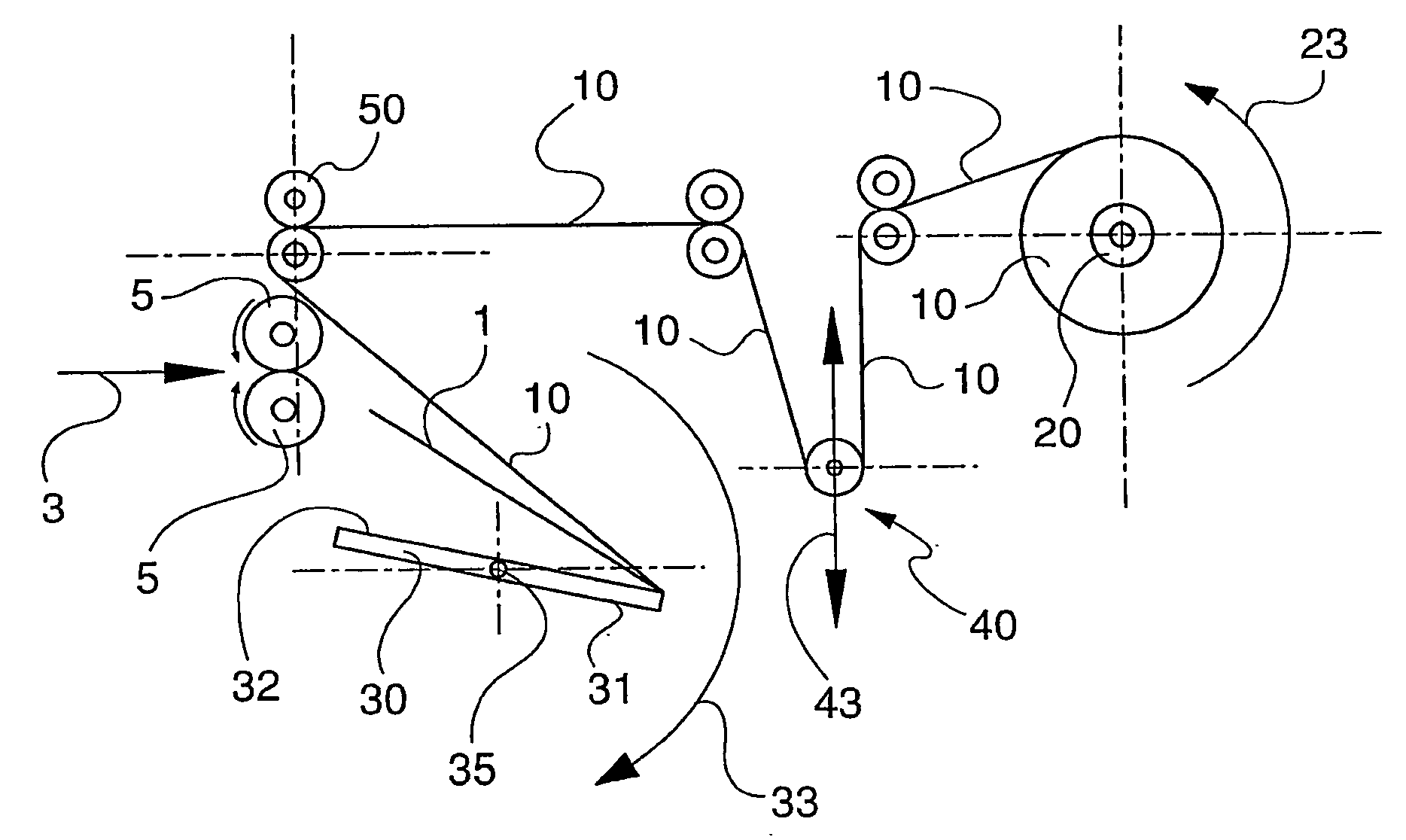

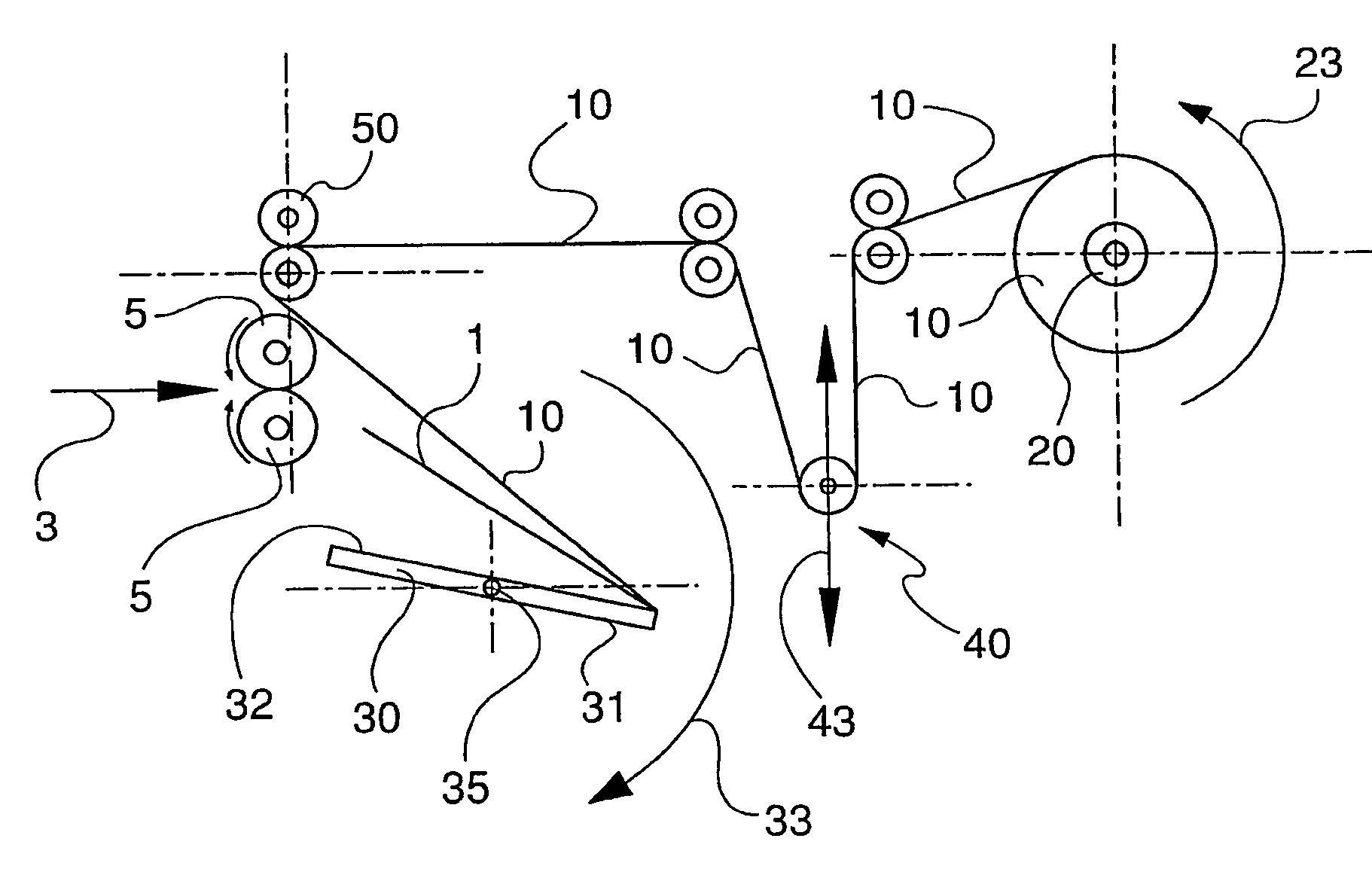

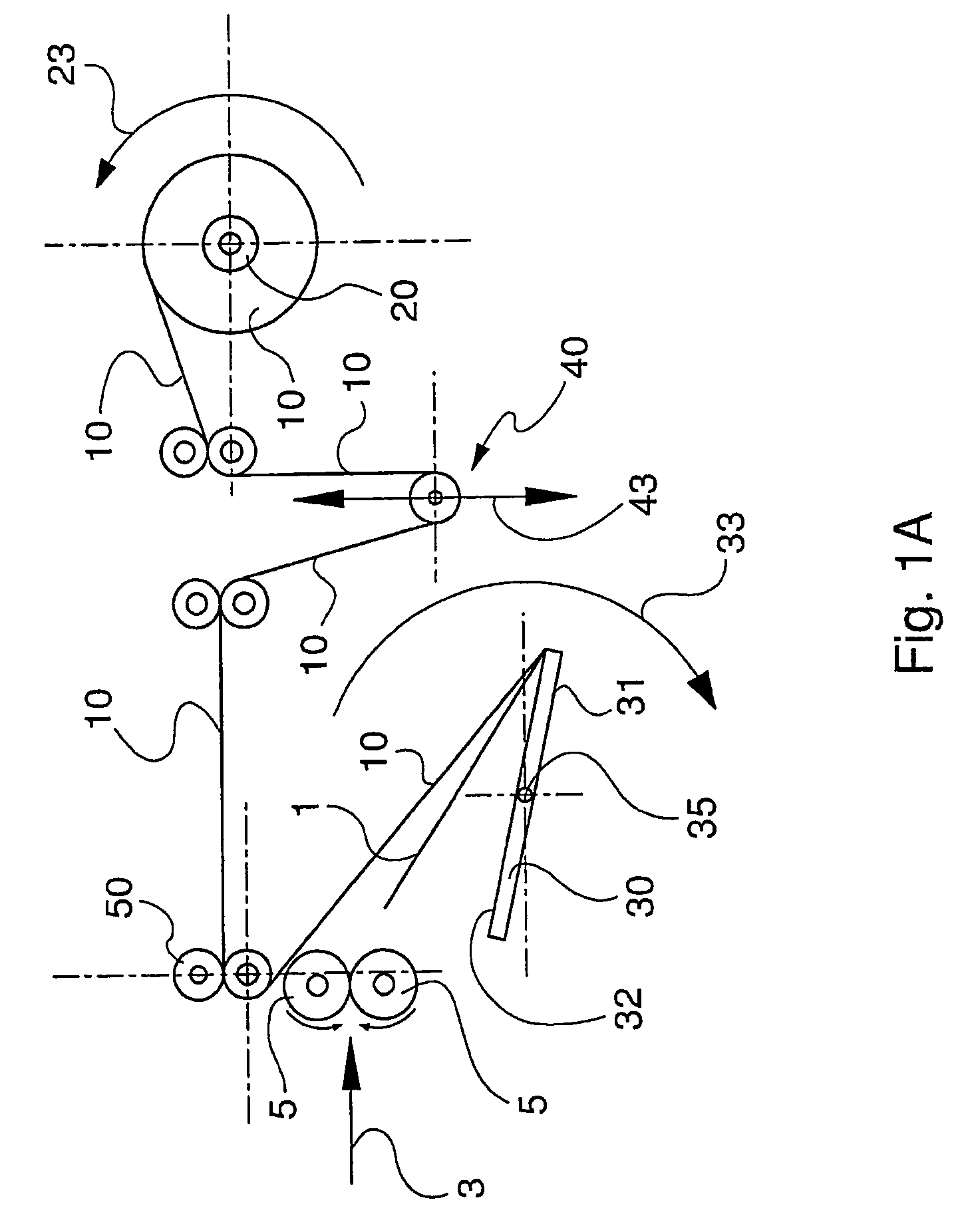

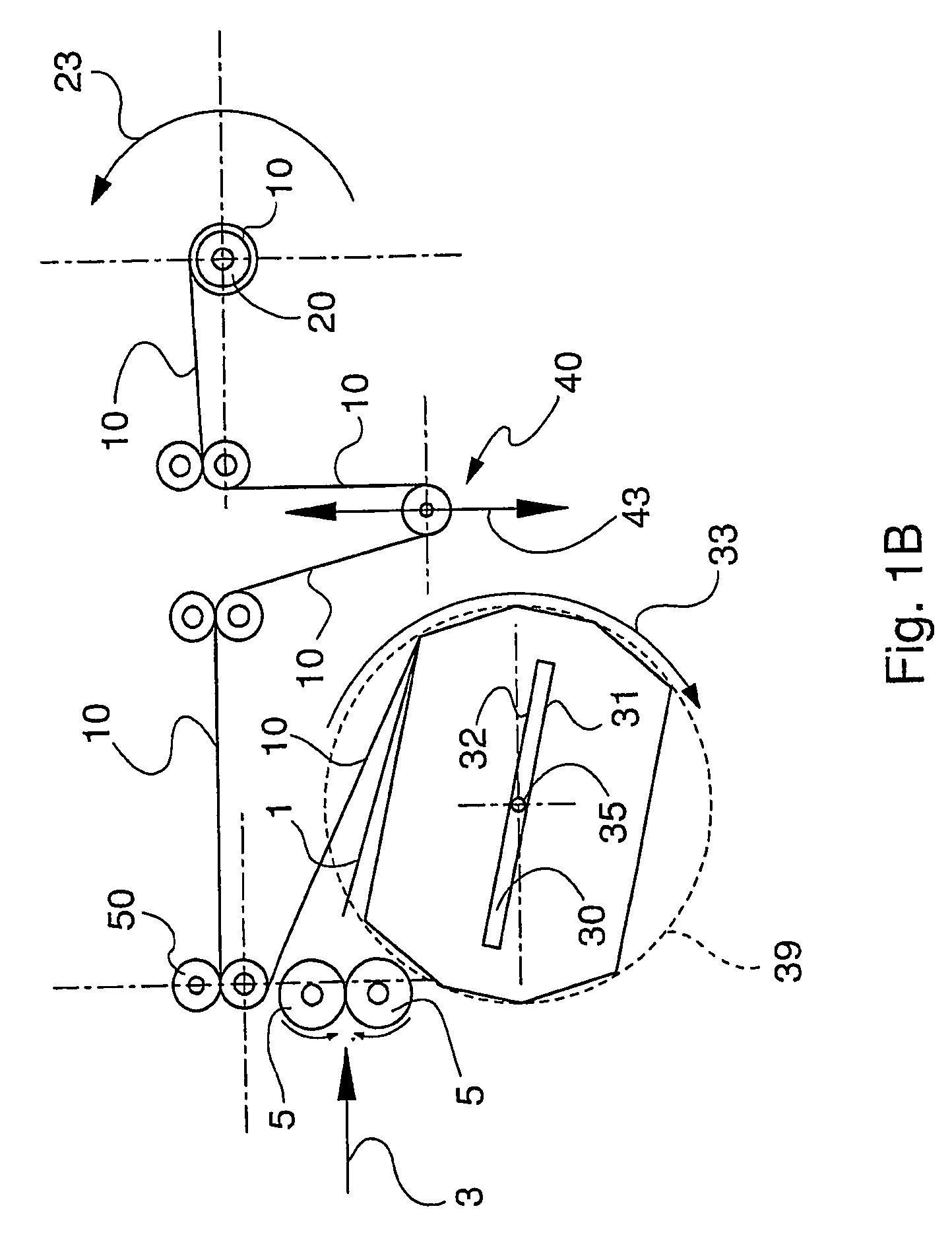

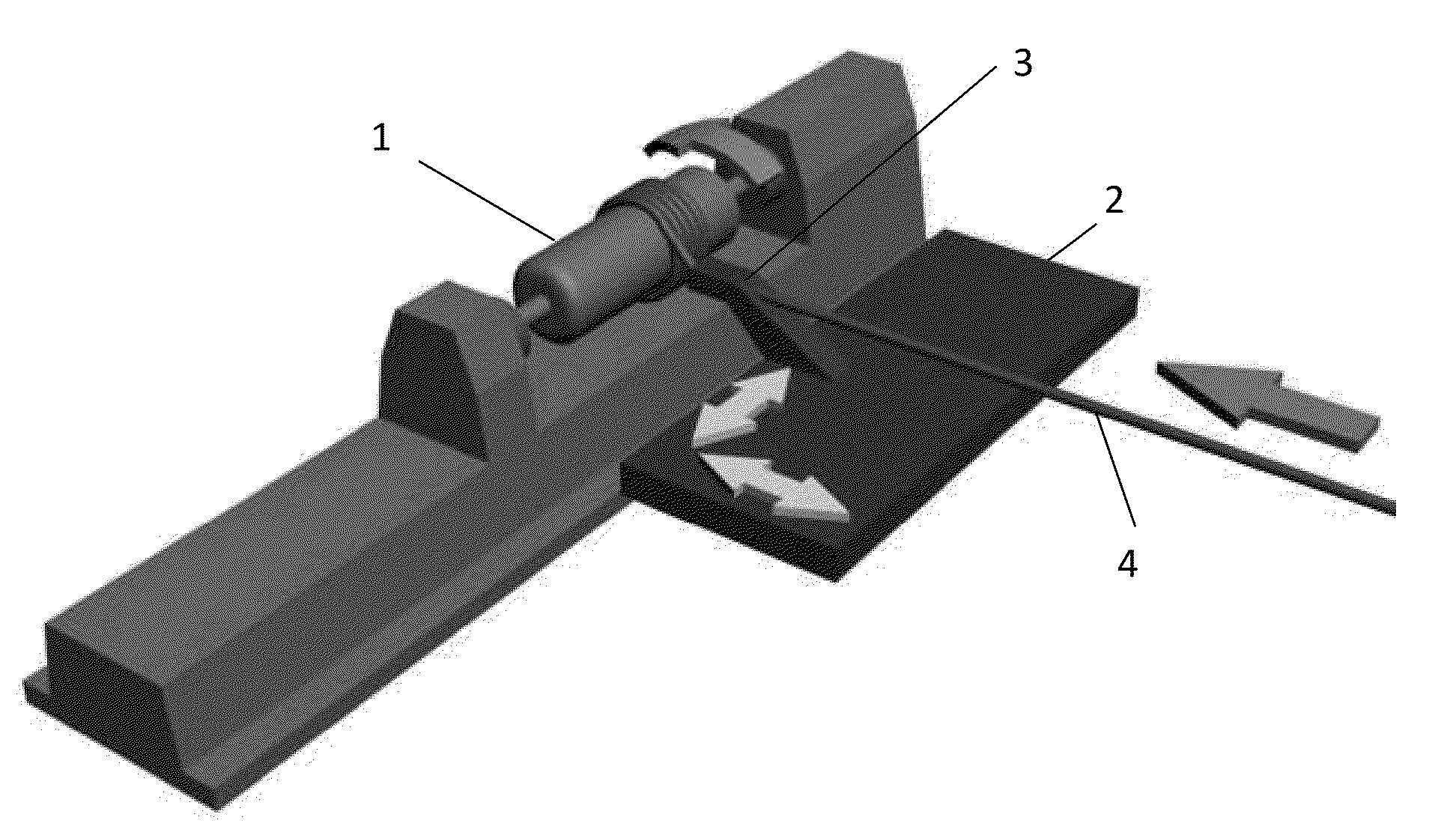

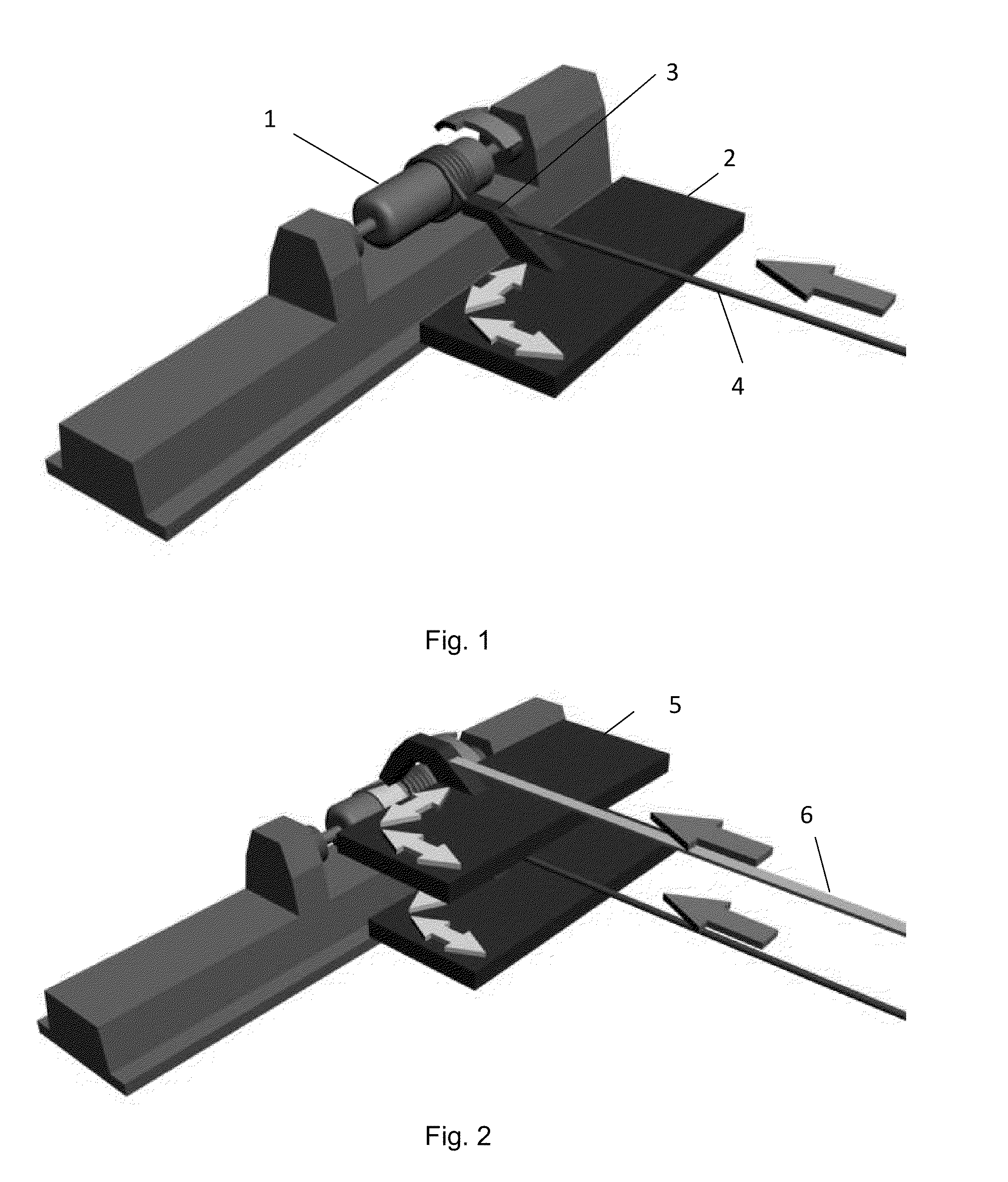

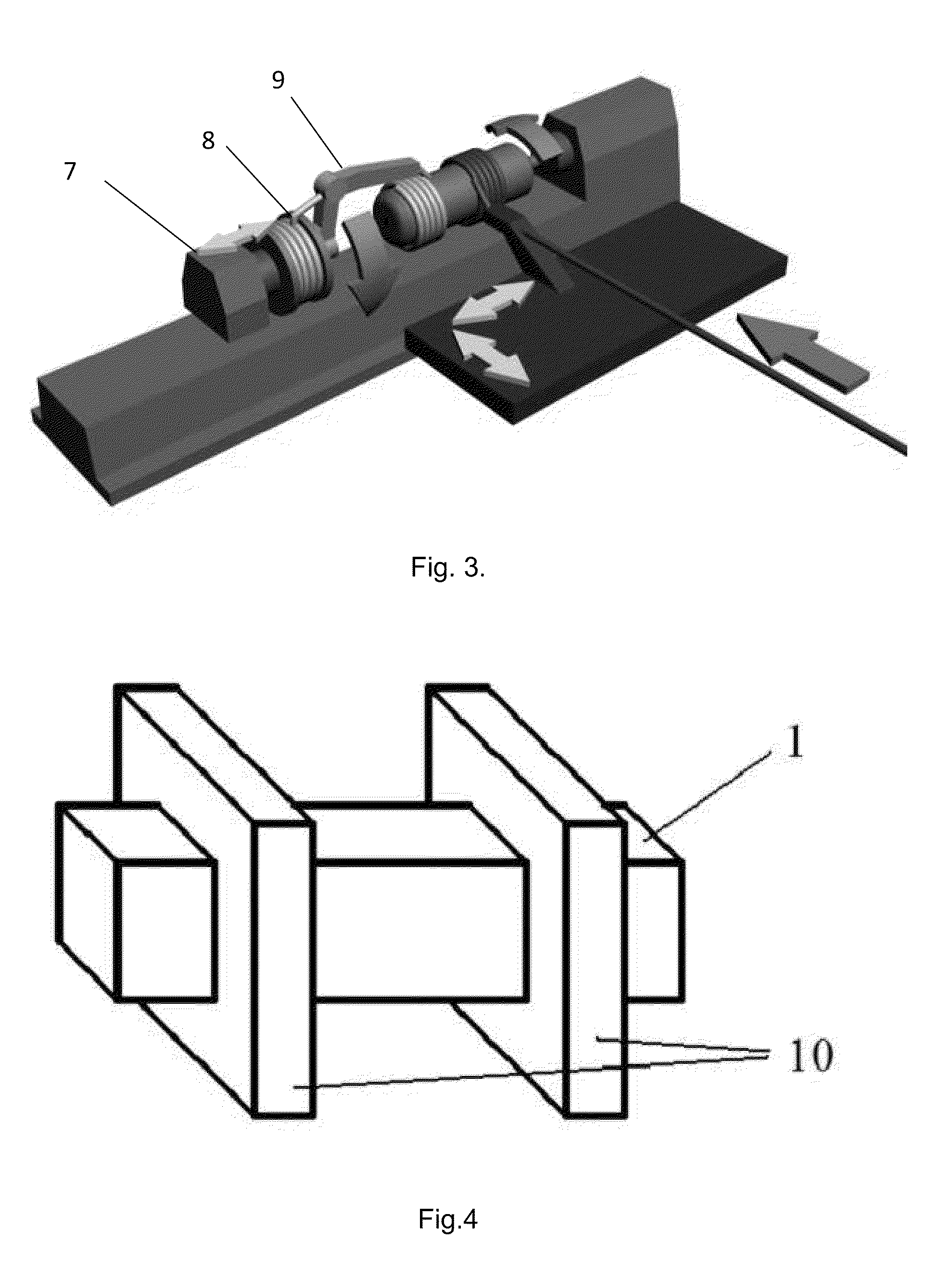

Filament Winding Automated System

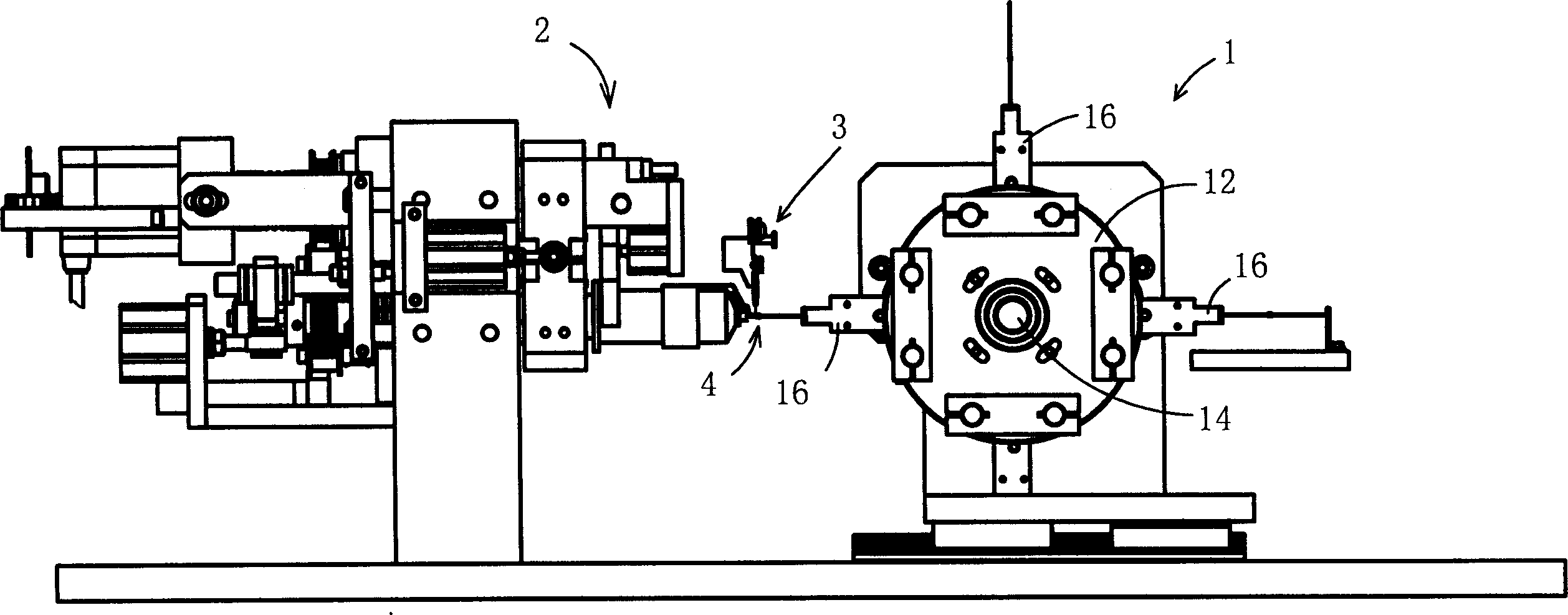

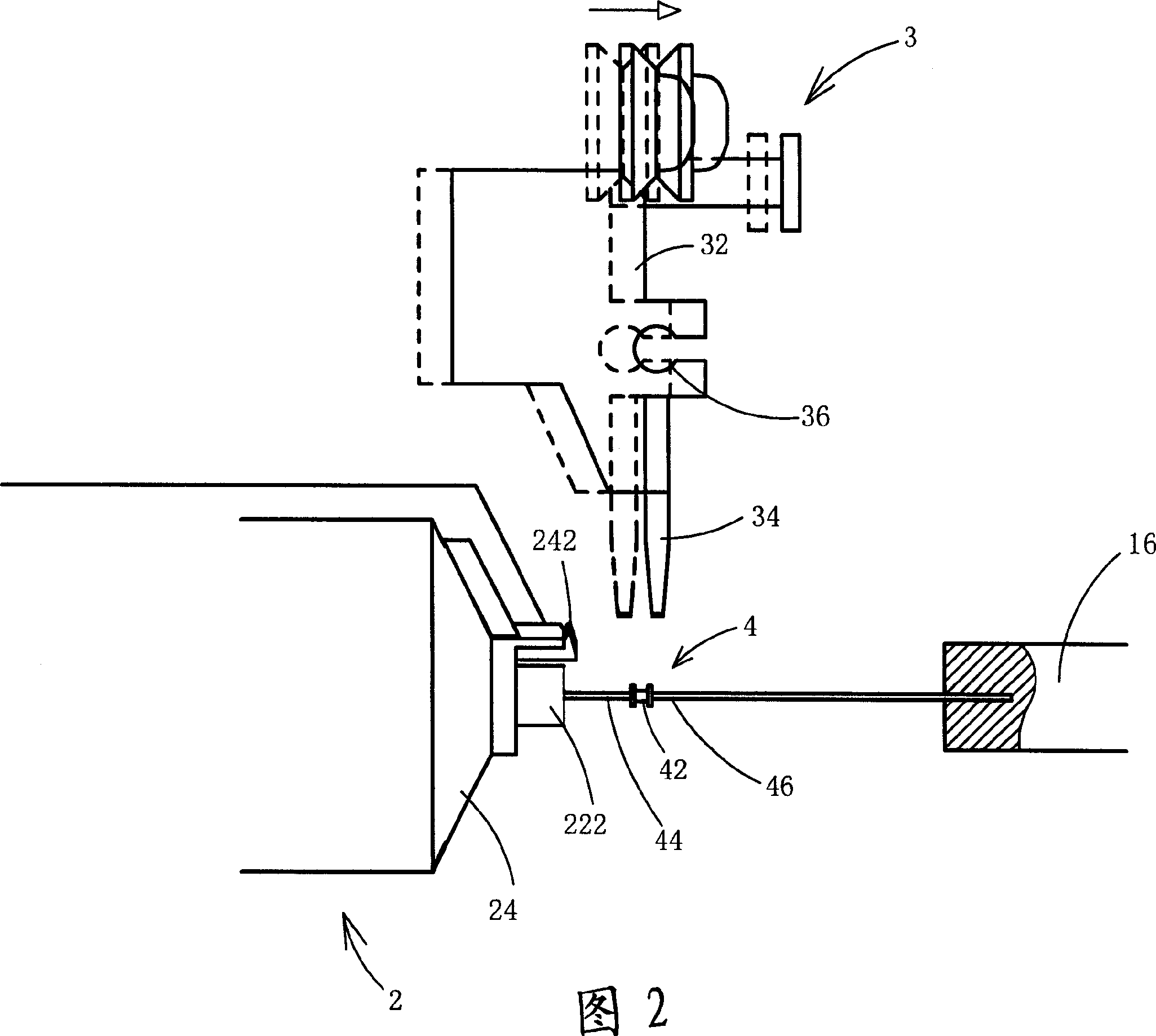

ActiveUS20090038759A1Increase productionLow costFilament handlingDomestic articlesFiber bundleEngineering

