Patents

Literature

81results about How to "Flip flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

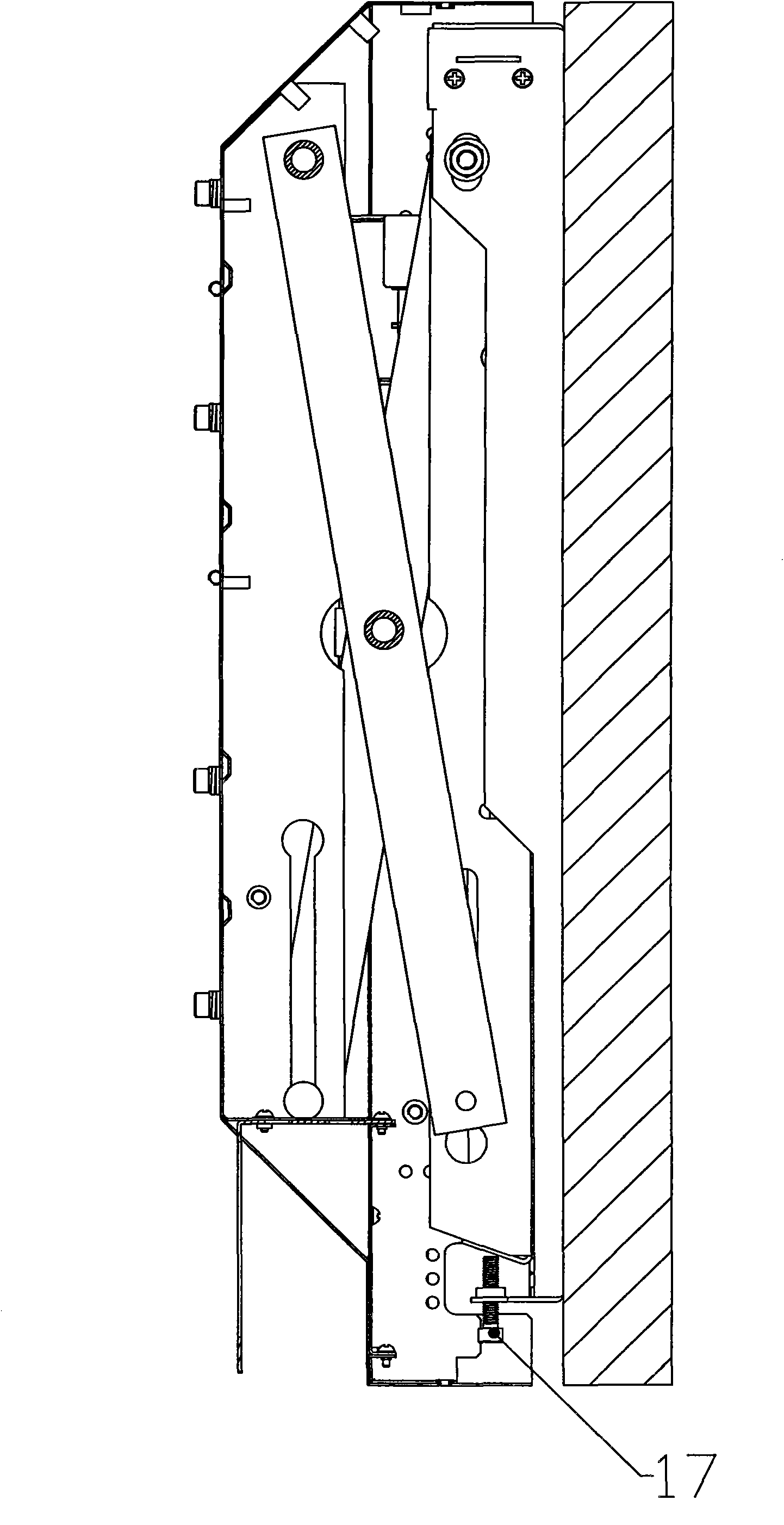

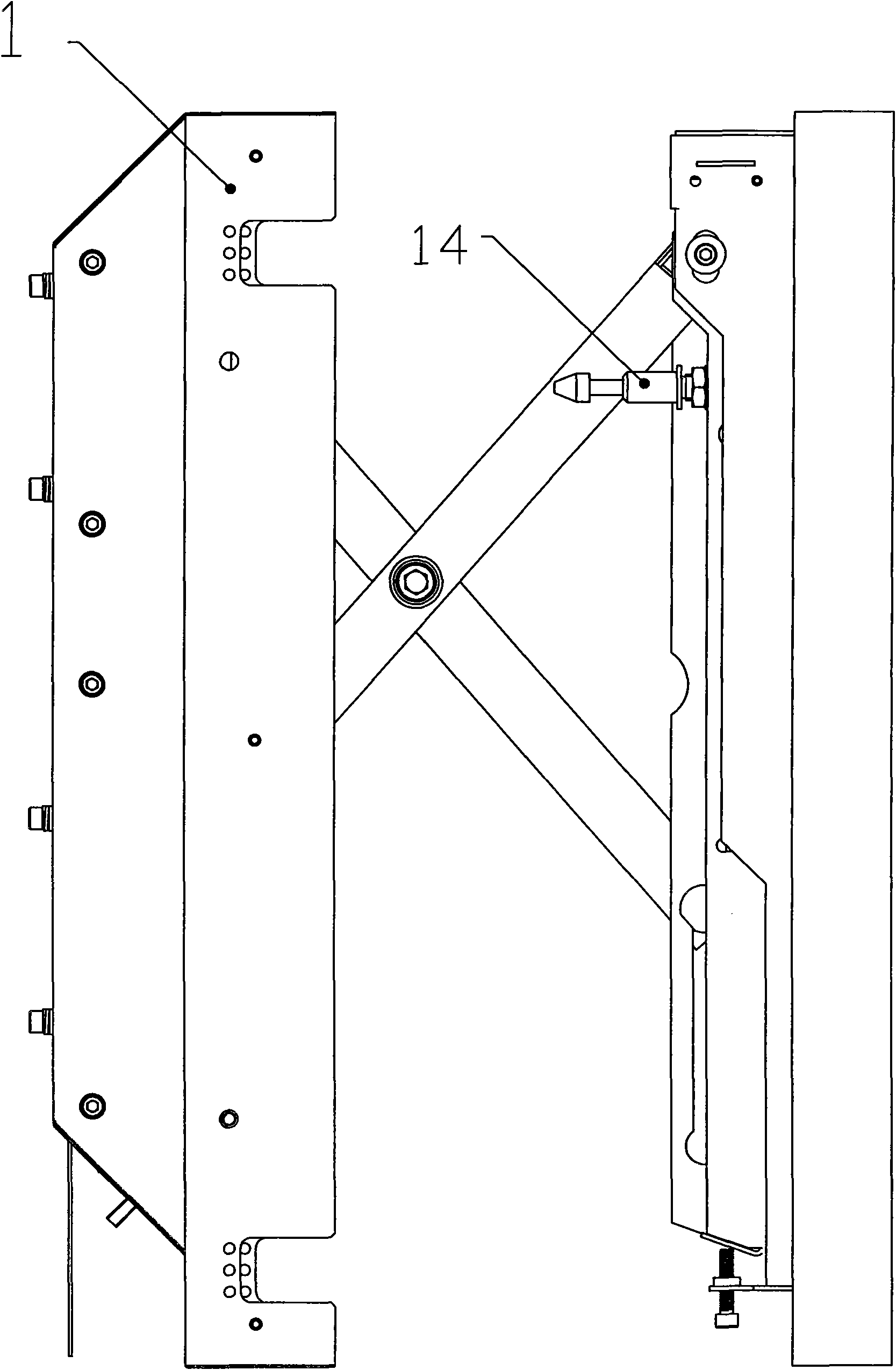

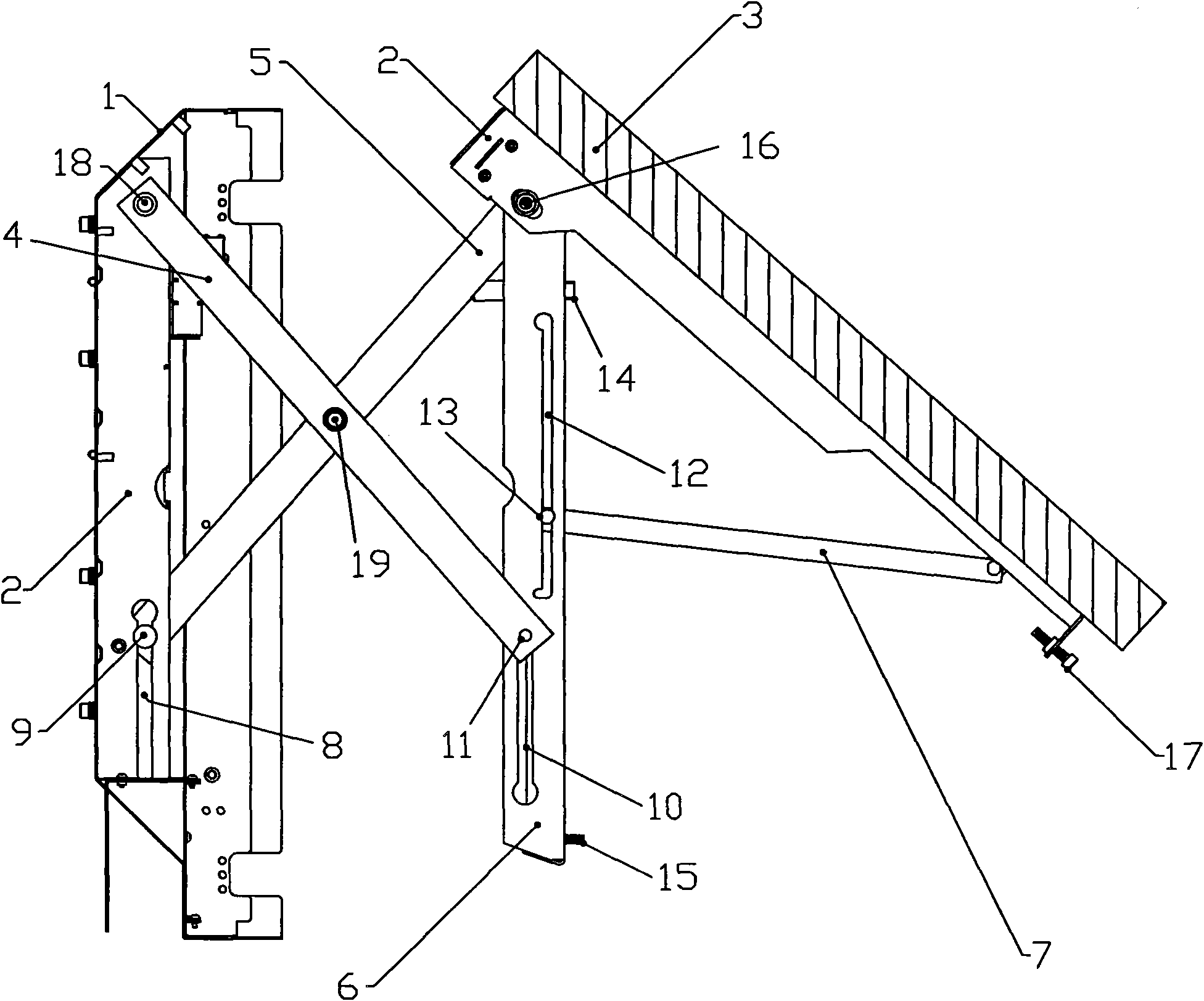

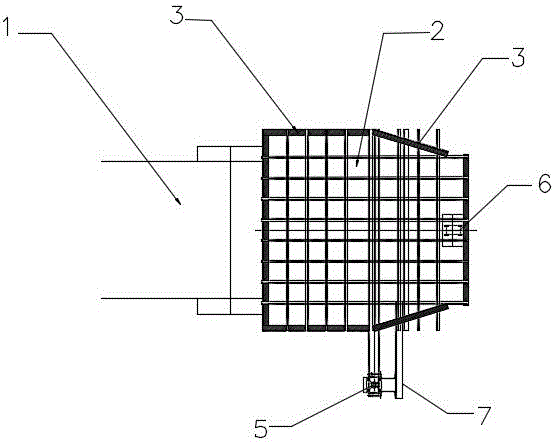

Translational overturning structure of joined screen display unit

ActiveCN102095064ARealize the translation functionSmooth forward movementStands/trestlesIdentification meansThree degrees of freedomEngineering

