Mobile overturn robot and multistation overturn method thereof

A robot and station technology, applied in the field of robotics, can solve the problems of difficult multi-station operation of the turning device, poor turning stability, etc., and achieve the effect of smooth and safe turning process, suitable for popularization and application, and stable turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

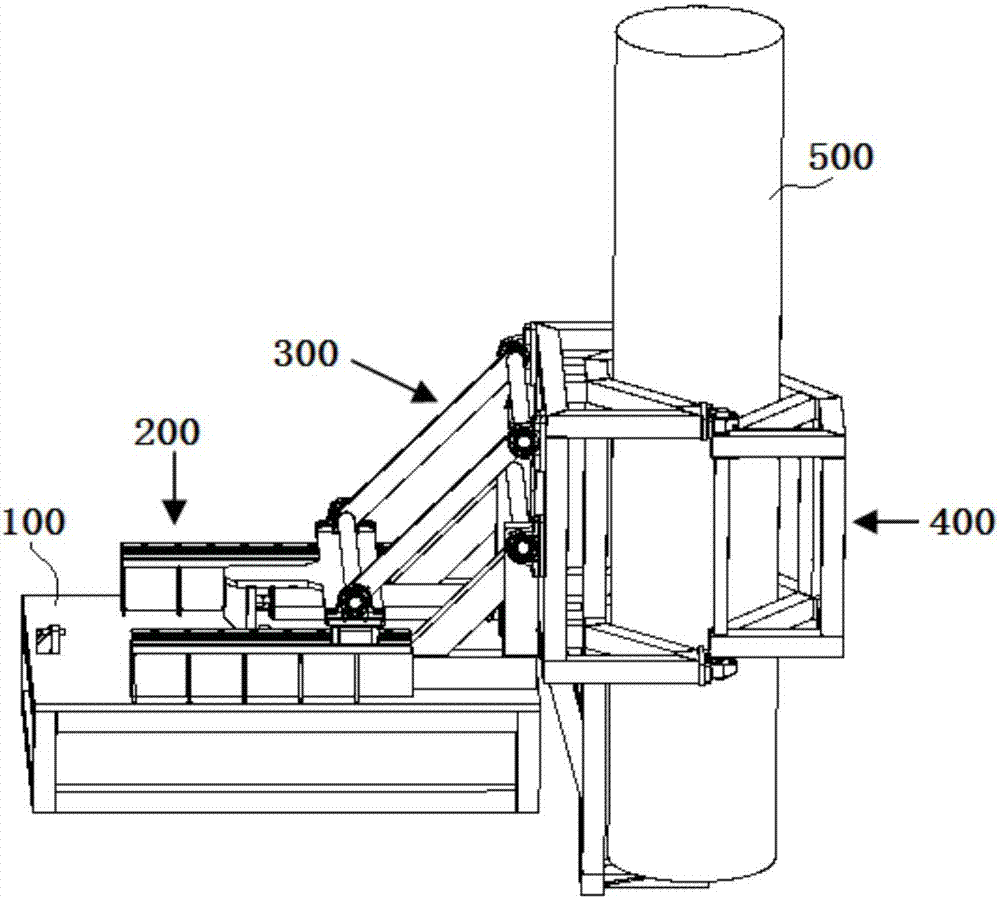

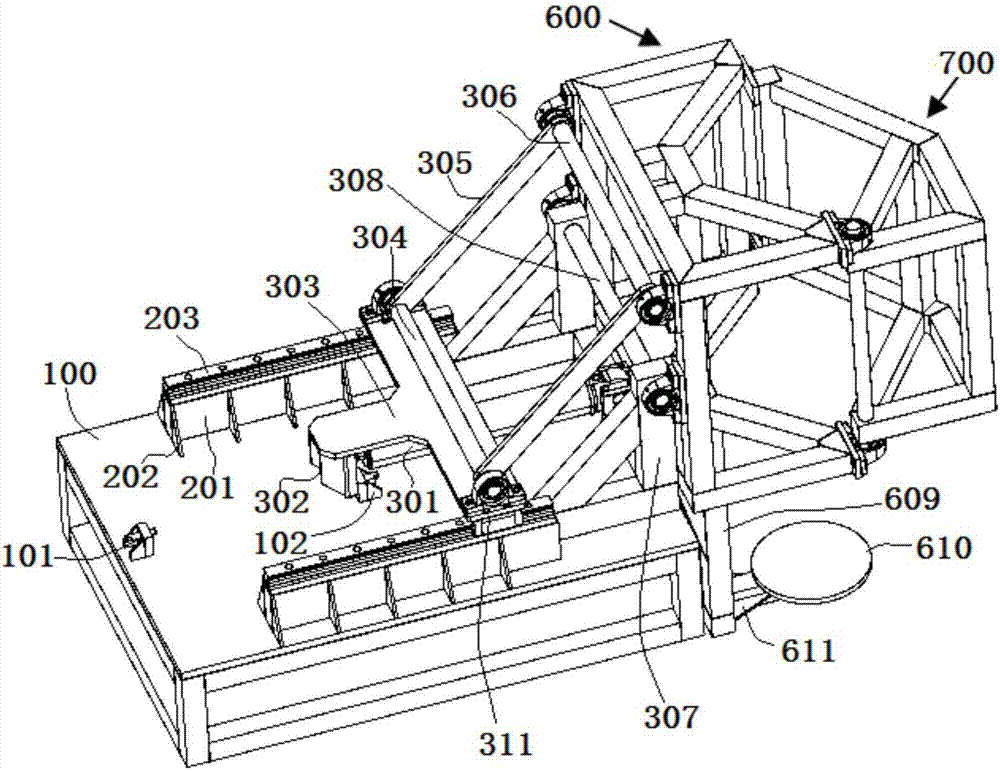

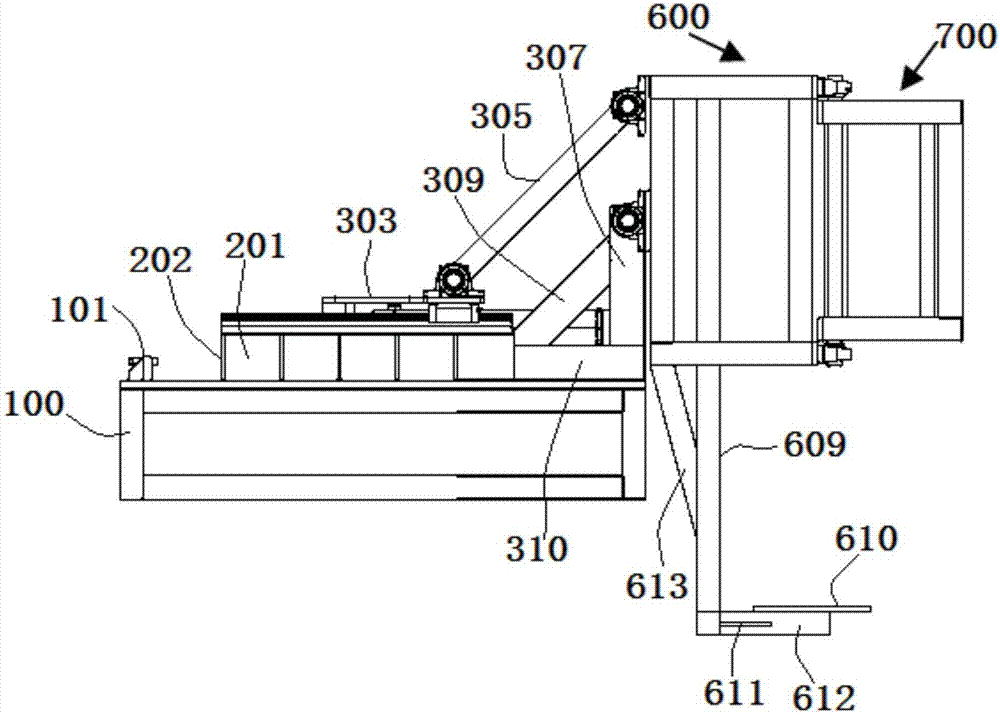

[0053] Such as Figure 1-Figure 11 As shown, the mobile overturning robot of the present embodiment includes an overturning device, a transfer trolley 800 and a driving track 900, and the overturning device is arranged on the transfer trolley 800 (the base 100 of the overturning device can be fixed on the transfer trolley 800 by bolts), and the transshipment trolley 800 cooperates with the driving track 900 of the production line, and the transfer trolley 800 is driven by a power device (a variety of conventional power devices can be used) to move along the driving track 900 to different stations, and the turning device is installed on the transfer trolley 800 to realize turning over The flexible turning operation of the device at different stations, that is, the flexible turning of workpieces at different stations, and the transfer operation of the turning device between different stations is simple, and the transfer trolley 800 runs quickly and stably, which can meet the fast...

Embodiment 2