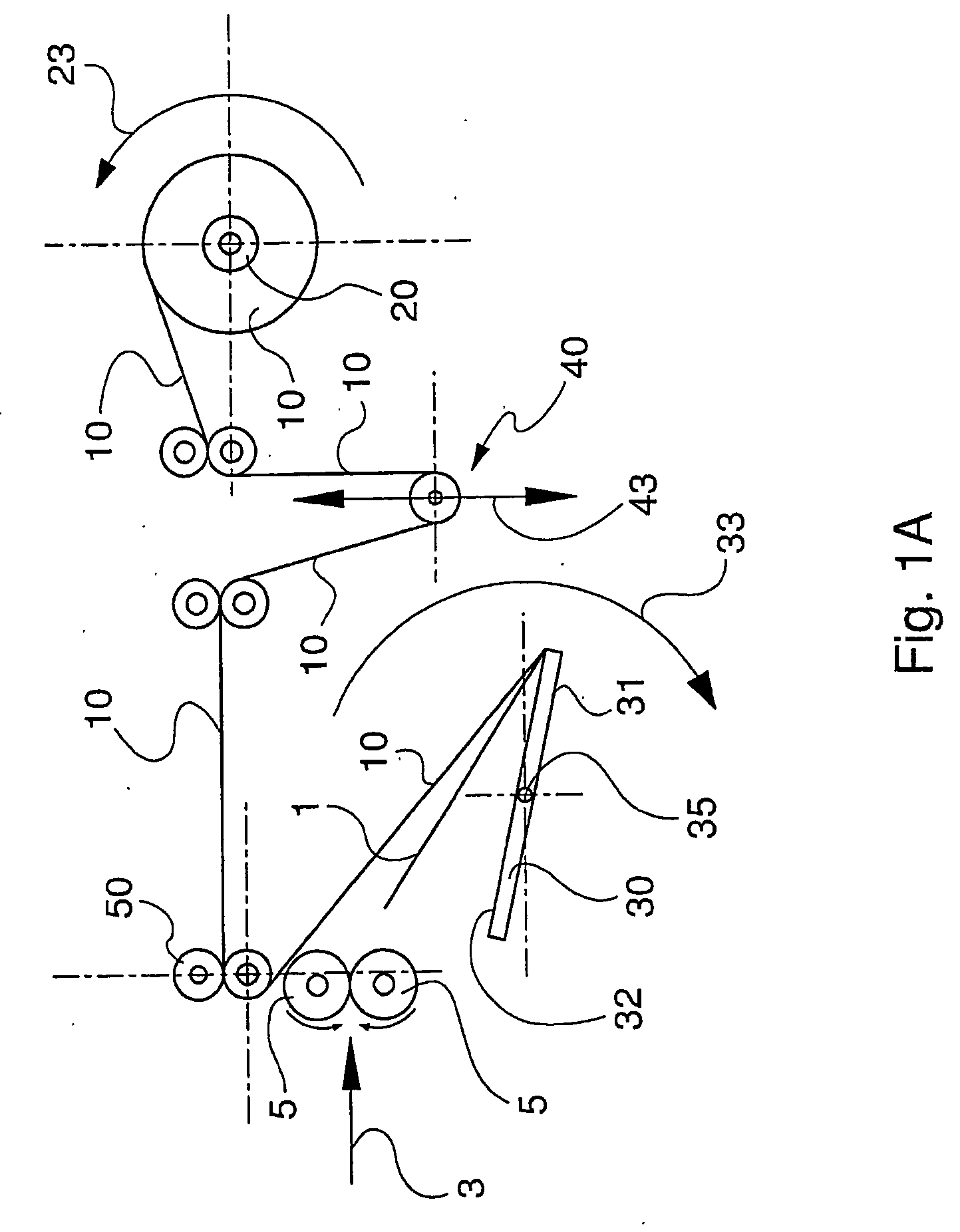

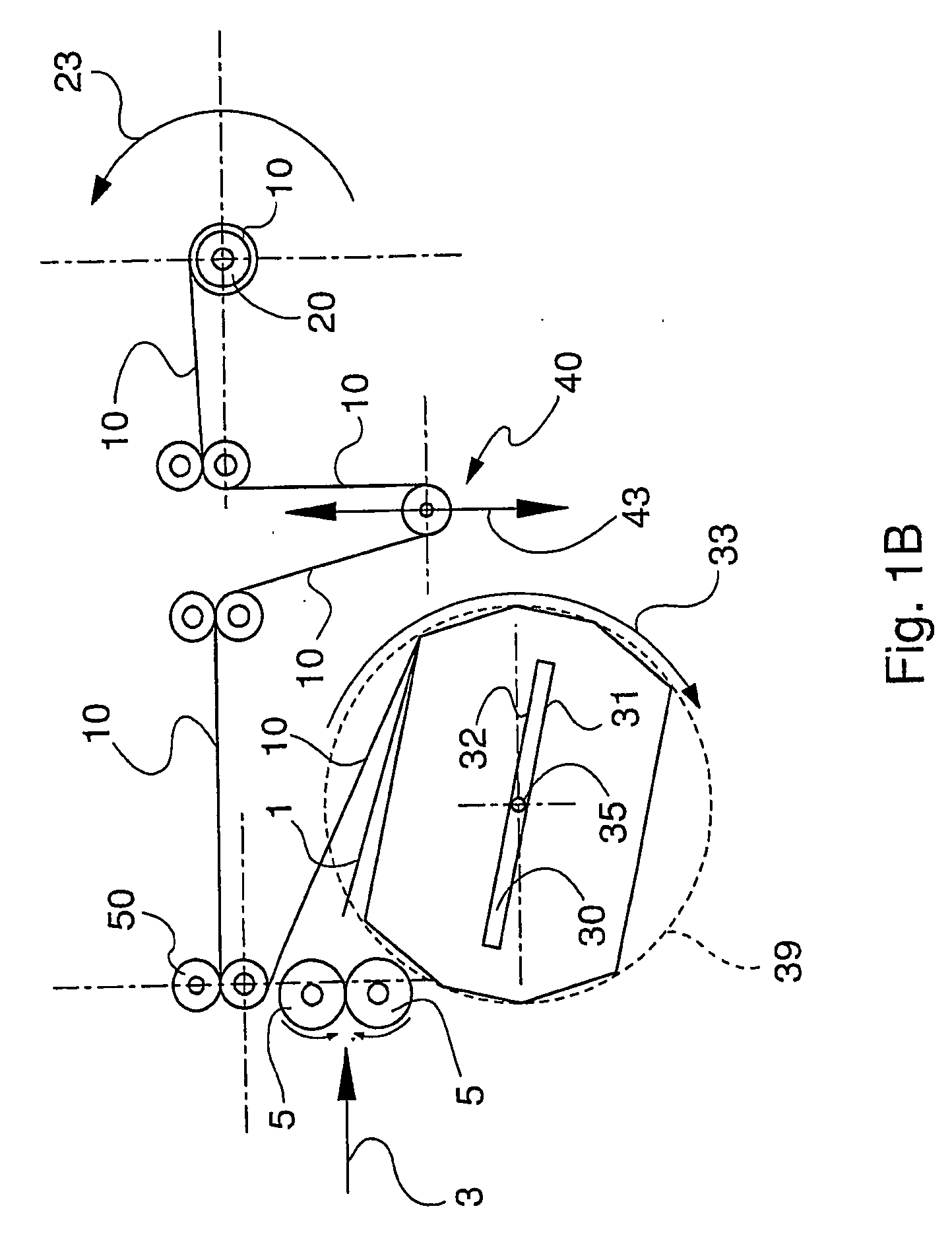

The present invention makes it possible to increase production efficiency while reducing costs. A filament winding automated system according to the present invention includes a winding device winding a fiber bundle R paid out from a head portion 12, 13, around a mandrel M1, an installing device 5 installing the mandrel around M1 which no fiber bundle has been wound yet, at a winding position, a discharging device 5 discharging the mandrel around which the fiber bundle has already been wound, from the winding position, a delivery device 3 holding and delivering the fiber bundle R from the mandrel around which the fiber bundle has already been wound to a mandrel M1 around which no fiber bundle has been wound yet, and a cutting device cutting the fiber bundle R, and after winding is completed, the delivery device 3 holds the fiber bundle R paid out from the head portion 12, 13, the cutting device cuts and separates the fiber bundle R from the mandrel around which the fiber bundle has already been wound, the discharging device 5 discharges the mandrel around which the fiber bundle has already been wound, the installing device installs the mandrel M1 around which no fiber bundle has been wound yet, and the winding device starts winding the fiber bundle R held by the delivery device 3, around the mandrel M1 around which no fiber bundle has been wound yet.

Owner:MURATA MASCH LTD

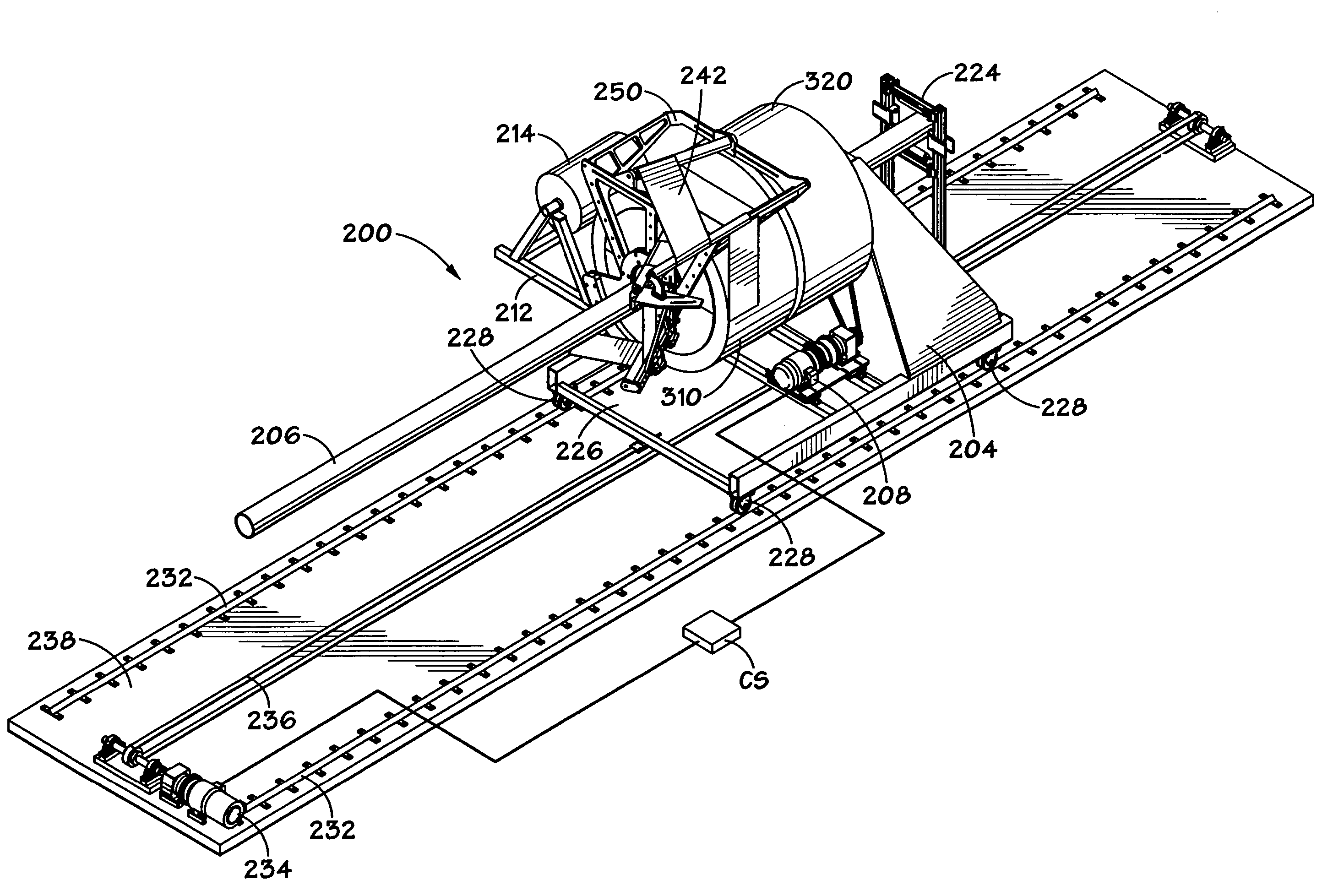

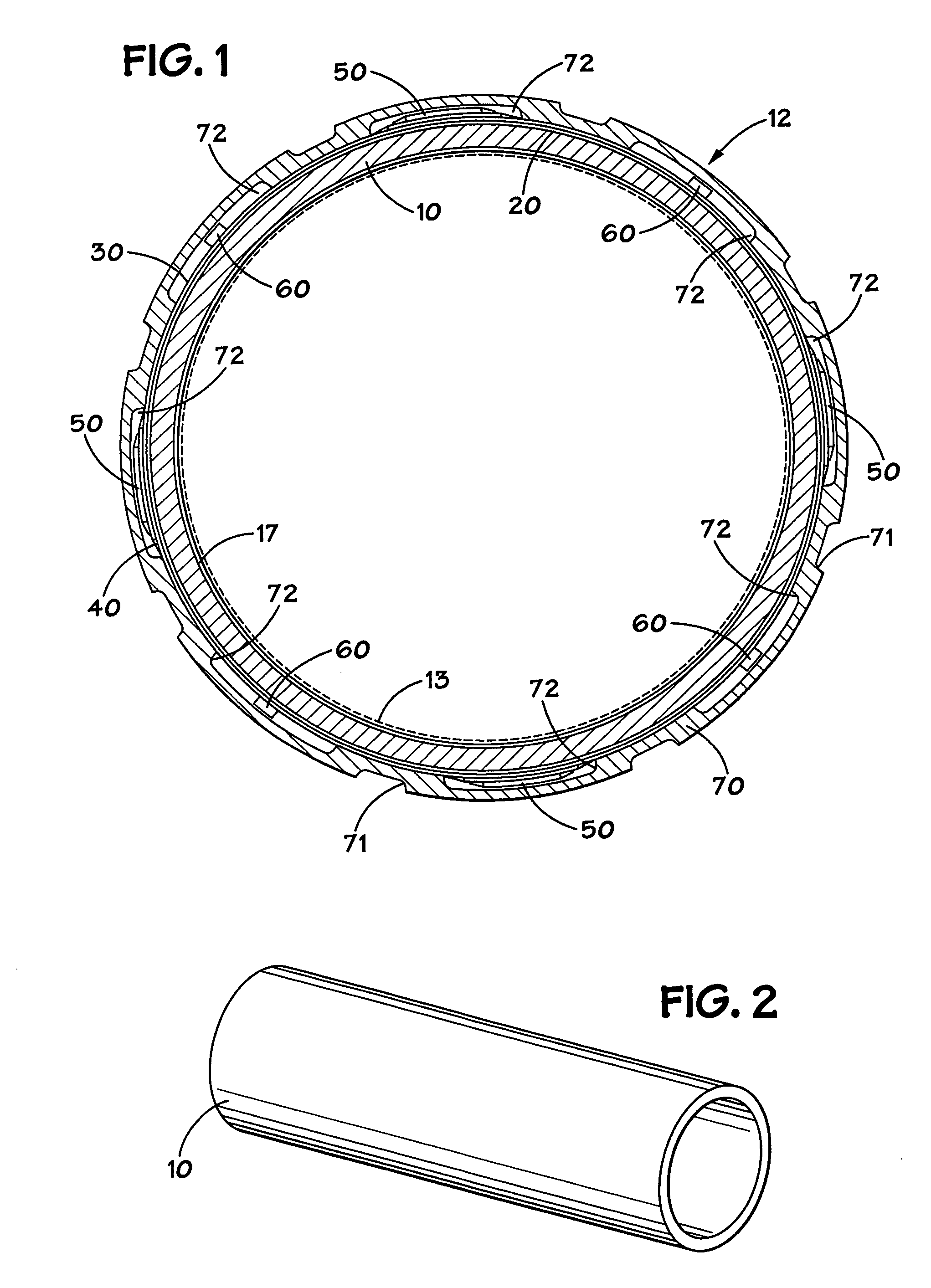

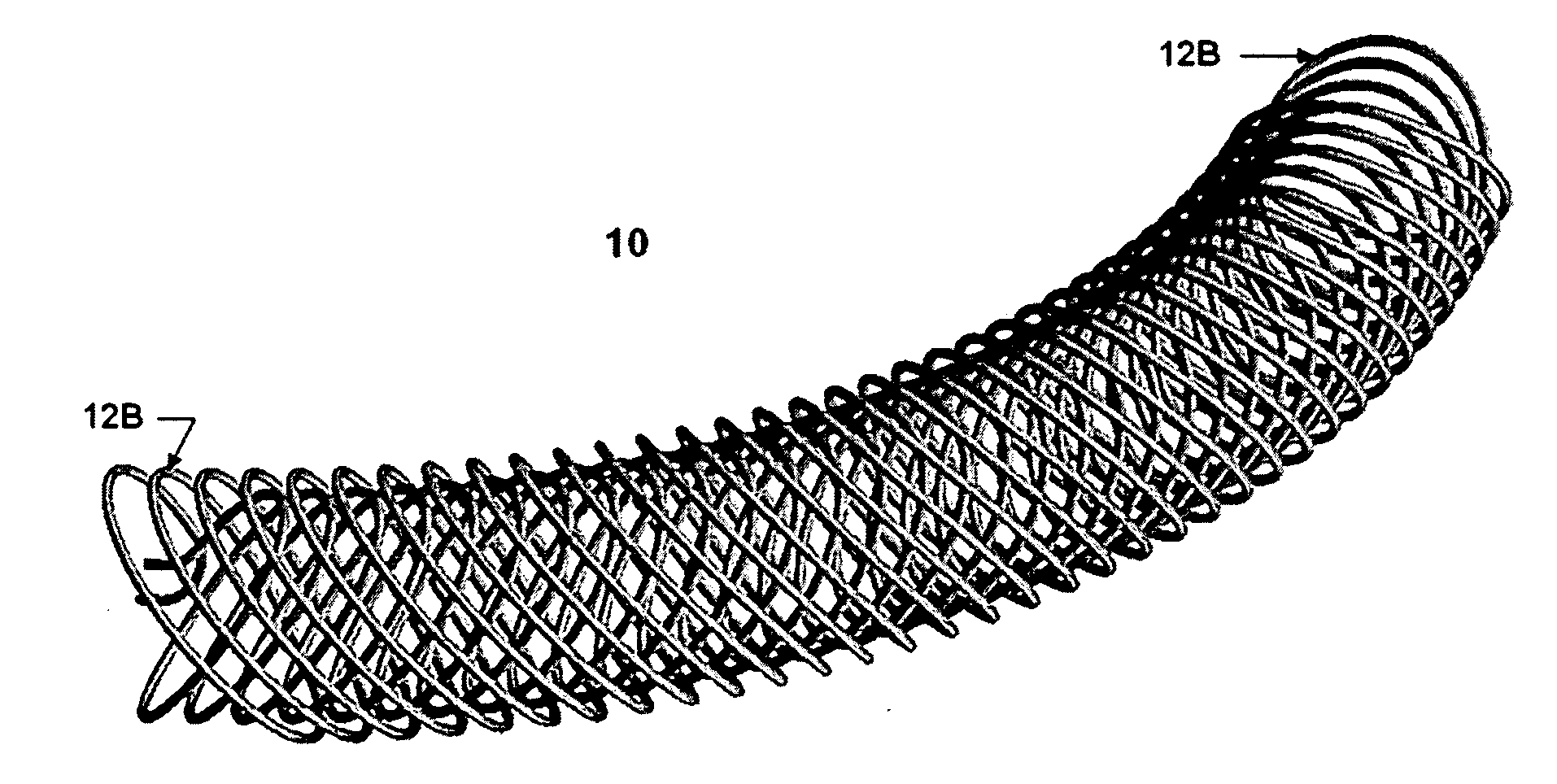

Systems and methods for making pipe liners

An apparatus for wrapping material onto and around a pipe, the apparatus including a shaft, the shaft rotatable by a driving apparatus, a payout core containing material to be wrapped onto a pipe, the payout core releasably mounted on the shaft, a deflection arm assembly secured to the shaft for rotation by the shaft, rotation of the shaft rotating the deflection arm assembly with respect to the payout core so that the deflection arm assembly takes material from the payout core and wraps the material onto a pipe adjacent the deflection arm assembly, each of the shaft and deflection arm assembly having a central opening through which is movable the pipe as the pipe is being wrapped.