Owner:南通卓效自动化有限公司

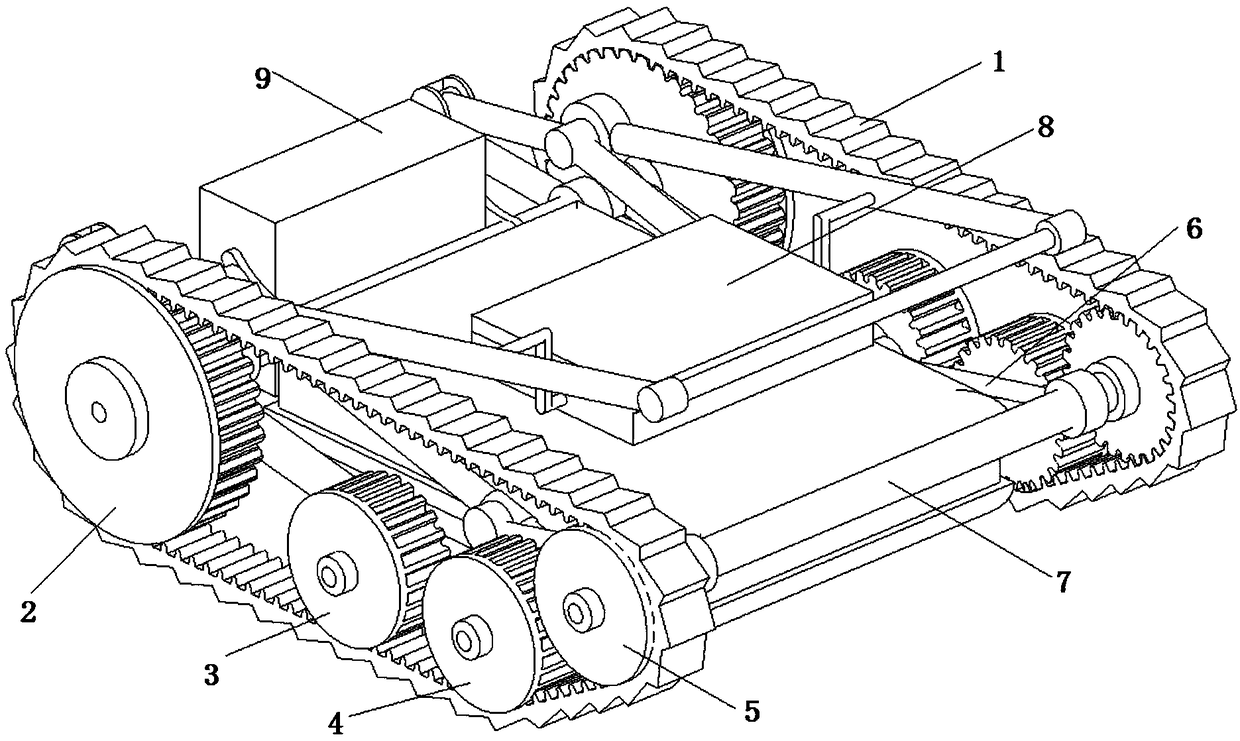

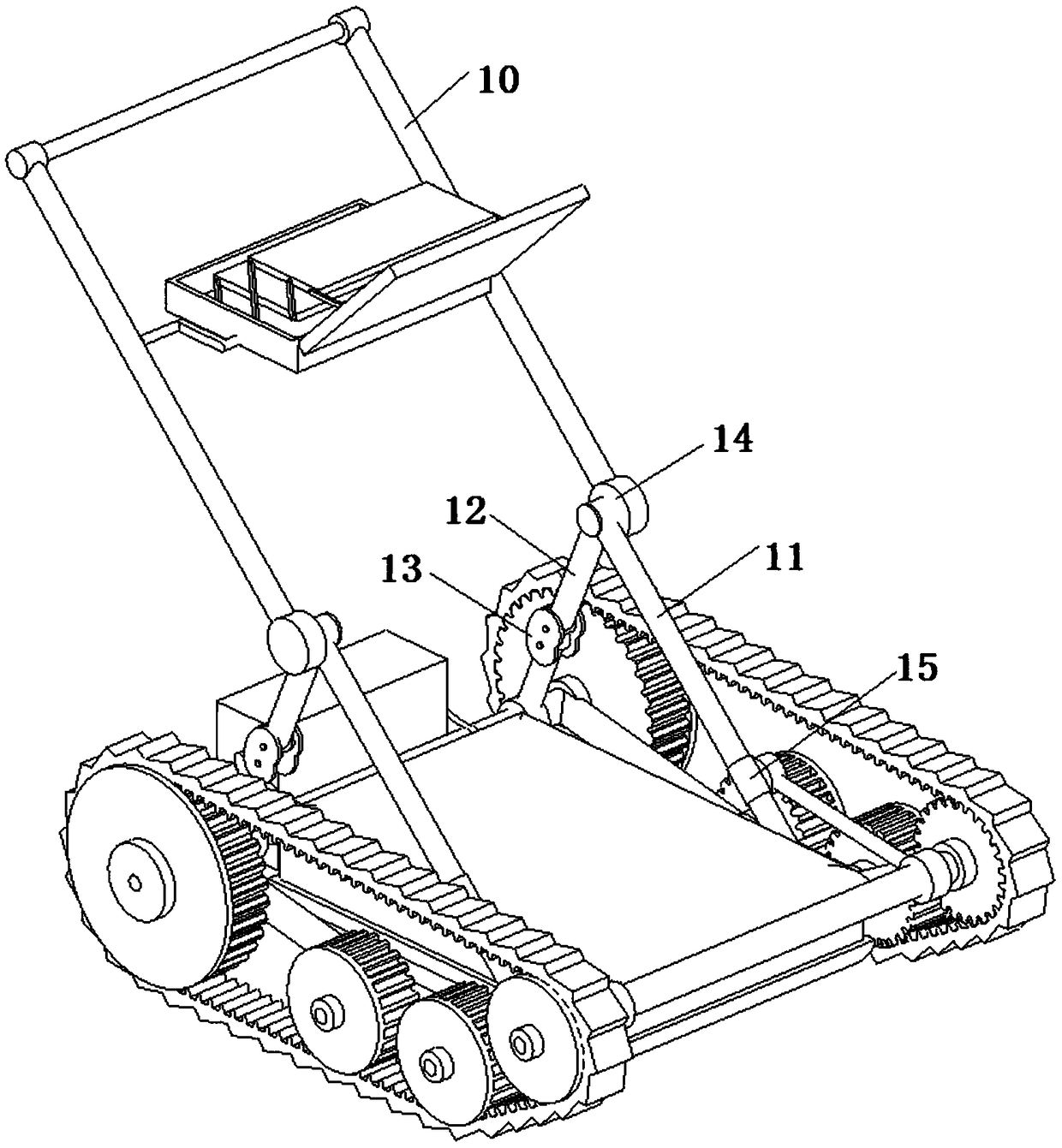

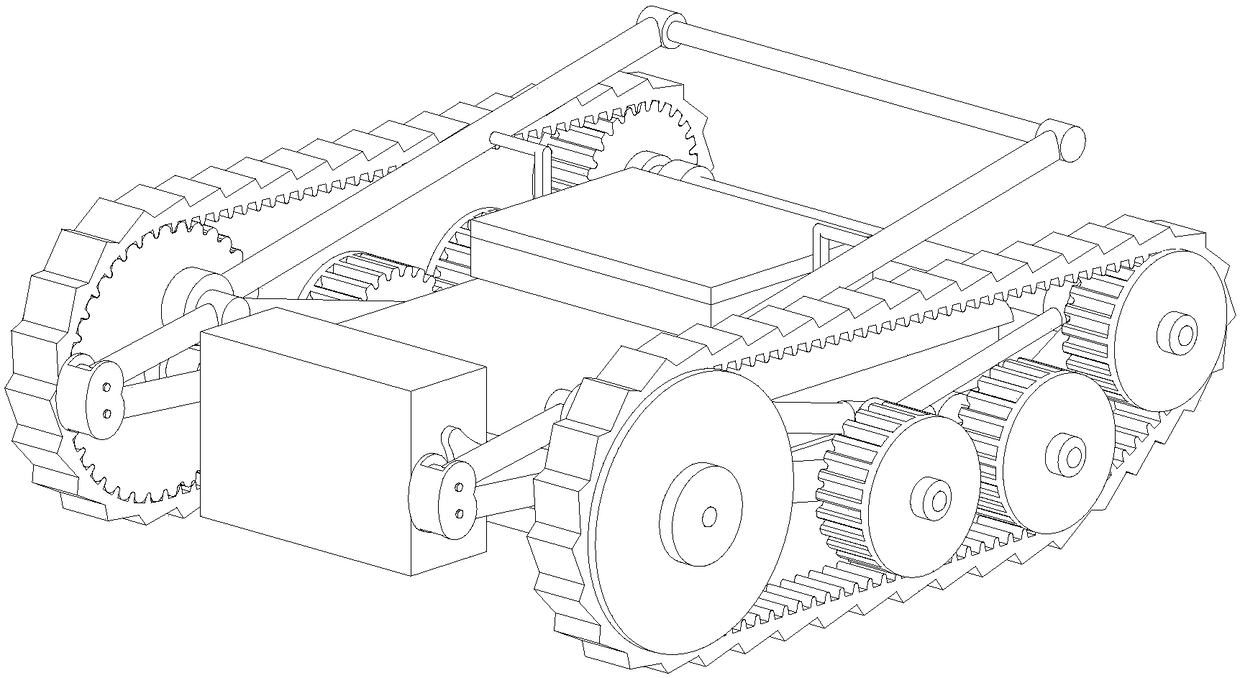

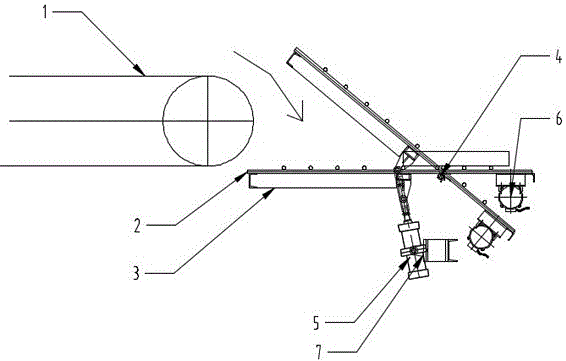

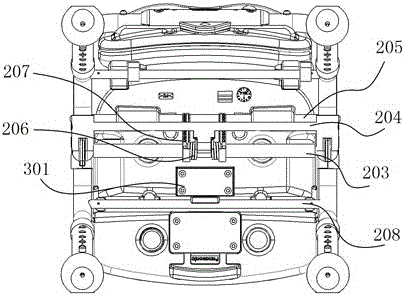

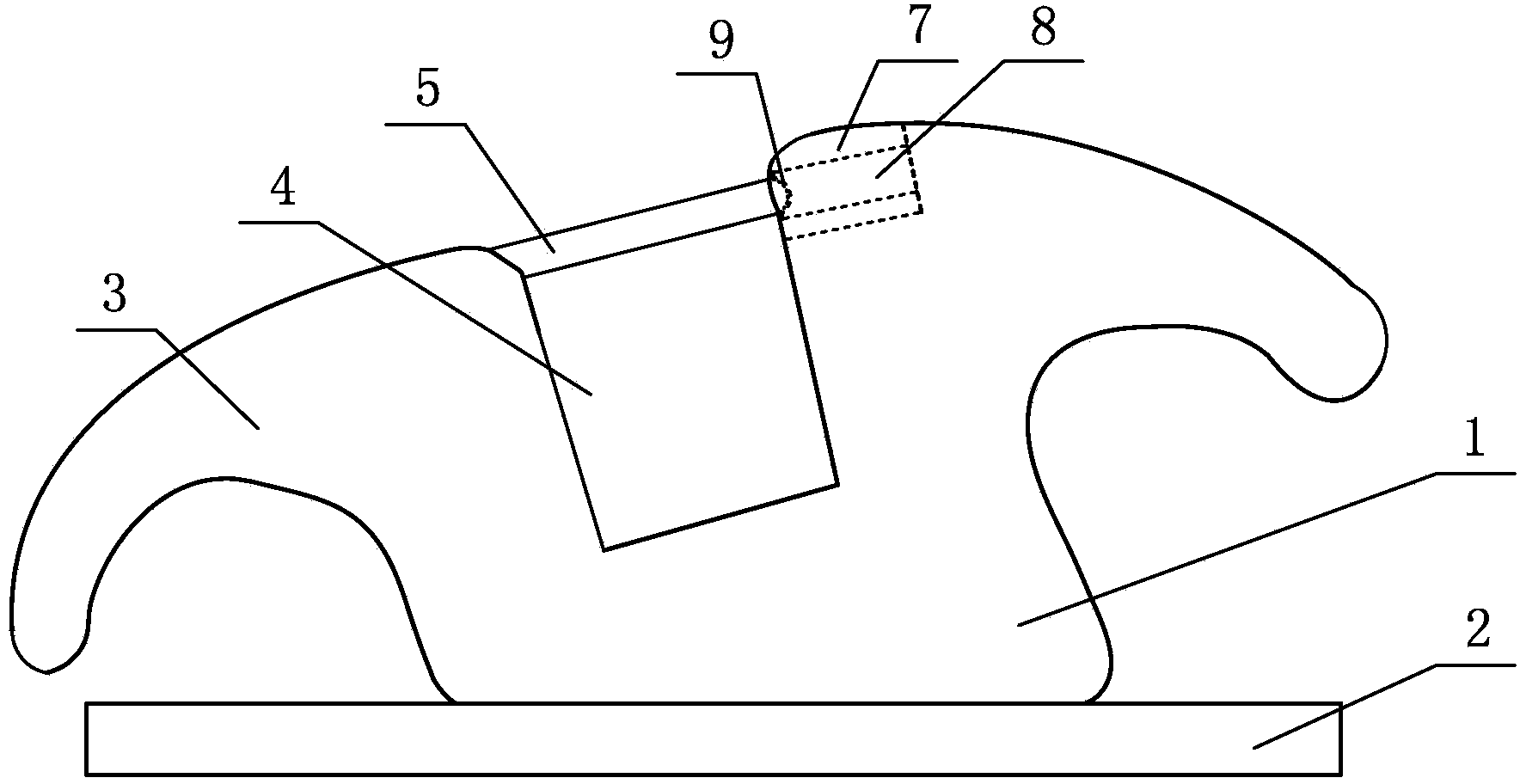

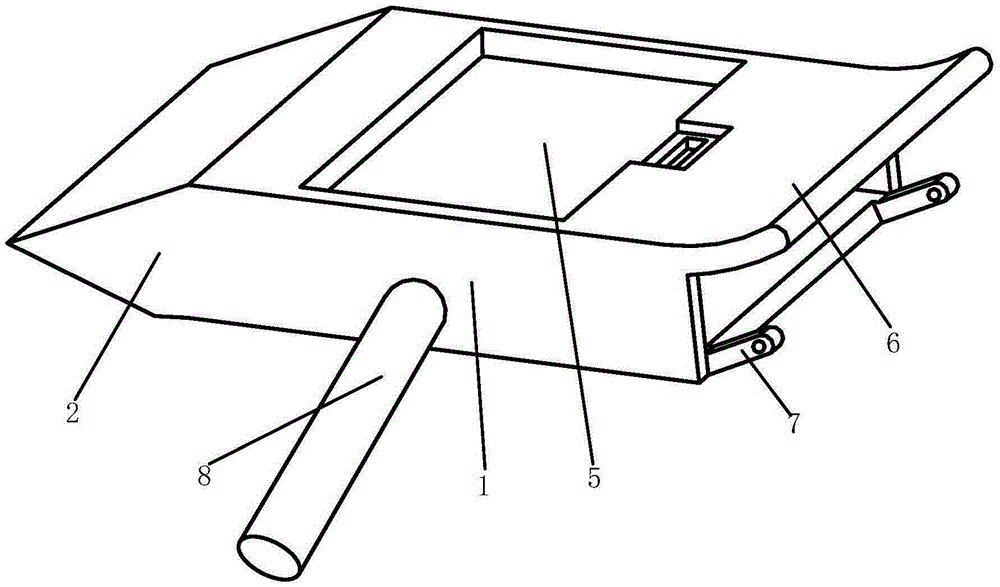

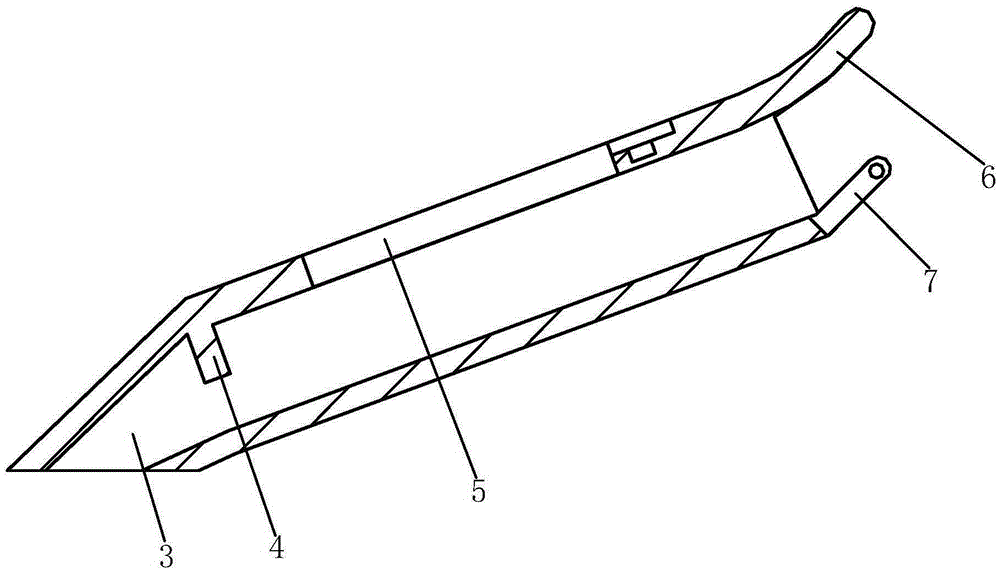

Folding geological radar detecting trolley

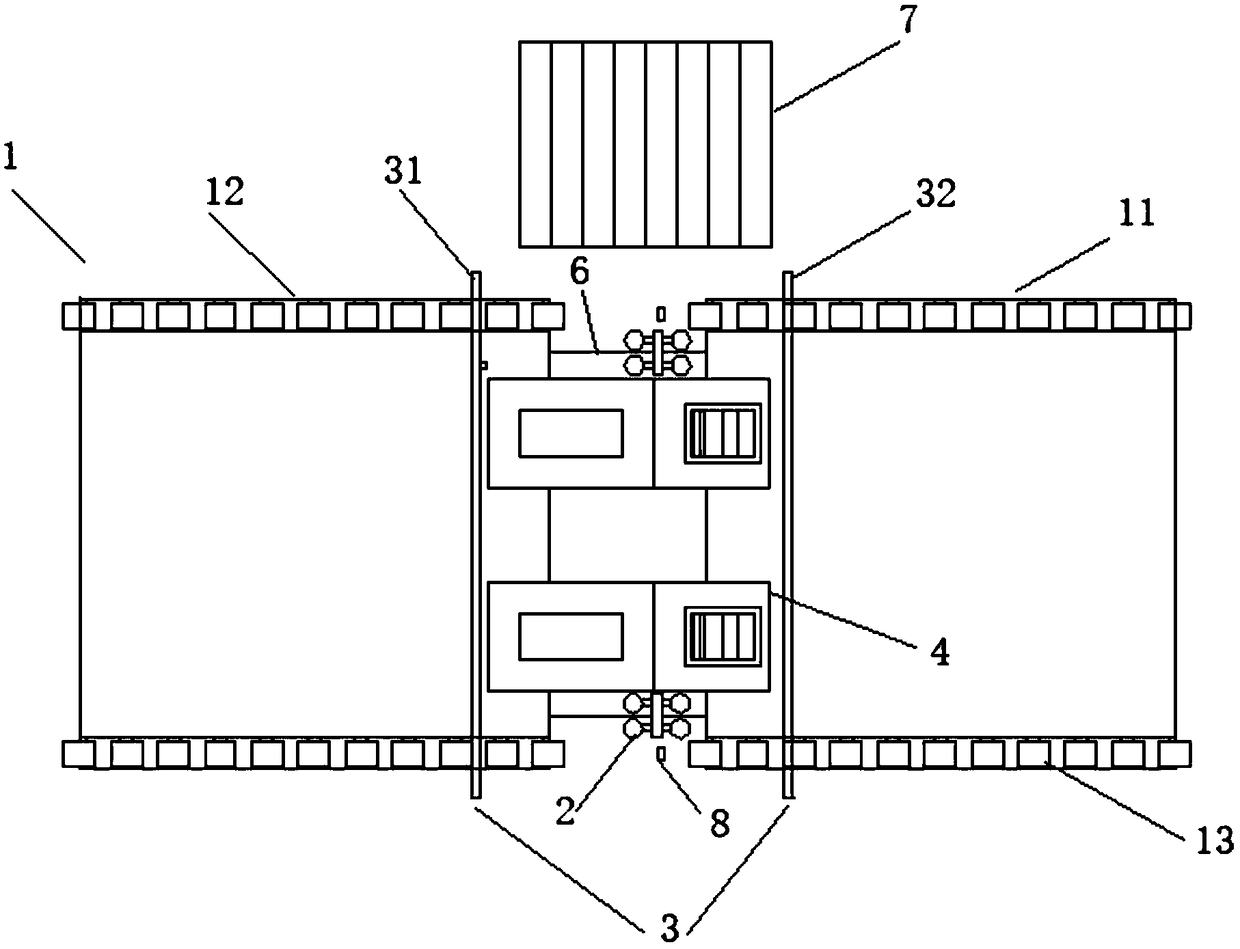

The invention discloses a folding geological radar detecting trolley which is composed of a vehicle frame system, a driving system, a folding system, a power supply box and an intensive equipment box.The driving system and the folding system are both mounted on the vehicle frame system, the power supply box is mounted on one side of the vehicle frame system, and the intensive equipment box is mounted on the folding system. The intensive equipment box can be placed in a vehicle frame, and the folding system is small in occupied space and is overturned flexibly; when a space is narrow, geological parameters of the narrow space are detected by deformation folding, the normal operation on various road conditions are achieved by hand pushing or folding deformation, and the work efficiency is ensured. A vehicle-mounted connecting front bumper is mounted at the front end of the vehicle frame to protect the vehicle frame and a vehicle-mounted radar detection device from impact. The intensiveequipment box is of a multi-layer structure, can accommodate a plurality of pieces of inspection equipment in intensive design, and can effectively protect key control devices such as display screensand control buttons.