[0060] The basic structure of the mobile overturning robot in this embodiment is the same as that in Example 1. Furthermore, in the overturning device in this embodiment, there is at least one lever at least between the first connecting rod 304 and the second connecting rod 306 at even intervals. Rods (not shown), there are two in the present embodiment, and two leverage rods are parallel to pull rod 305 respectively, and the setting of leverage rod can further enhance the overall structural strength and stability, and strengthen the first connecting rod 304 and The effective support of the second connecting rod 306 prevents its motion deformation and ensures its motion stability.

Embodiment 3

[0062] The mobile overturning robot of present embodiment, basic structure is the same as embodiment 2, and further, the overturning device among the present embodiment, as Figure 8 As shown, the guide rail 203 includes a bottom rail, and the two sides of the bottom rail are symmetrically provided with a first inner retraction section 204 extending obliquely inwardly, and an inner extension section 205 extends vertically above the first inner retraction section 204, and the inner extension section 205 The two sides of the outer extension section 207 are symmetrically provided with an outward extension section 206 extending obliquely outwards, an extension section 207 is vertically extended above the extension section 206, and a second inner contraction section 208 extending inward is symmetrically provided on both sides of the top of the extension section 207. The second retracted sections 208 on both sides are connected by a horizontal plane. The slide block 311 cooperates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com