Owner:SMART PIPE COMPANY

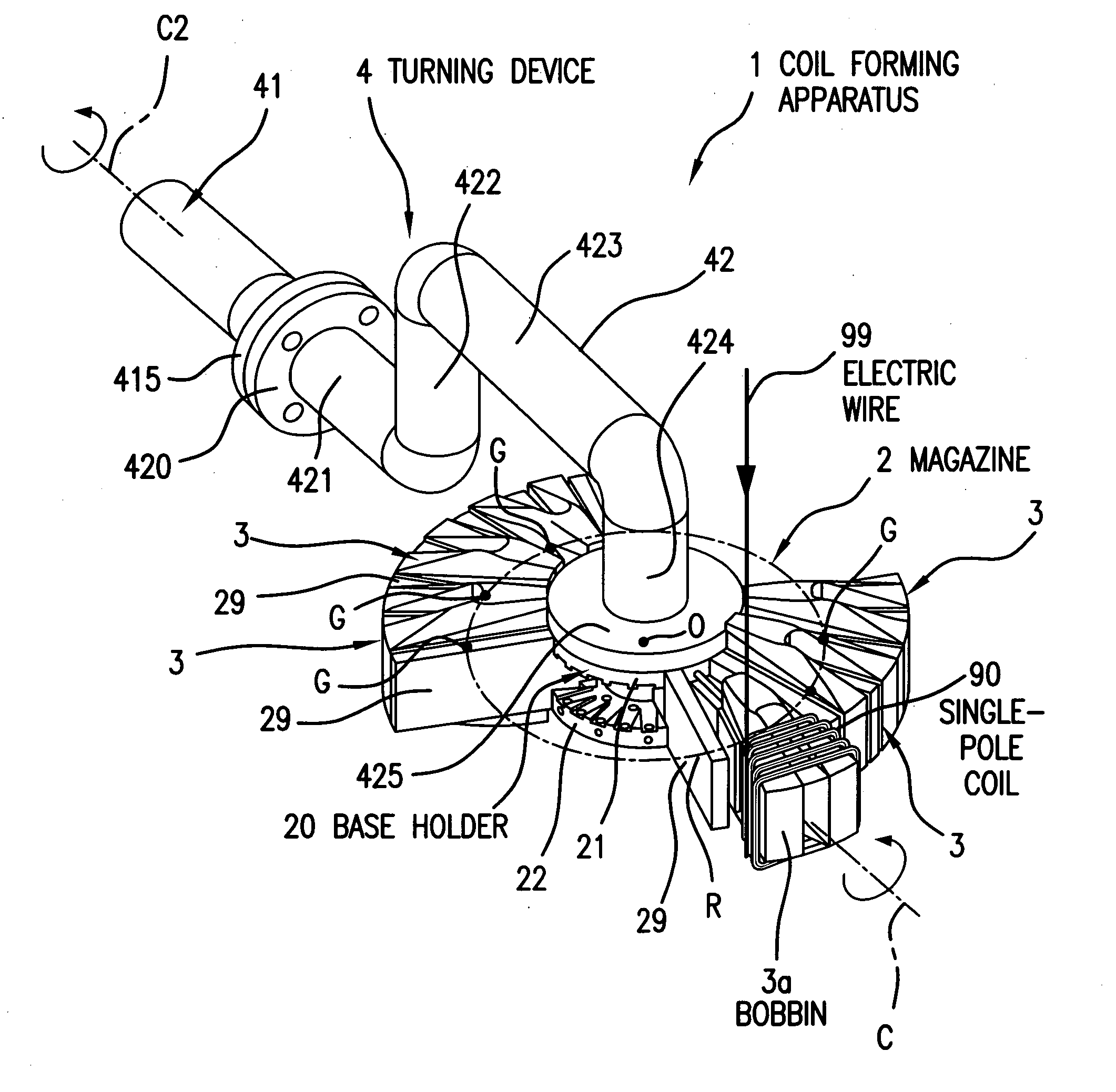

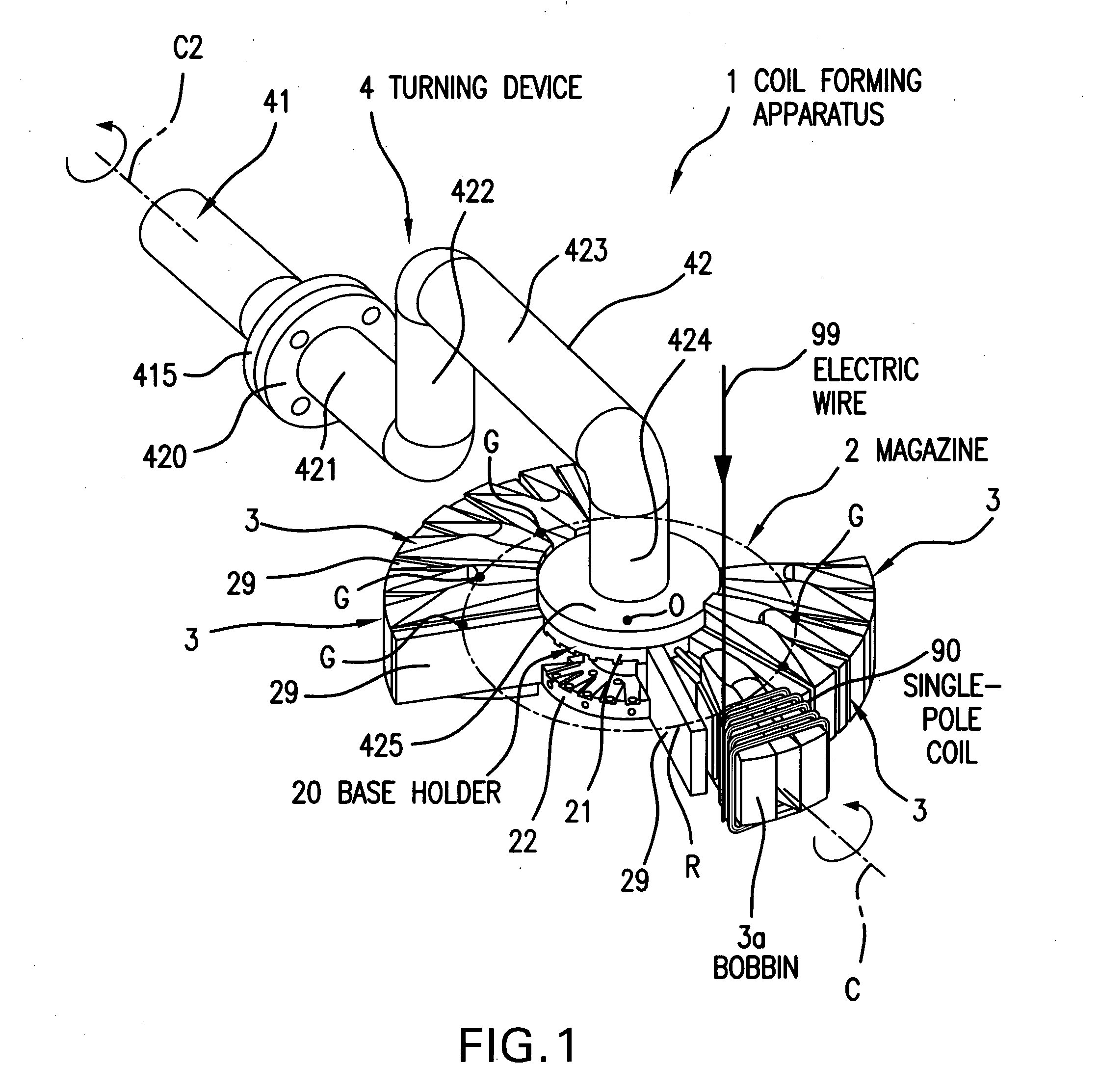

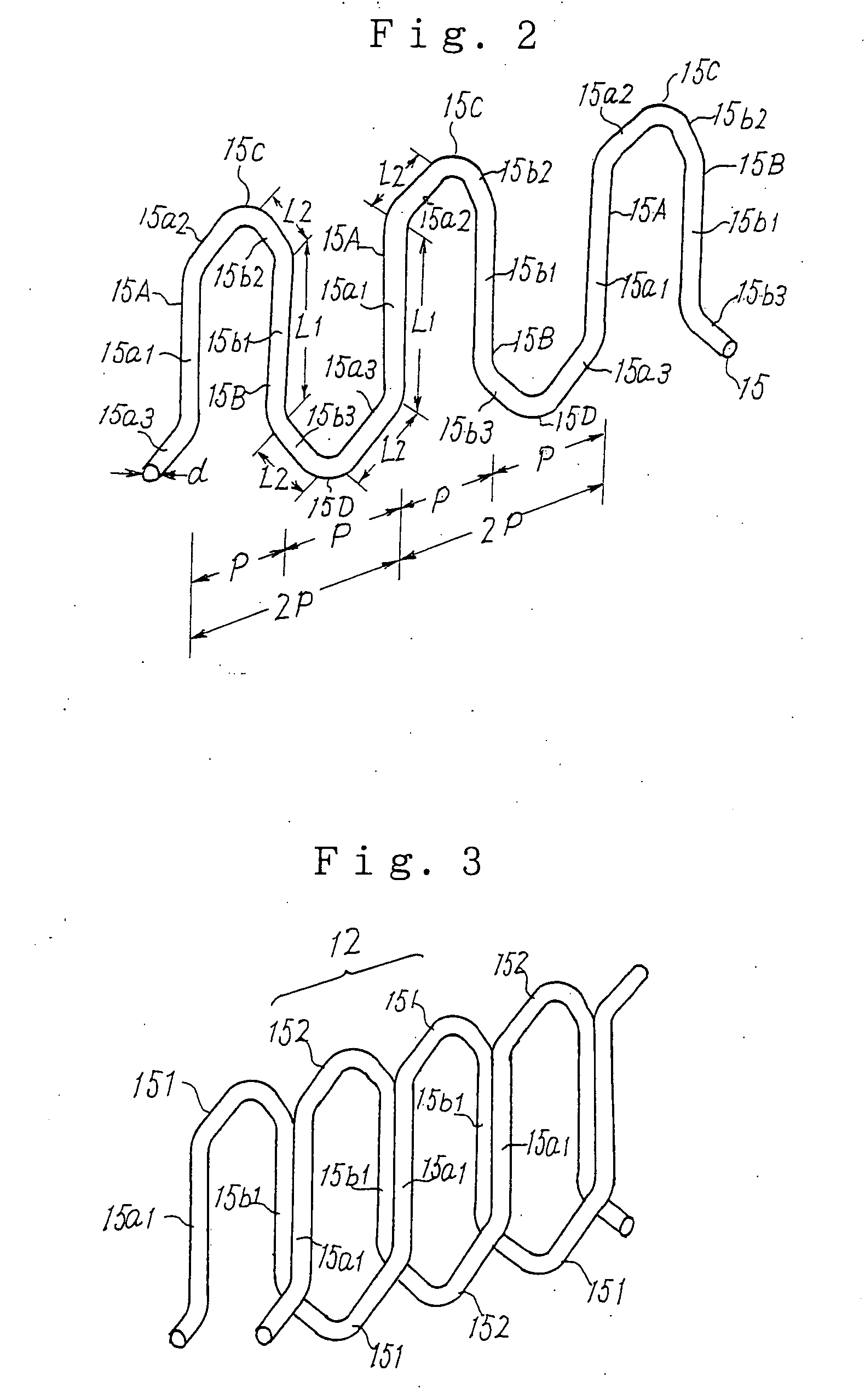

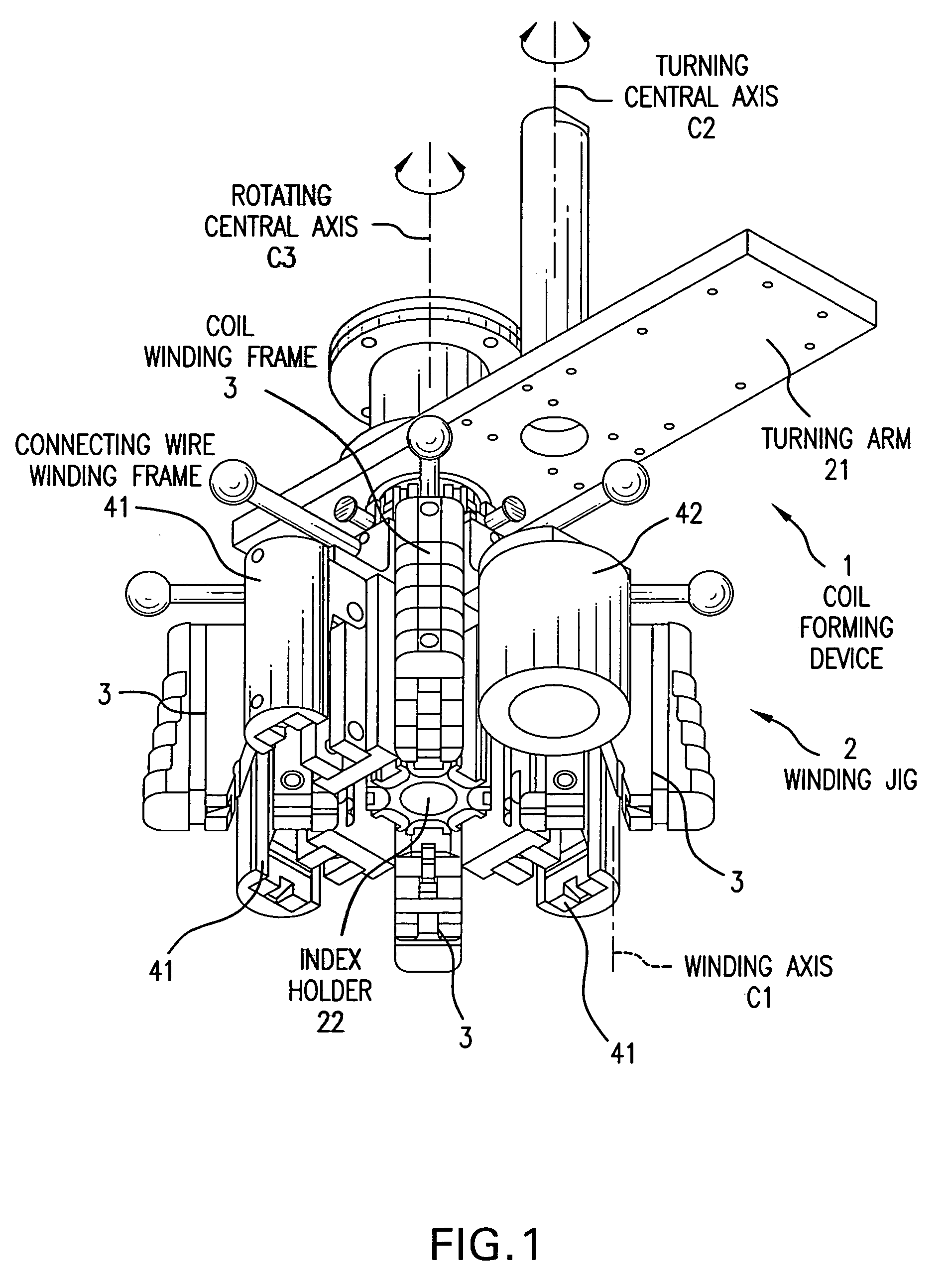

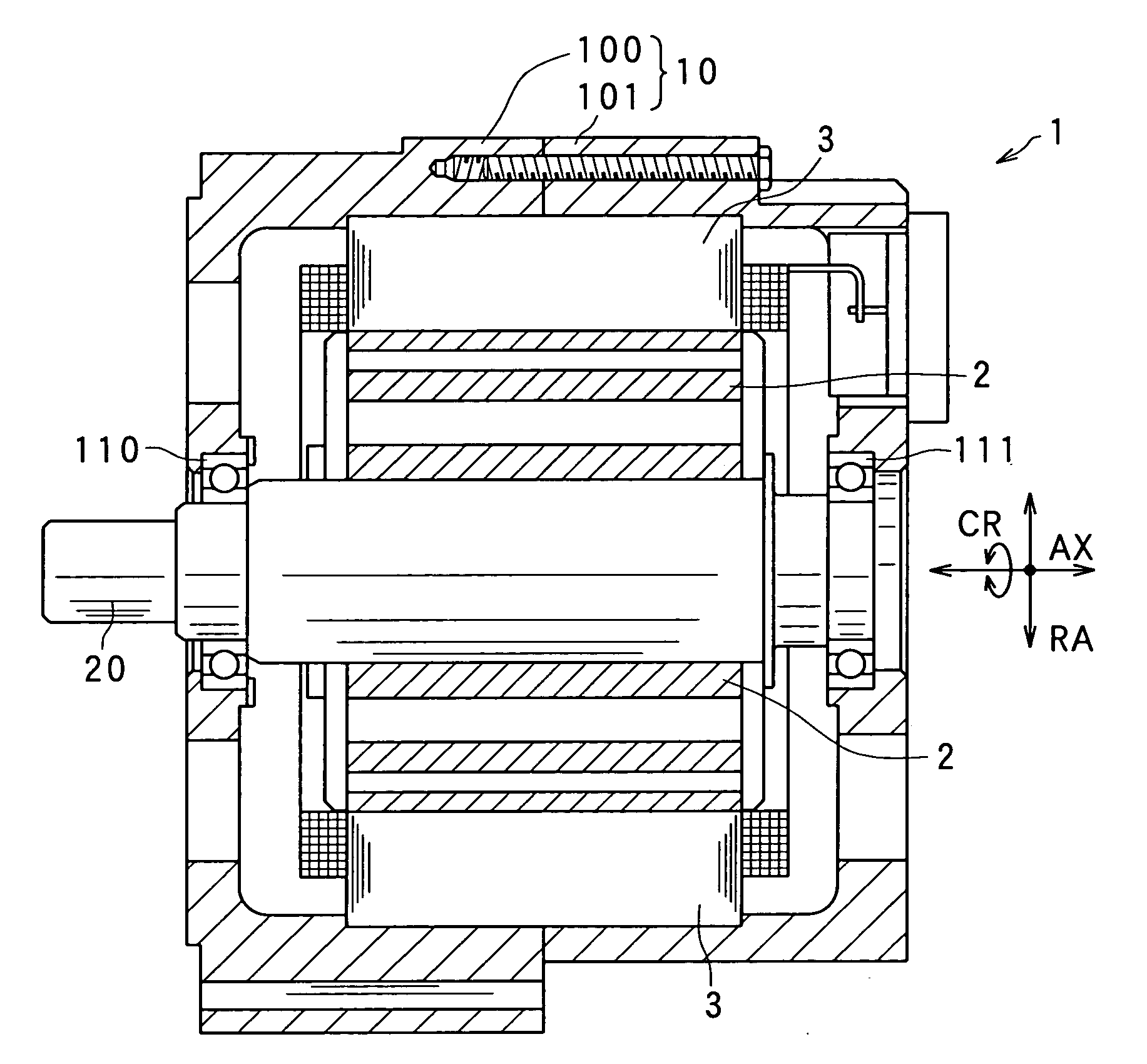

Coil forming method and coil forming device

InactiveUS20050133655A1Easy feedingWell formedManufacturing stator/rotor bodiesEmbedding prefabricated windingsBobbinReciprocating motion

A coil forming apparatus for forming a continuous-pole coil having a plurality of single-pole coils includes a winding jig rotatable around a center swing axis. The winding jig includes: a holder rotatable around a center axis of rotation different from center swing axis; and a plurality of coil bobbins arranged around said holder and mounted for reciprocal movement between advanced and retracted positions relative to the holder. Each individual coil bobbin has a winding axes which can be aligned with the center swing axis by turning the winding jig around the center axis of rotation. The single-pole coils having little twist can be stably formed for any coil bobbin to thereby form the continuous-pole coil.

Owner:AISIN AW CO LTD

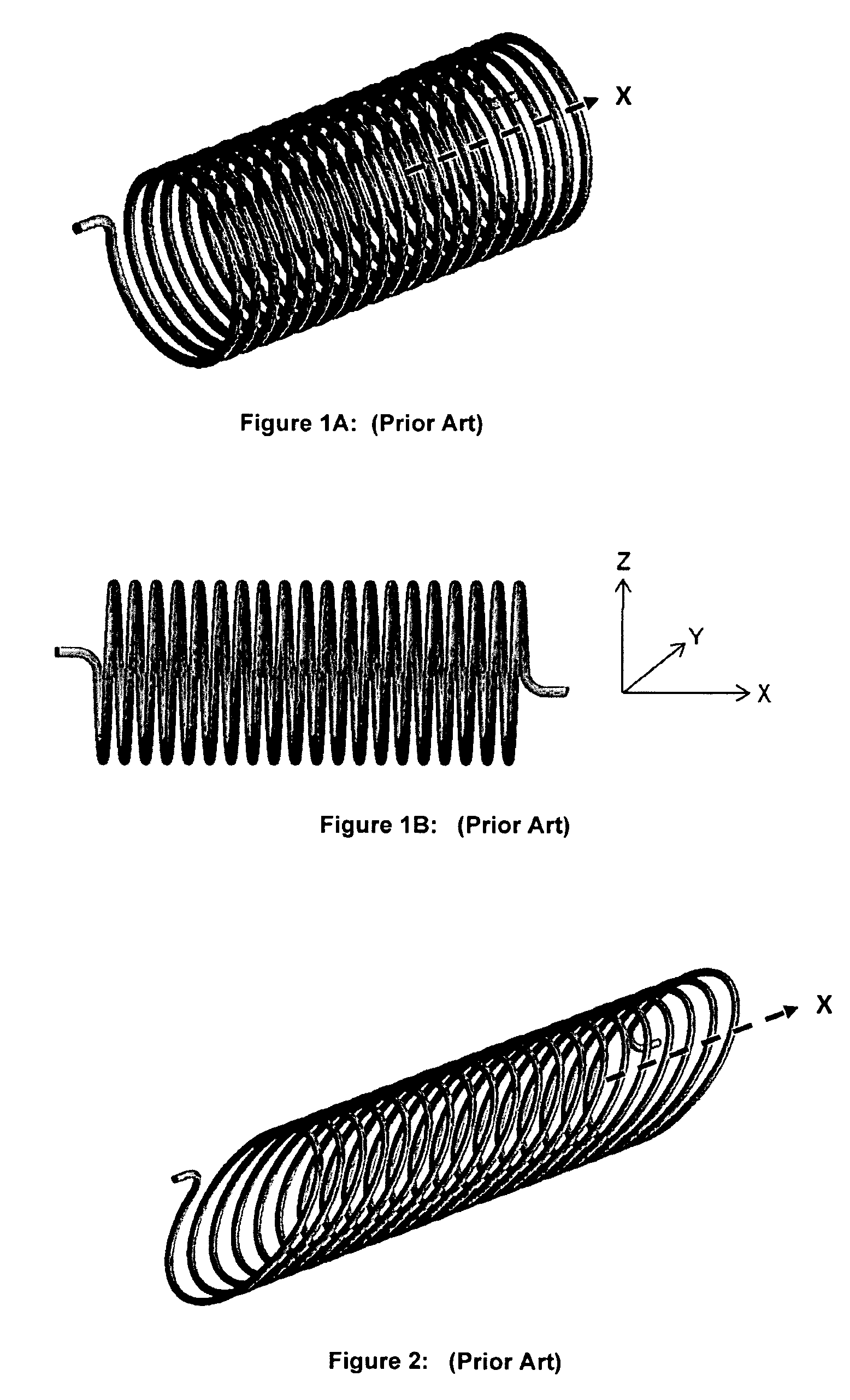

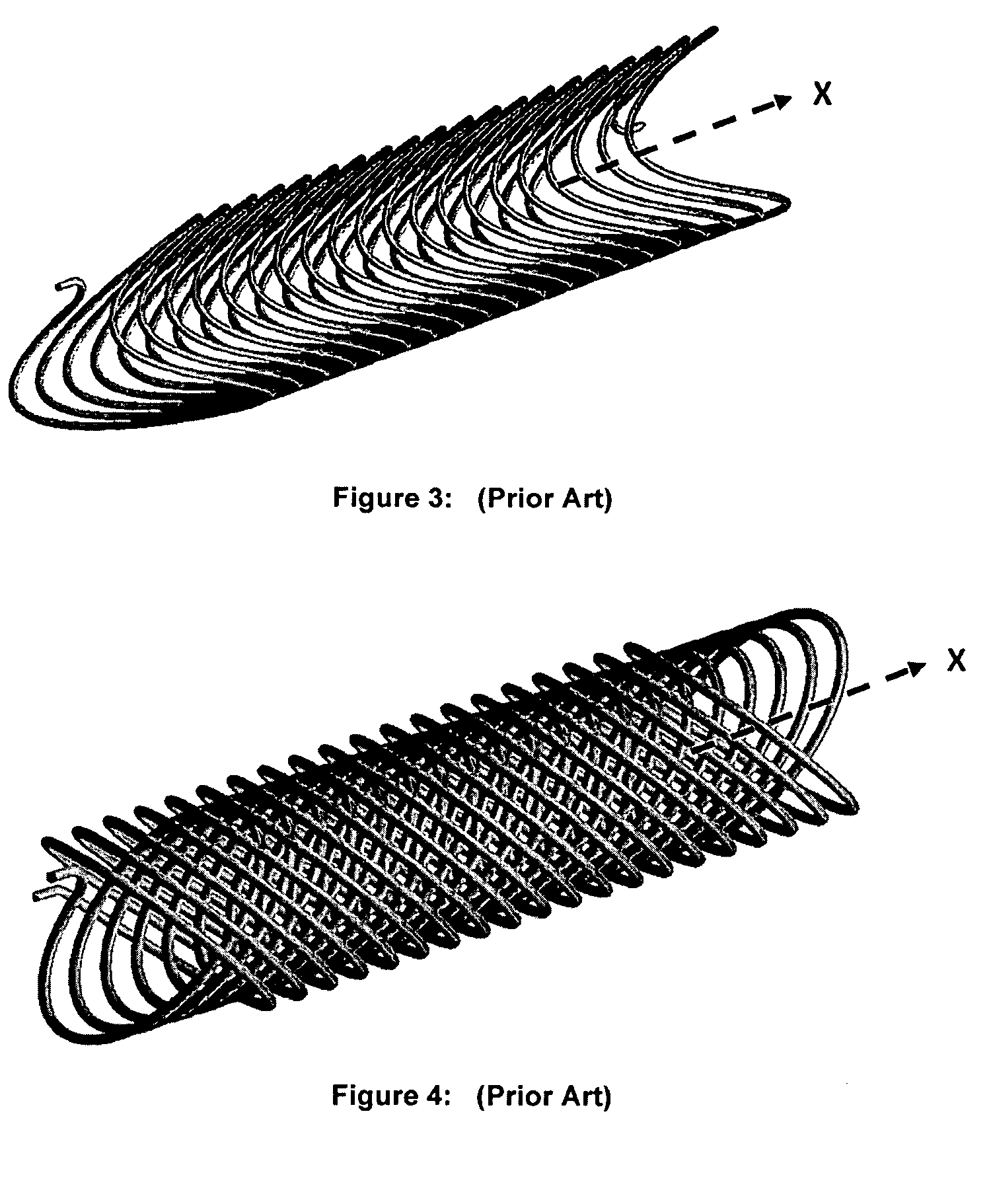

Method of Reducing Multipole Content In A Conductor Assembly During Manufacture

InactiveUS20090083969A1Weakening rangeSuppress generationSparking plugsSpark gapsElectrical conductorField specification

A method for manufacture of a conductor assembly. The assembly is of the type which, when conducting current, generates a magnetic field or in which, in the presence of a changing magnetic field, a voltage is induced. In an example embodiment one or more first coil rows are formed. The assembly has multiple coil rows about an axis with outer coil rows formed about inner coil rows. A determination is made of deviations from specifications associated with the formed one or more first coil rows. One or more deviations correspond to a magnitude of a multipole field component which departs from a field specification. Based on the deviations, one or more wiring patterns are generated for one or more second coil rows to be formed about the one or more first coil rows. The one or more second coil rows are formed in the assembly. The magnitude of each multipole field component that departs from the field specification is offset

Owner:ADVANCED MAGNET LAB

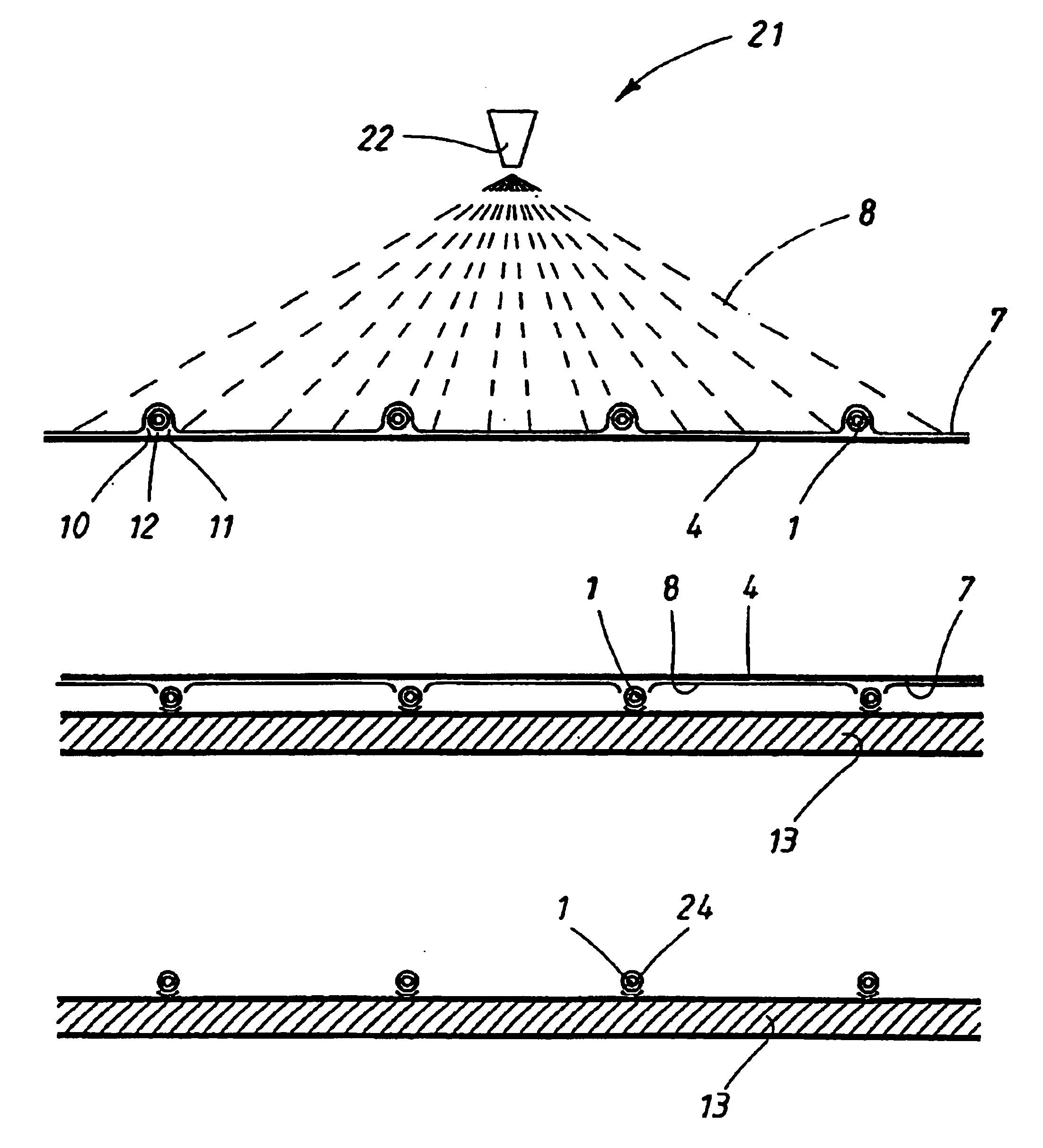

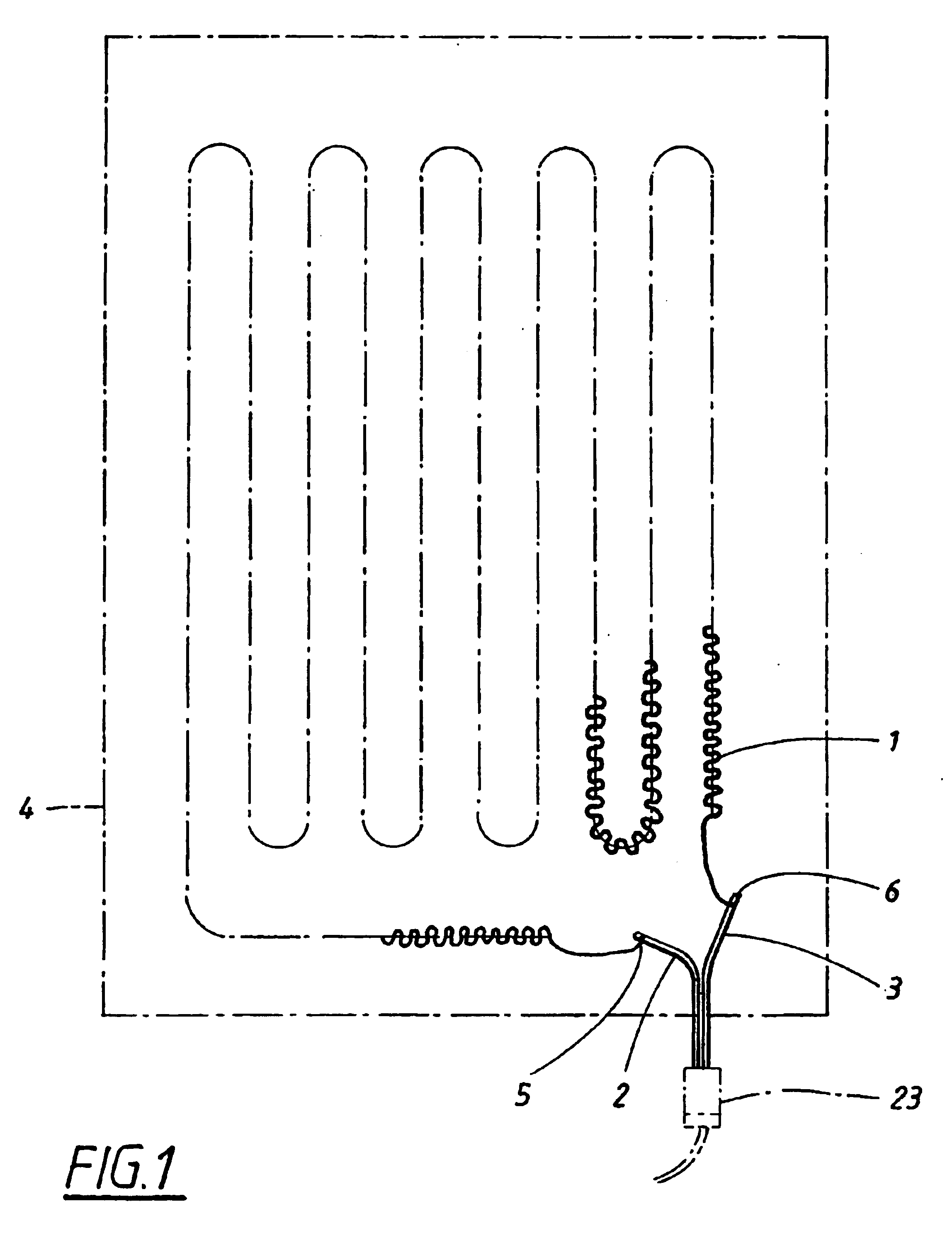

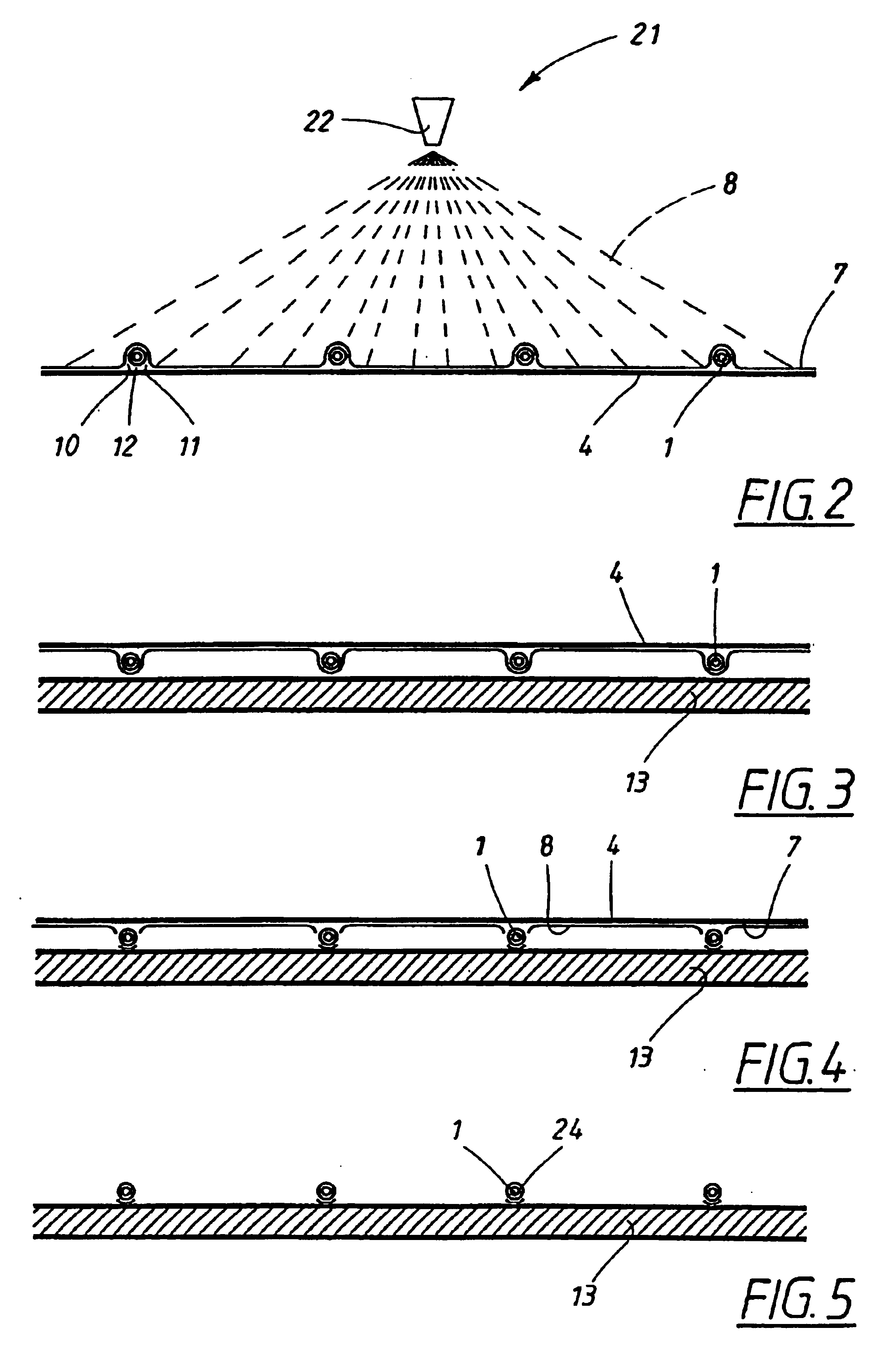

Method for manufacturing and application of heating element for heating in a vehicle

Method for production and application of a heating element for heating in vehicles where the heating element consists of heating wire defining at least one electric heating loop extending in a predetermined pattern including positioning the heating wire onto one side of a carrier; applying adhesive over the carrier, at least over areas where the heating wire is lying and over the heating wire, so the heating wire adheres to the surface of the carrier; transporting the carrier with the heating wire to a substrate, wherein the heating wire is adjacent to the substrate; pressing the heating wire against the substrate; heating and melting the adhesive to separate the heating wire from the carrier leaving the heating wire adhered to the substrate; and, removing the carrier, so the heating wire is released from the carrier and adheres to the substrate, to form the heating element for heating in the vehicle.