Owner:北京市政路桥锐诚科技有限公司

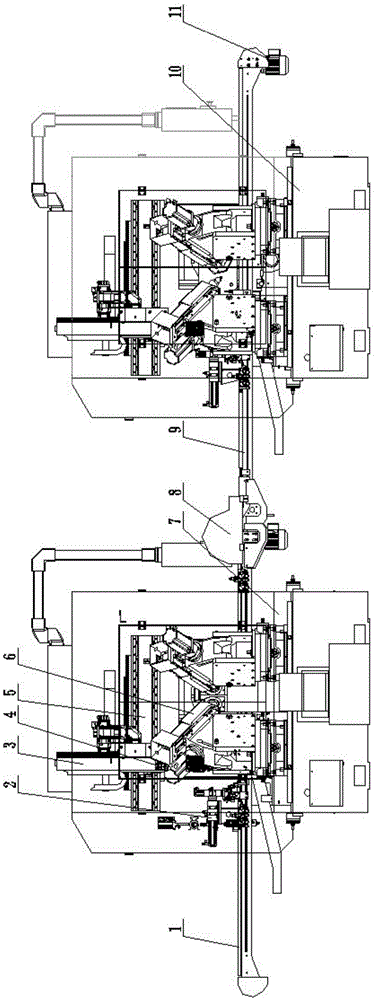

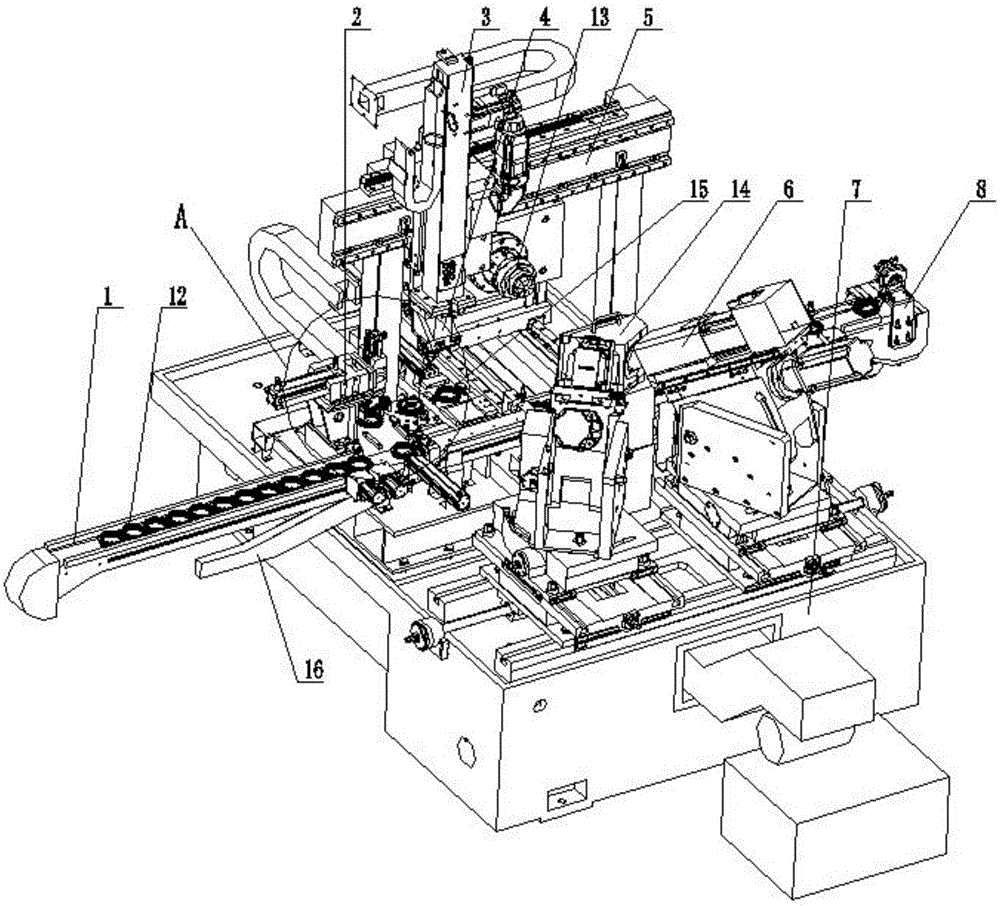

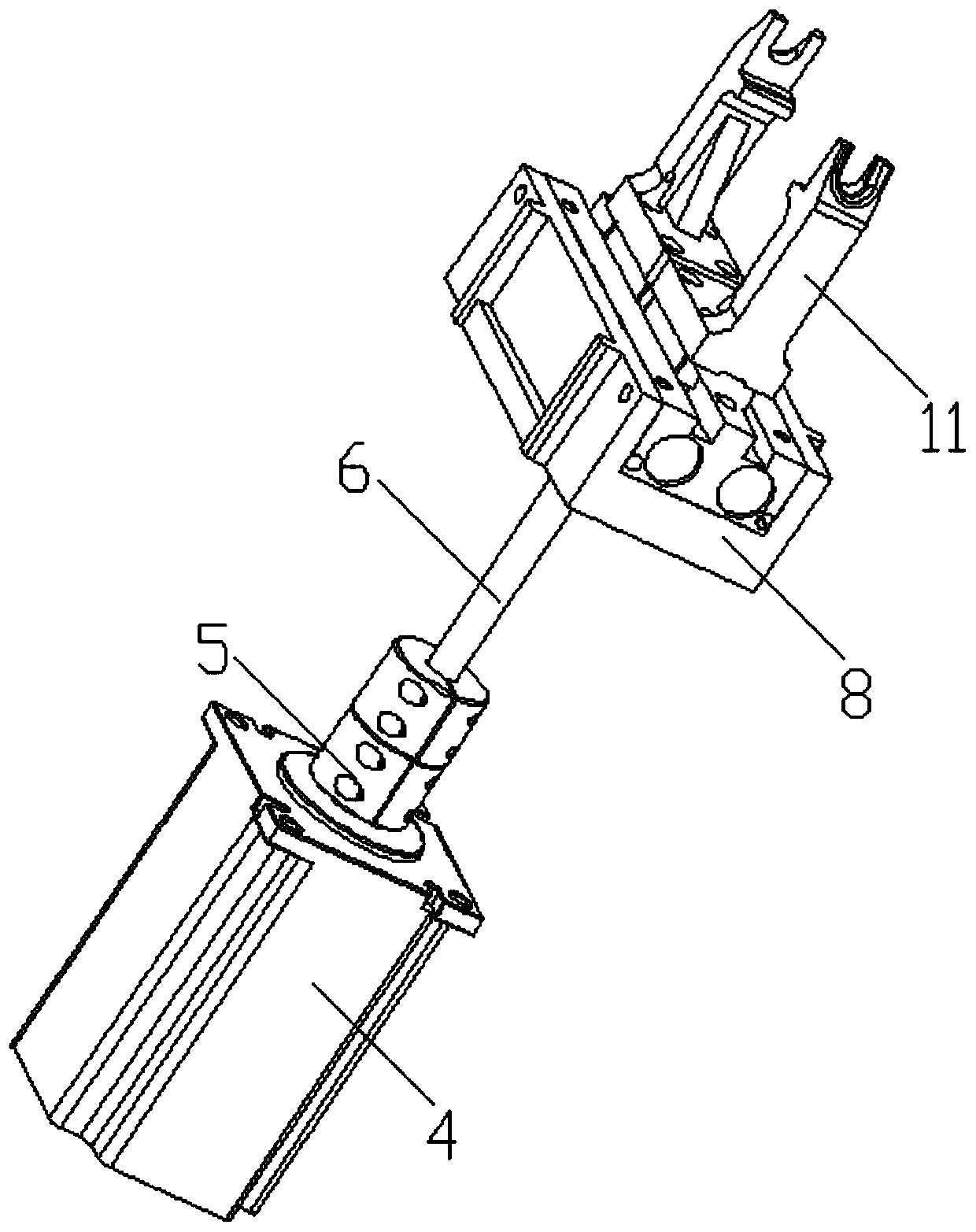

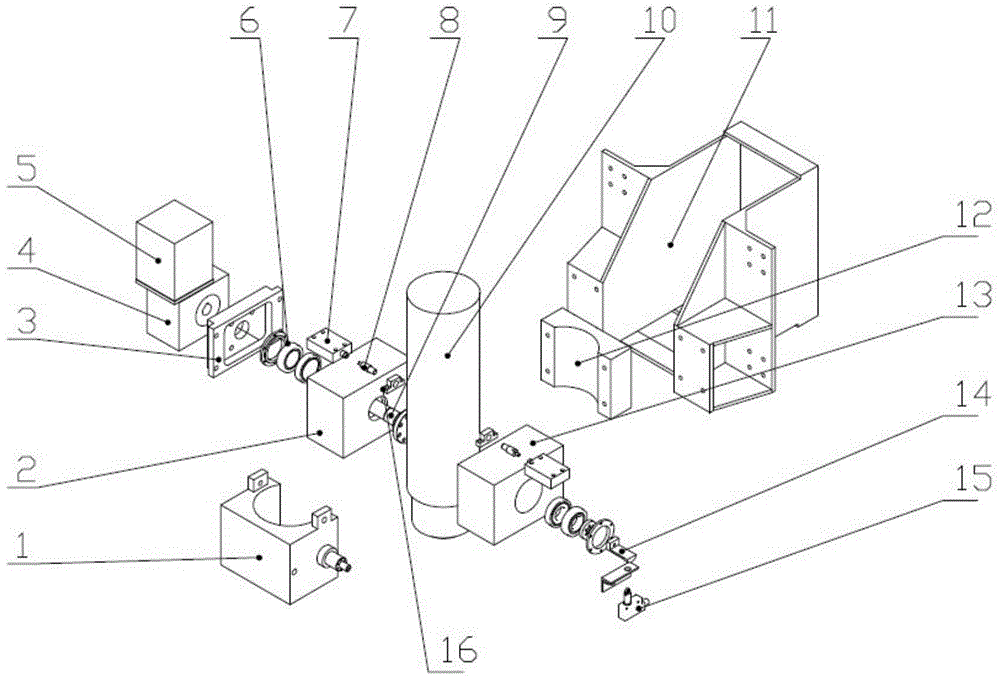

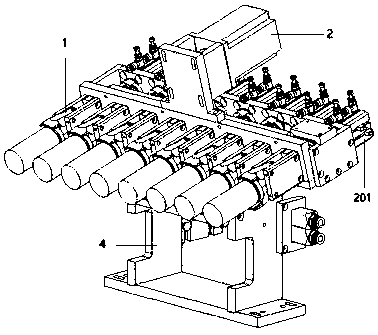

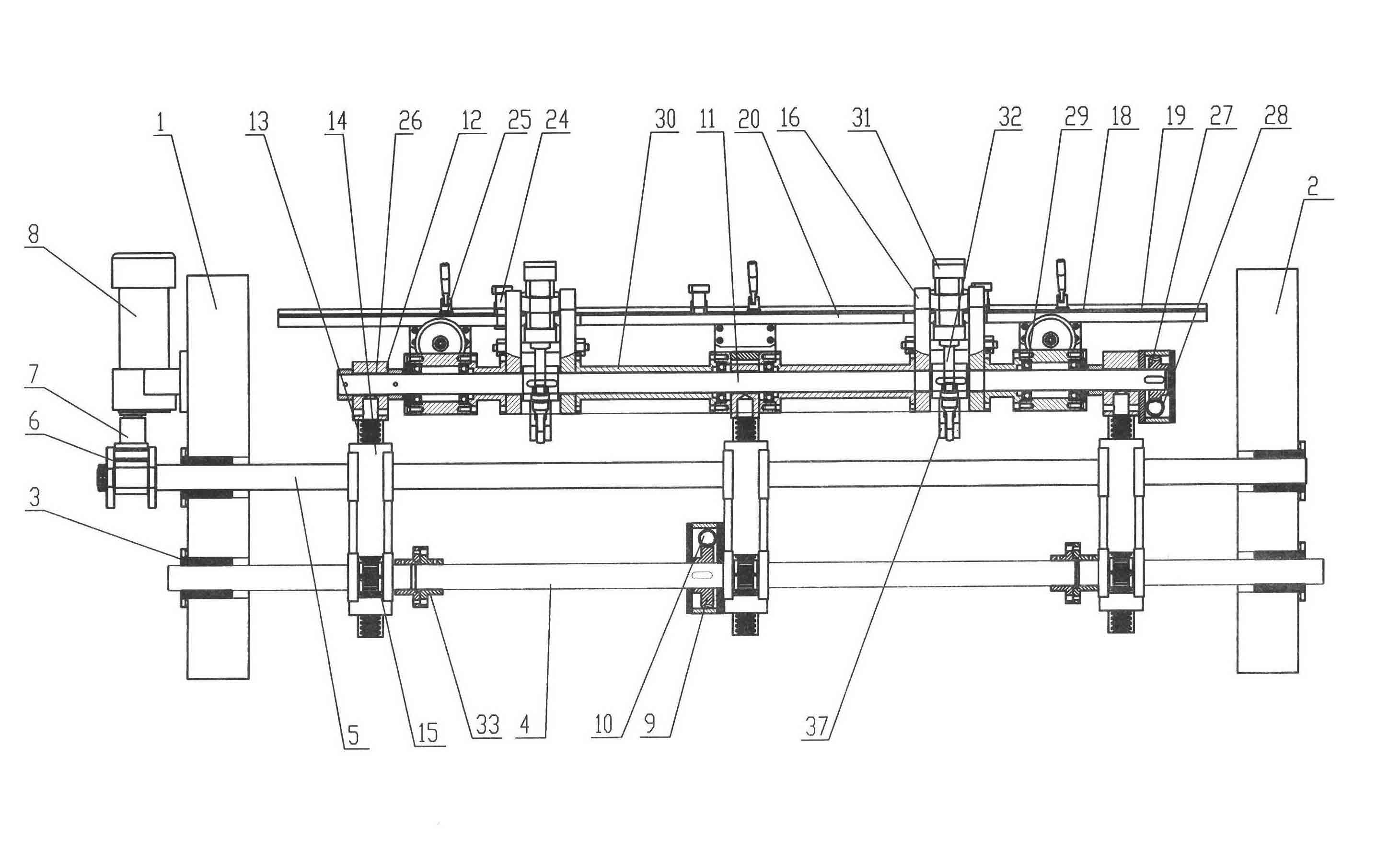

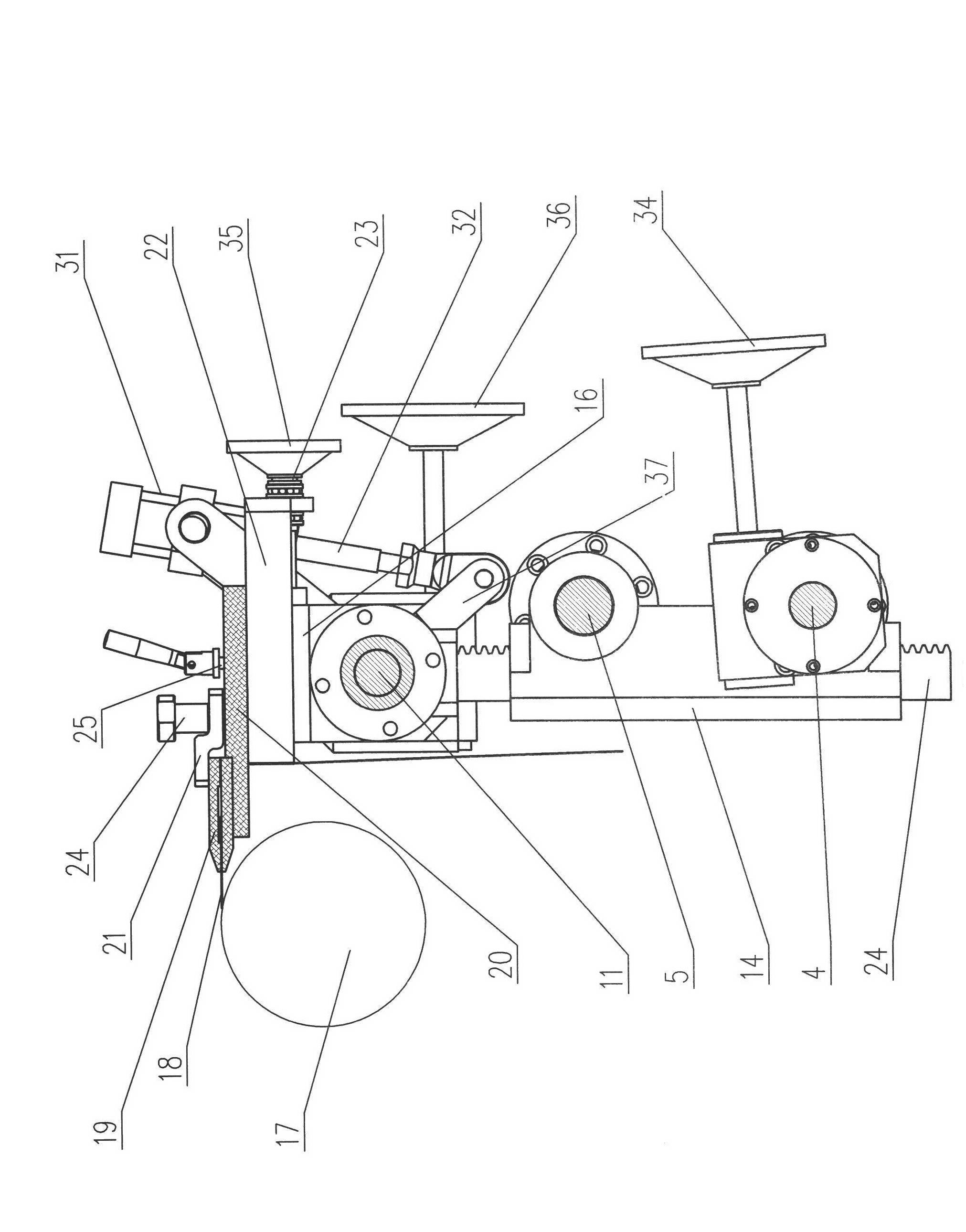

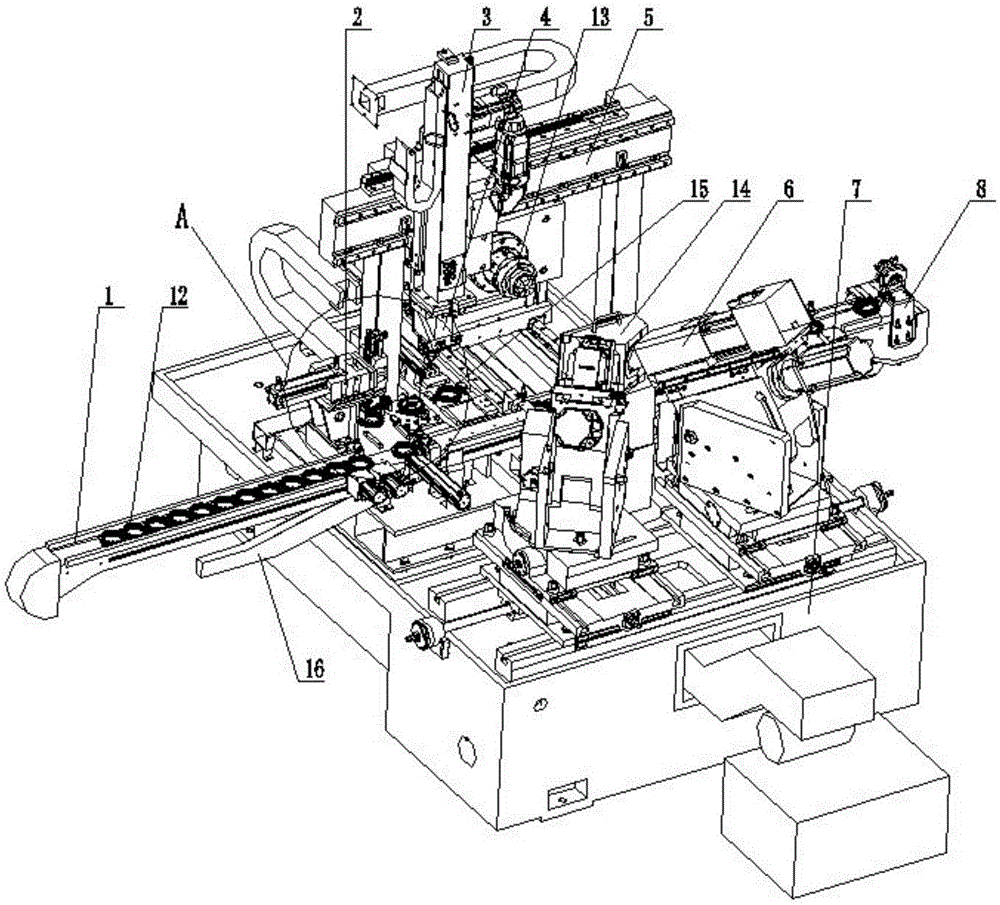

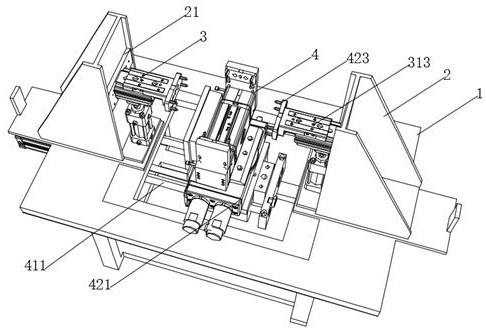

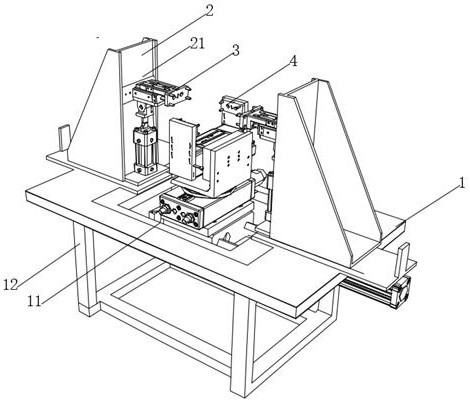

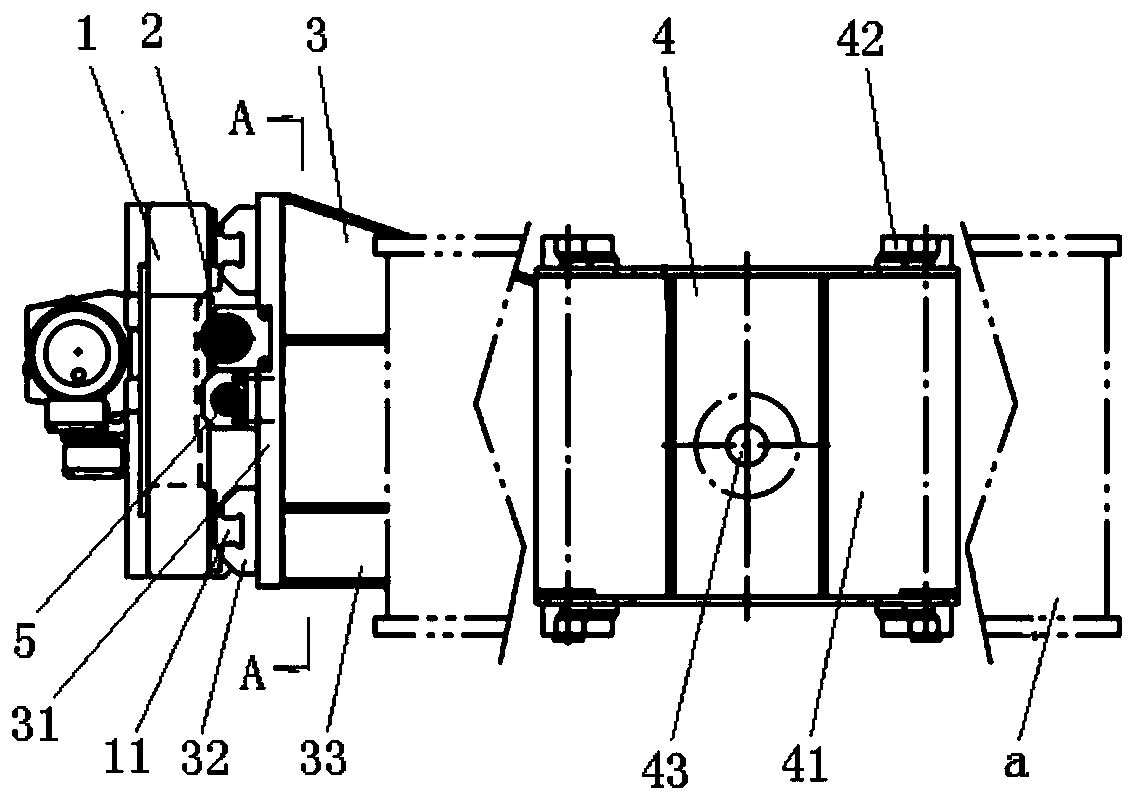

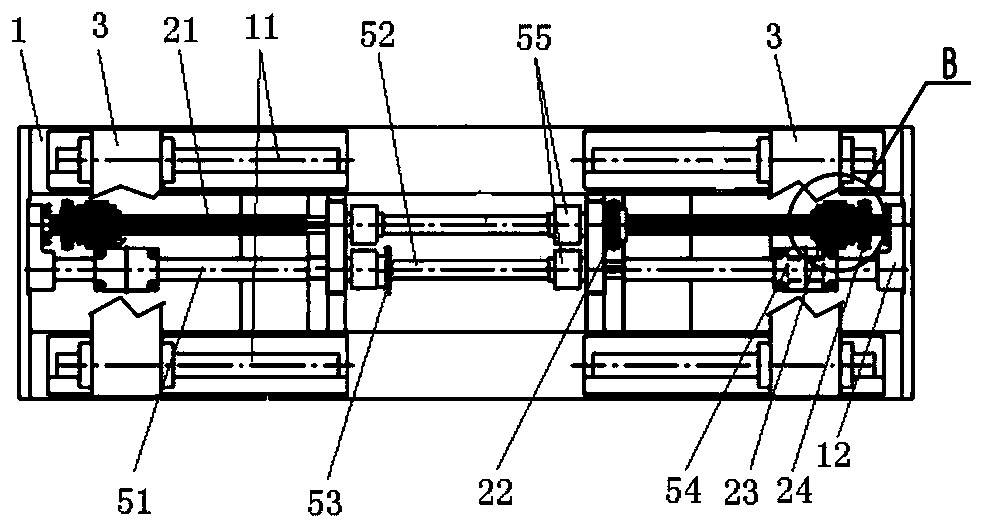

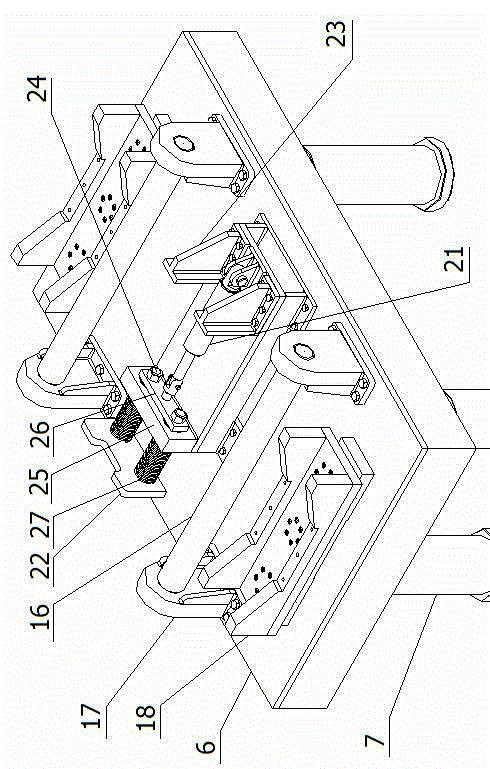

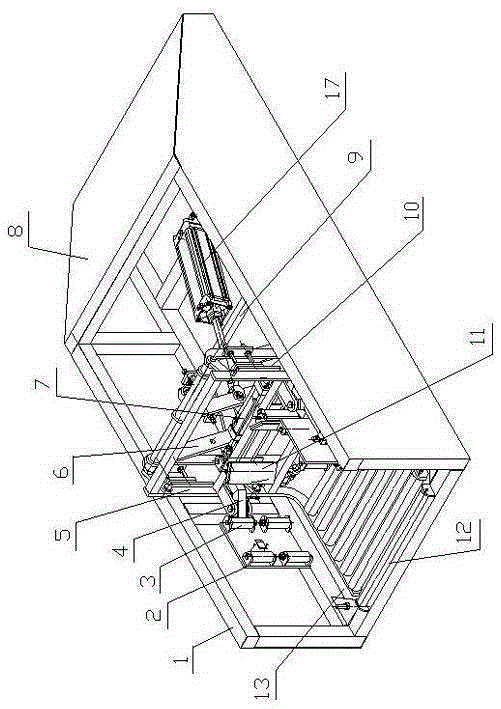

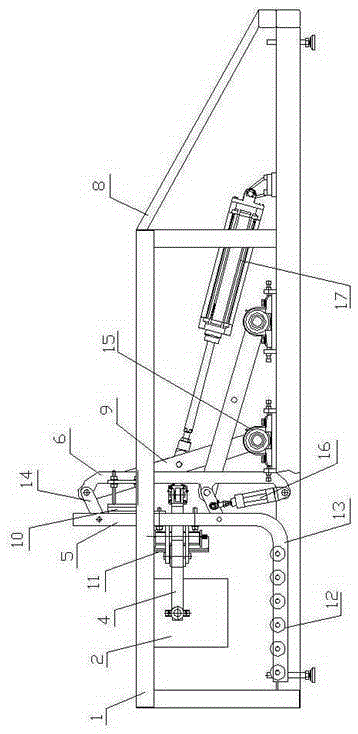

Double-face chamfering continuous machining system for gear sleeve of vehicle synchronizer

ActiveCN105149698AReduce configurationGuaranteed accuracyMetal working apparatusMaintainance and safety accessoriesDrive motorMachining system

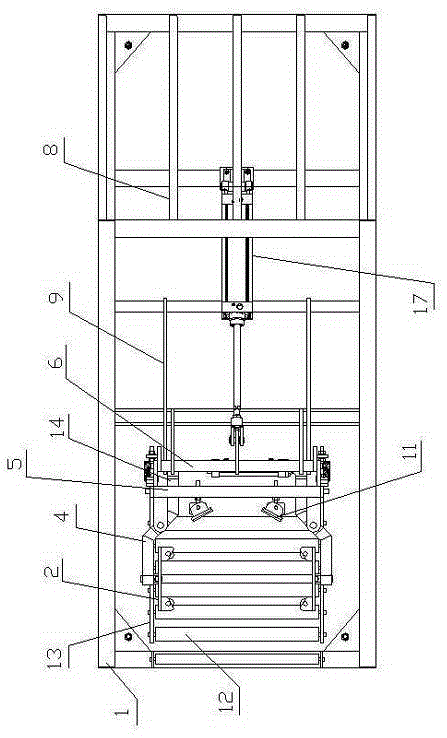

The invention relates to a double-face chamfering continuous machining system for a gear sleeve of a vehicle synchronizer. The double-face chamfering continuous machining system is formed by two same double-cutter machining chamfering machines and a linear feeding mechanism penetrating two chamfering machine machining stations transversely; the two same double-cutter machining chamfering machines are arranged into a row in parallel, each chamfering machine comprises a cutter for conducting chamfering machining, a workpiece driving machine head and a tooth alignment mechanism, a center line where the two cutters are located is arranged to right face the workpiece driving machine heads, tooth alignment mechanisms are arranged at front end working procedure components of the workpiece driving machine heads, and the workpiece driving machine heads are installed on a machine head base; each chamfering machine is horizontally and fixedly provided with a linear type feeding mechanism at the position, in front of the workpiece driving machine heads and behind the two cutters, of the corresponding machine body, and each linear type feeding mechanism is driven by a driving motor to drive a transmission belt in a material way to rotate; and a tooth sleeve turnover mechanism is installed between the two linear type feeding mechanisms, and pushing air cylinders are fixedly installed on the outer sides, corresponding to the tooth alignment mechanisms, of the material way. By means of the machining system, double-face chamfering machining of an overall tooth sleeve can be completed at a time, the production efficiency is greatly improved, meanwhile, allocation of a feeding mechanical arm and a feeding mechanism is omitted, and the overall machining area is decreased.

