Winding device and its winding method

A technology of winding and winding machine, which is applied in the direction of coil manufacturing, winding resistance components, etc., can solve the problems of difficulty in improving the yield of finished products, waste of wire use and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the structure, features and purpose of the present invention, the accompanying drawings and detailed description of preferred specific embodiments are as follows.

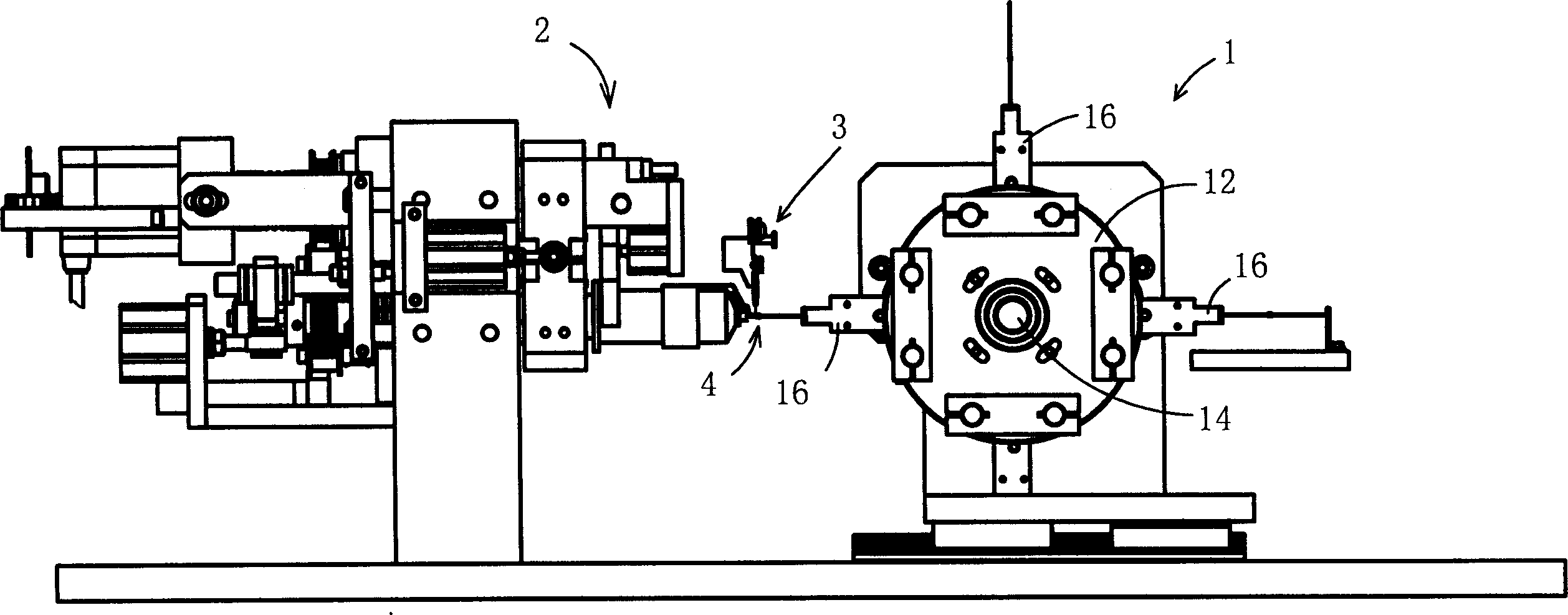

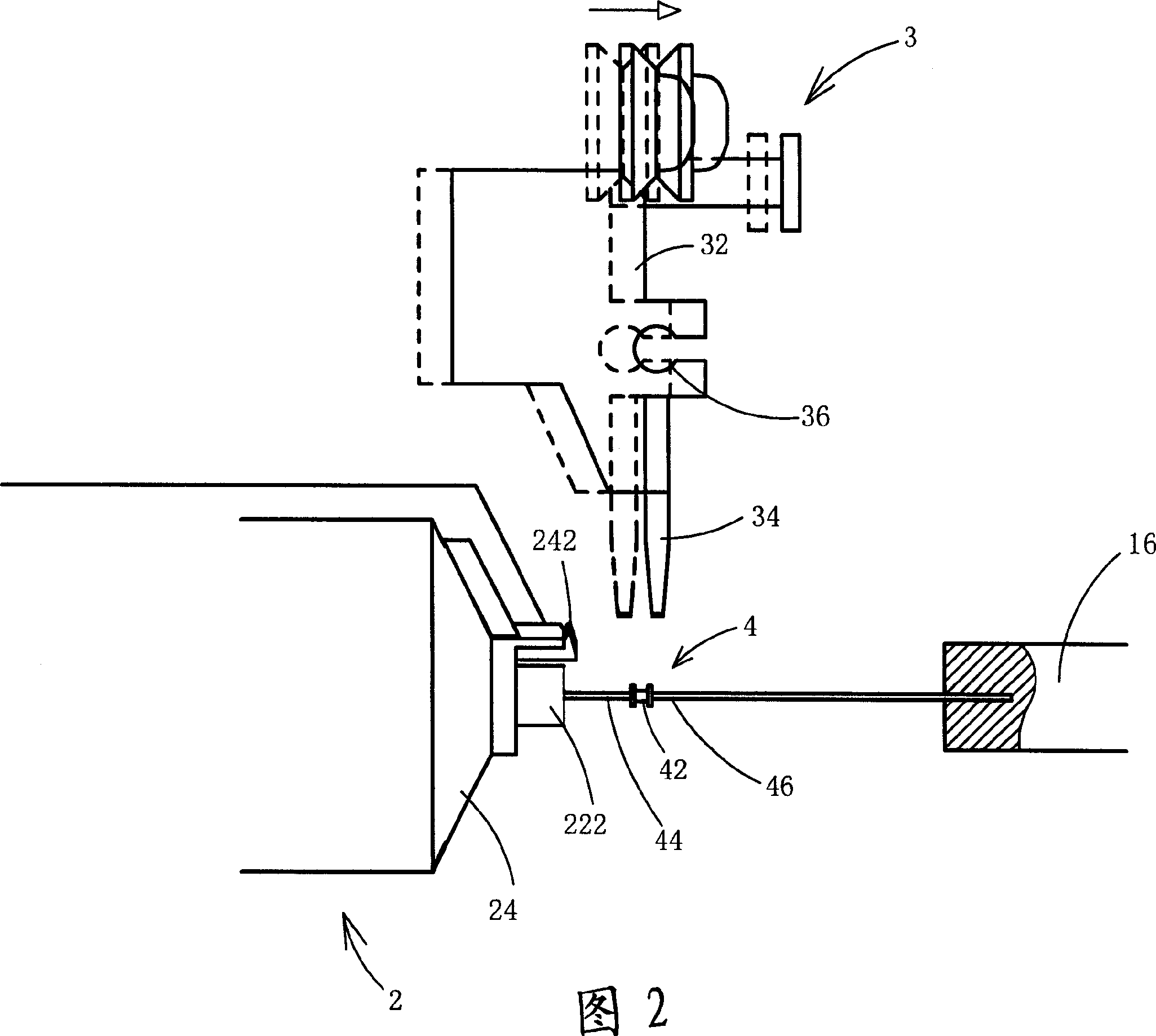

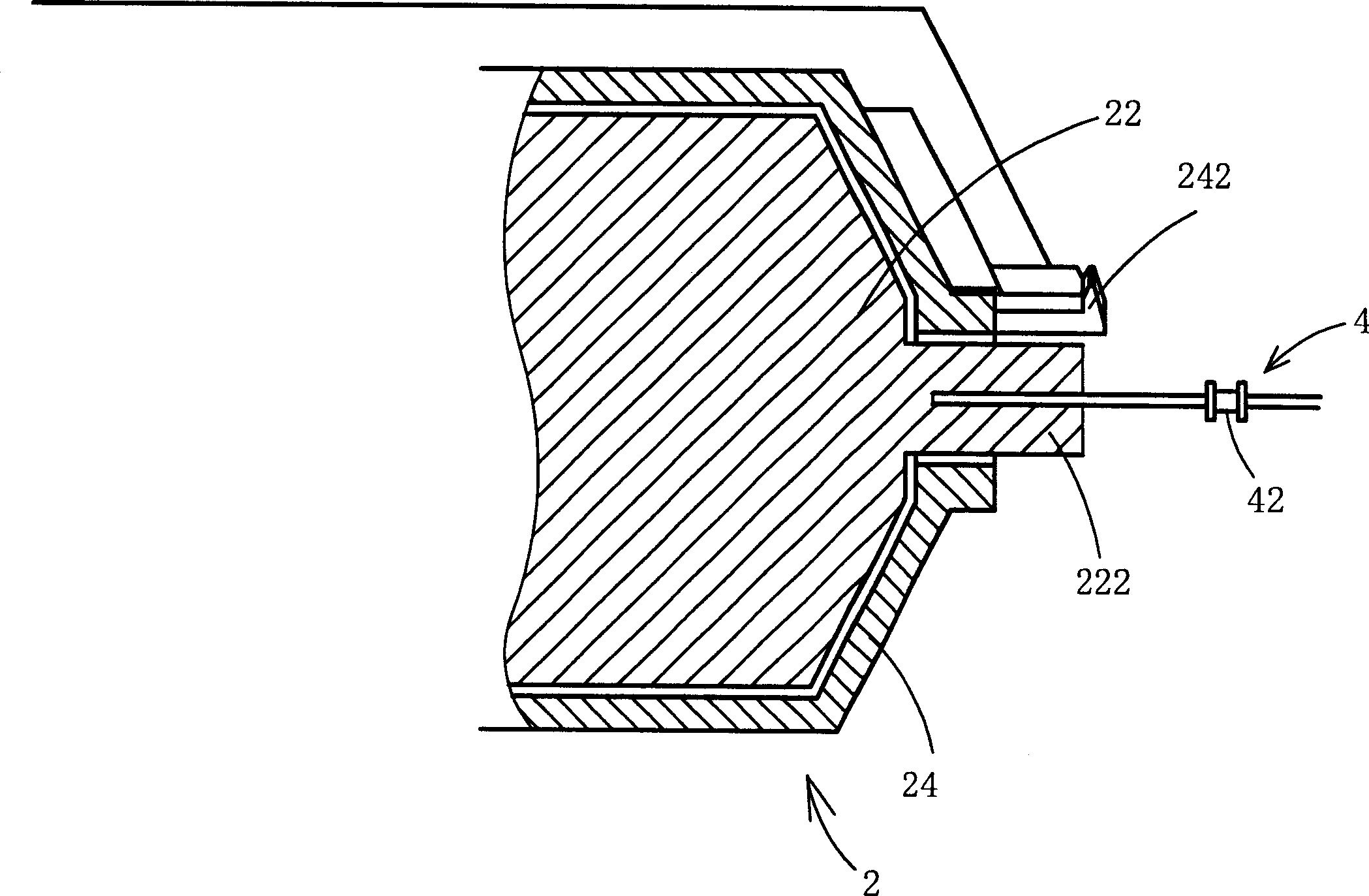

[0015] see figure 1 As shown in FIG. 2, it is a schematic diagram of a preferred embodiment of the winding device of the present invention. As shown in the figure, the thread winding device A includes a wheel device 1, a thread winding machine 2 and a wire supply device 3 respectively, the wheel device 1 has a wheel 12, and the wheel 12 is along the A rotating shaft 14 rotates, and a plurality of clamping assemblies 16 are respectively provided at the periphery of the rotating wheel 12, which can be used to clamp the pin 46 at one end of an electronic assembly 4 for processing; because in this embodiment, the The structure and operation method of the above-mentioned wheel device 1 belong to the application of the prior art, so it will not be repeated here.

[0016] Please als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com