Owner:KONGSBERG AUTOMOTIVE AB (SE)

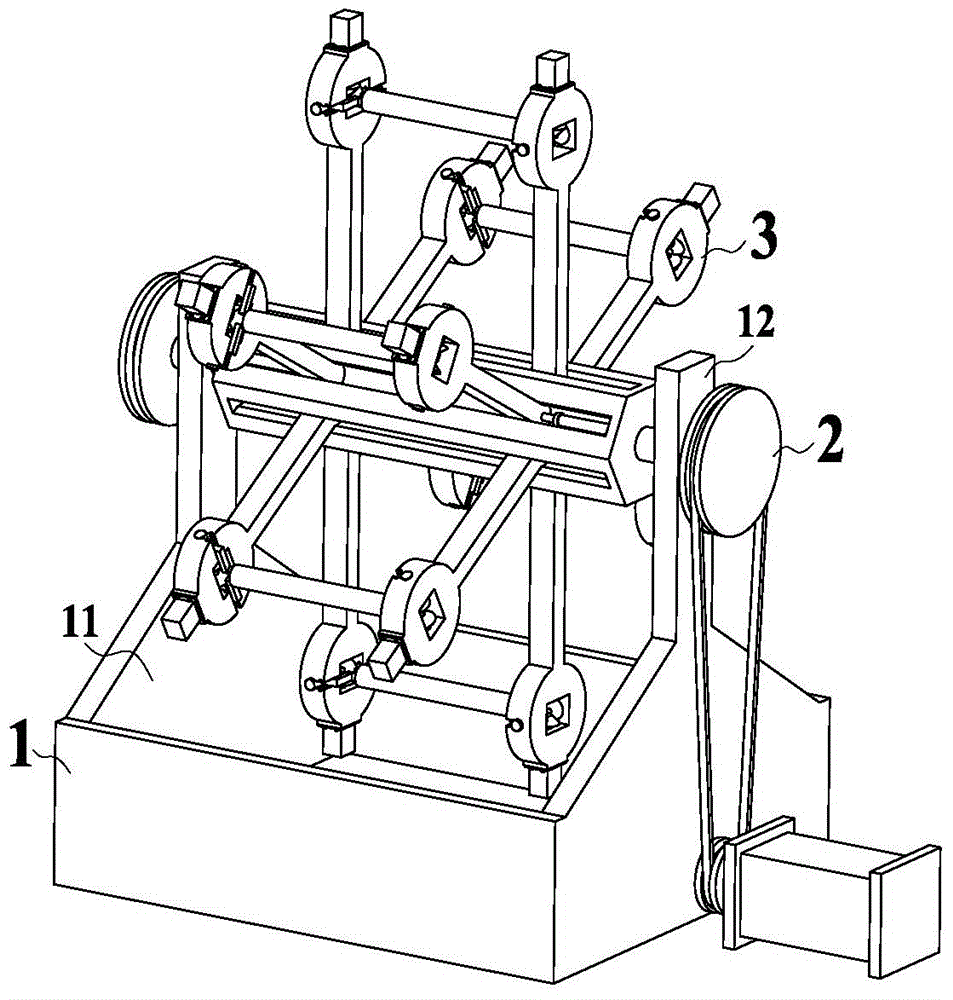

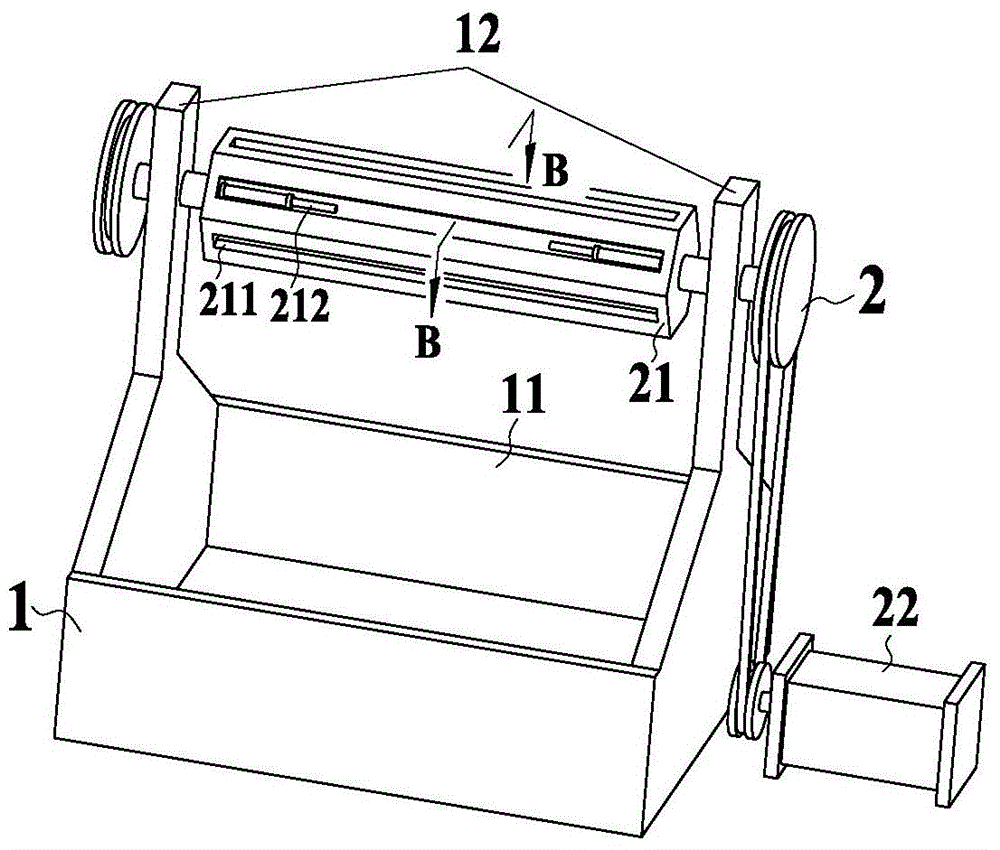

Protective paint transferring and dip-coating device for winding resistors

ActiveCN104882236AReduce stepsReduce labor intensityLiquid surface applicatorsCoatingsLacquerEngineering

The invention relates to the field of winding resistor paint coating devices and in particular relates to a protective paint transferring and dip-coating device for winding resistors. The device comprises a device body, a rotation device, a clamping device and a transferring device, wherein the device body comprises a paint containing slot, a front supporting plate and a rear supporting plate; the paint containing slot is a rectangular slot and is formed in the lower part of the device body. During work, protective paint is positioned in the paint containing slot; the rotation device is positioned in the middle of the device body; the clamping device is positioned around the rotation device and is positioned right above the paint containing slot; the transferring device is positioned at the right side of the device body. The protective paint transferring and dip-coating device can be used for filling up the defects that during the winding resistor paint coating, the degree of automation is low, the harm to a human body is caused and the like in the prior art, and achieving the aims of automatic transferring and automatic paint coating; the manual operation is reduced, the labor intensity of workers is reduced, the body health of the workers is facilitated, and the automatic operation is realized in the whole process; compared with that in the prior art, the paint coating efficiency is improved.

Owner:嘉兴威伏半导体有限公司

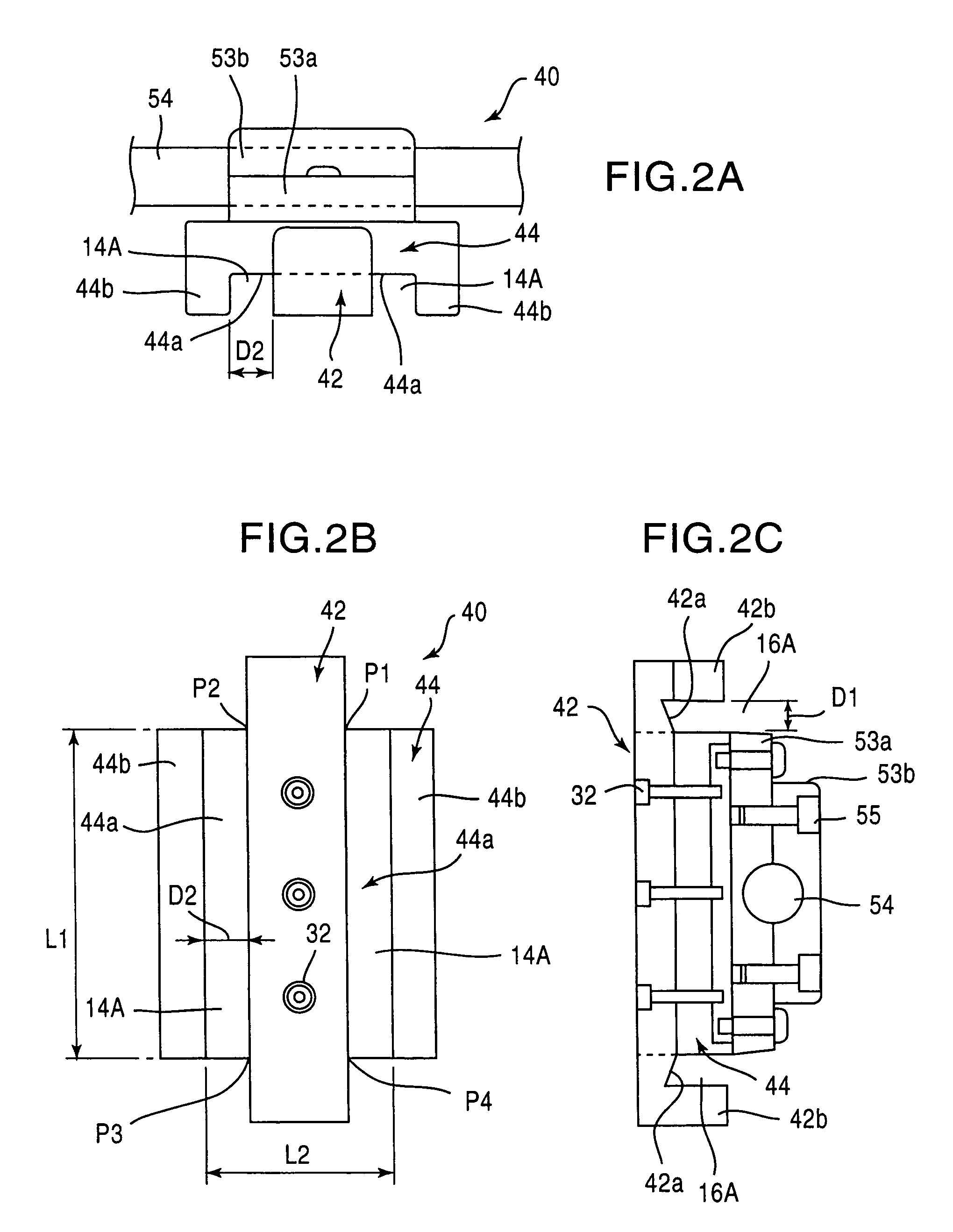

Apparatus and method for winding multi-layer coil in trapezoidal winding space

InactiveUS6910654B2Improve space factorEasy windingFilament handlingManufacturing dynamo-electric machinesBobbinSurface coil

A multi-layer coil is wound around a bobbin having a center pillar and a small and a large flanges connected to longitudinal ends of the center pillar. A winding space having a trapezoidal cross-section in a plane cut through the center axis of the bobbin is formed outside the center pillar between both flanges. To wind the multi-layer coil in this winding space, a turning position where a layer of the coil moves up to a higher layer is set by a position setter, and the turning position is automatically shifted layer by layer to form a sloped outer surface of the coil. The coil is wound in a shape fitting the trapezoidal winding space without reducing the winding speed. The space factor of the coil in the winding space is improved, making the coil compact in size.

Owner:DENSO CORP

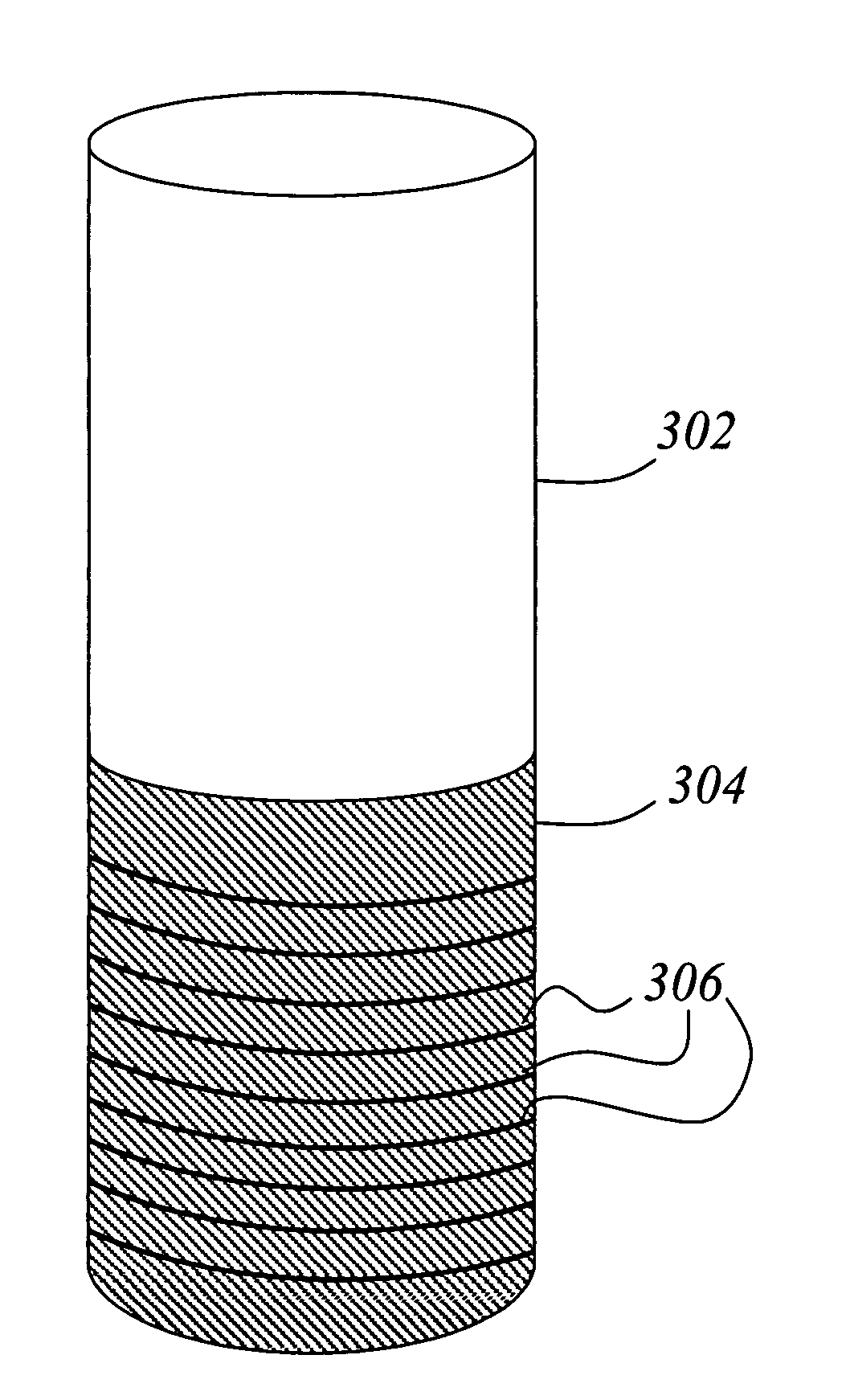

Method of suppressing sublimation in advanced thermoelectric devices

InactiveUS7480984B1Suppresses mass lossOvercome disadvantagesLine/current collector detailsEnvelope/housing resistor manufactureThermoelectric materialsMetal foil

A method of applying a physical barrier to suppress thermal decomposition near a surface of a thermoelectric material including applying a continuous metal foil to a predetermined portion of the surface of the thermoelectric material, physically binding the continuous metal foil to the surface of the thermoelectric material using a binding member, and heating in a predetermined atmosphere the applied and physically bound continuous metal foil and the thermoelectric material to a sufficient temperature in order to promote bonding between the continuous metal foil and the surface of the thermoelectric material. The continuous metal foil forms a physical barrier to enclose a predetermined portion of the surface. Thermal decomposition is suppressed at the surface of the thermoelectric material enclosed by the physical barrier when the thermoelectric element is in operation.