Owner:TIANJIN DAXIN PRECISION MECHANICAL EQUIP

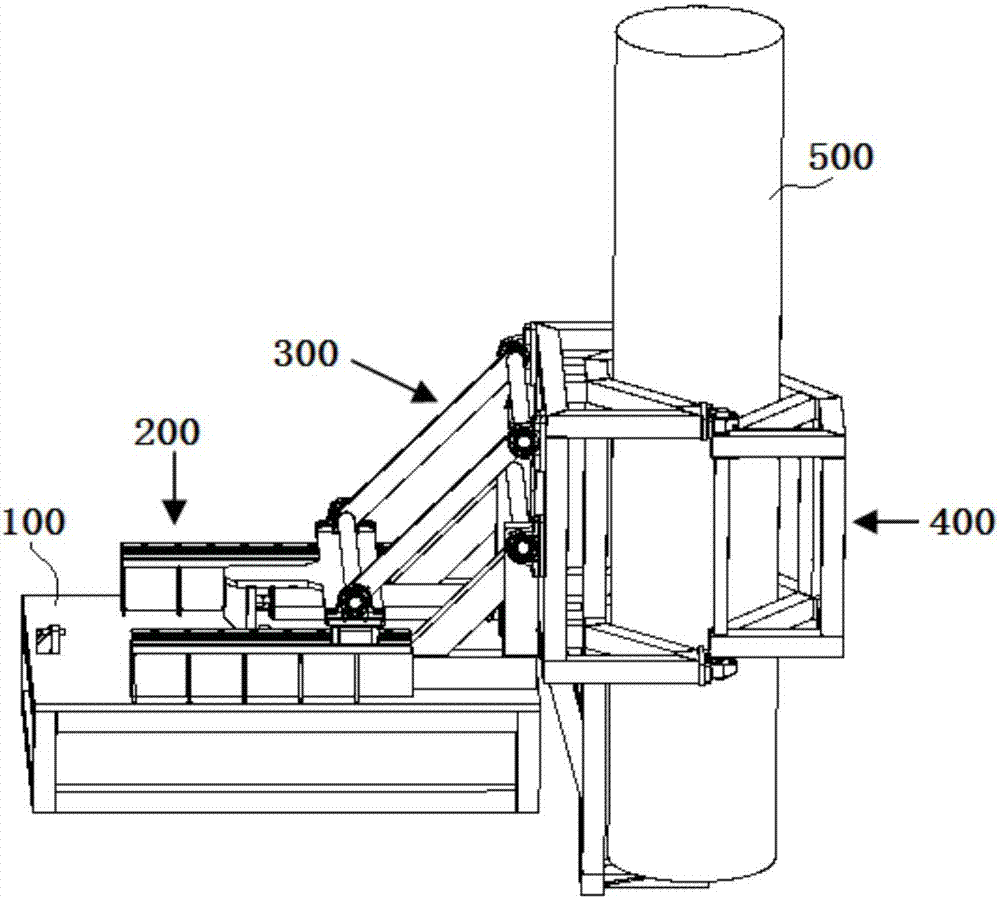

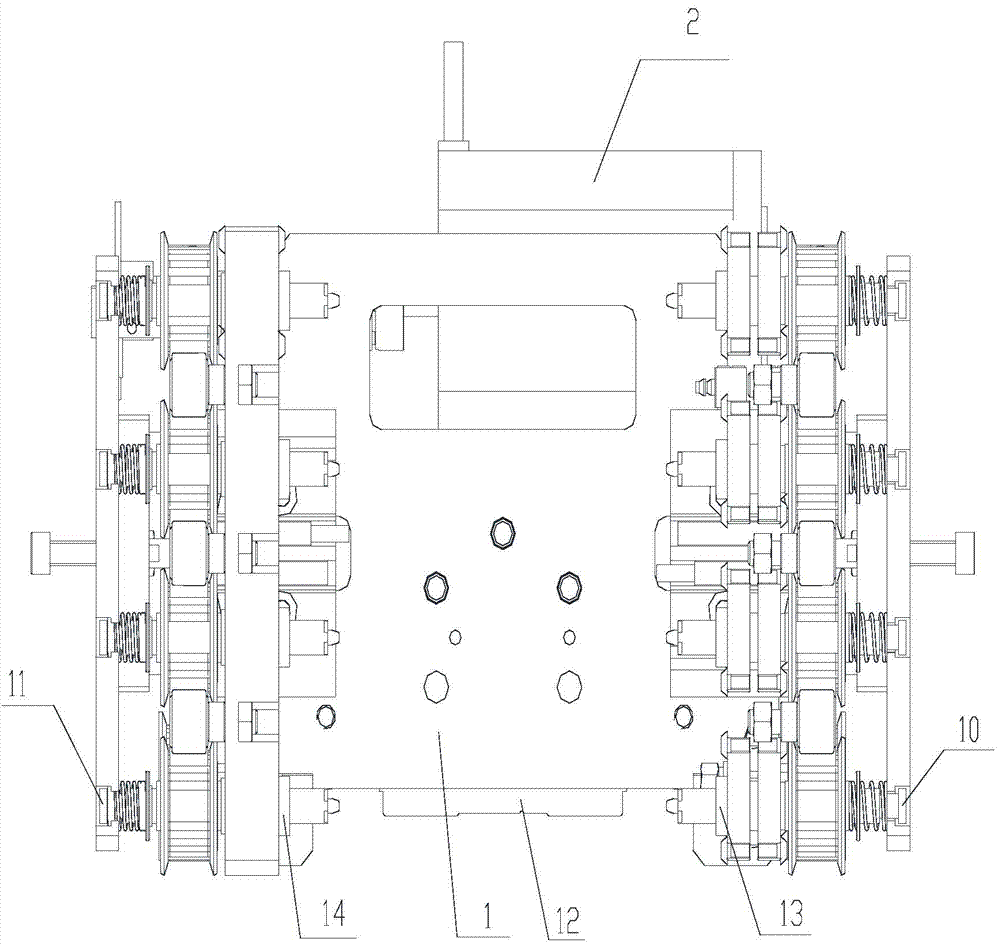

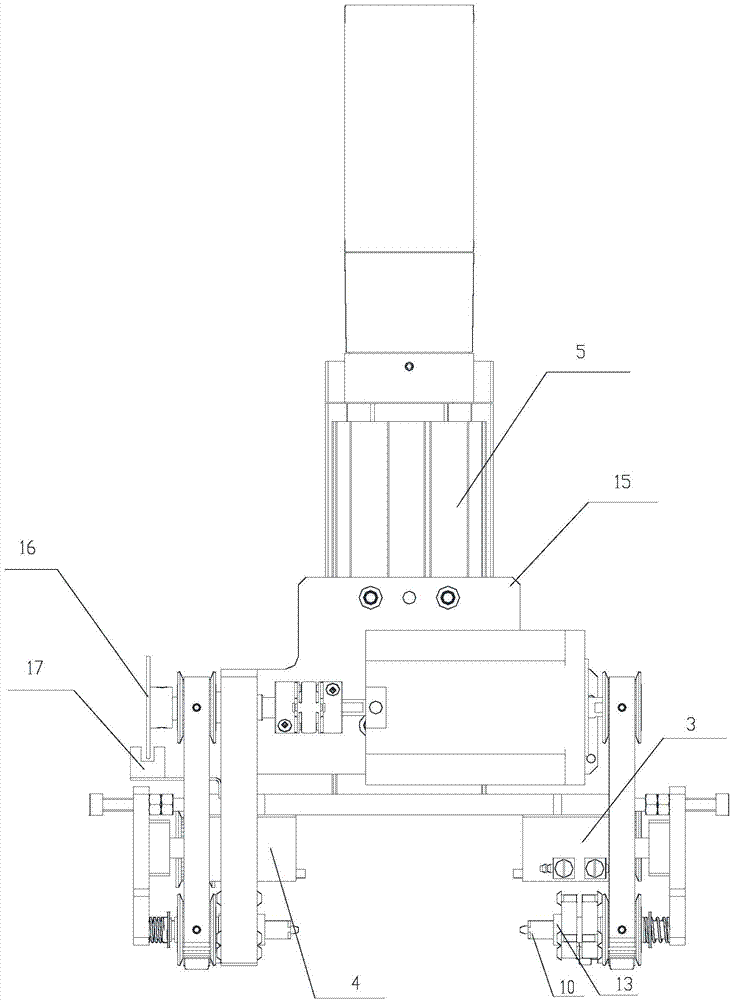

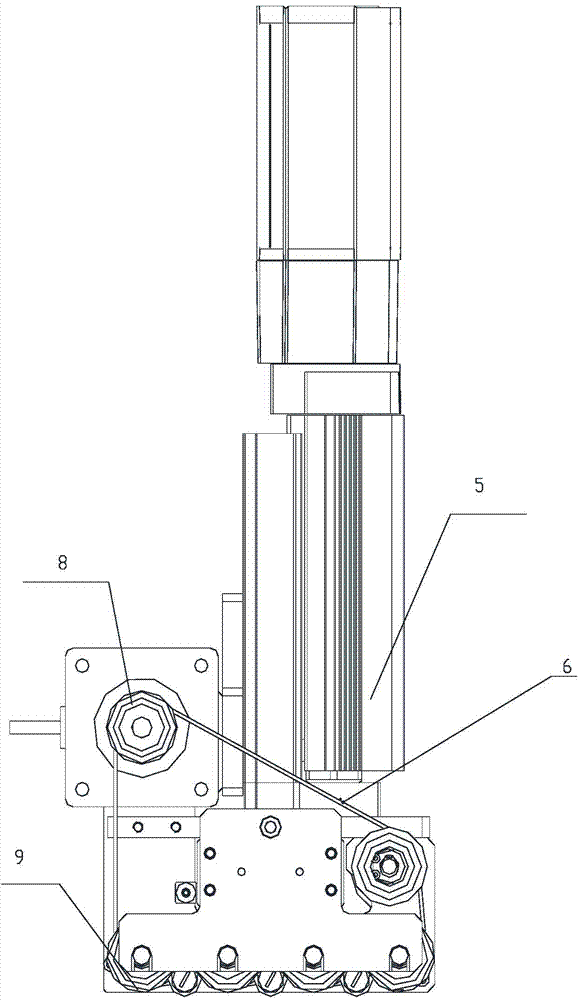

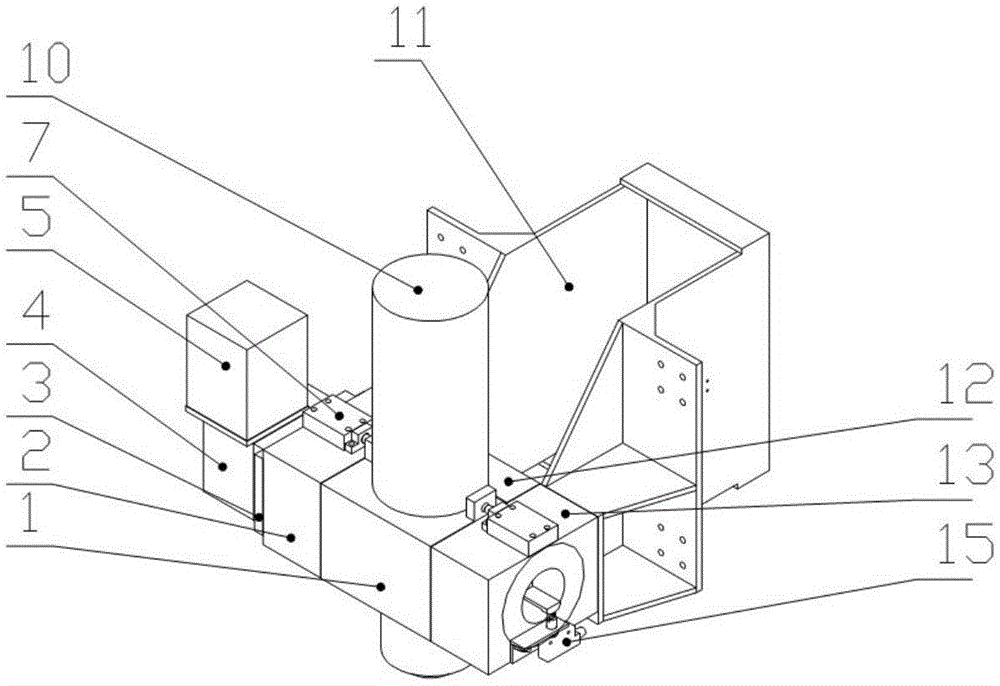

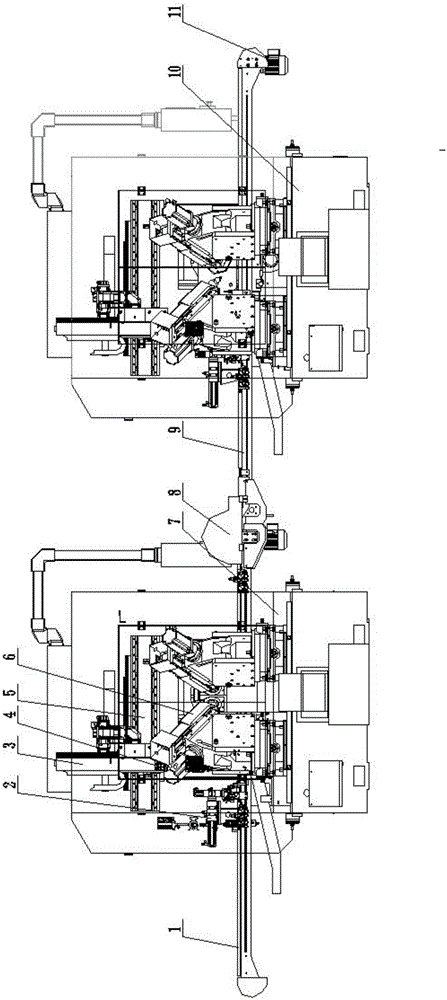

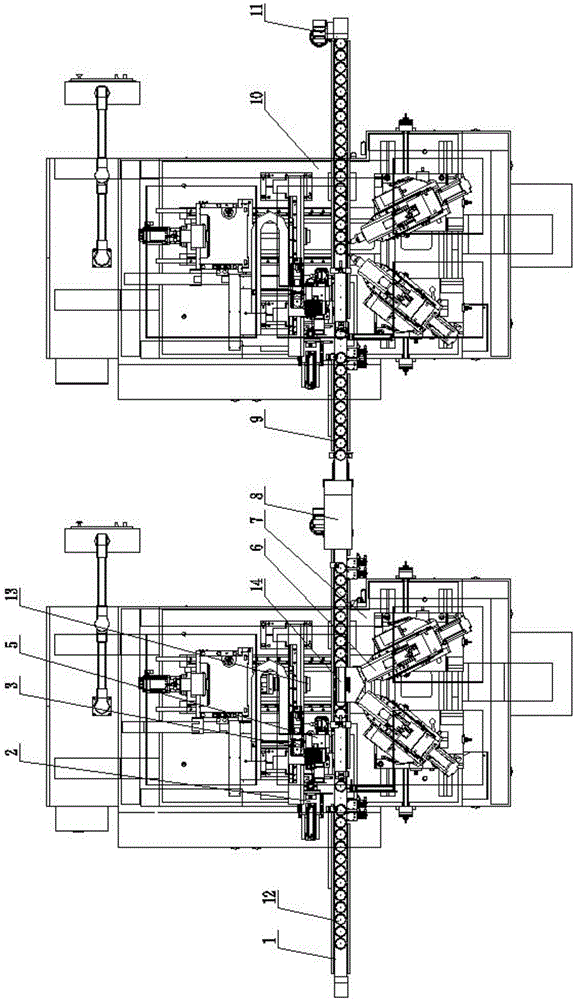

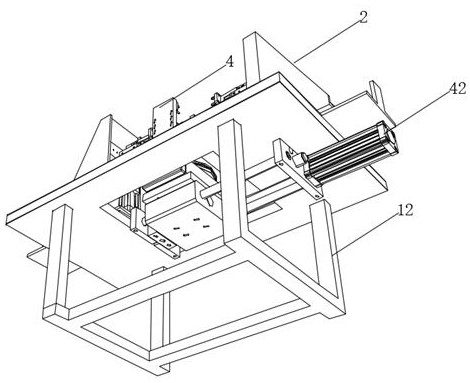

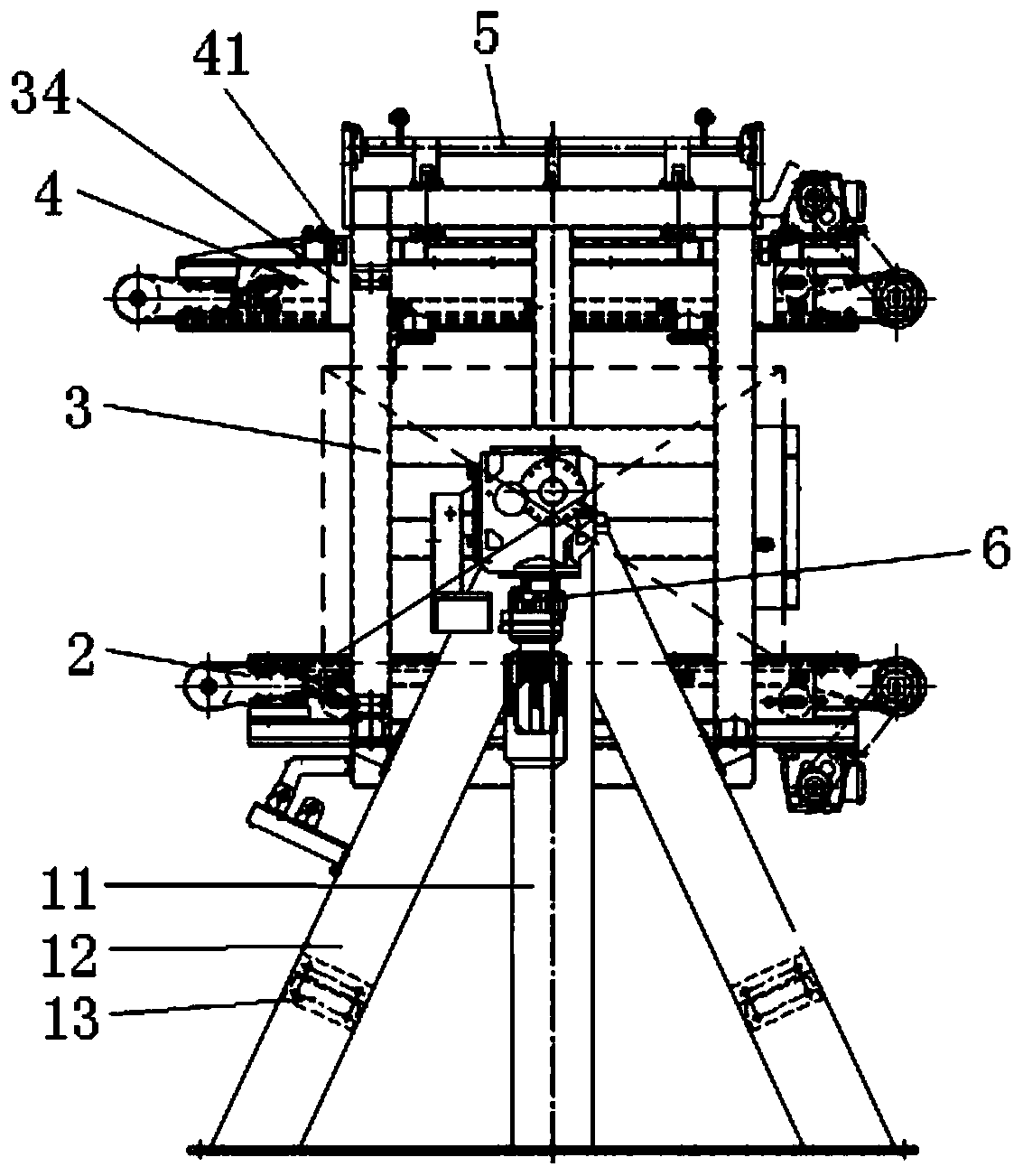

Mobile overturn robot and multistation overturn method thereof

The invention discloses a mobile overturn robot and a multistation overturn method thereof, and belongs to the field of robots. The mobile overturn robot comprises an overturn device, a transfer trolley, and a travelling rail. The overturn device is arranged on the transfer trolley. The transfer trolley transfers the overturn device to different processing stations to perform overturn operation along the travelling rail. The overturn device comprises a power mechanism, an orienteering mechanism, and a locking mechanism. The locking mechanism is used to fix a cylindrical member. The power mechanism comprises an oil cylinder and a pull rod. The pull rod is connected with the locking mechanism. The oil cylinder moves horizontally to drive the pull rod to pull the locking mechanism to overturn. The orienteering mechanism is used to control operation directions of the power mechanism. The mobile overturn robot can perform overturn operation on a workpiece on different stations, and satisfies fast-paced industrial production, and overturn is stable and production security is high.

Owner:安徽佩吉智能科技有限公司

Tool turning device and turning method thereof

Owner:GOERTEK INC

Double-arm magic cube robot

PendingCN110053059AAccurate collectionFast recognitionProgramme-controlled manipulatorGripping headsEngineeringManipulator

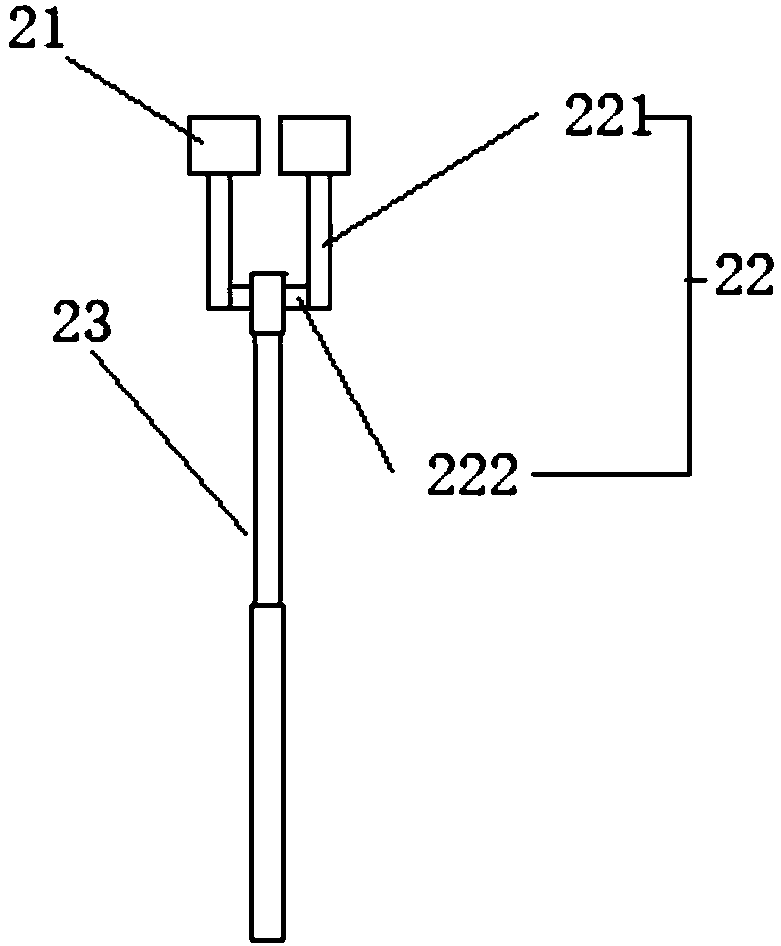

The invention relates to a double-arm magic cube robot which comprises a base plate, a frame, two manipulators and an image acquisition system. Each manipulator comprises a manipulator support, a rotating motor and a mechanical claw, wherein the rotating motor is arranged on the base plate through the manipulator support, and the rotating motor is connected with a long screw rod, the long screw rod is connected with the manipulator support through a rotary joint, the other end of the long screw rod extends upwards and is connected with a limiting plate, the mechanical claw is arranged on the limiting plate, the mechanical claw comprises a pair of claws and a driving mechanism used for driving the pair of claws to act, and supporting parts and U-shaped slot holes are arranged on the claws.Through a plurality of cameras, information acquisition is more accurate, and identification speed is faster; due to the fact that the corresponding supporting parts are arranged on the claws, a magiccube can be placed more accurately and conveniently, and meanwhile, the U-shaped slot holes are formed in the claws, so that inaccurate information acquisition caused by the fact that the claws blockthe magic cube is avoided; and each manipulator is provided with one pair of claws, the magic cube is more flexible to turn over, and the turning speed is higher.

Owner:WUYI UNIV

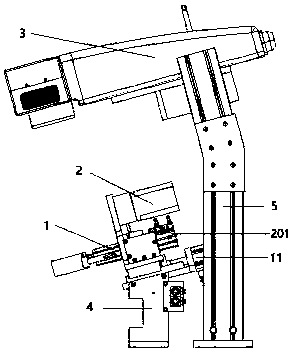

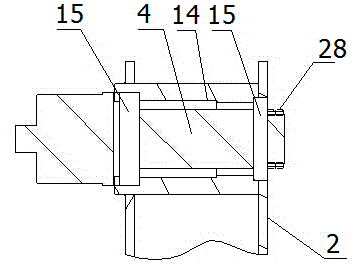

Spindle vertical-horizontal turnover device

ActiveCN104128973AFlip flexibleImprove reliabilityWood mortising machinesWood slotting machinesNumerical controlElectricity

The invention discloses a spindle vertical-horizontal turnover device, and belongs to the technical field of numerical control woodworking machines. The device comprises a spindle seat A, a left spindle swing bearing pedestal, a reducer fixing plate, a reducer, a driving motor, a turnover supporting component, locking air cylinders, a locating pin, a turnover transmission shaft, an electric spindle, a sliding plate, a spindle seat B, a right spindle swing bearing pedestal, a collision block, a sensor and a lead. The electric spindle drives a reduction motor through the driving motor, power is transmitted to the left spindle swing bearing pedestal and the right spindle swing bearing pedestal through the turnover transmission shaft, and the electric spindle is driven to rotate and change within the range of 0 to 90 degrees in the vertical plane. When the collision block collides with the sensor, turnover locating of the electric spindle can be achieved, and therefore precise locating of vertical and horizontal switching and turnover can be achieved. Vertical and horizontal turnover of the spindle is flexible, high reliability is achieved, cost is low, locating precision is high, machining precision is high, response speed is high, and production efficiency is improved. The device guarantees the machining precision of a workpiece and contributes to the construction of the wood-working machine industry of our country.

Owner:BEIJING UNIV OF TECH

Automatic turning system for battery cells

ActiveCN107597778AFlip flexibleFlip AccurateFinal product manufactureSecondary cells manufactureEngineeringAutomatic testing

The invention discloses an automatic turning system for battery cells. The automatic turning system for the battery cells comprises a turning mechanism used for turning the battery cells and a clamping mechanism used for clamping the battery cells when the battery cells are turned. The clamping mechanism comprises one or more clamping assemblies and a driving assembly used for controlling the clamping assemblies to stretch and retract. Each clamping assembly comprises a connecting rod and a clamping jaw, wherein one end of the connecting rod is connected with the clamping jaw, and the other end of the connecting rod is connected with the driving assembly. As the turning mechanism and the clamping mechanism are arranged, when the automatic turning system for the battery cells is applied toelectrode cleaning equipment, the turning mechanism can automatically turn the battery cells by 180 degrees, the clamping mechanism can clamp the battery cells in the turning process, and thus omnibearing cleaning of electrodes is achieved.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

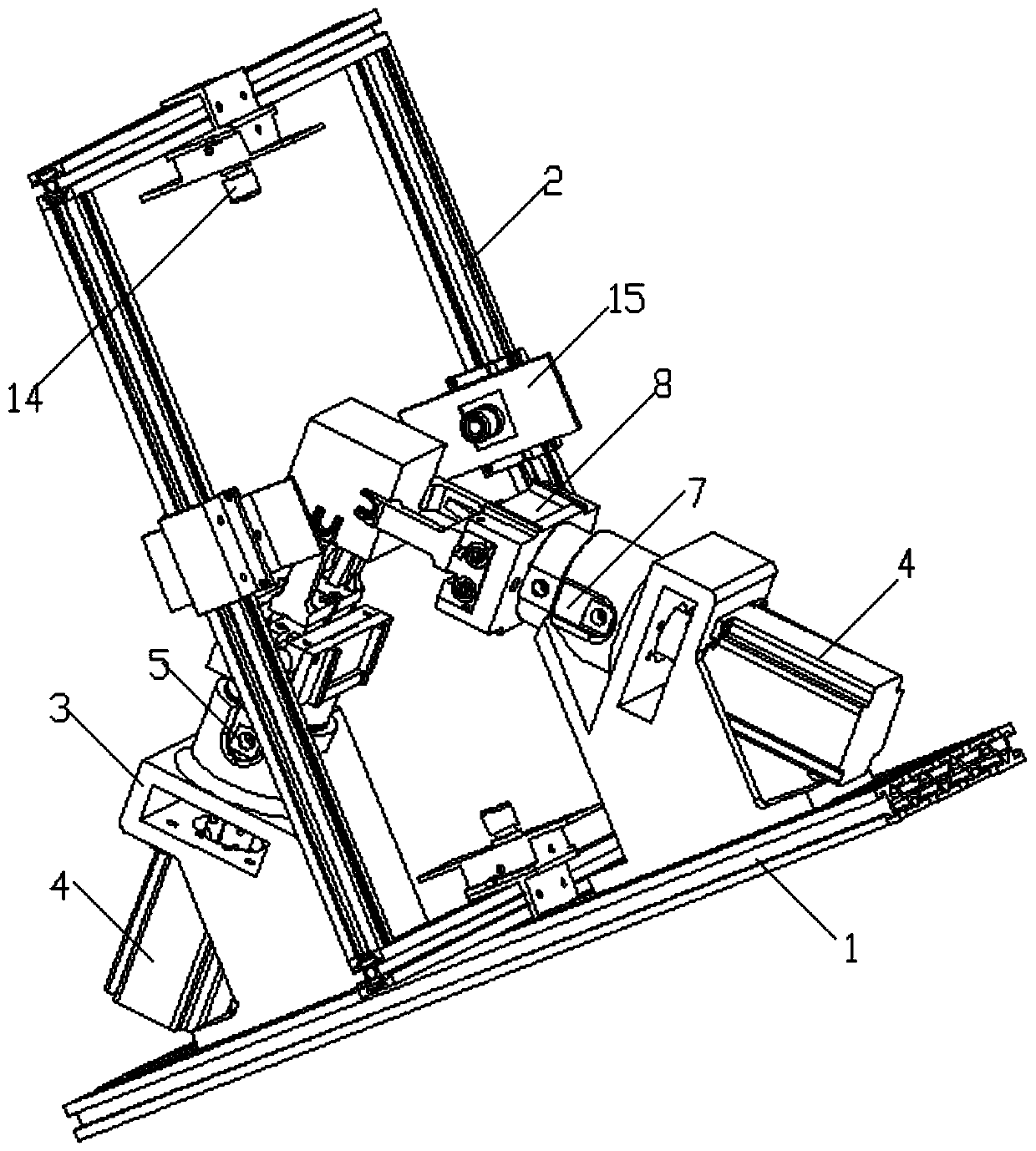

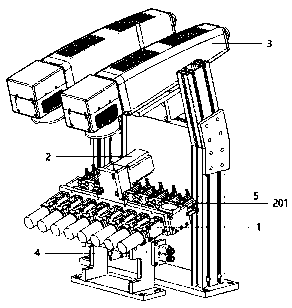

T-shaped elevator guide rail flatness detection system

InactiveCN108387189AConducive to flippingReduce momentumUsing optical meansEngineeringLaser transmitter

The invention relates to a T-shaped elevator guide rail flatness detection system, which comprises a support, a transverse conveying device, a longitudinal conveying device, a guide rail flatness detection device and a guide rail turnover device, wherein the transverse conveying device, the longitudinal conveying device, the guide rail flatness detection device and the guide rail turnover device are arranged on the support. The guide rail flatness detection device comprises a laser emitter and a laser receiving target, wherein the laser emitter and the laser receiving target are arranged on alinear rail spanning the transverse conveying device. The system adopts the laser detection method to detect the flatness of a guide rail. The system is accurate in detection result, simple and convenient to operate and free of complex machine equipment. According to the system, the automatic turnover of the guide rail is realized and the production efficiency is improved. The labor cost is saved,and the economic benefit of enterprises is improved. The turnover device is provided with a buffer mechanism, so that the impact when an elevator guide rail is in contact with a buffer block is reduced. The elevator guide rail is protected. Two cylinders are respectively arranged on the turnover device and the buffer driving device of the mechanism, so that the turnover block and the buffer blockcan be effectively controlled. Therefore, the turnover process can be well controlled.

Owner:吴江市通宇电梯轨道有限公司

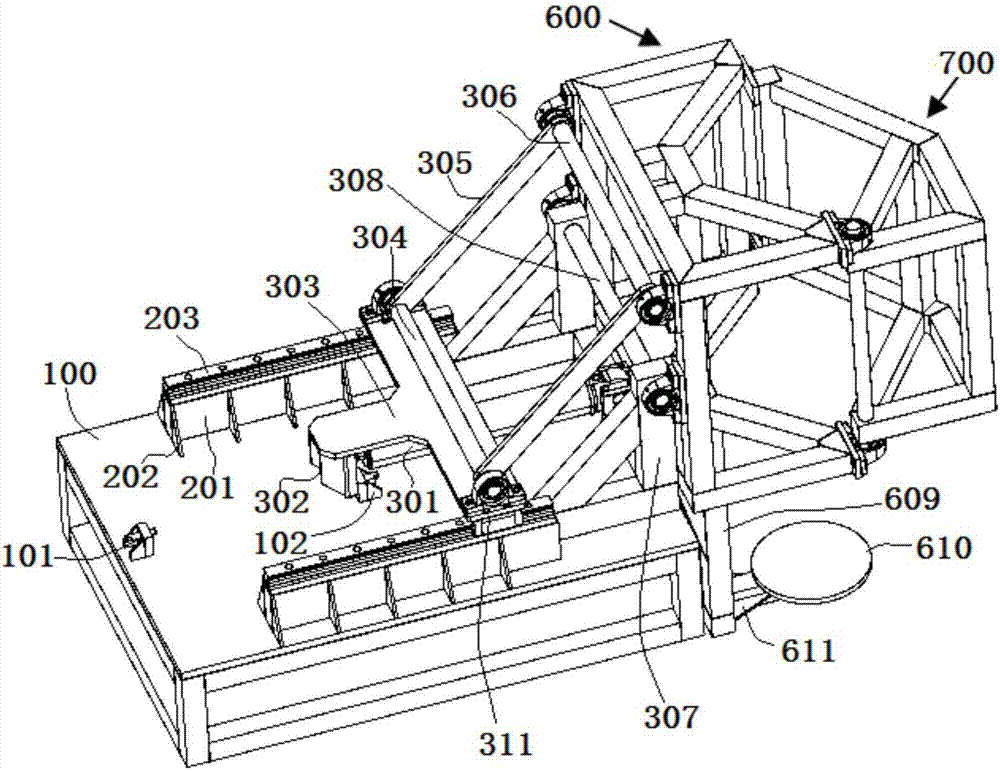

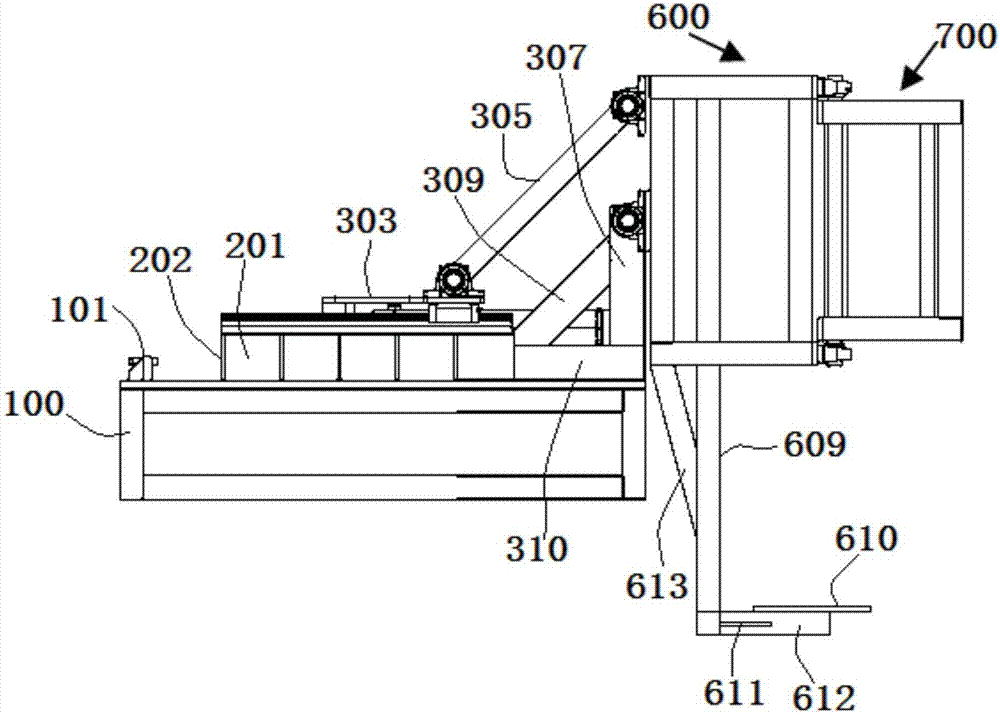

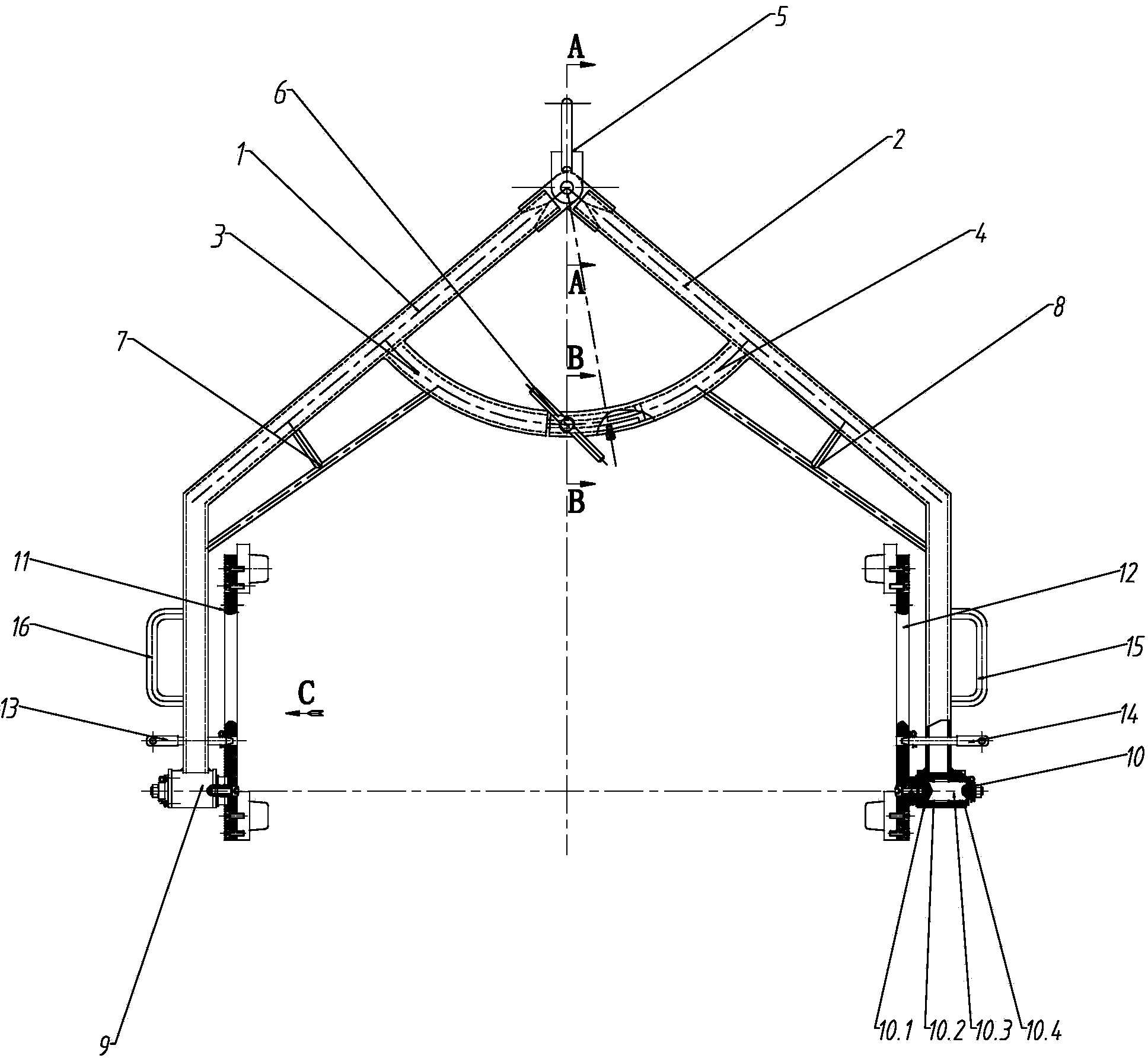

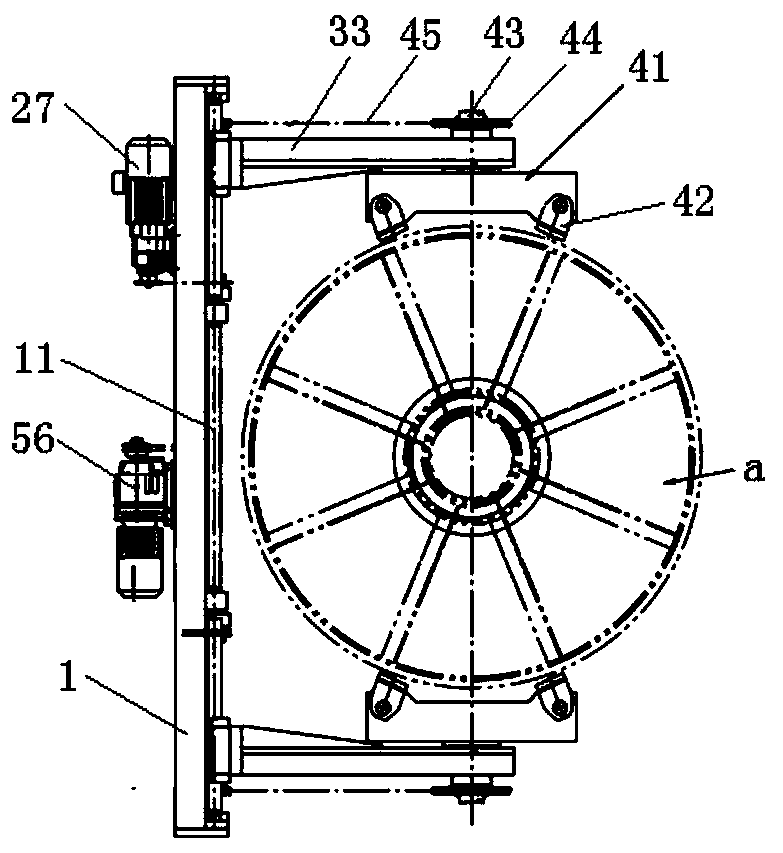

Herringbone overturn lifting appliance for cylinder body bobbin core set

The invention relates to an overturn lifting appliance, specifically relates to a herringbone overturn lifting appliance for hoisting cylinder body bobbin core set, and belongs to the technical field of lifting appliance. The herringbone overturn lifting appliance comprises a left lifting arm and a right lifting arm, the upper end of the right lifting arm and the upper end of the left lifting arm are in a rotation connection through a lifting assembly so as to form an integrated herringbone structure; one side, which faces the right lifting arm, of the left lifting arm is provided with a lifting arm slide track; one side, which faces the left lifting arm, of the right lifting arm is provided with a lifting arm slide block, which matches with the lifting arm slide track; the lifting arm slide block is arranged in the lifting arm slide track; the lower end of the left lifting arm is provided with a left-rotating assembly, the left-rotating assembly faces the right lifting arm side and is connected to a left clamping plate assembly; the lower end of the right lifting arm is provided with a right-rotating assembly, the right-rotating assembly faces the left lifting arm side and is connected to a right clamping plate assembly. The herringbone overturn lifting appliance has a simple, compact, and reasonable structure, can overturn agilely and reliably, can make work safe and stable, is laborsaving in operation, and avoids the falling off of the bobbin core set during the hoisting process.

Owner:无锡一汽铸造有限公司

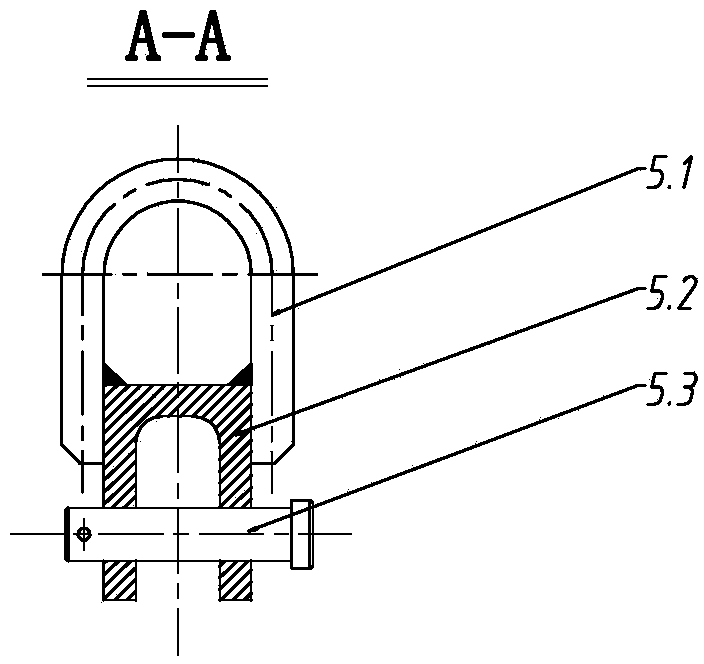

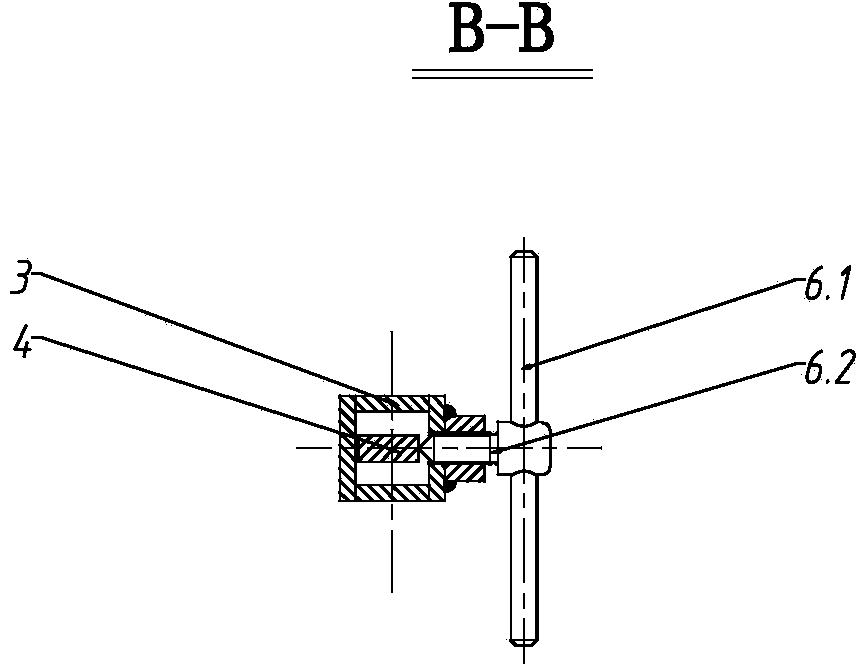

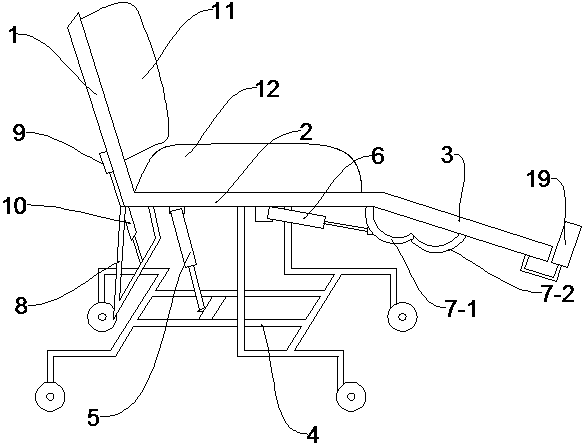

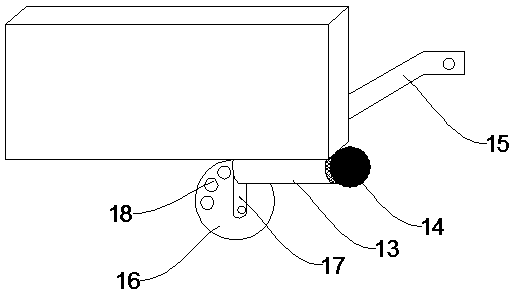

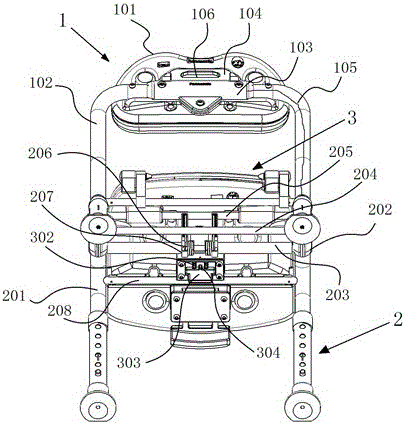

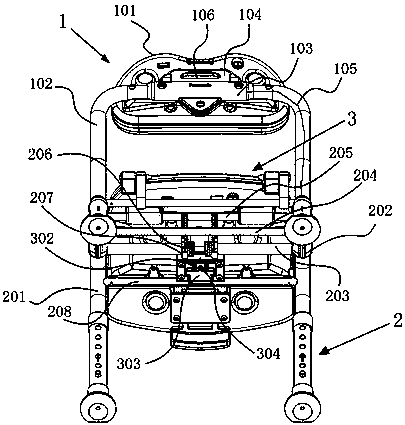

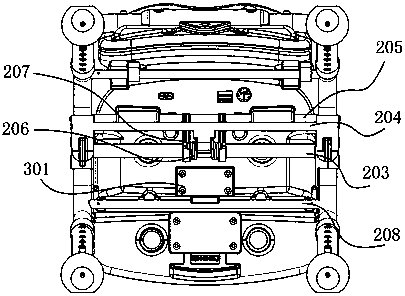

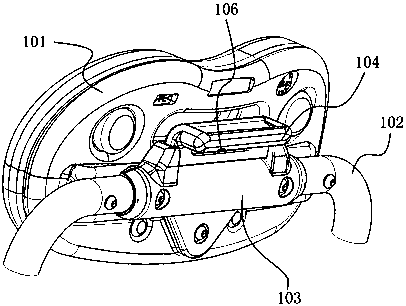

Flat electric wheelchair

PendingCN109172175ARunning speed is stableSimple structureWheelchairs/patient conveyanceWheelchairRest frame

The invention relates to the field of medical rehabilitation devices, in particular to a rehabilitation wheelchair. The invention relates to a flat electric wheelchair, comprising an electric seat frame, wherein the electric seat frame comprises a backrest frame, a cushion frame and a leg rest frame arranged in sequence; the backrest frame is rotatably connected with the cushion frame through a rotating shaft, and the leg rest frame is rotatably connected with the cushion frame through the rotating shaft; the seat rest frame is rotatably connected with the leg rest frame through the rotating shaft; the lower part of the cushion frame is fixedly connected with a movable frame, and three electric push rods are arranged, wherein the expansion and contraction of the electric push rods controlthe lifting ting and lowering of the cushion frame, the expansion and contraction of the electric push rods and the rotating of the movable push rods realize the turning over of the leg frame relativeto the cushion frame, and the expansion and contraction of the electric push rods 3 realize the turning over of the backrest frame relative to the cushion frame. The invention has the advantages of simple overall design, replacing the traditional complex connecting rod structure, lightweight and flexible turning of the whole wheelchair, stable running speed of the electric push rod, stable and smooth wheelchair in the process of unfolding and lying flat, and increased user comfort.

Owner:嘉兴邦泽科技有限公司

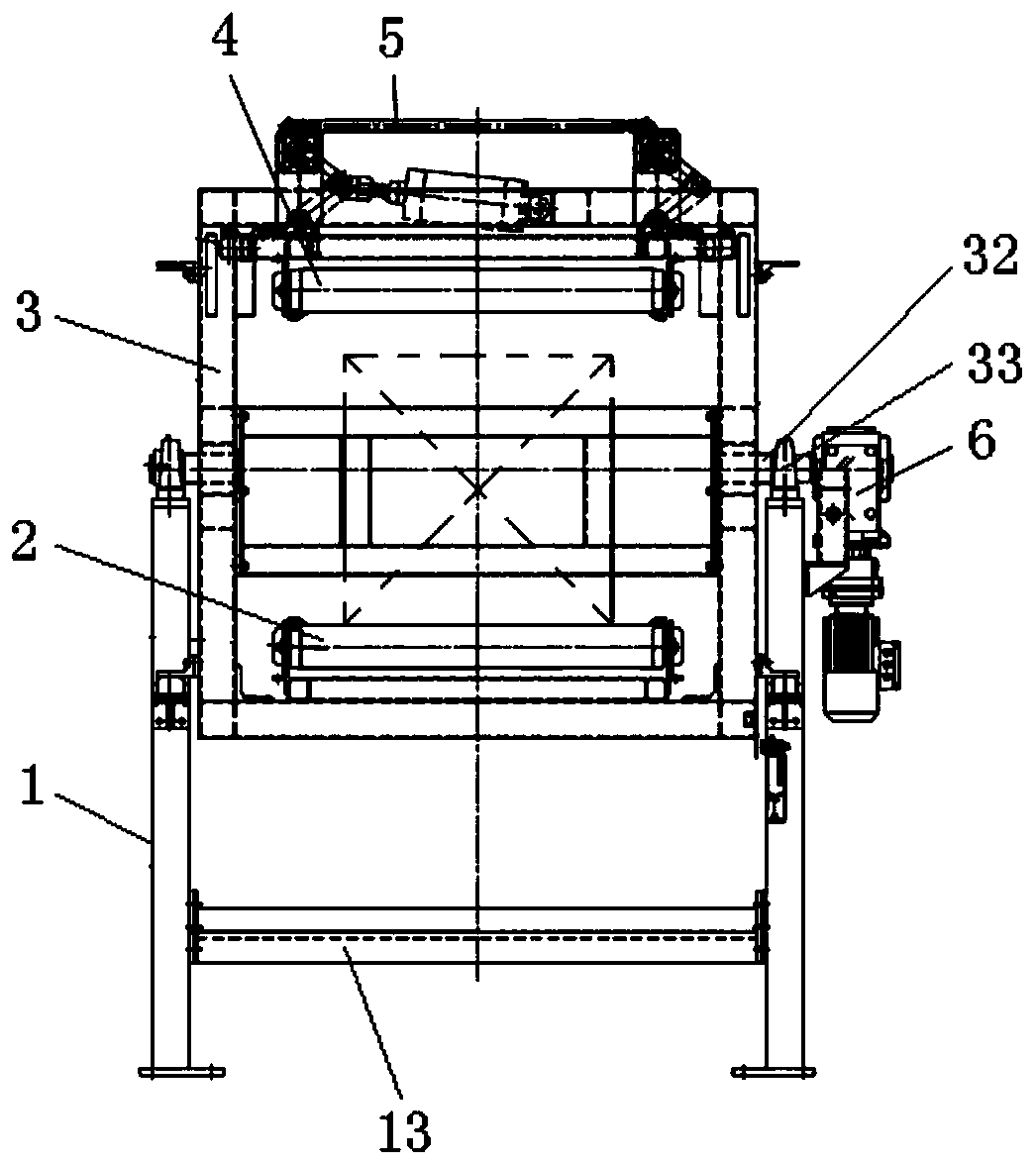

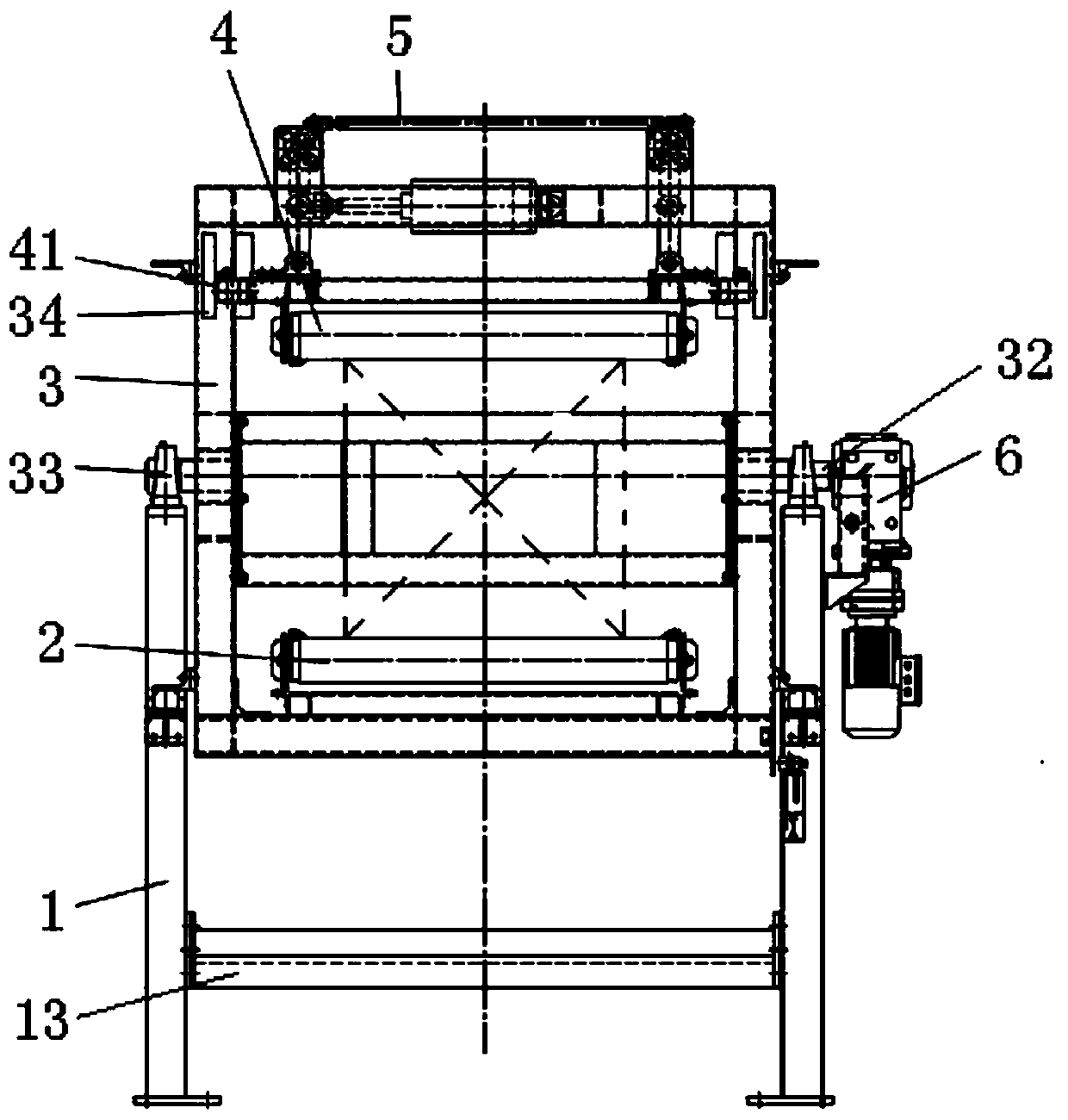

Turning plate type screening device

Disclosed is a turning plate type screening device. A screen plate is arranged on a rack of the turning plate type screening device. A vibration motor is arranged on the screen plate. The screen plate is connected with a rotary shaft and is driven by a telescoping cylinder to rotate around the rotary shaft. The rotary shaft is arranged between the vibration motor and the output end of the telescoping cylinder. Compared with the traditional mode that a vibration motor and a telescoping cylinder are located at the same end of a hinged shaft, the turning plate type screening device enables the rotary shaft to be arranged between the vibration motor and the telescoping cylinder, the self-weight of the vibration motor indirectly serves as a counterweight, force at the two ends of the screen plate can be better balanced, impact force generated when the screen plate rotates or returns can be reduced, rotation is more flexible, more power and energy of the motor are saved, and cost is further reduced. Moreover, the vibration motor is arranged at the end, away from the feeding side, of the screen plate so that a feeding screening area can generate a large amplitude and the screening effect is improved. Furthermore, the vibration motor is arranged in the middle in the width direction of the screen plate, so that a certain balance function is achieved, and the screen plate is prevented from tilting to one side in the width direction.

Owner:郑州力达自动化控制有限公司 +1

Film transfer scraper device

InactiveCN102602139ASmooth swingEasy to clean and replacePrinting press partsAgricultural engineering

The invention discloses a film transfer scraper device which is more stable to drive. The film transfer scraper device comprises a left wallboard, a right wallboard, a lower shaft and a middle shaft, wherein both ends of the lower shaft and the middle shaft are respectively arranged between the left wallboard and the right wallboard by linear bearings; one end of the middle shaft extends out of the left wallboard to be connected with a swing sleeve; the swing sleeve is connected with a speed reduction motor fixedly arranged on the left wallboard by an eccentric shaft; a worm gear and a worm which are matched are arranged on the lower shaft; an upper shaft is arranged above the middle shaft between the left wallboard and the right wallboard; three rack fixing seats are arranged on the upper shaft; the lower ends of the rack fixing seats are respectively connected with the upper ends of lifting racks; the lifting racks are arranged in rack seats; gears matched with the lifting racks are arranged on the lower shaft; tool rest fixing seats are arranged on the upper shaft; and the scraper device is arranged on the tool rest fixing seats.