Owner:NASA

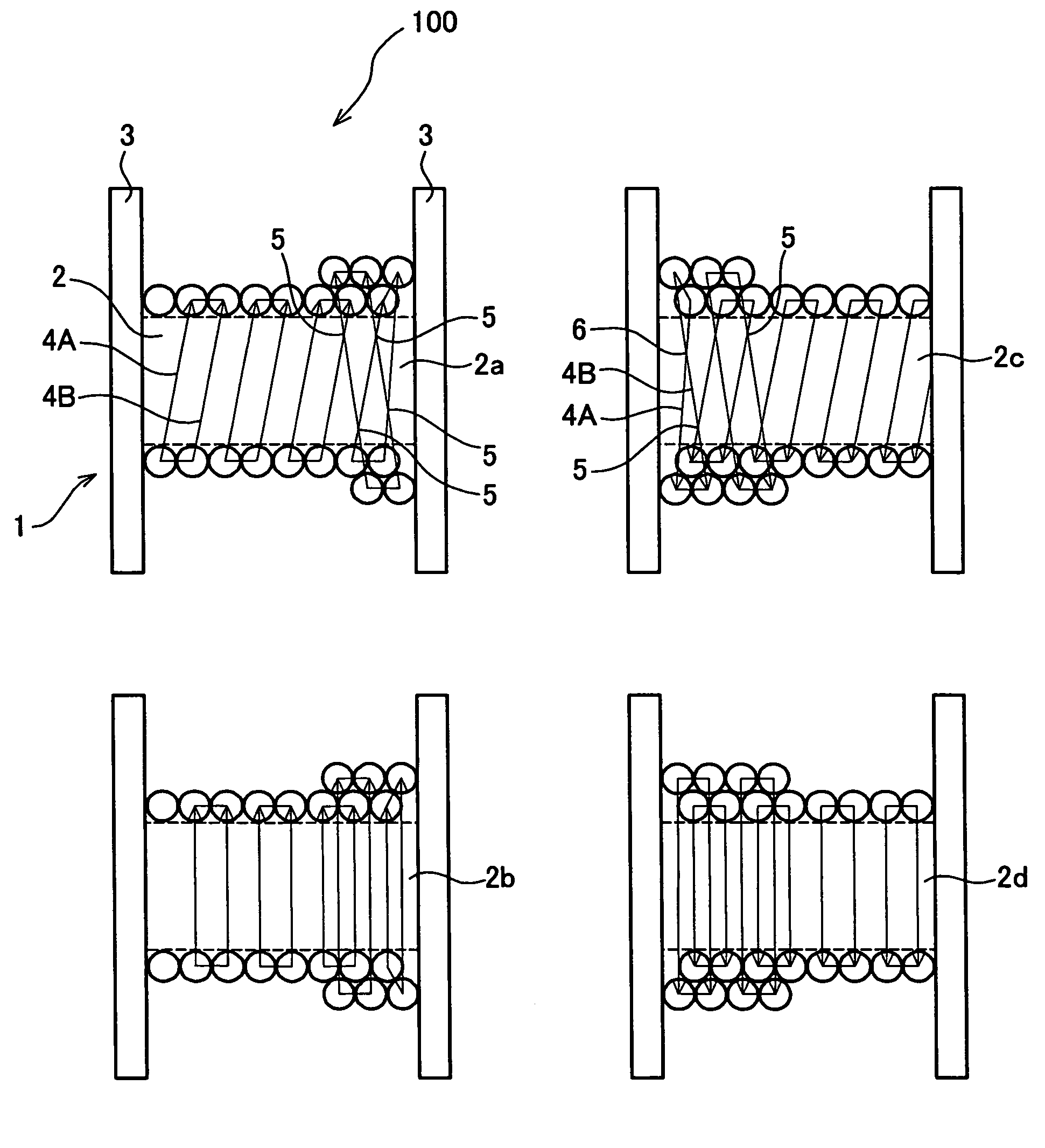

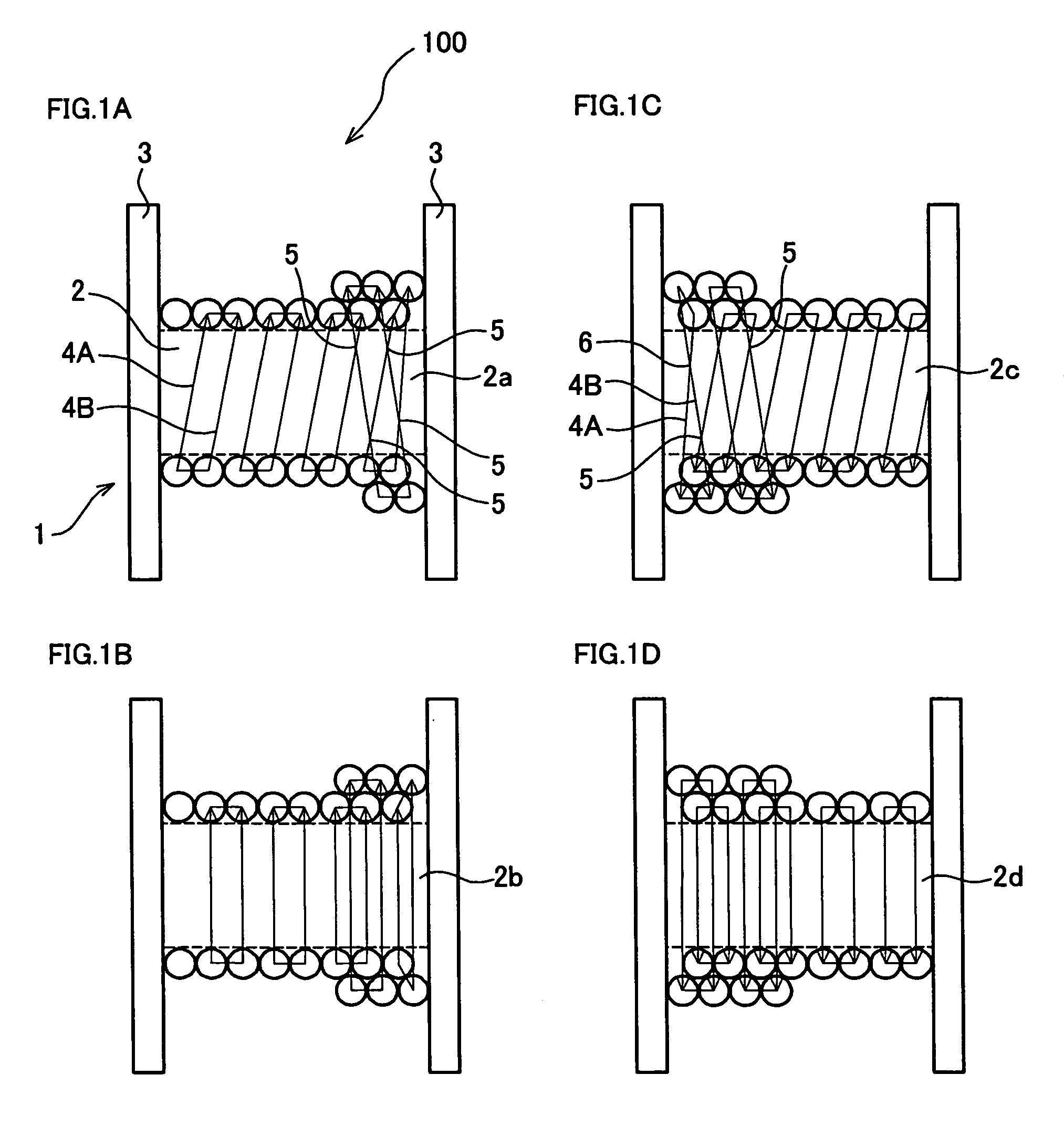

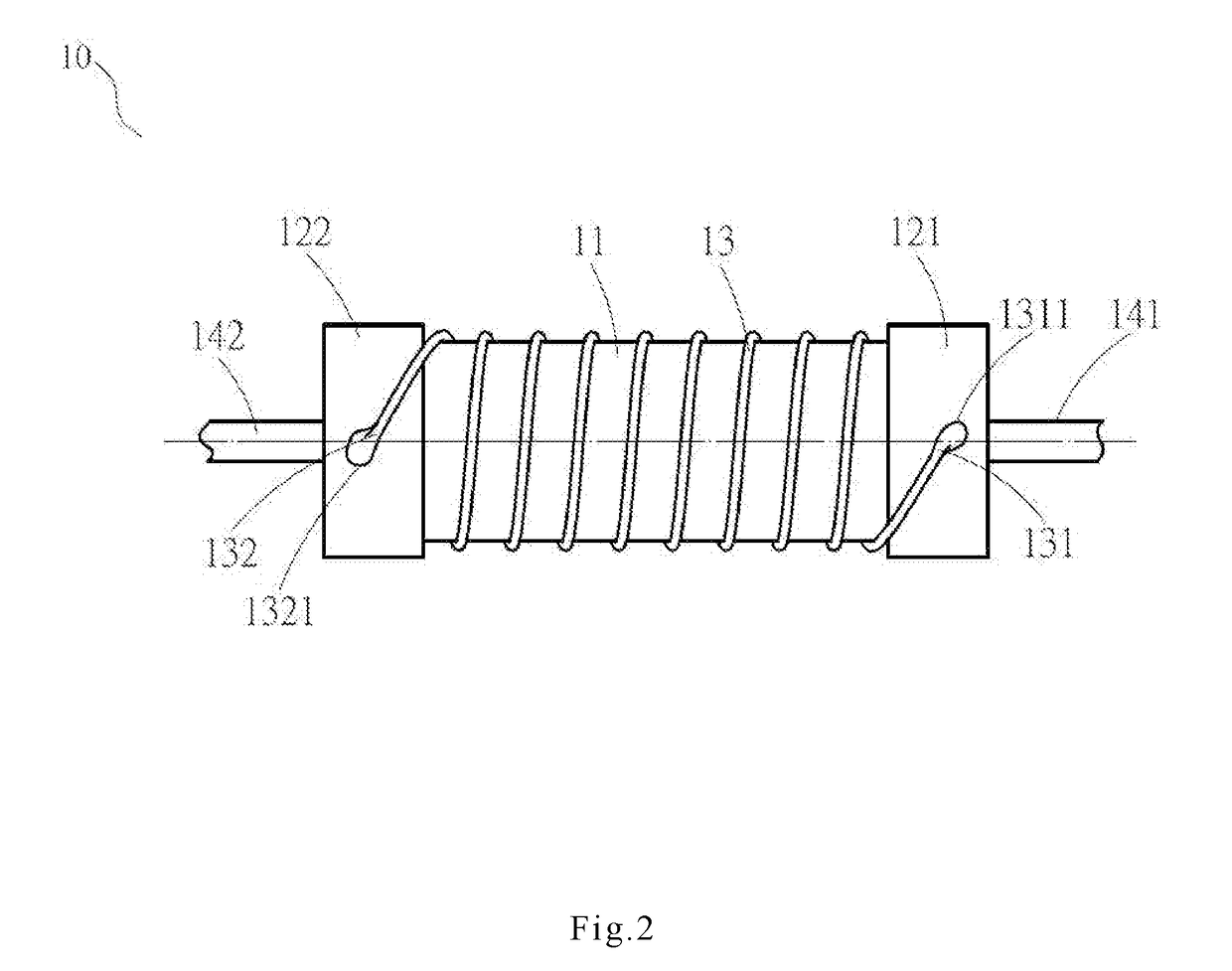

Multilayer coil, winding method of same, and winding apparatus of same

Owner:NITTOKU ENG CO LTD

Multilayer coil, winding method of same, and winding apparatus of same

Owner:NITTOKU ENG CO LTD

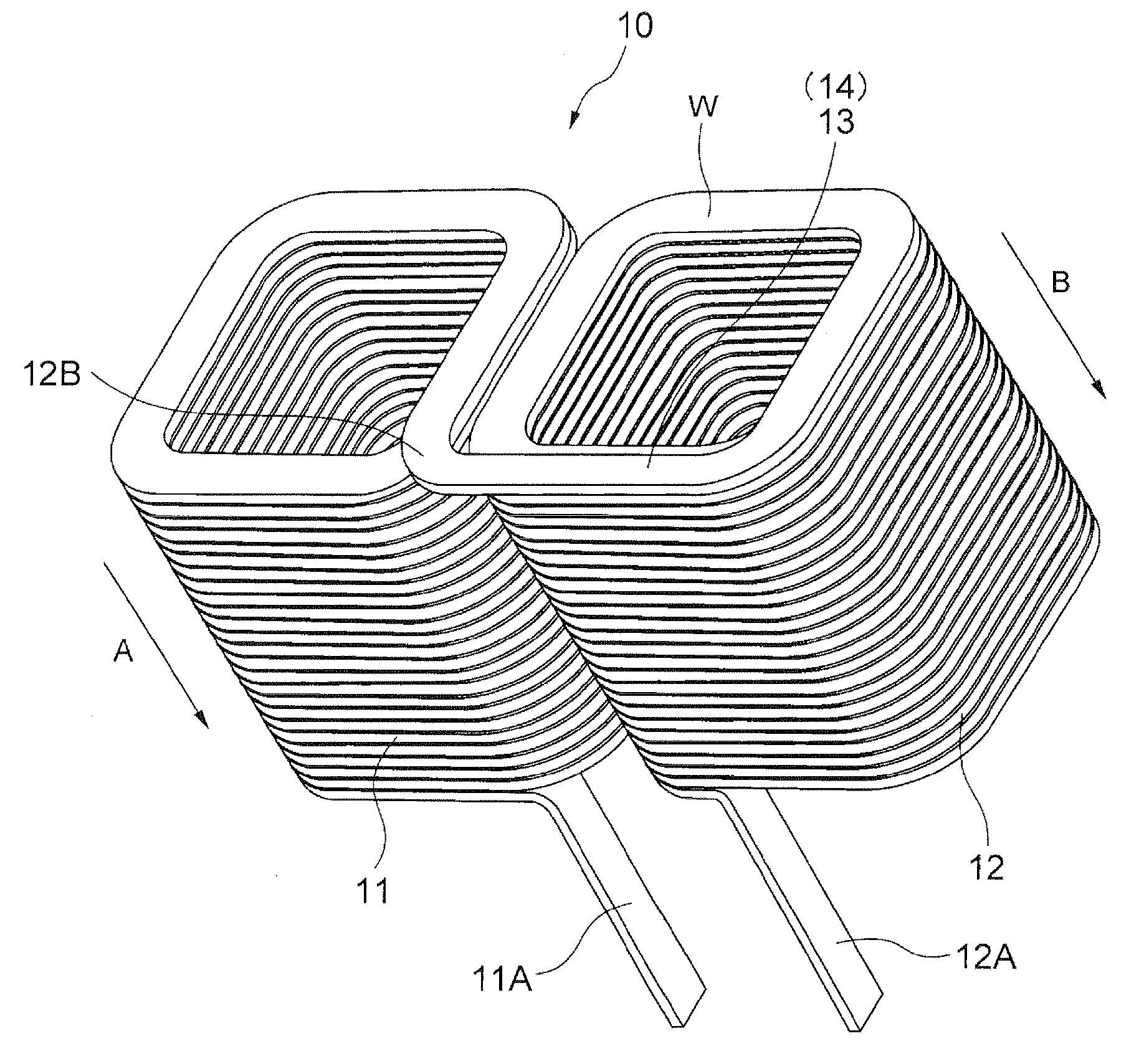

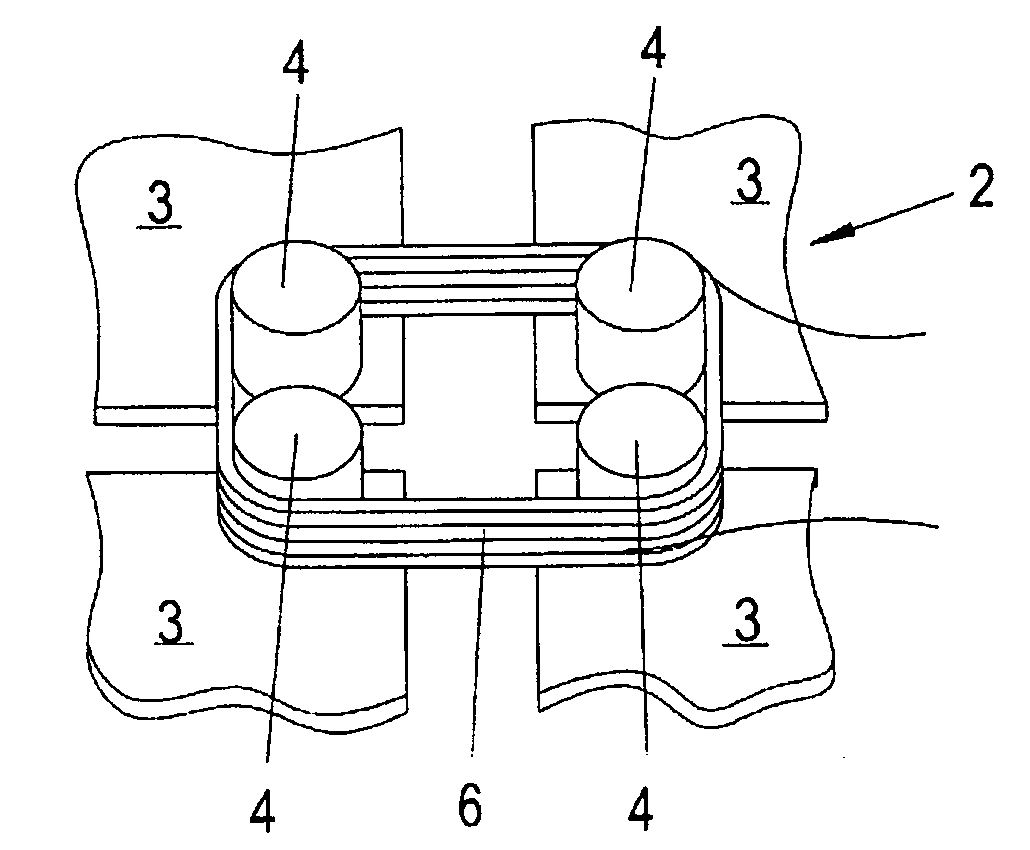

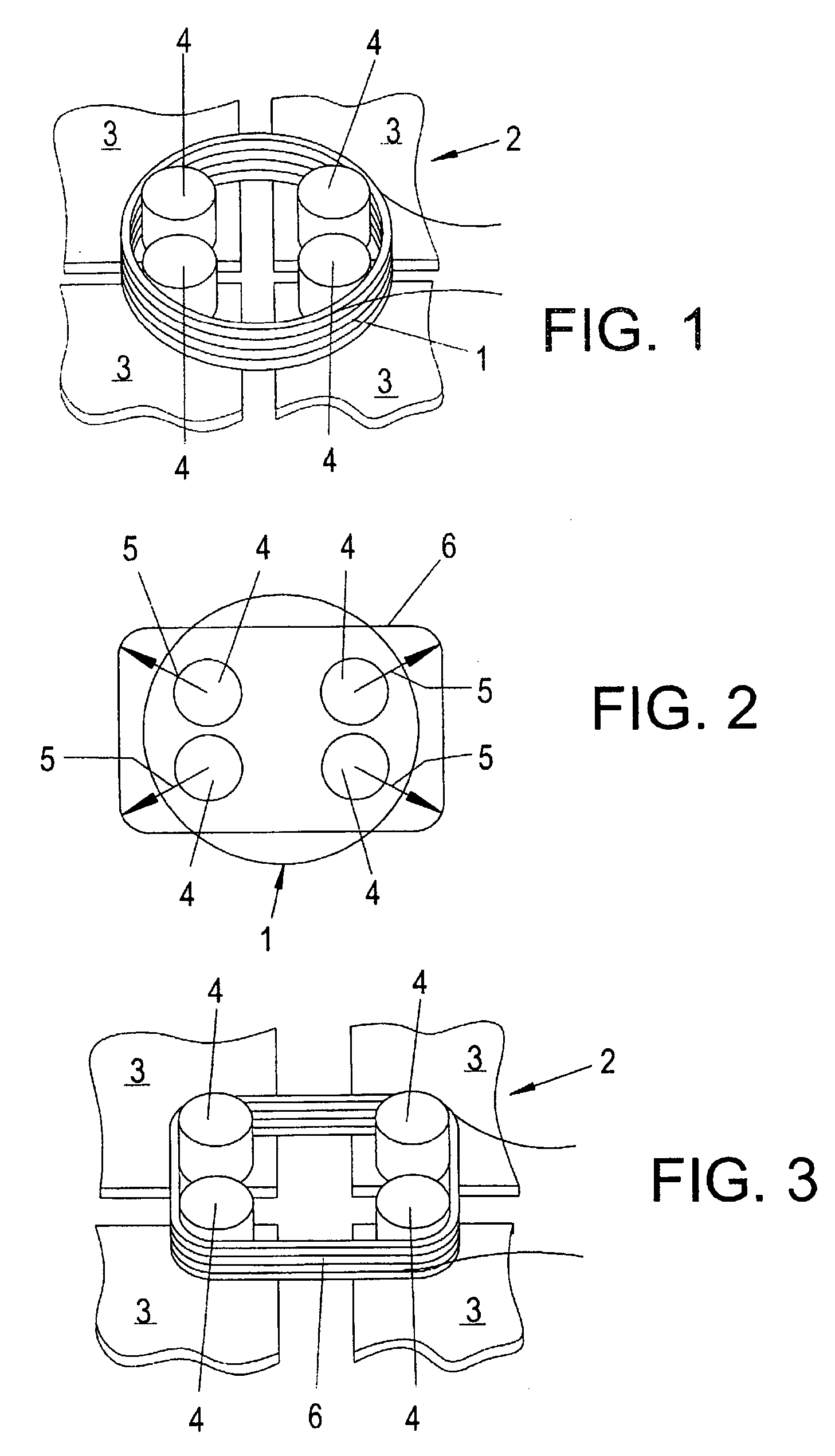

Linked coil formation device and method of forming linked coils

ActiveUS20100319802A1Efficient processingImprove efficiencyWire articlesTransformers/inductances detailsEngineeringConductor Coil

[Problem to be Solved] A first coil and a second coil are efficiently formed in the shape of a rectangular cylinder and in parallel to each other, by bending and processing a flat wire, and a linking part of each of the coils, is linked with the same material without welding or folding.[Means for Solving the Problem] Provided are: a first coil winding processing line having a first winding head forming a first coil part in the shape of a rectangular cylinder at one end part of a flat wire W; a second coil winding processing line disposed in parallel to the first coil winding processing line and having a second winding head on which a second coil part in the shape of a rectangular cylinder is formed at the other end part of the flat wire W and both of the coil parts are arranged to be adjacent to each other on an identical face; and a coil placement unit for conveying the flat wire W having the first coil part from the first coil winding processing line to the second coil winding processing line along each coil winding processing line.

Owner:TAMURA KK

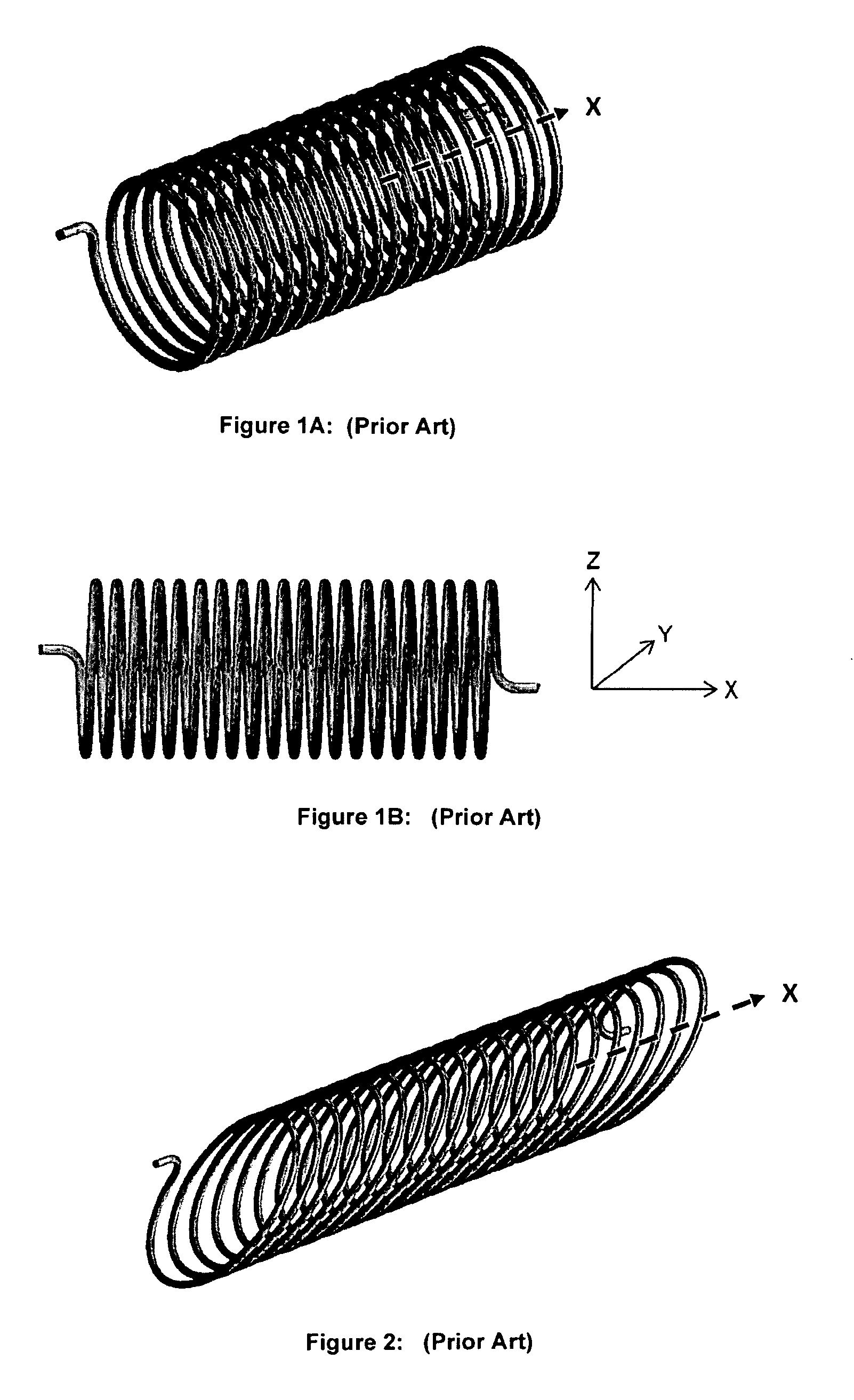

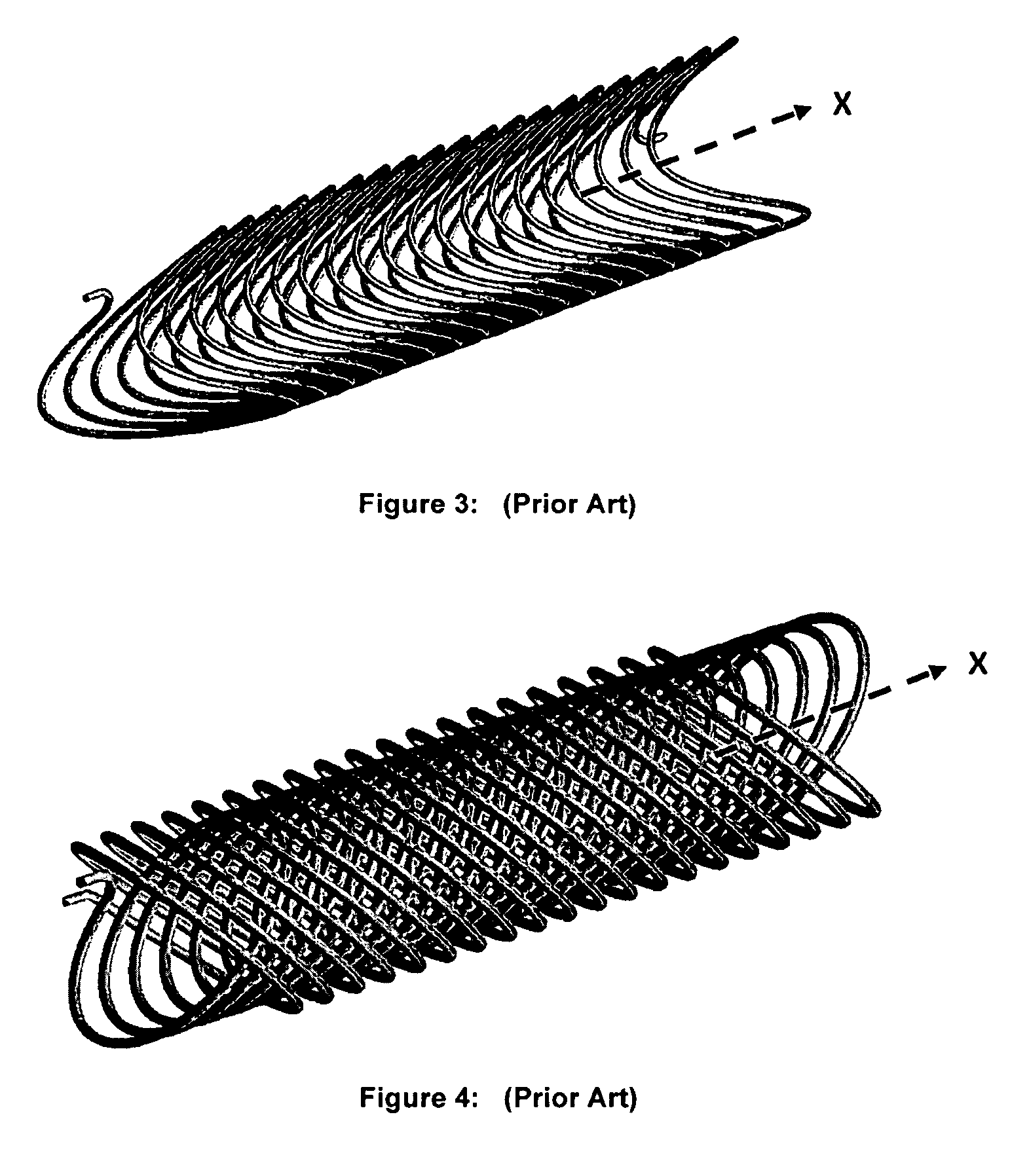

Conductor Assembly and Methods of Fabricating a Conductor Assembly With Coil Having An Arcate Shape Along A Curved Axis

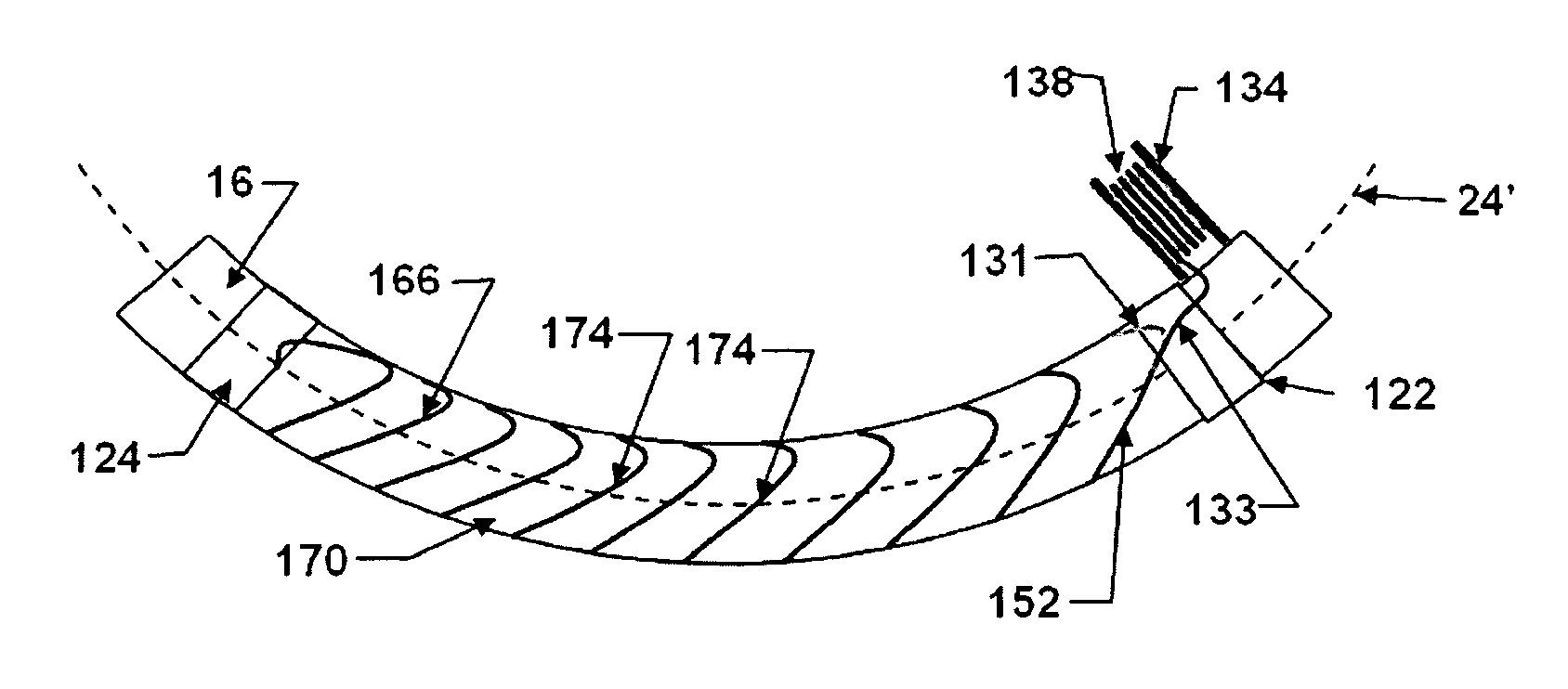

InactiveUS20090083967A1Reduce field strengthAvoid interferenceMagnetic measurementsWave amplification devicesArcuate shapeEngineering

A conductor assembly including a magnetic coil positioned about a curvilinear axis with one or more coil rows comprising conductive material having an arcuate shape. A generated field is characterized by a dipole component having a first magnitude, a quadrupole component having a second magnitude, a sextupole component having a third magnitude and a decupole component having a fourth magnitude. The third and fourth magnitudes each 10−3 the first magnitude or less. An associated method includes specifying, for a coil along a straight axis, a first magnetic field pattern including a main magnetic field component of a first order, specifying a first wiring pattern about the straight axis representable by a first series of points, generating a second series of points about a curvilinear axis specification to provide a second wiring pattern derived from the first series of points, characterizing a magnetic field which can be generated according to the second wiring pattern, identifying about the curvilinear axis a first magnitude magnetic field component of a second order, and generating a third wiring pattern along a straight axis with a third series of points based on the first series of points and incorporating a first modulation based on which a generated magnetic field includes a second multipole component of the second order capable of reducing the net field strength of components of the second order. A fourth series of points generated about a curvilinear axis provides a fourth wiring pattern derived from the third series of points.

Owner:ADVANCED MAGNET LAB

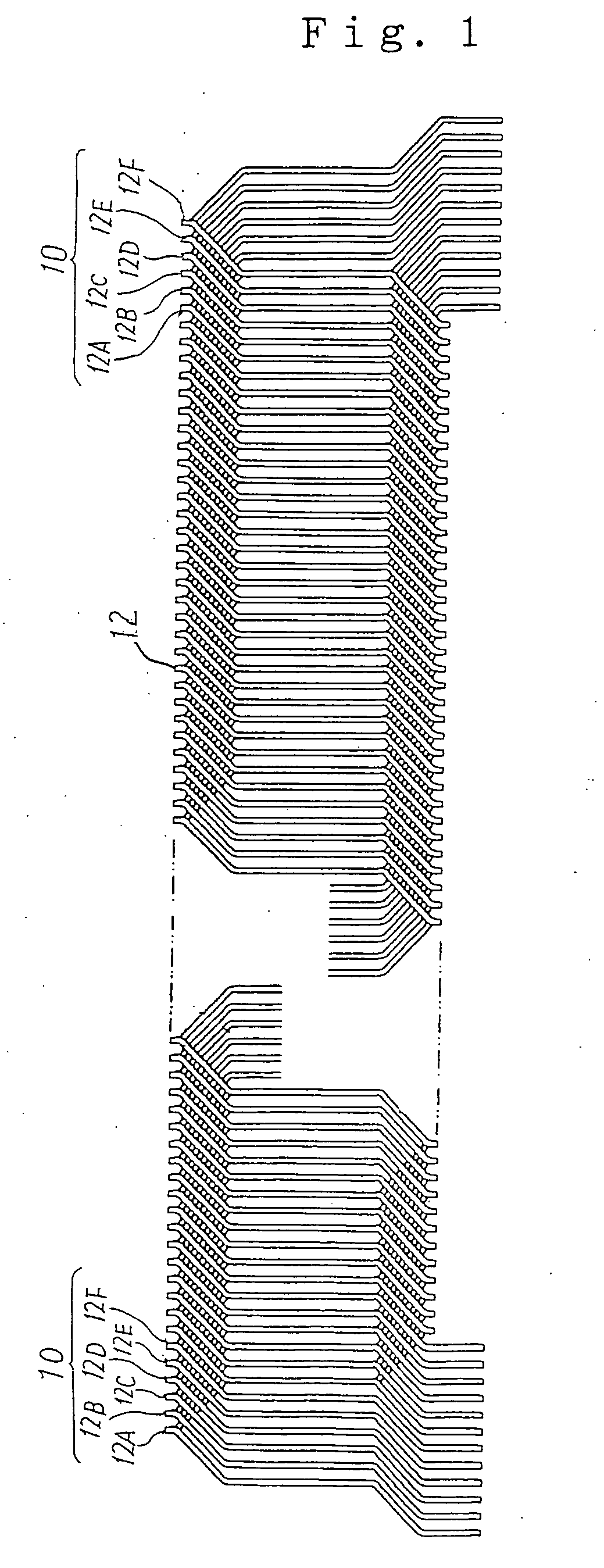

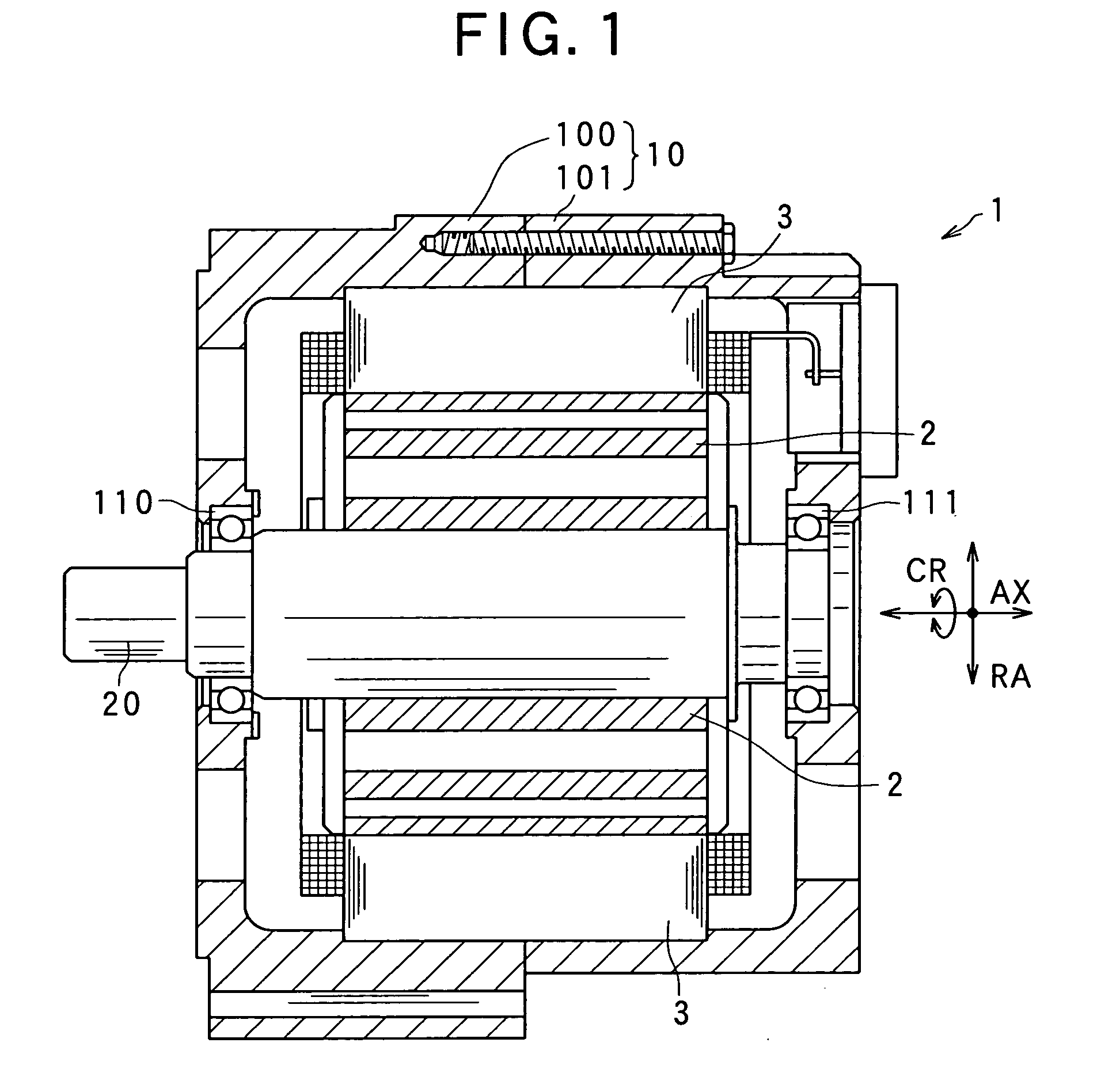

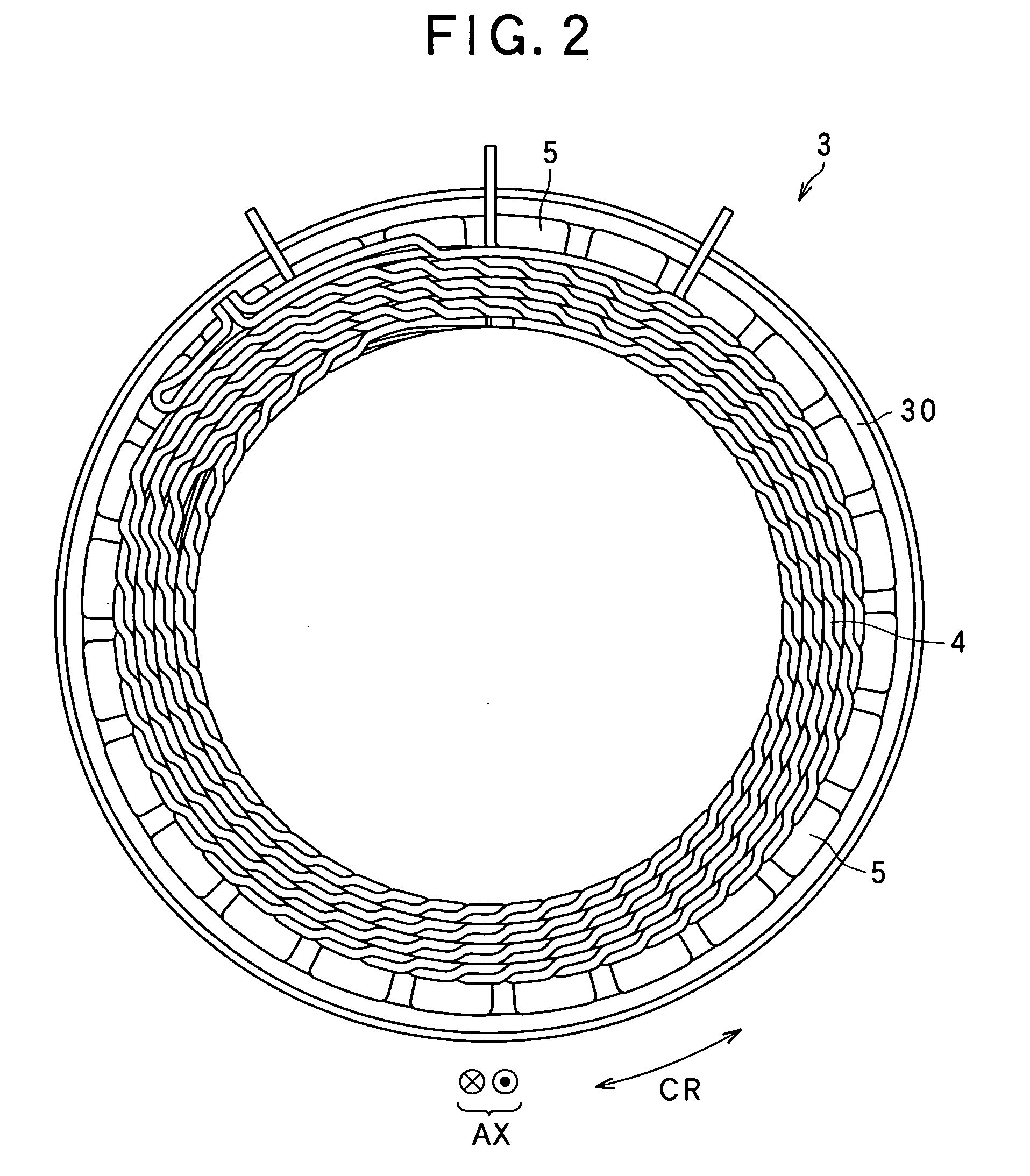

Process for producing winding assembly of dynamo-electric machine and production system of winding assembly

ActiveUS20060230603A1Reduce the number of timesEasy to adjustSynchronous generatorsElectrical transducersWire rodElectric machine

Owner:MITSUBISHI ELECTRIC CORP

Device and method for storing and/or dispensing rigid or flexible substantially planar items

InactiveUS20060097444A1Prevent slippingPreventing overlappingProjector film strip handlingCamera film strip handlingEngineeringBank note

Described herein are a device and a method for storing and / or dispensing plane, rigid, or flexible items, such as banknotes, cards or the like. The items are stored sequentially between successive windings of ribbon means which are wound and unwound between a supporting element, driven in rotation by at least one electric motor, and at least one take-up member. The supporting element has a non-circular cross section for obtaining one or more distinct resting surfaces on which the ribbon means are wound.

Owner:SPINETTI ALBERTO

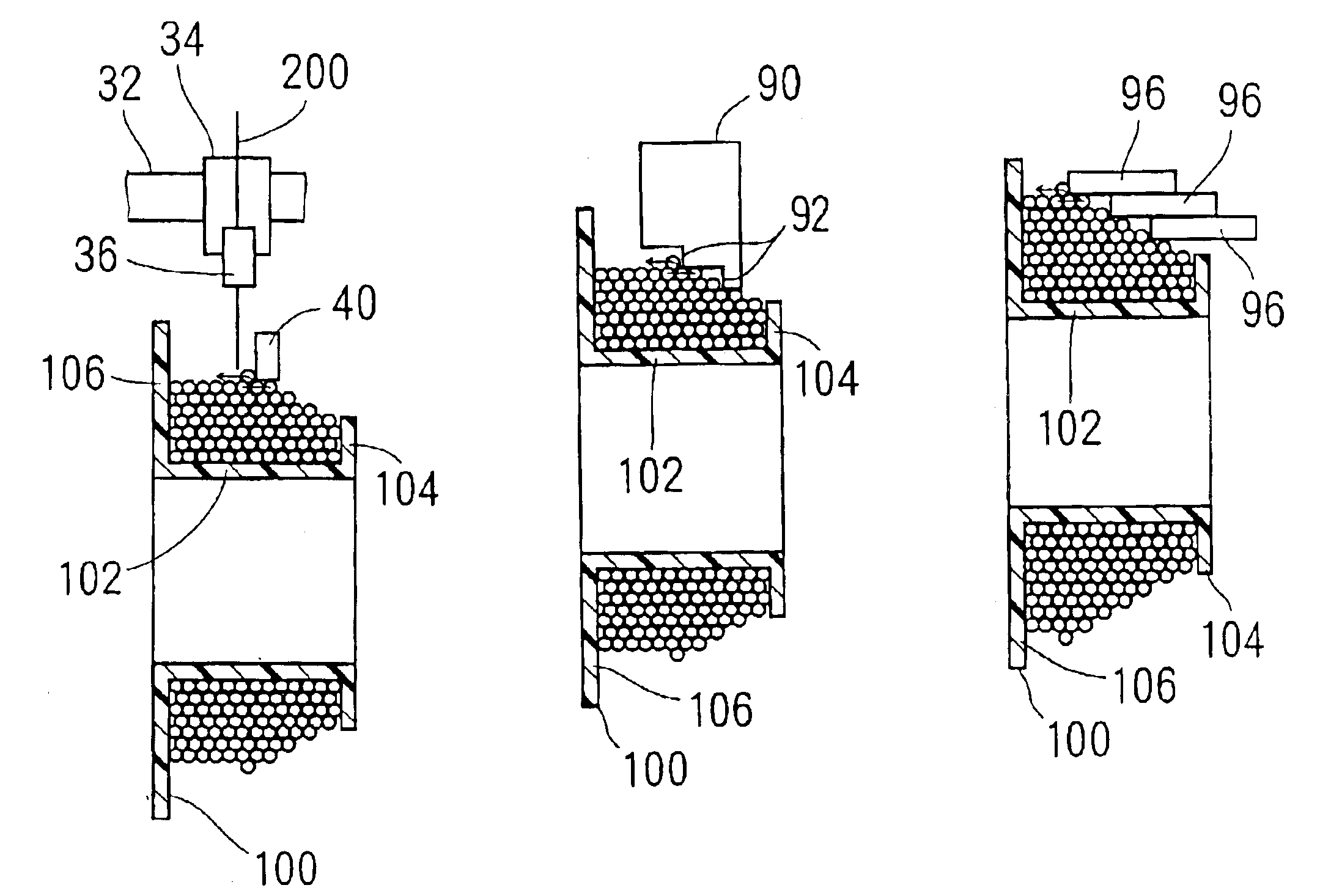

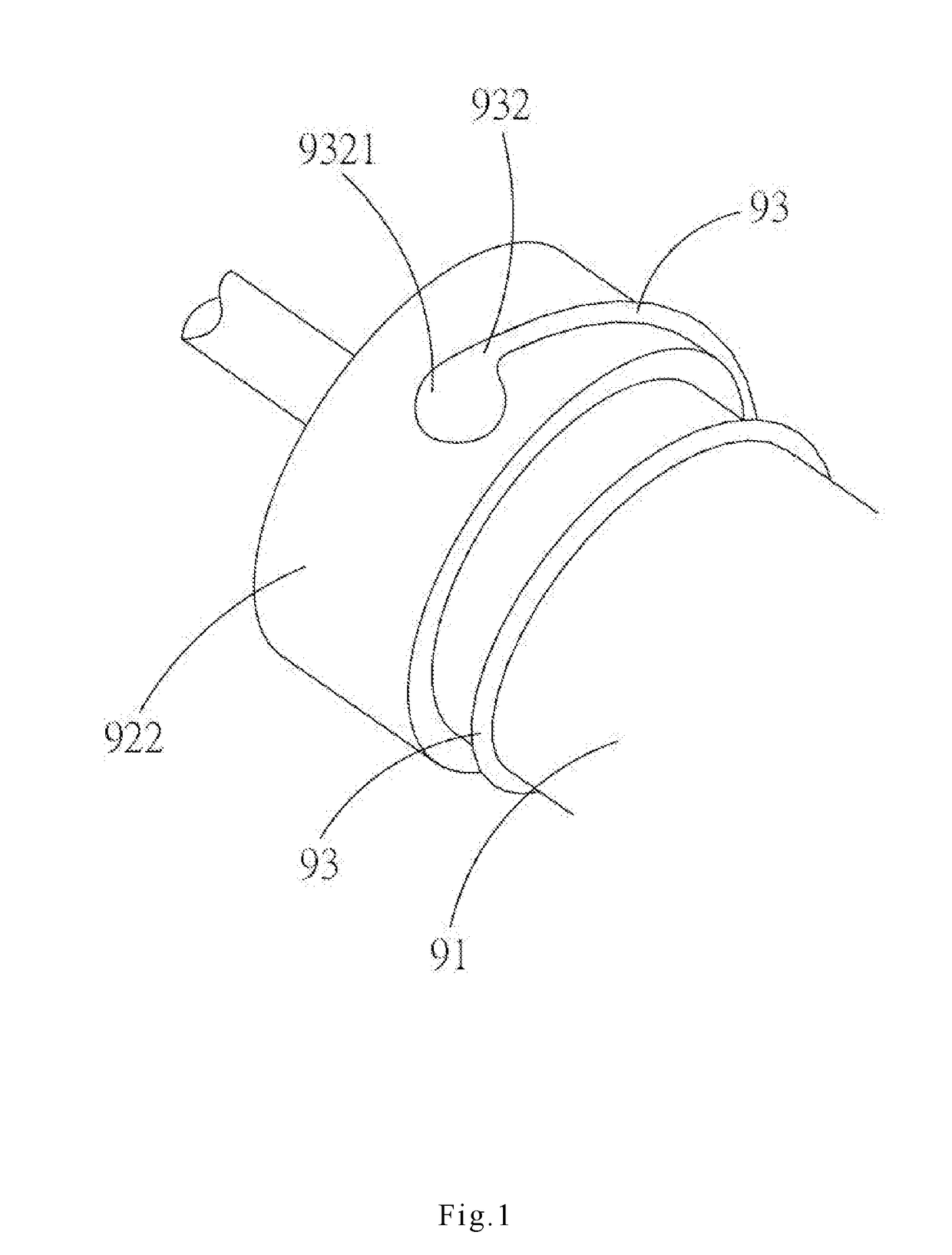

Electric cartridge type heater and method for manufacturing same

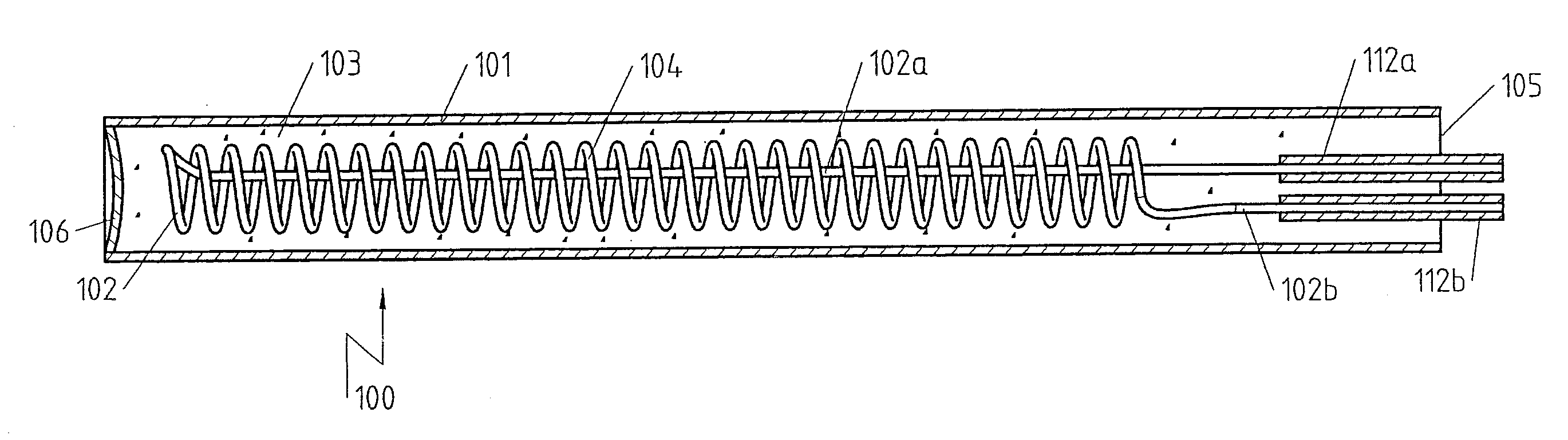

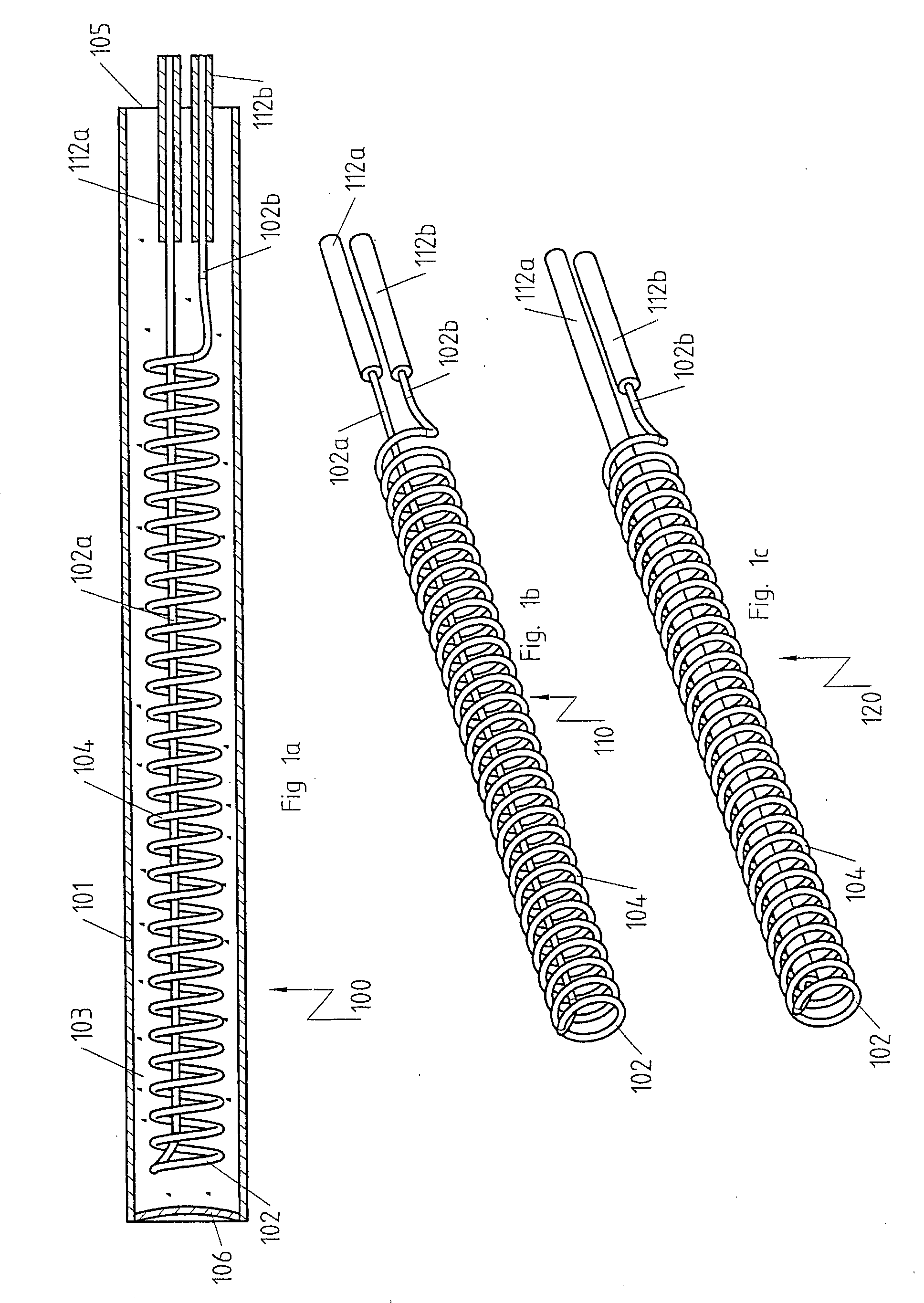

ActiveUS20150001206A1Simple and cost-effectiveEnvelope/housing resistor manufactureHeater elementsElectricityInterior space

An electric cartridge type heater (100, 200, 300, 400, 500, 600, 700, 800, 900, 1000) has at least one the tubular metallic jacket (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001), at least one electric heat conductor (102, 202, 302, 402, 502, 602, 702, 802, 902, 1002) arranged in the interior space of the tubular metallic jacket with two ends for electrically contacting the electric heat conductor, wherein the at least one electric heat conductor is electrically isolated from the tubular metallic jacket by an electrically insulating material (103, 203, 303, 403, 503, 603, 703, 903) arranged in the interior space of the tubular metallic jacket (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001). The electric heat conductor is self-supporting. A method is also provided for manufacturing such an electric cartridge type heater.

Owner:TUERK & HILLINGER

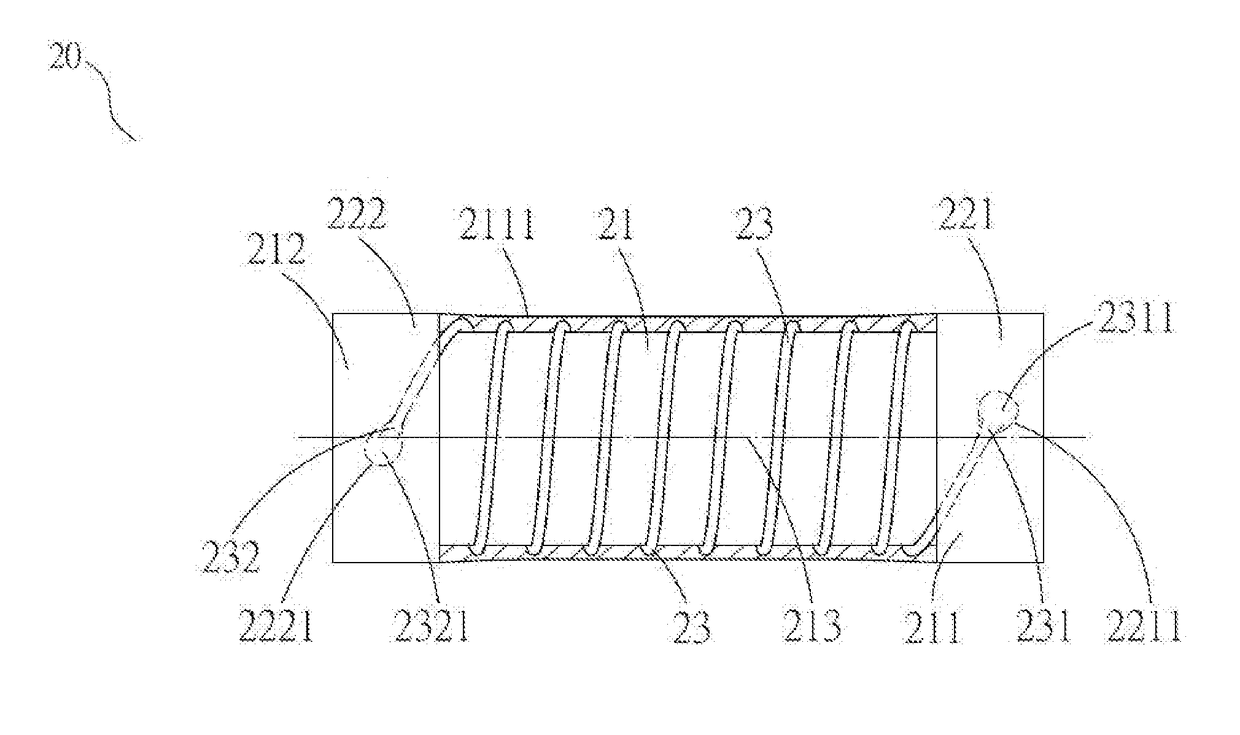

Wire-wound fuse resistor and method for manufacturing same

ActiveUS20180254163A1Envelope/housing resistor manufactureFuse device manufactureElectrical connectionConductor Coil

The present invention relates to a wire-wound fuse resistor, which has: an insulating rod which has a first end and a second end; one metal wire having a wire head and a wire tail, being helically wound around the insulating rod from the first end to the second end, and being cut at a middle portion thereof to form a first winding wire and a second winding wire, which are separated from each other; a connection part disposed at the cut portion for electrical connection between the first winding wire and the second winding wire, in which the melting temperature of the connection part is lower than that of the one wound metal wire, wherein the connection part is cut off depending on a predetermined melting temperature or melting speed of the wire-wound fuse resistor.

Owner:FIRST RESISTOR & CONDENSER

Device and method for storing and/or dispensing rigid or flexible substantially planar items

Described herein are a device and a method for storing and / or dispensing plane, rigid, or flexible items, such as banknotes, cards or the like. The items are stored sequentially between successive windings of ribbon means which are wound and unwound between a supporting element, driven in rotation by at least one electric motor, and at least one take-up member. The supporting element has a non-circular cross section for obtaining one or more distinct resting surfaces on which the ribbon means are wound.

Owner:SPINETTI ALBERTO

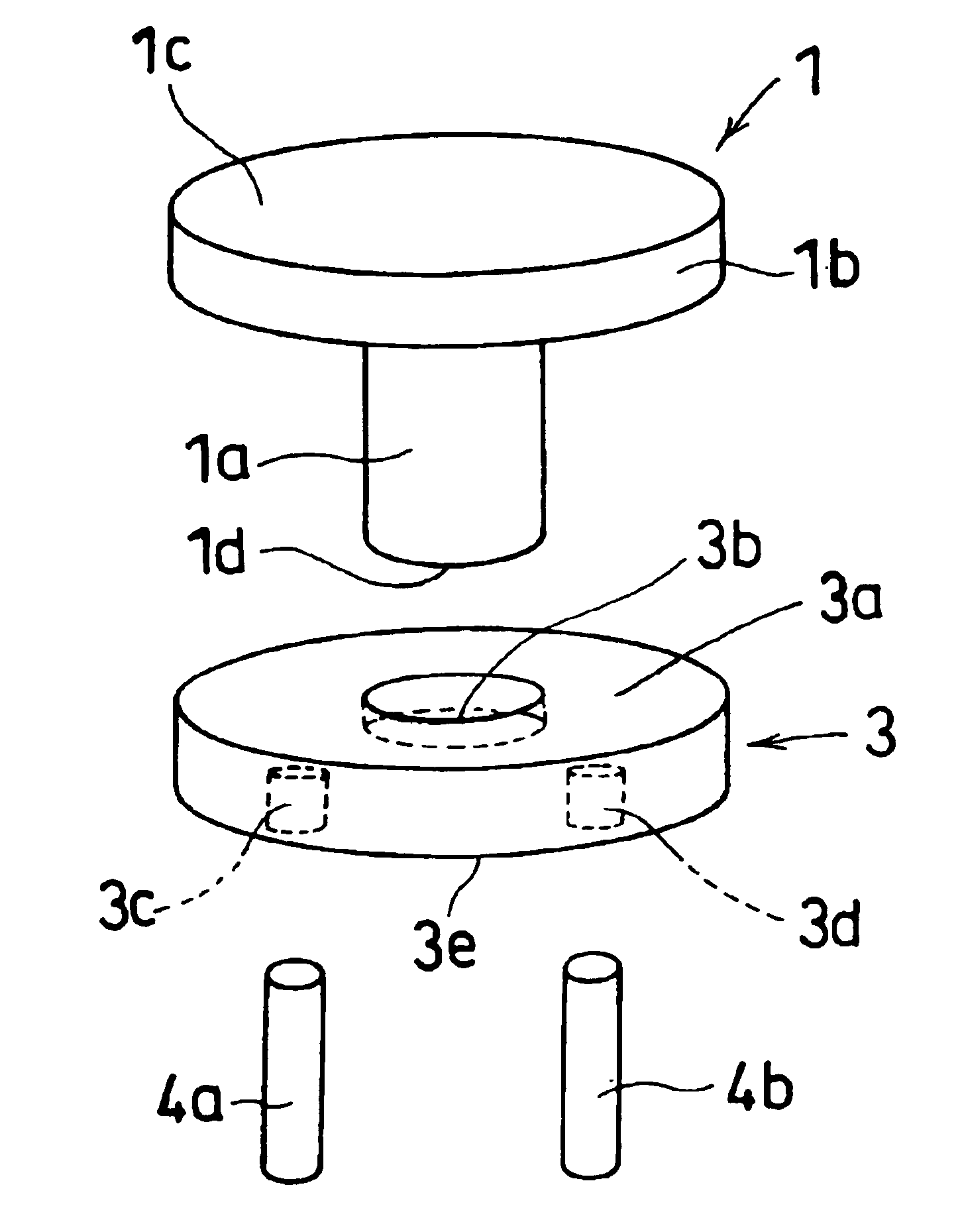

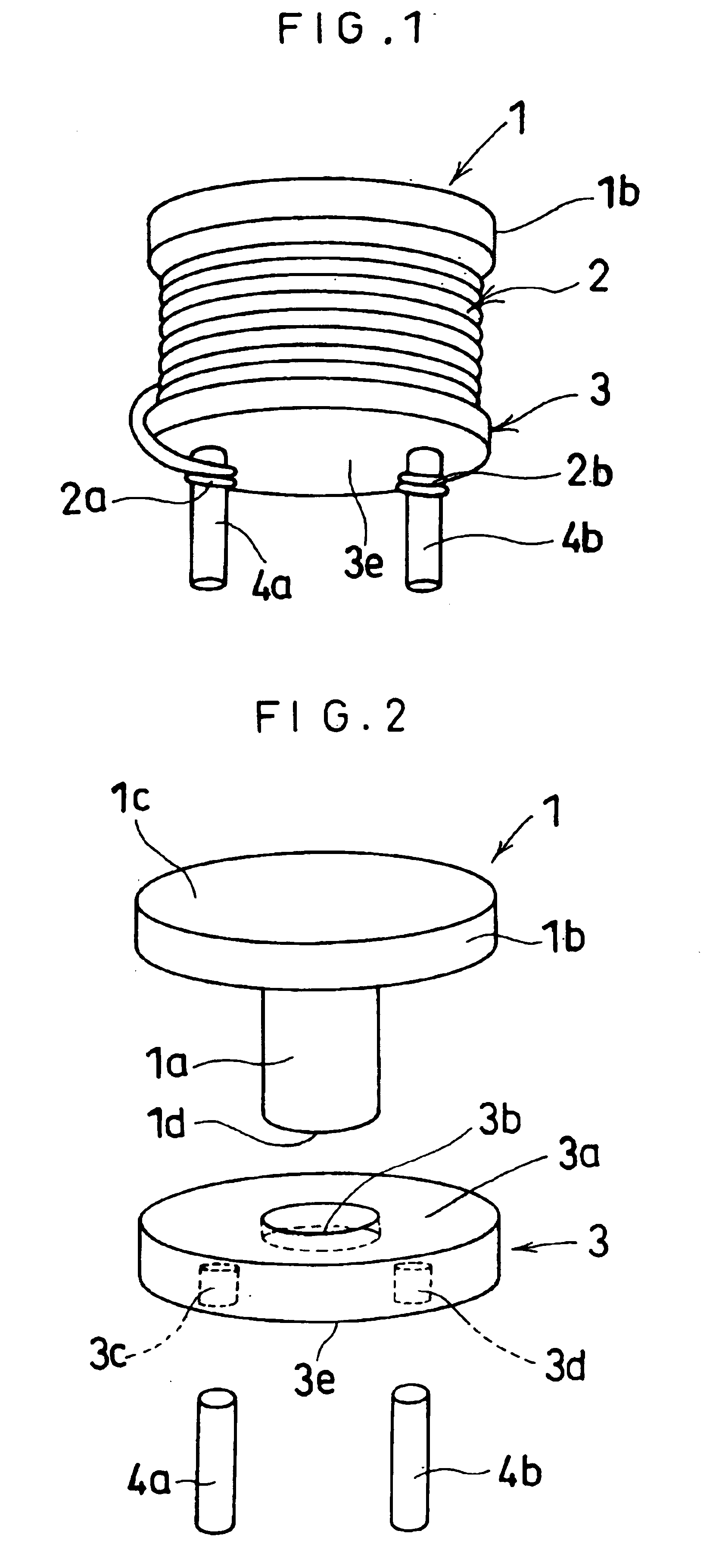

Drum type core with discrete structure

InactiveUS6927658B2Small sizeHigh surfaceTransformers/reacts mounting/support/suspensionTransformers/inductances casingsHigh surfaceFlange

A drum type core comprises: a flanged cylinder including a cylinder portion with a coil wound thereon, and a flange portion connected integrally with one end of the cylinder portion; and a flange piece having on its one side an engaging hole, into which the other end of the cylinder portion of the flanged cylinder is inserted. The flanged cylinder and the flange piece are made of respective different materials. The flanged cylinder has a higher permeability and saturation flux density than the flange piece, while the flange piece has a higher surface electrical resistance than the flanged cylinder. The flanged cylinder is entirely coated with a heat-resisting epoxy resin except an outer side of the flange portion. The flange piece is provided with terminal pins, around which lead wires of the coil passing by the circumference of the flange piece are bound.