Owner:YANCHENG YUANHUA MACHINERY

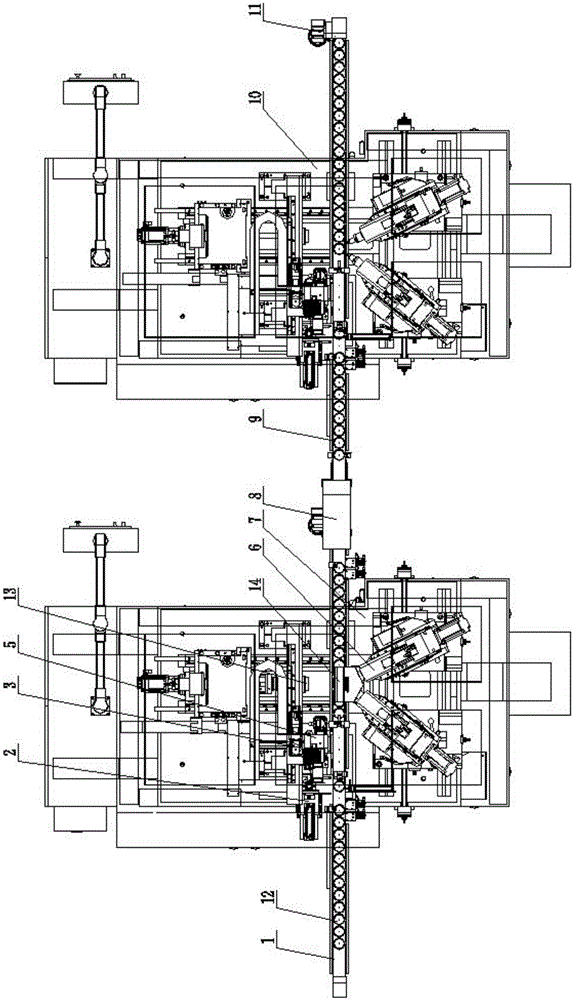

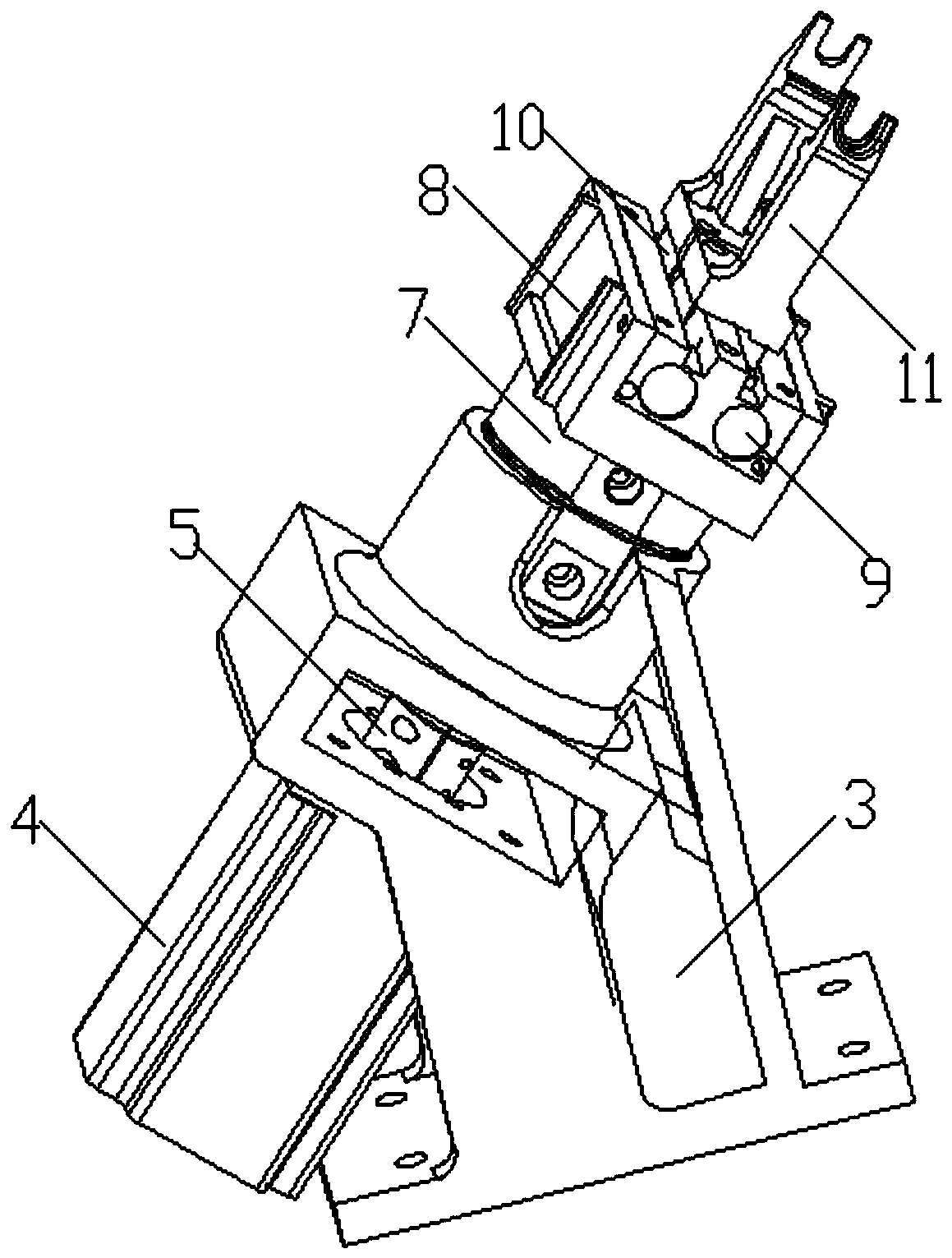

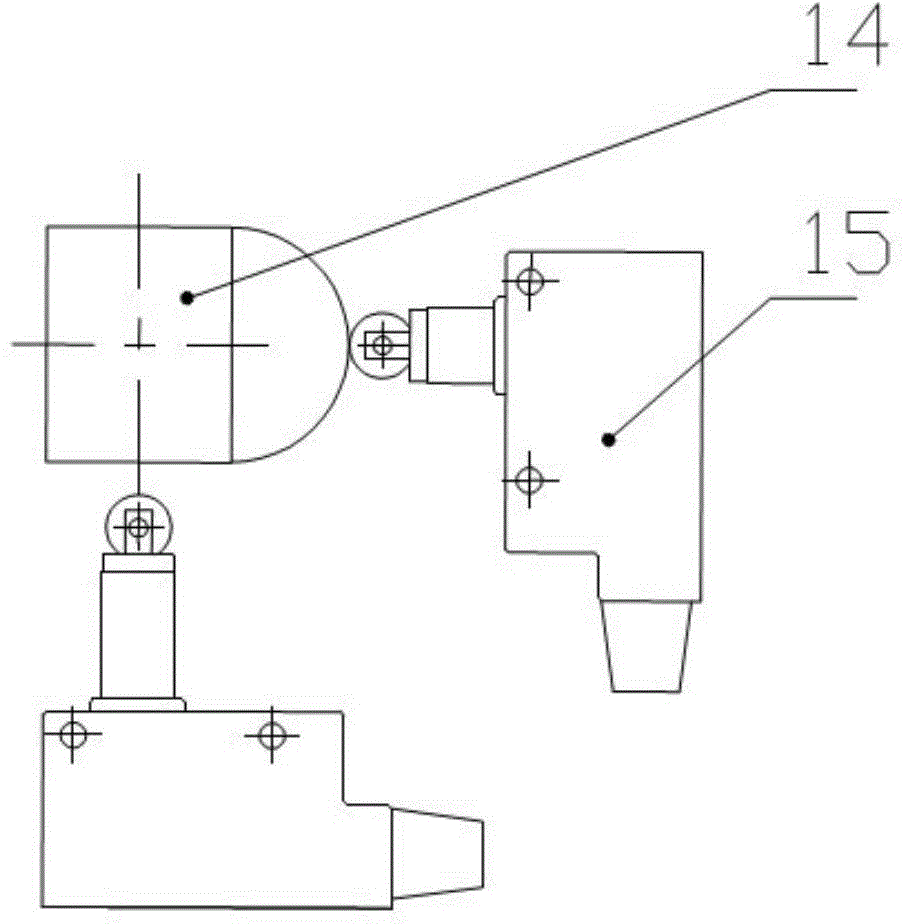

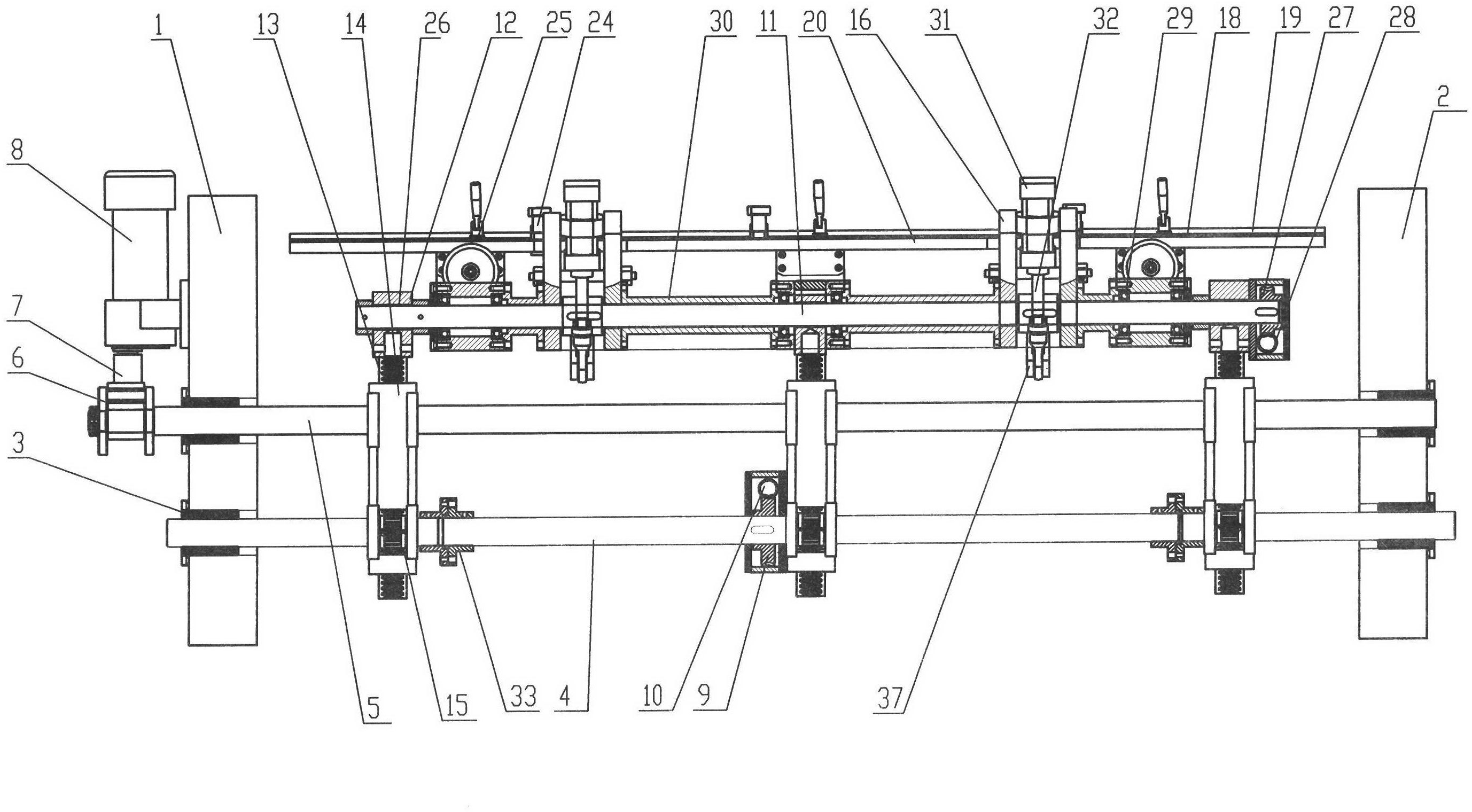

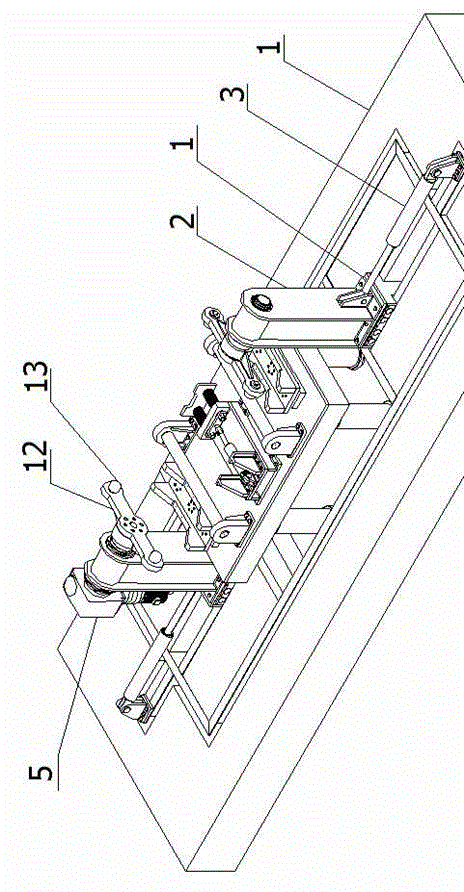

Linear feeding mechanism of double-face-chamfering continuous machining system for automobile synchronizer gear sleeve

InactiveCN105033358AReduce configurationGuaranteed accuracyMetal working apparatusGear-cutting machinesTransmission beltElectric machinery

The invention relates to a linear feeding mechanism of a double-face-chamfering continuous machining system for an automobile synchronizer gear sleeve. The machining system is formed by two same double-cutter-machining chamfering machines. Each chamfering machine comprises cutters for chamfering machining, a workpiece driving machine head and a tooth alignment mechanism. In each chamfering machine, a linear feeding mechanism body is horizontally and fixedly installed at the portion, in front of the corresponding workpiece driving machine head and behind the two corresponding cutters, of a machine body. Each linear feeding mechanism body rotates in the manner that a transmission belt in a material channel is driven by a driving motor. The feeding mechanism is scientific in structure and reasonable in design; the two linearly-arranged material channels are of reciprocating type structures, and therefore gear sleeve workpieces can be continuously conveyed without interruption; spacing air cylinders are further installed on the material channels, and therefore accurate spaced machining of the gear sleeve workpieces is guaranteed; and due to a gear sleeve overturning mechanism, the gear sleeve workpieces with one machined faces can be automatically overturned for chamfering the other faces, and overturning is flexible and nimble.

Owner:TIANJIN DAXIN PRECISION MECHANICAL EQUIP

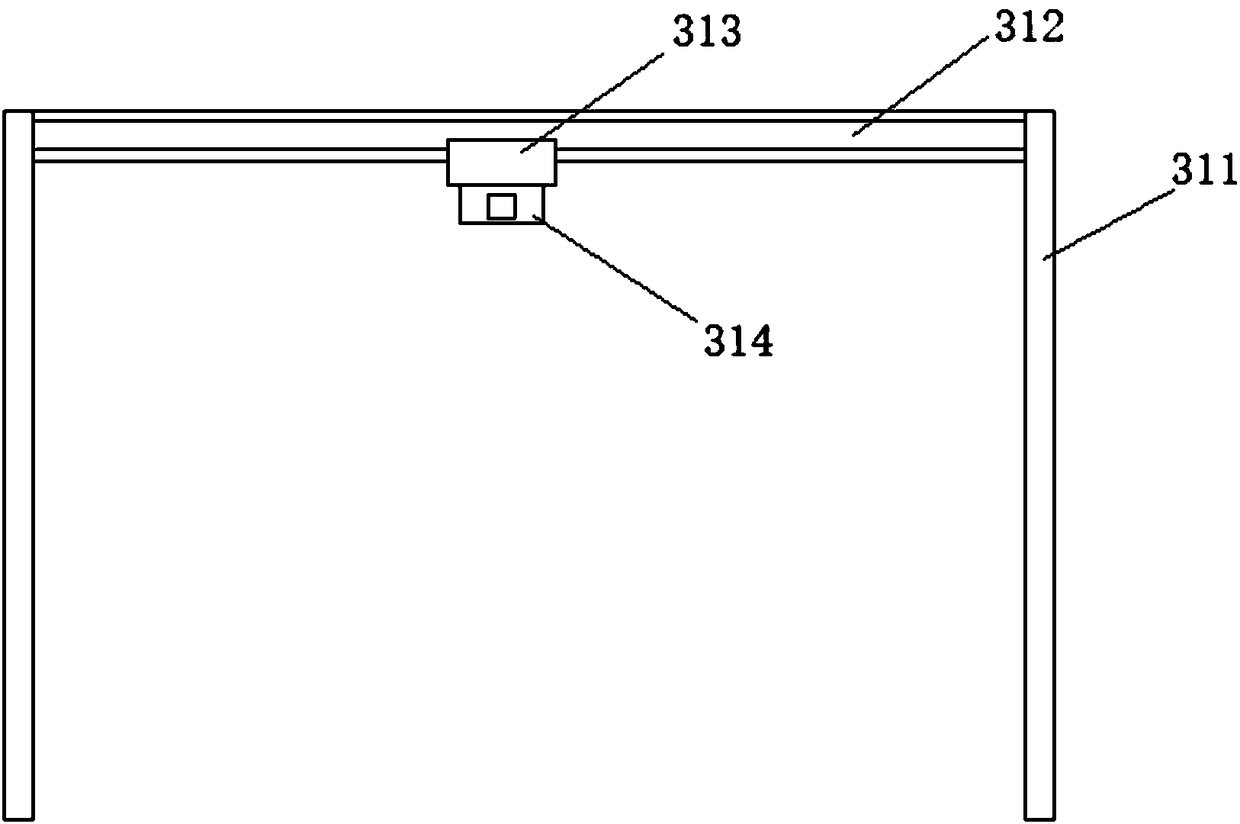

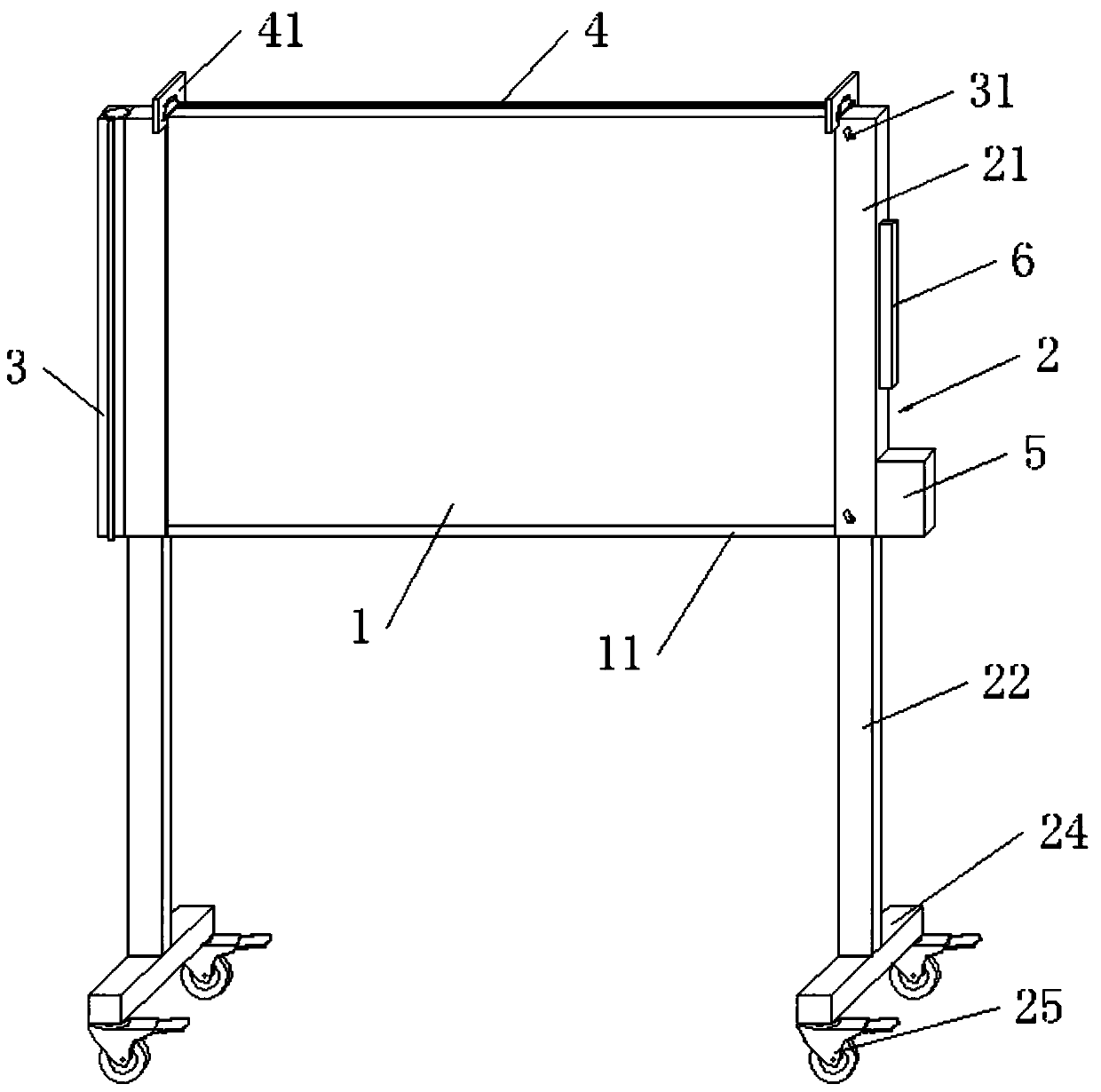

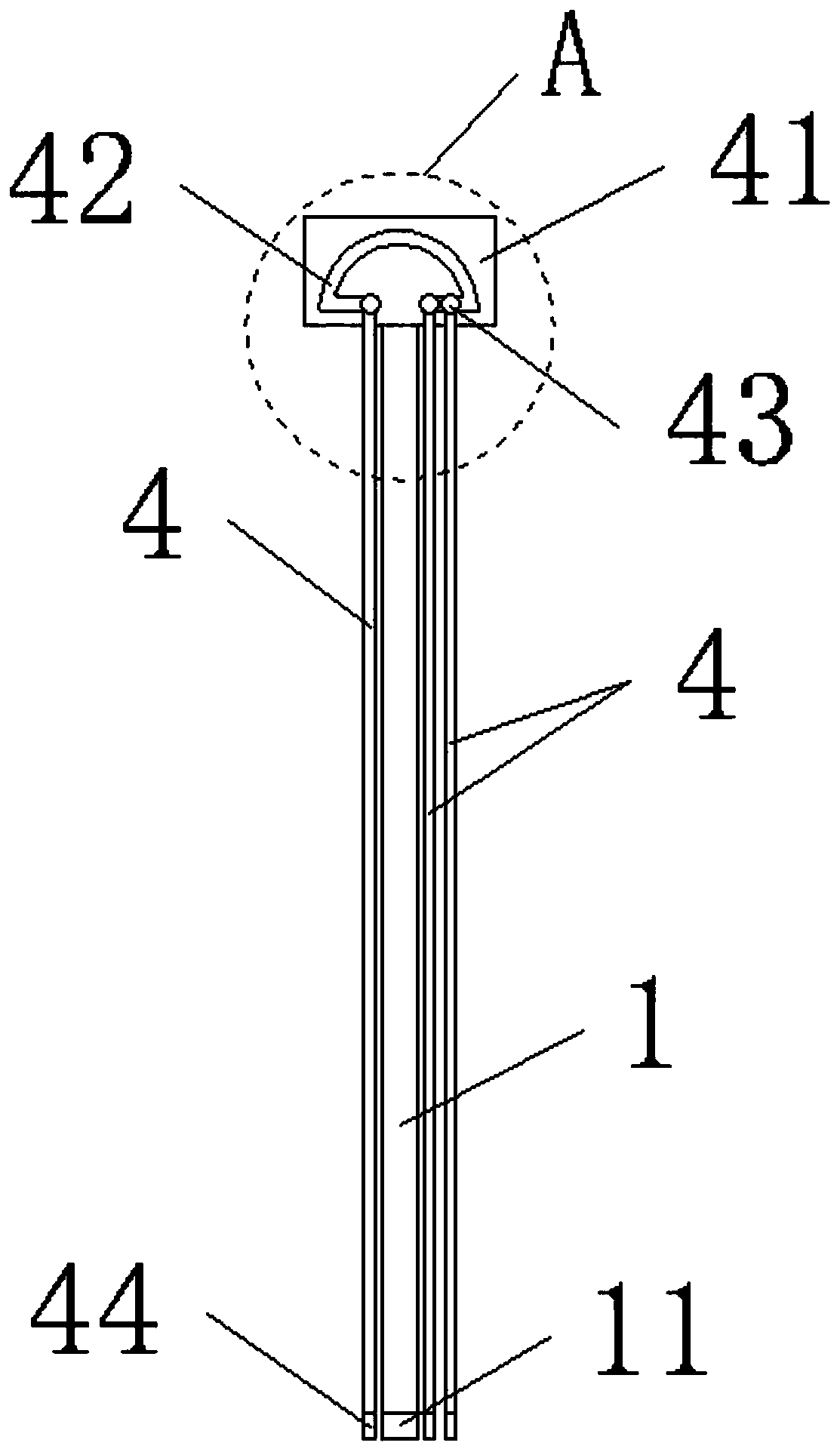

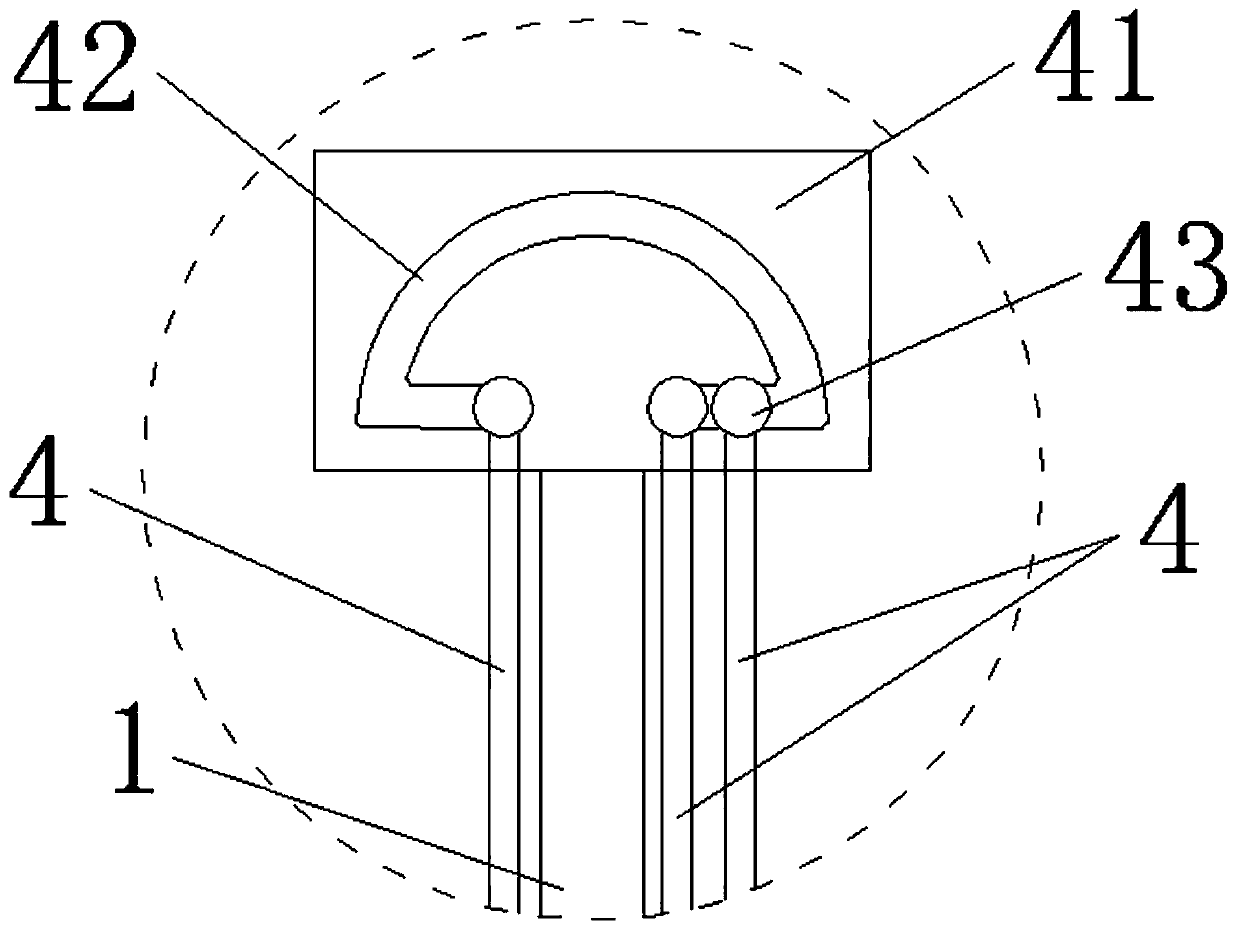

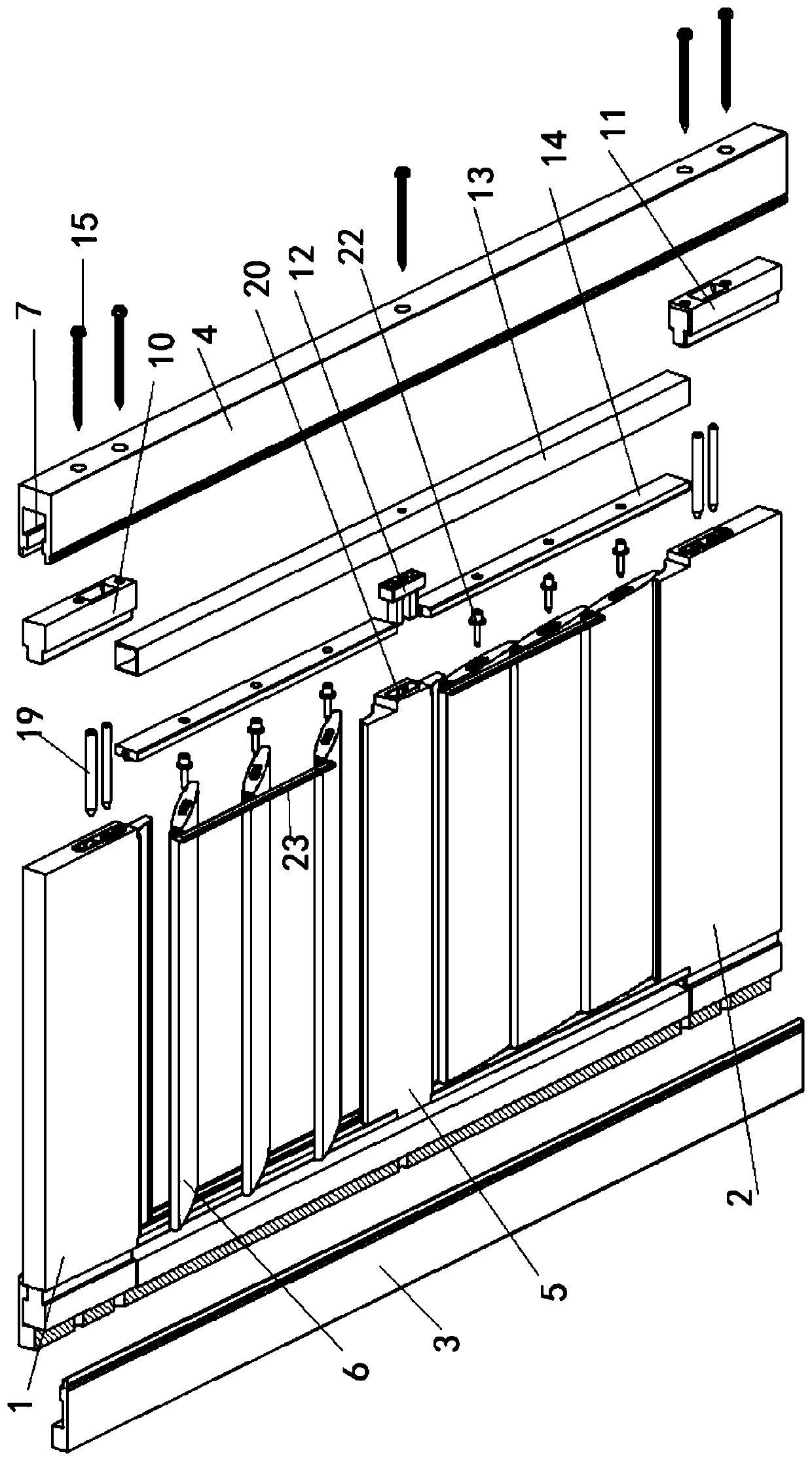

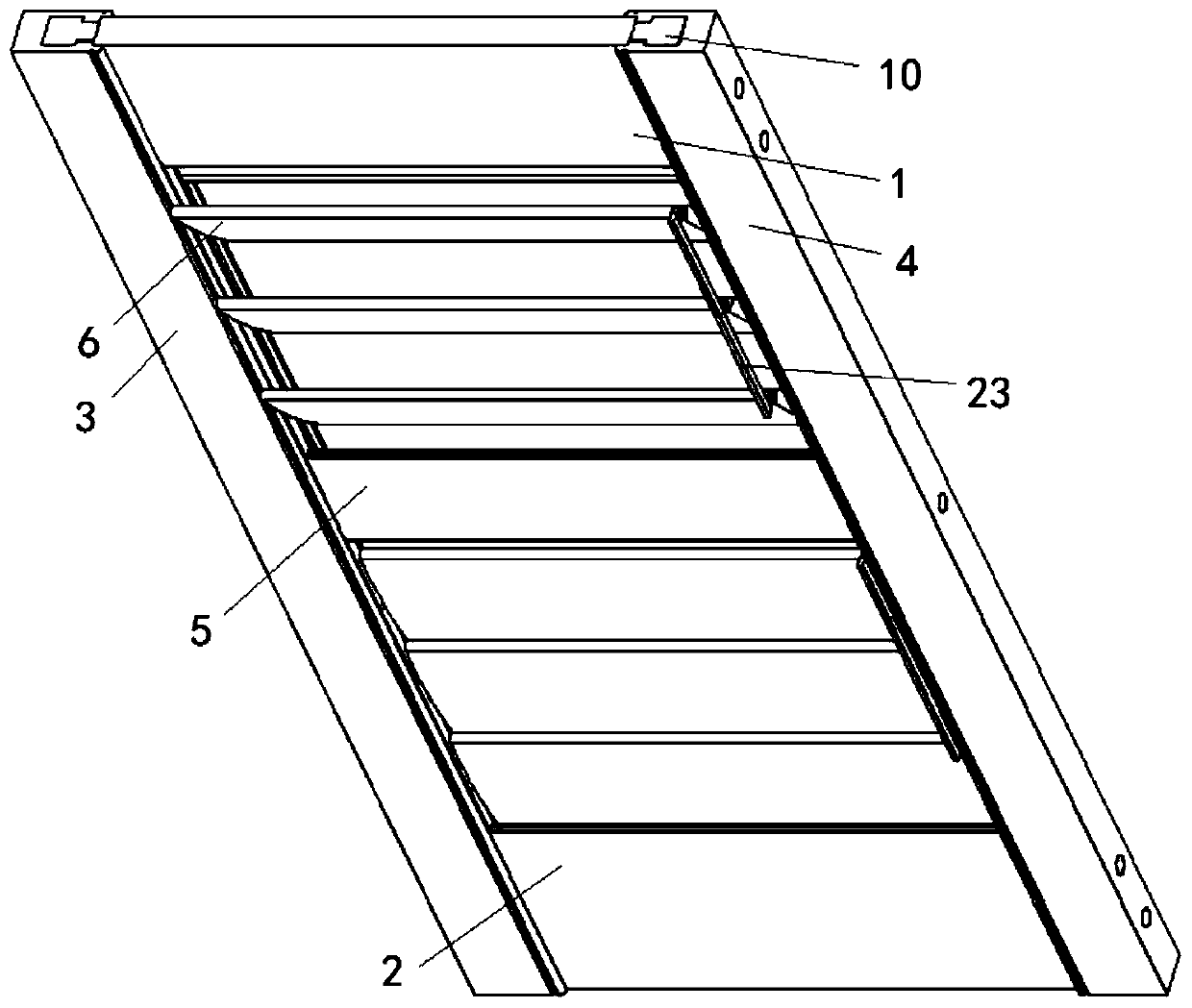

Teaching display board

The invention relates to the field of teaching instruments, and discloses a teaching display board. The teaching display board comprises a blackboard, a support frame, a projector curtain and at leastone auxiliary display board; the support frame comprises a first support frame body and a second support frame body which are installed on the two sides of the blackboard to support the blackboard and enable the blackboard to be in a vertical state; the projector curtain is mounted on the first support frame body, and the second support frame body is provided with a curtain hook; and the tops ofthe support frame bodies are provided with auxiliary display board seats, the two ends of the top of the auxiliary display board are mounted on the auxiliary display board seats, and the auxiliary display board is suitable for moving in the auxiliary display board seats so that the auxiliary display board can be on the front face or back face of the blackboard. The teaching display board can effectively increase the display space of the teaching display board, provides various display forms, can be moved and used, and is convenient and flexible to use.