Owner:MINEBEA CO LTD

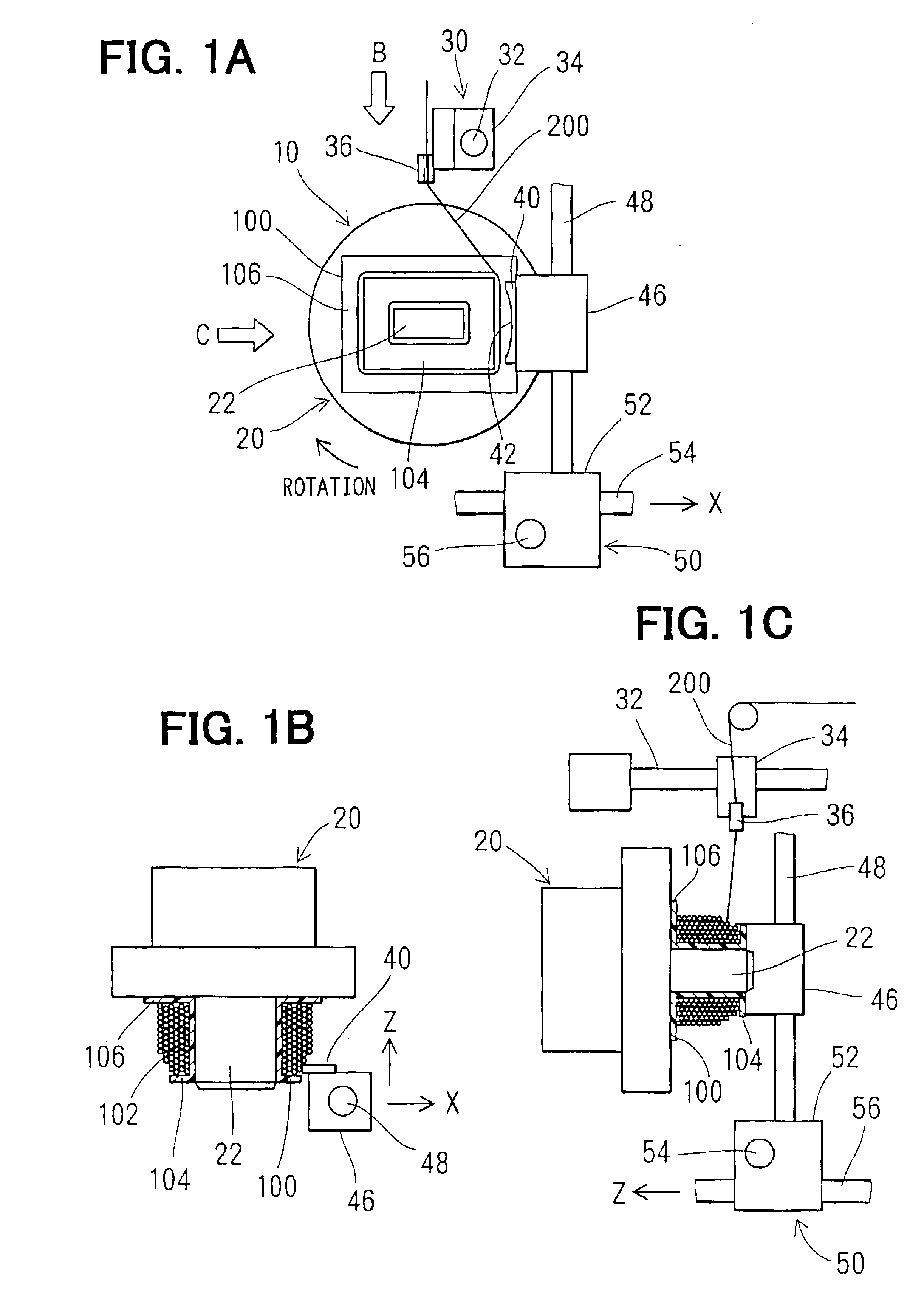

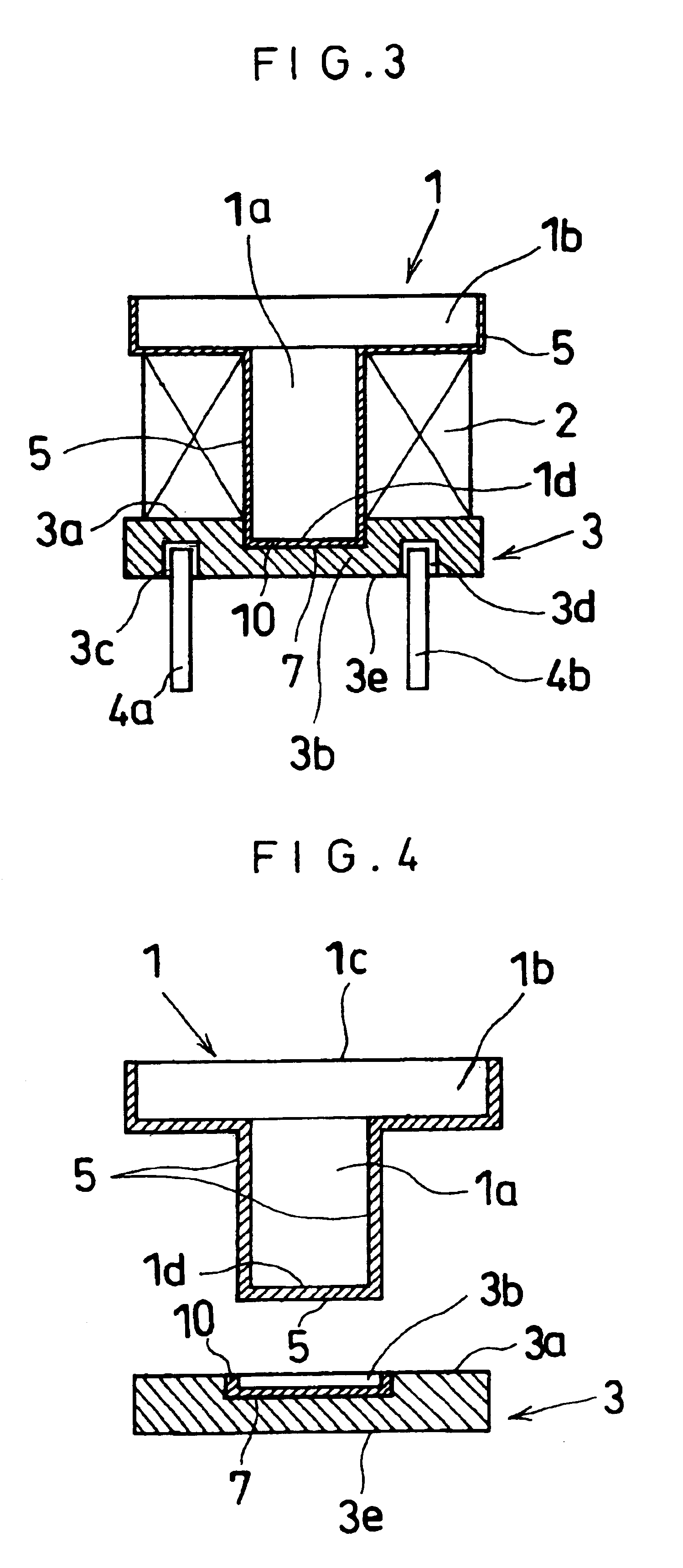

Method for winding a single coil of a coil unit for a linear motor

InactiveUS7082674B2Low-cost easy-to-redesignTransformers/inductances magnetic coresCoils manufactureEngineeringLinear motor

A rectangular single coil of a coil unit for a linear motor is fabracated by winding a single conductive wire. A winding former having locks for a conductive wire at positions corresponding to vertices of the rectangular single coil is rotated by 180 degrees about an X-axis, by 180 degrees about a Y-axis, alternately by first and second rotating mechanisms. Thereby, a single conductive wire fed out in the direction of a Z-axis from a conductive wire feeding out machine is wound while locked to the locks of the winding former in succession.

Owner:SUMITOMO HEAVY IND LTD

Method for making electrical windings for electrical apparatus and transformers and windings obtained by said method

ActiveUS20110163833A1Easy constructionReduce the numberTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerThin layer

This invention relates to a method of manufacturing electrical windings for electrical apparatus and transformers. This method comprises the following steps: manufacturing a metal mandrel defining the internal shape of the winding; installation of an internal insulation and support; installation of side rings; pouring impregnation compound on horizontally turning mandrel for obtaining a thin layer on the operational area of the mandrel and side surface of the side rings; optionally curing this layer; fixation of the first end wire using one of side rings; manufacturing winding with simultaneous pouring of compound onto the mandrel; possibly introducing intermediate insulation and / or reinforcing layers of preimpregnated reinforced plastics; optionally inserting premade sleeves around section of the winding; fixation of the second end wire using one of side rings; possibly introducing external insulation or reinforcing layers of preimpregnated reinforced plastics; possibly manufacturing secondary windings on top of the wound winding; curing the winding; extraction of the cured winding or a set of cured windings from the mandrel.The invention also relates to winding structures obtained by this method.

Owner:PULNIKOV SERGEY

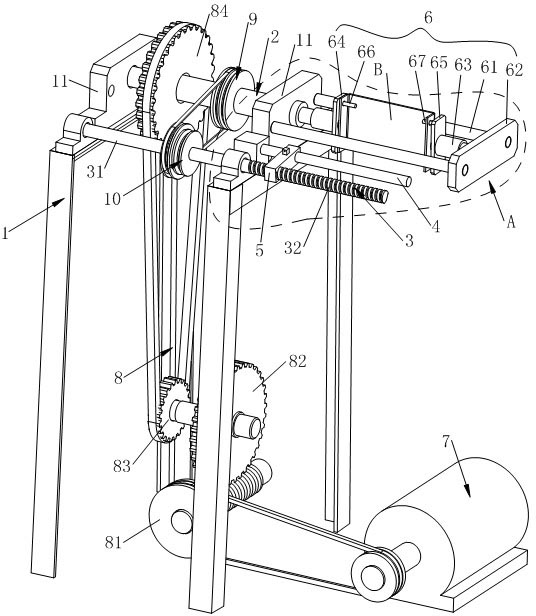

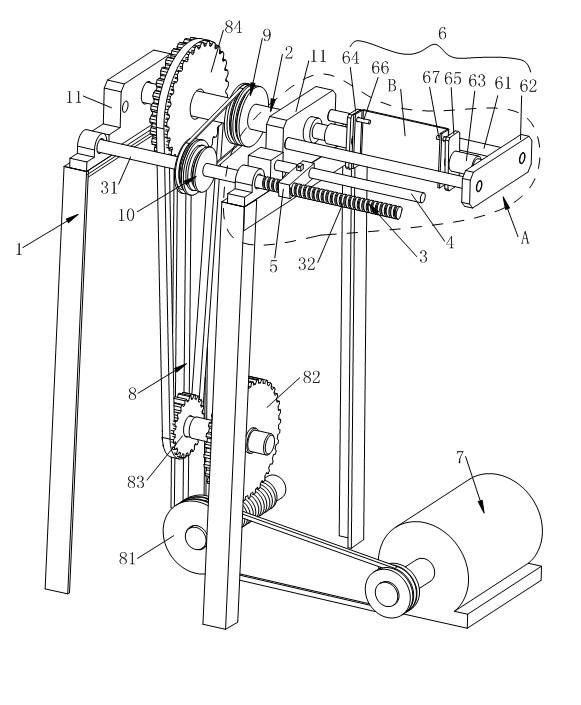

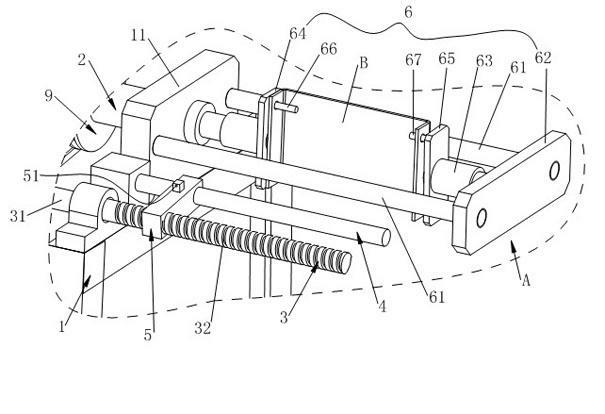

Wire winding device of special resistance plate

ActiveCN102693797AImprove efficiencyEnsure consistencyResistive element windingsReciprocating motionScrew thread

A wire winding device of a special resistance plate includes a rack, a first rotating rod, a second rotating rod, a guide rod, a threader, a fixing device and a drive device, wherein the first rotating rod is pivoted with the rack; the second rotating rod is in transmission connection with the first rotating rod, is in parallel with the first rotating rod, and is provided with a first section and a second section; the fist section is pivoted to the rack, and the second section is provided with threads; the guide rod is fixed on the rack and parallel with the second rotating rod; a threaded hole is arranged in the threader, the threader is connected with the guide rod and connected with the second section through the threaded hole; the fixing device is connected with the first rotating rod and opposite to the second section; the drive device drives the first rotating rod to rotate, the first rotating rod rotates to drive the fixing device to rotate around the axis of the first rotating rod, the first rotating rod rotates to drive the second rotating rod to rotate, and the second section of the second rotating rod is matched with the threaded hole of the threader to drive the threader to reciprocate along the guide rod. The wire winding device has high efficiency in producing resistance wires and can ensure the consistency of products.

Owner:张家港市泓溢电源科技有限公司

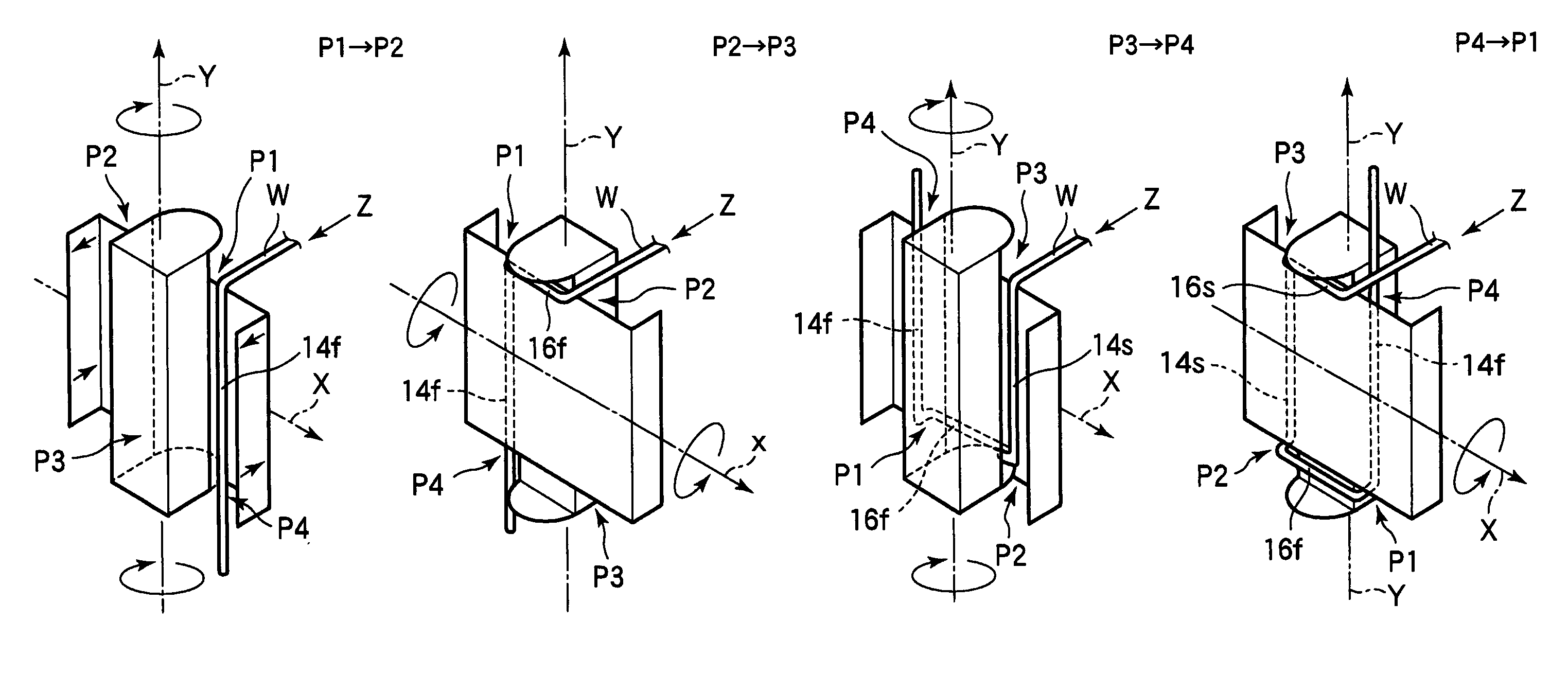

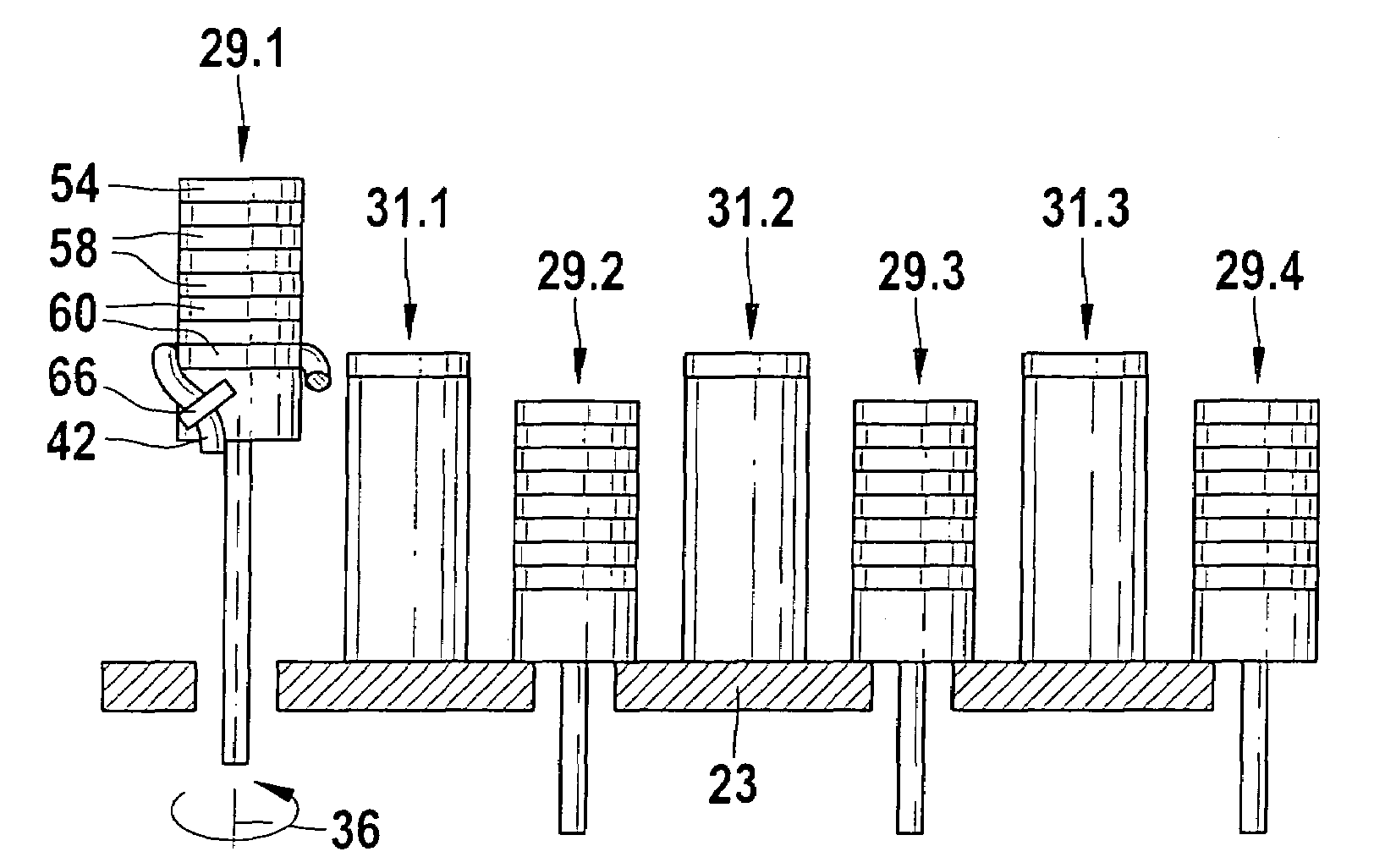

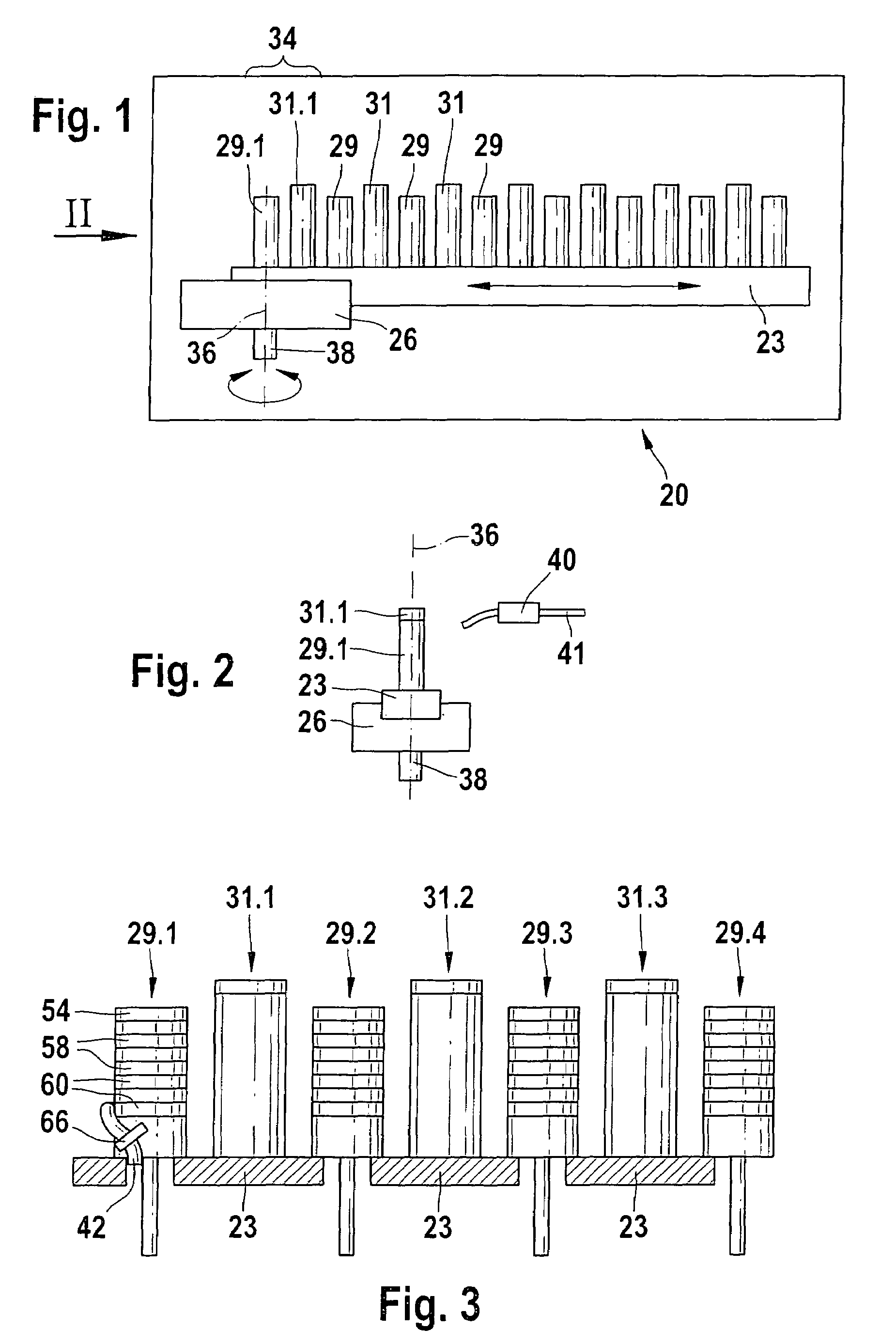

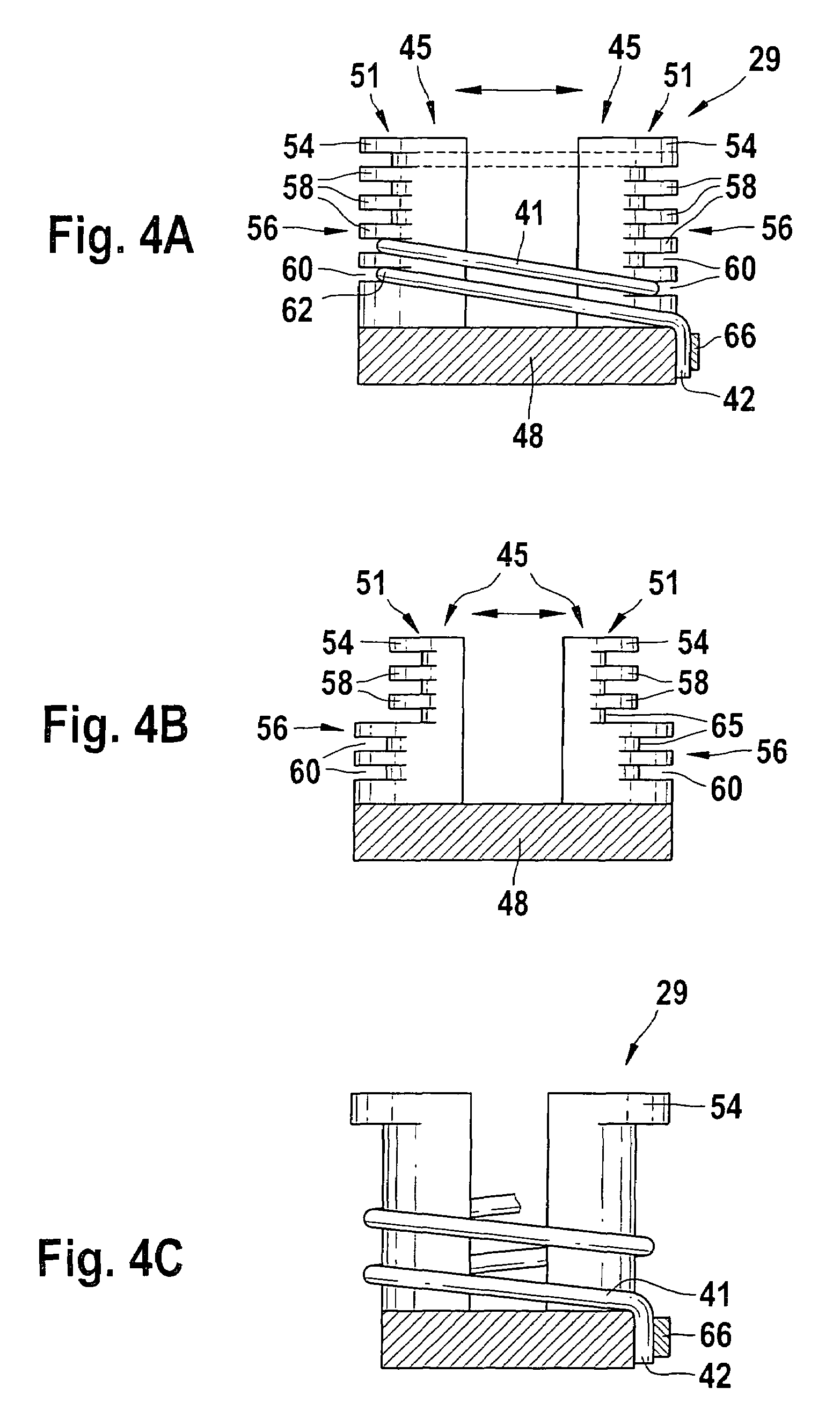

Coiling machine and method for the production of a coil

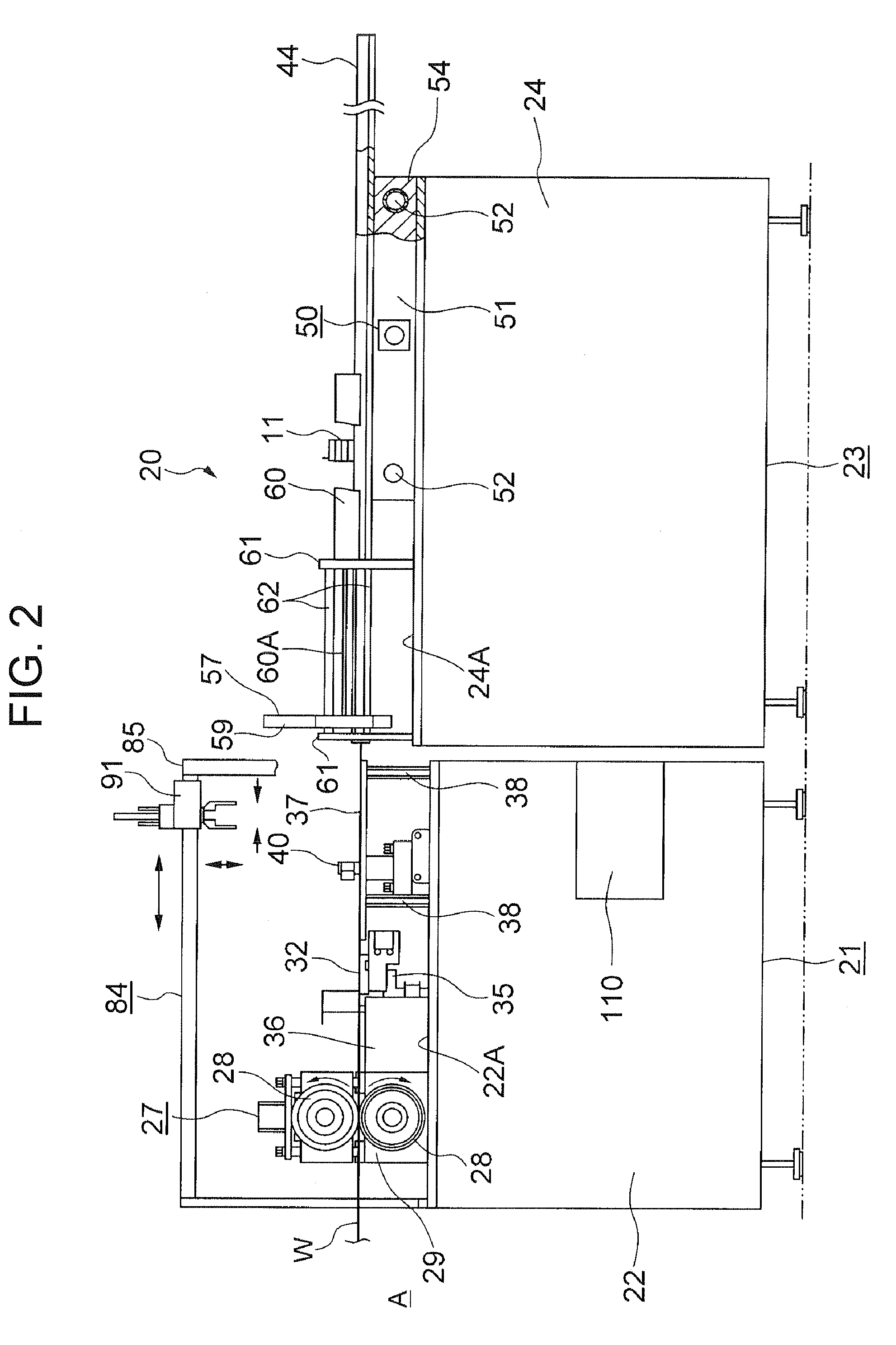

InactiveUS7543774B2Manufacturing stator/rotor bodiesApplying solid insulationWinding machineEngineering

A winding machine (20) has a carrier device (23) for winding a winding for an electrical machine. The carrier device (23) has at least one group (34) having a winding template (29) and an adjacent deflection element (31), and the winding template (29) and the adjacent deflection element (31) are displaceable relative to one another. In a method for producing a winding from at least one coil, at least one wire is wound around a winding template (29), producing at least one wire arrangement with at least one first coil side (68), at least one first deflection side (69), and at least one second coil (70), and a winding template (29) is displaced out of a plane for the winding process.