Owner:赣州市南康区万家源家具有限公司

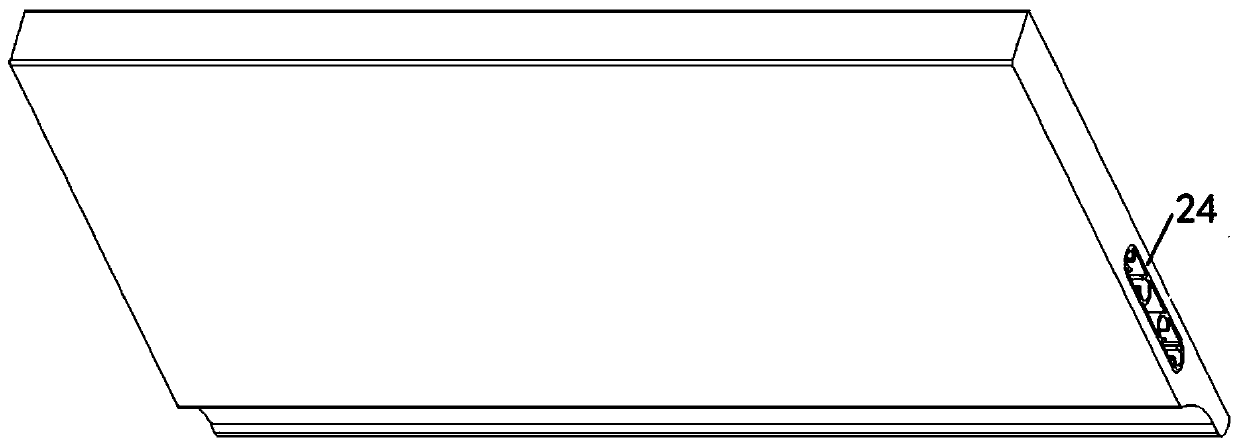

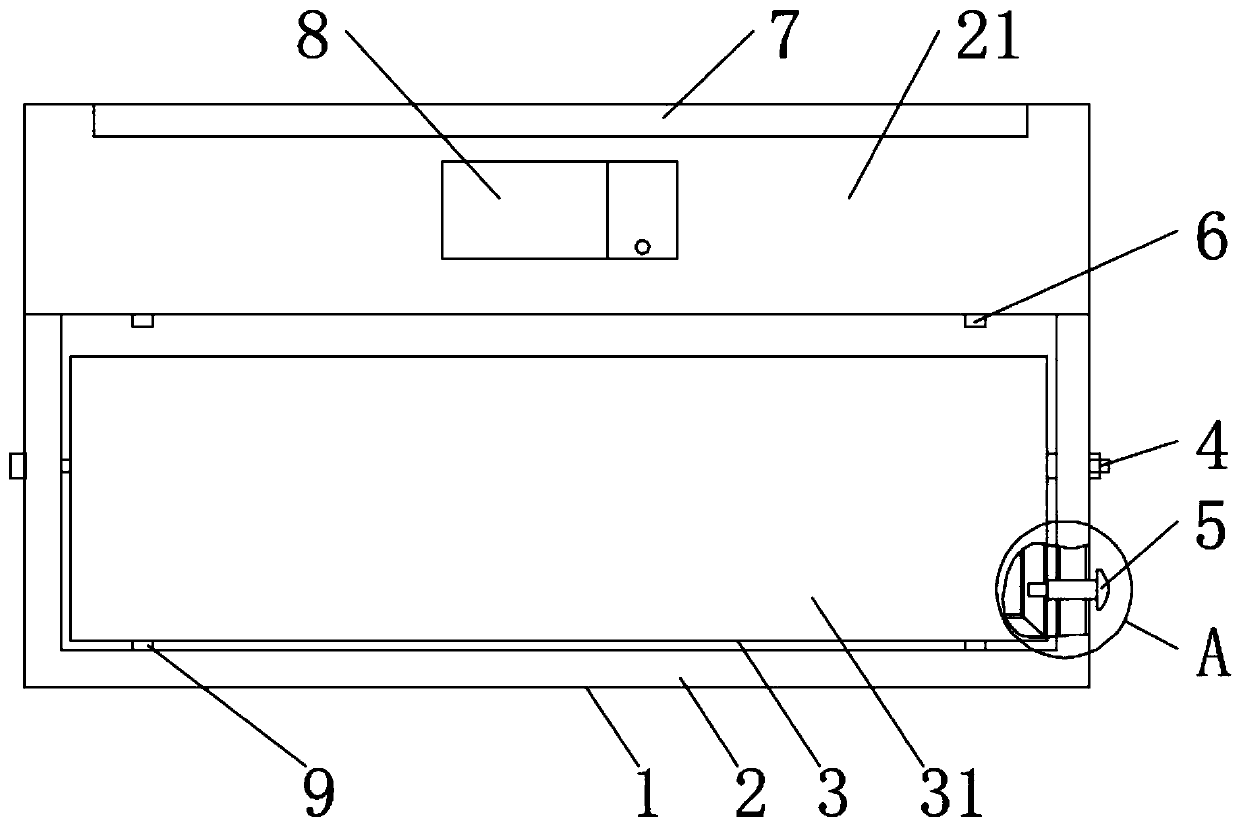

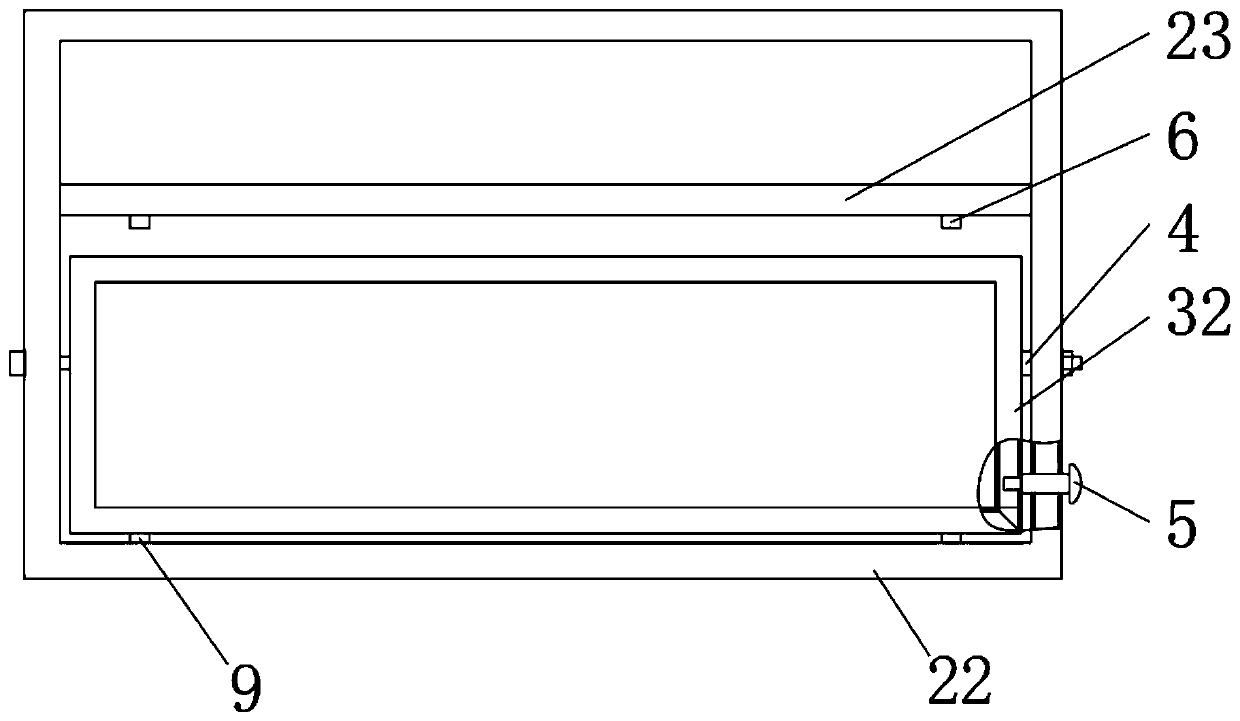

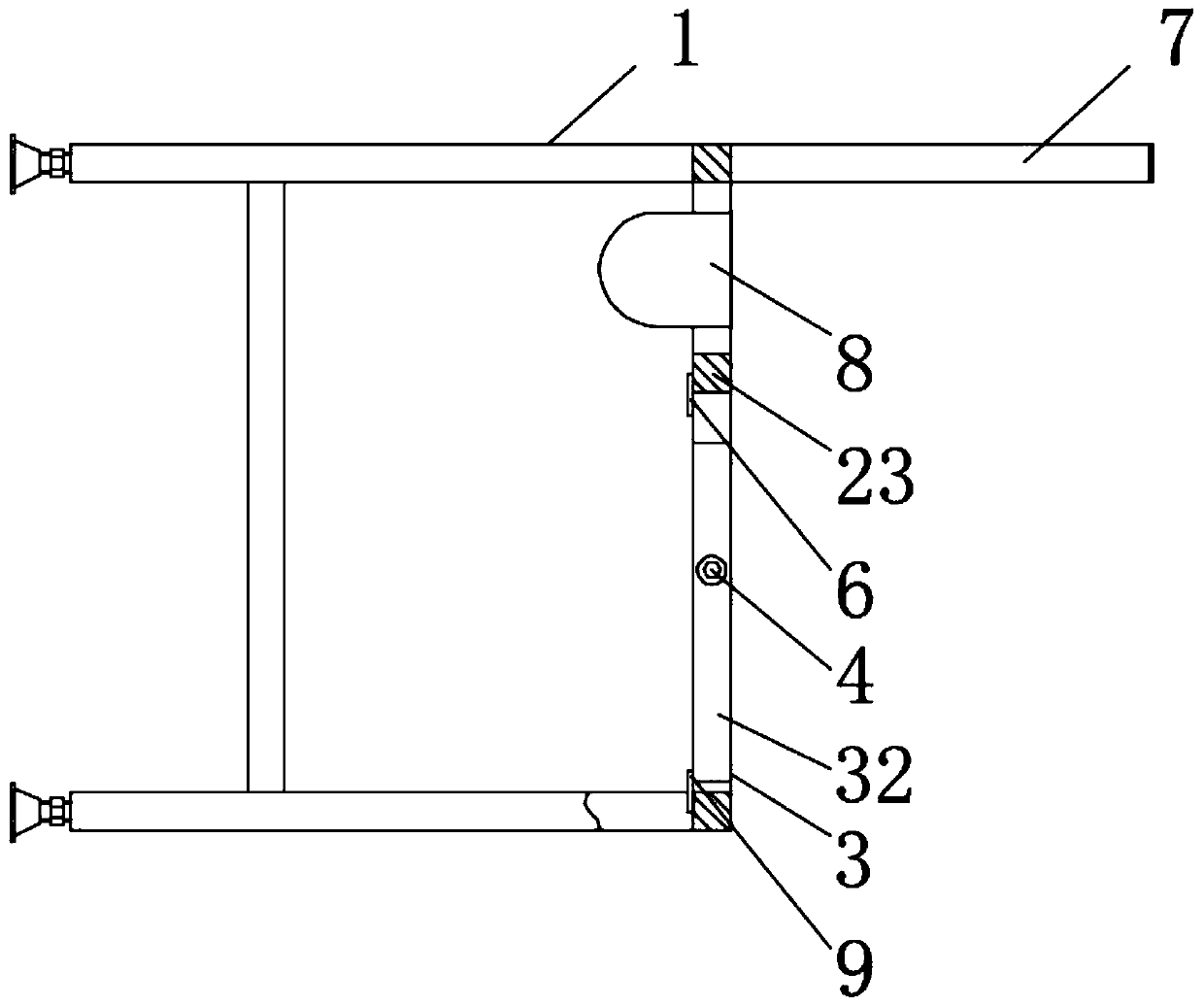

PVC (Poly Vinyl Chloride) foamed ventilated window

PendingCN109812206AReduce weightImprove assembly efficiencyWindow/door framesSpecial door/window arrangementsAgricultural engineeringAluminium

The invention provides a PVC (Poly Vinyl Chloride) foamed ventilated window which comprises an upper frame, a lower frame, a left frame, a right frame and blades mounted between the left frame and theright frame. Component slots are formed in both the left frame and the right frame; the component slots face the end parts of the blades; upper frame fixed parts are arranged at the upper parts of the component slots; lower frame fixed parts are arranged at the lower parts of the component slots; metal reinforcement pipes are arranged at the middle parts of the component slots; each component slot comprises a component slot inner layer and a component slot outer layer; the upper frame and the upper frame fixed parts are fixed together; the lower frame and the lower frame fixed parts are fixedtogether; the metal reinforcement pipes are embedded in the component slot inner layers; blade mounting rods are arranged outside the metal reinforcement pipes; the blade mounting rods are positionedon the component slot outer layer; and the end parts of the blades are rotatably mounted on the blade mounting rods. Due to adoption of a PVC material, the PVC foamed ventilated window is light in weight and damp-proof, cannot be mildewed and cannot breed bugs; an aluminium skeleton is arranged in the PVC foamed ventilated window, so that the PVC foamed ventilated window has performance of resisting to high and low temperature difference deformation and is firm and durable; and due to adoption of a detachable structure, the PVC foamed ventilated window is convenient to mount, has excellent maneuverability and is attractive in appearance.

Owner:SHANGHAI KENDA IND CO LTD

Convenient-to-operate PCB welding platform

The invention relates to the technical field of PCB processing, and particularly discloses a convenient-to-operate PCB welding platform, which comprises a workbench main body, a table surface, an overturning plate, a tool rack and a storage box, wherein the table surface comprises a table surface plate, a table surface frame and a blocking sheet lining rod, the table surface plate is fixedly connected to the front surface of the table surface frame close to the top, rotating shafts are fixedly connected to the centers, close to the top, of the left and right sides of a rotating plate frame, and the overturning plate is rotationally connected to the position, close to the bottom, of the inner wall of the table surface frame through a rotating shaft. According to the invention, the table surface is rotatably connected with the overturning plate through the rotating shaft, so that the purpose that the overturning plate can be flexibly turned over is achieved, the switching function of rapidly switching PCB welding tools is achieved, the space is saved, and the working efficiency and the welding precision are improved; and rotation of the overturning plate is relieved or limited by opening and closing the spring positioning pin, so that switching of rapid fixing and relieving of rotation limitation of the overturning plate is achieved, and the overturning plate can be rapidly and flexibly switched.

Owner:广州众维教育科技有限公司

Turnover device for hub casting detection

The invention provides a turnover device for hub casting detection. The turnover device comprises a fixing base, supporting bases are fixedly installed on the two sides of the top of the fixing base,first sliding grooves are formed in the inner sides of the two supporting bases, clamping mechanisms are slidably connected to the interiors of the first sliding grooves, an open groove is formed in the top of the fixing base, and a turnover mechanism is installed in the open groove. The two clamping mechanisms comprise first sliding blocks slidably connected with the interiors of the first sliding grooves. In the turnover device, through cooperation of mounting blocks and electric telescopic rods, clamping plates get close to each other to drive clamping columns to clamp and fix a hub castingand prevent the hub casting from falling off in the turnover process; first electric hydraulic rods ascend and descend to cooperate with the first sliding blocks to adjust the horizontal clamping height of the hub casting between the clamping plates, the time for adjusting manual carrying is saved, the personal safety is guaranteed, and the working efficiency is improved; and meanwhile, when theturnover mechanism turns over the hub casting, clamping adjustment of the hub casting is facilitated.

Owner:刁占柱

Synchronous clamping and turnover mechanism

PendingCN111017550AStable clampingRoll over stabilityConveyorsConveyor partsMedicinePharmaceutical drug

The invention provides a synchronous clamping and turnover mechanism, which comprises a support. The mechanism is characterized in that clamping mechanisms, a clamping driving mechanism, turnover mechanisms and an turnover driving mechanism are arranged on the support, wherein the number of the clamping mechanisms is two, the two clamping mechanisms are both connected to the support in a sliding mode and connected with the same clamping driving mechanism; each clamping mechanism is rotationally connected with the corresponding turnover mechanism; and the two turnover mechanisms are both connected with the same turnover driving mechanism. The two clamping mechanisms are driven by the same clamping driving mechanism to slide in a face-to face manner to synchronously clamp an object, and movein a back-to-back manner to synchronously loosen clamping of the object; and two turnover mechanisms are driven by the same turnover driving mechanism to overturn the clamped object, so that clampingis firm and reliable, turnover is flexible, and no pollutant is generated; and the synchronous clamping and turnover mechanism is suitable for clamping various articles, especially for clamping of amedicine extraction basket and turnover of medicines or extracts on the turnover face.

Owner:KUNMING XUBANG MACHINERY

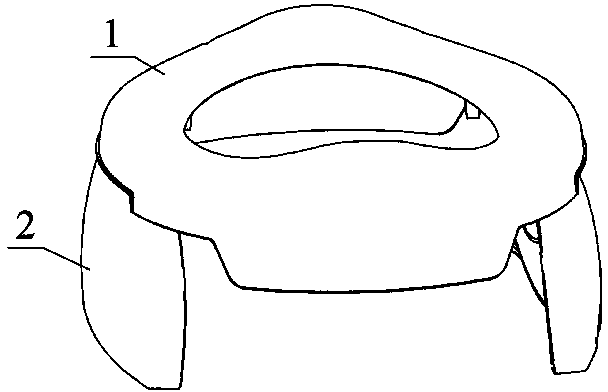

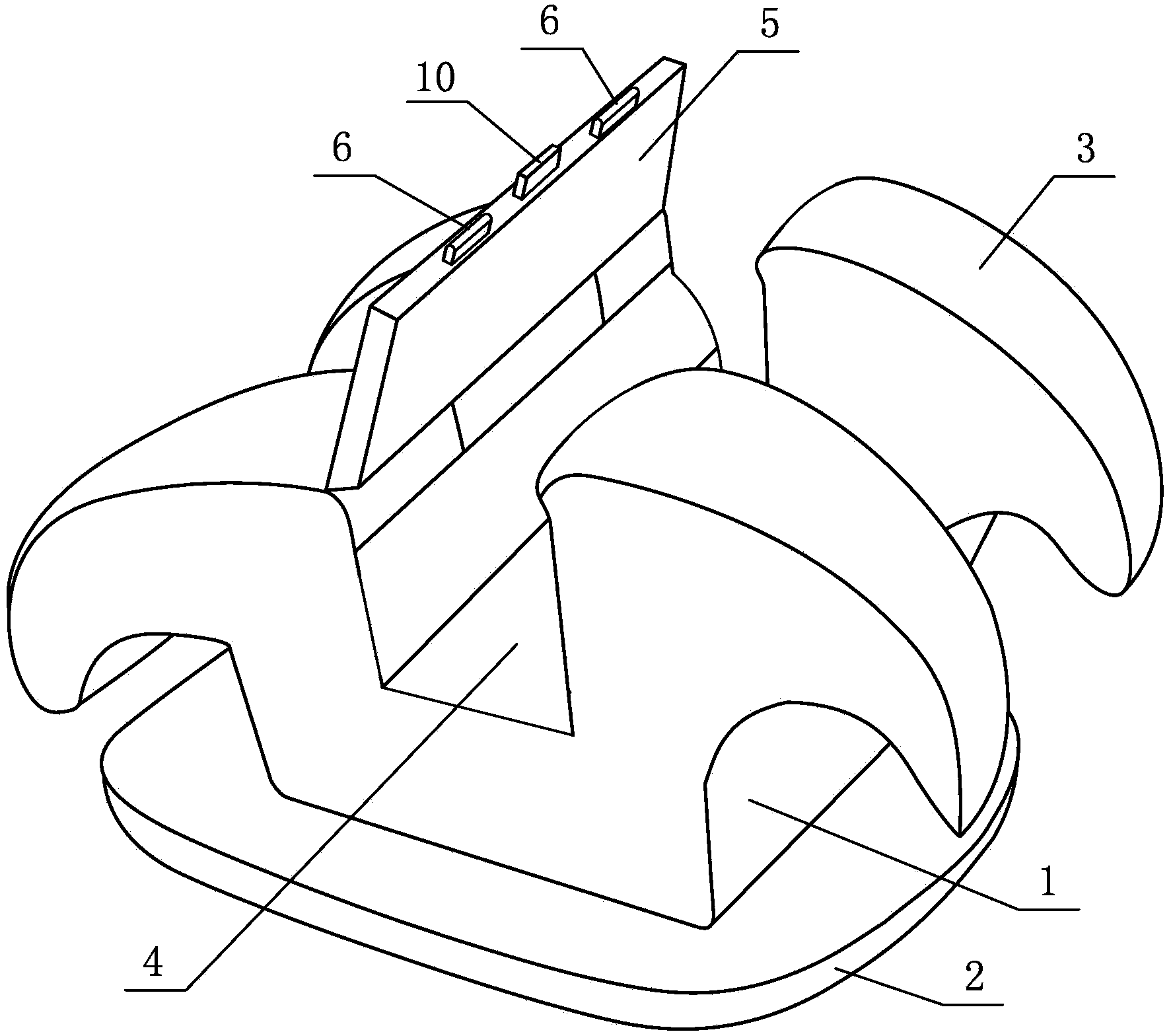

Multipurpose children defecation device and children seat with overturning bracket

The invention relates to a multipurpose children defecation device and children seat with an overturning bracket. At present, a special children defecation device which saves space and is convenient to carry is lacked; and a technical scheme capable of combining the special children defecation device, an adult water closet and a portable seat for children to have a reset is also lacked. The multipurpose children defecation device and children seat with the overturning bracket comprises a body, wherein the body is provided with at least one defecation hole, at least one sitting face and two or more connecting parts; the body is connected with the bracket through the connecting parts respectively; the bracket is provided with a bracket connecting part; the bracket connecting part is combined with the connecting parts to form an overturning connection; the bracket can be overturned relative to the body in virtue of certain external force. The children defecation device and children seat can be multipurpose by overturning the bracket, the operation is simple and convenient, the space is saved, and the children defecation device and children seat is convenient to carry.

Owner:易欣

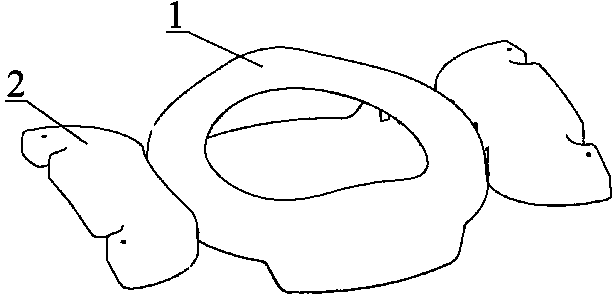

Folding bath chair

The invention discloses a folding bath chair, which comprises a chair back component, a chair leg assembly and a chair seat component, wherein a pull ring structure is arranged above a backrest fixing plate; the chair leg assembly is provided with front chair frames and back chair frames which are positioned at two ends of the chair seat component and support a chair seat; a turning mechanism is arranged on a torsional spring support post; a reset mechanism is arranged on the chair seat component; and a pressure spring drives a lock plate to contact a seat surface stress strut and to do to-and-fro telescopic movement. After the structure is used, the structure of the automatic turning mechanism is simple; the turning is flexible; the cost is low; the bath chair is automatically folded through the turning mechanism, so that the function of the automatically folding bath chair is reached; the bath chair can be folded by a user only by pulling a pull ring by a single hand; the use is convenient; and the folding bath chair is user-friendly.

Owner:江苏浙泰机电科技有限公司

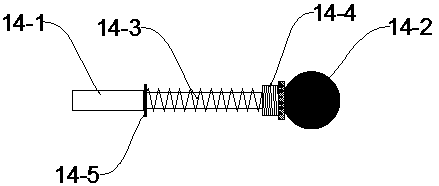

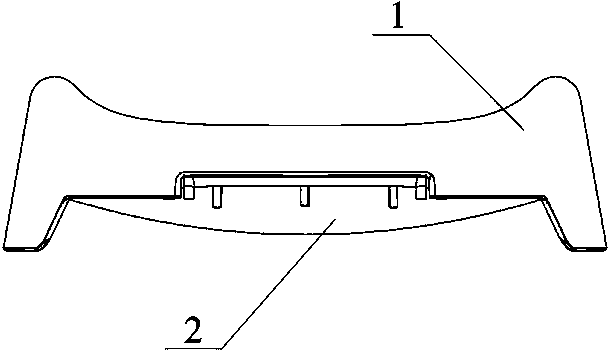

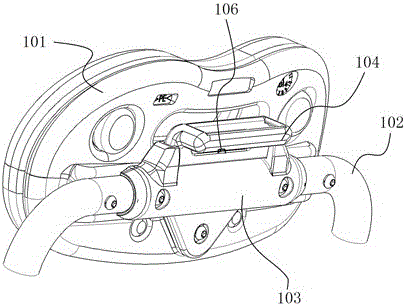

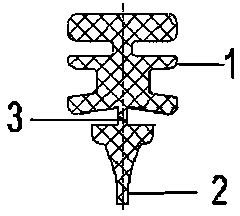

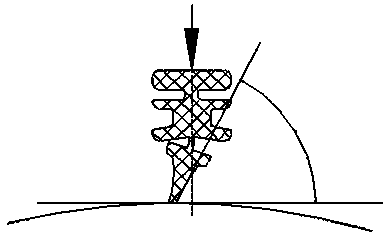

Orthodontic self-locking bracket

ActiveCN104306076AAvoid discomfortReduce clinical operation timeArch wiresBracketsArch wiresEngineering

The invention relates to an orthodontic self-locking bracket. The orthodontic self-locking bracket comprises a bracket matrix, wherein a metal net bottom is arranged at the bottom of the bracket matrix, the bracket matrix is provided with ligation wings and an arch wire ditch, the top of the arch wire ditch is provided with a cover slip which is arranged along the length direction of the arch wire ditch, one end of the cover slip is movably connected with the top part of the side wall of one side of the arch wire ditch, locking bulges are respectively arranged at the two sides of the end surface of the other end of the cover slip, and two grooves are respectively formed in the two ligation wings which are arranged at one side opposite to the connecting end of the cover slip and are internally provided with an elastic plate respectively. With the adoption of the orthodontic self-locking bracket, as the cover slip adopts a lifting type, force and reaction force during uncovering both disperse on the bracket, thus avoiding discomfort of teeth caused by abnormal force applied to the teeth, effectively avoiding the problem that the cover slip can not be opened or closed, greatly shortening clinic operation time of an orthodontic doctor, shortening treatment cycle of a patient and improving the rectification effect, so that when the aesthetic property and comfort of the orthodontic self-locking bracket are ensured, the orthodontic self-locking bracket also has the characteristics of stable structure, firm covering and good self-locking effect.

Owner:SHANDONG UNIV

A foldable bath chair

The invention discloses a folding bath chair, which comprises a chair back component, a chair leg assembly and a chair seat component, wherein a pull ring structure is arranged above a backrest fixing plate; the chair leg assembly is provided with front chair frames and back chair frames which are positioned at two ends of the chair seat component and support a chair seat; a turning mechanism is arranged on a torsional spring support post; a reset mechanism is arranged on the chair seat component; and a pressure spring drives a lock plate to contact a seat surface stress strut and to do to-and-fro telescopic movement. After the structure is used, the structure of the automatic turning mechanism is simple; the turning is flexible; the cost is low; the bath chair is automatically folded through the turning mechanism, so that the function of the automatically folding bath chair is reached; the bath chair can be folded by a user only by pulling a pull ring by a single hand; the use is convenient; and the folding bath chair is user-friendly.

Owner:江苏浙泰机电科技有限公司

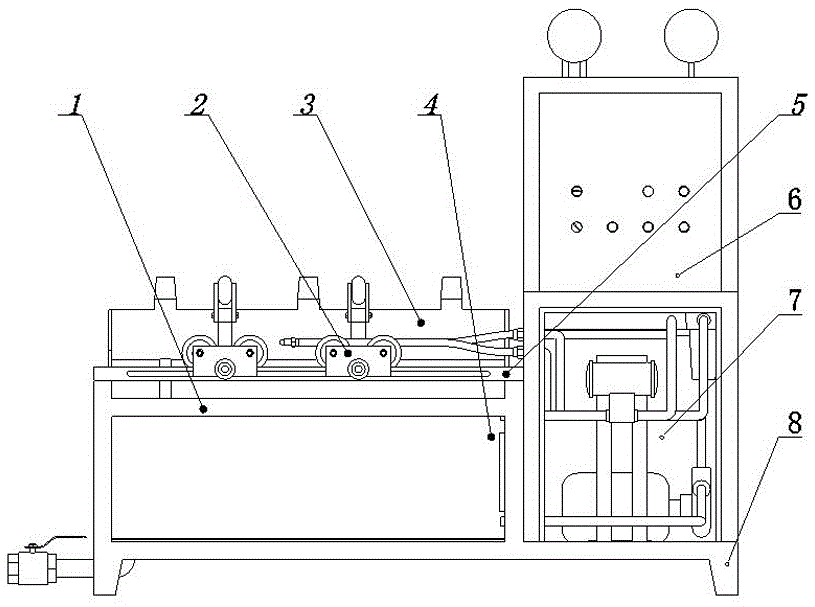

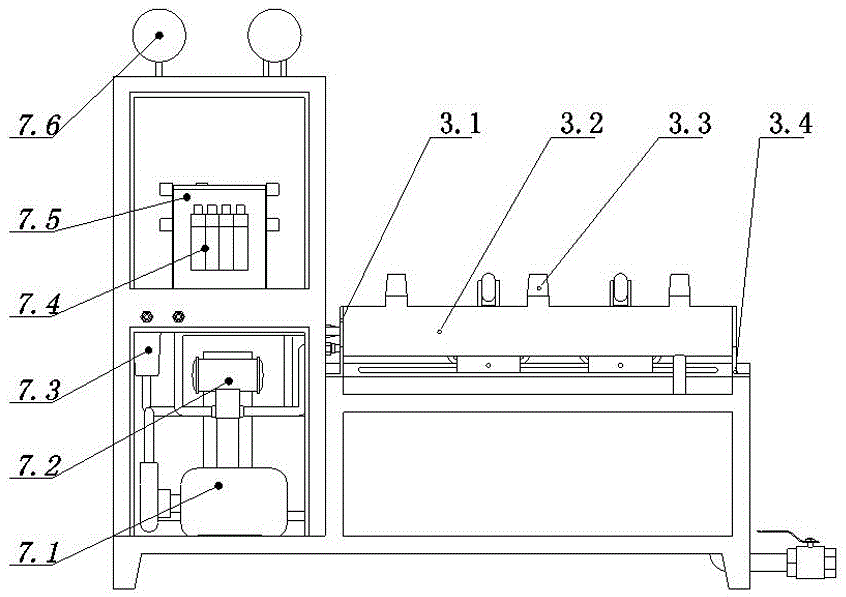

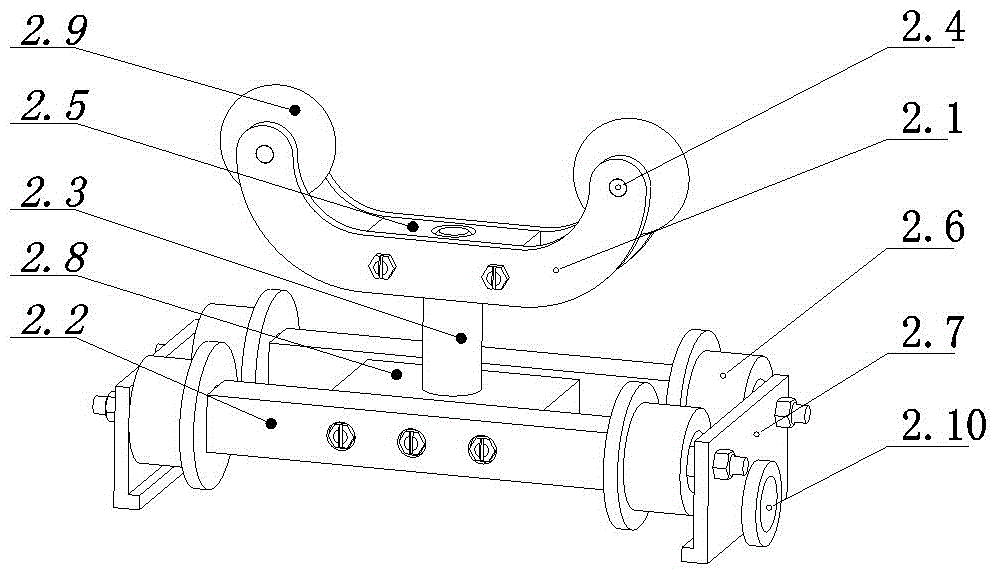

Micro-control air cylinder wind-water pressure testbed

ActiveCN105890846AEasy to installEasy to observeRailway vehicle testingFluid-tightness measurement using fluid/vacuumEngineeringVehicle detection

The present invention relates to the railway vehicle detection equipment technology field, in particular to a micro-control air cylinder wind-water pressure testbed which is used for detecting the performance of an air cylinder on a railway vehicle by the microcomputer control, and is simple in detection program and is time-saving and labor-saving in operation. The micro-control air cylinder wind-water pressure testbed comprises a rack, air cylinder fastening tools, a pressure release cylinder, a water tank, guide rails, a chassis, a water and wind supply system and supporting feet. The rack is a stepped shape of which the left is low and the right is high, the two air cylinder fastening tools are arranged in front of the upper end of the left side of the rack and are both in slip connection with the rack via the guide rails. The two guide rails are parallel with each other and are placed horizontally, and the pressure release cylinder is fixed behind the upper end of the left side of the rack. The water tank is fixed inside the left side of the rack, and the water and wind supply system is arranged inside the right side of the rack. The micro-control air cylinder wind-water pressure testbed of the present invention is mainly used for the detection of the railway vehicle air cylinder.

Owner:中电科鹏跃电子科技有限公司

Self-locking type box overturning machine

PendingCN110271875AEasy to feedStable clamping forceBottle emptyingLoading/unloadingEngineeringSelf locking

The invention provides a self-locking type box overturning machine. A supporting frame, a rotating frame and conveyors are included. The self-locking type box overturning machine is characterized in that the rotating frame is arranged on the supporting frame, and symmetrically provided with the box entering and box outgoing conveyors; the conveying faces of the box entering and box outgoing conveyors are arranged in opposite directions; and the box outgoing conveyor is fixed to the rotating frame through a self-locking type synchronous lifting mechanism. After a box conveniently enters the box entering conveyor, the box outgoing conveyor is driven by the self-locking type synchronous lifting mechanism to stretch out so that the conveying face of the box outgoing conveyor can clamp the box; then along with rotation of the rotating frame, after the box entering and box outgoing conveyors and the box are overturned by 180 degrees, the box outgoing conveyor is driven by the self-locking type synchronous lifting mechanism to retract out so that clamping on the box can be released, and then the box overturned by 180 degrees is conveyed out through the box outgoing conveyor. The box overturning machine can be used for stably clamping the box, clamping and stretching and retracting are synchronous, mechanical self locking is achieved, it is guaranteed that the box keeps a consistent clamping force in the whole overturning process, the problem that due to the fact that clamping is not stable, after the box is loose, materials are scattered is solved, the structure is simple, clamping is reliable, and overturning is flexible.

Owner:KUNMING XUBANG MACHINERY

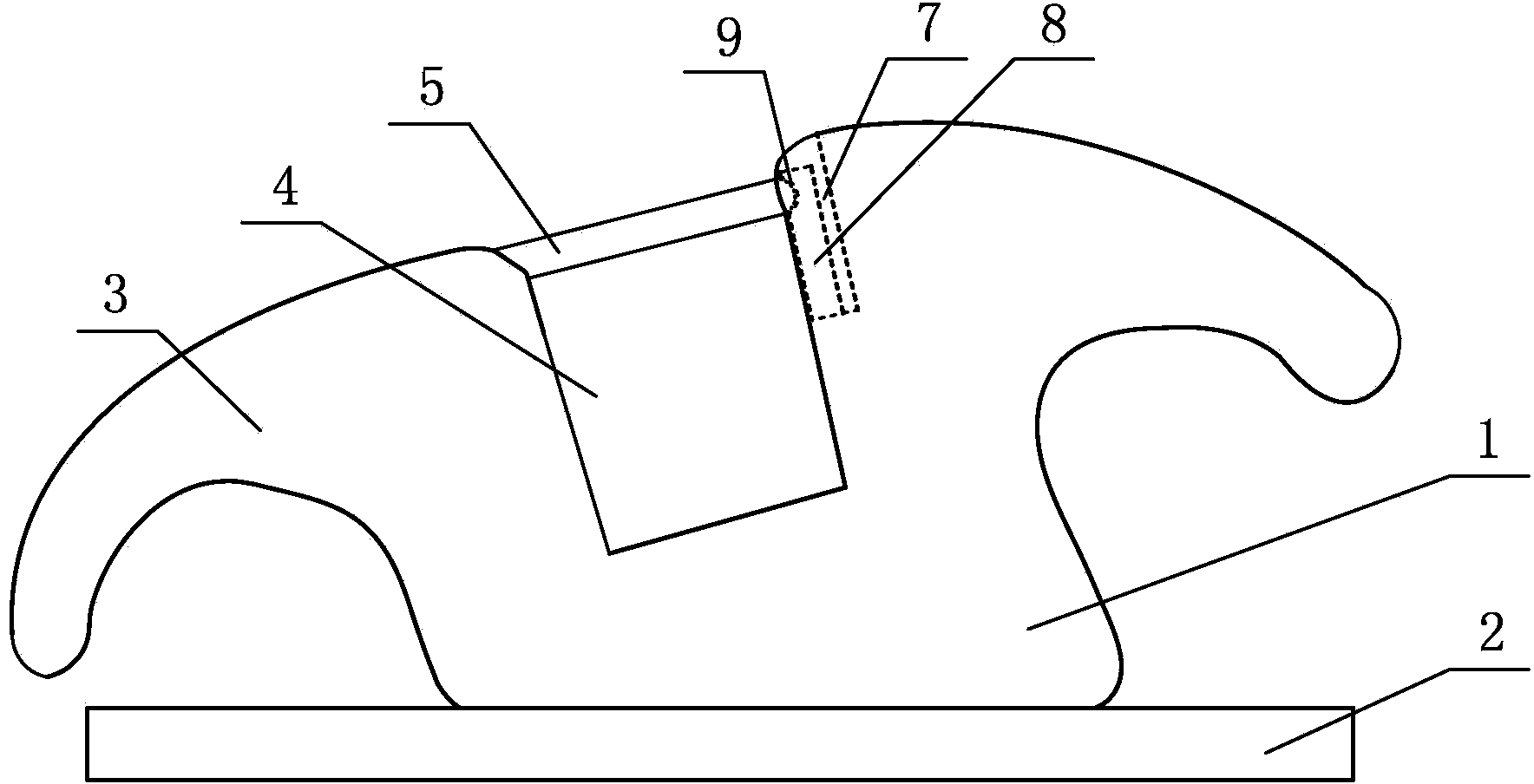

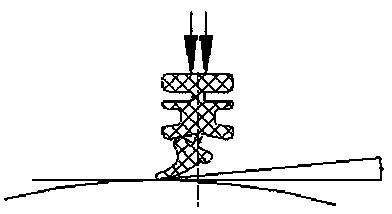

Car wiper wiping piece adhesive tape with novel structure

The invention discloses car wiper wiping piece adhesive tape with a novel structure. The car wiper wiping piece adhesive tape is characterized that the car wiper wiping piece adhesive tape comprises an adhesive tape body (1), the section of the adhesive tape body is shaped like a Chinese character 'wang', the height of a turnover bridge (3) is increased to the range from 1.5mm to 2mm, the thickness of a wiping blade (2) is increased to the range from 0.8mm to 0.9mm, and accordingly the thickness of the turnover bridge (3) is increased to the range from 0.8mm to 1.0mm. The car wiper wiping piece adhesive tape solves the problems that when the pressure of an existing wiping arm is small, the existing wiping arm does not easily wipe due to turnover of the adhesive tape, and the wiping angle is larger than 60 degrees; when the pressure is large, the wiping angle is smaller than 30 degrees, and the wiping effect of the adhesive tape is poor, and the wiping effect is good both when the pressure of the wiping arm is large and when the pressure of the wiping arm is small.

Owner:GUIYANG WANJIANG AVIATION ELECTROMECHANICAL

Diesel engine cylinder turning chuck

The invention discloses a diesel engine cylinder turning chuck. The chuck comprises a base, and a cylinder clamping unit is arranged on the base and comprises clamping supports which are arranged at the two ends of the base oppositely and hydraulic cylinders for driving the clamping supports to move towards the opposite direction. Sliding blocks are arranged at the bottoms of the clamping supports, and sliding grooves in sliding fit with the sliding blocks are formed in the base. Rotation shafts in rotation fit with the clamping supports are arranged on the clamping supports along the opposite directions of the clamping supports, drive motors for driving the rotation shafts to rotate are arranged on any clamping support, and chucks for clamping a diesel engine cylinder body are arranged at the opposite ends of the two rotation shafts. The chuck is simple in structure, convenient to use, stable in diesel engine cylinder body clamping and flexible in turning; operators can turn the cylinder body to clean different faces well, and the work efficiency is improved.

Owner:CHONGQING HONGYI MACHINERY

Housing of froth skimmer for pre-cooking water

InactiveCN105310464AReduce suction pressureImprove the ability to absorb impuritiesCooking vesselsMeat processing devicesEngineering

The invention relates to a housing of a froth skimmer for pre-cooking water. The housing comprises a rectangular enclosure. The left end of the enclosure is provided with a downwardly bent portion. The lower end face of the downwardly bent portion is provided with a through hole. The upper end face of the enclosure is provided with a changing hole. The right of the enclosure inclines rightwardly up. A handle is fixed to the front end face of the enclosure. A hinge plate is arranged at the right end of a bottom plate of the enclosure. The hinge plate is evenly provided with round holes. The froth skimmer can turn flexibly and fully press froth into the enclosure, the froth pressed into the enclosure soon attaches to a filter layer, water passing through the filter layer can continue flowing out of a water outlet, water suction pressure of the filter layer is reduced, and the ability of the filter layer to suck and receive impurities is improved. The used filter layer, sponge, can be taken out from a flip cover for changing and cleaning, so that the device is reusable and the application cost of the device is lowered.

Owner:芜湖市禾森食品有限公司

A drum turning and unloading device

The invention relates to a round barrel overturning material pouring device, which is provided with a fixing frame, wherein the front end of the fixing frame is provided with a round barrel inlet, the back end of the fixing frame is provided with a material pouring platform in an inclined way from the front side to the back side, a overturning mechanism is arranged in the fixing frame arranged between the material pouring platform and the round barrel inlet, a overturning work surface is arranged on the overturning mechanism, a round barrel fixing device is arranged on the overturning work surface, and a reciprocating impact mechanism is arranged between the round barrel fixing device and the overturning work surface. Through the arrangement of the overturning mechanism, the manual material pouring is simulated; the round barrel fixing device is adopted, so the slide falling cannot occur during the round barrel overturning; a swinging arm is adopted, the swinging arm is hinged to clamp claws, and the space between the clamp claws can be regulated according to the diameter size of the round barrel; a four-connecting-rod swinging mechanism is adopted, so that the overturning of the round barrel is more flexible, and the operability of the device is higher; the reciprocating impact mechanism is adopted, so materials in the round barrel can be thoroughly poured, the work intensity is reduced, and the waste due to material residue in the round barrel can be avoided; and the manual overturning outer bag disengaging is simulated, and the material pouring efficiency is improved.

Owner:连云港宝畅流体输送设备有限公司

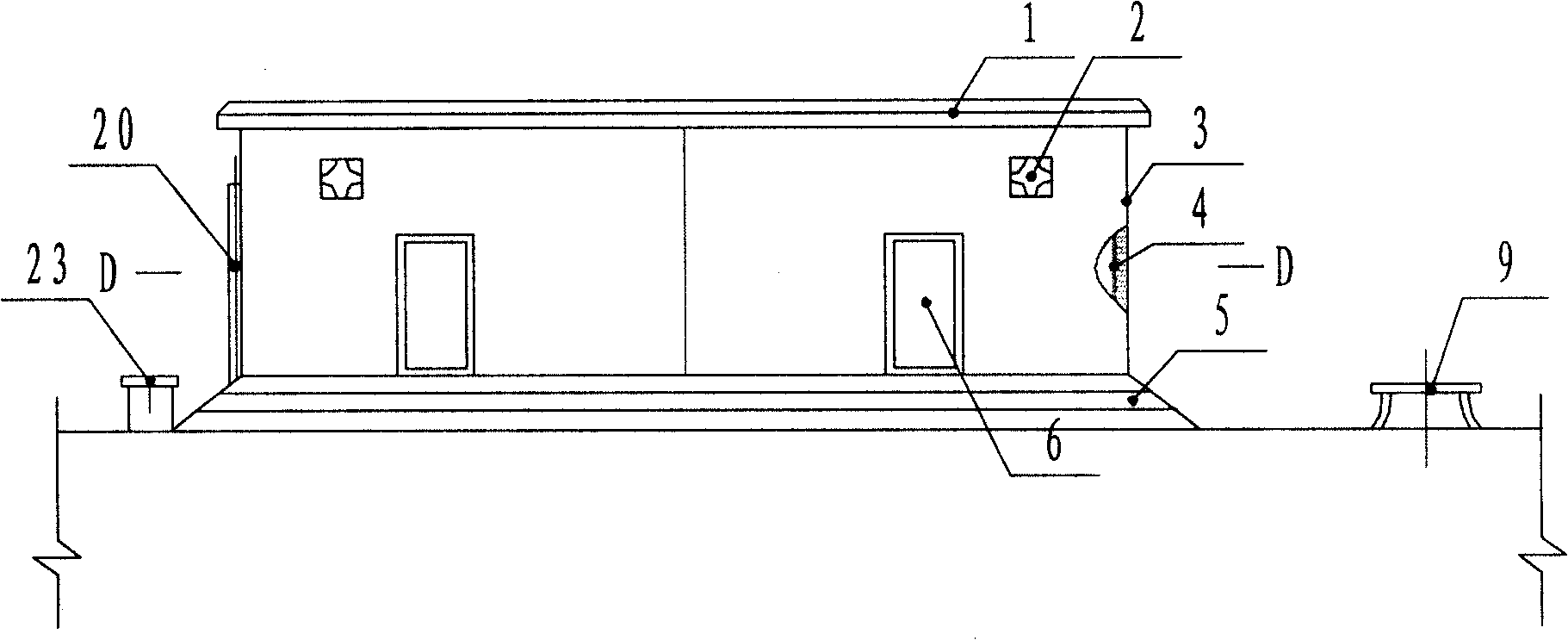

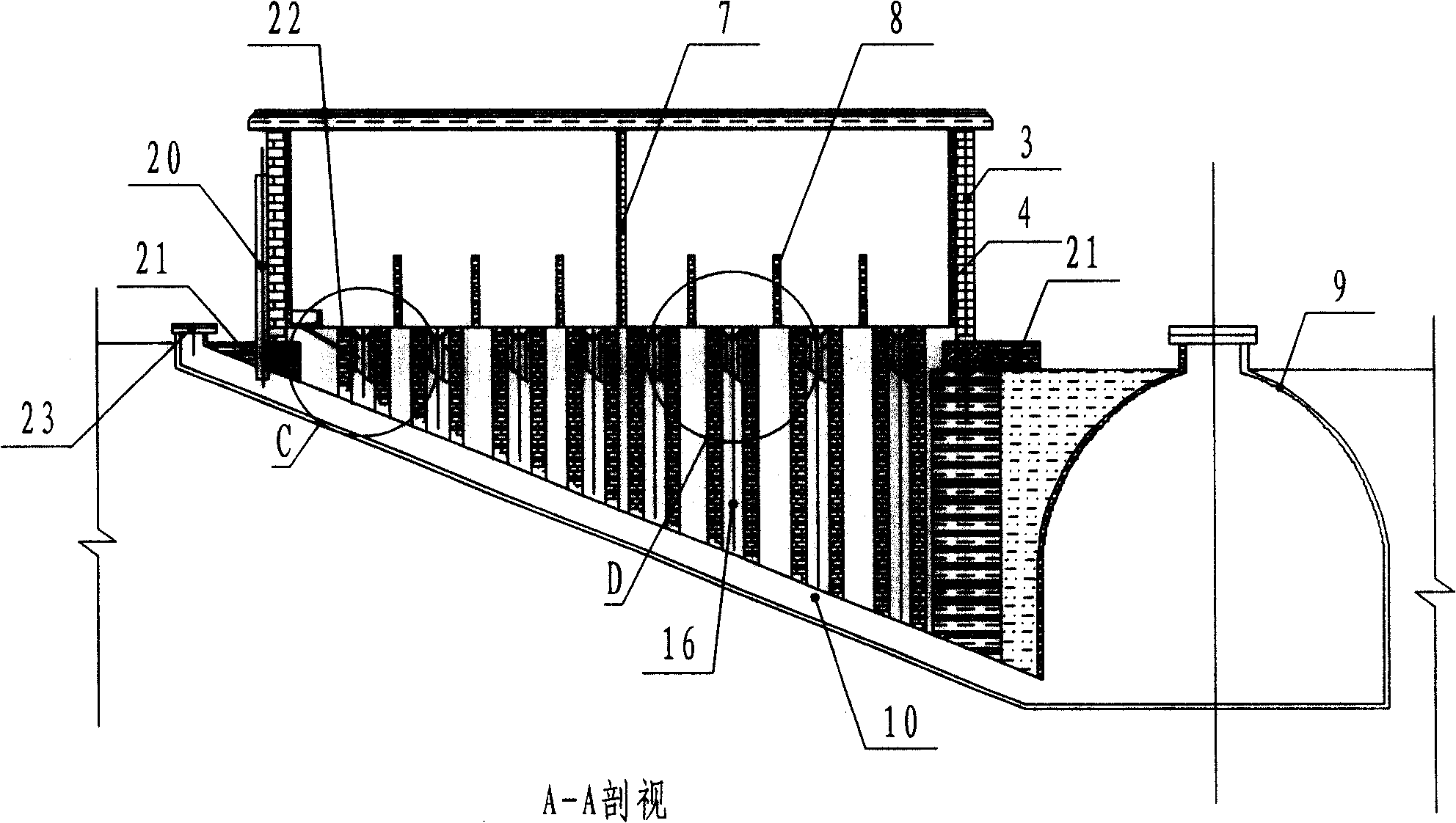

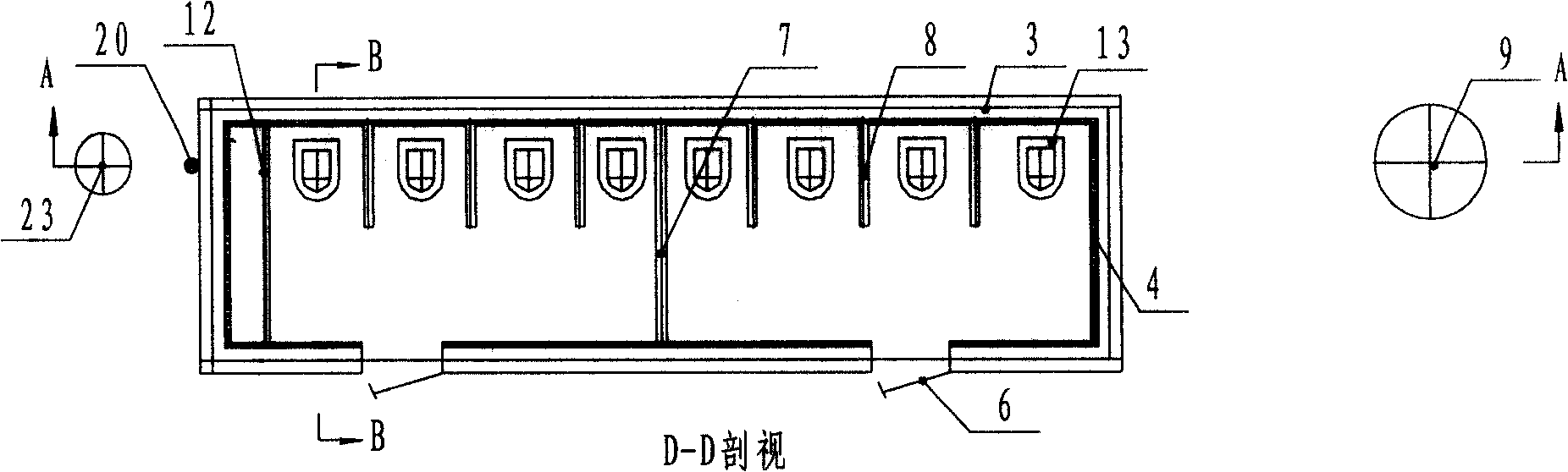

Self-flowing type dung or urine collecting environment protection public lavatory

InactiveCN101245669ANo pollutionRaise the ground temperatureBathroom accessoriesSmall buildingsEngineeringFecaluria

The invention discloses a gravity fecaluria diversity environmental-friendly public lavatory which is used in public places and is provided with a roof 1 on the upper part of a house wall body 3, a door 6 at two sides and a closed partition 7 in the interior; on a platform 22 of a base 5, the lower opening of each stool utensil 13 is arranged in a division wall 16; the straight pipe odor removal device 15 of a balance oblique turning plate 17 is arranged at the lower port clamped by a fixed socket 14; a urinal 12 at the front part of the stool utensil 13 is provided with an oblique collecting duct 11, spliced with the odor removal device 15, and connected with a run-through fecaluria oblique slideway 10 at the lower part; the opening at the upper end is higher than a flushing gas vent 23 arranged outside the wall of the platform 22, while the inlet at the lower end is connected with a manure pit 9; a ventilation vent pipe 20 is vertically arranged outside the house wall body 3 and communicated with the oblique slideway 10, so as to exhaust odor. The squatting pots are arranged according to visitor flowrate, which saves construction cost by 20 percent than the public lavatory with the same area; the public lavatory is environmentally friendly and flushing-free and has diversified fecaluria, which is applicable for building public health care public lavatories in offices, the open fairs of city and countryside, as well as enterprises and public institutions.

Owner:刘兴山 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com