Owner:SEG AUTOMOTIVE GERMANY GMBH

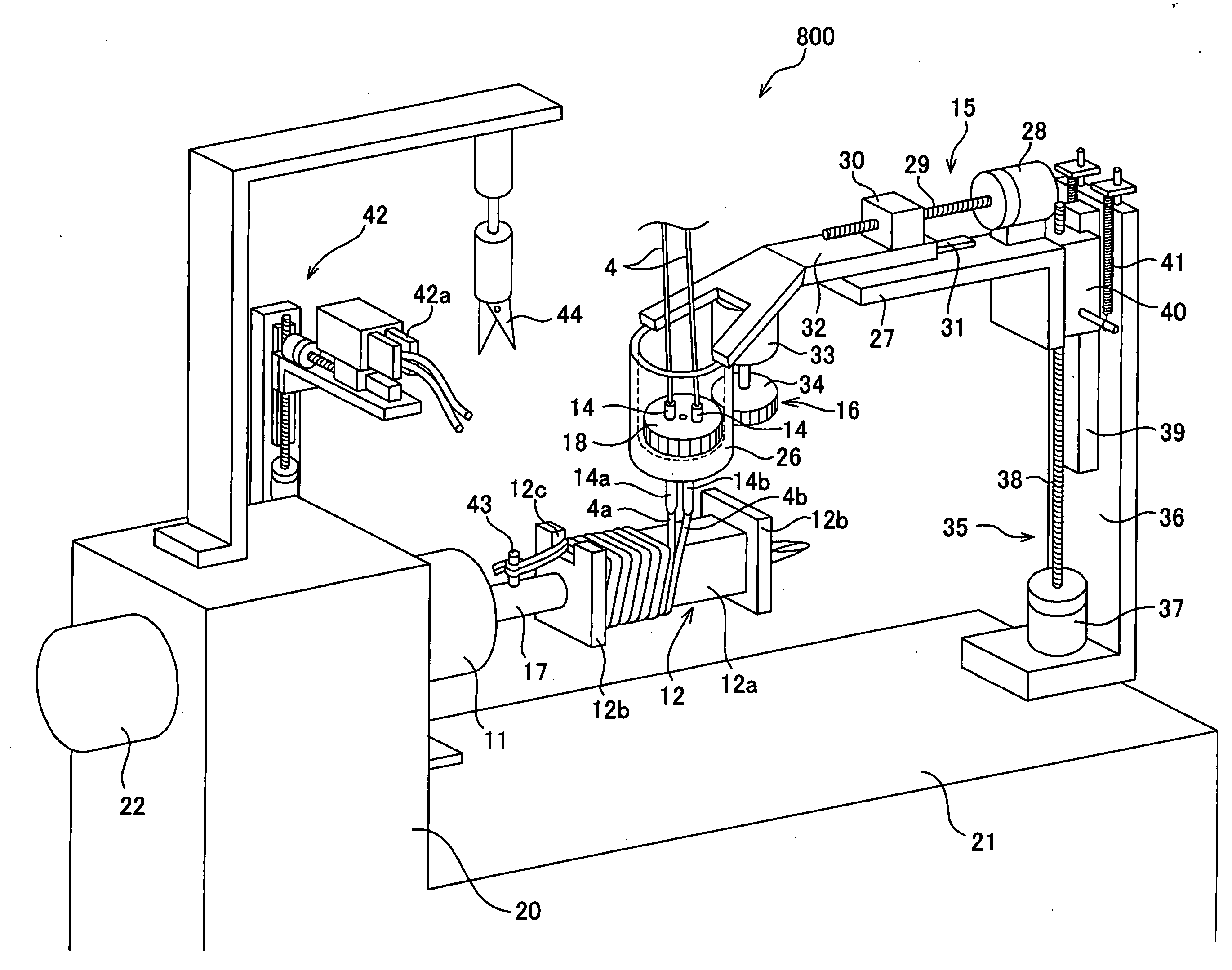

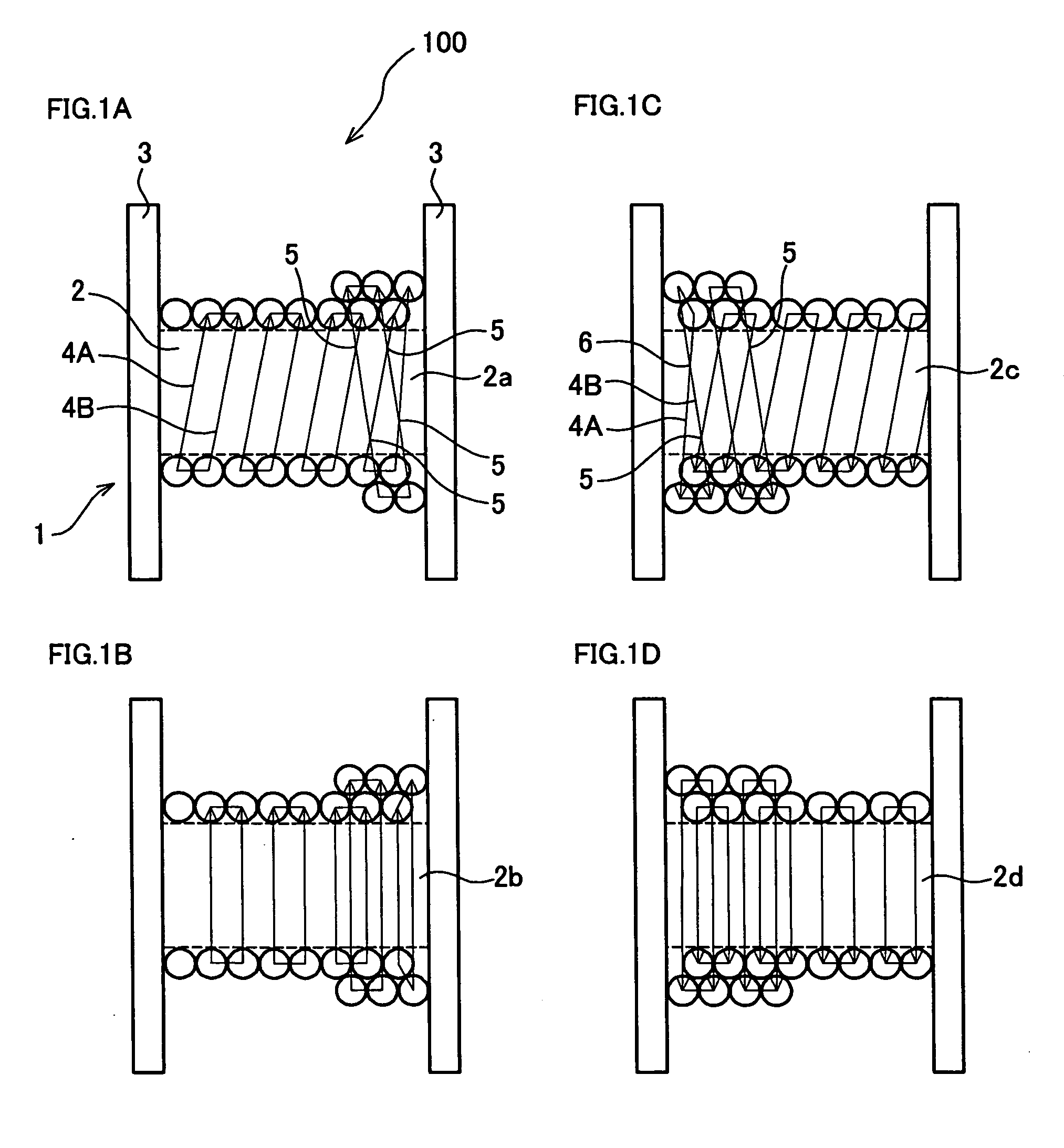

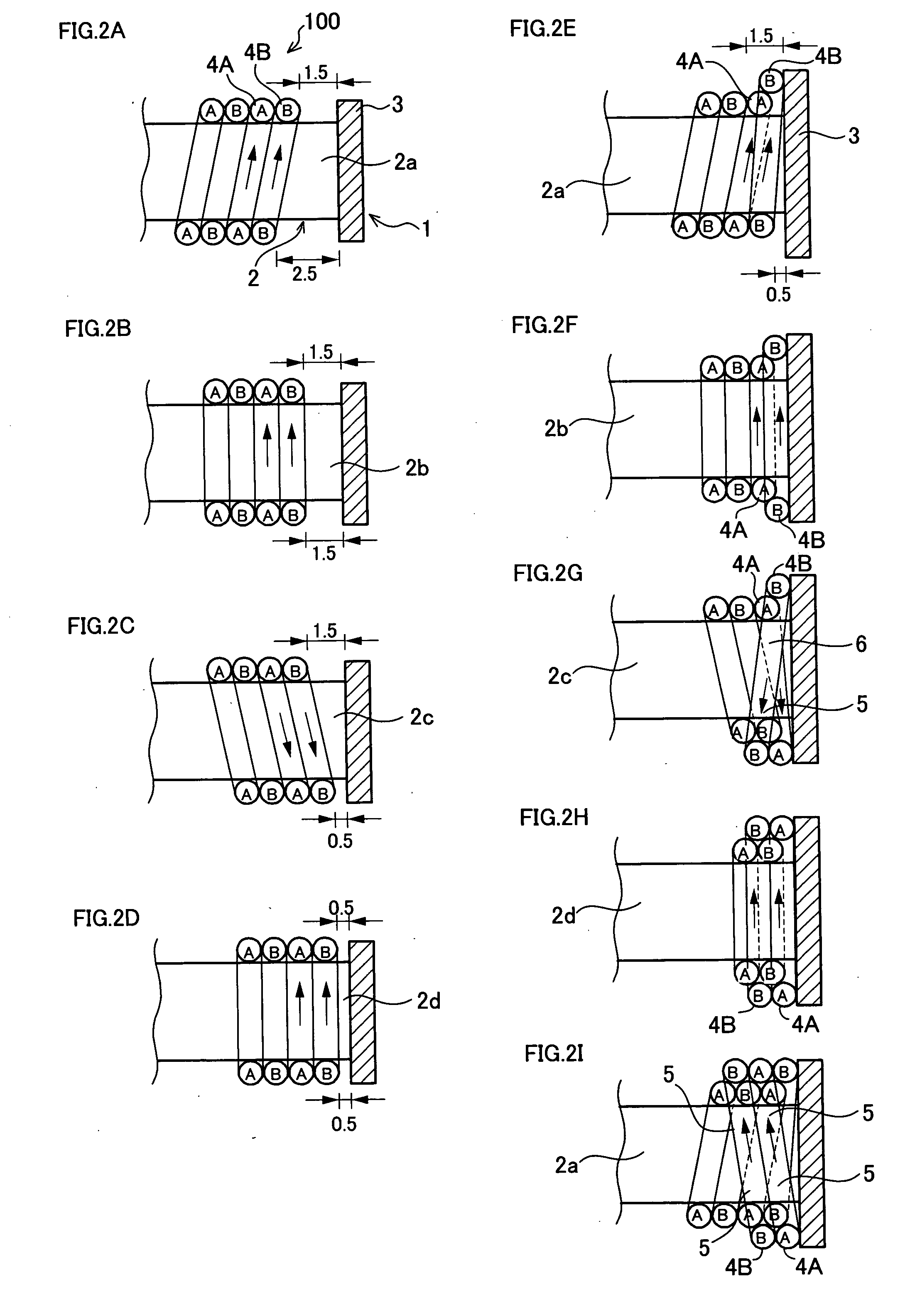

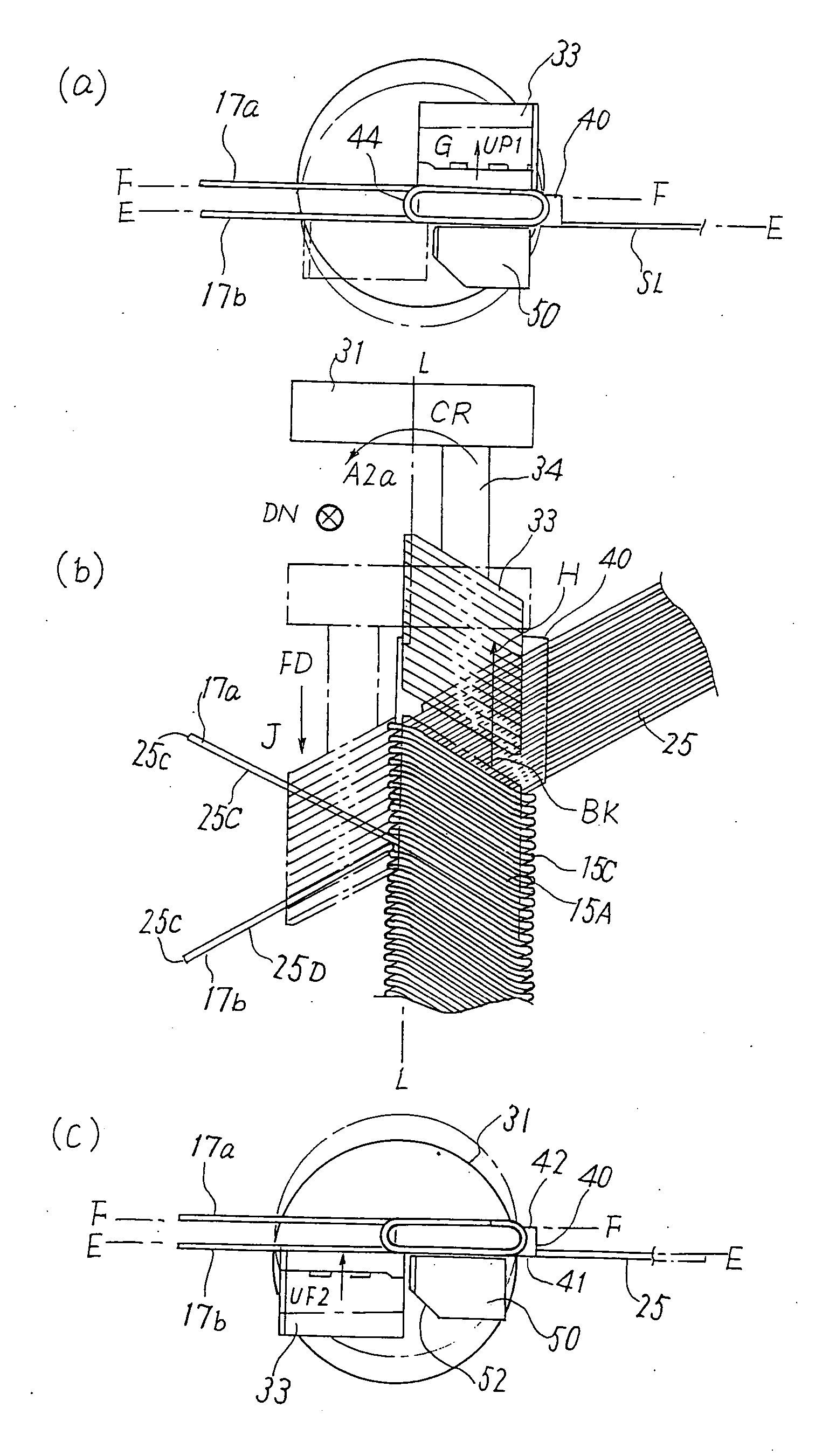

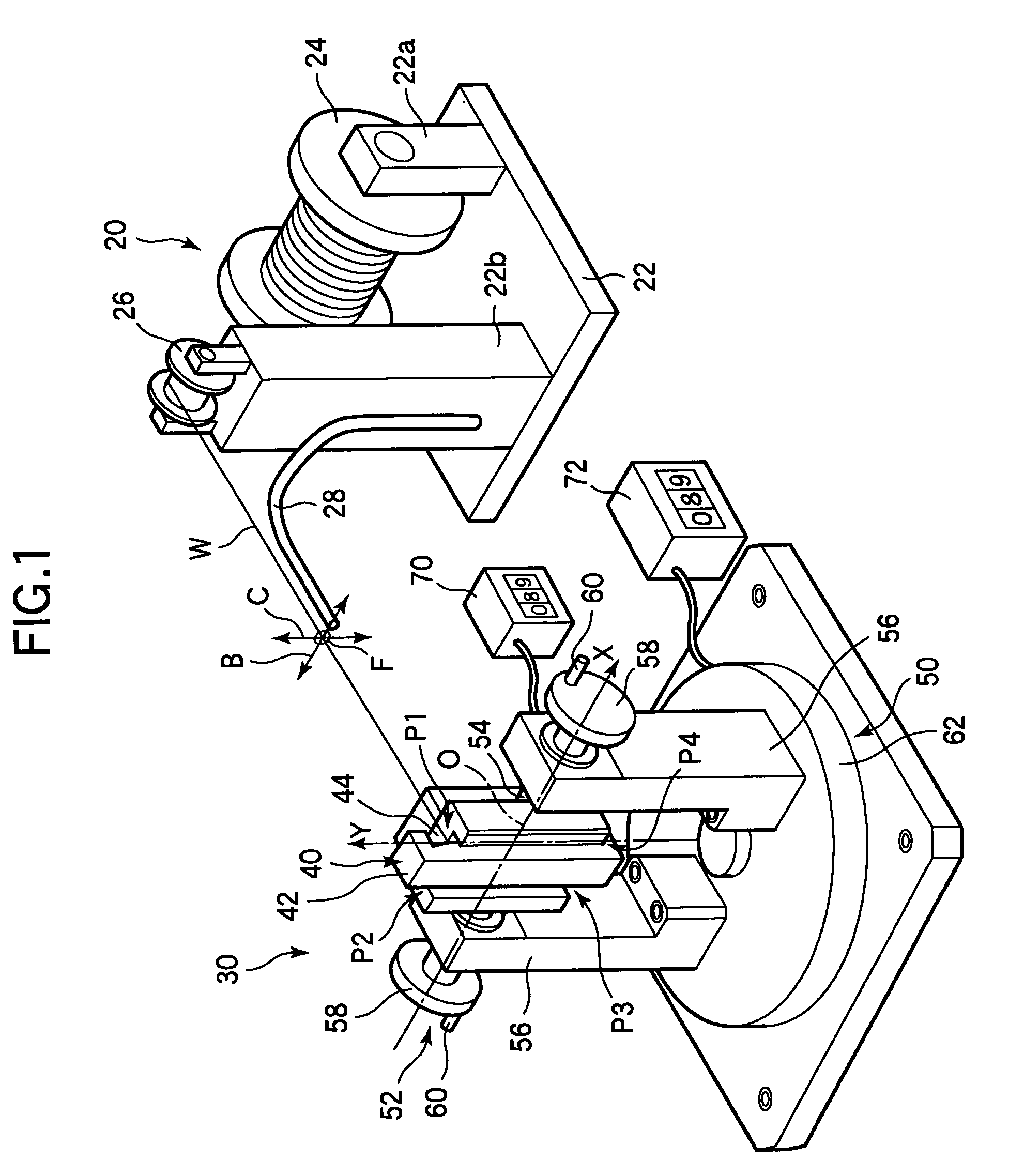

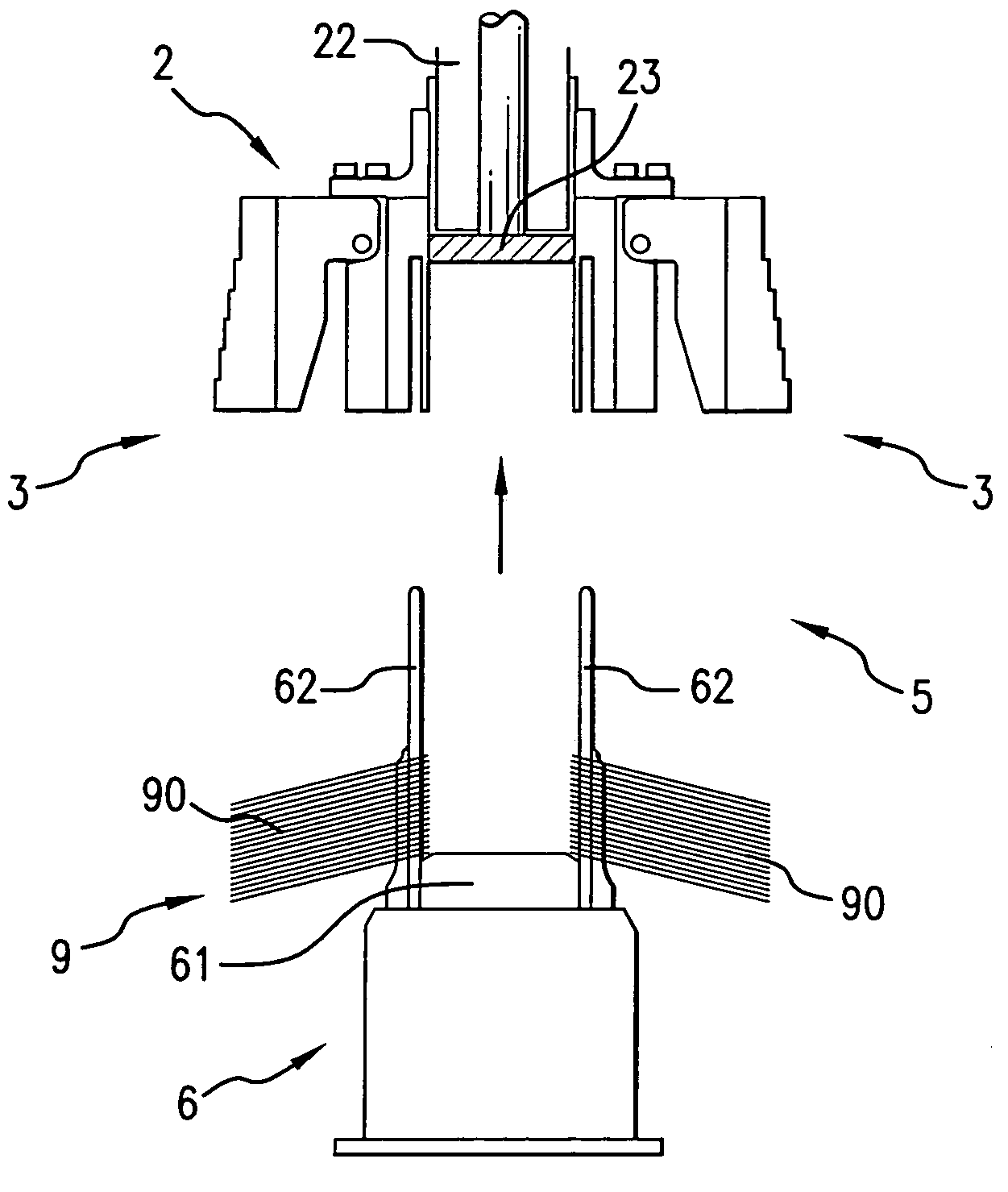

Coil forming and inserting device and coil forming and inserting method

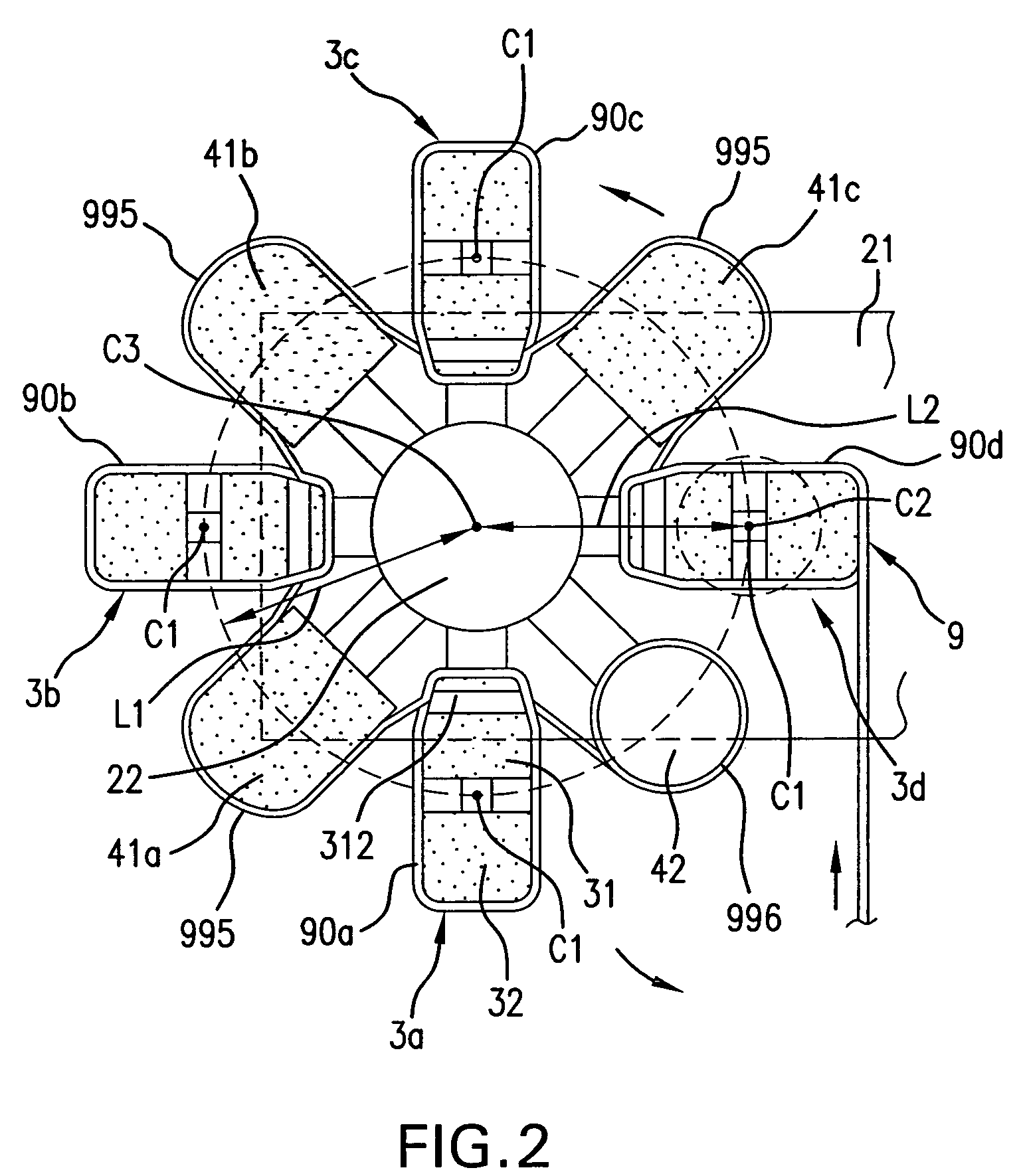

InactiveUS7467648B2Constant lengthReliably delivering each monopole coilLine/current collector detailsWire articlesInterposerEngineering

A coil forming and insertion apparatus includes plural coil winding frames, a winding jig for forming a multipole coil, plural coil receiving portions, and an inserter jig for inserting and arranging the multipole coil in slots of a stator core. The coil forming and insertion apparatus has each coil receiving portion opposed to a coil winding frame, the multipole coil is formed by connecting the monopole coils wound on the coil winding frames and the multipole coil is transferred from the winding jig to the inserter jig.

Owner:AISIN AW CO LTD

Winding device and its winding method

InactiveCN1822261AAvoid wastingReduce consumptionCoils manufactureResistive element windingsEngineeringConductor Coil

Present invention relates to a wire winder. It contains an inner rotor shaft having collet for holding said electronic assembly connecting pin, an outer rotation sleeve set outer part of said inner rotor shaft, wire feeding device set between rotating wheel device and winder having a lead rod for winding wire on said electronic assembly.

Owner:廖木山

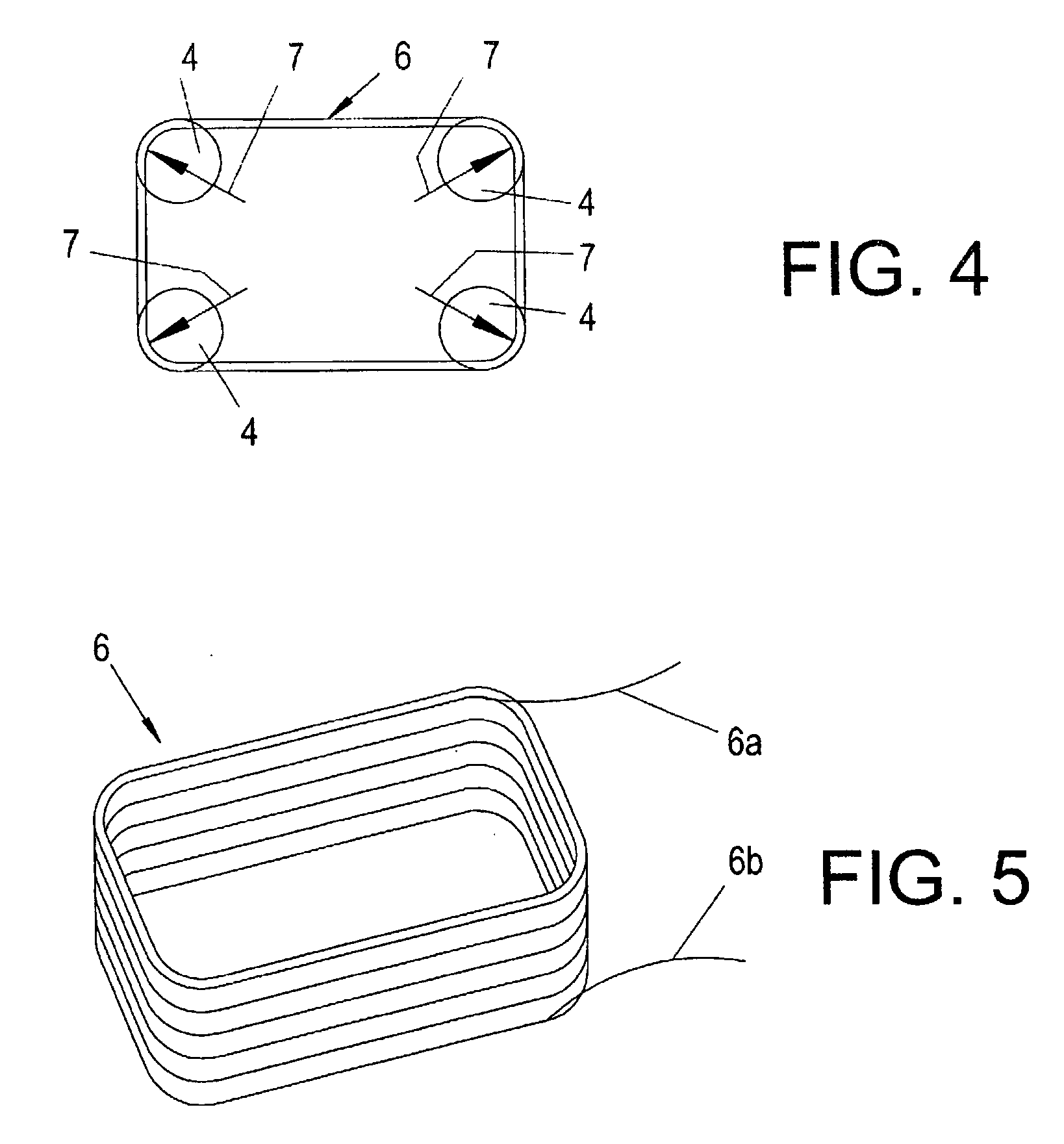

Method of Manufacturing a Coil

InactiveUS20080001016A1Electrical transducersTransformers/inductances magnetic coresEngineeringMechanical engineering

Method of manufacturing a coil (6) with a cross section differing from a circular ring cross section, in which method a circular cylindrical coil (1) with a circular ring cross section is first wound and then reshaped into a coil (6) with the other cross section differing from the circular ring cross section, wherein at least two axially parallel fingers (4) of an expander (2) are temporarily inserted into the coil interior for reshaping the wound circular cylindrical coil (1) and are displaced in a diverging relative movement after the insertion and while doing so expand the initially circular cylindrical coil (1) into the coil (6) with the different cross section.

Owner:SOUND SOLUTIONS INTERNATIONAL COMPANY LTD

Method of manufacturing coil for stators mounted in rotary electric machines

ActiveUS20100000077A1Stable deliveryStable conveyanceElectrical transducersMagnetic circuit stationary partsElectric machineStator coil

In manufacturing a stator coil for rotary electric machine having phase windings, plural conductive shaped wire members are integrated mutually to form an integrated body. Each shaped wire member has plural straight portions, and plural turn portions alternately connecting adjacent straight portions at each of both ends of each straight portion. The body has plural straight superposed portions each formed by mutually superposing the plural straight portions. A wound-up body has plural straight stack portions. The straight portions are fitted to respective fitting grooves of an alignment member, the fitting grooves being formed in the alignment member at intervals each corresponding to the size of a gap between adjacent straight stack portions. The integrated body is wound about a core member together with the alignment member, with the straight portions being fitted to the alignment member to form the wound-up body.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com